Tuning the Magnetic Properties of Two-Dimensional MXenes by Chemical Etching

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization

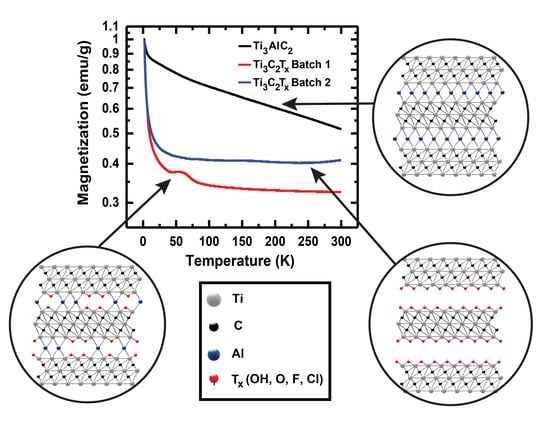

3. Results and Discussion

4. Conclusions

5. Addendum

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Gogotsi, Y.; Anasori, B. The rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [PubMed]

- Lipatov, A.; Lu, H.; Alhabeb, M.; Anasori, B.; Gruverman, A.; Gogotsi, Y.; Sinitskii, A. Elastic properties of 2D Ti3C2Tx MXene monolayers and bilayers. Sci. Adv. 2018, 4, eaat0491. [Google Scholar] [CrossRef]

- Zheng, J.; He, R.; Wan, Y.; Zhao, P.; Guo, P.; Jiang, Z. Half-metal state of a Ti2C monolayer by asymmetric surface decoration. Phys. Chem. Chem. Phys. 2019, 21, 3318–3326. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, H.; Liu, J.; Xie, X.; Yang, R.; Li, Y.; Hong, S.; Yu, Z. Highly conductive transition metal carbide/carbonitride (MXene)@ polystyrene nanocomposites fabricated by electrostatic assembly for highly efficient electromagnetic interference shielding. Adv. Funct. Mater. 2017, 27, 1702807. [Google Scholar] [CrossRef]

- Limbu, T.B.; Chitara, B.; Orlando, J.D.; Cervantes, M.Y.G.; Kumari, S.; Li, Q.; Tang, Y.; Yan, F. Green synthesis of reduced Ti3C2Tx MXene nanosheets with enhanced conductivity, oxidation stability, and SERS activity. J. Mater. Chem. C 2020, 8, 4722–4731. [Google Scholar] [CrossRef]

- Zhang, C.J.; Pinilla, S.; McEvoy, N.; Cullen, C.P.; Anasori, B.; Long, E.; Park, S.; Seral-Ascaso, A.; Shmeliov, A.; Krishnan, D. Oxidation stability of colloidal two-dimensional titanium carbides (MXenes). Chem. Mater. 2017, 29, 4848–4856. [Google Scholar] [CrossRef]

- Ashton, M.; Mathew, K.; Hennig, R.G.; Sinnott, S.B. Predicted surface composition and thermodynamic stability of MXenes in solution. J. Phys. Chem. C 2016, 120, 3550–3556. [Google Scholar] [CrossRef]

- Zhan, X.; Si, C.; Zhou, J.; Sun, Z. MXene and MXene-based composites: Synthesis, properties and environment-related applications. Nanoscale Horiz. 2020, 5, 235–258. [Google Scholar] [CrossRef]

- Hart, J.L.; Hantanasirisakul, K.; Lang, A.C.; Anasori, B.; Pinto, D.; Pivak, Y.; van Omme, J.T.; May, S.J.; Gogotsi, Y.; Taheri, M.L. Control of MXenes’ electronic properties through termination and intercalation. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Huang, Z.; Zhi, C. Environmental Stability of MXenes as Energy Storage Materials. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, D.; Liang, Z. Two-dimensional MXenes for energy storage and conversion applications. Mater. Today Energy 2017, 5, 22–36. [Google Scholar] [CrossRef]

- Ng, V.M.H.; Huang, H.; Zhou, K.; Lee, P.S.; Que, W.; Xu, J.Z.; Kong, L.B. Recent progress in layered transition metal carbides and/or nitrides (MXenes) and their composites: Synthesis and applications. J. Mater. Chem. A 2017, 5, 3039–3068. [Google Scholar]

