Challenges in the Forging of Steel-Aluminum Bearing Bushings

Abstract

1. Introduction

2. Survey of Current Literature

3. Materials and Methods

3.1. Initial and Final Geometry

3.2. Heating Strategy

3.3. Forging Process

4. Results and Discussion

5. Conclusions

- The design of an appropriate heating strategy represents a key issue and one of the main challenges for the forming of dissimilar material combinations. Therefore, the bimetal workpieces have to be heated inhomogeneously in order to ensure specific forging temperatures for both of materials;

- Within this work, a specific heating concept in accordance with geometry and material combination was developed and realized by means of induction heating. With the temperature gradients achieved with heating strategies A and B, it was possible to ensure a sufficient formability for steel–aluminum workpieces assembled with a clearance fit. Subsequently, inhomogeneously heated hybrid workpieces were successfully formed to bearing bushings. Following strategy C, forming at inappropriate temperatures results in material fracture;

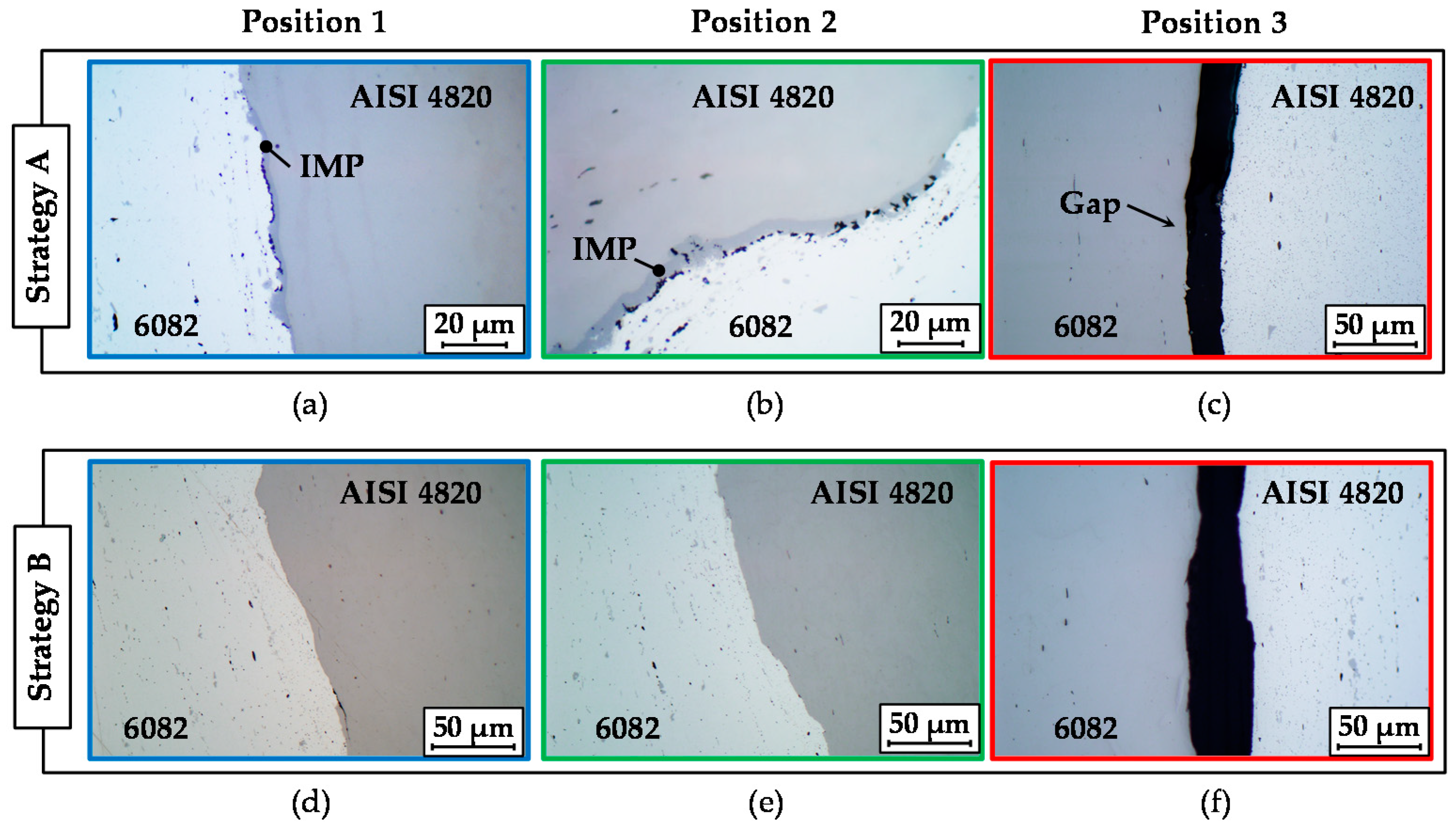

- With the strategies A and B, a complete metallurgical joint was observed in the upper part of the forgings exposed to high deformation. Moreover, insular intermetallic phases along the joining zone were observed with strategy A. By contrast, insufficient bonding with some partial separations with a maximal gap size of 40 μm was indicated in the bottom part with a lower deformation;

