Influence of Boundary Conditions on Numerical Homogenization of High Performance Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Methodology

2.2. Recipes for Modelled HPC

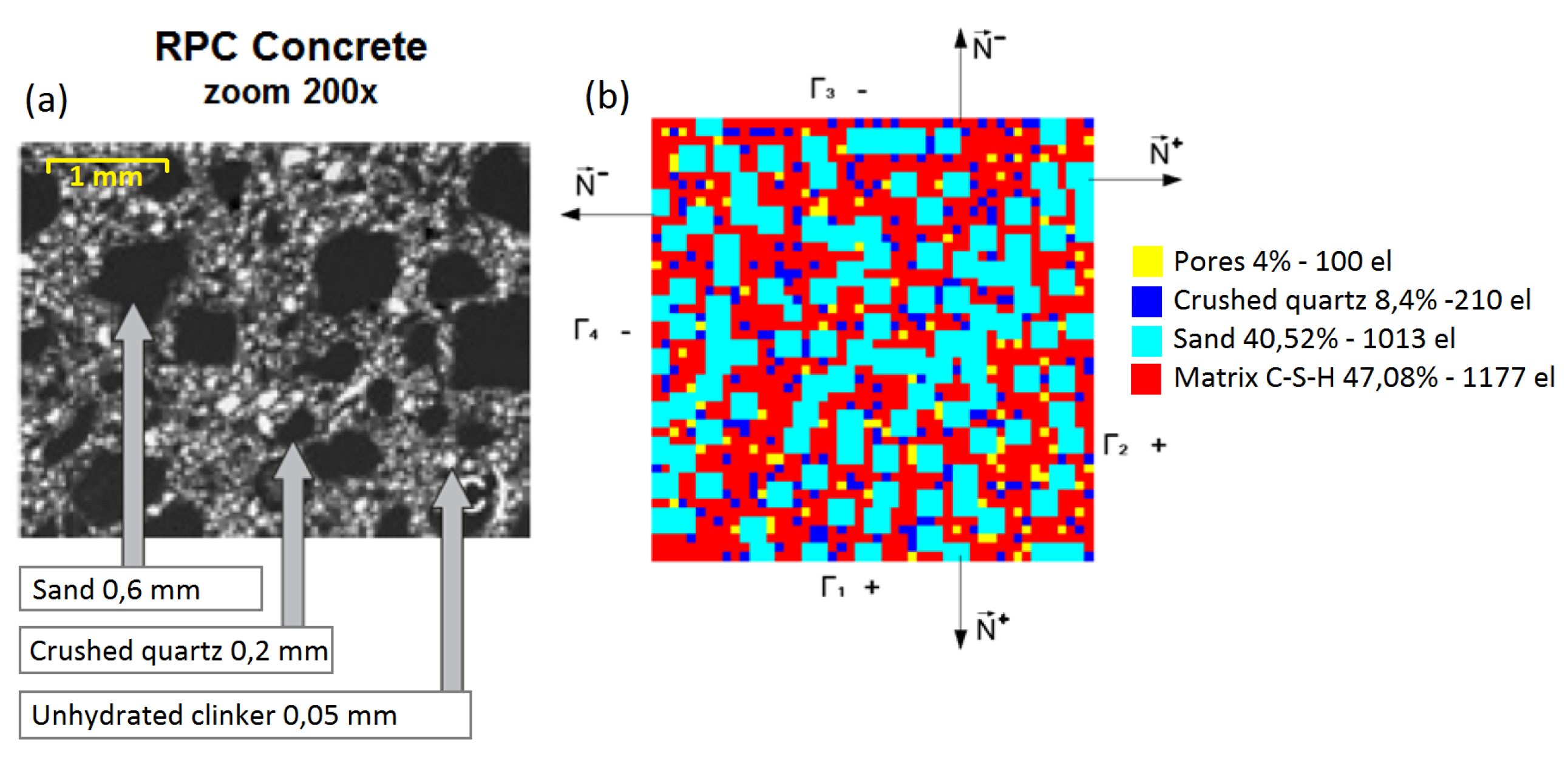

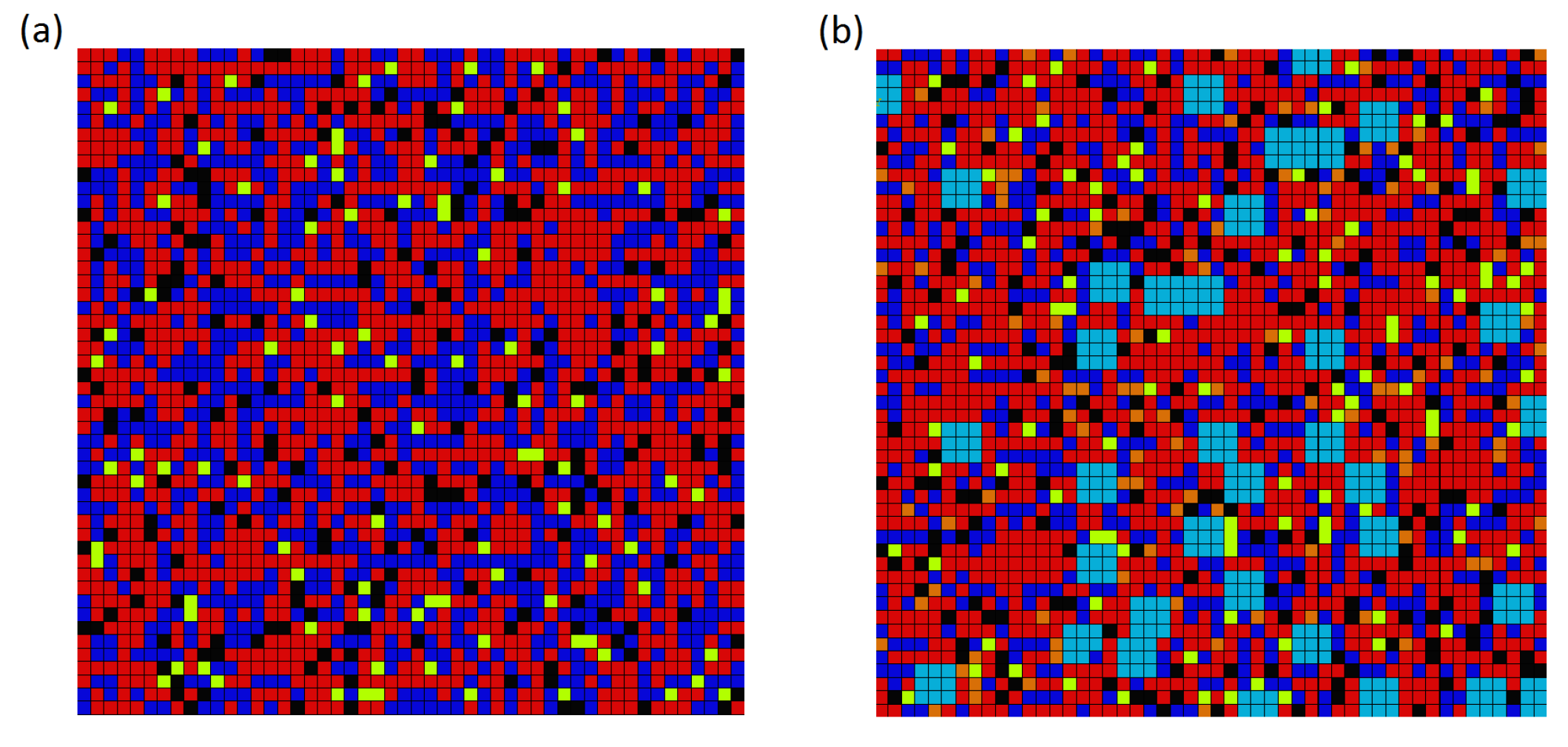

2.3. Microstructure of Modeled HPC

- cement matrix (red): E = 55,000 MPa, = 0.17, CDP (see Section 2.4), 49.8 wt%

- fine quartz sand (dark blue): E = 48,200 MPa, = 0.20, 37.4 wt%

- steel micro fibres (black): E = 210,000 MPa, = 0.30, yield stress = 2100 MPa, 8.8 wt%

- air voids (yellow): empty space (no finite elements), 4 wt%.

