Influence of Laboratory Long-Term Aging on Selected Fracture Parameters of Asphalt Mixtures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Asphalt Mixture Variants

2.2. Fracture Testing Methods

3. Results

3.1. Three Point Bending on Beam Specimens

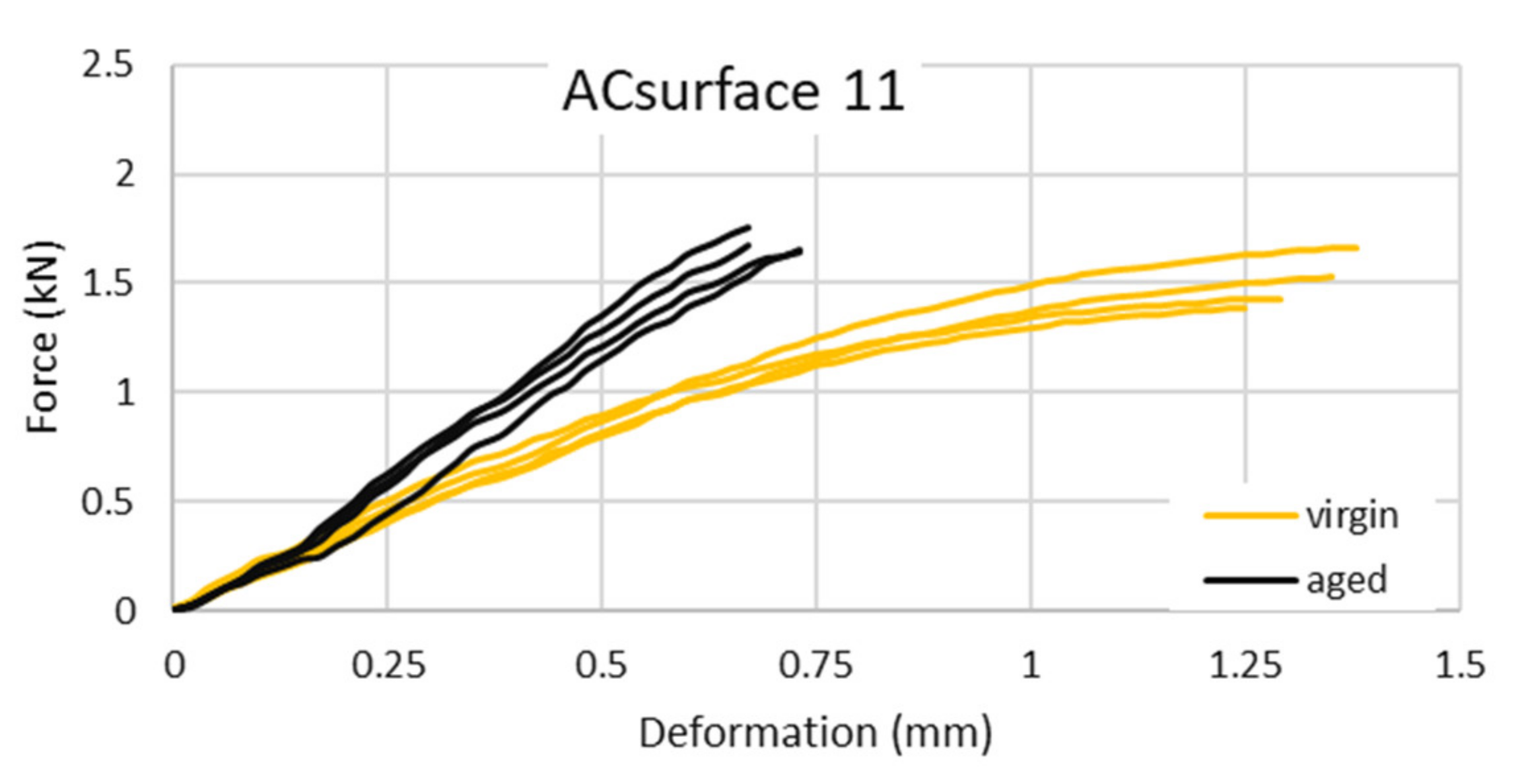

3.2. Semi-Circular Bending Test

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, H.; Mohammadafzali, M. Long-term aging of recycled binders. Proj. Number Dv29 Two 977 01 florida Dep. Transp. 2015. [Google Scholar]

- Zhang, H.; Zhu, C.Y.J.; Shi, C.; Zhang, D. Influence of surface modification on physical and ultraviolet aging resistance of bitumen containing inorganic nanoparticles. Constr. Build. Mater. 2015, 98, 735–740. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N.; Juang, H.C. Model developments of long-term aged asphalt binders. Constr. Build. Mater. 2012, 37, 248–256. [Google Scholar] [CrossRef]

