Bending Strength of Wood Treated with Propolis Extract and Silicon Compounds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wood Samples

2.2. Wood Treatment Preparations

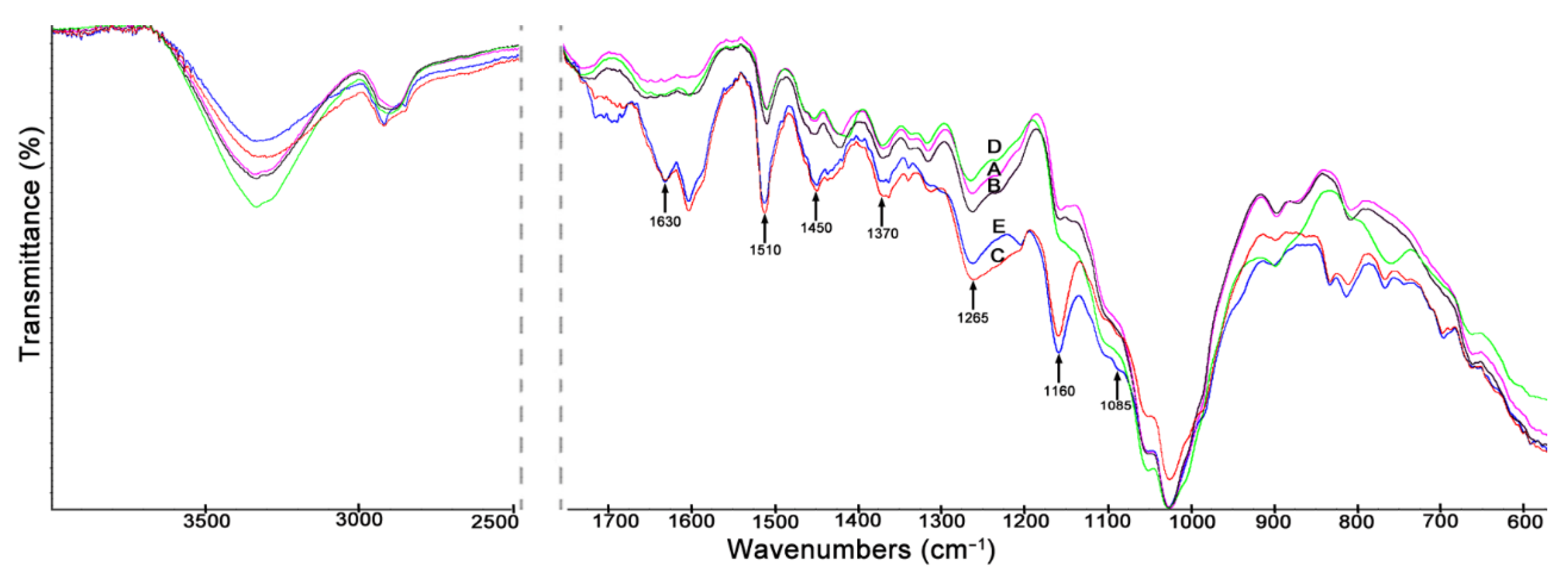

2.3. Wood Treatment

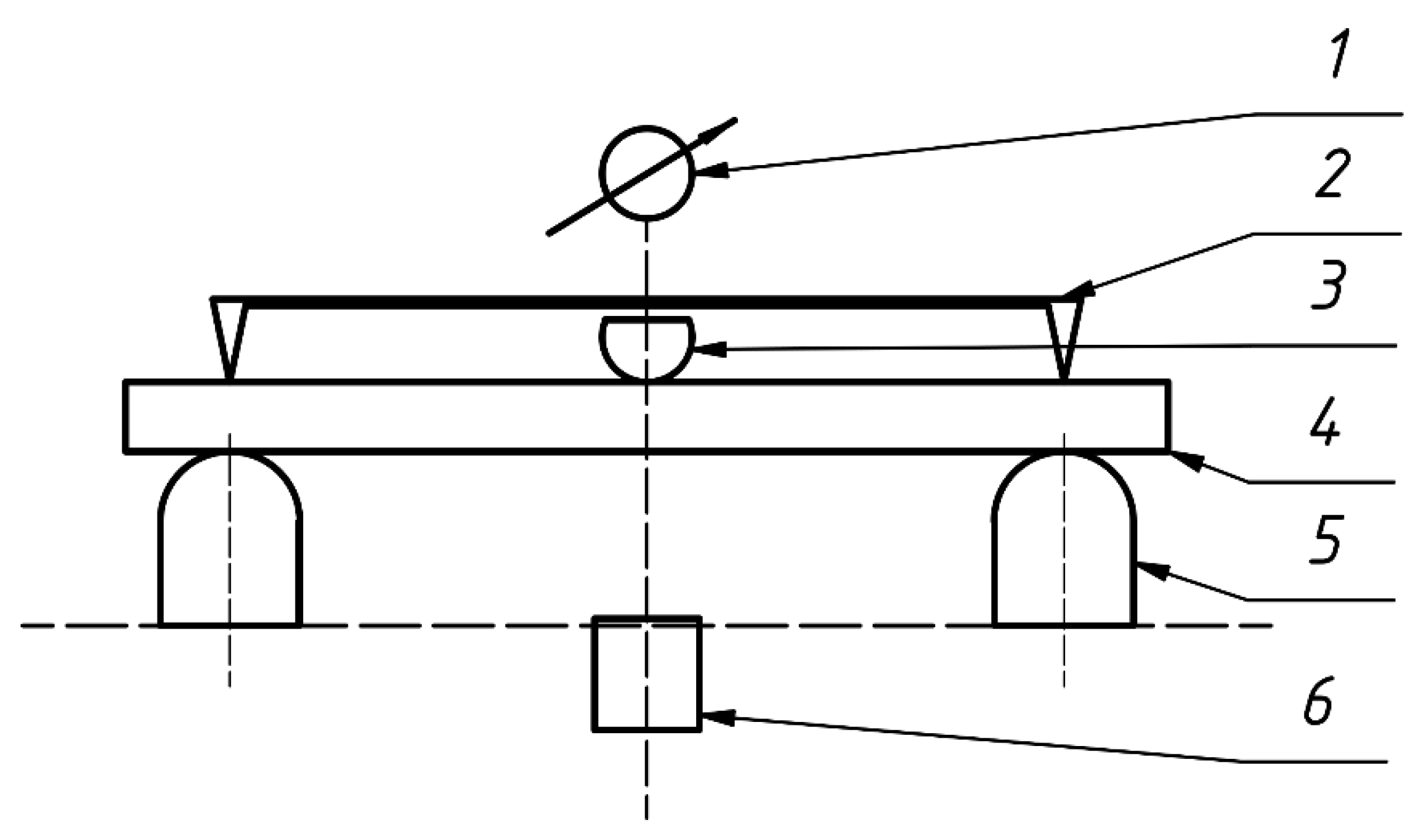

2.4. Static Bending Strength

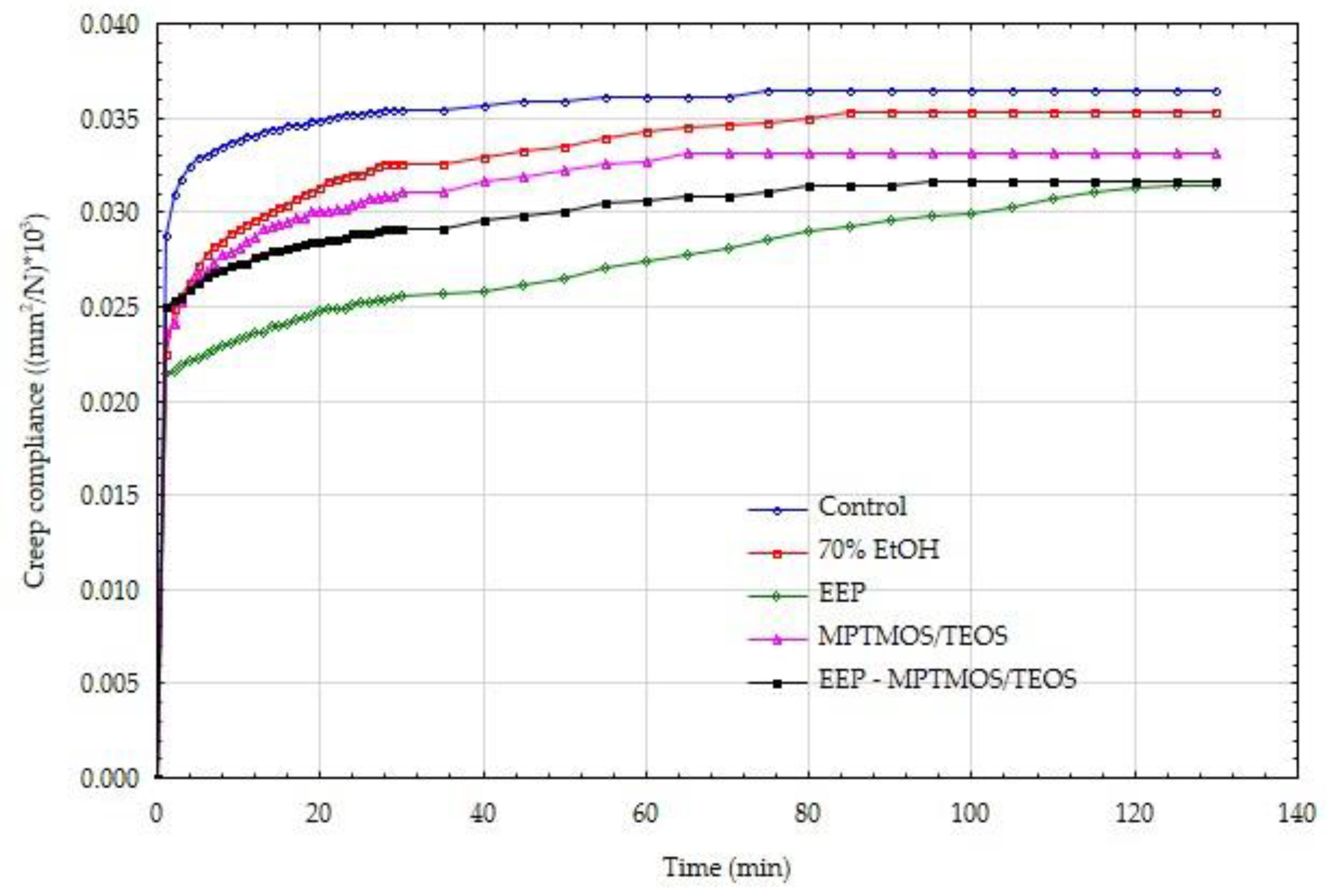