- A metallographical study including SEM and EDS investigations revealed an intermetallic phase of FexAly type with a thickness of approximately 4–7 µm in the steel–aluminum joint after the forming process with strategy A;

- According to the determined atomic percentage of 71.06 at.% for aluminum and 26.90 at.% for iron, the first assumptions indicate the prevalence of Fe2Al5 within the investigated intermetallic layer. This assumption has been confirmed with the help of nanoindention tests with high hardness values above 10 GPa, which correspond to the literature values of Fe2Al5 [31].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Politis, D.J.; Lin, J.; Dean, T.A. Investigation of material flow in forging bi-metal components. In Proceedings of the 14th International Conference on Metal Forming, Krakow, Poland, 16–19 September 2012; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012; pp. 231–234. [Google Scholar]

- Behrens, B.-A.; Bistron, M.; Kueper, A.; Möhwald, K. Investigation of load adapted gears and shafts manufactured by compound-forging. J. Adv. Manuf. Syst. 2008, 7, 175–182. [Google Scholar] [CrossRef]

- Uhe, J.; Behrens, B.-A. Manufacturing of Hybrid Solid Components by Tailored Forming. In Proceedings of the 9th Congress of the German Academic Association for Production Technology (WGP), Hamburg, Germany, 30 September–2 October 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 199–208. [Google Scholar]

- Avitzur, B. Handbook of Metal-Forming Processes; Wiley: New York, USA, 1983. [Google Scholar]

- Kong, T.F.; Chan, L.C.; Lee, T.C. Experimental Study of Effects of Process Parameters in Forge-Welding Bimetallic Materials: AISI 316L Stainless Steel and 6063 Aluminum Alloy. Strain 2009, 45, 373–379. [Google Scholar] [CrossRef]

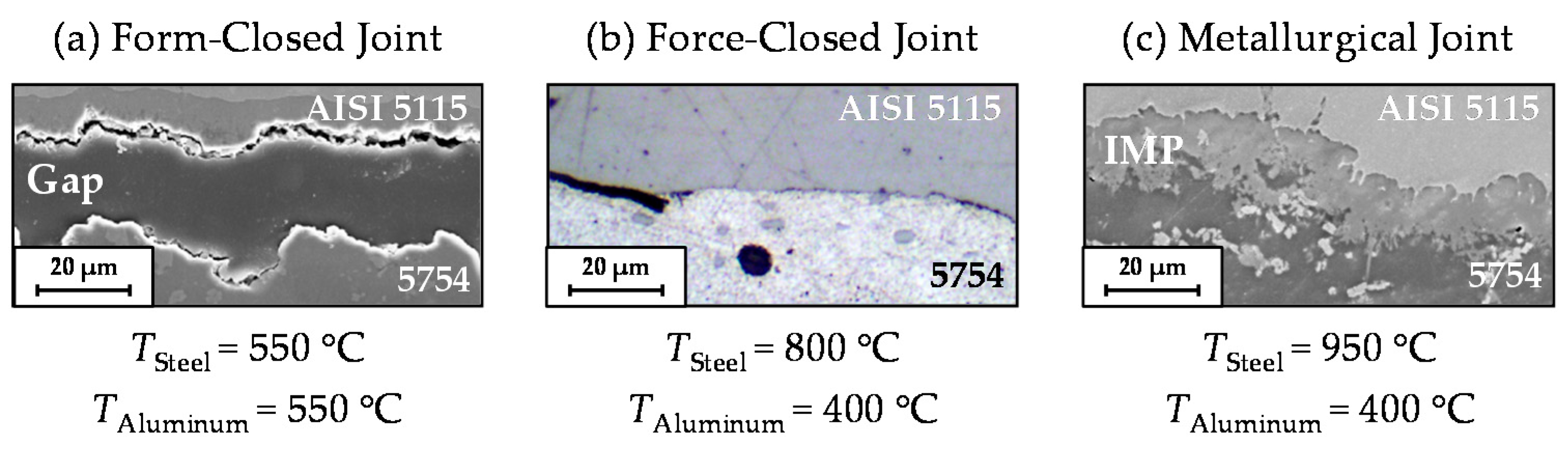

- Wohletz, S.; Groche, P. Temperature Influence on Bond Formation in Multi-material Joining by Forging. Proc. Eng. 2014, 81, 2000–2005. [Google Scholar] [CrossRef]

