Influence of Compound Modification of Oil Sands De-Oiled Asphalt and Polyphosphoric Acid on High- and Low-Temperature Performance of Styrene-Butadiene-Styrene-Modified Asphalt

Abstract

:1. Introduction

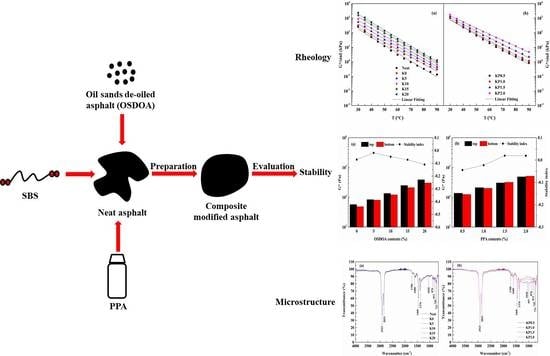

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

2.3. Test Methods

2.3.1. Conventional Performance Tests

2.3.2. Rheological Property Tests

- (1)

- DSR test

- (2)

- MSCR test

- (3)

- BBR test

2.3.3. Storage Test

2.3.4. Microscopic Morphology Tests

- (1)

- FM test

- (2)

- FTIR test

3. Results

3.1. Conventional Properties

3.2. Rheological Properties

3.2.1. Frequency Sweep Tests

3.2.2. Temperature Sweep Tests

3.2.3. Viscous Flow Behavior

3.2.4. Creep and Recovery Behavior

3.2.5. Low-Temperature Creep Behavior

3.2.6. Fatigue Behavior

3.3. Storage Stability

3.4. Microstructure

4. Conclusions

- (1)

- The compound modification of OSDOA/PPA on SBS-modified asphalt markedly improves the resistance to permanent deformation. Furthermore, the low-temperature PG grade of composite modified binder can be guaranteed to reach −28 °C by optimizing the concentration of OSDOA and PPA.

- (2)

- Fatigue resistance of SBS-modified asphalt is degraded by the compound modification of OSDOA and PPA. Moreover, the effect of OSDOA on the fatigue behavior of SBS-modified binder is far greater than that of PPA.

- (3)

- The composite modified asphalt has excellent storage stability, which is verified by fluorescence images. FTIR analysis reveals that physical and chemical interactions coexist during the OSDOA/PPA modification process.

- (4)

- By a comprehensive consideration of the balance of high- and low-temperature properties and storage stability, the optimal doses of OSDOA and PPA are determined to be 10 wt% and 1.0 wt%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Carreau, P.J.; Bousmina, M.; Bonniot, F. The viscoelastic properties of polymer-modified asphalts. Can. J. Chem. Eng. 2000, 78, 495–503. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D. Effect of Synthetic Fibers and Hydrated Lime in Porous Asphalt Mixture Using Multi-Criteria Decision-Making Techniques. Materials 2020, 13, 675. [Google Scholar] [CrossRef] [Green Version]

- Nowoświat, A.; Sorociak, W.; Żuchowski, R. The impact of the application of thin emulsion mat microsurfacing on the level of noise in the environment. Constr. Build. Mater. 2020, 263, 120626. [Google Scholar] [CrossRef]

- Afonso, M.L.; Dinis-Almeida, M.; Fael, C. Study of the porous asphalt performance with cellulosic fibres. Constr. Build. Mater. 2017, 135, 104–111. [Google Scholar] [CrossRef] [Green Version]

- Shan, L.; Qi, X.; Duan, X.; Liu, S.; Chen, J. Effect of styrene-butadiene-styrene (SBS) on the rheological behavior of asphalt binders. Constr. Build. Mater. 2020, 231, 117076. [Google Scholar] [CrossRef]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Ren, S.; Shi, J. Effects of polymerized sulfur on rheological properties, morphology and stability of SBS modified asphalt. Constr. Build. Mater. 2017, 150, 860–871. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, J.; Li, P.; Yue, X.; Bing, H. Analysis of viscous flow properties of styrene–butadiene–styrene-modified asphalt. Constr. Build. Mater. 2019, 229, 116881. [Google Scholar] [CrossRef]

