Concept of Similarity Method for Prediction of Fatigue Life of Pavement Structures with HiMA Binder in Asphalt Layers

Abstract

:1. Introduction

1.1. Background

1.2. Basis of Research

1.3. Objective

1.4. Scope of the Research Program

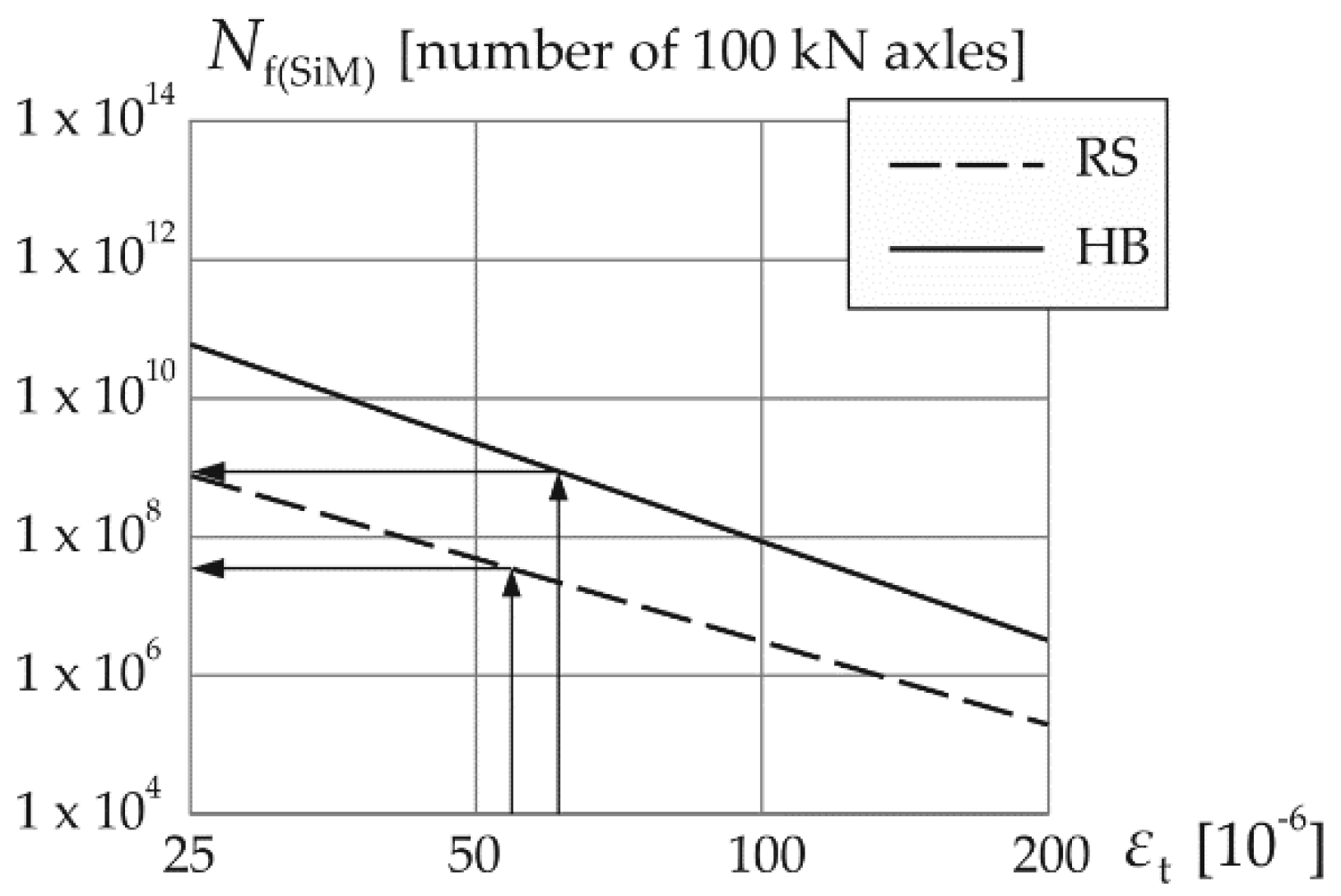

- the Similarity Method (the obtained value hereinafter referred to as “SiM fatigue life”, marked as Nf(SiM)),

- empirical formulas of the AASHTO 2004 method (the obtained value hereinafter referred to as “structural fatigue life”, marked Nf(struct)) [31],

- fatigue equations determined in laboratory (the obtained value hereinafter referred to as “laboratory fatigue life”, denoted Nf(lab)) [17].

