Review about the Application of Fractal Theory in the Research of Packaging Materials

Abstract

:1. Introduction

2. Basic Theory of Fractal

2.1. The Concept of Fractal

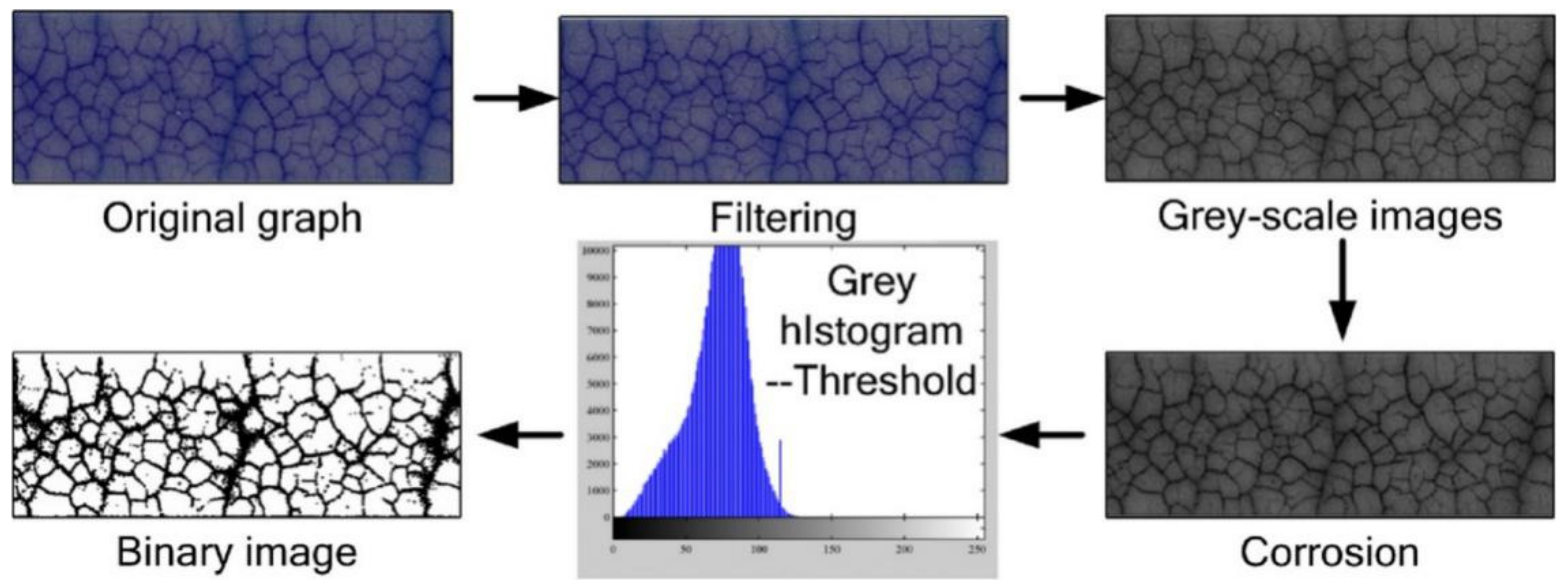

2.2. Fractal Feature Extraction and Fractal Dimension Calculation

3. Properties and Fractal Analysis of Metals and Ceramics

3.1. Fractal and Properties Analysis of Metal Packaging Materials

3.2. Fractal and Property Analysis of Ceramics

4. Properties and Fractal of Polymers and Their Composites in the Packaging Field

4.1. Fractal in the Preparation of Polymers and Their Composites in the Packaging Field

4.2. Fractal Characteristics and Fractal Dimension of Polymers and Their Composites in the Packaging Field

4.3. Relationship between Fractal Dimension and Properties of Polymers and Their Composites in the Packaging Industry

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mandelbrot, B.B. Stochastic Models for the Earth’s Relief, the Shape and the Fractal Dimension of the Coastlines, and the Number-area Rule for Islands. Proc. Natl. Acad. Sci. USA 1975, 72, 3825–3828. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Ji, Z.; Zhang, Y.; Yu, Q.; Ma, C. A Contact Mechanics Model for Rough Surfaces Based on a New Fractal Characterization Method. Int. J. Appl. Mech. 2018, 10, 1850069. [Google Scholar] [CrossRef]