- Ahmedzade, P. The investigation and comparison effects of SBS and SBS with new reactive terpolymer on the rheological properties of bitumen. Constr. Build. Mater. 2013, 38, 285–291. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: As-phalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic be-havior of modified asphalts. Curr. Opin. Colloid. In. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Li, R.; Zhang, Y.; Wei, J.; Lv, Y.; Ding, X. Reinforcement effect of fiber and deoiled asphalt on high viscosity rubber/SBS modified asphalt mortar. Pet. Sci. 2014, 11, 454–459. [Google Scholar] [CrossRef] [Green Version]

- Xiang, L.; Li, Z.; Cheng, J. Construction asphalt prepared by chemical treatment of deoiled asphalt. Pet. Sci. Technol. 2016, 34, 920–926. [Google Scholar] [CrossRef]

- Li, H.-P.; Shen, J. Production of Paving Asphalt by Blending RFCC Slurry in Deoiled Asphalt. Pet. Sci. Technol. 2009, 27, 46–55. [Google Scholar] [CrossRef]

- Liang, M.; Liu, S.; Fan, W.; Xin, X.; Luo, H.; Xing, B. Rheological and chemical characterization of deoiled asphalt modified with FCC slurry. Mater. Struct. 2015, 49, 3607–3617. [Google Scholar] [CrossRef]

- Cheng, J.; Xiang, L.; Li, Z. Road Asphalt Prepared by High Softening Point De-oiled Asphalt From Residuum Solvent Deasphalting. Pet. Sci. Technol. 2014, 32, 2575–2583. [Google Scholar] [CrossRef]

- Tong, Y.; Shen, B.; Liu, J.; Ning, A. Solvent deasphalting of Saudi residue to produce 30# hard asphalt. Pet. Sci. Technol. 2016, 34, 1777–1782. [Google Scholar] [CrossRef]

- Alam, S.; Hossain, Z. Changes in fractional compositions of PPA and SBS modified asphalt binders. Constr. Build. Mater. 2017, 152, 386–393. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Oliviero Rossi, C.; Caputo, P.; Falvo, T. Rheological effects on bitumen of poly-phosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for SBS and SBR compound modified asphalts with polyphosphoric acid and sulfur. Constr. Build. Mater. 2013, 43, 461–468. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C.; Zhang, Y. Research for SEBS/PPA compound-modified asphalt. J. Appl. Polym. Sci. 2017, 135, 46085. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Wang, H.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Liu, X.; Li, T.; Zhang, H. Short-term aging resistance investigations of polymers and polyphosphoric acid modified asphalt binders under RTFOT aging process. Constr. Build. Mater. 2018, 191, 787–794. [Google Scholar] [CrossRef]

- Ramayya, V.V.; Ram, V.V.; Krishnaiah, S.; Sandra, A.K. Performance of VG30 paving grade bitumen modified with polyphosphoric acid at medium and high temperature regimes. Constr. Build. Mater. 2016, 105, 157–164. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. D36, Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society for Testing and Materials. D5, Standard Test Method for Penetration of Bituminous Materials; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- American Society for Testing and Materials. D113, Standard Test Method for Ductility of Asphalt Materials; ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- American Society for Testing and Materials. D4402, Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures using a Rotational Viscometer; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- American Society for Testing and Materials. D4124, Standard Test Method for Separation of Asphalt into Four Fractions; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. JTG E20—2011, Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; MOT: Beijing, China, 2011.

- Ameri, M.; Mansourian, A.; Ashani, S.S.; Yadollahi, G. Technical study on the Iranian Gilsonite as an additive for modification of asphalt binders used in pavement construction. Constr. Build. Mater. 2011, 25, 1379–1387. [Google Scholar] [CrossRef]

- He, R.; Zheng, S.; Chen, H.; Kuang, D. Investigation of the physical and rheological properties of Trinidad lake asphalt modified bitumen. Constr. Build. Mater. 2019, 203, 734–739. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. M 320, Standard Specification for Performance-Graded Asphalt Binder; AASHTO: Washington, DC, USA, 2010. [Google Scholar]

