Solution-Processed Efficient Blue Phosphorescent Organic Light-Emitting Diodes (PHOLEDs) Enabled by Hole-Transport Material Incorporated Single Emission Layer

Abstract

:1. Introduction

2. Materials and Methods

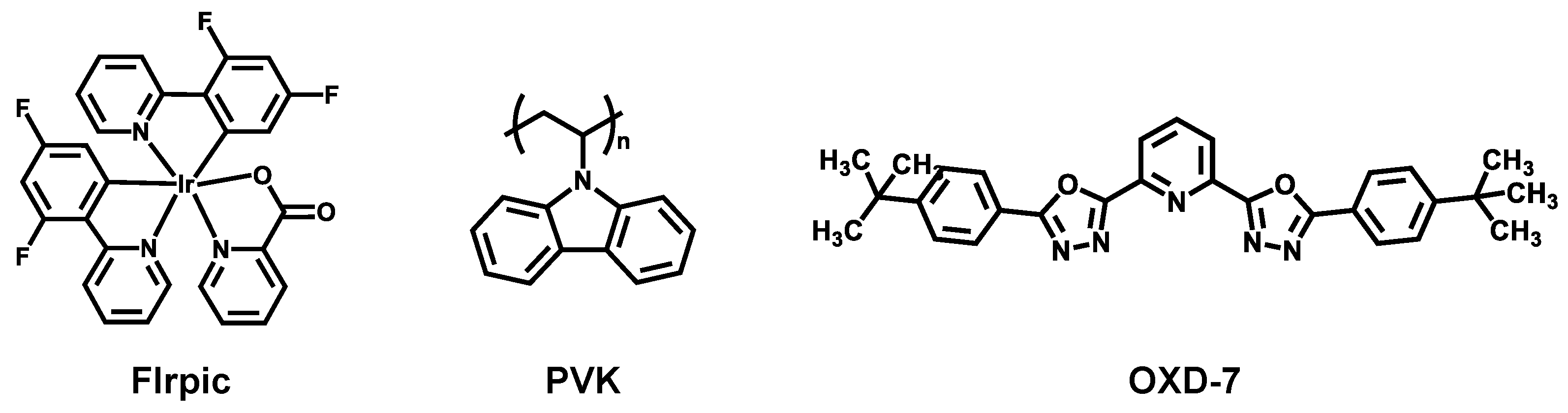

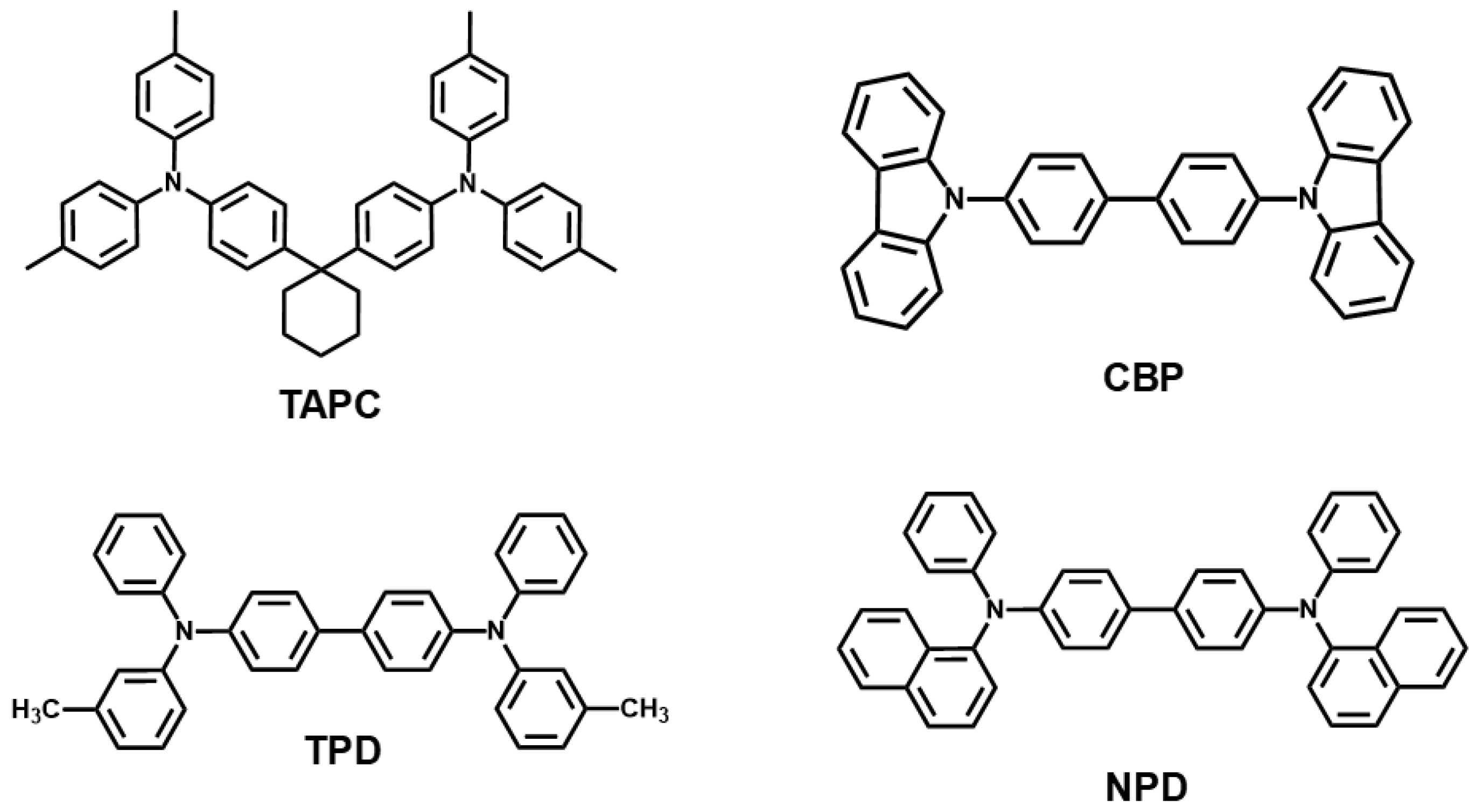

2.1. Materials

2.2. Device Fabrication

2.3. Device Characterization

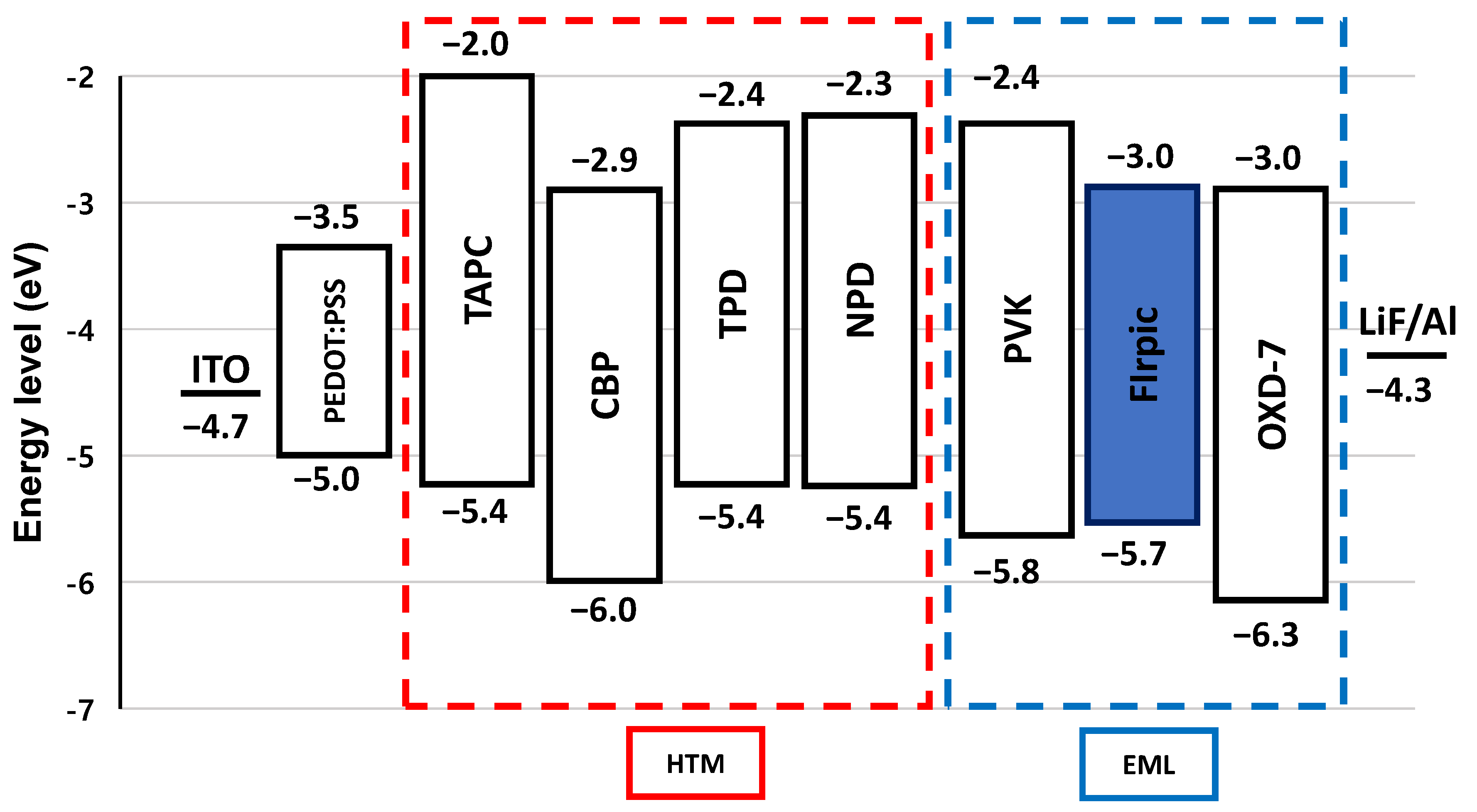

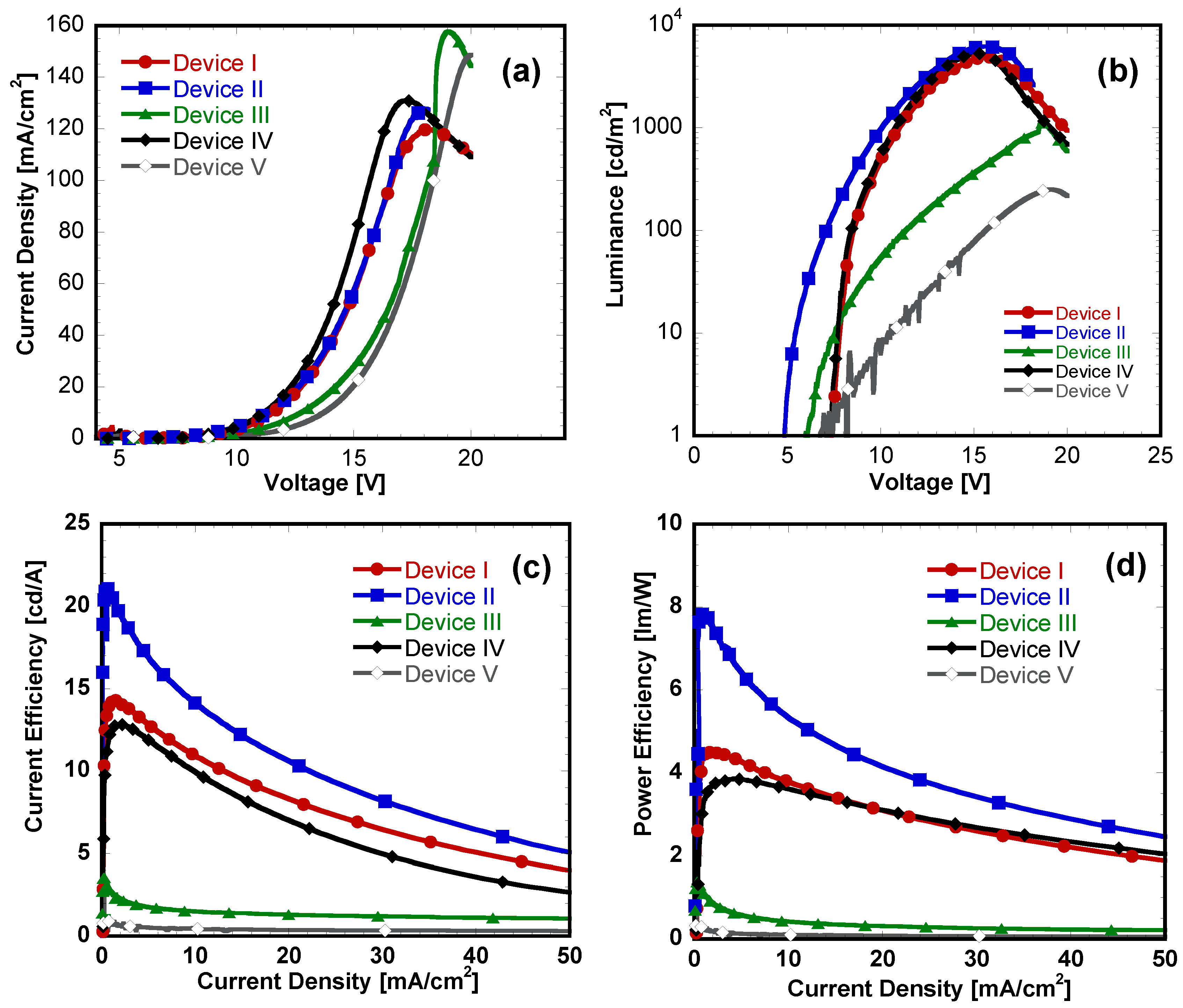

