Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

- Cement (Secil, Portugal): CEM II/B-L 32.5 N, according to EN 197-1 [19];

- Calcium hydrated lime powder-air lime (Calcidrata S.A., Portugal): Class CL80-S, according to EN 459-1 [20];

- Sand (Areipor—Areias Portuguesas S.A., Portugal): Sieved river sand to obtain the size range previously defined;

- Coir fibers (waste from an insulation company—Amorim Cork Insulation, Portugal): With lengths of 1.5 cm and 3.0 cm.

2.2. Mix Design

2.3. Methods

- Consistency of fresh mortar (by flow table)—EN 1015-3 [23]. Three samples per mortar.

- Bulk density of fresh mortar—EN 1015-6 [24]. Three samples per mortar.

- Dry bulk density of hardened mortar—EN 1015-10 [25], at 28, 90, 180, and 365 days. Three prisms per mortar.

- Flexural strength of hardened mortar—EN 1015-11 [26], at 28, 90, 180, and 365 days. Three prisms per mortar.

- Compressive strength of hardened mortar—EN 1015-11 [26], at 28, 90, 180, and 365 days. Six prisms per mortar.

- Dynamic modulus of elasticity by resonance frequency of hardened mortar—EN 14146 [27], at 28, 90, 180, and 365 days. Three prisms per mortar.

- Ultrasound pulse velocity of hardened mortar—EN 12504-4 [28]. To measure this property, two methods were applied: direct and indirect. In the direct method, the electrodes are on opposite sides of the prisms and, in the indirect method, the electrodes are on the same surface of the prisms. The direct method measures the wave’s propagation time between extremities and the indirect method makes the measurements in small increasing distances on the same surface. This test evaluates the mortar’s compactness; a lower wave propagation velocity indicates a less compact material, since it means a greater volume of intercepted voids. Three prisms per mortar at 28 days.

- Open porosity—EN 1936 [29]. Three samples per mortar, resulting from the compressive strength test at 28 and 365 days.

