Resistance to Growth of Molds for Wood Modified with Hydrophobic Hybrid Silica Gel Containing Copper Amine Complexes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hybrid Sol-Gel Process for Wood Modification

2.3. Leaching Resistance Test

2.4. Resistance to Growth of Molds Test

2.5. Characterization

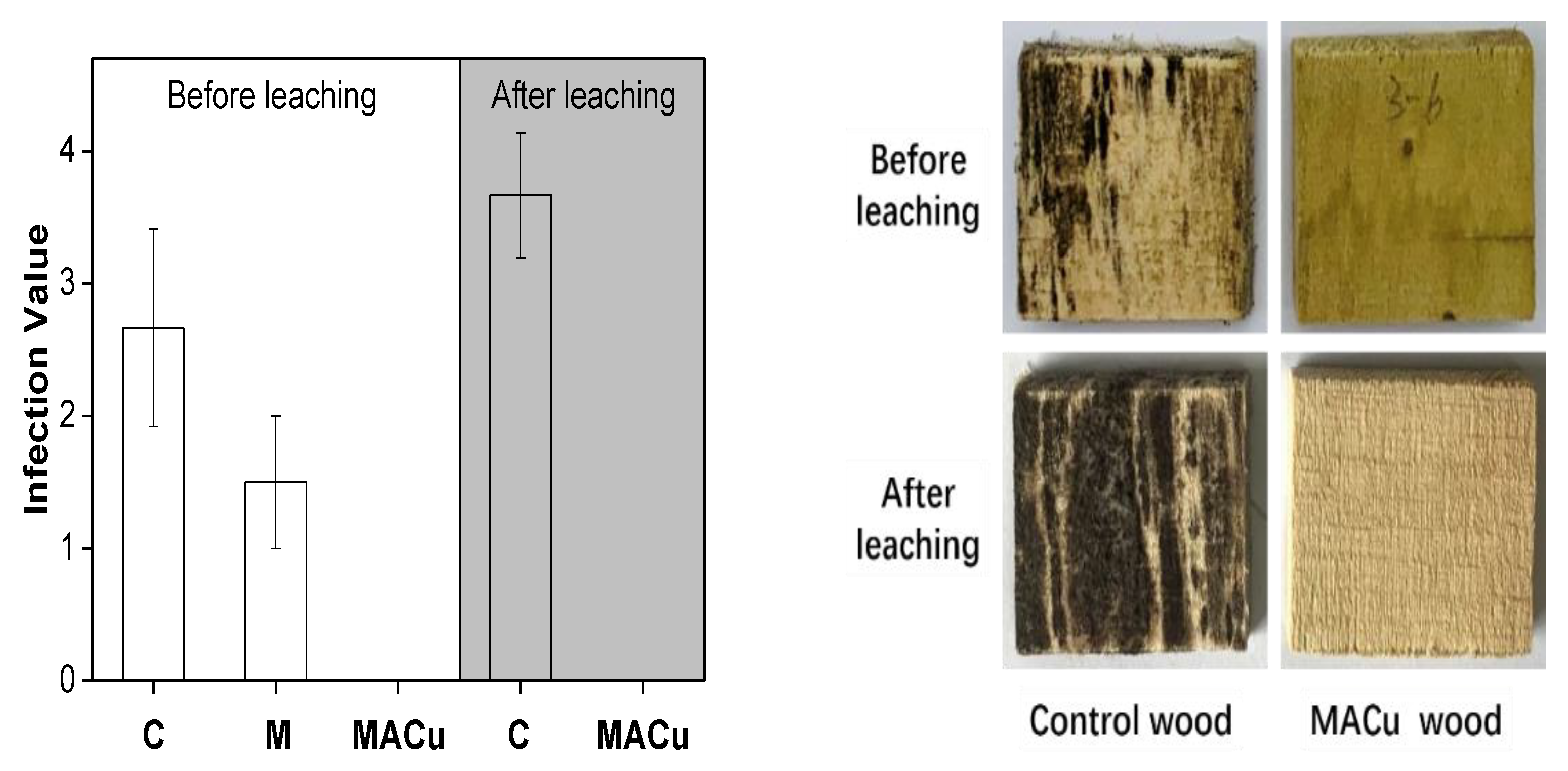

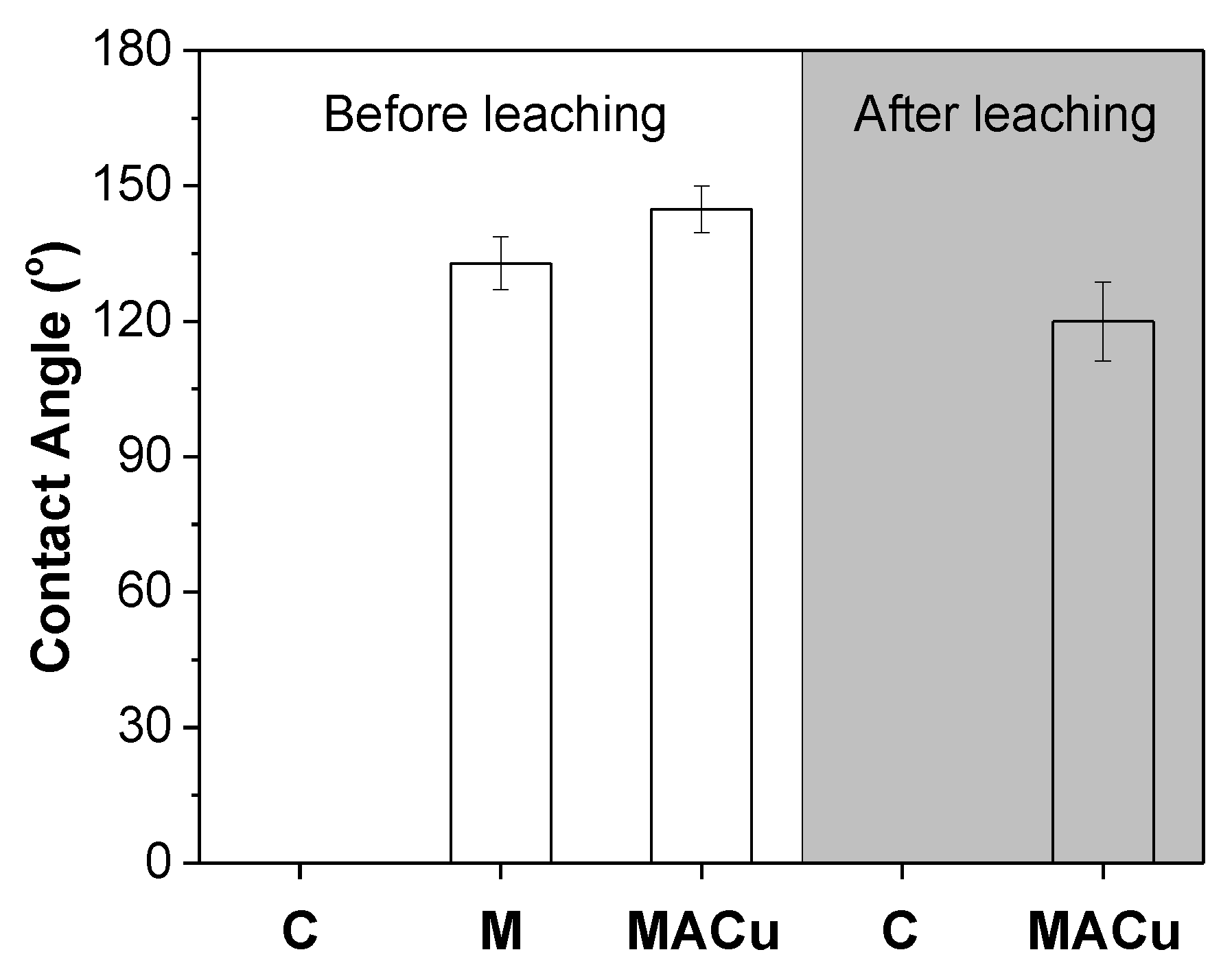

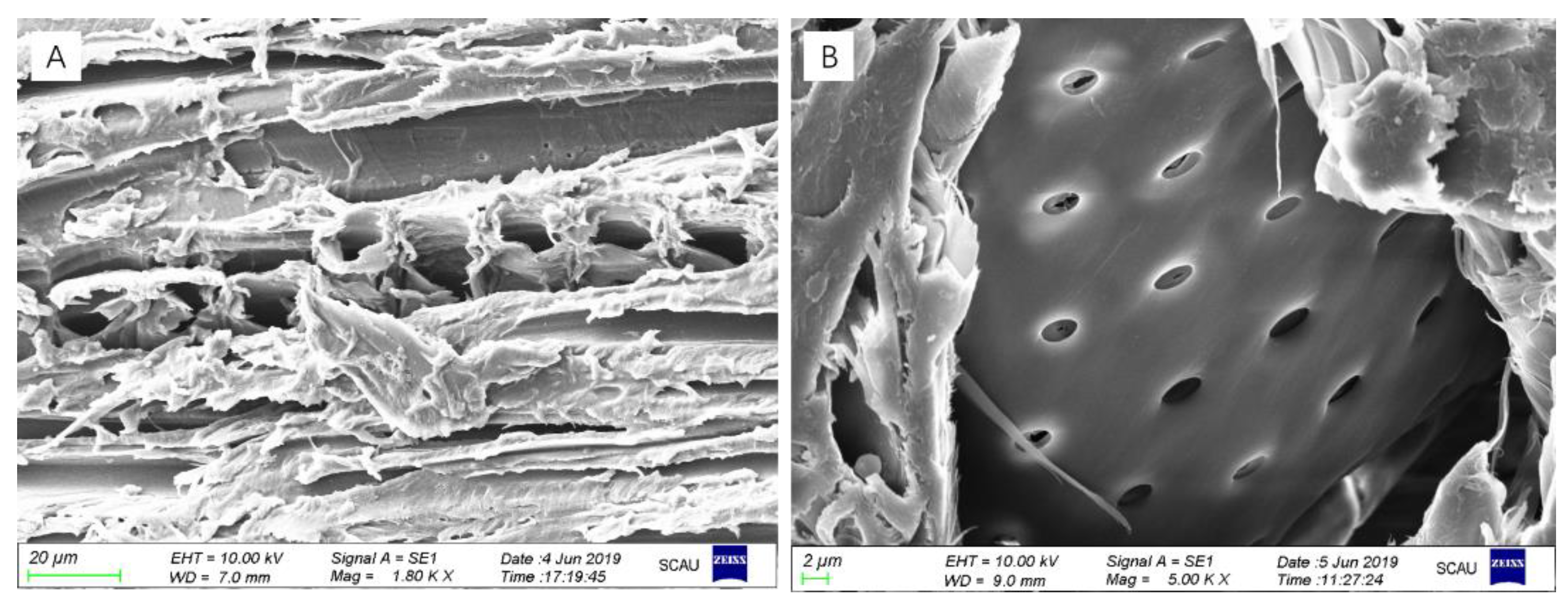

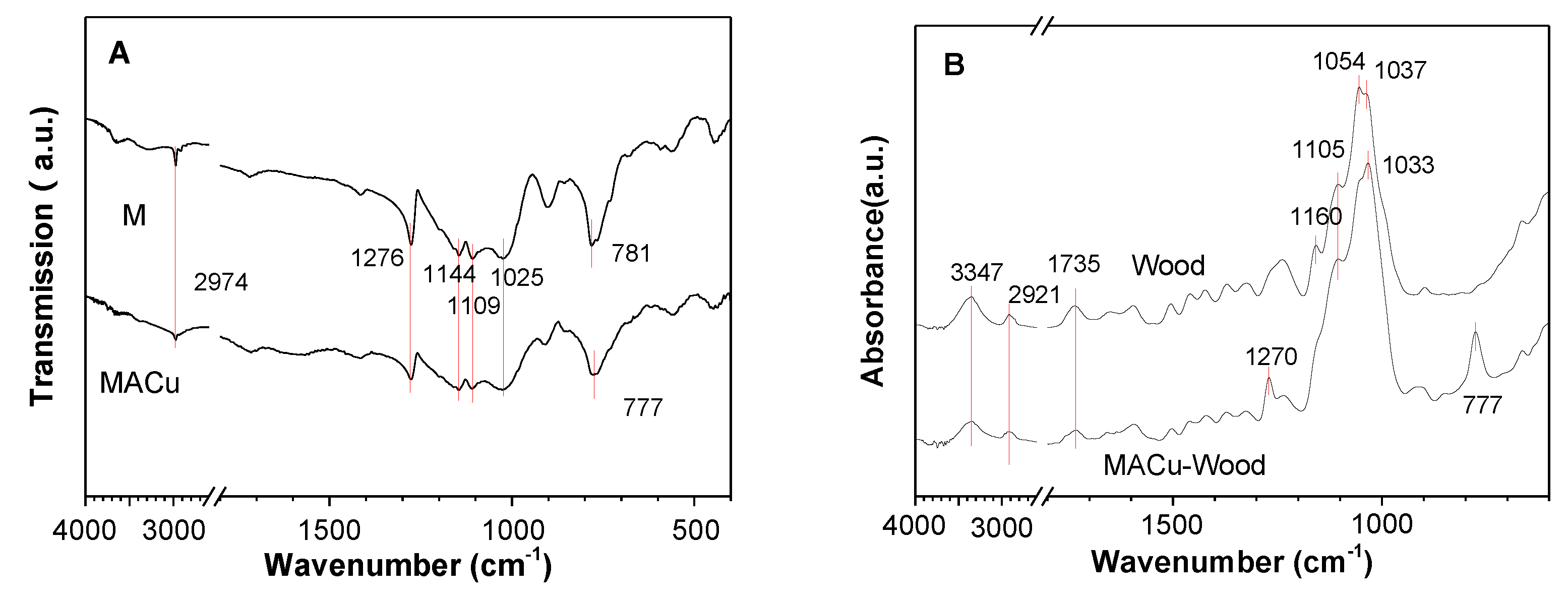

3. Results and Discussion

3.1. Results