- Pang, J.; Mendes, R.G.; Bachmatiuk, A.; Zhao, L.; Ta, H.Q.; Gemming, T.; Liu, H.; Liu, Z.; Rummeli, M.H. Applications of 2D MXenes in energy conversion and storage systems. Chem. Soc. Rev. 2019, 48, 72–133. [Google Scholar] [CrossRef]

- Li, Y.; Shao, H.; Lin, Z.; Lu, J.; Liu, L.; Duployer, B.; Persson, P.O.Å.; Eklund, P.; Hultman, L.; Li, M. A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nat. Mater. 2020, 19, 894–899. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, N.; Legut, D.; Si, C.; Zhang, Q.; Du, S.; Germann, T.C.; Francisco, J.S.; Zhang, R. Rational design of flexible two-dimensional MXenes with multiple functionalities. Chem. Rev. 2019, 119, 11980–12031. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, Y.; Zhang, X.; Abdolhosseinzadeh, S.; Sheng, H.; Lan, W.; Pakdel, A.; Heier, J.; Nüesch, F. Two-dimensional transition metal carbides and nitrides (MXenes): Synthesis, properties, and electrochemical energy storage applications. Energy Environ. Mater. 2020, 3, 29–55. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Hu, M.; Ling, H.; Zhu, X. MXenes: Focus on optical and electronic properties and corresponding applications. Nanophotonics 2020, 9, 1601–1620. [Google Scholar] [CrossRef]

- Hantanasirisakul, K.; Alhabeb, M.; Lipatov, A.; Maleski, K.; Anasori, B.; Salles, P.; Ieosakulrat, C.; Pakawatpanurut, P.; Sinitskii, A.; May, S.J. Effects of synthesis and processing on optoelectronic properties of titanium carbonitride MXene. Chem. Mater. 2019, 31, 2941–2951. [Google Scholar] [CrossRef]

- Dong, L.; Kumar, H.; Anasori, B.; Gogotsi, Y.; Shenoy, V.B. Rational design of two-dimensional metallic and semiconducting spintronic materials based on ordered double-transition-metal MXenes. J. Phys. Chem. Lett. 2017, 8, 422–428. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wu, Y.; Yuan, X.; Zeng, G.; Zhou, J.; Wang, X.; Chew, J.W. Clay-inspired MXene-based electrochemical devices and photo-electrocatalyst: State-of-the-art progresses and challenges. Adv. Mater. 2018, 30, 1704561. [Google Scholar] [CrossRef] [PubMed]

- Sinha, A.; Zhao, H.; Huang, Y.; Lu, X.; Chen, J.; Jain, R. MXene: An emerging material for sensing and biosensing. TrAC Trend Anal. Chem. 2018, 105, 424–435. [Google Scholar] [CrossRef]

- Berdiyorov, G.R. Optical properties of functionalized Ti3C2T2 (T=F, O, OH) MXene: First-principles calculations. AIP Adv. 2016, 6, 055105. [Google Scholar] [CrossRef]

- Jiang, X.; Kuklin, A.V.; Baev, A.; Ge, Y.; Ågren, H.; Zhang, H.; Prasad, P.N. Two-dimensional MXenes: From morphological to optical, electric, and magnetic properties and applications. Phys. Rep. 2020, 848, 1–58. [Google Scholar] [CrossRef]

- Khazaei, M.; Ranjbar, A.; Arai, M.; Sasaki, T.; Yunoki, S. Electronic properties and applications of MXenes: A theoretical review. J. Mater. Chem. C 2017, 5, 2488–2503. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Yu, J.; Hang, Y.; Li, Y.; Guo, Y.; Xu, Y.; Sun, X.; Zhou, J.; Guo, W. Tunable electronic and magnetic properties of two-dimensional materials and their one-dimensional derivatives. Wiley Interdiscip. Rev. Comput. Mol. Sci. 2016, 6, 324–350. [Google Scholar] [CrossRef]

- Anasori, B.; Gogotsi, Y. 2D Metal Carbides and Nitrides (MXenes); Springer: Cham, Switzerland, 2019. [Google Scholar]

- He, J.; Lyu, P.; Nachtigall, P. New two-dimensional Mn-based MXenes with room-temperature ferromagnetism and half-metallicity. J. Mater. Chem. C 2016, 4, 11143–11149. [Google Scholar] [CrossRef]