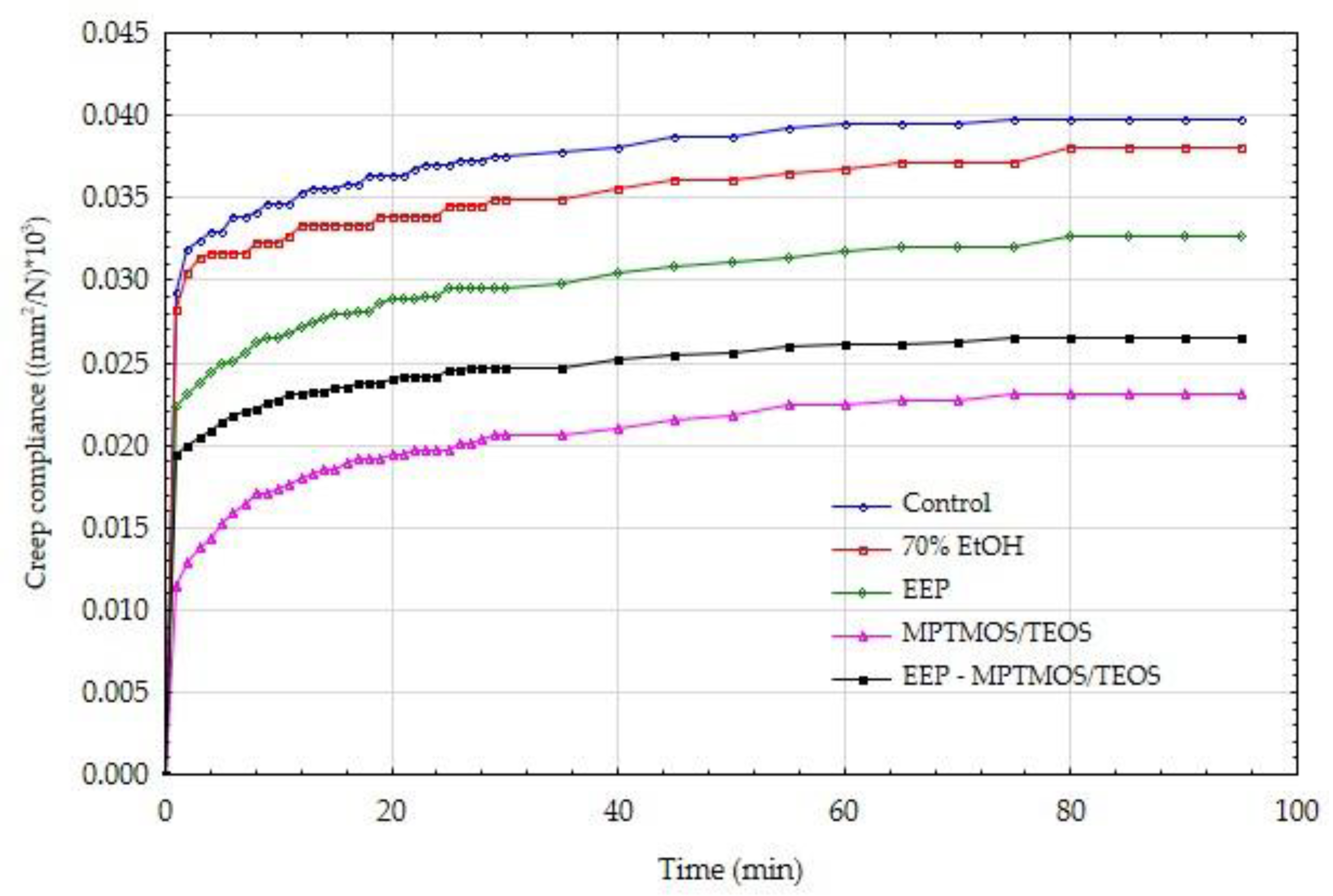

2.5. Rheological Wood Properties

2.6. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.7. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons, Ltd.: Chichester, UK, 2006; ISBN 9780470021729. [Google Scholar]

- Jones, D.; Sandberg, D.; Goli, G.; Todaro, L. Wood Modification in Europe: A State-of-the Art About pRocesses, Products and Applications; Firenze University Press: Firenze, Italy, 2019; ISBN 9788864539706. [Google Scholar]

- Pernak, J.; Zabielska-Matejuk, J.; Kropacz, A.; Foksowicz-Flaczyk, J. Ionic liquids in wood preservation. Holzforschung 2004, 58, 286–291. [Google Scholar] [CrossRef]

- Reinprecht, L.; Grznárik, T. Biological durability of Scots pine (Pinus sylvestris L.) sapwood modified with selected organo-silanes. Wood Res. 2015, 60, 687–696. [Google Scholar]

- Can, A.; Palanti, S.; Sivrikaya, H.; Hazer, B.; Stefanı, F. Physical, biological and chemical characterisation of wood treated with silver nanoparticles. Cellulose 2019, 26, 5075–5084. [Google Scholar] [CrossRef]

