Rapid 3 s Curing: What Happens in Deep Layers of New Bulk-Fill Composites?

Abstract

1. Introduction

- curing protocol,

- curing depth and

- aging.

2. Materials and Methods

2.1. Materials

2.2. Methods

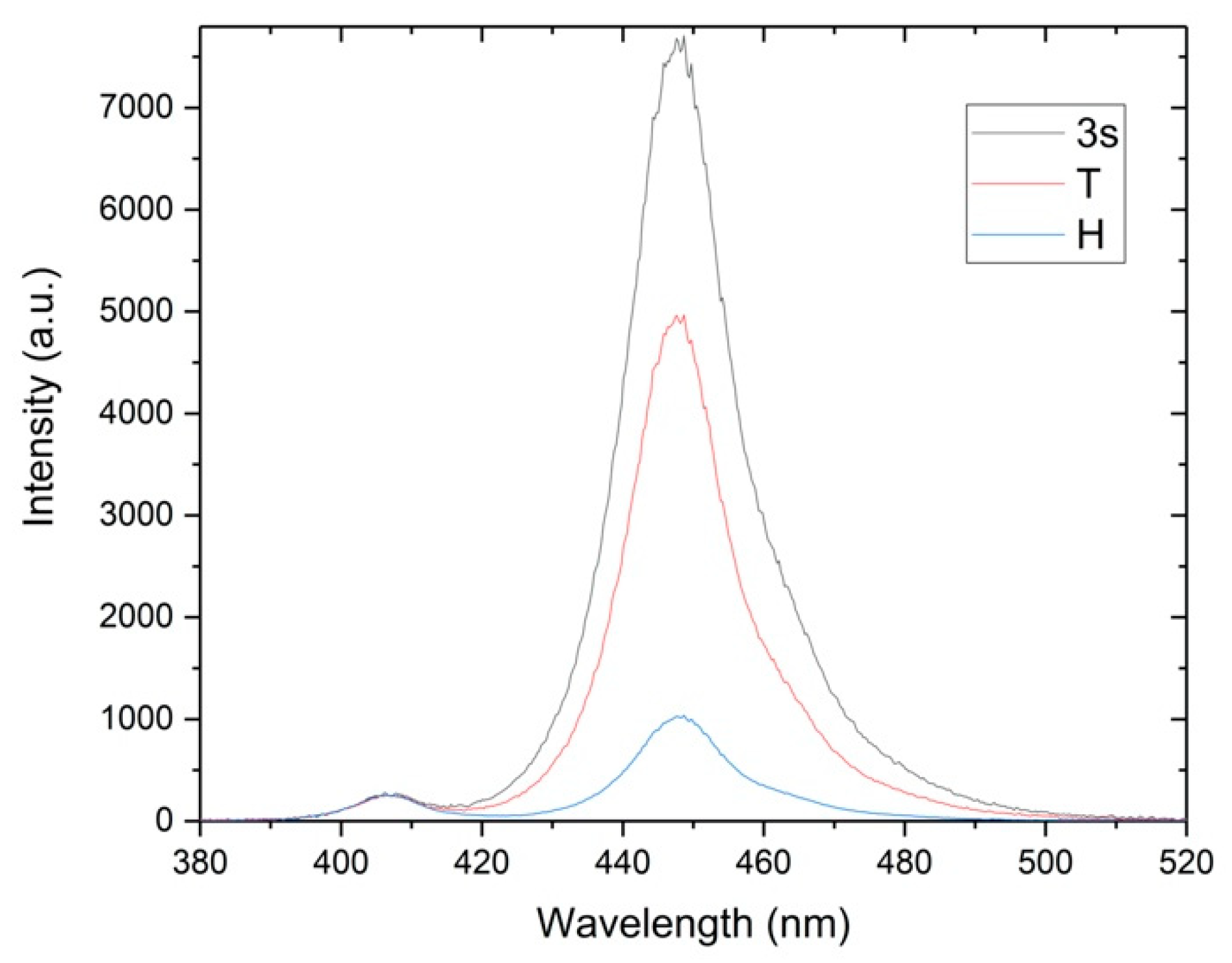

2.2.1. Characterization of the Curing Light

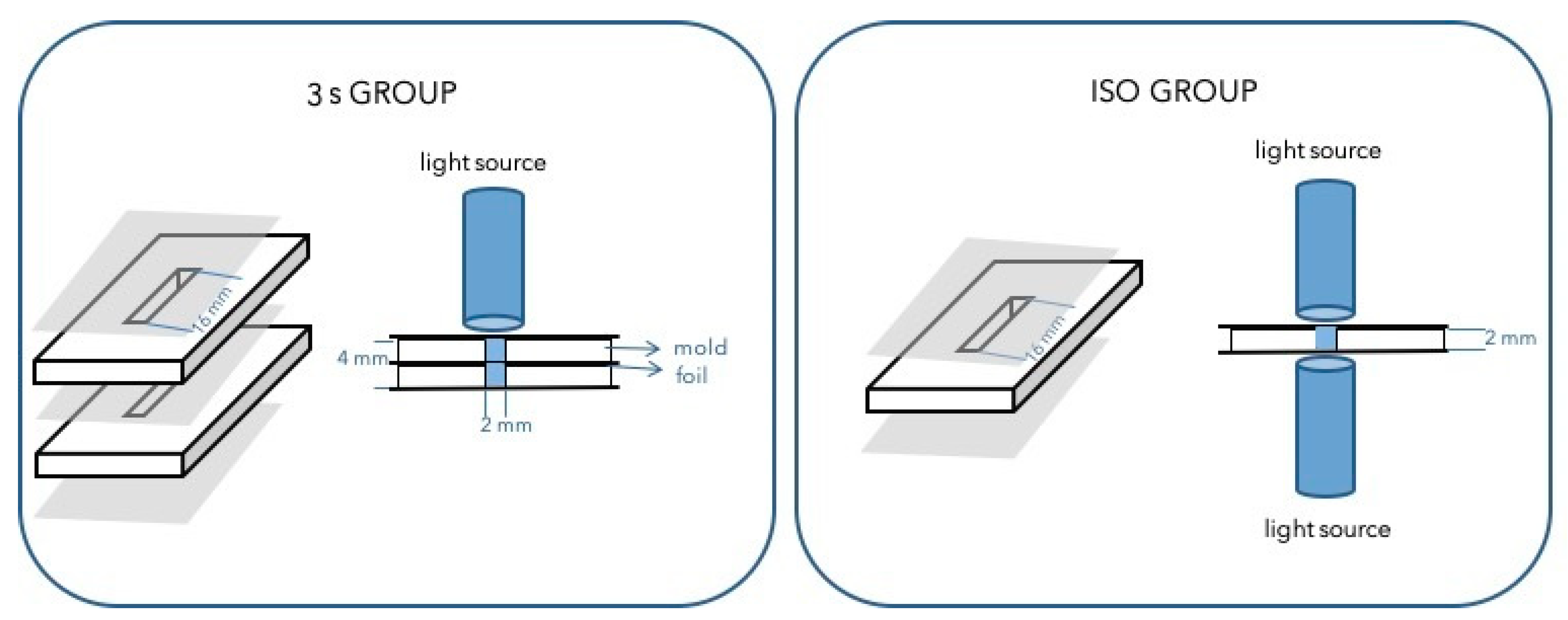

2.2.2. Flexural Strength and Flexural Modulus

- ISO group—specimens polymerized according to ISO 4049 [27]—6 × 20 s with 950 mW/cm2 (3 times on each side, 6 times in total), n = 10/material/time point;

- 3 s group—double, stacked specimens polymerized 3 × 3 s with 2700 mW/cm2 on only one side (3 times in total), n = 10/depth/material/time point.

- 1 day (saline),

- 30 days (saline), and

- 33 days (30 days in saline and 3 days in 70% ethanol).