3. Results and Discussion

3.1. Workability

3.2. Dry Bulk Density

3.3. Dynamic Modulus of Elasticity

3.4. Ultra-Sound Pulse Velocity

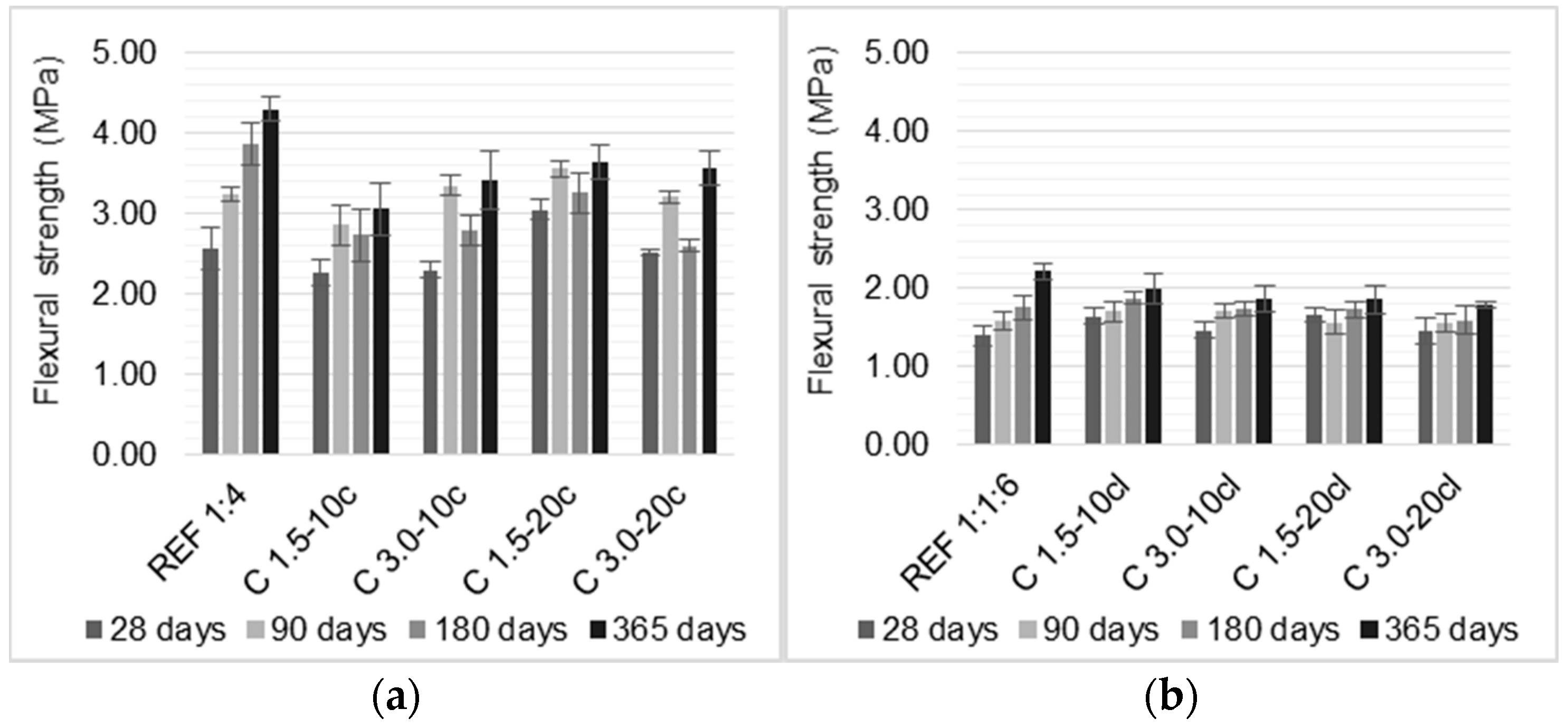

3.5. Compressive and Flexural Strengths

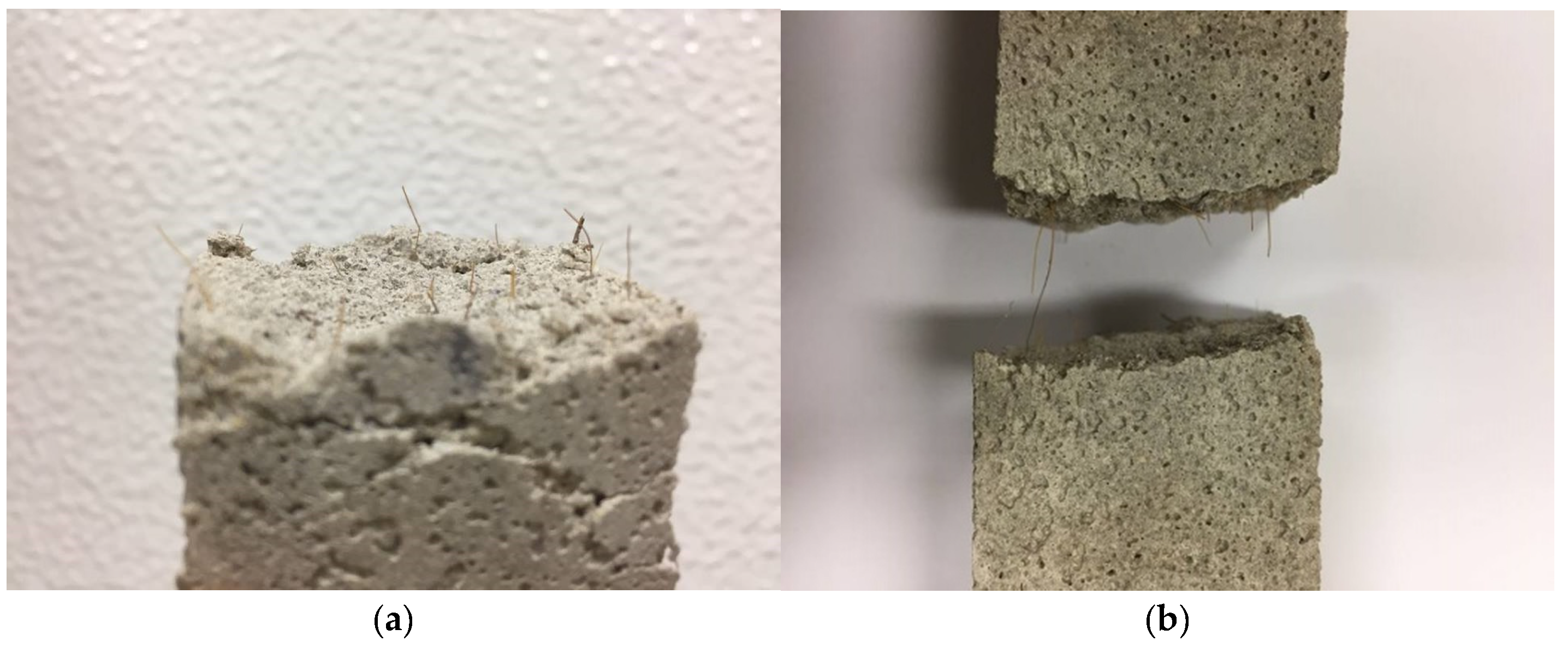

3.6. Cracking Behaviour

3.7. Open Porosity

4. Conclusions

- Coir fiber addition reduces the mortars’ workability, regardless of the type of binder used. As increasing the fiber length and volume fraction, a higher mixing water content is required to achieve the intended consistency when compared to the reference mortars.

- The mortars with coir fibers presented a more ductile behavior and less susceptibility to cracking than that of the control mortars, since they presented lower modulus of elasticity and higher fracture toughness. The addition of coir fibers also increased the porosity of the mortars due to the fibers’ clustering inside the matrix.

- Concerning the mechanical behavior of the mortars, the coir fiber addition improved in the first ages of the mortars. Over time, the coir fibers did not significantly affect their compressive and flexural strengths.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hwang, C.L.; Tran, V.A.; Hong, J.W.; Hsieh, Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Ghavami, K.; Toledo Filho, R.D.; Barbosa, N.P. Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 1999, 21, 39–48. [Google Scholar] [CrossRef]

- Kicińska-Jakubowska, A.; Bogacz, E.; Zimniewska, M. Review of Natural Fibers. Part I-Vegetable Fibers. J. Nat. Fibers 2012, 9, 150–167. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Savastano, H.; Agopyan, V.; Nolasco, A.M.; Pimentel, L. Plant fibre reinforced cement components for roofing. Constr. Build. Mater. 1999, 13, 433–438. [Google Scholar] [CrossRef]

- Syed, H.; Nerella, R.; Madduru, S.R.C. Role of coconut coir fiber in concrete. Mater. Today Proc. 2019, 27, 1104–1110. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [Green Version]