- Anderson, D.A.; Lapalu, L.; Marasteanu, M.O.; Le Hir, Y.M.; Martin, D.; Planche, J.P. Low-temperature thermal cracking of asphalt binders as ranked by strength and fracture properties. Transp. Res. Rec. J. Transp. Res. Board 2001, 1766, 1–6. [Google Scholar] [CrossRef]

- Wu, S.; Pang, L.; Mo, L.; Chen, Y.; Zhu, G. Influence of aging on the evolution of structure, morphology and rheology of base and SBS modified bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

- Young, S.D.; Amirkhanian, S.N.; Kim, K.W. Analysis of unbalanced binder oxidation level in recycled asphalt mixture using GPC. Constr. Build. Mater. 2008, 22, 1253–1260. [Google Scholar]

- Mohammadafzali, M.; Ali, H.; Musselman, J.; Sholar, G.; Rilko, W. Aging of Rejuvenated Asphalt Binders. Adv. Mater. Sci. Eng. 2017, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Omranian, S.R.; Hamzah, M.O.; Valentin, J.; Mohd Hasan, M.R. Determination of optimal mix from the standpoint of short term aging based on asphalt mixture fracture properties using response surface method. Constr. Build. Mater. 2018, 179, 35–48, ISSN 0950-0618. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Sadeghnejad, M.; Ebrahimnia, R. Fracture resistance of asphalt mixtures under mixed-mode I/II loading at low-temperature: Without and with nano SiO2. Constr. Build. Mater. 2021, 266, 120954. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Tang, B. Effects of rejuvenator on performance-based properties of rejuvenated asphalt binder and mixtures. Constr. Build. Mater. 2007, 21, 958–964. [Google Scholar] [CrossRef]

- Ayman, W.A.; Mehta, Y.A.; Nolan, A.; Purdy, C.; Bennert, T. Investigation of the impacts of aging and RAP percentages on effectiveness of asphalt binder rejuvenators. Constr. Build. Mater. 2016, 110, 211–217. [Google Scholar] [CrossRef]

- Bell, A. Summary report on the aging of asphalt-aggregate systems. Transp. Res. Board 1989, 10, 1–121. [Google Scholar]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook; Thomas Telford: London, UK, 2003. [Google Scholar]

- Biligiri, K.; Said, S.; Hakim, H. Asphalt mixtures’ crack propagation assessment using semi-circular bending tests. Int. J. Pavement Res. Technol. 2012, 5, 209–217. [Google Scholar]

- Colbert, B.; You, Z. The properties of asphalt binder blended with variable quantities of recycled asphalt using short term and long term aging simulations. Constr. Build. Mater. 2012, 26, 552–557. [Google Scholar] [CrossRef]

- Fernández-Gómez, W.D.; Rondón Quintana, H.; Reyes Lizcano, F. A review of asphalt and asphalt mixture aging. Una Revisión. Ing. E Investig. 2013, 33, 5–12. [Google Scholar]

- Aliha, M.R.M.; Shaker, S. Effect of bitumen type, temperature and aging on mixed I/II fracture toughness of asphalt binders-experimental and theoretical assessment. Theor. Appl. Fract. Mech. 2020, 110, 102801. [Google Scholar] [CrossRef]

- Yin, A.; Yang, X.; Zeng, G.; Gai, H. Fracture simulation of pre-cracked heterogeneous asphalt mixture beam with movable three-point bending load. Constr. Build. Mater. 2014, 65, 232–242. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.; Kim, M.J.; Kim, D.; Shin, H.O. Self-healing capability of asphalt concrete with carbon-based materials. J. Mater. Res. Technol. 2019, 8, 827–839. [Google Scholar] [CrossRef]

- Zeng, G.; Yang, X.; Yin, A.; Bai, F. Simulation of damage evolution and crack propagation in three-point bending pre-cracked asphalt mixture beam. Constr. Build. Mater. 2014, 55, 323–332. [Google Scholar] [CrossRef]

- Hasni, H.; Jiao, P.; Alavi, A.H.; Chatti, K. A new apagesroach for damage detection in asphalt concrete pavements using battery-free wireless sensors with non-constant injection rates. Measurement 2017, 110, 217–229. [Google Scholar] [CrossRef]

- Stewerd, C.M.; Oputa, C.W.; Garcia, E. Effect of specimen thickness on the fracture resistance of hot mix asphalt in the disk-shaped compact tension (DCT) configuration. Constr. Build. Mater. 2018, 160, 487–496. [Google Scholar]