2.2.3. Degree of Conversion

2.2.4. Statistical Analysis

3. Results

3.1. Characterization of the Curing Light

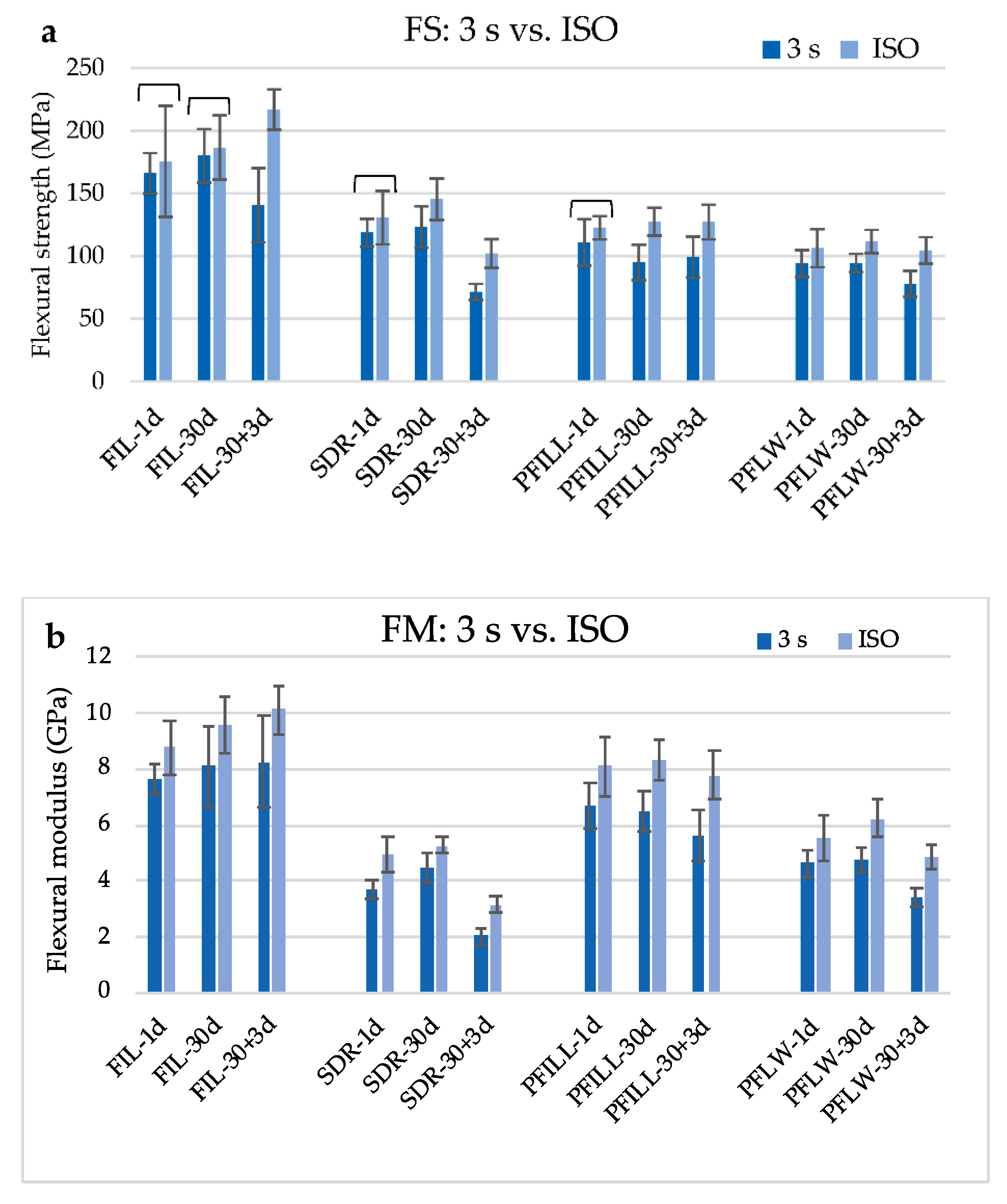

3.2. Flexural Strength and Flexural Modulus

3.2.1. 3 s vs. ISO

3.2.2. 3 s Group—Depth and Aging

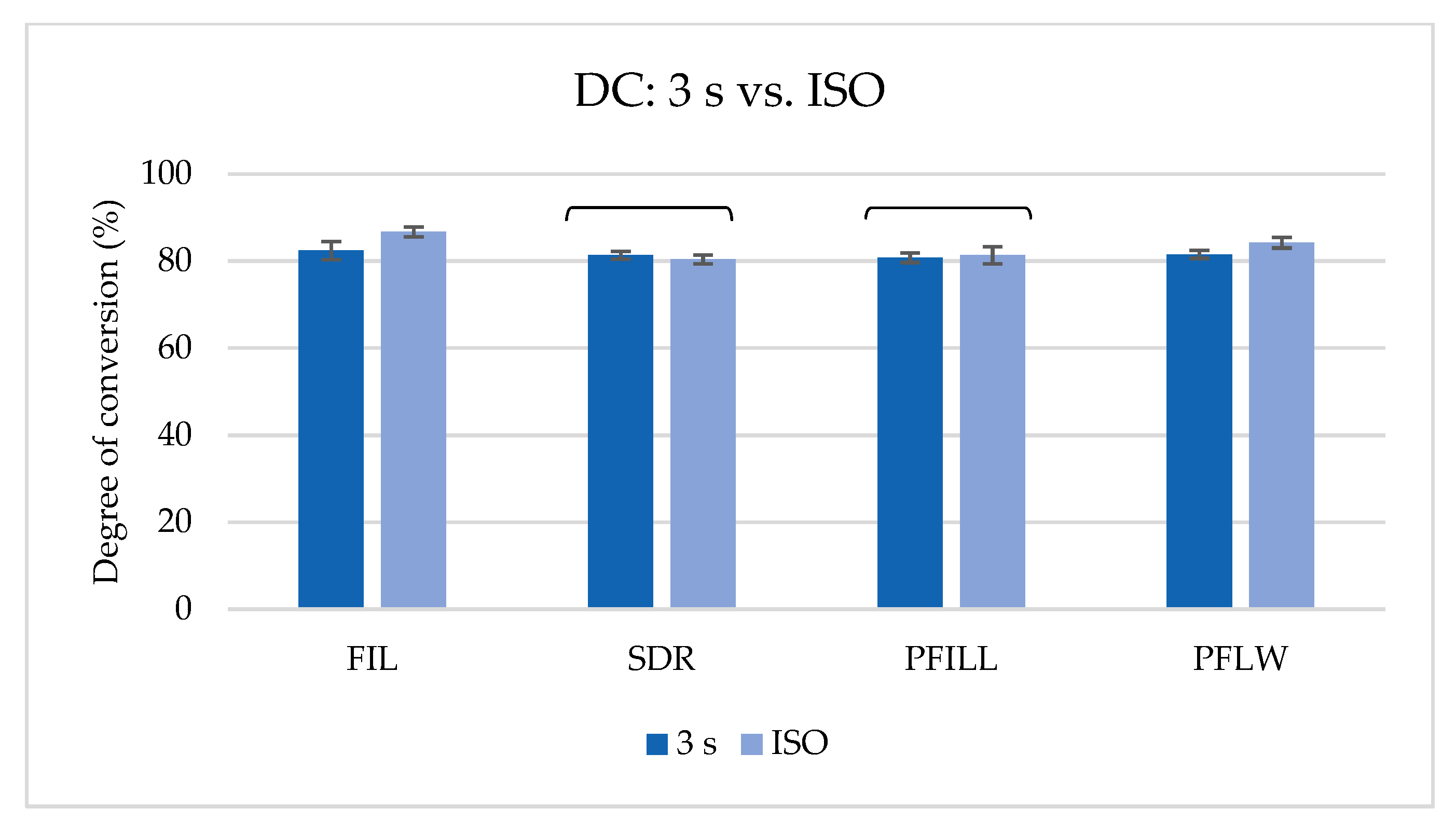

3.3. Degree of Conversion

3.3.1. 3 s vs. ISO

3.3.2. 3 s Group—Curing Depth

4. Discussion

4.1. Curing Protocol

4.2. Curing Depth

4.3. Aging

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sabbagh, J.; McConnell, R.J.; McConnell, M.C. Posterior composites: Update on cavities and filling techniques. J. Dent. 2017, 57, 86–90. [Google Scholar] [CrossRef] [PubMed]