- Agopyan, V.; Savastano, H.; John, V.M.; Cincotto, M.A. Developments on vegetable fibre-cement based materials in São Paulo, Brazil: An overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Andiç-Çakir, Ö.; Sarikanat, M.; Tüfekçi, H.B.; Demirci, C.; Erdoǧan, Ü.H. Physical and mechanical properties of randomly oriented coir fiber-cementitious composites. Compos. Part B Eng. 2014, 61, 49–54. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Impact strength of a few natural fibre reinforced cement mortar slabs: A comparative study. Cem. Concr. Compos. 2005, 27, 547–553. [Google Scholar] [CrossRef]

- Sathiparan, N.; Rupasinghe, M.N.; Pavithra, B.H. Performance of coconut coir reinforced hydraulic cement mortar for surface plastering application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- Al-Zubaidi, A.B. Effect of natural fibers on mechanical properties of green cement mortar. AIP Conf. Proc. 2018, 1968, 020003. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Ghavami, K.; Sanjuán, M.A.; England, G.L. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Pederneiras, C.M.; Veiga, R.; Brito, J. De Effects of the Incorporation of Waste Fibres on the Cracking Resistance of Mortars: A Review. Int. J. Green Technol. 2018, 4, 38–46. [Google Scholar]

- European Committee for Standardization. Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar; EN 998-1; European Committee for Standardization (CEN): Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements; EN 197-1; European Committee for Standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. Building Lime; Part 1: Definitions, Specifications and Conformity Criteria; EN 459-1; European Committee for Standardization (CEN): Brussels, Belgium, 2015. [Google Scholar]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Hamzaoui, R.; Guessasma, S.; Mecheri, B.; Eshtiaghi, A.M.; Bennabi, A. Microstructure and mechanical performance of modified mortar using hemp fibres and carbon nanotubes. Mater. Des. 2014, 56, 60–68. [Google Scholar] [CrossRef]