- Kumar, A.; Pavla, R.; Sever, S.A.; Humar, M.; Pavlič, M.; Jan, T.; Petr, H.; Zigon, J.; Petric, M. Influence of surface modification of wood with octadecyltrichlorosilane on its dimensional stability and resistance against Coniophora puteana and molds. Cellulose 2016, 23, 3249–3263. [Google Scholar] [CrossRef]

- Cui, H.; Li, Q. Nano-titanium dioxide coating of Chinese fir treated by high-temperature steam to improve the anticorrosion and surface hydrophobicity. For. Prod. J. 2020, 70, 158–164. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Tian, H.; Qi, D.; Wang, R. Wood functional modification based on deposition of nanometer copper film by magnetron sputtering. For. Prod. J. 2020, 70, 340–349. [Google Scholar] [CrossRef]

- Baur, S.I.; Easteal, A.J. Improved photoprotection of wood by chemical modification with silanes: NMR and ESR studies. Polym. Adv. Technol. 2013, 24, 97–103. [Google Scholar] [CrossRef]

- Panov, D.; Terziev, N. Study on some alkoxysilanes used for hydrophobation and protection of wood against decay. Int. Biodeterior. Biodegrad. 2009, 63, 456–461. [Google Scholar] [CrossRef]

- Ghosh, S.C.; Militz, H.; Mai, C. Modification of Pinus sylvestris L. wood with quat- and amino-silicones of different chain lengths. Holzforschung 2013, 67, 421–427. [Google Scholar] [CrossRef]

- Reinprecht, L.; Vacek, V.; Grznárik, T. Enhanced fungal resistance of Scots pine (Pinus sylvestris L.) sapwood by treatment with methyltrimethoxysilane and benzalkoniumchloride. Eur. J. Wood Wood Prod. 2017, 75, 817–824. [Google Scholar] [CrossRef]

- Eikenes, M.; Alfredsen, G.; Christensen, B.E.; Militz, H.; Solheim, H. Comparison of chitosans with different molecular weights as possible wood preservatives. J. Wood Sci. 2005, 51, 387–394. [Google Scholar] [CrossRef]

- Teacă, C.A.; Roşu, D.; Mustaţă, F.; Rusu, T.; Roşu, L.; Roşca, I.; Varganici, C.D. Natural bio-based products for wood coating and protection against degradation: A review. BioResources 2019, 14, 4873–4901. [Google Scholar] [CrossRef]

- Pánek, M.; Reinprecht, L.; Hulla, M. Ten essential oils for beech wood protection—Efficacy against wood-destroying fungi and moulds, and effect on wood discoloration. BioResources 2014, 9, 5588–5603. [Google Scholar] [CrossRef] [Green Version]

- Humar, M.; Lesar, B. Efficacy of linseed- and tung-oil-treated wood against wood-decay fungi and water uptake. Int. Biodeterior. Biodegrad. 2013, 85, 223–227. [Google Scholar] [CrossRef]

- Akcay, C.; Birinci, E.; Birinci, C.; Kolayli, S. Durability of wood treated with propolis. BioResources 2020, 15, 1547–1562. [Google Scholar]

- Castaldo, S.; Capasso, F. Propolis, an old remedy used in modern medicine. Fitoterapia 2002, 73, 1–6. [Google Scholar] [CrossRef]

- Salas, A.L.; Alberto, M.R.; Zampini, I.C.; Cuello, A.S.; Maldonado, L.; Ríos, J.L.; Schmeda-Hirschmann, G.; Isla, M.I. Biological activities of polyphenols-enriched propolis from Argentina arid regions. Phytomedicine 2016, 23, 27–31. [Google Scholar] [CrossRef]

- Toreti, V.C.; Sato, H.H.; Pastore, G.M.; Park, Y.K. Recent progress of propolis for its biological and chemical compositions and its botanical origin. Evid. Based Complement. Altern. Med. 2013, 2013. [Google Scholar] [CrossRef]