- Van Ende, A.; De Munck, J.; Lise, D.P.; Van Meerbeek, B. Bulk-Fill Composites: A Review of the Current Literature. J. Adhes. Dent. 2017, 19, 95–109. [Google Scholar] [CrossRef] [PubMed]

- Todd, J. Scientific Documentation 3s PowerCure. Available online: https://www.ivoclarvivadent.com/zoolu-website/media/document/46892/3s+PowerCure+System (accessed on 11 January 2020).

- Sadeghyar, A.; Watts, D.C.; Schedle, A. Limited reciprocity in curing efficiency of bulk-fill resin-composites. Dent. Mater. 2020, 36, 997–1008. [Google Scholar] [CrossRef] [PubMed]

- Daugherty, M.M.; Lien, W.; Mansell, M.R.; Risk, D.L.; Savett, D.A.; Vandewalle, K.S. Effect of high-intensity curing lights on the polymerization of bulk-fill composites. Dent. Mater. 2018, 34, 1531–1541. [Google Scholar] [CrossRef] [PubMed]

- Selig, D.; Haenel, T.; Hausnerová, B.; Moeginger, B.; Labrie, D.; Sullivan, B.; Price, R.B. Examining exposure reciprocity in a resin based composite using high irradiance levels and real-time degree of conversion values. Dent. Mater. 2015, 31, 583–593. [Google Scholar] [CrossRef]

- Randolph, L.D.; Palin, W.M.; Watts, D.C.; Genet, M.; Devaux, J.; Leloup, G.; Leprince, J.G. The effect of ultra-fast photopolymerisation of experimental composites on shrinkage stress, network formation and pulpal temperature rise. Dent. Mater. 2014, 30, 1280–1289. [Google Scholar] [CrossRef]

- Randolph, L.D.; Palin, W.M.; Bebelman, S.; Devaux, J.; Gallez, B.; Leloup, G.; Leprince, J.G. Ultra-fast light-curing resin composite with increased conversion and reduced monomer elution. Dent. Mater. 2014, 30, 594–604. [Google Scholar] [CrossRef]

- Hadis, M.; Leprince, J.G.; Shortall, A.C.; Devaux, J.; Leloup, G.; Palin, W.M. High irradiance curing and anomalies of exposure reciprocity law in resin-based materials. J. Dent. 2011, 39, 549–557. [Google Scholar] [CrossRef]

- Da Silva, E.M.; Poskus, L.T.; Guimaraes, J.G.; de Araujo Lima Barcellos, A.; Fellows, C.E. Influence of light polymerization modes on degree of conversion and crosslink density of dental composites. J. Mater. Sci. Mater. Med. 2008, 19, 1027–1032. [Google Scholar] [CrossRef]

- Ivoclar Vivadent, A. Tetric PowerFill: Instructions for use. 2020. Available online: https://www.ivoclarvivadent.com.hr/zoolu-website/media/document/57158/Tetric+PowerFill (accessed on 11 January 2020).

- Ivoclar Vivadent, A. Tetric PowerFlow: Instructions for use. 2020. Available online: https://www.ivoclarvivadent.com.hr/zoolu-website/media/document/46818/Tetric+PowerFlow (accessed on 11 January 2020).