- European Committee for Standardization. Methods of Test for Mortar for Masonry—PART 3: Determination of Consistence of Fresh Mortar (by Flow Table); EN 1015-3; European Committee for Standardization (CEN): Brussels, Belgium, 1999. [Google Scholar]

- European Committee for Standardization. Methods of Test for Mortar for Masonry—Part 6: Determination of Bulk Density of Fresh Mortar; EN 1015-6; European Committee for Standardization (CEN): Brussels, Belgium, 1998. [Google Scholar]

- European Committee for Standardization. Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar; EN 1015-10; European Committee for Standardization (CEN): Brussels, Belgium, 1999. [Google Scholar]

- European Committee for Standardization. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; EN 1015-11; European Committee for Standardization (CEN): Brussels, Belgium, 1999. [Google Scholar]

- European Committee for Standardization. Natural Stone Test Methods. Determination of the Dynamic Elastic Modulus of Elasticity (by Measuring the Fundamental Resonance Frequency); EN 14146; European Committee for Standardization (CEN): Brussels, Belgium, 2004. [Google Scholar]

- European Committee for Standardization. Testing Concrete in Structures. Part 4: Determination of Ultrasonic Pulse Velocity; EN 12504-4; European Committee for Standardization (CEN): Brussels, Belgium, 2007. [Google Scholar]

- European Committee for Standardization. Natural Stone Test Methods. Determination of Real Density and Apparent Density and Total and Partial Open Porosity; EN 1936; European Committee for Standardization (CEN): Brussels, Belgium, 2007. [Google Scholar]

- Pederneiras, C.M.; Veiga, R.; de Brito, J. Rendering mortars reinforced with natural sheep’s wool fibers. Materials 2019, 12, 3648. [Google Scholar] [CrossRef] [Green Version]

- Rupasinghe, M.N.; Sathiparan, N. Mechanical behavior of masonry strengthened with coir fiber reinforced hydraulic cement mortar as surface plaster. J. Struct. Eng. Appl. Mech. 2019, 2, 12–24. [Google Scholar] [CrossRef]

- Centre scientifique et technique du bâtiment. Certification CSTB des Enduits Monocouches D’imperméabilisation, Modalités D’essais; Cahier 2669-4; Centre scientifique et technique du bâtiment: Marne-la-Vallée, France, 1993. [Google Scholar]

- Coutts, R.S.P. Flax fibres as a reinforcement in cement mortars. Int. J. Cem. Compos. Light. Concr. 1983, 5, 257–262. [Google Scholar] [CrossRef]

- Pereira, M.V.; Fujiyama, R.; Darwish, F.; Alves, G.T. On the Strengthening of Cement Mortar by Natural Fibers. Mater. Res. 2015, 18, 177–183. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.; Zhou, Z.; Jiang, M.; Xu, X.; Wang, Z.; Hui, D. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Compos. Part B Eng. 2015, 78, 153–161. [Google Scholar] [CrossRef]

- Zhang, T.; Dieckmann, E.; Song, S.; Xie, J.; Yu, Z.; Cheeseman, C. Properties of magnesium silicate hydrate (M-S-H) cement mortars containing chicken feather fibres. Constr. Build. Mater. 2018, 180, 692–697. [Google Scholar] [CrossRef]

- Benaimeche, O.; Carpinteri, A.; Mellas, M.; Ronchei, C.; Scorza, D.; Vantadori, S. The influence of date palm mesh fibre reinforcement on flexural and fracture behaviour of a cement-based mortar. Compos. Part B Eng. 2018, 152, 292–299. [Google Scholar] [CrossRef] [Green Version]

| Component | Apparent Bulk Density (kg/m3) |

|---|---|

| Cement | 975.5 |

| Air-lime | 565.7 |

| Sand | 1230.8 |

| Coir 1.5 cm | 5.4 |

| Coir 3.0 cm | 2.6 |

| Mortar | Water (mL) | Cement (g) | Air-Lime (g) | Sand (g) | Coir Fiber (g) | Incorporation |