- Bazzaz, M.; Darabi, M.K.; Little, D.N.; Garg, N. Effect of Evotherm-M1 on Properties of Asphaltic Materials Used at NAPMRC Testing Facility. J. Test. Eval. 2020, 48, 2256–2269. [Google Scholar] [CrossRef]

- Pei, X.; Fan, W.; Liu, Y.; Qian, C.; Wang, Y.; Jiang, Y.; Chen, S.; Wang, Z.; Han, L. The effect of oil sands de-oiled asphalt on rheological properties, compatibility, and stability of asphalt binder. Constr. Build. Mater. 2020, 263, 120594. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Luo, H.; Wang, X.; Xing, B. Investigation of the rheological properties and storage stability of CR/SBS modified asphalt. Constr. Build. Mater. 2015, 74, 235–240. [Google Scholar] [CrossRef]

- Subhy, A. Advanced analytical techniques in fatigue and rutting related characterisations of modified bitumen: Liter-ature review. Constr. Build. Mater. 2017, 156, 28–45. [Google Scholar] [CrossRef]

- Cardone, F.; Ferrotti, G.; Frigio, F.; Canestrari, F. Influence of polymer modification on asphalt binder dynamic and steady flow viscosities. Constr. Build. Mater. 2014, 71, 435–443. [Google Scholar] [CrossRef]

- Sybilski, D. Zero-shear viscosity of bituminous binder and its relation to bituminous mixture’s rutting resistance. Transp. Res. Rec. 1996, 1535, 15–21. [Google Scholar] [CrossRef]

- Vargas, M.A.; Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, mi-crostructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar] [CrossRef]

- Qian, C.; Fan, W.; Ren, F.; Lv, X.; Xing, B. Influence of polyphosphoric acid (PPA) on properties of crumb rubber (CR) modified asphalt. Constr. Build. Mater. 2019, 227, 117094. [Google Scholar] [CrossRef]

- Liang, P.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; Ren, S. Improving thermo-rheological behavior and compatibility of SBR modified asphalt by addition of polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 139, 183–192. [Google Scholar] [CrossRef]

- Huang, W.; Tang, N. Characterizing SBS modified asphalt with sulfur using multiple stress creep recovery test. Constr. Build. Mater. 2015, 93, 514–521. [Google Scholar] [CrossRef]

- Nuñez, J.Y.M.; Domingos, M.D.I.; Faxina, A.L. Susceptibility of low-density polyethylene and polyphosphoric ac-id-modified asphalt binders to rutting and fatigue cracking. Constr. Build. Mater. 2014, 73, 509–514. [Google Scholar] [CrossRef]

- Zhang, L.; Xing, C.; Gao, F.; Li, T.-S.; Tan, Y.-Q. Using DSR and MSCR tests to characterize high temperature performance of different rubber modified asphalt. Constr. Build. Mater. 2016, 127, 466–474. [Google Scholar] [CrossRef]

- Günay, T.; Ahmedzade, P. Physical and rheological properties of nano-TiO2 and nanocomposite modified bitumens. Constr. Build. Mater. 2020, 243, 118208. [Google Scholar] [CrossRef]

- Domingos, M.D.I.; Faxina, A.L.; Bernucci, L.L.B. Characterization of the rutting potential of modified asphalt binders and its correlation with the mixture’s rut resistance. Constr. Build. Mater. 2017, 144, 207–213. [Google Scholar] [CrossRef]

- Zhang, J.; Walubita, L.F.; Faruk, A.N.M.; Karki, P.; Simate, G.S. Use of the MSCR test to characterize the asphalt binder properties relative to HMA rutting performance—A laboratory study. Constr. Build. Mater. 2015, 94, 218–227. [Google Scholar] [CrossRef]

- Darabi, M.K.; Huang, C.-W.; Bazzaz, M.; Masad, E.; Little, D. Characterization and validation of the nonlinear viscoelastic-viscoplastic with hardening-relaxation constitutive relationship for asphalt mixtures. Constr. Build. Mater. 2019, 216, 648–660. [Google Scholar] [CrossRef]