- Popova, M.; Giannopoulou, E.; Skalicka-Woźniak, K.; Graikou, K.; Widelski, J.; Bankova, V.; Kalofonos, H.; Sivolapenko, G.; Gaweł-Bȩben, K.; Antosiewicz, B.; et al. Characterization and biological evaluation of propolis from Poland. Molecules 2017, 22, 1159. [Google Scholar] [CrossRef]

- Wagh, V.D. Propolis: A wonder bees product and its pharmacological potentials. Adv. Pharmacol. Sci. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Miguel, M.G.; Nunes, S.; Dandlen, S.A.; Cavaco, A.M.; Antunes, M.D. Phenols, flavonoids and antioxidant activity of aqueous and methanolic extracts of propolis (Apis mellifera L.) from Algarve, South Portugal. Food Sci. Technol. 2014, 34, 16–23. [Google Scholar] [CrossRef] [Green Version]

- Casado-Sanz, M.M.; Silva-Castro, I.; Ponce-Herrero, L.; Martín-Ramos, P.; Martín-Gil, J.; Acuña-Rello, L. White-rot fungi control on Populus spp. wood by pressure treatments with silver nanoparticles, chitosan oligomers and propolis. Forests 2019, 10, 885. [Google Scholar] [CrossRef] [Green Version]

- Silva-Castro, I.; Casados-Sanz, M.; Alonso-Cortés, A.L.; Martín-Ramos, P.; Martín-Gil, J.; Acuña-Rello, L. Chitosan-based coatings to prevent the decay of Populus spp. wood caused by Trametes versicolor. Coatings 2018, 8, 415. [Google Scholar] [CrossRef] [Green Version]

- Woźniak, M.; Kwaśniewska-Sip, P.; Krueger, M.; Roszyk, E.; Ratajczak, I. Chemical, biological and mechanical characterization of wood treated with propolis extract and silicon compounds. Forests 2020, 11, 907. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Jankowska, A.; Mamiński, M.; Marciszewska, K.; Ciurzycki, W.; Tulik, M. The wood of scots pine (Pinus sylvestris L.) from post-agricultural lands has suitable properties for the timber industry. Forests 2020, 11, 1033. [Google Scholar] [CrossRef]

- EN 384 Structural timber. Determination of Characteristic Values of Mechanical Properties and Density; CEN Comite Europeen de Normalisation: Bruxelles, Belgium, 2018. [Google Scholar]

- Lopes, D.B.; Mai, C.; Militz, H. Mechanical properties of chemically modified Portuguese pinewood. Maderas Cienc. y Tecnol. 2015, 17, 179–194. [Google Scholar] [CrossRef] [Green Version]

- Fojutowski, A.; Noskowiak, A.; Kot, M.; Kropacz, A.; Stangierska, A. The assessment of mechanical properties of wood treated with ionic liquids. Drewno 2010, 184, 21–38. [Google Scholar]

- Boonstra, M.J.; Van Acker, J.; Tjeerdsma, B.F.; Kegel, E.V. Strength properties of thermally modified softwoods and its relation to polymeric structural wood constituents. Ann. For. Sci. 2007, 64, 679–690. [Google Scholar] [CrossRef] [Green Version]

- Mubarok, M.; Militz, H.; Dumarçay, S.; Gérardin, P. Beech wood modification based on in situ esterification with sorbitol and citric acid. Wood Sci. Technol. 2020, 54, 479–502. [Google Scholar] [CrossRef] [Green Version]

- Pries, M.; Wagner, R.; Kaesler, K.H.; Militz, H.; Mai, C. Acetylation of wood in combination with polysiloxanes to improve water-related and mechanical properties of wood. Wood Sci. Technol. 2013, 47, 685–699. [Google Scholar] [CrossRef] [Green Version]

- Meier, P.; Kaps, T.; Kallavus, U. Swelling of pinewood (Pinus sylvestris) in binary aqueous solutions of organic substances. Mater. Sci. 2005, 11, 140–145. [Google Scholar]