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tao, Y.; Yang, C.; Qin, J. Organic host materials for phosphorescent organic light-emitting diodes. Chem. Soc. Rev. 2011, 40, 2943–2970. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, E.; Earmme, T.; Jenekhe, S.A. New Solution-Processable Electron Transport Materials for Highly Efficient Blue Phosphorescent OLEDs. Adv. Funct. Mater. 2011, 40, 3889–3899. [Google Scholar] [CrossRef]

- Yook, K.S.; Lee, J.Y. Solution processed deep blue phosphorescent organic light-emitting diodes with over 20% external quantum efficiency. Org. Electron. 2011, 12, 1711–1715. [Google Scholar] [CrossRef]

- Lee, J.; Chen, H.-F.; Batagoda, T.; Coburn, C.; Djurovich, P.I.; Thompson, M.E.; Forrest, S.R. Deep blue phosphorescent organic light-emitting diodes with very high brightness and efficiency. Nat. Mater. 2016, 15, 92–98. [Google Scholar] [CrossRef] [PubMed]

- Sasabe, H.; Kido, J. Development of high performance OLEDs for general lighting. J. Mater. Chem. 2013, 1, 1699–1707. [Google Scholar] [CrossRef]

- Zhang, T.; Li, A.; Sheng, R.; Sun, M.; Chen, P. Highly Efficient Single-Layer Phosphorescent Organic Light-Emitting Diodes Based on Co-Host Structure. Materials 2020, 13, 2029. [Google Scholar] [CrossRef] [PubMed]