- cement matrix (red): E = 55,000 MPa, = 0.17, CDP (see Section 2.4), 48.2 wt%

- fine quartz sand (dark blue): E = 48,200 MPa, = 0.20, 22.6 wt%

- thick quartz sand (sky blue): E = 73,200 MPa, = 0.20, 12.3 wt%

- steel micro fibres (black): E = 210,000 MPa, = 0.30, yield stress = 2100 MPa, 8.6 wt%

- steel fibres (orange): E = 210,000 MPa, = 0.30, yield stress = 1100 MPa, 4.3 wt%

- air voids (yellow): empty space (no finite elements), 4 wt%.

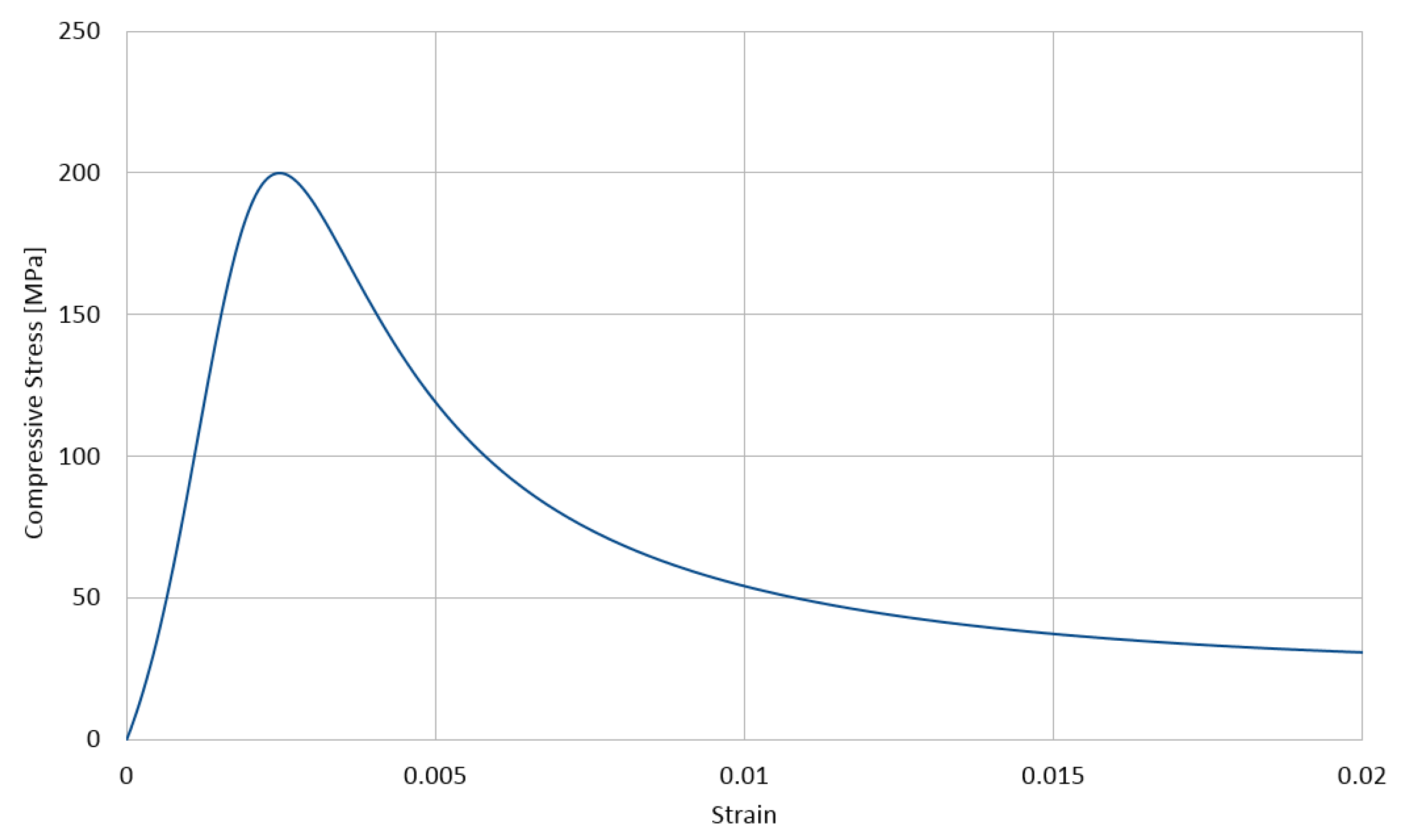

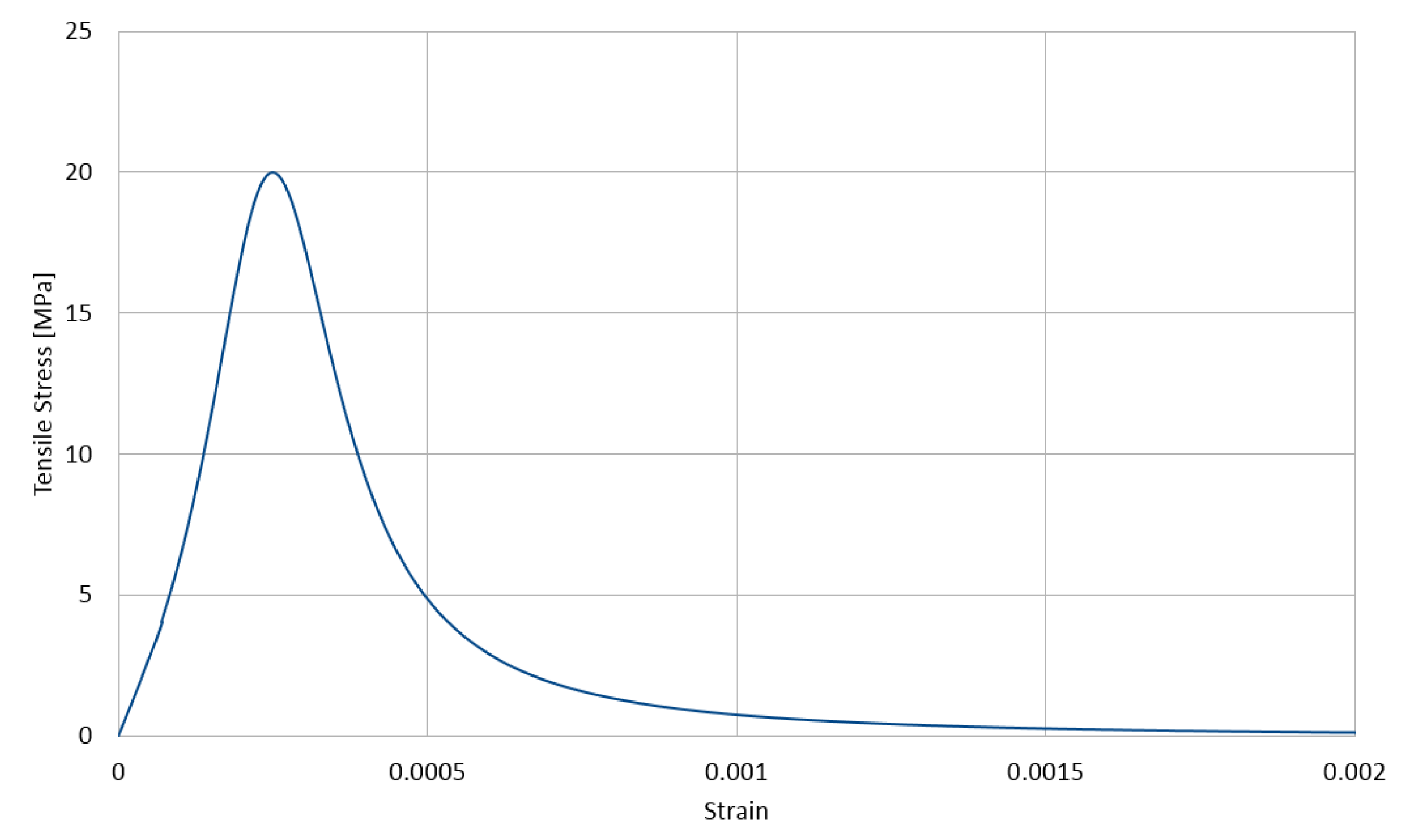

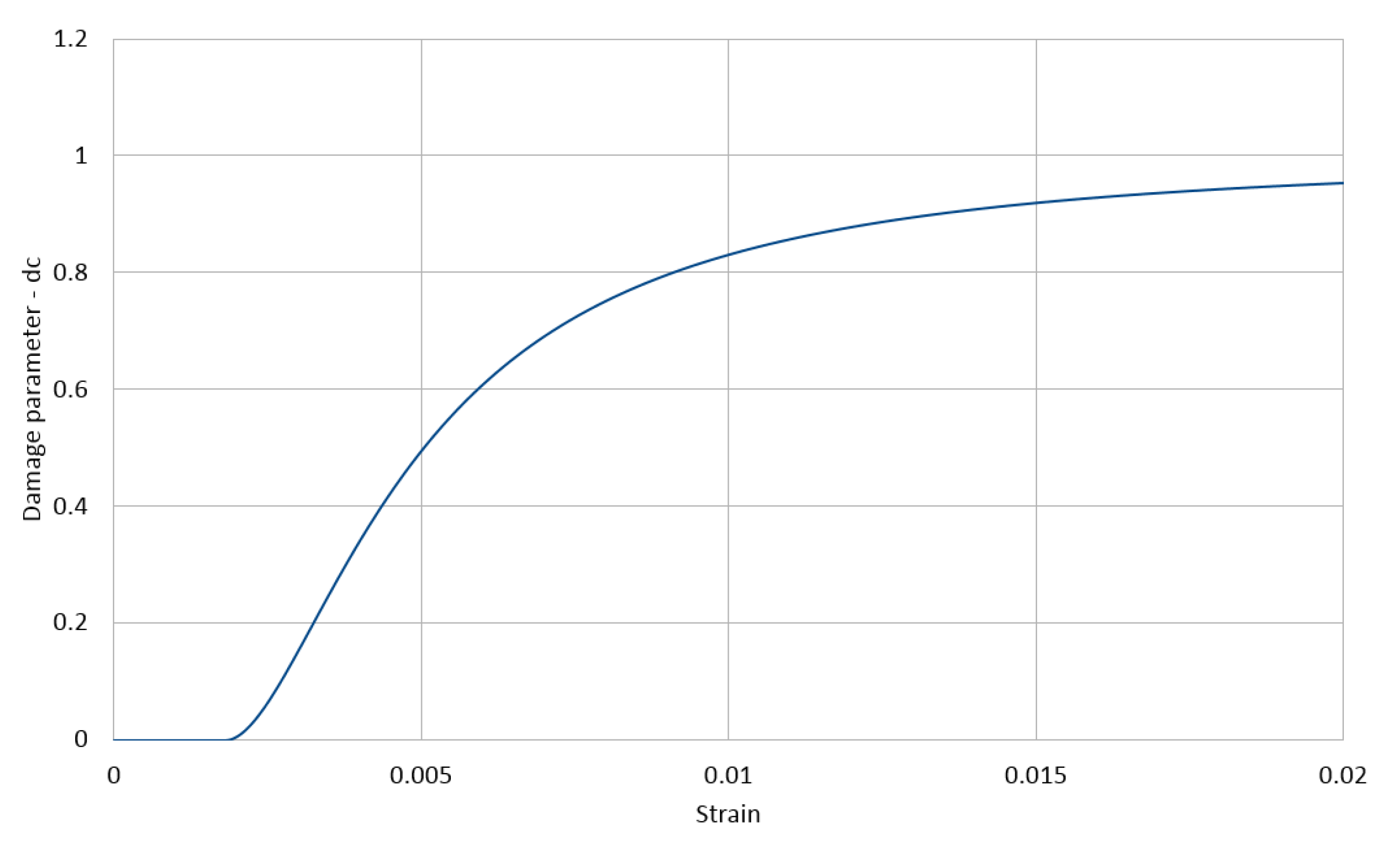

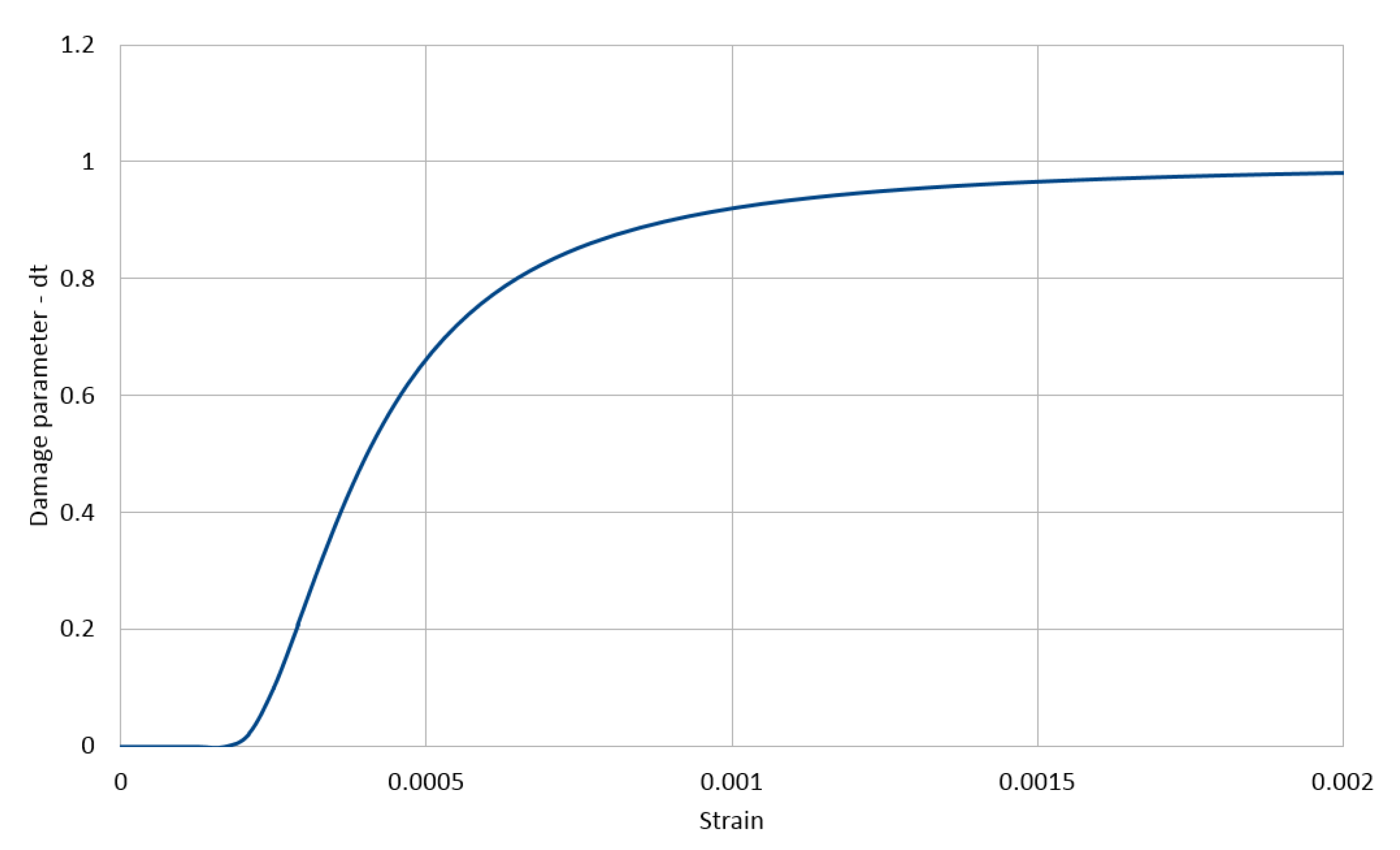

2.4. Parameters of Concrete Damage Plasticity (CDP) Model

- —the internal friction angle of concrete. In the CDP model, is defined as the inclination angle of the Drucker–Prager surface asymptote to hydrostatic axis of the meridional plane;

- m—eccentricity of the surface of the plastic potential. This is the distance measured along the hydrostatic axis between the apex of the Drucker–Prager hyperbola and the intersection of the asymptote of this hyperbola, calculated in practice as a ratio of tensile strength to strength for compression;

- —number specifying the compressive strength ratio in a two-axis state for the strength in a single-axis state;

- —parameter defining the shape of the surface of the plastic potential on a deviatoric plane;

- —viscoplasticity parameter, used to regularize the concrete constitutive equations.