- Gorsche, C.; Griesser, M.; Gescheidt, G.; Moszner, N.; Liska, R. β-Allyl Sulfones as Addition–Fragmentation Chain Transfer Reagents: A Tool for Adjusting Thermal and Mechanical Properties of Dimethacrylate Networks. Macromolecules 2014, 47, 7327–7336. [Google Scholar] [CrossRef]

- Gorsche, C.; Koch, T.; Moszner, N.; Liska, R. Exploring the benefits of β-allyl sulfones for more homogeneous dimethacrylate photopolymer networks. Polym. Chem. 2015, 6, 2038–2047. [Google Scholar] [CrossRef]

- Ilie, N.; Watts, D.C. Outcomes of ultra-fast (3 s) photo-cure in a RAFT-modified resin-composite. Dent. Mater. 2020, 36, 570–579. [Google Scholar] [CrossRef] [PubMed]

- Graf, N.; Ilie, N. Long-Term Stability of a RAFT-Modified Bulk-Fill Resin-Composite under Clinically Relevant Versus ISO-Curing Conditions. Materials 2020, 13, 5350. [Google Scholar] [CrossRef] [PubMed]

- Algamaiah, H.; Silikas, N.; Watts, D.C. Conversion kinetics of rapid photo-polymerized resin composites. Dent. Mater. 2020, 36, 1266–1274. [Google Scholar] [CrossRef]

- Par, M.; Marovic, D.; Attin, T.; Tarle, Z.; Taubock, T.T. Effect of rapid high-intensity light-curing on polymerization shrinkage properties of conventional and bulk-fill composites. J. Dent. 2020, 101, 103448. [Google Scholar] [CrossRef]

- Par, M.; Marovic, D.; Attin, T.; Tarle, Z.; Taubock, T.T. The effect of rapid high-intensity light-curing on micromechanical properties of bulk-fill and conventional resin composites. Sci. Rep. 2020, 10, 10560. [Google Scholar] [CrossRef]

- Hayashi, J.; Tagami, J.; Chan, D.; Sadr, A. New bulk-fill composite system with high irradiance light polymerization: Integrity and degree of conversion. Dent. Mater. 2020, 36, 1615–1623. [Google Scholar] [CrossRef]

- Musanje, L.; Darvell, B.W. Curing-light attenuation in filled-resin restorative materials. Dent. Mater. 2006, 22, 804–817. [Google Scholar] [CrossRef]

- Par, M.; Repusic, I.; Skenderovic, H.; Sever, E.K.; Marovic, D.; Tarle, Z. Real-time Light Transmittance Monitoring for Determining Polymerization Completeness of Conventional and Bulk Fill Dental Composites. Oper. Dent. 2018, 43, E19–E31. [Google Scholar] [CrossRef]

- Tarle, Z.; Attin, T.; Marovic, D.; Andermatt, L.; Ristic, M.; Taubock, T.T. Influence of irradiation time on subsurface degree of conversion and microhardness of high-viscosity bulk-fill resin composites. Clin. Oral Investig. 2015, 19, 831–840. [Google Scholar] [CrossRef]

- Haugen, H.J.; Marovic, D.; Par, M.; Thieu, M.K.L.; Reseland, J.E.; Johnsen, G.F. Bulk Fill Composites Have Similar Performance to Conventional Dental Composites. Int. J. Mol. Sci. 2020, 21, 5136. [Google Scholar] [CrossRef] [PubMed]

- Comba, A.; Scotti, N.; Maravić, T.; Mazzoni, A.; Carossa, M.; Breschi, L.; Cadenaro, M. Vickers Hardness and Shrinkage Stress Evaluation of Low and High Viscosity Bulk-Fill Resin Composite. Polymers 2020, 12, 1477. [Google Scholar] [CrossRef] [PubMed]

- Al-Ahdal, K.; Ilie, N.; Silikas, N.; Watts, D.C. Polymerization kinetics and impact of post polymerization on the Degree of Conversion of bulk-fill resin-composite at clinically relevant depth. Dent. Mater. 2015, 31, 1207–1213. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO 4049:2009 Dentistry—Polymer-Based Filling, Restorative and Luting Materials; International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- Par, M.; Tarle, Z.; Hickel, R.; Ilie, N. Mechanical properties of experimental composites containing bioactive glass after artificial aging in water and ethanol. Clin. Oral Investig. 2019, 23, 2733–2741. [Google Scholar] [CrossRef]

- 3M. Filtek One Bulk Fill Restaurative. Shrinkage, stress and bulk fill restoratives 2020. Available online: https://multimedia.3m.com/mws/media/1317665O/1317663m-filtek-one-bulk-fill-restorative-shrink-stressand-bulk-fill-restoratives.pdf (accessed on 11 January 2020).