- Byeon, S.Y.; Lee, K.H.; Lee, J.Y. Suppression of device degradation mechanism by triphenylsilyl group substitution of the host for blue phosphorescent organic light-emitting diodes. J. Ind. Eng. Chem. 2020, 86, 144–149. [Google Scholar] [CrossRef]

- Im, Y.; Han, S.H.; Lee, J.Y. Bipolar type indolocarbazole host for green phosphorescent organic light-emitting diodes. J. Ind. Eng. Chem. 2018, 66, 381–386. [Google Scholar] [CrossRef]

- Lee, S.E.; Oh, J.H.; Baek, H.J.; Kim, S.; Do, Y.R.; Kim, Y.K. Realization of high-color-quality white-by-blue organic light-emitting diodes with yellow and red phosphor films. J. Lumin. 2018, 207, 195–200. [Google Scholar] [CrossRef]

- Lee, S.J.; Seo, J.H.; Kim, J.H.; Kim, H.M.; Lee, K.H.; Yoon, S.S.; Kim, Y.K. Efficient triplet exciton confinement of white organic light-emitting diodes using a heavily doped phosphorescent blue emitter. Thin Solid Films 2010, 518, 6184–6187. [Google Scholar] [CrossRef]

- Song, W.; Lee, J.Y. Degradation Mechanism and Lifetime Improvement Strategy for Blue Phosphorescent Organic Light-Emitting Diodes. Adv. Opt. Mater. 2017, 5, 1600901. [Google Scholar] [CrossRef]

- Yook, K.S.; Lee, J.Y. Organic Materials for Deep Blue Phosphorescent Organic Light-Emitting Diodes. Adv. Mater. 2012, 24, 3169–3190. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Song, D.W.; Chopra, N.; De Somer, P.; So, F. Organic Infrared Upconversion Device. Adv. Mater. 2010, 22, 2260–2263. [Google Scholar] [CrossRef] [PubMed]

- Earmme, T.; Ahmed, E.; Jenekhe, S.A. Solution-processed highly efficient blue phosphorescent polymer light-emitting diodes enabled by a new electron transport material. Adv. Mater. 2010, 22, 4744–4748. [Google Scholar] [CrossRef] [PubMed]

- Earmme, T.; Jenekhe, S.A. High-performance multilayered phosphorescent OLEDs by solution-processed commercial electron-transport materials. J. Mater. Chem. 2012, 22, 4660–4668. [Google Scholar] [CrossRef]

- Earmme, T.; Jenekhe, S.A. Improved electron injection and transport by use of baking soda as a low-cost, air-stable, n-dopant for solution-processed phosphorescent organic light-emitting diodes. Appl. Phys. Lett. 2013, 102, 233305. [Google Scholar] [CrossRef]

- Gong, X.; Robinson, M.R.; Ostrowski, J.C.; Moses, D.; Bazan, G.C.; Heeger, A.J. High-Efficiency Polymer-Based Electrophosphorescent Devices. Adv. Mater. 2002, 14, 581–585. [Google Scholar] [CrossRef]

- Khalifa, M.B.; Vaufrey, D.; Bouazizi, A.; Tardy, J.; Maaref, H. Hole injection and transport in ITO/PEDOT/PVK/Al diodes. Mater. Sci. Eng. C 2002, 21, 277–282. [Google Scholar] [CrossRef]

- Borsenberger, P.M.; Magin, E.H.; Fitzgerald, J.J. Concentration dependence of the hole mobility of 1,1-bis((di-4-tolylamino)phenyl)cyclohexane (TAPC) doped polystyrene (PS). J. Phys Chem. 1993, 97, 9213–9216. [Google Scholar] [CrossRef]

- Matsushima, H.; Naka, S.; Okada, H.; Onnagawa, H. Organic electrophosphorescent devices with mixed hole transport material as emission layer. Curr. Appl. Phys. 1993, 97, 9213–9216. [Google Scholar] [CrossRef]