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jin, C.; Li, J.; Han, S.; Wang, J.; Yao, Q.; Sun, Q. Silver mirror reaction as an approach to construct a durable, robust superhydrophobic surface of bamboo timber with high conductivity. J. Alloys Compd. 2015, 635, 300–306. [Google Scholar] [CrossRef]

- Eaton, R.A.; Hale, M.D.C. Wood: Decay, Pests, and Protection; Chapman and Hall: London, UK, 1993. [Google Scholar]

- Tascioglu, C.; Cooper, P.; Ung, T. Effects of delayed drying and CO2 application on copper amine fixation in ACQ treatedred pine. Eur. J. Wood Wood Prod. 2009, 67, 7–12. [Google Scholar] [CrossRef]

- Mourant, D.; Yang, D.-Q.; Lu, X.; Riedl, B.; Roy, C. Copper and boron fixation in wood by pyrolytic resins. Bioresour. Technol. 2009, 100, 1442–1449. [Google Scholar] [CrossRef] [PubMed]

- Palanti, S.; Predieri, G.; Vignali, F.; Feci, E.; Casoli, A.; Conti, E. Copper complexes grafted to functionalized silica gel as wood preservatives against the brown rot fungus Coniophora puteana. Wood Sci. Technol. 2011, 45, 707–718. [Google Scholar] [CrossRef]

- Palanti, S.; Feci, E.; Predieri, G.; Vignali, F. A wood treatment based on siloxanes and boric acid against fungal decay and coleopter Hylotrupes bajulus. Int. Biodeterior. Biodegrad. 2012, 75, 49–54. [Google Scholar] [CrossRef]

- Vignali, F.; Predieri, G.; Feci, E.; Palanti, S.; Baratto, M.C.; Basosi, R.; Callone, E.; Müller, K. Interpenetration of wood with NH2R-functionalized silica xerogels anchoring copper (II) for preservation purposes. J. Sol.-Gel. Sci. Technol. 2011, 60, 445–456. [Google Scholar] [CrossRef]

- Bergamonti, L.; Berzolla, A.; Chiappini, E.; Feci, E.; Maistrello, L.; Palanti, S.; Predieri, G.; Vaccari, G. Polyamidoamines (PAAs) functionalized with siloxanes as wood preservatives against fungi and insects. Holzforschung 2016, 71, 65–75. [Google Scholar] [CrossRef]

