Study of the Effects of Initial Cutting Conditions and Transition Period on Ultimate Tool Life when Machining Inconel 718

Abstract

:1. Introduction

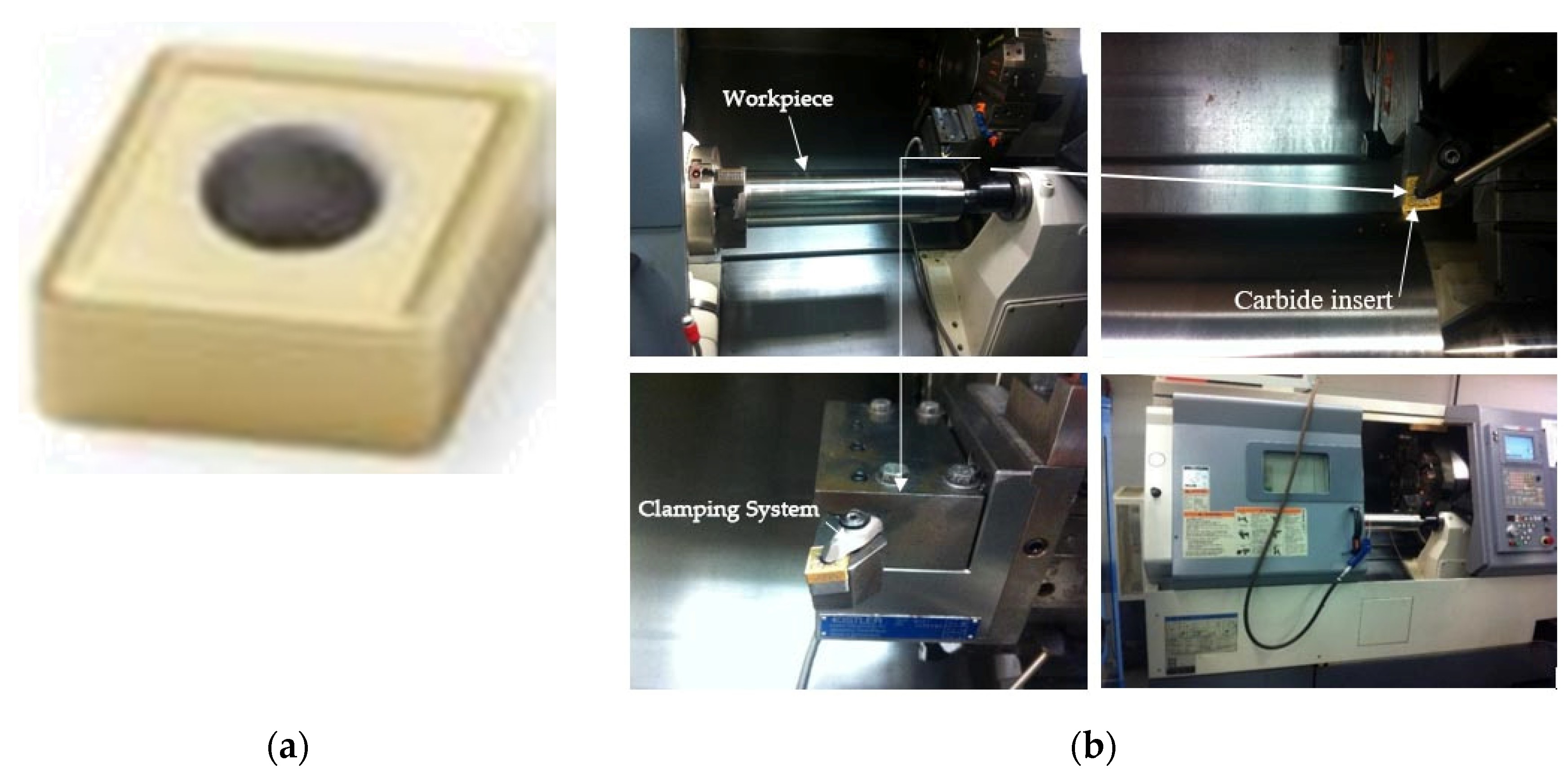

2. Experimental Work

2.1. Experimental Plan

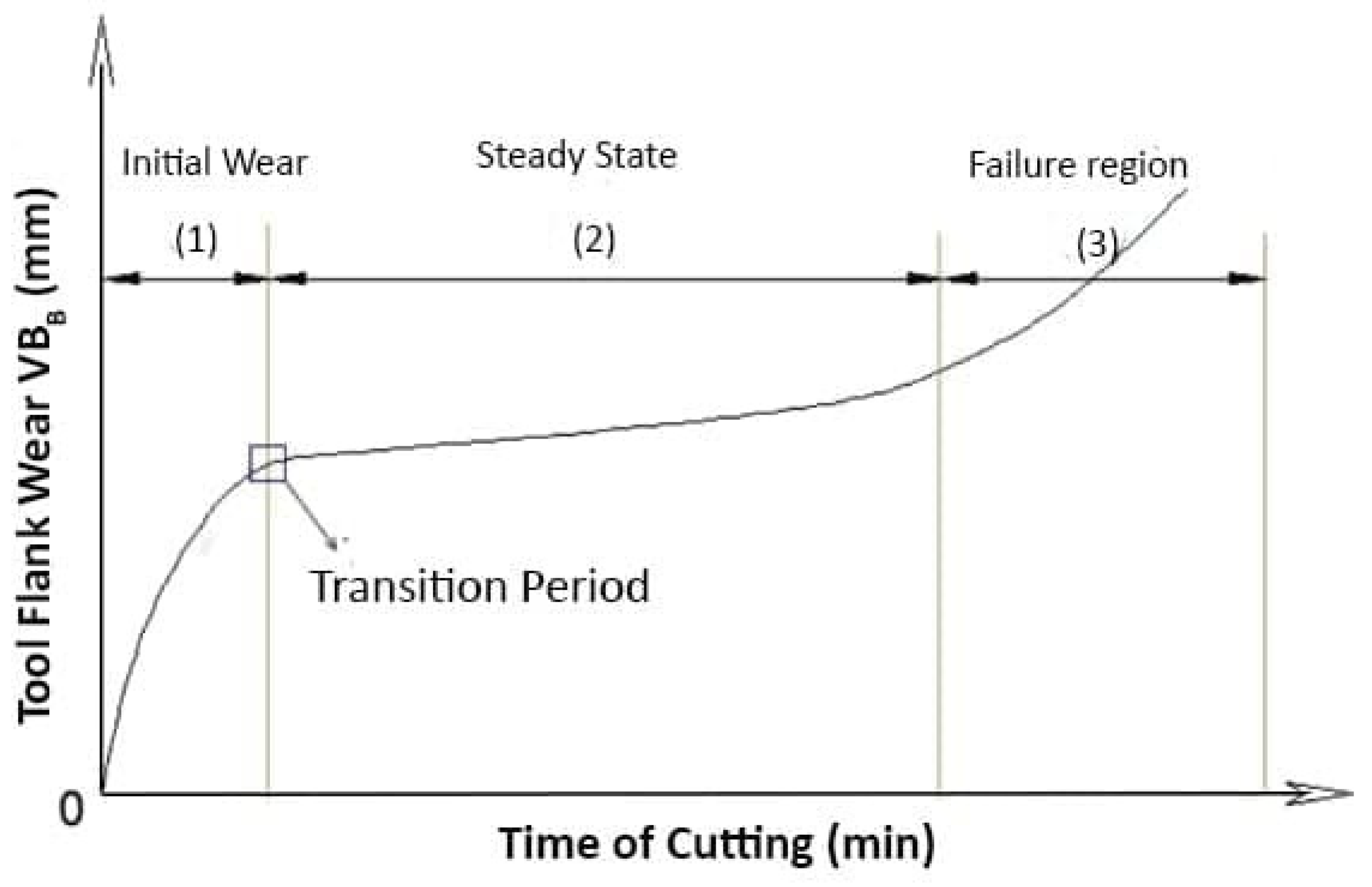

2.2. Tool Wear Measurement

3. Result and Discussion

3.1. Effects of Cutting Parameters on Tool Life

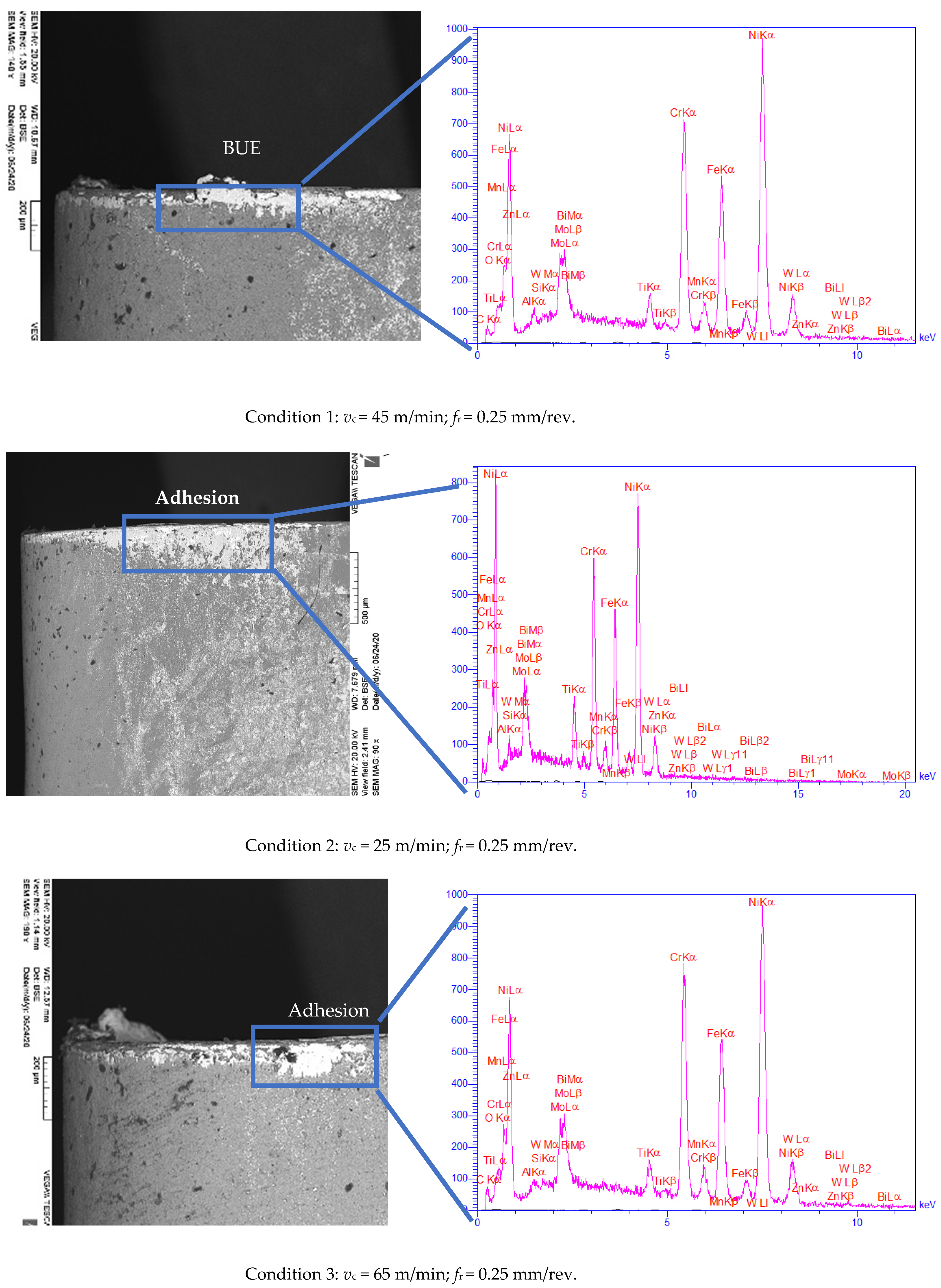

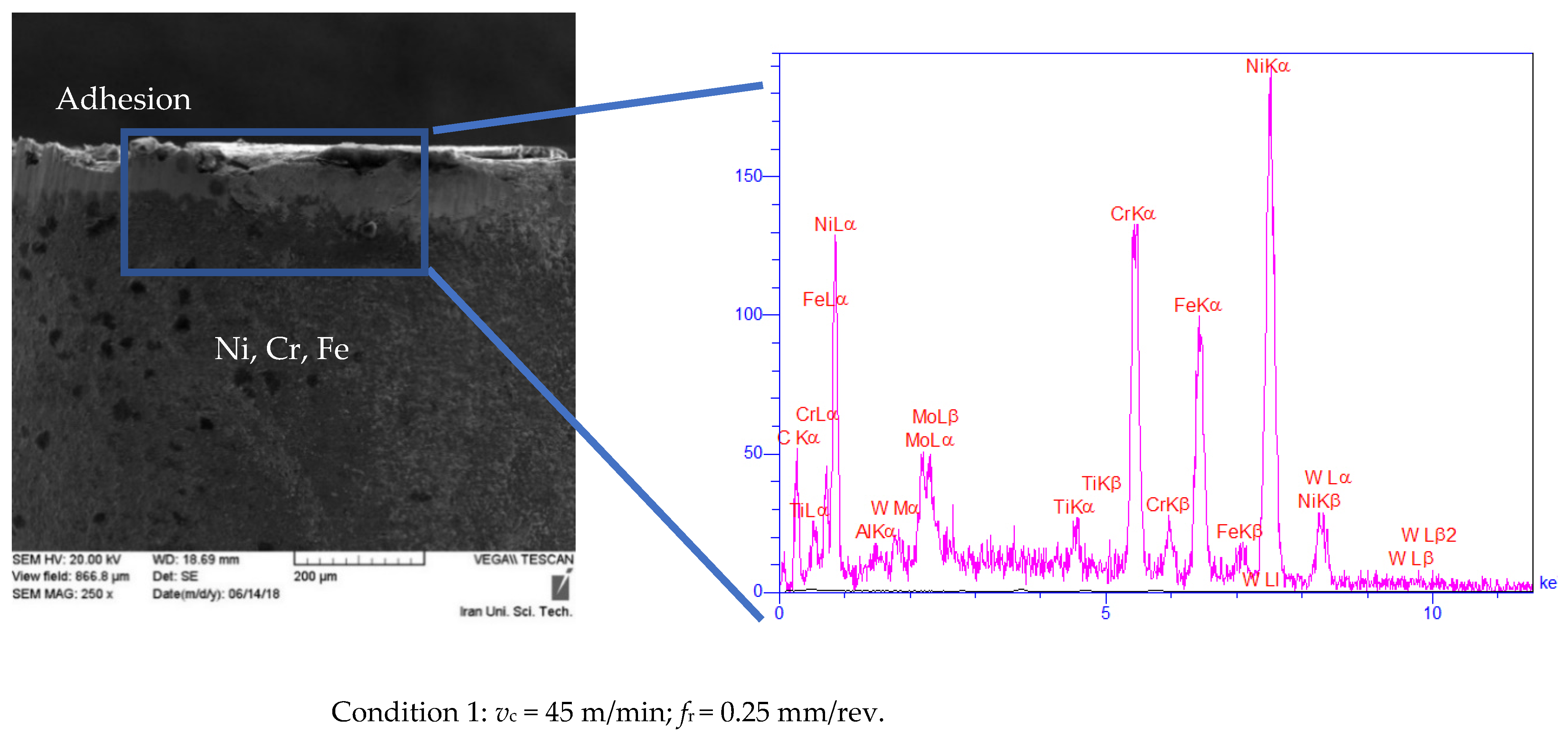

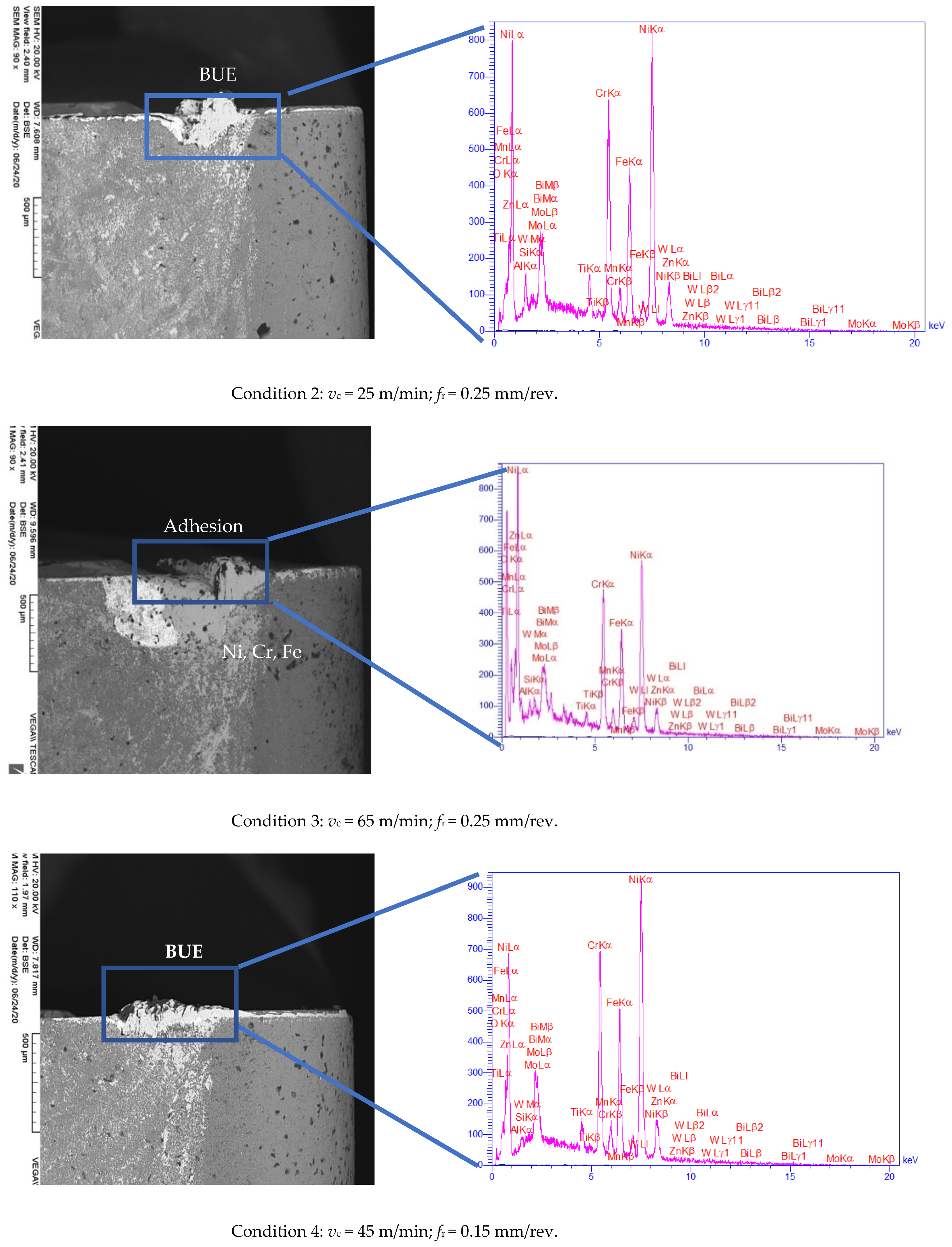

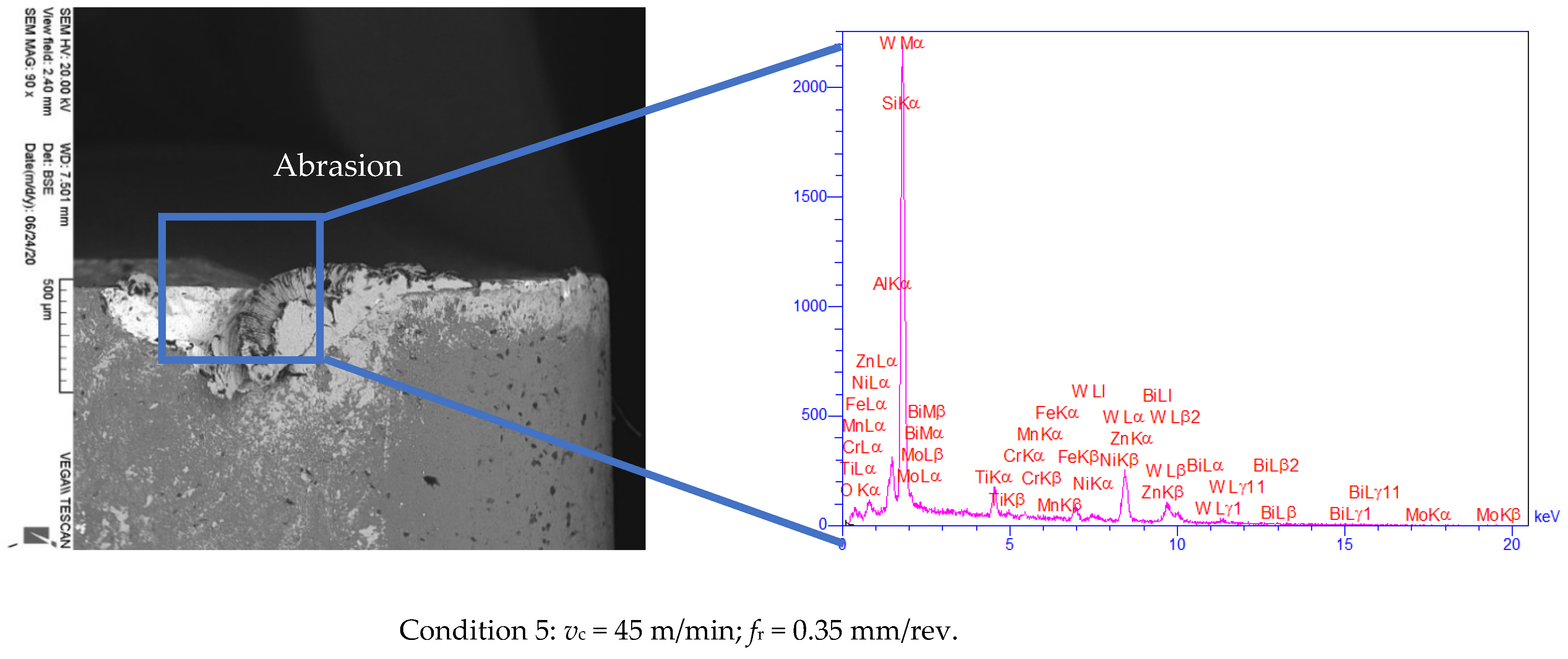