2.5. Numerical Homogenization and Boundary Conditions

2.5.1. Linear Displacement Boundary Conditions (DBC)

2.5.2. Uniform Traction Boundary Conditions (TBC)

2.5.3. Periodic Boundary Conditions (PBC)

3. Results and Discussion

3.1. Test Example: Homogeneous and Linear Elastic RVE with Hole

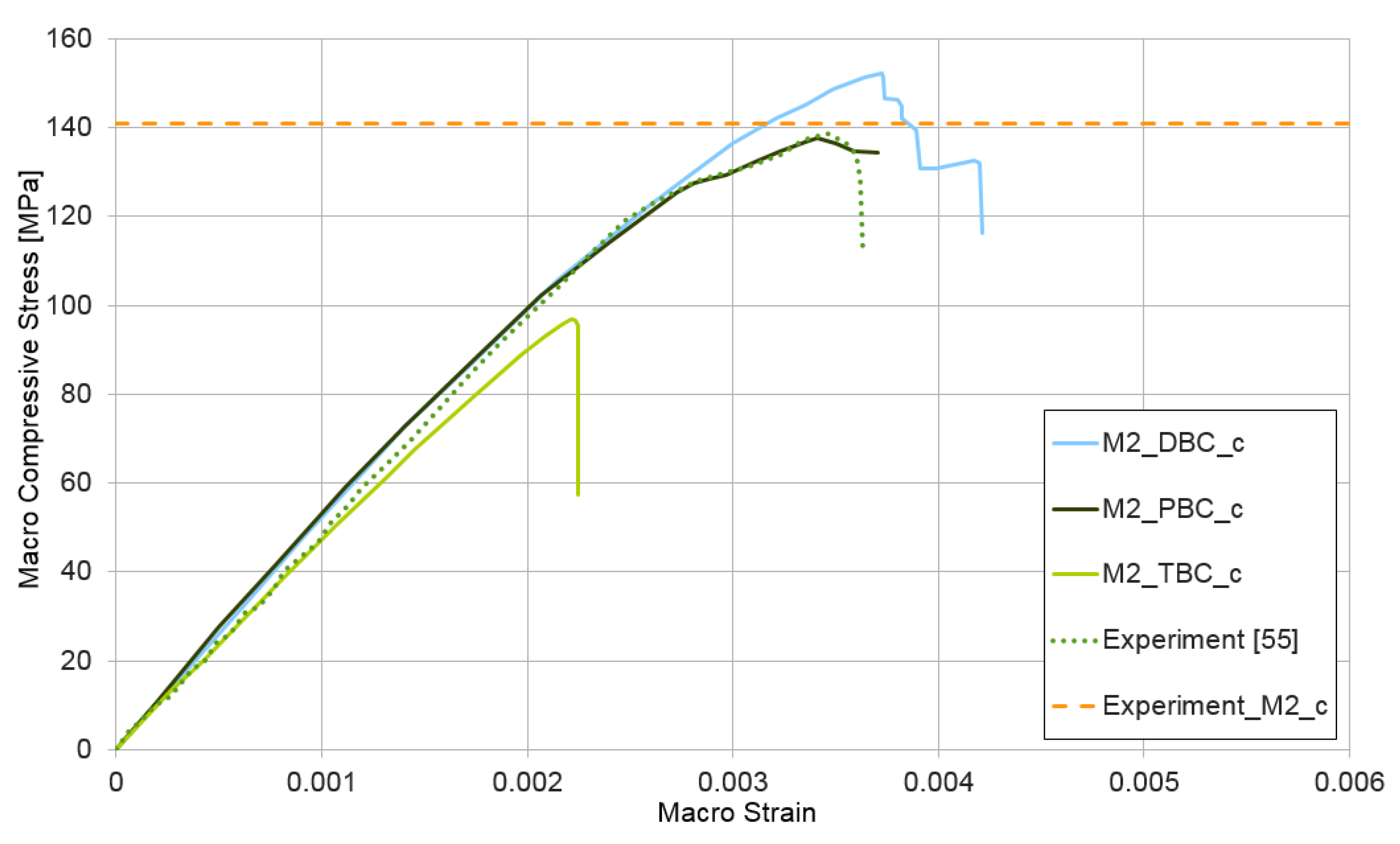

3.2. Compression Test for Mixtures I and II