- Shen, Y.; Klein, M.W.; Jacobs, D.B.; Scott, J.C.; Malliaras, G.G. Mobility-Dependent Charge Injection into an Organic Semiconductor. Phys. Rev. Lett. 2001, 86, 3867–3870. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lee, J.; Forrest, S.R. Tenfold increase in the lifetime of blue phosphorescent organic light-emitting diodes. Nat. Commun. 2014, 5, 5008. [Google Scholar] [CrossRef] [PubMed]

- Swayamprabha, S.S.; Nagar, M.R.; Yadav, R.A.K.; Gull, S.; Dubey, D.K.; Jou, J.-H. Hole-transporting materials for organic light-emitting diodes: An overview. J. Mater. Chem. C 2019, 7, 7144–7158. [Google Scholar]

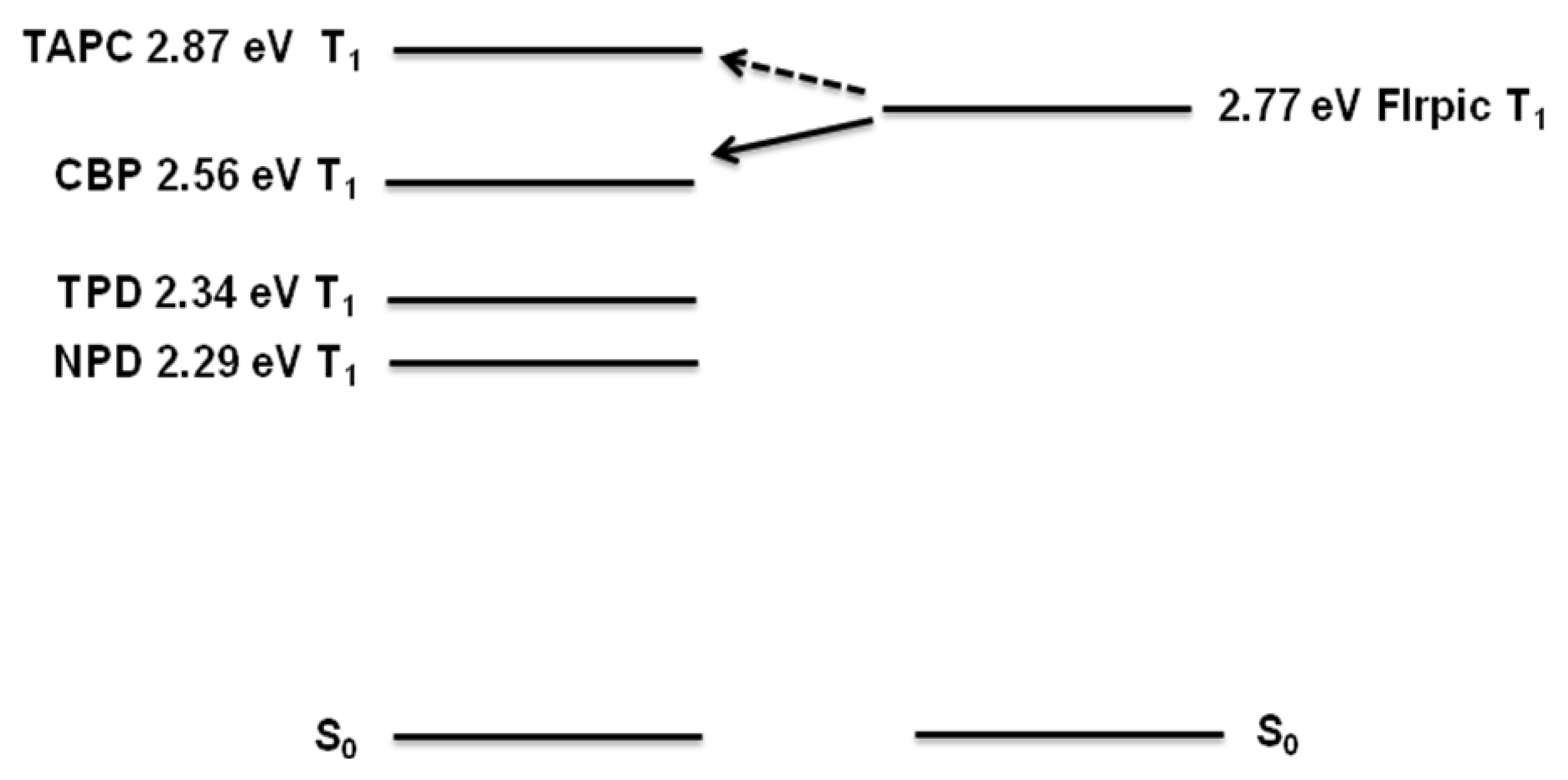

- Goushi, K.; Kwong, R.; Brown, J.J.; Sasabe, H.; Adachi, C. Triplet exciton confinement and unconfinement by adjacent hole-transport layers. J. Appl. Phys. 2004, 95, 7798–7802. [Google Scholar] [CrossRef]

- Wu, P.G.; Brand, L. Resonance Energy Transfer: Methods and Applications. Anal. Biochem. 1994, 218, 1–13. [Google Scholar] [CrossRef]

| Device | Incorporated HTM | Turn-On Voltage 1 (V) | Drive Voltage (V) | Current Density 2 (mA/cm2) | Max Luminance (cd/m2) | Device Efficiency (CE (cd/A)), (EQE (%)) |

|---|---|---|---|---|---|---|

| Device I (w/o HTM) | None | 7.2 ± 0.1 | 15.8 ± 0.1 | 75.9 ± 2.4 | 4870 ± 30 | 14.3 ± 0.07, 7.2 ± 0.04 |

| Device II (w/ TAPC) | TAPC | 4.8 ± 0.1 | 15.8 ± 0.1 | 73.0 ± 2.3 | 6220 ± 30 | 21.1 ± 0.11, 10.6 ± 0.05 |