2. The Similarity Method

- The S1 (reference) structure contains asphalt layers only with such road asphalt for which the correct Nf fatigue life formula for the S1 structure, i.e., C = Cstruct and α = αstruct are known and widely accepted—for example, the specific formulas of AASHTO, Asphalt Institute, Shell, etc. (cf. the RS structure presented in Section 3.1).

- The S2 (analyzed) pavement structure differs from the S1 structure only by one factor, i.e.,

- the binder type in the lowest asphalt layer or

- the binder type in all asphalt layers

(for example, highly modified asphalt HiMA used instead of unmodified binder). - Fatigue curves, i.e., A = Alab and α = αlab coefficients for the asphalt mixtures used in the asphalt base course of the S1 and S2 structures have been determined in the laboratory.

3. Calculation Data

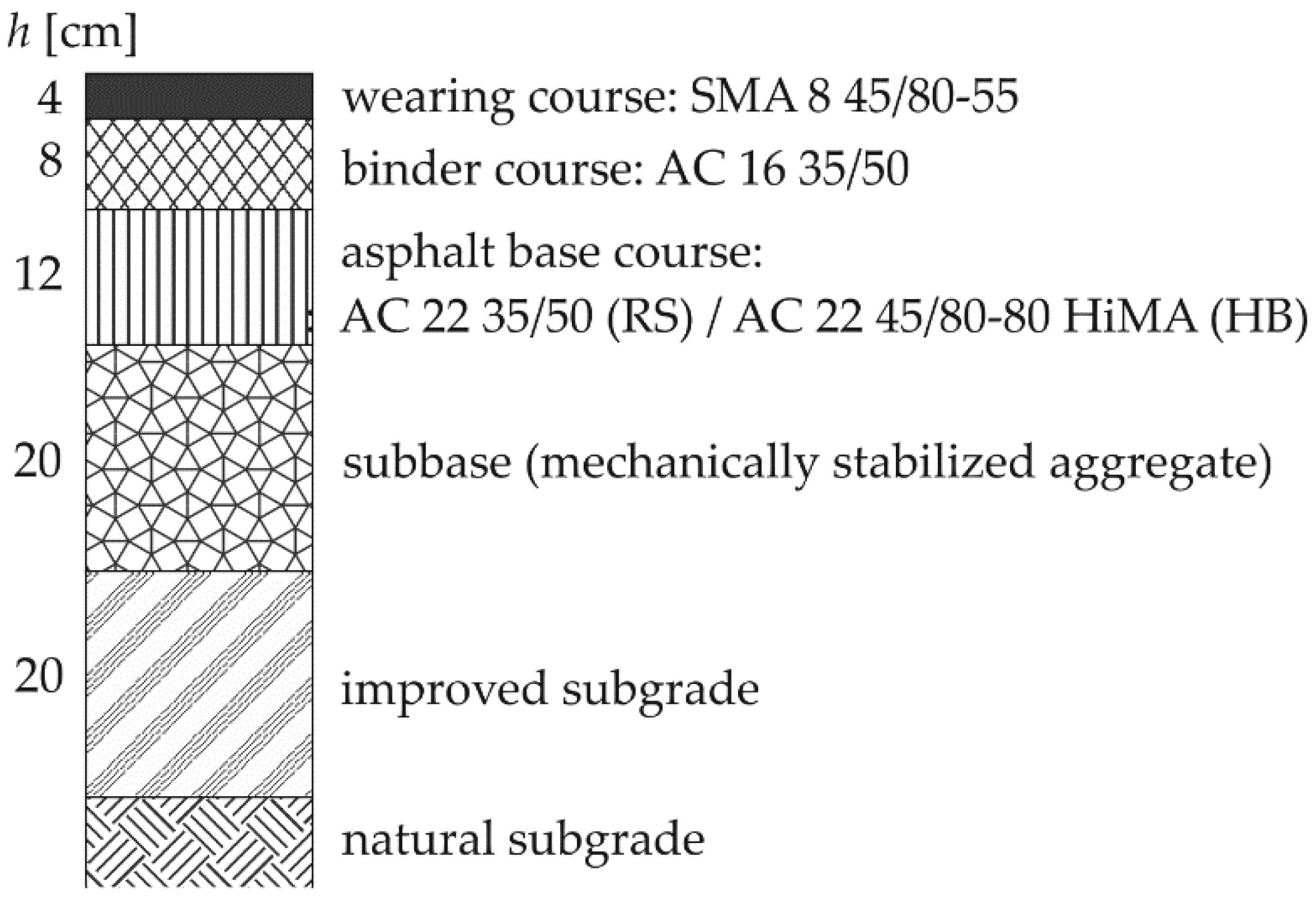

3.1. Pavement Structure

- HB structure (HiMA base)—structure using highly modified asphalt HiMA binder in the AC 22 base course [49], other material parameters as in the RS structure.