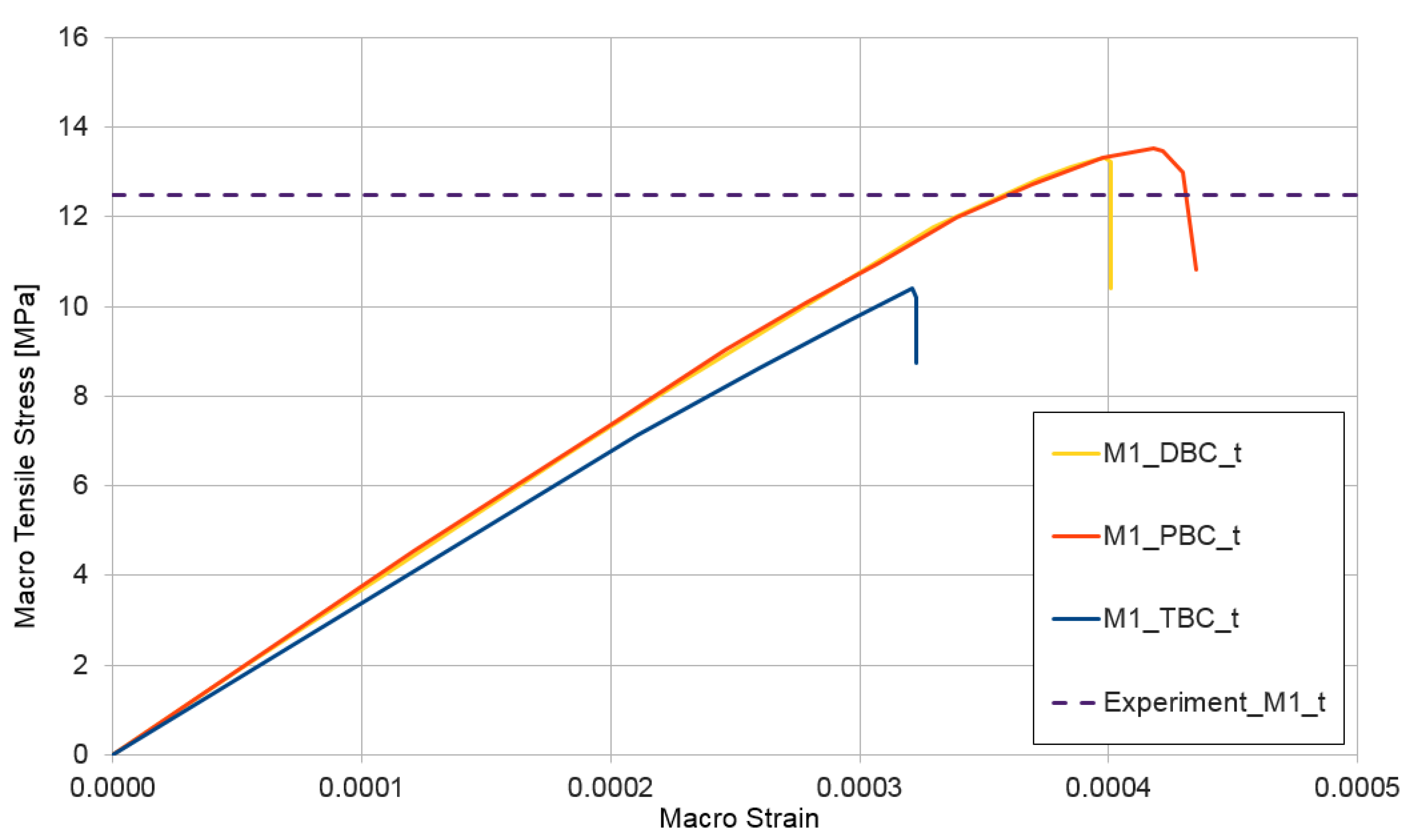

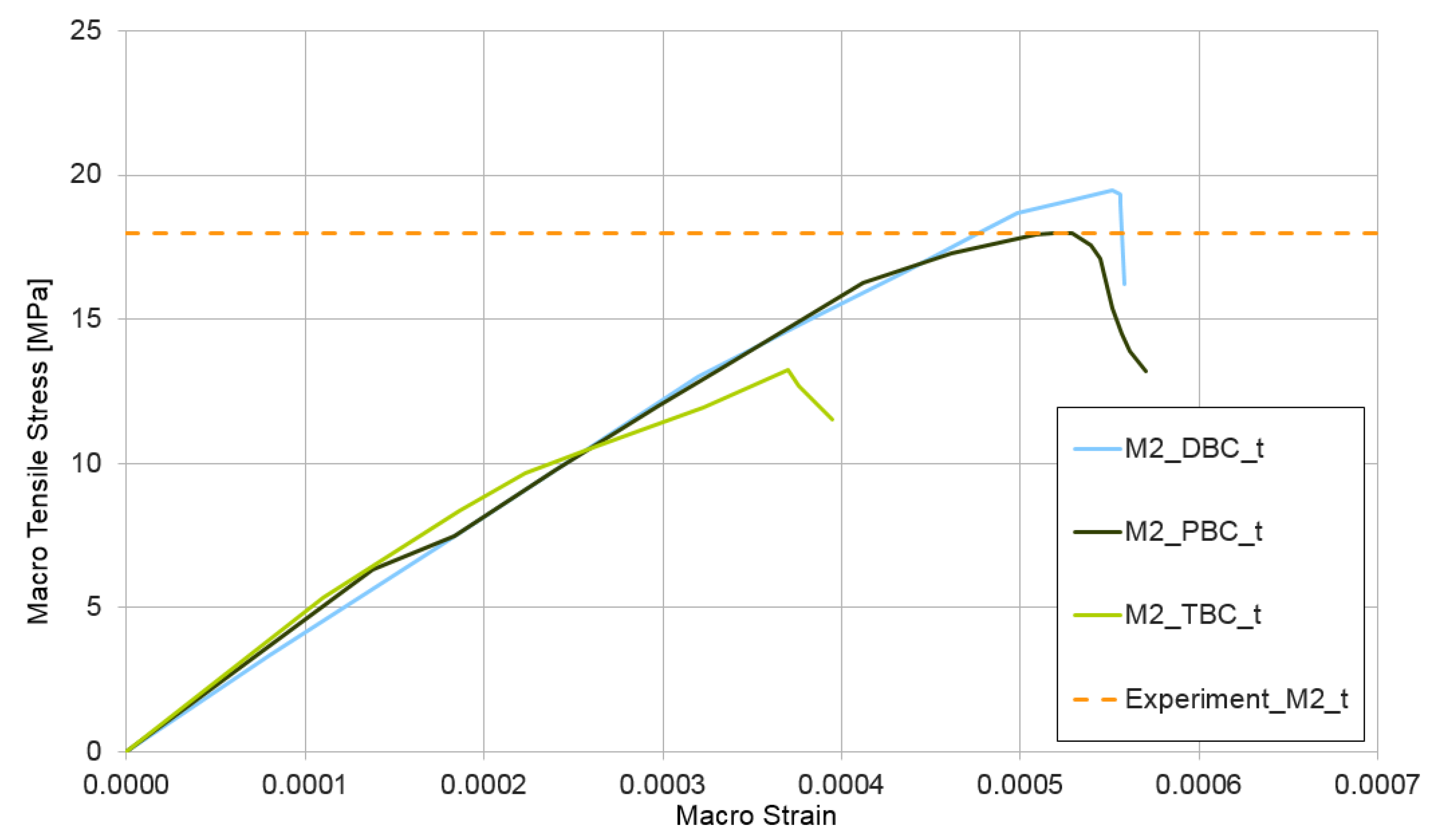

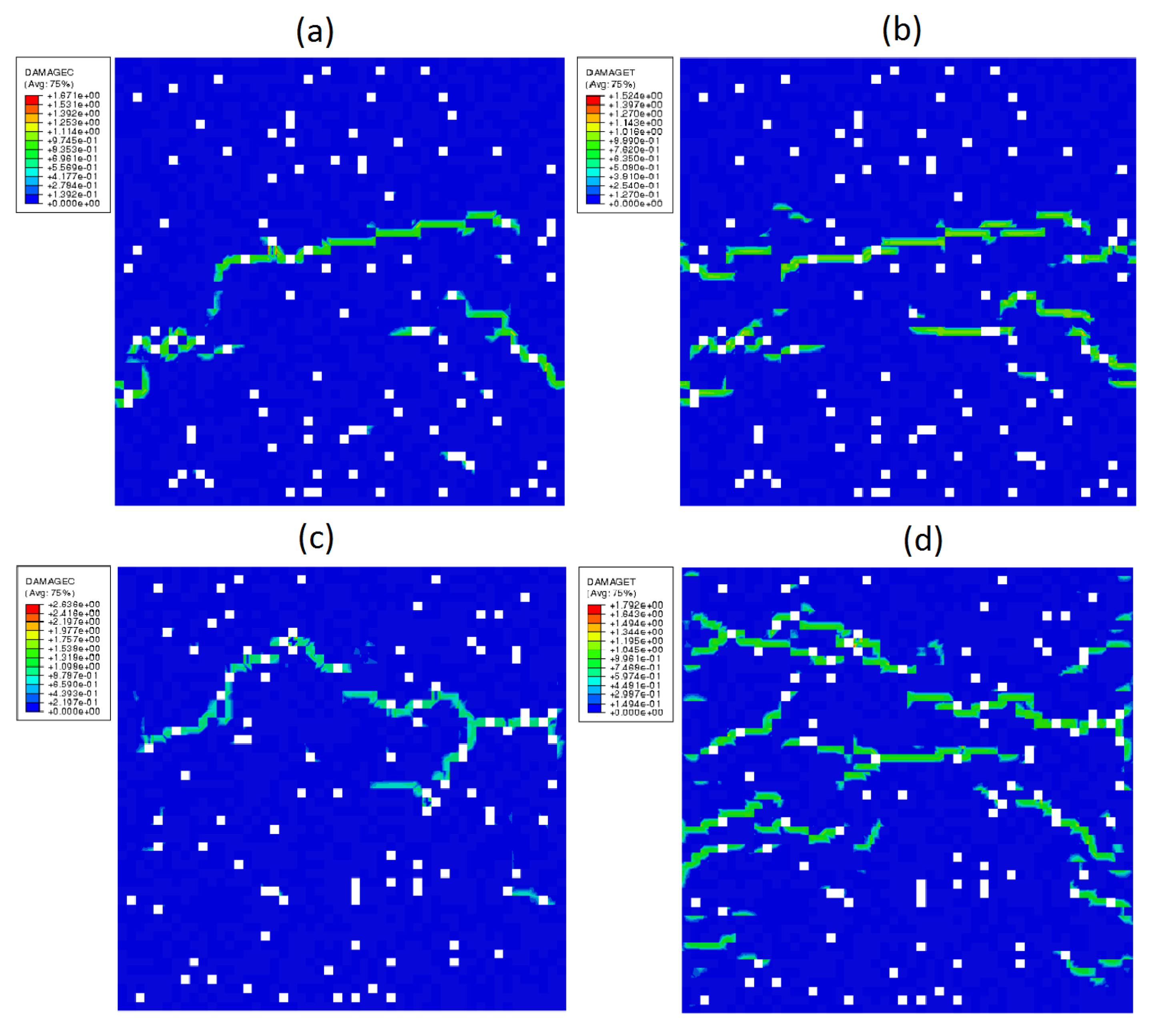

3.3. Tensile Test for Mixture I and II

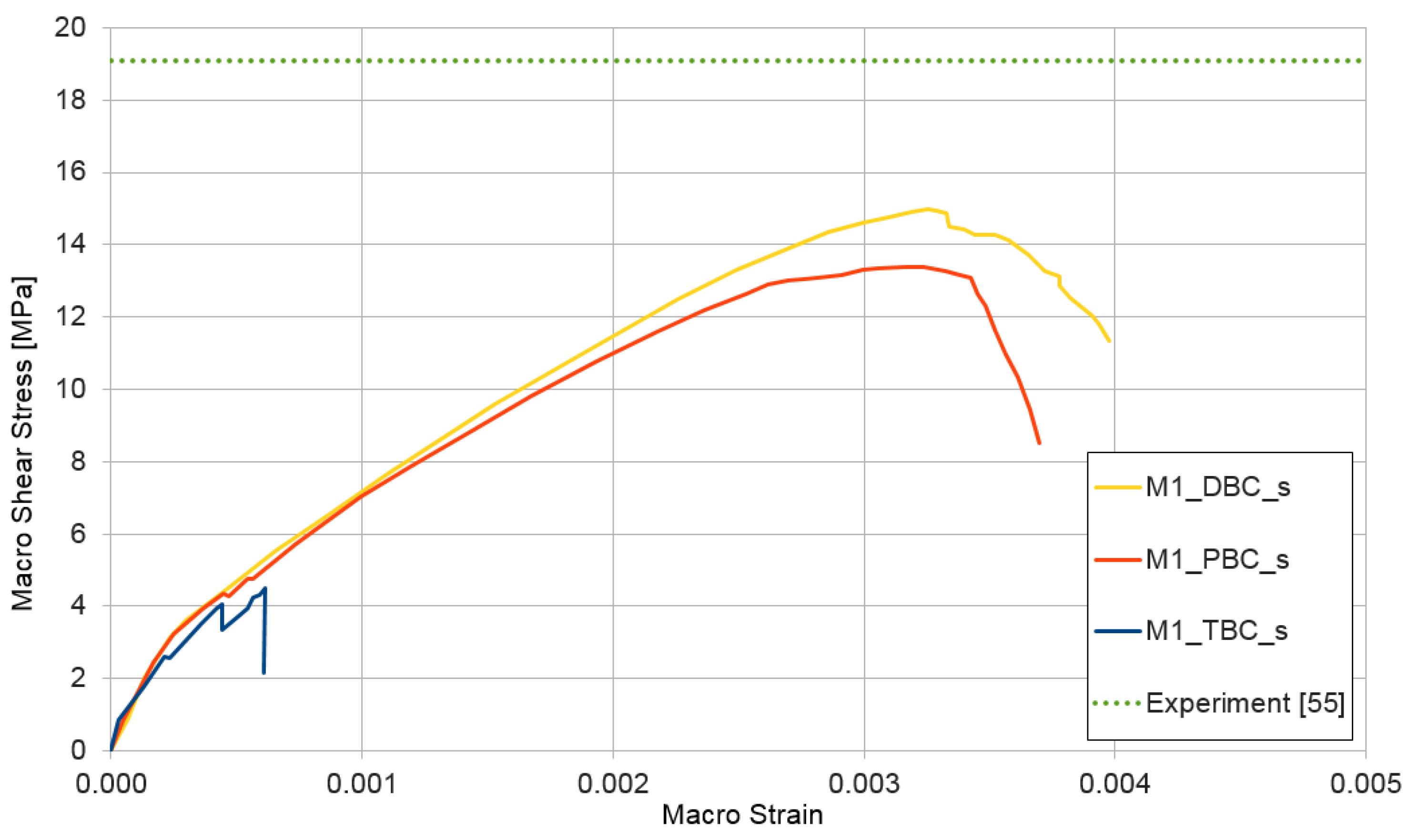

3.4. Shear Test for Mixture I and II

4. Concluding Remarks

- The periodic boundary conditions (PBC) lead to stable results for the full range of deformations up to failure in all performed numerical calculations.

- In the compression and tensile tests, the upper estimate of values of macro-parameters is reached for mixture I by imposing the PBC whereas for mixture II by imposing the applied displacement boundary conditions (DBC).

- Use of the DBC provides the upper estimate of values of macro-parameters in the shear test for both mixtures I and II.