- Bergamonti, L.; Graiff, C.; Tegoni, M.; Predieri, G.; Bellot-Gurlet, L.; Lottici, P.P. Raman and NMR kinetics study of the formation of amidoamines containing N-hydroxyethyl groups and investigations on their Cu(II) complexes in water. Spectrochim. Acta Part. Mol. Biomol. Spectrosc. 2017, 171, 515–524. [Google Scholar] [CrossRef]

- Bergamonti, L.; Graiff, C.; Tegoni, M.; Predieri, G.; Elviri, L.; Palanti, S.; Paris, C.; Cappelletto, E.; Maggio, R.D.; Lottici, P.P. Facile preparation of functionalized poly(amidoamine)s with biocidal activity on wood substrates. Eur. Polym. J. 2019, 116, 232–241. [Google Scholar] [CrossRef]

- Bussjaeger, S.; Daisey, G.; Simmons, R.; Spindel, S.; Williams, S. Mildew and mildew control for wood surfaces. J. Coat. Technol. 1999, 71, 67–69. [Google Scholar]

- Liese, W. Research on bamboo. Wood Sci. Technol. 1987, 21, 189–209. [Google Scholar]

- Sun, F.; Bao, B.; Ma, L.; Chen, A.; Duan, X. Mould-resistance of bamboo treated with the compound of chitosan-copper complex and organic fungicides. J. Wood Sci. 2012, 58, 51–56. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Bao, Y.; Chen, Y.; Huang, C.; Li, N.; He, S.; Chen, Z. Wet chemical synthesis of ZnO nanocoating on the surface of bamboo timber with improved mould-resistance. J. Saudi Chem. Soc. 2017, 21, 920–928. [Google Scholar] [CrossRef]

- Yu, Y.; Jiang, Z.; Tian, G.; Wang, H.; Song, Y. Improving photostability and antifungal performance of bamboo with nanostructured zinc oxide. Wood Fiber Sci. 2011, 43, 293–304. [Google Scholar]

- Yu, Y.; Jiang, Z.; Wang, G.; Tian, G.; Wang, H.; Song, Y. Surface functionalization of bamboo with nanostructured ZnO. Wood Sci. Technol. 2012, 46, 781–790. [Google Scholar] [CrossRef]

- Li, J.; Zheng, H.; Sun, Q.; Han, S.; Fan, B.; Yao, Q.; Yan, C.; Jin, C. Fabrication of superhydrophobic bamboo timber based on an anatase TiO2 film for acid rain protection and flame retardancy. Rsc. Adv. 2015, 5, 62265–62272. [Google Scholar] [CrossRef]

- Li, J.; Yu, H.; Wu, Z.; Wang, J.; He, S.; Ji, J.; Li, N.; Bao, Y.; Huang, C.; Chen, Z.; et al. Room temperature synthesis of crystalline anatase TiO2 on bamboo timber surface and their short-term antifungal capability under natural weather conditions. Colloid. Surf. A 2016, 508, 117–123. [Google Scholar] [CrossRef]

- Guo, H.; Bachtiar, E.V.; Ribera, J.; Heeb, M.; Schwarze, F.W.M.R.; Burgert, I. Non-biocidal preservation of wood against brown-rot fungi with TiO2/Ce Xerogel. Green Chem. 2018, 20, 1375–1382. [Google Scholar] [CrossRef]

- Xie, G.; Zhou, Y.; Cao, Y.; Li, L. Anti-Mildew Properties of Copper Cured Heat-Treated Wood. Bioresour. 2018, 13, 5643–5655. [Google Scholar]

- Wang, J.; Sun, Q.; Sun, F.; Zhang, Q.; Jin, C. Layer-by-layer self-assembly of reduced graphene oxide on bamboo timber surface with improved decay resistance. Eur. J. Wood Wood Prod. 2018, 76, 1223–1231. [Google Scholar] [CrossRef]