- NCHRP 09-57. Experimental Design for Field Validation of Laboratory Tests to Assess Cracking Resistance of Asphalt Mixtures. In CRACKING TESTS WORKSHOP (February 11-12 2015); Texas A&M Transportation Institute: Newport Beach, CA, USA, 2015. [Google Scholar]

- Transportation Research Board of the National Academies. NCHRP. Report 530. Evaluation of Indirect Tensile Test (IDT) Procedures for Low-Temperature Performance of Hot Mix Asphalt; Transportation Research Board: Washington, DC, USA, 2004. [Google Scholar]

- Nsengiyumva, G. Development of Semi-Circular Bending (SCB) Fracture Test for Bituminous Mixtures. Master Thesis, Faculty of The Graduate College at the University of Nebraska, Lincoln, Nebraska, 2015. [Google Scholar]

- Omranian, S.R.; Hamzah, M.O.; Hasan, R.M.H. Introducing New Indicators to Evaluate Fracture Properties of Asphalt Mixtures Using Semicircular Bending Test. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 541–549. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Fazaeli, H.; Aghajani, S.; Moghadas Nejad, F. Effect of temperature and air void on mixed mode fracture toughness of modified asphalt mixtures. Constr. Build. Mater. 2015, 95, 545–555. [Google Scholar] [CrossRef]

- Molenaar, A.A.A.; Scarpas, A.; Liu, X.; Erkens, G. Semi-circular bending test; simple but useful. Asph. Paving Technol. Assoc. Asph. Paving Technol. Proc. Tech. 2002, 71, 794–815. [Google Scholar]

- Willis, R.; Timm, D.; West, R.; Powell, B.; Robbins, M.; Taylor, A.; Smit, A. Phase III NCAT Test Track Findings; (NCAT Report 09-08); National Center for Asphalt Technology: Auburn, AL, USA, 2009. [Google Scholar]

- Ma, T.; Huang, M.H.; Zhao, Y.L.; Zhang, Y. Evaluation of diffusion and distribution of the rejuvenator for hot asphalt recycling. Constr. Build. Mater. 2015, 98, 530–536. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahmadi, A. Evaluation of fracture resistance of asphalt mixes involving steel slag and RAP: Susceptibility to aging level and freeze and thaw cycles. Constr. Build. Mater. 2017, 157, 748–756. [Google Scholar] [CrossRef]

- Saeidi, H.; Aghayan, I. Investigating the effects of aging and loading rate on low-temperature cracking resistance of core-based asphalt samples using semi-circular bending test. Constr. Build. Mater. 2016, 126, 682–690. [Google Scholar] [CrossRef]

- Czech Standardization Agency. EN 12697-44. In Bituminous Mixtures. Test Methods. Crack Propagation by Semi-Circular Bending Test; BSI: London, UK, 2019. [Google Scholar]

- Czech Standardization Agency. EN 12697-30. In Bituminous Mixtures. Test Methods. Specimen Preparation by Impact Compactor; BSI: London, UK, 2020. [Google Scholar]

- Vacková, P. Research and Evaluation of Selected Properties Influencing Durability of Asphalt Pavements. Dissertaion Thesis, Faculty of Civil Engeneering, Czech Technical University in Prague, Prague, Czech Republic, 2020. [Google Scholar]

- Vacková, P.; Valentin, J. What information can be provided by the asphalt crack propagation test done on semicylindric specimens? In Proceedings of the World Multidisciplinary Civil Engineering—Architecture—Urban Planning Symposium, Prague, Czech Republic, 1–5 September 2020. [Google Scholar]

- Czech Ministry of Transport. TP 151. Technical Condition of Ministry of Transport. High Modulus Asphalt Concretes (HMAC); 2001. Available online: http://www.pjpk.cz/data/USR_001_2_8_TP/TP_151.pdf (accessed on 10 February 2021).