- Application of the traction boundary conditions (TBC) leads in all analyzed cases to a lower estimate of values of the macro-parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Rahman, S.; Molyneaux, T.; Patnaikuni, I. Ultra high performance concrete: Recent applications and research. Aust. J. Civ. Eng. 2005, 2, 13–20. [Google Scholar] [CrossRef]

- Russel, H.G.; Graybeal, B.A. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community. Natl. Transp. Libr. 2013. [Google Scholar]

- Mattei, N.J.; Mehrabadi, M.M.; Zhu, H. A micromechanical constitutive model for the behavior of concrete. Mech. Mater. 2007, 39, 357–379. [Google Scholar] [CrossRef]

- Reda, M.M.; Shrive, N.G.; Gillott, J.E. Microstructural investigation of innovative UHPC. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Okereke, M.I.; Akpoyomare, A.I.; Bingley, M.S. Virtual testing of advanced composites, cellular materials and biomaterials: A review. Compos. Part B Eng. 2014, 60, 637–662. [Google Scholar] [CrossRef]

- Le Hoang, A.; Fehling, E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra high performance concrete. Constr. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Barnett, S.J.; Lataste, J.F.; Parry, T.; Millard, S.G.; Soutsos, M.N. Assessment of fibre orientation in ultra high performance fibre reinforced concrete and its effect on flexural strength. Mater. Struct. 2010, 43, 1009–1023. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Yoon, Y.S. Structural performance of ultra-high-performance concrete beams with different steel fibers. Eng. Struct. 2015, 102, 409–423. [Google Scholar] [CrossRef]

- Denisiewicz, A.; Kula, K.; Socha, T.; Kwiatkowski, G. Influence of silica fume addition on selected properties of fine-grained concrete. Civ. Environ. Eng. Rep. 2018, 3, 166–176. [Google Scholar] [CrossRef]

- Denisiewicz, A.; Śliwa, M.; Kula, K.; Socha, T. Experimental investigation of concrete with recycled aggregates for suitability in concrete structures. Appl. Sci. 2019, 9, 5010. [Google Scholar] [CrossRef]

- He, S.; Qiu, J.; Li, J.; Yang, E.H. Strain hardening ultra-high performance concrete (SHUHPC) incorporating CNF-coated polyethylene fibers. Cem. Concr. Res. 2017, 98, 50–60. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative flexural behavior of Hybrid Ultra High Performance Fiber Reinforced Concrete with different macro fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar] [CrossRef]

- Tai, Y.S.; El-Tawil, S.; Chung, T.H. Performance of deformed steel fibers embedded in ultra-high performance concrete subjected to various pullout rates. Cem. Concr. Res. 2016, 89, 1–13. [Google Scholar] [CrossRef]

- Sorelli, L.; Constantinides, G.; Ulm, F.J.; Toutlemonde, F. The nano-mechanical signature of Ultra High Performance Concrete by statistical nanoindentation techniques. Cem. Concr. Res. 2008, 38, 1447–1456. [Google Scholar] [CrossRef]

- Denisiewicz, A.; Socha, T.; Kula, K.; Pasula, M. Influence of steel and polypropylene fibers addition on selected properties of fine-grained concrete. Civ. Environ. Eng. Rep. 2018, 4, 138–148. [Google Scholar] [CrossRef]

- Kabele, P. Multiscale framework for modeling of fracture in high performance fiber reinforced cementitious composites. Eng. Fract. Mech. 2007, 74, 194–209. [Google Scholar] [CrossRef]

- Kim, S.Y.; Jang, H.G.; Yang, C.M.; Yang, B. Multiscale prediction of thermal conductivity for nanocomposites containing crumpled carbon nanofillers with interfacial characteristics. Compos. Sci. Technol. 2018, 155, 169–176. [Google Scholar] [CrossRef]

- Yang, B.J.; Souri, H.; Kim, S.; Ryu, S.; Lee, H.K. An analytical model to predict curvature effects of the carbon nanotube on the overall behavior of nanocomposites. J. Appl. Phys. 2014, 116, 033511. [Google Scholar] [CrossRef]

- Qin, Q.H.; Yang, Q.S. Macro-Micro Theory on Multifield Coupling Behavior of Heterogeneous Materials; Springer: Berlin, Germany, 2008. [Google Scholar]

- Hashin, Z. Analysis of composites materials—A survey. J. Appl. Mech. 1983, 50, 481–505. [Google Scholar] [CrossRef]

- Hill, R. Elastic properties of reinforced solids: Some theoretical principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Ostoja-Starzewski, M. Scale effects in plasticity of random media: Status and challenges. Int. J. Plast. 2005, 21, 1119–1160. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion and related problems. Proc. R. Soc. 1957, 241, 376–396. [Google Scholar]

- Hill, R. A self-consistent mechanics of composites materials. J. Mech. Phys. Solids 1965, 13, 213–222. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Mater. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Bensoussan, A.; Lion, J.L.; Papanicolaou, G. Asymptotic Analysis for Periodic Structures; North-Holland: Amsterdam, The Netherlands; New York, NY, USA; Oxford, UK, 1978. [Google Scholar]

- Sanchez-Palencia, E. Non-Homogeneous Media and Vibration Theory; Lectures notes in Physics; Springer-Verlag: Berlin/Heidelberg, Germany; New York, NY, USA, 1980. [Google Scholar]

- Strzelecki, T.; Auriault, J.L.; Bauer, J.; Kostecki, S.; Puła, W. Mechanics of Heterogeneous Media: Theory of Homogenization; Lower Silesian Scientific Publisher: Wrocław, Poland, 1996. (In Polish) [Google Scholar]

- Fish, J.; Yu, Q. Two-scale damage modeling of brittle composites. Compos. Sci. Technol. 2001, 61, 2215–2222. [Google Scholar] [CrossRef]

- Ghosh, S.; Lee, K.; Moorthy, S. Two scale analysis of heterogeneous elastic-plastic materials with asymptotic homogenization and Voronoi cell finite element model. Comput. Methods Appl. Mech. Eng. 1996, 132, 63–116. [Google Scholar] [CrossRef]

- Fishman, L.; McCoy, J.J. A unified view of bulk property theories for stochastic and periodic media. J. Appl. Math. Phys. 1981, 32, 45–61. [Google Scholar] [CrossRef]

- McCoy, J.J. Macroscopic response of continua with random microstructures. Mech. Today 1981, 6, 1–40. [Google Scholar]

- Guan, X.; Liu, X.; Jia, X.; Yuan, Y.; Cui, J.; Mang, H.A. A stochastic multiscale model for predicting mechanical properties of fiber reinforced concrete. Int. J. Solids Struct. 2015, 56–57, 280–289. [Google Scholar] [CrossRef]

- Geers, M.G.D.; Kouznetsova, V.G.; Brekelmans, W.A.M. Multi-scale computational homogenization: Trends and challenges. J. Comput. Appl. Math. 2010, 234, 2175–2182. [Google Scholar] [CrossRef]

- Kouznetsova, V.G.; Geers, M.G.D.; Brekelmans, W.A.M. Multi-scale second-order computational homogenization of multi-phase materials: A nested finite element solution strategy. Comput. Methods Appl. Mech. Eng. 2004, 193, 5525–5550. [Google Scholar] [CrossRef]

- Schröder, J. A numerical two-scale homogenization scheme: The FE2-method. Plasticity and Beyond: Microstructures, Crystal-Plasticity and Phase Transitions; Schröder, J., Hackl, K., Eds.; CISM Courses and Lectures Vol. 550; Springer: Berlin/Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2014; pp. 1–64. [Google Scholar]

- Miehe, C.; Koch, A. Computational micro-to-macro tran-sitions of discretized microstructures undergoing small strains. Arch. Appl. Mech. 2002, 72, 300–317. [Google Scholar] [CrossRef]

- Hain, M.; Wriggers, P. Numerical homogenization of hardened cement paste. Comput. Mech. 2008, 42, 197–212. [Google Scholar] [CrossRef]

- Tian, Z.; Bian, C. Numerical modeling of elastic modulus for cement paste using homogenization method. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2013, 28, 751–760. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Cheyrezy, M.; Maret, V.; Frouin, L. Microstructural analysis of RPC (Reactive Powder Concrete). Cem. Concr. Res. 1995, 25, 1491–1500. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of Ultra-High Performance Concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Di Luzio, G. Nonlocal microplane model with strain-softening yield limits. Int. J. Solids Struct. 2004, 41, 7209–7240. [Google Scholar] [CrossRef]