3.2. Experimental Characterization of Wear Morphology

4. Conclusions

- Less initial tool wear was observed under a lower cutting speed (vc = 25 m/min) and feed rate (fr = 0.15 mm/rev).

- In most cases, BUE and adhesion were predominant wear mechanisms in the transition period (t < 4 s).

- In all cases, the BUE was exhibited as the major wear mode in cutting conditions at the steady-state, while both adhesion and abrasion were observed. Such observations could be attributed to the severe interactions between the hard particles of the Inconel 718 material and the cutting tool.

- When the vBmax of 300 μm at constant cutting speed (45 m/min) was achieved, increasing the initial feed rate decreased the tool life by about 67%.

- Applying the lower initial cutting speed, i.e., 25 m/min, increased the tool life by about 50% when the insert reached the vBmax of 300 µm in comparison with those at higher initial cutting speeds.

- In general, it could be concluded that using optimum levels of cutting parameters in the transition period of cutting process may prolong tool life.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nalbant, M.; Altın, A.; Gökkaya, H. The effect of cutting speed and cutting tool geometry on machinability properties of nickel-base Inconel 718 super alloys. Mater. Des. 2007, 28, 1334–1338. [Google Scholar] [CrossRef]

- Ezugwu, E.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Dudzinski, D.; Devillez, A.; Moufki, A.; Larrouquère, D.; Zerrouki, V.; Vigneau, J. A review of developments towards dry and high speed machining of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2004, 44, 439–456. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V.; Sergi, V.; Schipani, A.; Cinque, S. Dissimilar autogenous disk-laser welding of Haynes 188 and Inconel 718 superalloys for aerospace applications. Int. J. Adv. Manuf. Technol. 2013, 68, 1809–1820. [Google Scholar] [CrossRef]

- Asgari, A. Cutting Conditions Optimisation of Titanium Metal Matrix Composites in Turning and Face Milling. Master’s Thesis, École Polytechnique de Montréal, Montréal, QC, Canada, 2015. [Google Scholar]

- Kamali Zadeh, S. Initial Tool Wear Mechanisms in Turning of Titanium Metal Matrix Composites. Master’s Thesis, École Polytechnique de Montréal, Montréal, QC, Canada, 2016. [Google Scholar]

- Astakhov, V.P. Cutting Tool Wear, Tool Life and Cutting Tool Physical Resource. In Tribology and Interface Engineering Series; Elsevier: Amsterdam, The Netherlands, 2006; Volume 52, pp. 1–425. [Google Scholar]

- Duong, X.; Mayer, J.; Balazinski, M. Initial tool wear behavior during machining of titanium metal matrix composite (TiMMCs). Int. J. Refract. Met. Hard Mater. 2016, 60, 169–176. [Google Scholar] [CrossRef]