3.2. Mechanical Model of Pavement and Materials. Material Parameters

3.3. Pavement Load

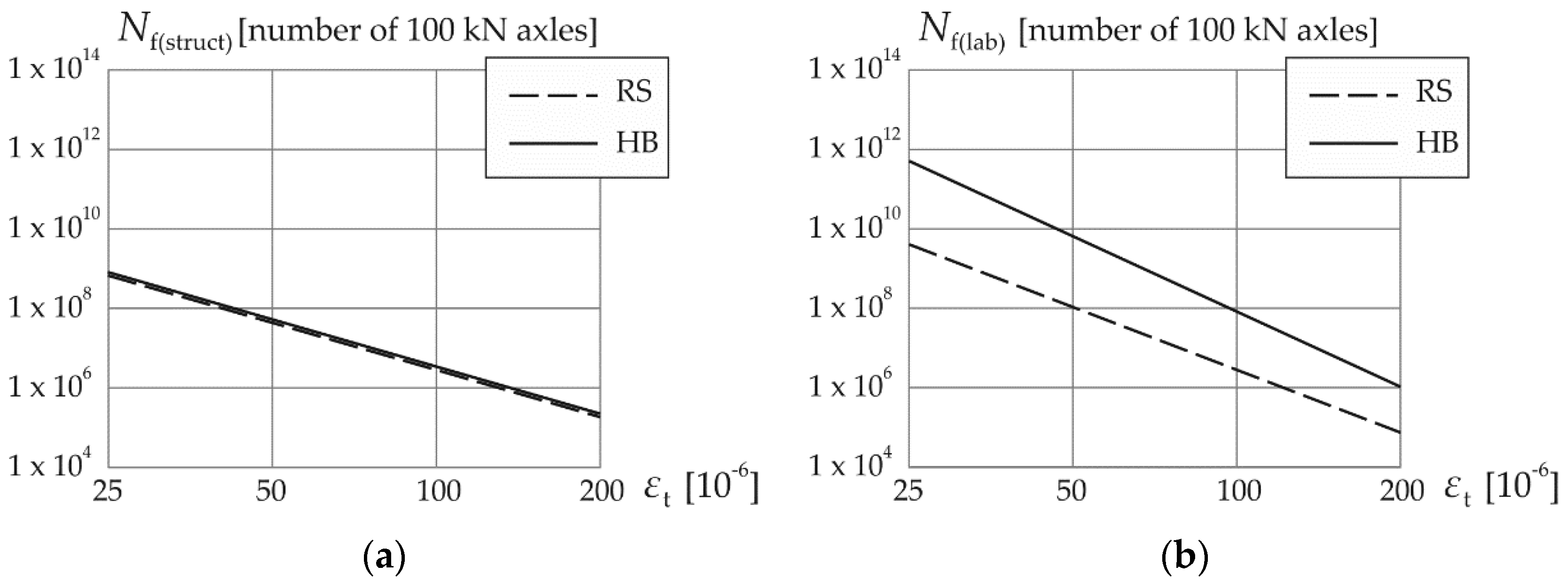

3.4. Design Life Based on AASHTO 2004

3.5. Laboratory Fatigue Life

4. Calculation Results and Discussion

5. Method Testing

- gradation of the asphalt mixture used in the base course, changing from AC 22 to AC 16 with a higher binder content (material sensitivity)—HB-A structure (mix AC 16 W 45/80-80 HiMA in the HB-A structure and AC 16 W 35/50 in its reference structure, material data not previously mentioned are shown in Table 8),

- thickness of the AC 22 PMB 45/80-80 HiMA asphalt base (geometric sensitivity), change from 12 cm to 16 cm—HB-B structure,

- strengthening of the improved subgrade layer (sensitivity due to subgrade stiffness), change from 300 MPa to 400 MPa—HB-C structure,

- value of the assumed FC index of bottom-up fatigue cracks on the road surface, change from 5% to 10% (sensitivity due to the definition of fatigue failure of the pavement)—HB-D structure.