- Ma, J.; Liu, D.; Chen, Y. Random Fractal Characters and Length Uncertainty of the Continental Coastline of China. J. Earth Syst. Sci. 2016, 125, 1615–1621. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.-Q.; Xie, W.-J.; Zhou, W.-X.; Sornette, D. Multifractal Analysis of Financial Markets: A Review. Rep. Prog. Phys. 2019, 82. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dimri, V.P.; Ganguli, S.S. Fractal Theory and Its Implication for Acquisition, Processing and Interpretation (API) of Geophysical Investigation: A Review. J. Geol. Soc. India 2019, 93, 142–152. [Google Scholar] [CrossRef]

- Tang, S.W.; He, Q.; Xiao, S.Y.; Huang, X.Q.; Zhou, L. Fractal Plasmonic Metamaterials: Physics and Applications. Nanotechnol. Rev. 2015, 4, 277–288. [Google Scholar] [CrossRef] [Green Version]

- Jeldres, R.I.; Fawell, P.D.; Florio, B.J. Population Balance Modelling to Describe the Particle Aggregation Process: A review. Powder Technol. 2018, 326, 190–207. [Google Scholar] [CrossRef]

- Klamut, J.; Kutner, R.; Gubiec, T.; Struzik, Z.R. Multibranch Multifractality and the Phase Transitions in Time Series of Mean Interevent Times. Phys. Rev. E 2020, 101. [Google Scholar] [CrossRef] [PubMed]

- Nayak, S.R.; Mishra, J.; Palai, G. Analysing roughness of surface through fractal dimension: A review. Image Vis. Comput. 2019, 89, 21–34. [Google Scholar] [CrossRef]

- Wen, F.; Fan, H.; Zhai, S.; Zhang, K.; Liu, F. Pore characteristics analysis and numerical seepage simulation of antifreeze permeable concrete. Constr. Build. Mater. 2020, 255, 119310. [Google Scholar] [CrossRef]

- Sand, A.E.; Dudarev, S.L.; Nordlund, K. High-energy collision cascades in tungsten: Dislocation loops structure and clustering scaling laws. EPL 2013, 103, 46003. [Google Scholar] [CrossRef] [Green Version]

- Fataf, N.A.; Gowrisankar, A.; Banerjee, S. In search of self-similar chaotic attractors based on fractal function with variable scaling approximately. Phys. Scr. 2020, 95, 075206. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, D.; Chen, M.; Wang, J.; Zhao, H.; Li, Y.; Zhang, Z.; Xie, T.; Wang, F.; Li, X.; et al. Assembling Shape-Persistent High-Order Sierpiński Triangular Fractals. iScience 2020, 23, 101064. [Google Scholar] [CrossRef] [PubMed]

- Dong, L. Mechanical response of Ti–6Al–4V hierarchical architected metamaterials. Acta Mater. 2019, 175, 90–106. [Google Scholar] [CrossRef]

- Ding, X.; Xiao, X.; Lv, X.-F.; Wu, D.; Pan, Y. Analysis of Similarities and Differences between Acoustic Emission and Charge Signal Based on Fractal Characteristics of Coal Fracture. Adv. Civ. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Hasegawa, T.; Mizutaka, S. Structure of percolating clusters in random clustered networks. Phys. Rev. E 2020, 101, 062310. [Google Scholar] [CrossRef]

- Karimpouli, S.; Tahmasebi, P. 3D multi-fractal analysis of porous media using 3D digital images: Considerations for heterogeneity evaluation. Geophys. Prospect. 2019, 67, 1082–1093. [Google Scholar] [CrossRef]

- Huan, X.; Shi, K.; Yan, J.; Lin, S.; Li, Y.; Jia, X.; Yang, X. High performance epoxy composites prepared using recycled short carbon fiber with enhanced dispersibility and interfacial bonding through polydopamine surface-modification. Compos. Part. B Eng. 2020, 193, 107987. [Google Scholar] [CrossRef]

- Zuo, X.; Tang, X.; Zhou, Y. Influence of sampling length on estimated fractal dimension of surface profile. Chaos Solitons Fractals 2020, 135, 109755. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, Q.; Wu, X.; Wu, L.; Lin, J.-H. Exploring the Interfacial Phase and π–π Stacking in Aligned Carbon Nanotube/Polyimide Nanocomposites. Nanomaterials 2020, 10, 1158. [Google Scholar] [CrossRef] [PubMed]