- Karandikar, J.M.; Abbas, A.E.; Schmitz, T.L. Tool life prediction using Bayesian updating. Part 2: Turning tool life using a Markov Chain Monte Carlo approach. Precis. Eng. 2014, 38, 18–27. [Google Scholar] [CrossRef]

- Wu, J.; Tian, H. Functionally-fitted block methods for ordinary differential equations. J. Comput. Appl. Math. 2014, 271, 356–368. [Google Scholar] [CrossRef]

- Xavior, M.A.; Manohar, M.; Jeyapandiarajan, P.; Madhukar, P.M. Tool Wear Assessment During Machining of Inconel 718. Procedia Eng. 2017, 174, 1000–1008. [Google Scholar] [CrossRef]

- Grzesik, W.; Niesłony, P.; Habrat, W.; Sieniawski, J.; Laskowski, P. Investigation of tool wear in the turning of Inconel 718 superalloy in terms of process performance and productivity enhancement. Tribol. Int. 2018, 118, 337–346. [Google Scholar] [CrossRef]

- Duong, X.-T.; Balazinski, M.; Mayer, R. Chaotic Tool Wear During Machining of Titanium Metal Matrix Composite (TiMMCs). In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Duong, X.T. Chaos Theory Applied to Analyze Tool Wear during Machining of Titanium Metal Matrix Composite (TiMMCs). Ph.D. Thesis, École Polytechnique de Montréal, Montréal, QC, Canada, 2015. [Google Scholar]

- Aramesh, M. Life estimation with variable cutting conditions when machining titanium metal matrix composites (Ti-MMCs). In Machinability of Titanium Metal Matrix Composites. Ph.D. Thesis, Polytechnique Montreal, Montréal, QC, Canada, 2015. [Google Scholar]

- Aramesh, M.; Shaban, Y.; Yacout, S.; Attia, H.; Kishawy, H.A.; Balazinski, M. Survival life analysis applied to tool life estimation with variable cutting conditions when machining titanium metal matrix composites (Ti-MMCs). Mach. Sci. Technol. 2016, 20, 132–147. [Google Scholar] [CrossRef]

- Memarianpour, M.; Niknam, S.A.; Turenne, S.; Balazinski, M. Initial Tool Wear Mechanism in Dry and Lubricated Turning of Inconel 718. In International Conference on Engineering Research and Applications; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2018; pp. 390–397. [Google Scholar]

- Sayit, E.; Aslantas, K.; Çiçek, A. Tool wear mechanism in interrupted cutting conditions. Mater. Manuf. Process. 2009, 24, 476–483. [Google Scholar] [CrossRef]

- Akhtar, W.; Sun, J.; Sun, P.; Chen, W.; Saleem, Z. Tool wear mechanisms in the machining of Nickel based super-alloys: A review. Front. Mech. Eng. 2014, 9, 106–119. [Google Scholar] [CrossRef]

- Bhatt, A.; Attia, H.; Vargas, R.; Thomson, V. Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol. Int. 2010, 43, 1113–1121. [Google Scholar] [CrossRef]

- Zou, B.; Chen, M.; Huang, C.; An, Q. Study on surface damages caused by turning NiCr20TiAl nickel-based alloy. J. Mater. Process. Technol. 2009, 209, 5802–5809. [Google Scholar] [CrossRef]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and Wear of Cutting Tools in High-Speed Machining of Inconel 718 and Ti6Al6V-2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Jindal, P.; Santhanam, A.; Schleinkofer, U.; Shuster, A. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Li, L.; He, N.; Wang, M.; Wang, Z. High speed cutting of Inconel 718 with coated carbide and ceramic inserts. J. Mater. Process. Technol. 2002, 129, 127–130. [Google Scholar] [CrossRef]

- Ezugwu, E.; Bonney, J. Effect of high-pressure coolant supply when machining nickel-base, Inconel 718, alloy with coated carbide tools. J. Mater. Process. Technol. 2004, 153, 1045–1050. [Google Scholar] [CrossRef]

- Devillez, A.; Schneider, F.; Dominiak, S.; Dudzinski, D.; Larrouquere, D. Cutting forces and wear in dry machining of Inconel 718 with coated carbide tools. Wear 2007, 262, 931–942. [Google Scholar] [CrossRef]