6. Conclusions

- The Similarity Method is promising as means of rough estimation of fatigue life under structural conditions and avoids the problems associated with classical calculation methods of fatigue life, e.g., the Asphalt Institute method and AASHTO 2004. It can be assessed that the Similarity Method enables taking into account the predicted “fatigue life of the asphalt mixture under laboratory conditions” in estimations of the “structural fatigue life” for new asphalt materials with different properties than those assumed in the AI, AASHTO and similar equations, e.g., when a highly modified binder (HiMA) is used in the lowest asphalt layer.

- The “SiM” hypothesis proposed in this paper assumes that the lifespan values obtained using the AASHTO method are realistic (on the basis of a certain projection) and to some extent proportional to the relation between laboratory fatigue characteristics of the mixtures with and without HiMA used in the asphalt base courses. It proved suitable for evaluation of the fatigue life of asphalt mixtures with HiMA. This will enable inclusion of new materials, such as HiMA asphalt mixtures, in pavement structure design.

- Sensitivity analysis of the SiM method with four different variables (material, geometric, subgrade, cracking index) showed that the SiM method is sufficiently sensitive to changes in these variables. It was also noted that the greatest sensitivity of the method is exhibited in the case of material used in the asphalt base course (change from AC 22 to AC 16)—increasing Nf(SIM) about 12 times. The change in the FC crack rate from 5% to 10% resulted in a change (increase) in Nf(SiM) over 2 times. This is similar to the effect of increasing the thickness of the asphalt base by 33% (from 12 to 16 cm). The impact of the improved subgrade strengthening turned out to be the smallest (a 20% change in Nf(SiM)) among the tested parameters.

- Based on the results of Nf(SiM) tests, obtained indirectly from laboratory fatigue tests of asphalt mixtures, it was possible to rank the tested structures according to the influence of the binder and the type of mixture on the service life of the structure Nf due to fatigue cracking. The obtained ranking according to Nf(SIM) was in accordance with the current state of knowledge on the behavior of different types of binder and asphalt. Therefore, in comparison with classical calculation methods, the correct result of assessment of the tested structures was obtained.

- The SiM method is relatively simple, and the associated efforts are limited to sample preparation and testing in order to determine the laboratory fatigue equation. The tests are performed on samples of the asphalt base course of the analyzed pavement and its reference pavement with standard neat binders. This effort is significantly lower than the effort of construction of a pavement test section and determination of its effective fatigue life through testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kluttz, R.Q.; Molenaar, A.A.; Van de Ven, M.F.; Poot, M.R.; Liu, X.; Scarpas, A.; Scholten, E.J. Modified Base Courses for Reduced Pavement Thickness and Improved Longevity. In Proceedings of the International Conference on Perpetual Pavement, Columbus, OH, USA, 30 September–2 October 2009. [Google Scholar]

- Kluttz, R.Q.; Willis, J.R.; Molenaar, A.A.; Scarpas, T.; Scholten, E. Fatigue Performance of Highly Modified Asphalt Mixtures in Laboratory and Field Environment. In Proceedings of the 7th RILEM International Conference on Cracking in Pavements; Springer: Dordrecht, The Netherlands, 2012; pp. 687–696. [Google Scholar]

- Kluttz, R.Q.; Jellema, E.; Woldekidan, M.F.; Huurman, M. Highly modified bitumen for prevention of winter damage in OGFCs. In Airfield and Highway Pavement 2013: Sustainable and Efficient Pavements; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 1075–1087. [Google Scholar]

- Timm, D.H.; Robbins, M.M.; Kluttz, R.Q. Full-Scale Structural Characterization of a Highly Polymer-Modified Asphalt Pavement. In Proceedings of the Transportation Research Board 90th Annual Meeting, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Timm, D.H.; Powell, R.; Willis, J.R.; Kluttz, R. Pavement Rehabilitation Using High Polymer Asphalt Mix. In Proceedings of the Transportation Research Board 91st Annual Meeting, Washington, DC, USA, 22–26 January 2012. [Google Scholar]

- Timm, D.H.; Robbins, M.M.; Willis, J.R.; Tran, N.; Taylor, A.J. Field and Laboratory Study of High-Polymer Mixtures at the NCAT Test Track: Final Report; NCAT Report; National Center for Asphalt Technology, Auburn University: Auburn, AL, USA, 2013. [Google Scholar]

- Willis, J.R.; Taylor, A.; Tran, N.H.; Kluttz, B.; Timm, D.H. Laboratory Evaluation of High Polymer Plant-Produced Mixtures. Road Mater. Pavement Des. 2012, 13, 260–280. [Google Scholar] [CrossRef]