- De Borst, R.; Verhoosel, C.V. Gradient damage vs phase-field approaches for fracture: Similarities and differences. Comput. Methods Appl. Mech. Engrg. 2016, 312, 78–94. [Google Scholar] [CrossRef]

- Kuhl, E.; Ramm, E.; de Borst, R. An anisotropic gradient damage model for quasi-brittle materials. Comput. Methods Appl. Mech. Engrg. 2000, 183, 87–103. [Google Scholar] [CrossRef]

- Zreid, I.; Kaliske, M. A gradient enhanced plasticity–damage microplane model for concrete. Comput. Mech. 2018, 62, 1239–1257. [Google Scholar] [CrossRef]

- Svenning, E.; Fagerström, M.; Larsson, F. Computational homogenization of microfractured continua using weakly periodic boundary conditions. Comput. Methods Appl. Mech. Engrg. 2016, 299, 1–21. [Google Scholar] [CrossRef]

- Javili, A.; Saeb, S.; Steinmann, P. Aspects of implementing constant traction boundary conditions in computational homogenization via semi-Dirichlet boundary conditions. Comput. Mech. 2017, 59, 21–35. [Google Scholar] [CrossRef][Green Version]

- Espadas-Escalante, J.J.; van Dijk, N.P.; Isaksson, P. A study on the influence of boundary conditions in computational homogenization of periodic structures with application to woven composites. Compos. Struct. 2017, 160, 529–537. [Google Scholar] [CrossRef]

- Denisiewicz, A.; Kuczma, M. Two-scale modelling of reactive powder concrete. Part I: Representative volume element and solution of the corresponding boundary value problem. Civ. Environ. Eng. Rep. 2013, 10, 41–61. [Google Scholar]

- Denisiewicz, A.; Kuczma, M. Two-scale modelling of reactive powder concrete. Part II: Numerical simulations. Eng. Trans. 2015, 63, 35–54. [Google Scholar]

- Denisiewicz, A.; Kuczma, M. Two-scale modelling of reactive powder concrete. Part III: Experimental tests and validation. Eng. Trans. 2015, 63, 55–76. [Google Scholar]

- Denisiewicz, A.; Kuczma, M. Two-scale numerical homogenization of the constitutive parameters of reactive powder concrete. Int. J. Multiscale Comput. Eng. 2014, 12, 361–374. [Google Scholar] [CrossRef]

- Song, J.; Liu, S. Properties of reactive powder concrete and its application in highway bridge. Adv. Mater. Sci. Eng. 2016, 2016, 5460241. [Google Scholar] [CrossRef]

- Abaqus 6.12 Documentation; Dassault Systèmes Simulia Corp.: Johnston, RI, USA, 2012.

- Lejeunes, S.; Bourgeois, S. Une Toolbox Abaqus pour le Calcul de Propriétés Effectives de Milieux Hétérogènes; CSMA 2011, 10e Colloque National en Calcul des Structures 9-13 Mai 2011, Giens, France. 2011. 8p. Available online: https://hal.archives-ouvertes.fr/hal-00592866 (accessed on 1 January 2021).

- Zdeb, T.; Śliwiński, J. Reactive powder concrete—Mechanical properties and microstructure. Build. Ind. Technol. Archit. 2010, 51, 51–55. (in Polish). [Google Scholar]

- Hillerborg, A.; Modeer, M.; Petersson, P.E. Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 1976, 6, 773–782. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Oñate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–329. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 8, 892–900. [Google Scholar] [CrossRef]

- Drucker, D.C.; Prager, W. Soil mechanics and plastic analysis or limit design. Q. Appl. Math. 1952, 10, 157–165. [Google Scholar] [CrossRef]

- Kuczma, M.; Whiteman, J.R. Variational inequality formulation for flow theory plasticity. Int. J. Eng. Sci. 1995, 33, 1153–1169. [Google Scholar] [CrossRef]

- Saenz, L.P. Discussion of paper “Equation for stress-strain curve of concrete” by Desai P. and Krishnan S. J. Am. Concr. Inst. 1964, 61, 1229–1235. [Google Scholar]

- Oden, J.T.; Prudhome, S.; Hammerand, D.C.; Kuczma, M. Modeling error and adaptivity in nonlinear continuum mechanics. Comput. Methods Appl. Mech. Eng. 2001, 190, 6663–6684. [Google Scholar] [CrossRef]

- Jhurani, C.; Demkowicz, L. Multiscale modeling using goal-oriented adaptivity and numerical homogenization.Part I: Mathematical formulation and numerical results & Part II: Algorithms for the Moore-Penrose pseudoinverse. Comput. Methods Appl. Mech. Eng. 2012, 213–216, 399–417, 418–426. [Google Scholar]

| Component | Mixture I [kg/m] | wt% | Mixture II [kg/m] | wt% |

|---|---|---|---|---|

| Cement CEM I 42.5R | 905 | 34.2 | 905 | 33.2 |

| Silica fume | 230 | 8.7 | 230 | 8.4 |

| Quartz sand 0.063–0.4 mm OS 36 | 702 | 26.6 | 330 | 12.1 |

| Quartz sand 0.04–0.125 mm OS 38 | 285 | 10.8 | 285 | 10.5 |

| Quartz sand 0.2–0.8 mm OS 30 | - | - | 335 | 12.3 |

| Water | 260 | 9.8 | 260 | 9.5 |

| Superplasticizer Woerment FM 787 BASF | 29.6 | 1.1 | 29.6 | 1.1 |

| Micro steel fibres DM 6/0.17 KrampeHarex | 233 | 8.8 | 233 | 8.6 |

| Steel fibres DW 38/1.0 N KrampeHarex | - | - | 117 | 4.3 |

| Density | 2645 | - | 2725 | - |

| m | ||||

|---|---|---|---|---|

| 0.1 | 1.16 | 0.667 | 0 |

| A | B | C | D | |

|---|---|---|---|---|

| Compression | 0.00002 | −0.01003 | 3.25030 | −59.29370 |

| Tension | 0.00002 | 0.02236 | −651.59869 | 1885015.6 |

| Mixture_BC | Compression | Tensile | Shear | |||

|---|---|---|---|---|---|---|

| [MPa] | [-] | [MPa] | [-] | [MPa] | [-] | |

| M1_PBC | 110.91 | 13.50 | 13.40 | |||

| M1_DBC | 107.18 | 13.30 | 14.9 | |||

| M1_TBC | 45.55 | 10.40 | 4.49 | |||

| M2_PBC | 137.77 | 18.00 | 12.90 | |||

| M2_DBC | 151.21 | 19.50 | 15.60 | |||

| M2_TBC | 96.61 | 13.20 | 8.43 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Denisiewicz, A.; Kuczma, M.; Kula, K.; Socha, T. Influence of Boundary Conditions on Numerical Homogenization of High Performance Concrete. Materials 2021, 14, 1009. https://doi.org/10.3390/ma14041009

Denisiewicz A, Kuczma M, Kula K, Socha T. Influence of Boundary Conditions on Numerical Homogenization of High Performance Concrete. Materials. 2021; 14(4):1009. https://doi.org/10.3390/ma14041009

Chicago/Turabian StyleDenisiewicz, Arkadiusz, Mieczysław Kuczma, Krzysztof Kula, and Tomasz Socha. 2021. "Influence of Boundary Conditions on Numerical Homogenization of High Performance Concrete" Materials 14, no. 4: 1009. https://doi.org/10.3390/ma14041009

APA StyleDenisiewicz, A., Kuczma, M., Kula, K., & Socha, T. (2021). Influence of Boundary Conditions on Numerical Homogenization of High Performance Concrete. Materials, 14(4), 1009. https://doi.org/10.3390/ma14041009