| Device III (w/TPD) | TPD | 6.6 ± 0.1 | 18.7 ± 0.1 | 150.4 ± 2.7 | 1110 ± 10 | 3.7 ± 0.03, 1.9 ± 0.02 |

| Device IV (w/CBP) | CBP | 7.2 ± 0.1 | 15.4 ± 0.1 | 81.3 ± 2.5 | 5280 ± 20 | 12.9 ± 0.06, 6.5 ± 0.04 |

| Device V (w/NPD) | NPD | 6.9 ± 0.1 | 19.1 ± 0.1 | 128.0 ± 3.3 | 250 ± 10 | 0.4 ± 0.02, 0.2 ± 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Earmme, T. Solution-Processed Efficient Blue Phosphorescent Organic Light-Emitting Diodes (PHOLEDs) Enabled by Hole-Transport Material Incorporated Single Emission Layer. Materials 2021, 14, 554. https://doi.org/10.3390/ma14030554

Earmme T. Solution-Processed Efficient Blue Phosphorescent Organic Light-Emitting Diodes (PHOLEDs) Enabled by Hole-Transport Material Incorporated Single Emission Layer. Materials. 2021; 14(3):554. https://doi.org/10.3390/ma14030554

Chicago/Turabian StyleEarmme, Taeshik. 2021. "Solution-Processed Efficient Blue Phosphorescent Organic Light-Emitting Diodes (PHOLEDs) Enabled by Hole-Transport Material Incorporated Single Emission Layer" Materials 14, no. 3: 554. https://doi.org/10.3390/ma14030554

APA StyleEarmme, T. (2021). Solution-Processed Efficient Blue Phosphorescent Organic Light-Emitting Diodes (PHOLEDs) Enabled by Hole-Transport Material Incorporated Single Emission Layer. Materials, 14(3), 554. https://doi.org/10.3390/ma14030554