- Von Quintus, H.L.; Mallela, J.; Jiang, J. Quantification of the Effects of Polymer-Modified Asphalt for Reducing Pavement Distress; ER-215; Asphalt Institute: Lexington, KY, USA, 2004. [Google Scholar]

- West, R.; Timm, D.; Willis, J.R.; Powell, R.; Tran, N.; Watson, D.; Sakhaeifar, M.; Robbins, M.; Brown, R.; Vargas-Nordcbeck, A. Phase IV NCAT Pavement Test Track Findings: Draft Report; NCAT Report; National Center for Asphalt Technology, Auburn University: Auburn, AL, USA, 2012. [Google Scholar]

- Nagórska, M.; Nagórski, R.; Błażejowski, K. Selected Aspects of Design Lifespan of Flexible Pavement with Anti-Fatigue Course. Arch. Civ. Eng. 2015, 61, 103–118. [Google Scholar] [CrossRef] [Green Version]

- PN-EN 13398:2017-12, 2017. Bitumen and Bituminous Binders—Determination of the Elastic Recovery of Modified Bitumen; PKN: Warsaw, Poland, 2017. [Google Scholar]

- Vaitkus, A.; Vorobjovas, V.; Kleizienė, R.; Šernas, O.; Gražulytė, J. Modified Asphalt Mixtures for Heavy Duty Pavement Wearing Layers. Constr. Build. Mater. 2017, 131, 503–511. [Google Scholar] [CrossRef]

- Blazejowski, K.; Wójcik-Wiśniewska, M. Bitumen Handbook; Orlen Asfalt: Płock, Poland, 2017; Available online: https://www.orlen-asfalt.pl/EN/TECHNICALINFORMATION/Production/Documents/Bitumen-Handbook-2017.pdf (accessed on 9 January 2021).

- Błażejowski, K.; Wójcik-Wiśniewska, M.; Baranowska, W.; Ostrowski, P. Highly Modified Binders ORBITON HiMA. Application Guide 2019; Orlen Asfalt: Płock, Poland, 2019; Available online: https://www.orbiton.pl/docs/Highly%20modified%20binders.pdf (accessed on 9 January 2021).

- Błażejowski, K.; Wójcik-Wiśniewska, M.; Černý, R.; Jisa, P. Low-Temperature Properties of Bituminous Binders and Asphalt Mixtures. In Proceedings of the 29th International Baltic Road Conference, Tallin, Estonia, 27–30 August 2017. [Google Scholar]

- Wesołowska, M.; Ryś, D. Analysis of the Fatigue Life of Neat and Modified Bitumens Using Linear Amplitude Sweep Test. Roads Bridges Drogi Mosty 2018, 17, 317–336. [Google Scholar] [CrossRef]

- Błażejowski, K.; Wójcik-Wiśniewska, M.; Baranowska, W.; Ostrowski, P.; Černý, R.; Jisa, P. Fatigue Performance of Bituminous Binders Tested by Linear Amplitude Sweep Test. In Proceedings of the International Symposium on Asphalt Pavement & Environment, Padua, Italy, 11–13 September 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 385–394. [Google Scholar]

- Błażejowski, K.; Wójcik-Wiśniewska, M.; Peciakowski, H.; Olszacki, J. The Performance of a Highly Modified Binders for Heavy Duty Asphalt Pavements. Transp. Res. Procedia 2016, 14, 679–684. [Google Scholar] [CrossRef] [Green Version]

- Błażejowski, K.; Ostrowski, P.; Wójcik-Wiśniewska, M.; Baranowska, W. Mieszanki i Nawierzchnie z ORBITON HIMA (Asphalt Mixtures and Pavements with ORBITION HiMA); Orlen Asfalt: Płock, Poland, 2020. (In Polish) [Google Scholar]

- Sun, L. Structural Behavior of Asphalt Pavements: Intergrated Analysis and Design of Conventional and Heavy Duty Asphalt Pavement; Butterworth-Heinemann: Oxford, UK, 2016; ISBN 0-12-802893-9. [Google Scholar]

- Molenaar, A.A.A.; Van de Ven, M.F.C.; Liu, X.; Scarpas, A.; Medani, T.O.; Scholten, E.J. Advanced Mechanical Testing of Polymer Modified Base Course Mixes. In Proceedings of the 4th Eurasphalt & Eurobitume Congress, Copenhagen, Denmark, 21–23 May 2008; pp. 842–853. [Google Scholar]

- Rajbongshi, P.; Das, A. A Systematic Approach of Field Calibration of Fatigue Equation for Asphalt Pavements. Road Mater. Pavement Des. 2009, 10, 109–124. [Google Scholar] [CrossRef]

- Rechnerische Dimensionierung von Asphaltstraßen; RVS 03.08.68; Bundesministerium für Verkehr, Innovation und Technologie: Vienna, Austria, 2018.