- Politis, D.J.; Lin, J.; Dean, T.A.; Balint, D.S. An investigation into the forging of Bi-metal gears. J. Mater. Process. Technol. 2014, 214, 2248–2260. [Google Scholar] [CrossRef]

- Wu, P.; Wang, B.; Lin, J.; Zuo, B.; Li, Z.; Zhou, J. Investigation on metal flow and forming load of bi-metal gear hot forging process. Int. J. Adv. Manuf. Technol. 2017, 88, 2835–2847. [Google Scholar] [CrossRef]

- Estrin, Y.; Beygelzimer, Y.; Kulagin, R. Design of architectured materials based on mechanically driven structural and compositional patterning. Adv. Eng. Mater. 2019, 21, 1900487. [Google Scholar] [CrossRef]

- Chavdar, B.; Goldstein, R.; Ferguson, L. Hot Hydroforging for Lightweighting. Proc. IDE 2015, 5, 117–128. [Google Scholar]

- Goldstein, R.; Chavdar, B.; Ferguson, L. Modeling of the Heating Sequences of Lightweight Steel/Aluminum Bimaterial Billets for Hot Forging and Hot Hydroforging. In Proceedings of the 23rd IFHTSE Congress, Savannah, GA, USA, 18–21 April 2016; pp. 18–22. [Google Scholar]

- Kosch, K.G. Grundlagenuntersuchungen zum Verbundschmieden hybrider Bauteile aus Stahl und Aluminium. Ph.D. Thesis, Leibniz Universität Hannover, IFUM, Garbsen, Germany, 2018. [Google Scholar]

- Kosch, K.G.; Behrens, B.-A. Herstellung lokal anforderungs-optimierter Hybridbauteile durch Verbundschmieden. Schmiede-J. 2013, 3, 60–63. [Google Scholar]

- Kubaschewski, O. Iron—Binary Phase Diagrams; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Achar, D.R.G.; Ruge, J.; Sundaresan, S. Joining Aluminum to Steel with Particular Reference to Welding II. Aluminum 1980, 56, 220–223. [Google Scholar]

- Manesh, H.D.; Taheri, A.K. Bond strength and formability of an aluminum-clad steel sheet. J. Alloys Compd. 2008, 361, 138–143. [Google Scholar] [CrossRef]

- Achar, D.R.G.; Ruge, J.; Sundaresan, S. Metallurgical and Mechanical Investigations of Aluminum-Steel Welds I. Aluminum 1980, 56, 391–397. [Google Scholar]

- Rathod, M.J.; Kutsuna, M. Joining of aluminum alloy 5052 and low-carbon steel by laser roll welding. Weld. J. 2004, 83, 16. [Google Scholar]

- Sundman, B.; Ohnuma, I.; Dupin, N.; Kattner, U.R.; Fries, S.G. An assessment of the entire Al–Fe system including D03 ordering. Acta Mater. 2009, 57, 2896–2908. [Google Scholar] [CrossRef]

- Thürer, S.E.; Peddinghaus, J.; Heimes, N.; Bayram, F.C.; Bal, B.; Uhe, J.; Behrens, B.-A.; Maier, H.J.; Klose, C. Lateral angular co-extrusion: Geometrical and mechanical properties of compound profiles. Metals 2020, 10, 1162. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Kosch, K.G. Development of the heating and forming strategy in compound forging of hybrid steel-aluminum parts. Materialwissenschaft und Werkstofftechnik 2011, 42, 973–978. [Google Scholar] [CrossRef]

- Nemkov, V. Magnetic flux control in induction installations. In Proceedings of the International Conference on Heating by Electromagnetic Sources, Padua, Italy, 21–24 May 2013. [Google Scholar]

- Huang, C.; Kou, S. Liquation cracking in full-penetration AI-Mg-Si welds. Weld. J. 2004, 84, 111–122. [Google Scholar]

- Behrens, B.-A.; Chugreev, A.; Matthias, T. Hybride Lagerbuchsen aus Aluminium und Stahl. Werkstatttechnik Online 2018, 10, 691–697. [Google Scholar]

- Jaske, C.E. Low-Cycle Fatigue of AISI 1010 Steel at Temperatures Up to 1200 F (649 C). J. Press. Vessel Technol. 1977, 99, 423–443. [Google Scholar] [CrossRef]