- Shortall, A.C.; Palin, W.M.; Burtscher, P. Refractive Index mismatch and Monomer Reactivity Influence Composite Curing Depth. J. Dent. Res. 2008, 87, 84–88. [Google Scholar] [CrossRef]

- Par, M.; Lapas-Barisic, M.; Gamulin, O.; Panduric, V.; Spanovic, N.; Tarle, Z. Long Term Degree of Conversion of two Bulk-Fill Composites. Acta Stomatol. Croat. 2016, 50, 292–300. [Google Scholar] [CrossRef]

- Stansbury, J.W. Dimethacrylate network formation and polymer property evolution as determined by the selection of monomers and curing conditions. Dent. Mater. 2012, 28, 13–22. [Google Scholar] [CrossRef]

- Cuevas-Suarez, C.E.; Pimentel-Garcia, B.; Rivera-Gonzaga, A.; Alvarez-Gayosso, C.; Ancona-Meza, A.L.; Grazioli, G.; Zamarripa-Calderon, E. Examining the Effect of Radiant Exposure on Commercial Photopolimerizable Dental Resin Composites. Dent. J. 2018, 6, 55. [Google Scholar] [CrossRef]

- Asmussen, E.; Peutzfeldt, A. Flexural strength and modulus of a step-cured resin composite. Acta Odontol. Scand. 2004, 62, 87–90. [Google Scholar] [CrossRef]

- Sakaguchi, R.L.; Ferracane, J.L. Effect of light power density on development of elastic modulus of a model light-activated composite during polymerization. J. Esthet. Restor. Dent. 2001, 13, 121–130. [Google Scholar] [CrossRef]

- Bucuta, S.; Ilie, N. Light transmittance and micro-mechanical properties of bulk fill vs. conventional resin based composites. Clin. Oral Investig. 2014, 18, 1991–2000. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N. Sufficiency of curing in high-viscosity bulk-fill resin composites with enhanced opacity. Clin. Oral Investig. 2019, 23, 747–755. [Google Scholar] [CrossRef] [PubMed]

- Fronza, B.M.; Ayres, A.P.A.; Pacheco, R.R.; Rueggeberg, F.A.; Dias, C.T.S.; Giannini, M. Characterization of Inorganic Filler Content, Mechanical Properties, and Light Transmission of Bulk-fill Resin Composites. Oper. Dent. 2017, 42, 445–455. [Google Scholar] [CrossRef] [PubMed]

- Par, M.; Repusic, I.; Skenderovic, H.; Tarle, Z. Wavelength-dependent light transmittance in resin composites: Practical implications for curing units with different emission spectra. Clin. Oral Investig. 2019, 23, 4399–4409. [Google Scholar] [CrossRef]

- Bazˇant, Z.P.; Chen, E.-P. Scaling of Structural Failure. Appl. Mech. Rev. 1997, 50, 593–627. [Google Scholar] [CrossRef]

- Carpinteri, A. Fractal nature of material microstructure and size effects on apparent mechanical properties. Mech. Mater. 1994, 18, 89–101. [Google Scholar] [CrossRef]

- El-Askary, F.S.; Botros, S.A.; Soliman, Z.D.E.-D.; Nassif, M.S.A.; Özcan, M. Flexure strength of methacrylate- and ormocer-based bulk fill resin composites: Effect of material thickness and distance to photo-polymerization device. J. Adhes. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Soh, M.S.; Yap, A.U.J. Influence of curing modes on crosslink density in polymer structures. J. Dent. 2004, 32, 321–326. [Google Scholar] [CrossRef]

- Sideridou, I.; Tserki, V.; Papanastasiou, G. Study of water sorption, solubility and modulus of elasticity of light-cured dimethacrylate-based dental resins. Biomaterials 2003, 24, 655–665. [Google Scholar] [CrossRef]