- Carpenter, S.H.; Ghuzlan, K.A.; Shen, S. Fatigue Endurance Limit for Highway and Airport Pavements. Transp. Res. Rec. 2003, 1832, 131–138. [Google Scholar] [CrossRef]

- Hu, S.; Lee, S.-I.; Walubita, L.F.; Zhou, F.; Scullion, T. Incorporation of Endurance Limit in the Mechanistic-Empirical Flexible Perpetual Pavement Design. Transp. Res. Rec. 2018, 2672, 108–121. [Google Scholar] [CrossRef]

- Monismith, C.C.; McLean, D.B. Structural Design Considerations. Road J. Road Eng. Assoc. 1976, 1, 12–31. [Google Scholar]

- Nunn, M. Long-Life Flexible Roads. In Proceedings of the Eighth International Conference on Asphalt Pavements Federal Highway Administration, Seattle, WA, USA, 10–14 August 1997. [Google Scholar]

- Nunn, M. Design of Long-Life Roads for Heavy Traffic. In Proceedings of the Focussing on Performance: AAPA Pavements Industry Conference, Queensland, Australia, 20–23 September 1998. [Google Scholar]

- Willis, J.R.; Timm, D.H.; Taylor, A.J.; Tran, N.H.; Kvasnak, A. Correlating Laboratory Fatigue Endurance Limits to Field-Measured Strains. J. Assoc. Asph. Paving Technol. 2011, 80, 135–160. [Google Scholar]

- Shen, S.; Carpenter, S.H. Application of the Dissipated Energy Concept in Fatigue Endurance Limit Testing. Transp. Res. Rec. 2005, 1929, 165–173. [Google Scholar] [CrossRef]

- Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures. Final Report; NCHRP 1-37A; ARA Inc., AASHTO: Champaign, IL, USA, 2004.

- Ryś, D.; Jaskuła, P.; Jaczewski, M.; Pszczoła, M. Application and Evaluation of M-EPDG for Performance Analysis of Polish Typical Flexible and Rigid Pavements. Roads Bridges Drogi Mosty 2019, 18, 283–302. [Google Scholar] [CrossRef]

- Research and Development of the Asphalt Institute’s Thickness Design Manual; Asphalt Institute: Lexington, KY, USA, 1982.

- Shell Pavement Design Manual: Asphalt Pavements and Overlays for Road Traffic; Shell International Petroleum Company Limited, Shell Center: London, UK, 1978.

- Conception et Dimensionnement Des Structures de Chaussée: Guide Technique; Ministère de l’Équipement, des Transports et du Tourisme: Paris, France, 1994.

- Navrhování Vozovek Pozemních Komunikací. Technické Podmínky; Dodatek TP 170; Ministerstvo Dopravy, Odbor Silniční Infrastruktury: Praha, Czech Republic, 2010.

- Kluttz, R.Q.; Kim, Y.R.; Dongre, R. Performance modeling of a highly modified asphalt pavement. In Advances in Materials and Pavement Performance Prediction; CRC Press: Boca Raton, FL, USA, 2018; pp. 57–61. ISBN 978-0-429-45779-1. [Google Scholar]

- Judycki, J.; Jaskula, P.; Pszczoła, M.; Ryś, D.; Jaczewski, M.; Alenowicz, J.; Dołżycki, B.; Stienss, M. Analizy i Projektowanie Konstrukcji Nawierzchni Podatnych i Półsztywnych (Analysis and Design of Flexible and Semi-Rigid Pavement Structures); Wydawnictwa Komunikacji i Łączności: Warsaw, Poland, 2014; ISBN 978-83-206-1928-7. [Google Scholar]

- AASHTO Guide for Design of Pavement Structures 1993; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1993; ISBN 978-1-56051-055-0.

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Hand, A.J. Fatigue-Based Structural Layer Coefficient of High Polymer-Modified Asphalt Mixtures. Transp. Res. Rec. 2020, 2674, 232–247. [Google Scholar] [CrossRef]

- EN 12697-24:2018. Bituminous Mixtures—Test Methods—Part 24: Resistance to Fatigue; BSI: London, UK, 2018.