- Bay, N.; Clemensen, C.; Juelstorp, O.; Wanheim, T. Bond strength in cold roll bonding. CIRP Ann. 1985, 34, 221–224. [Google Scholar] [CrossRef]

- Peng, X.K.; Heness, G.; Yeung, W.Y. Effect of rolling temperature on interface and bond strength development of roll bonded copper/aluminium metal laminates. J. Mater. Sci. 1999, 34, 277–281. [Google Scholar] [CrossRef]

- Jank, N.; Staufer, H.; Bruckner, J. Schweißverbindungen von Stahl mit Aluminium–eine Perspektive für die Zukunft. BHM Berg-und Hüttenmännische Monatshefte 2008, 153, 189–192. [Google Scholar] [CrossRef]

- Mukae, S.; Nishio, K.; Kato, M.; Inoue, T.; Sumitomo, K. Effect of heat treatment on bond characteristics of aluminium clad steel: Production and characteristics of vacuum roll bonded clad materials (2nd Report). Weld. Int. 1995, 9, 384–389. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Kosch, K.G. Influence of different alloying elements on the intermetallic phase seam thickness of compound forged steel-aluminum parts. Prod. Eng. 2011, 5, 517–522. [Google Scholar] [CrossRef]

- Matysik, P.; Jozwiak, S.; Czujko, T. Characterization of low-symmetry structures from phase equilibrium of Fe-Al system—Microstructures and mechanical properties. Materials 2015, 8, 914–931. [Google Scholar] [CrossRef] [PubMed]

| Phase | Lattice Structure | Al Content, at.% | Hardness, HV | Density, g/cm3 |

|---|---|---|---|---|

| α-Fe | Body-centered cubic (BCC) | 0–44.6 | Up to 140 | 7.90 |

| Fe3Al | Ordered BCC | 23.6–34.1 | 250–350 | 6.67 |

| FeAl | Ordered BCC | 23.3–54.9 | 400–520 | 5.37 |

| Fe2Al7 | Complex BCC | 63.0 | 650–680 | Not specified |

| FeAl2 | Triclinic | 65.6–66.9 | 1000–1050 | 4.36 |

| Fe2Al5 | Orthorhombic | 70.0–73.3 | 1000–1050 | 4.11 |

| FeAl3 | Monoclinic | 74.5–76.6 | 820–1100 | 3.95 |

| Al | Face-centered cubic (FCC) | 99.998–100 | Up to 40 | 2.7 |

| Material | Temperature, °C | Strain Rate, s−1 | Flow Stress, MPa |

|---|---|---|---|

| AISI 4820 | 700–750 | 1 | 150–220 |

| 10 | 200–280 | ||

| 6082 | 450–500 | 1 | ~30 |

| 10 | ~40 |

| Measurement Region | Material | Elemental Distribution, at.% | |||||

|---|---|---|---|---|---|---|---|

| Al | Mg | Si | Fe | Cr | Mn | ||

| 1 | 6082 | 98.80 | 0.79 | 0.04 | 0.37 | - | - |

| 2 | AISI 4820 | - | - | 0.66 | 97.93 | 0.87 | 0.54 |

| 3 | Intermetallic layer | 71.06 | - | 1.48 | 26.90 | 0.33 | 0.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behrens, B.-A.; Uhe, J.; Petersen, T.; Klose, C.; Thürer, S.E.; Diefenbach, J.; Chugreeva, A. Challenges in the Forging of Steel-Aluminum Bearing Bushings. Materials 2021, 14, 803. https://doi.org/10.3390/ma14040803

Behrens B-A, Uhe J, Petersen T, Klose C, Thürer SE, Diefenbach J, Chugreeva A. Challenges in the Forging of Steel-Aluminum Bearing Bushings. Materials. 2021; 14(4):803. https://doi.org/10.3390/ma14040803

Chicago/Turabian StyleBehrens, Bernd-Arno, Johanna Uhe, Tom Petersen, Christian Klose, Susanne E. Thürer, Julian Diefenbach, and Anna Chugreeva. 2021. "Challenges in the Forging of Steel-Aluminum Bearing Bushings" Materials 14, no. 4: 803. https://doi.org/10.3390/ma14040803

APA StyleBehrens, B.-A., Uhe, J., Petersen, T., Klose, C., Thürer, S. E., Diefenbach, J., & Chugreeva, A. (2021). Challenges in the Forging of Steel-Aluminum Bearing Bushings. Materials, 14(4), 803. https://doi.org/10.3390/ma14040803