- Tzoganakis, C.; Price, B.C.; Hatzikiriakos, S.G. Fractal analysis of the sharkskin phenomenon in polymer melt extrusion. J. Rheol. 1993, 37, 355–366. [Google Scholar] [CrossRef]

- McMurphy, T.B.; Harris, C.A.; Griggs, J.A. Accuracy and precision of fractal dimension measured on model surfaces. Dent. Mater. 2014, 30, 302–307. [Google Scholar] [CrossRef]

- Liang, Z.; Feng, Z.; GuangXiang, X. Comparison of Fractal Dimension Calculation Methods for Channel Bed Profiles. Procedia. Eng. 2012, 28, 252–257. [Google Scholar] [CrossRef] [Green Version]

- Florio, B.J.; Fawell, P.; Small, M. The use of the perimeter-area method to calculate the fractal dimension of aggregates. Powder Technol. 2019, 343, 551–559. [Google Scholar] [CrossRef]

- Gurjar, R.; Upadhyay, D.K.; Kanaujia, B.K.; Kumar, A. A compact modified sierpinski carpet fractal UWB MIMO antenna with square-shaped funnel-like ground stub. AEU Int. J. Electron. Commun. 2020, 117, 153126. [Google Scholar] [CrossRef]

- Yousif, S.A.; Abdul-Wahed, H.Y.; Al-Saidi, N.M.G. Extracting a new fractal and semi-variance attributes for texture images. In Proceedings of the 3rd International Conference of Mathematical Sciences (ICMS 2019), Maltepe University, Istanbul, Turkey, 4–8 September 2019; p. 080006. [Google Scholar] [CrossRef]

- Akhmetkhanov, R.S. The Patterns of the Power Spectral Density Distribution of Fractal and Multifractal Processes. J. Mach. Manuf. Reliab. 2018, 47, 235–240. [Google Scholar] [CrossRef]

- Melnyk, V.M.; Rud’, V.D.; Melnyk, Y.A. Correctness of Fractal Analysis of Fractographic Surface Microstructure According to Digital SEM Photogrammetry. Powder Met. Met. Ceram. 2018, 57, 353–360. [Google Scholar] [CrossRef]

- Dobrescu, G.; Papa, F.; State, R.; Fangli, I.; Balint, I. Particle size distribution of Pt–Cu bimetallic nanoparticles by fractal analysis. Powder Technol. 2015, 269, 532–540. [Google Scholar] [CrossRef]

- Chądzyński, G.W.; Staszczuk, P.; Sternik, D.; Blachnio, M. Studies of physico-chemical properties and fractal dimensions of MgB2 superconductor surface. J. Therm. Anal. Calorim. 2011, 108, 985–989. [Google Scholar] [CrossRef]

- Li, P.; Zhang, T.; Wang, B.; Dou, Z. Grey Level Threshold Used to Extract Fractal Characteristic Parameter of Surface Topography Image. J. Northeast. Univ. 2006, 27, 57–60. [Google Scholar]

- Sun, H.; Mašín, D.; Najser, J.; Neděla, V.; Navrátilová, E. Fractal characteristics of pore structure of compacted bentonite studied by ESEM and MIP methods. Acta Geotech. 2019, 15, 1655–1671. [Google Scholar] [CrossRef]

- Vajda, P.; Felinger, A. Multilayer adsorption on fractal surfaces. J. Chromatogr. A 2014, 1324, 121–127. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trypolskyi, A.I.; Didenko, O.Z.; Strizhak, P.E. Relation of Fractal Characteristics with Structural Parameters of Nanosized ZrO2 Determined by Various Methods. Theor. Exp. Chem. 2019, 55, 246–249. [Google Scholar] [CrossRef]

- Nian, D.; Fu, Z. Extended self-similarity based multi-fractal detrended fluctuation analysis: A novel multi-fractal quantifying method. Commun. Nonlinear Sci. Numer. Simul. 2019, 67, 568–576. [Google Scholar] [CrossRef]

- Anitas, E.M.; Marcelli, G.; Szakács, Z.; Todoran, R.; Todoran, D. Structural Properties of Vicsek-like Deterministic Multifractals. Symmetry 2019, 11, 806. [Google Scholar] [CrossRef] [Green Version]