- Boudibi, S.; Sakaa, B.; Benguega, Z.; Fadlaoui, H.; Othman, T.; Bouzidi, N. Spatial prediction and modeling of soil salinity using simple cokriging, artificial neural networks, and support vector machines in El Outaya plain, Biskra, southeastern Algeria. Acta Geochim. 2021, 1–19. [Google Scholar] [CrossRef]

- Jalal, M.; Nassir, N.; Jalal, H.; Arabali, P. On the strength and pulse velocity of rubberized concrete containing silica fume and zeolite: Prediction using multivariable regression models. Constr. Build. Mater. 2019, 223, 530–543. [Google Scholar] [CrossRef]

- Kaseer, F.; Arambula-Mercado, E.; Cucalon, L.G.; Martin, A.E. Performance of asphalt mixtures with high recycled materials content and recycling agents. Int. J. Pavement. Eng. 2020, 21, 863–877. [Google Scholar] [CrossRef]

- Edwards, Y.; Tasdemir, Y.; Isacsson, U. Rheological effects of commercial waxes and polyphosphoric acid in bitumen 160/220—low temperature performance. Fuel 2006, 85, 989–997. [Google Scholar] [CrossRef]

- Ziari, H.; Amini, A.; Goli, A. The effect of different aging conditions and strain levels on relationship between fatigue life of asphalt binders and mixtures. Constr. Build. Mater. 2020, 244, 118345. [Google Scholar] [CrossRef]

- Ziari, H.; Nasiri, E.; Amini, A.; Ferdosian, O. The effect of EAF dust and waste PVC on moisture sensitivity, rutting resistance, and fatigue performance of asphalt binders and mixtures. Constr. Build. Mater. 2019, 203, 188–200. [Google Scholar] [CrossRef]

- Nazari, H.; Naderi, K.; Nejad, F.M. Improving aging resistance and fatigue performance of asphalt binders using inorganic nanoparticles. Constr. Build. Mater. 2018, 170, 591–602. [Google Scholar] [CrossRef]

- Shafabakhsh, G.A.; Rajabi, M.; Sahaf, A. The fatigue behavior of SBS/nanosilica composite modified asphalt binder and mixture. Constr. Build. Mater. 2019, 229, 116796. [Google Scholar] [CrossRef]

- Ren, S.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; He, Y.; Shi, J. Investigating the effects of SBR on the properties of gilsonite modified asphalt. Constr. Build. Mater. 2018, 190, 1103–1116. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Liu, S.; Wei, J. Rheological behaviors, and microstructure of SBS/CR composite modified hard asphalt. Constr. Build. Mater. 2016, 115, 285–293. [Google Scholar] [CrossRef]

- Zani, L.; Giustozzi, F.; Harvey, J. Effect of storage stability on chemical and rheological properties of polymer-modified asphalt binders for road pavement construction. Constr. Build. Mater. 2017, 145, 326–335. [Google Scholar] [CrossRef]

- Liang, M.; Liang, P.; Fan, W.; Qian, C.; Xin, X.; Shi, J.; Nan, G. Thermo-rheological behavior and compatibility of modified asphalt with various styrene–butadiene structures in SBS copolymers. Mater. Des. 2015, 88, 177–185. [Google Scholar] [CrossRef]

- Hanyu, A.; Ito, T.; Kasahara, A.; Saito, K. Effect of the morphology of sbs modified asphalt on mechanical properties of binder and performance of mixture. J. Pavement Eng. JSCE 2004, 9, 65–72. [Google Scholar] [CrossRef]

- Hou, X.; Lv, S.; Chen, Z.; Xiao, F. Applications of Fourier transform infrared spectroscopy technologies on asphalt materials. Measurement 2018, 121, 304–316. [Google Scholar] [CrossRef]

- Liang, M.; Ren, S.; Fan, W.; Wang, H.; Cui, W.; Zhao, P. Characterization of fume composition and rheological properties of asphalt with crumb rubber activated by microwave and TOR. Constr. Build. Mater. 2017, 154, 310–322. [Google Scholar] [CrossRef]