- Zhong, S.; Xu, B.; Cui, A.; Li, S.; Liao, S.; Wang, G.; Liu, G.; Sun, B. Robust net magnetic moment in Janus V-based nitride MXenes: Insight from first-principles calculations. ACS Omega 2019, 5, 864–870. [Google Scholar] [CrossRef]

- Zhang, P.; Xiang, M.; Liu, H.; Yang, C.; Deng, S. Novel two-dimensional magnetic titanium carbide for methylene blue removal over a wide pH range: Insight into removal performance and mechanism. ACS Appl. Mater. Interfaces 2019, 11, 24027–24036. [Google Scholar] [CrossRef]

- Sun, W.; Xie, Y.; Kent, P.R.C. Double transition metal MXenes with wide band gaps and novel magnetic properties. Nanoscale 2018, 10, 11962–11968. [Google Scholar] [CrossRef] [PubMed]

- Siriwardane, E.M.D.; Çakir, D. Strain engineering of electronic and magnetic properties of double-transition metal ferromagnetic semiconductor MXenes. J. Appl. Phys. 2019, 125, 082527. [Google Scholar] [CrossRef]

- Kumar, H.; Frey, N.C.; Dong, L.; Anasori, B.; Gogotsi, Y.; Shenoy, V.B. Tunable magnetism and transport properties in nitride MXenes. ACS Nano 2017, 11, 7648–7655. [Google Scholar] [CrossRef] [PubMed]

- Khazaei, M.; Arai, M.; Sasaki, T.; Chung, C.; Venkataramanan, N.S.; Estili, M.; Sakka, Y.; Kawazoe, Y. Novel electronic and magnetic properties of two-dimensional transition metal carbides and nitrides. Adv. Funct. Mater. 2013, 23, 2185–2192. [Google Scholar] [CrossRef]

- Babar, Z.U.D.; Anwar, S.; Mumtaz, M.; Iqbal, M.; Zheng, R.; Akinwande, D.; Rizwan, S. Peculiar magnetic behaviour and meissner effect in two-dimensional layered Nb2C MXene. 2D Mater. 2020, 7, 035012. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Ghosh, D.; Pati, S.K. Effects of point defects on the magnetoelectronic structures of MXenes from first principles. Phys. Chem. Chem. Phys. 2018, 20, 4012–4019. [Google Scholar] [CrossRef]

- Iqbal, M.; Fatheema, J.; Noor, Q.; Rani, M.; Mumtaz, M.; Zheng, R.; Khan, S.A.; Rizwan, S. Co-existence of magnetic phases in two-dimensional MXene. Mater. Today Chem. 2020, 16, 100271. [Google Scholar] [CrossRef]

- Lv, P.; Li, Y.; Wang, J. Monolayer Ti2C MXene: Manipulating magnetic properties and electronic structures by an electric field. Phys. Chem. Chem. Phys. 2020, 22, 11266–11272. [Google Scholar] [CrossRef]

- Scheibe, B.; Tadyszak, K.; Jarek, M.; Michalak, N.; Kempiński, M.; Lewandowski, M.; Peplińska, B.; Chybczyńska, K. Study on the magnetic properties of differently functionalized multilayered Ti3C2Tx MXenes and Ti-Al-C carbides. Appl. Surf. Sci. 2019, 179, 216–224. [Google Scholar] [CrossRef]

- Yoon, Y.; Le, T.A.; Tiwari, A.P.; Kim, I.; Barsoum, M.W.; Lee, H. Low temperature solution synthesis of reduced two dimensional Ti3C2 MXenes with paramagnetic behaviour. Nanoscale 2018, 10, 22429–22438. [Google Scholar] [CrossRef]

- Sang, X.; Xie, Y.; Lin, M.; Alhabeb, M.; van Aken, K.L.; Gogotsi, Y.; Kent, P.R.; Xiao, K.; Unocic, R.R. Atomic defects in monolayer titanium carbide (Ti3C2Tx) MXene. ACS Nano 2016, 10, 9193–9200. [Google Scholar] [CrossRef] [PubMed]