|---|---|---|---|---|---|---|

| REF 1:4 | 445 | 487.8 | - | 2461.6 | 0 | 0% |

| C 1.5-10c | 415 | 439.1 | - | 2215.4 | 1.4 | 10% of 1.5 cm |

| C 3.0-10c | 430 | 439.1 | - | 2215.4 | 0.7 | 10% of 3.0 cm |

| C 1.5-20c | 370 | 390.2 | - | 1969.3 | 2.7 | 20% of 1.5 cm |

| C 3.0-20c | 400 | 390.2 | - | 1969.3 | 1.3 | 20% of 3.0 cm |

| REF 1:1:6 | 465 | 304.8 | 176.8 | 2307.8 | 0 | 0% |

| C 1.5-10cl | 425 | 274.4 | 159.1 | 2077.0 | 1.4 | 10% of 1.5 cm |

| C 3.0-10cl | 420 | 274.4 | 159.1 | 2077.0 | 0.7 | 10% of 3.0 cm |

| C 1.5-20cl | 396 | 243.9 | 141.4 | 1846.2 | 2.7 | 20% of 1.5 cm |

| C 3.0-20cl | 396 | 243.9 | 141.4 | 1846.2 | 1.3 | 20% of 3.0 cm |

| Mortar | Water/Binder Ratio | Bulk Density (kg/m3) |

|---|---|---|

| REF 1:4 | 0.91 | 2005 ± 4 |

| C 1.5-10c | 0.94 | 1959 ± 16 |

| C 3.0-10c | 0.97 | 1971 ± 5 |

| C 1.5-20c | 0.94 | 1940 ± 30 |

| C 3.0-20c | 1.02 | 1989 ± 15 |

| REF 1:1:6 | 0.98 | 1999 ± 8 |

| C 1.5-10cl | 0.99 | 1989 ± 18 |

| C 3.0-10cl | 0.98 | 2000 ± 7 |

| C 1.5-20cl | 1.03 | 1986 ± 8 |

| C 3.0-20cl | 1.03 | 1993 ± 8 |

| Mortar | Dynamic Modulus of Elasticity (MPa) | Flexural Strength (MPa) | Compressive Strength (MPa) | E/σf | σf/σc | Fracture Toughness (N·mm) |

|---|---|---|---|---|---|---|

| REF 1:4 | 16,210 | 2.56 | 9.66 | 6332 | 0.27 | 195 |

| C 1.5-10c | 13,560 | 2.27 | 7.64 | 5974 | 0.30 | 225 |

| C 3.0-10c | 13,740 | 2.31 | 7.22 | 5948 | 0.32 | 192 |

| C 1.5-20c | 15,010 | 3.06 | 9.78 | 4905 | 0.31 | 393 |

| C 3.0-20c | 14,360 | 2.52 | 8.09 | 5698 | 0.31 | 217 |

| REF 1:1:6 | 9820 | 1.40 | 5.27 | 7014 | 0.27 | 135 |

| C 1.5-10cl | 7020 | 1.65 | 4.35 | 4255 | 0.38 | 155 |

| C 3.0-10cl | 7860 | 1.47 | 4.44 | 5347 | 0.33 | 149 |

| C 1.5-20cl | 8240 | 1.67 | 4.24 | 4934 | 0.39 | 212 |

| C 3.0-20cl | 8290 | 1.47 | 4.30 | 5639 | 0.34 | 223 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maia Pederneiras, C.; Veiga, R.; de Brito, J. Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars. Materials 2021, 14, 823. https://doi.org/10.3390/ma14040823

Maia Pederneiras C, Veiga R, de Brito J. Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars. Materials. 2021; 14(4):823. https://doi.org/10.3390/ma14040823

Chicago/Turabian StyleMaia Pederneiras, Cinthia, Rosário Veiga, and Jorge de Brito. 2021. "Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars" Materials 14, no. 4: 823. https://doi.org/10.3390/ma14040823

APA StyleMaia Pederneiras, C., Veiga, R., & de Brito, J. (2021). Physical and Mechanical Performance of Coir Fiber-Reinforced Rendering Mortars. Materials, 14(4), 823. https://doi.org/10.3390/ma14040823