- Olabemiwo, O.M.; Esan, A.O.; Adediran, G.O.; Bakare, H.O. The performance of Agbabu natural bitumen modified with polyphosphoric acid through fundamental and Fourier transform infrared spectroscopic investigations. Case Stud. Constr. Mater. 2016, 5, 39–45. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 2010, 24, 410–418. [Google Scholar] [CrossRef]

- Ge, D.; Yan, K.; You, L.; Wang, Z. Modification mechanism of asphalt modified with Sasobit and Polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 143, 419–428. [Google Scholar] [CrossRef]

- Masson, J.-F. Brief Review of the Chemistry of Polyphosphoric Acid (PPA) and Bitumen. Energy Fuels 2008, 22, 2637–2640. [Google Scholar] [CrossRef] [Green Version]

- Masson, J.-F.; Gagné, M. Polyphosphoric Acid (PPA)-Modified Bitumen: Disruption of the Asphaltenes Network Based on the Reaction of Nonbasic Nitrogen with PPA. Energy Fuels 2008, 22, 3402–3406. [Google Scholar] [CrossRef] [Green Version]

- Masson, J.-F.; Gagné, M. Ionic Pairs in Polyphosphoric Acid (PPA)-Modified Bitumen: Insights from Model Compounds. Energy Fuels 2008, 22, 3390–3394. [Google Scholar] [CrossRef] [Green Version]

- Masson, J.F.; Collins, P. Ftir Study of The Reaction of Polyphosphoric Acid and Modelbitumen Sulfur Compounds. Energy Fuels 2009, 23, 440–442. [Google Scholar] [CrossRef] [Green Version]

| Item | Neat Asphalt | Specifications |

|---|---|---|

| Softening point (°C) | 47.2 | ASTM D36 [28] |

| Penetration (25 °C, 0.1 mm) | 87 | ASTM D5 [29] |

| Ductility (10 °C, cm) | >100 | ASTM D113 [30] |

| Viscosity (135 °C, Pa·s) | 0.595 | ASTM D4402 [31] |

| Saturates (wt%) | 28.63 | ASTM D4124 [32] |

| Aromatics (wt%) | 34.04 | ASTM D4124 |

| Resins (wt%) | 37.21 | ASTM D4124 |

| Asphaltenes (wt%) | 0.12 | ASTM D4124 |

| Item | SBS |

|---|---|

| Density (g/cm3) | 0.94 |

| Melt Flow Rate (g/10 min) | <0.5 |

| Styrene to Butadiene | 30/70 |

| Elongation at Break (%) | 750 |

| Tensile Strength (MPa) | 24 |

| Hardness | 76 |

| Structure | Linear |

| Item | OSDOA | Specifications |

|---|---|---|

| Softening point (°C) | 135 | ASTM D36 |

| Penetration (25 °C, 0.1 mm) | 0 | ASTM D5 |

| Saturates (wt%) | 3.45 | ASTM D4124 |

| Aromatics (wt%) | 23.03 | ASTM D4124 |

| Resins (wt%) | 34.48 | ASTM D4124 |

| Asphaltenes (wt%) | 39.04 | ASTM D4124 |

| Item | PPA |

|---|---|

| Concentration of P2O5 (%) | >85 |

| Density (g/cm3) | 2.06 |

| Molecular weight | 337.9 |

| Boiling point (°C) | 300 |

| Specific heat (J/g·°C) | 1.487 |

| Item | SBS (wt%) | OSDOA (wt%) | PPA (wt%) |

|---|---|---|---|

| K0 | 4 | 0 | 0 |

| K5 | 5 | 0 | |

| K10 | 10 | 0 | |

| K15 | 15 | 0 | |

| K20 | 20 | 0 | |

| KP0.5 | 10 | 0.5 | |

| KP1.0 | 10 | 1.0 | |

| KP1.5 | 10 | 1.5 | |

| KP2.0 | 10 | 2.0 |

| Item | Penetration (25 °C, 0.1 mm) | Softening point (°C) | Ductility (10 °C, cm) | Viscosity (135 °C, Pa·s) | Fraass Breaking Point (°C) |