- Li, J.; Su, M.; Wang, A.; Wu, Z.; Chen, Y.; Qin, D.; Jiang, Z. In Situ Formation of Ag Nanoparticles in Mesoporous TiO2 Films Decorated on Bamboo via Self-Sacrificing Reduction to Synthesize Nanocomposites with Efficient Antifungal Activity. Int. J. Mol. Sci. 2019, 20, 5497. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, J.; Zhuang, X.; Pan, X.; Yu, H.; Sun, F.; Song, J.; Jin, C.; Jiang, Y. Improved mould resistance and antibacterial activity of bamboo coated with ZnO/graphene. R. Soc. Open Sci. 2018, 5, 180173–180184. [Google Scholar] [CrossRef] [PubMed]

- Ren, D.; Li, J.; Xu, J.; Wu, Z.; Bao, Y.; Li, N.; Chen, Y. Efficient antifungal and flame-retardant properties of ZnO-TiO2-layered double-nanostructures coated on bamboo substrate. Coat. 2018, 8, 341. [Google Scholar] [CrossRef]

- Goffredo, G.B.; Citterio, B.; Biavasco, F.; Stazi, F.; Barcelli, S.; Munafo, P. Nanotechnology on wood: The effect of photocatalytic nanocoatings against Aspergillus niger. J. Cult. Herit. 2017, 27, 125–136. [Google Scholar] [CrossRef]

- Xie, Y.; Krause, A.; Militz, H.; Mai, C. Weathering of uncoated and coated wood treated with methylated 1,3-dimethylol-4,5-dihydroxyethyleneurea (mDMDHEU). Holz. Als. Roh. Und. Werkst. 2008, 66, 455–464. [Google Scholar] [CrossRef]

- Guillemot, G.; Despax, B.; Raynaud, P.; Zanna, S.; Marcus, P.; Schmitz, P.; Mercier-Bonin, M. Plasma deposition of silver nanoparticles onto stainless steel for the prevention of fungal biofilms: A case study on Saccharomyces cerevisiae. Plasma Process. Polym. 2008, 5, 228–238. [Google Scholar] [CrossRef]

- Wang, D.; Hu, C.; Gu, J.; Tu, D.; Wang, G.; Jiang, M.; Zhang, W. Bamboo surface coated with polymethylsilsesquioxane/Cu-containing nanoparticles (PMS/CuNP) xerogel for superhydrophobic and anti-mildew performance. J. Wood Sci. 2020, 66, 1–8. [Google Scholar] [CrossRef]

- Donath, S.; Militz, H.; Mai, C. Wood modification with alkoxysilanes. Wood Sci. Technol. 2004, 38, 555–566. [Google Scholar] [CrossRef]

- AWPA E11-16. Standard Method for Accelerated Evaluation of Preservative Leaching; American Wood Protection Association: Hoover, AL, USA, 2016. [Google Scholar]

- ASTM D3273-16. Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Li, S.; Zhang, S.; Wang, X. Fabrication of superhydrophobic cellulose-based materials through a solution-immersion process. Langmuir 2008, 24, 5585–5590. [Google Scholar] [CrossRef]

- Pandey, K.K.; Pitman, A.J. FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int. Biodeterior. Biodegrad. 2003, 52, 151–160. [Google Scholar] [CrossRef]

- Donath, S.; Militz, H.; Mai, C. Creating water-repellent effects on wood by treatment with silanes. Holzforschung 2006, 60, 40–46. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Farahani, M.R.M.; Hale, M.D.C. The use of organo alkoxysilane coupling agents for wood preservation. Holzforschung 2004, 58, 316–325. [Google Scholar] [CrossRef]