- Hopman, P.C. The Visco-Elastic Multilayer Program VEROAD. HERON 1996, 41. Available online: https://repository.tudelft.nl/islandora/object/uuid:a03ed318-fe99-437f-969f-6bb1fb068efa (accessed on 18 January 2021).

- Pronk, A.C. The Huet-Sayegh model: A simple and excellent rheological model for master curves of asphaltic mixes. In Asphalt Concrete: Simulation, Modeling, and Experimental Characterization; American Society of Civil Engineers: Reston, VA, USA, 2006; pp. 73–82. [Google Scholar]

- Svasdisant, T.; Schorsch, M.; Baladi, G.Y.; Pinyosunun, S. Mechanistic Analysis of Top-Down Cracks in Asphalt Pavements. Transp. Res. Rec. 2002, 1809, 126–136. [Google Scholar] [CrossRef]

- Roque, R.; Birgisson, B.; Drakos, C.; Dietrich, B. Development and Field Evaluation of Energy-Based Criteria for Top-down Cracking Performance of Hot Mix Asphalt (with Discussion). J. Assoc. Asph. Paving Technol. 2004, 73, 229–260. [Google Scholar]

- Tian, Y.; Lee, J.; Nantung, T.; Haddock, J.E. Calibrating the Mechanistic–Empirical Pavement Design Guide Rutting Models Using Accelerated Pavement Testing. Transp. Res. Rec. 2018, 2672, 304–314. [Google Scholar] [CrossRef]

- Pasquini, E.; Bocci, M.; Ferrotti, G.; Canestrari, F. Laboratory Characterisation and Field Validation of Geogrid-Reinforced Asphalt Pavements. Road Mater. Pavement Des. 2013, 14, 17–35. [Google Scholar] [CrossRef]

- PN-EN 12591:2010, 2010. Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumens; PKN: Warsaw, Poland, 2010.

- EN 13108-1:2016. Bituminous Mixtures—Requirements—Part 1: Asphalt Concrete; BSI: London, UK, 2016.

- GDDKiA Asphalt Pavements on National Roads—WT-2 2014 Part 1—Asphalt Mixtures—Technical Requirements. 2014; (In Polish). Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/d/dokumenty-techniczne_8162/Dokumenty%20techniczne/WT2%20cz1.pdf (accessed on 18 January 2021).

- EN 14023:2009. Bitumen and Bituminous Binders. Specification Framework for Polymer Modified Bitumens; BSI: London, UK, 2009.

- PN-EN 14023:2011/Ap1:2014, 2011; Polish National Amendment to EN 14023:2009 with Requirements for Binders Applied in Poland; PKN: Warsaw, Poland, 2014.

- Nagórski, R. Mechanika Nawierzchni Drogowych w Zarysie; PWN: Warszawa, Poland, 2014. [Google Scholar]

- Pronk, A.C. Revival of the Huet-Sayegh Response Model; DWW-2003-29; RHED: Delft, The Netherland, 2003. [Google Scholar]

- Regulation of the Polish Minister of Transport and Maritime Economy for Public Roads, 1999, Amendment 5—Design of Pavement Structure. J. Laws Repub. Pol. 1999, 43, 430.

| Binder | Specification | Penetration@25 °C EN 1426 (0.1 mm) | Softening Point R&B EN 1427 (°C) | Elastic Recovery EN 13398 (%) | PG AASHTO M320 |

|---|---|---|---|---|---|

| 35/50 | EN 12591 | 43 | 53.5 | - | 70–22 |

| PMB 45/80-80 HiMA | EN 14023 Polish appendix 2014 | 69 | 92 | 95 | 88–28 |

| PMB 45/80-55 | EN 14023 Polish appendix 2014 | 65 | 59 | 85 | 70–28 |

| Asphalt Mixture | ηa (MPa·s) | ηb (MPa·s) | Ea (MPa) | Ep (MPa) | ka (-) | hb (-) |

|---|---|---|---|---|---|---|

| SMA 8 PMB 45/80-55 | 1053 | 2790 | 28,500 | 200 | 0.22 | 0.66 |

| AC 16 35/50 | 19,482 | 66,240 | 27,600 | 210 | 0.26 | 0.73 |

| AC 22 35/50 | 36,717 | 110,152 | 18,800 | 450 | 0.26 | 0.80 |

| AC 22 PMB 45/80-80 HiMA | 4463 | 16,065 | 18,900 | 500 | 0.27 | 0.73 |

| Asphalt Mixture | Dynamic Modulus T = 10 °C, f = 10 Hz |E*|(MPa) | Poisson’s Ratio ν (-) | Binder Content Va (% v/v) | Voids in Asphalt Mix Vv (% v/v) |