- Zhou, J.; Bushlya, V.; Ståhl, J.-E. An investigation of surface damage in the high speed turning of Inconel 718 with use of whisker reinforced ceramic tools. J. Mater. Process. Technol. 2012, 212, 372–384. [Google Scholar] [CrossRef]

- Kursuncu, B.; Caliskan, H.; Guven, S.Y.; Panjan, P. Improvement of cutting performance of carbide cutting tools in milling of the Inconel 718 superalloy using multilayer nanocomposite hard coating and cryogenic heat treatment. Int. J. Adv. Manuf. Technol. 2018, 97, 467–479. [Google Scholar] [CrossRef]

- Memarianpour, M.; Niknam, S.A.; Turenne, S.; Balazinski, M. Initial tool wear behavior in high-speed turning of Inconel 718. Trans. Can. Soc. Mech. Eng. 2019, 44, 395–404. [Google Scholar] [CrossRef]

- Altin, A.; Nalbant, M.; Taskesen, A. The effects of cutting speed on tool wear and tool life when machining Inconel 718 with ceramic tools. Mater. Des. 2007, 28, 2518–2522. [Google Scholar] [CrossRef]

- Khamsehzadeh, H. Behaviour of ceramic cutting tools when machining superalloys. Ph.D. Thesis, University of Warwick, Coventry, UK, 1991. [Google Scholar]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool vibrations, and CNC Design; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Ezugwu, E.; Wang, Z.; Machado, A. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

| Element | (wt %) | Element | (wt %) |

|---|---|---|---|

| Ni | 53.4 | Si | 0.12 |

| Cr | 18.8 | Mn | 0.07 |

| Cb | 5.27 | Cu | 0.07 |

| Mo | 2.99 | C | 0.03 |

| Ti | 1.02 | P | 0.01 |

| Al | 0.50 | Fe | Balance |

| Co | 0.17 |

| Cutting Conditions | Transition Period (0–4 s) | Cutting Conditions after 4 s | ||

|---|---|---|---|---|

| vc (m/min) | fr (mm/rev) | vc (m/min) | fr (mm/rev) | |

| 1 | 45 | 0.25 | 45 | 0.25 |

| 2 | 25 | 0.25 | ||

| 3 | 65 | 0.25 | ||

| 4 | 45 | 0.15 | ||

| 5 | 45 | 0.35 | ||

| Cutting Time (s) | vBmax (mm) | ||||

|---|---|---|---|---|---|

| Cutting Condition 1 | Cutting Condition 2 | Cutting Condition 3 | Cutting Condition 4 | Cutting Condition 5 | |

| 4 | 0.0994 | 0.0817 | 0.1583 | 0.1110 | 0.1260 |

| 8 | 0.2045 | 0.0905 | 0.2092 | 0.1190 | 0.1846 |

| 16 | 0.2756 | 0.1964 | 0.2741 | 0.1850 | 0.3127 |

| 26 | 0.3644 | 0.2745 | 0.4970 | 0.2700 | 0.5100 |

| 46 | 0.4412 | 0.3393 | 0.6373 | 0.3200 | 0.5627 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memarianpour, M.; Niknam, S.A.; Turenne, S.; Balazinski, M. Study of the Effects of Initial Cutting Conditions and Transition Period on Ultimate Tool Life when Machining Inconel 718. Materials 2021, 14, 592. https://doi.org/10.3390/ma14030592

Memarianpour M, Niknam SA, Turenne S, Balazinski M. Study of the Effects of Initial Cutting Conditions and Transition Period on Ultimate Tool Life when Machining Inconel 718. Materials. 2021; 14(3):592. https://doi.org/10.3390/ma14030592

Chicago/Turabian StyleMemarianpour, Morvarid, Seyed Ali Niknam, Sylvain Turenne, and Marek Balazinski. 2021. "Study of the Effects of Initial Cutting Conditions and Transition Period on Ultimate Tool Life when Machining Inconel 718" Materials 14, no. 3: 592. https://doi.org/10.3390/ma14030592

APA StyleMemarianpour, M., Niknam, S. A., Turenne, S., & Balazinski, M. (2021). Study of the Effects of Initial Cutting Conditions and Transition Period on Ultimate Tool Life when Machining Inconel 718. Materials, 14(3), 592. https://doi.org/10.3390/ma14030592