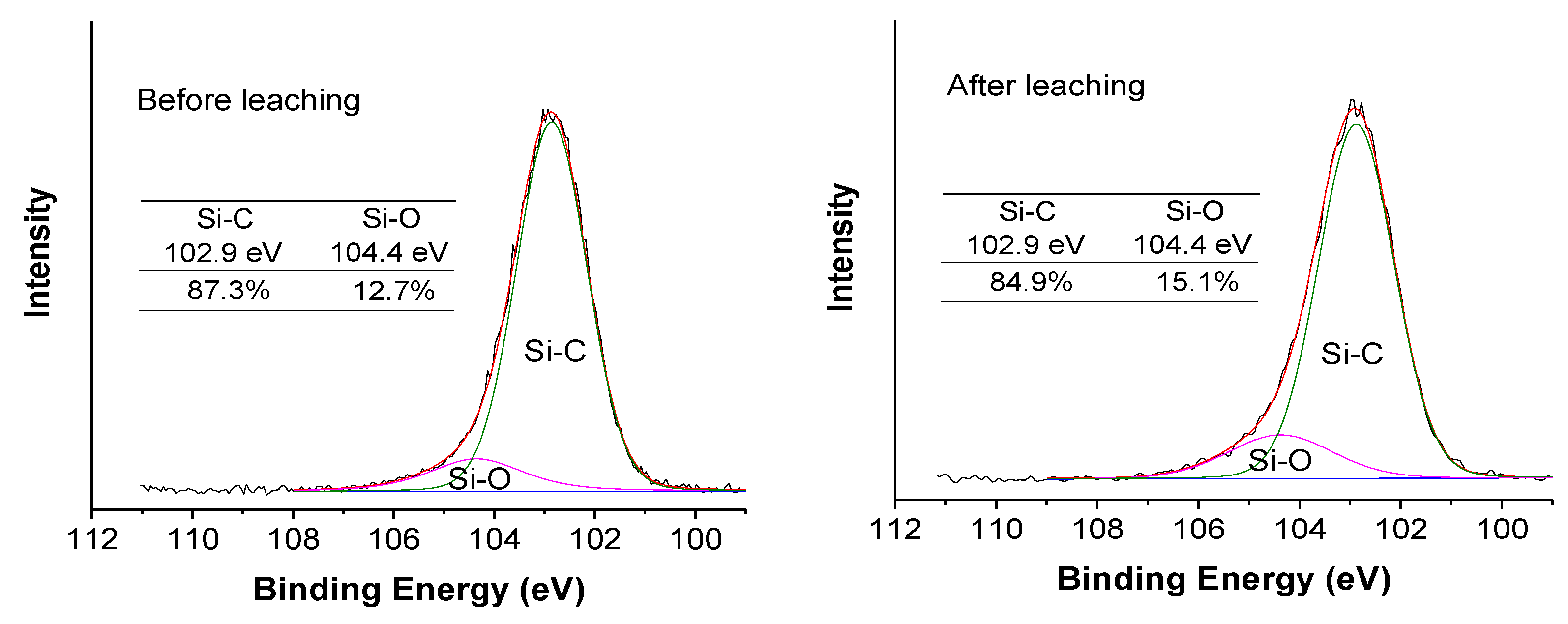

- Malecha, K.; Gancarz, I.; Tylus, W. Argon plasma-assisted PDMS–LTCC bonding technique for microsystem applications. J. Micromech. Microeng. 2010, 20, 115006–115014. [Google Scholar] [CrossRef]

- Bücker, M.; Jäger, C.; Pfeifer, D.; Unger, B. Evidence of Si–O–C bonds in cellulosic materials modified by sol–gel-derived silica. Wood Sci. Technol. 2014, 48, 1033–1047. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, S.; Hu, C.; Lin, X.; Gu, J.; Yun, H.; Zhang, W. Resistance to Growth of Molds for Wood Modified with Hydrophobic Hybrid Silica Gel Containing Copper Amine Complexes. Materials 2021, 14, 577. https://doi.org/10.3390/ma14030577

Hao S, Hu C, Lin X, Gu J, Yun H, Zhang W. Resistance to Growth of Molds for Wood Modified with Hydrophobic Hybrid Silica Gel Containing Copper Amine Complexes. Materials. 2021; 14(3):577. https://doi.org/10.3390/ma14030577

Chicago/Turabian StyleHao, Shaokun, Chuanshuang Hu, Xiuyi Lin, Jin Gu, Hong Yun, and Weiwei Zhang. 2021. "Resistance to Growth of Molds for Wood Modified with Hydrophobic Hybrid Silica Gel Containing Copper Amine Complexes" Materials 14, no. 3: 577. https://doi.org/10.3390/ma14030577

APA StyleHao, S., Hu, C., Lin, X., Gu, J., Yun, H., & Zhang, W. (2021). Resistance to Growth of Molds for Wood Modified with Hydrophobic Hybrid Silica Gel Containing Copper Amine Complexes. Materials, 14(3), 577. https://doi.org/10.3390/ma14030577