- Yasaei, P.; Tu, Q.; Xu, Y.; Verger, L.; Wu, J.; Barsoum, M.W.; Shekhawat, G.S.; Dravid, V.P. Mapping hot spots at heterogeneities of few-layer Ti3C2 MXene sheets. ACS Nano 2019, 13, 3301–3309. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Zhang, W.; Yuan, H.; Jin, C.; Zhang, L.; Huang, H.; Liang, C.; Xia, Y.; Zhang, J.; Gan, Y.; et al. Pillared structure design of MXene with ultralarge interlayer spacing for high-performance lithium-ion capacitors. ACS Nano 2017, 11, 2459–2469. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Luo, H.; Wang, Y.; Zeng, S.; Deng, L.; Zhou, X.; Zhang, H.; Peng, S. Ti3C2 MXene: A promising microwave absorbing material. RSC Adv. 2018, 8, 2398–2403. [Google Scholar] [CrossRef]

- Sun, W.; Zhao, Y.; Cheng, X.; He, J.; Lu, J. Surface Functionalization of Single-Layered Ti3C2Tx MXene and Its Application in Multilevel Resistive Memory. ACS Appl. Mater. Interfaces 2020, 12, 9865–9871. [Google Scholar] [CrossRef]

- Ding, G.; Zeng, K.; Zhou, K.; Li, Z.; Zhou, Y.; Zhai, Y.; Zhou, L.; Chen, X.; Han, S. Configurable multi-state non-volatile memory behaviors in Ti3C2 nanosheets. Nanoscale 2019, 11, 7102–7110. [Google Scholar] [CrossRef]

- Ran, J.; Gao, G.; Li, F.; Ma, T.; Du, A.; Qiao, S. Ti3C2 MXene co-catalyst on metal sulfide photo-absorbers for enhanced visible-light photocatalytic hydrogen production. Nat. Commun. 2017, 8, 1–10. [Google Scholar] [CrossRef]

- Mojtabavi, M.; VahidMohammadi, A.; Liang, W.; Beidaghi, M.; Wanunu, M. Single-molecule sensing using nanopores in two-dimensional transition metal carbide (MXene) membranes. ACS Nano 2019, 13, 3042–3053. [Google Scholar] [CrossRef]

- Barsoum, M.W. MAX Phases: Properties of Machinable Ternary Carbides and Nitrides; John Wiley & Sons: Weinheim, Germany, 2013. [Google Scholar]

- Finkel, P.; Barsoum, M.W.; Hettinger, J.D.; Lofland, S.E.; Yoo, H.I. Low-temperature transport properties of nanolaminates Ti3AlC2 and Ti4AlN3. Phys. Rev. B 2003, 67, 235108. [Google Scholar] [CrossRef]

- Yamada, I.; Toda, F.; Kawaguchi, S.; d’Astuto, M. Various magnetic states for novel layered cobalt oxides CaCo6O11 and BaCo6O11. Mater. Chem. Front. 2019, 3, 2696–2701. [Google Scholar] [CrossRef]

- Noor, Q.; Zahra, S.A.; Serma, M.I.; Abuoudah, C.K.; Iqbal, M.Z.; Akinwande, D.; Rizwan, S. Silicon carbide-assisted co-existence of magnetic phases in well-optimized Ti3SiC2-etched MXene. Ceram. Int. 2020, 46, 27419–27425. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allen-Perry, K.; Straka, W.; Keith, D.; Han, S.; Reynolds, L.; Gautam, B.; Autrey, D.E. Tuning the Magnetic Properties of Two-Dimensional MXenes by Chemical Etching. Materials 2021, 14, 694. https://doi.org/10.3390/ma14030694

Allen-Perry K, Straka W, Keith D, Han S, Reynolds L, Gautam B, Autrey DE. Tuning the Magnetic Properties of Two-Dimensional MXenes by Chemical Etching. Materials. 2021; 14(3):694. https://doi.org/10.3390/ma14030694

Chicago/Turabian StyleAllen-Perry, Kemryn, Weston Straka, Danielle Keith, Shubo Han, Lewis Reynolds, Bhoj Gautam, and Daniel E. Autrey. 2021. "Tuning the Magnetic Properties of Two-Dimensional MXenes by Chemical Etching" Materials 14, no. 3: 694. https://doi.org/10.3390/ma14030694

APA StyleAllen-Perry, K., Straka, W., Keith, D., Han, S., Reynolds, L., Gautam, B., & Autrey, D. E. (2021). Tuning the Magnetic Properties of Two-Dimensional MXenes by Chemical Etching. Materials, 14(3), 694. https://doi.org/10.3390/ma14030694