|---|---|---|---|---|

| SMA 8 PMB 45/80-55 | 8087 | 0.3 | 16.36 | 2.2 |

| AC 16 35/50 | 14,818 | 0.3 | 10.49 | 5.4 |

| AC 22 35/50 | 11,563 | 0.3 | 9.86 | 5.2 |

| AC 22 PMB 45/80-80 HiMA | 8668 | 0.3 | 9.93 | 5.8 |

| Layer (Material) | Young’s Modulus of Elasticity E (MPa) | Poisson’s Ratio ν (-) |

|---|---|---|

| Subbase (mechanically stabilized aggregate) | 400 | 0.30 |

| Improved subgrade (soil stabilized with cement) | 300 | 0.30 |

| Natural subgrade (natural soil) | 100 | 0.35 |

| Asphalt Mixture for Asphalt Base Course | A1 | A0 |

|---|---|---|

| AC 22 35/50 | −5.2853 | 17.007 |

| AC 22 PMB 45/80-80 HiMA | −6.3487 | 20.598 |

| Method | Coefficient | Pavement Structure Variant | |

|---|---|---|---|

| RS | HB | ||

| AASHTO 2004 equations | Astruct | 14.386 | 14.433 |

| αstruct | 3.9492 | 3.9492 | |

| Laboratory | Alab | 17.007 | 20.598 |

| αlab | 5.2853 | 6.3487 | |

| SiM | ASiM | 14.386 | 17.424 |

| αSiM | 3.9492 | 4.7438 | |

| Critical Strains and Predicted Fatigue Life [Millions of 100 kN Axles] | Pavement Structure Variant | |

|---|---|---|

| RS | HB | |

| εh (10−6) | 54.1 | 63.1 |

| Nf(struct) | 35 | 21 |

| Nf(lab) | 70 | 1474 |

| Nf(SiM) | 35 | 765 |

| ηa (MPa·s) | ηb (MPa·s) | Ea (MPa) | Ep (MPa) | ka (-) | hb (-) | ν (-) | A1 | A0 |

|---|---|---|---|---|---|---|---|---|

| 3019 | 9662 | 27,500 | 230 | 0.26 | 0.58 | 0.3 | −7.0748 | 22.698 |

| Critical Strains, Coefficients and Predicted Fatigue Life | Pavement Structure Variant | |||||

|---|---|---|---|---|---|---|

| HB | HB-A | HB-B | HB-C | HB-D | ||

| εh (10−6) | 63.1 | 57.3 | 51.2 | 61.0 | 63.1 | |

| AASHTO 2004 equations | Astruct | 14.433 | 14.407 | 14.425 | 14.433 | 14.737 |

| αstruct | 3.9492 | 3.9492 | 3.9492 | 3.9492 | 3.9492 | |

| Nf(struct) [millions of 100 kN axles] | 21 | 29 | 47 | 24 | 42 | |

| HB-X/HB ratio | 1.0 | 1.4 | 2.2 | 1.1 | 2.0 | |

| SiM | ASiM | 17.424 | 20.349 | 17.414 | 17.424 | 17.792 |

| αSiM | 4.7438 | 5.8960 | 4.7438 | 4.7438 | 4.7438 | |

| Nf(SiM) [millions of 100 kN axles] | 765 | 9661 | 2031 | 903 | 1786 | |

| HB-X/HB ratio | 1.0 | 12.6 | 2.7 | 1.2 | 2.3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Złotowska, M.; Nagórski, R.; Błażejowski, K. Concept of Similarity Method for Prediction of Fatigue Life of Pavement Structures with HiMA Binder in Asphalt Layers. Materials 2021, 14, 480. https://doi.org/10.3390/ma14030480

Złotowska M, Nagórski R, Błażejowski K. Concept of Similarity Method for Prediction of Fatigue Life of Pavement Structures with HiMA Binder in Asphalt Layers. Materials. 2021; 14(3):480. https://doi.org/10.3390/ma14030480

Chicago/Turabian StyleZłotowska, Magdalena, Roman Nagórski, and Krzysztof Błażejowski. 2021. "Concept of Similarity Method for Prediction of Fatigue Life of Pavement Structures with HiMA Binder in Asphalt Layers" Materials 14, no. 3: 480. https://doi.org/10.3390/ma14030480