- Meier, P.; Stöör, E.; Kaps, T.; Kallavus, U. Mechanical properties of pinewood (Pinus sylvestris) swollen in organic liquids | Orgaanilistes ainetes pundunud puidu mehaanilised omadused. Proc. Est. Acad. Sci. 2006, 55, 125–133. [Google Scholar]

- ISO 13061-2:2014. Physical and Mechanical Properties of Wood—Test. Methods for Small Clear Wood Specimens—Part. 2: Determination of Density for Physical and Mechanical Tests; International Organization for Standarization: Geneva, Switzerland, 2014. [Google Scholar]

- ISO 13061-1:2014. Physical and Mechanical Properties of Wood—Test. Methods for Small Clear Wood Specimens—Part. 1: Determination of Moisture Content for Physical and Mechanical Tests; International Organization for Standarization: Geneva, Switzerland, 2014. [Google Scholar]

- PN-77/D-04103. Wood. Determination of Static Bending Strength; Polish Committee for Standarization: Warsaw, Poland, 1977. [Google Scholar]

- PN-63/D-04117. Physical and Mechanical Properties of Wood. Determination of the Elasticity Coefficient for Static Bending; Polish Committee for Standarization: Warsaw, Poland, 1963. [Google Scholar]

- Larnøy, E.; Dantz, S.; Eikenes, M.; Militz, H. Screening of properties of modified chitosan-treated wood. Wood Mater. Sci. Eng. 2006, 1, 59–68. [Google Scholar] [CrossRef]

- Bollmus, S.; Beeretz, C.; Militz, H. Tensile and impact bending properties of chemically modified Scots pine. Forests 2020, 11, 84. [Google Scholar] [CrossRef] [Green Version]

- Ming-Li, L.; Chun-Feng, L.; Yan-Long, L. Physical and mechanical properties of modified poplar wood by heat treatment and impregnation of sodium silicate solution. Wood Res. 2019, 64, 145–153. [Google Scholar]

- Dong, Y.; Yan, Y.; Zhang, S.; Li, J.; Wang, J. Flammability and physical–mechanical properties assessment of wood treated with furfuryl alcohol and nano-SiO2. Eur. J. Wood Wood Prod. 2015, 73, 457–464. [Google Scholar] [CrossRef]

- Simsek, H.; Baysal, E.; Peker, H. Some mechanical properties and decay resistance of wood impregnated with environmentally-friendly borates. Constr. Build. Mater. 2010, 24, 2279–2284. [Google Scholar] [CrossRef]

- Kollmann, F.F.P.; Côté, W.A. Principles of Wood Science and Technology; Springer: Berlin/Heidelberg, Germany, 1968. [Google Scholar]

- Woźniak, M.; Ratajczak, I.; Lis, B.; Krystofiak, T. Hydrophobic properties of wood traeted with propolis-silane formulations. Wood Res. 2018, 63, 517–524. [Google Scholar]

- Donath, S.; Militz, H.; Mai, C. Creating water-repellent effects on wood by treatment with silanes. Holzforschung 2006, 60, 40–46. [Google Scholar] [CrossRef]

- Toba, K.; Yamamoto, H.; Yoshida, M. Crystallization of cellulose microfibrils in wood cell wall by repeated dry-and-wet treatment, using X-ray diffraction technique. Cellulose 2013, 20, 633–643. [Google Scholar] [CrossRef]

- Åkerholm, M.; Salmén, L. The oriented structure of lignin and its viscoelastic properties studied by static and dynamic FT-IR spectroscopy. Holzforschung 2003, 57, 459–465. [Google Scholar] [CrossRef]

- Schiffmann, K.I. Nanoindentation creep and stress relaxation tests of polycarbonate: Analysis of viscoelastic properties by different rheological models. Int. J. Mater. Res. 2006, 97, 1199–1211. [Google Scholar] [CrossRef]