- European Committee for Standardization. CEN/TS 12697-52. Bituminous Mixtures. Test Methods. Conditioning to Address Oxidative Ageing; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Haoran, Z.; Gang, X.; Minghui, G.; Jun, Y. Recycling long-term-aged asphalts using bio-binder/plasticizer-based rejuvenator. Constr. Build. Mater. 2017, 147, 117–129. [Google Scholar] [CrossRef]

- Guangji, X.; Hao, W.; Wei, S. Molecular dynamics study of rejuvenator effect on RAP binder: Diffusion behavior and molecular structure. Constr. Build. Mater. 2018, 158, 1046–1054. [Google Scholar]

- Haghshenas, H.F.; Kim, Y.K.; Kommidi, S.R.; Nguyen, D.; Haghshenas, F.D.; Morton, M. Evaluation of long-term effects of rejuvenation on reclaimed binder properties based on chemical-rheological tests and analyses. Mater. Struct. 2018, 51, 1–13. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Omranian, S.R.; Golchin, B. A review on the effects of aging on properties of asphalt binders and mixtures. Casp. J. Appl. Sci. Res. 2015, 4, 15–34. [Google Scholar]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Karlsson, R.; Isacsson, U. Application of FTIR-ATR to characterization of bitumen rejuvenator diffusion. J. Mater. Civ. Eng. 2003, 15, 157–165. [Google Scholar] [CrossRef]

- Karlsson, R.; Isacsson, U. Laboratory studies of diffusion in bitumen using markers. J. Mater. Sci. 2003, 38, 2835–2844. [Google Scholar] [CrossRef]

| ALL | Modified | Unmodified | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KIc | WFmax | W | R | W3PB | KIc | WFmax | W | R | W3PB | KIc | WFmax | W | R | W3PB | |

| Mean | 1.03 | 1.05 | 0.96 | 1.15 | 0.95 | 1.06 | 1.05 | 0.96 | 1.17 | 0.96 | 1.01 | 1.04 | 0.97 | 1.12 | 0.94 |

| Stand. error | 0.01 | 0.03 | 0.03 | 0.01 | 0.02 | 0.02 | 0.04 | 0.04 | 0.02 | 0.03 | 0.01 | 0.05 | 0.05 | 0.02 | 0.02 |

| St.deviation | 0.12 | 0.28 | 0.25 | 0.17 | 0.23 | 0.11 | 0.23 | 0.21 | 0.19 | 0.26 | 0.1 | 0.33 | 0.28 | 0.14 | 0.2 |

| Minimum | 0.74 | 0.48 | 0.49 | 0.81 | 0.51 | 0.82 | 0.61 | 0.58 | 0.81 | 0.53 | 0.82 | 0.48 | 0.49 | 0.83 | 0.51 |

| Maximum | 1.38 | 1.63 | 1.62 | 1.78 | 2.09 | 1.38 | 1.49 | 1.31 | 1.78 | 2.09 | 1.23 | 1.63 | 1.62 | 1.46 | 1.71 |

| Count | 88 | 71 | 70 | 147 | 145 | 43 | 34 | 34 | 76 | 73 | 42 | 37 | 36 | 71 | 73 |

| Virgin | with RA | ||||||||||||||

| KIc | WFmax | W | R | W3PB | KIc | WFmax | W | R | W3PB | Legend: | |||||

| Mean | 1.04 | 1.06 | 0.94 | 1.16 | 0.98 | 1.03 | 1.04 | 0.99 | 1.14 | 0.91 | KIc = fracture toughness | ||||

| Stand. error | 0.02 | 0.05 | 0.04 | 0.02 | 0.03 | 0.02 | 0.05 | 0.04 | 0.02 | 0.02 | WFmax = fracture work till Fmax | ||||

| St. deviation | 0.11 | 0.28 | 0.25 | 0.19 | 0.25 | 0.12 | 0.29 | 0.24 | 0.14 | 0.2 | W = total fracture work | ||||

| Minimum | 0.82 | 0.58 | 0.49 | 0.81 | 0.53 | 0.74 | 0.48 | 0.58 | 0.82 | 0.51 | R = flexural strength | ||||

| Maximum | 1.38 | 1.49 | 1.35 | 1.78 | 2.09 | 1.31 | 1.63 | 1.62 | 1.46 | 1.71 | W3PB = fracture work | ||||

| Count | 46 | 35 | 35 | 78 | 73 | 42 | 36 | 35 | 68 | 72 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vacková, P.; Valentin, J.; Belhaj, M. Influence of Laboratory Long-Term Aging on Selected Fracture Parameters of Asphalt Mixtures. Materials 2021, 14, 811. https://doi.org/10.3390/ma14040811

Vacková P, Valentin J, Belhaj M. Influence of Laboratory Long-Term Aging on Selected Fracture Parameters of Asphalt Mixtures. Materials. 2021; 14(4):811. https://doi.org/10.3390/ma14040811

Chicago/Turabian StyleVacková, Pavla, Jan Valentin, and Majda Belhaj. 2021. "Influence of Laboratory Long-Term Aging on Selected Fracture Parameters of Asphalt Mixtures" Materials 14, no. 4: 811. https://doi.org/10.3390/ma14040811