|---|---|---|---|---|---|

| K0 | 73 | 55.4 | 60 | 0.127 | −14 |

| K5 | 50 | 58.4 | 35 | 0.167 | −13 |

| K10 | 38 | 63.6 | 22 | 2.005 | −12 |

| K15 | 28 | 67.2 | 10 | 2.730 | −11 |

| K20 | 24 | 69.0 | 5 | 3.365 | −10 |

| KP0.5 | 37 | 64.6 | 20 | 2.480 | −12 |

| KP1.0 | 35 | 67.8 | 14 | 2.915 | −13 |

| KP1.5 | 30 | 73.2 | 10 | 5.963 | −13 |

| KP2.0 | 26 | 80.5 | 8 | 9.538 | −13 |

| Samples | Failure Temperature (°C) |

|---|---|

| Neat | 70.95 |

| K0 | 77.00 |

| K5 | 80.57 |

| K10 | 83.94 |

| K15 | 87.79 |

| K20 | 90.08 |

| KP0.5 | 86.50 |

| KP1.0 | 89.68 |

| KP1.5 | 95.98 |

| KP2.0 | 105.32 |

| Samples | s | ||

|---|---|---|---|

| Neat | 303.89 | 25.24 | 0.4942 |

| K0 | 1351.96 | 0.10 | 0.1219 |

| K5 | 2037.21 | 0.22 | 0.1476 |

| K10 | 3546.26 | 0.21 | 0.1616 |

| K15 | 5255.00 | 0.18 | 0.1667 |

| K20 | 8540.31 | 0.15 | 0.1799 |

| KP0.5 | 5340.60 | 0.11 | 0.1645 |

| KP1.0 | 7663.38 | 0.08 | 0.1682 |

| KP1.5 | 16,429.90 | 0.07 | 0.2083 |

| KP2.0 | 48,136.47 | 0.05 | 0.2518 |

| Samples | Fatigue Temperature (°C) |

|---|---|

| Neat | 11.99 |

| K0 | 10.64 |

| K5 | 16.05 |

| K10 | 17.91 |

| K15 | 23.30 |

| K20 | 26.02 |

| KP0.5 | 18.29 |

| KP1.0 | 19.04 |

| KP1.5 | 19.79 |

| KP2.0 | 20.27 |

| Samples | Softening Point (°C) | Differences (°C) | |

|---|---|---|---|

| Top | Bottom | ||

| K0 | 59.4 | 54.9 | 4.5 |

| K5 | 59.0 | 58.4 | 0.6 |

| K10 | 64.4 | 61.0 | 3.4 |

| K15 | 71.4 | 66.7 | 4.7 |

| K20 | 77.5 | 68.6 | 8.9 |

| KP0.5 | 71.3 | 68.6 | 2.7 |

| KP1.0 | 74.1 | 73.1 | 1.0 |

| KP1.5 | 77.7 | 78.4 | −0.7 |

| KP2.0 | 82.9 | 83.5 | −0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, X.; Fan, W. Influence of Compound Modification of Oil Sands De-Oiled Asphalt and Polyphosphoric Acid on High- and Low-Temperature Performance of Styrene-Butadiene-Styrene-Modified Asphalt. Materials 2021, 14, 797. https://doi.org/10.3390/ma14040797

Pei X, Fan W. Influence of Compound Modification of Oil Sands De-Oiled Asphalt and Polyphosphoric Acid on High- and Low-Temperature Performance of Styrene-Butadiene-Styrene-Modified Asphalt. Materials. 2021; 14(4):797. https://doi.org/10.3390/ma14040797

Chicago/Turabian StylePei, Xiaoguang, and Weiyu Fan. 2021. "Influence of Compound Modification of Oil Sands De-Oiled Asphalt and Polyphosphoric Acid on High- and Low-Temperature Performance of Styrene-Butadiene-Styrene-Modified Asphalt" Materials 14, no. 4: 797. https://doi.org/10.3390/ma14040797

APA StylePei, X., & Fan, W. (2021). Influence of Compound Modification of Oil Sands De-Oiled Asphalt and Polyphosphoric Acid on High- and Low-Temperature Performance of Styrene-Butadiene-Styrene-Modified Asphalt. Materials, 14(4), 797. https://doi.org/10.3390/ma14040797