- De Borst, K.; Jenkel, C.; Montero, C.; Colmars, J.; Gril, J.; Kaliske, M.; Eberhardsteiner, J. Mechanical characterization of wood: An integrative approach ranging from nanoscale to structure. Comput. Struct. 2013, 127, 53–67. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Lin, L.; Fu, F. The difference of creep compliance for wood cell wall CML and secondary S2 layer by nanoindentation. Mech. Time-Dependent Mater. 2019. [Google Scholar] [CrossRef]

- Meier, P.; Kallavus, U.; Rohumaa, A.; Kaps, T. Multiple swelling of pinewood (Pinus sylvestris) in binary and ternary mixtures of ethanol, acetone and water. Mater. Sci. 2006, 12, 25–30. [Google Scholar]

| Wood Sample | Moisture Content (%) | Density of Wood before Treatment (kg/m3) | Density of Wood after Treatment (kg/m3) | Retention (kg/m3) |

|---|---|---|---|---|

| Control | 10.2 ± 0.1 | 637.1 ± 17.2 | 637.1 ± 17.2 | - |

| 70% EtOH | 9.8 ± 0.3 | 637.9 ± 17.9 | 626.0 ± 17.6 | 6.2 ± 0.2 |

| EEP | 8.0 ± 0.2 | 638.5 ± 17.6 | 699.0 ± 18.0 | 95.2 ± 3.1 |

| MPTMOS/TEOS | 8.2 ± 0.4 | 639.7 ± 19.1 | 650.0 ± 18.1 | 61.6 ± 2.6 |

| EEP–MPTMOS/TEOS | 8.1 ± 0.3 | 640.5 ± 16.1 | 720.0 ± 15.9 | 151.4 ± 6.6 |

| MC | Wood Sample | MOR (MPa) | MOEL (MPa) | WML (J) |

|---|---|---|---|---|

| Dry | Control | 124.0 ± 6.8 a | 16,876 ± 725 b | 0.806 ± 0.071 a |

| 70% EtOH | 126.6 ± 7.5 a | 16,537 ± 876 a,b | 0.847 ± 0.089 a,b | |

| EEP | 137.6 ± 6.8 b | 16,109 ± 677 a | 0.939 ± 0.067 b | |

| MPTMOS/TEOS | 124.4 ± 5.3 a | 15,724 ± 651 a,b | 0.792 ± 0.073 a | |

| EEP–MPTMOS/TEOS | 136.6 ± 7.1 b | 15,628 ± 844 a | 0.932 ± 0.066 b | |

| >FSP | Control | 58.6 ± 4.3 a | 11,110 ± 666 a | 0.664 ± 0.129 a |

| 70% EtOH | 52.1 ± 4.2 a | 10,867 ± 837 a | 0.613 ± 0.074 a | |

| EEP | 72.3 ± 10.8 b | 11,720 ± 488 a | 0.761 ± 0.126 a | |

| MPTMOS/TEOS | 55.7 ± 3.7 a | 11,428 ± 406 a | 0.689 ± 0.123 a | |

| EEP–MPTMOS/TEOS | 102.7 ± 5.3 c | 13,100 ± 628 b | 1.042 ± 0.119 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woźniak, M.; Mania, P.; Roszyk, E.; Ratajczak, I. Bending Strength of Wood Treated with Propolis Extract and Silicon Compounds. Materials 2021, 14, 819. https://doi.org/10.3390/ma14040819

Woźniak M, Mania P, Roszyk E, Ratajczak I. Bending Strength of Wood Treated with Propolis Extract and Silicon Compounds. Materials. 2021; 14(4):819. https://doi.org/10.3390/ma14040819

Chicago/Turabian StyleWoźniak, Magdalena, Przemysław Mania, Edward Roszyk, and Izabela Ratajczak. 2021. "Bending Strength of Wood Treated with Propolis Extract and Silicon Compounds" Materials 14, no. 4: 819. https://doi.org/10.3390/ma14040819