- Ilie, N.; Hilton, T.J.; Heintze, S.D.; Hickel, R.; Watts, D.C.; Silikas, N.; Stansbury, J.W.; Cadenaro, M.; Ferracane, J.L. Academy of Dental Materials guidance-Resin composites: Part I—Mechanical properties. Dent. Mater. 2017, 33, 880–894. [Google Scholar] [CrossRef]

- Matošević, D.; Pandurić, V.; Janković, B.; Knežević, A.; Klarić, E.; Tarle, Z. Light Intensity of Curing Units in Dental Offices in Zagreb, Croatia. Acta Stomatol. Croat. 2011, 45, 31–40. [Google Scholar]

- Price, R.B.; Ferracane, J.L.; Shortall, A.C. Light-Curing Units: A Review of What We Need to Know. J. Dent. Res. 2015, 94, 1179–1186. [Google Scholar] [CrossRef]

- Curtis, A.R.; Shortall, A.C.; Marquis, P.M.; Palin, W.M. Water uptake and strength characteristics of a nanofilled resin-based composite. J. Dent. 2008, 36, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Ilie, N.; Hickel, R. Investigations on mechanical behaviour of dental composites. Clin. Oral Investig. 2009, 13, 427–438. [Google Scholar] [CrossRef] [PubMed]

- Sideridou, I.D.; Karabela, M.M.; Bikiaris, D.N. Aging studies of light cured dimethacrylate-based dental resins and a resin composite in water or ethanol/water. Dent. Mater. 2007, 23, 1142–1149. [Google Scholar] [CrossRef] [PubMed]

| Viscosity | Material (Manufacturer, Abbreviation) | Resin | Filler wt%/vol% | Photoinitiators |

|---|---|---|---|---|

| High- viscosity | Filtek One Bulk Fill Restorative, 3M ESPE, St. Paul, MN, USA (FIL) | AUDMA, DDDMA, proprietary AFM | 76.5/58.5 | CQ/amine |

| Tetric PowerFill, Ivoclar Vivadent, Schaan, Liechtenstein (PFILL) | Bis-GMA, Bis-EMA, UDMA, PBPA, DCP, β-allyl sulfone | 76/53 | CQ/amine, Ivocerin | |

| Low- viscosity | SDR Plus Bulk Fill Flowable, Dentsply Caulk; Milford, CT, USA (SDR) | Modified UDMA, TEGDMA, dimethacrylate and trimethacrylate resins | 70.5/47.4 | CQ/amine |

| Tetric PowerFlow, Ivoclar Vivadent, Schaan, Liechtenstein (PFLW) | Bis-GMA, Bis-EMA, UDMA, DCP | 68/46 | CQ/amine, Ivocerin |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marovic, D.; Par, M.; Crnadak, A.; Sekelja, A.; Negovetic Mandic, V.; Gamulin, O.; Rakić, M.; Tarle, Z. Rapid 3 s Curing: What Happens in Deep Layers of New Bulk-Fill Composites? Materials 2021, 14, 515. https://doi.org/10.3390/ma14030515

Marovic D, Par M, Crnadak A, Sekelja A, Negovetic Mandic V, Gamulin O, Rakić M, Tarle Z. Rapid 3 s Curing: What Happens in Deep Layers of New Bulk-Fill Composites? Materials. 2021; 14(3):515. https://doi.org/10.3390/ma14030515

Chicago/Turabian StyleMarovic, Danijela, Matej Par, Ana Crnadak, Andjelina Sekelja, Visnja Negovetic Mandic, Ozren Gamulin, Mario Rakić, and Zrinka Tarle. 2021. "Rapid 3 s Curing: What Happens in Deep Layers of New Bulk-Fill Composites?" Materials 14, no. 3: 515. https://doi.org/10.3390/ma14030515

APA StyleMarovic, D., Par, M., Crnadak, A., Sekelja, A., Negovetic Mandic, V., Gamulin, O., Rakić, M., & Tarle, Z. (2021). Rapid 3 s Curing: What Happens in Deep Layers of New Bulk-Fill Composites? Materials, 14(3), 515. https://doi.org/10.3390/ma14030515