- Lugito, G.; Nagarajan, S.; Woo, E.M. Explosive Fibonacci-sequence growth into unusual sector-face morphology in poly (l-lactic acid) crystallized with polymeric diluents. Sci. Rep. 2020, 10, 10811. [Google Scholar] [CrossRef] [PubMed]

- Xi, C.; Zhang, S.; Xiong, G.; Zhao, H.; Yang, Y. Two-dimensional multifractal cross-correlation analysis. Chaos Solitons Fractals 2017, 96, 59–69. [Google Scholar] [CrossRef]

- Kovalenko, A. Fractal characterization of nanostructured materials. Nanosyst. Physics Chem. Math. 2019, 10, 42–49. [Google Scholar] [CrossRef]

- Qadri, M.O.; Namazi, H. Fractal-based analysis of the relationship between the surface finish of workpiece and chip formation in milling operation. Fractals 2020, 28, 28. [Google Scholar] [CrossRef]

- Card, J.P.; Hyde, J.M.; Giversen, T. Discrimination of Surface Textures Using Fractal Methods. MRS Proc. 1994, 367, 113. [Google Scholar] [CrossRef] [Green Version]

- Torkhov, N.A.; Novikov, V.A. Fractal geometry of the surface potential in electrochemically deposited platinum and palladium films. Semiconductors 2009, 43, 1071–1077. [Google Scholar] [CrossRef]

- Thomas, T.R.; Rosen, B.G. Surfaces generated by abrasive finishing processes as self-affine fractals. Int. J. Surf. Sci. Eng. 2009, 3, 275. [Google Scholar] [CrossRef]

- Lashgari, A.; Ghamami, S.; Shahbazkhany, S.; Salgado, G.; Glossman-Mitnik, D. Fractal Dimension Calculation of a Manganese-Chromium Bimetallic Nanocomposite Using Image Processing. J. Nanomater. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Mitic, V.V.; Paunovic, V.; Purenović, J.; Jankovic, S.; Kocic, L.; Antolović, I.; Rancic, D. The contribution of fractal nature to BaTiO3-ceramics microstructure analysis. Ceram. Int. 2012, 38, 1295–1301. [Google Scholar] [CrossRef]

- Zamen, S.; Niri, E.D. Fractal analysis of nonlinear ultrasonic waves in phase-space domain as a quantitative method for damage assessment of concrete structures. NDT E Int. 2020, 111, 102235. [Google Scholar] [CrossRef]

- Xia, D.; Song, S.; Wang, J.; Shi, J.; Bi, H.; Gao, Z. Determination of corrosion types from electrochemical noise by phase space reconstruction theory. Electrochem. Commun. 2012, 15, 88–92. [Google Scholar] [CrossRef]

- Gu, G.-F.; Zhou, W.-X. Detrending moving average algorithm for multifractals. Phys. Rev. E 2010, 82, 011136. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lyapunova, E.; Chudinov, V.; Sokovikov, M.; Uvarov, S.; Naimark, O.; Hwang, Y.-M.; Alexandrov, S. Scaling properties of fracture surfaces of dynamically loaded aluminium alloy specimens. In Proceedings of the 2012 7th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 24–26 October 2012; pp. 175–177. [Google Scholar] [CrossRef]

- Oborin, V.; Bayandin, Y.; Sokovikov, M.; Naimark, O. Multifractal analysis of morphology of AlMg6 alloy fracture surface under consecutive dynamic and gigacycle loading. In Proceedings of the International Conference on Advanced Materials with Hierarchical Structure for New Technologies and Reliable Structures 2017 (AMHS’17), Tomsk, Russia, 9–13 October 2017. [Google Scholar]

- Kosheleva, E.V.; Sel’Chenkova, N.I.; Sokolov, S.S.; Trunin, I.R.; Uchaev, A.Y. On the Similarity of Dynamic Destructive Processes in Metals of Different Geometry under the Effect of External Impacts with Various Amplitude-Time Characteristics. Phys. At. Nucl. 2018, 81, 1477–1483. [Google Scholar] [CrossRef]

- Kumar, J.; Ananthakrishna, G. Modeling the complexity of acoustic emission during intermittent plastic deformation: Power laws and multifractal spectra. Phys. Rev. E 2018, 97, 012201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Шибкoв, А.; Denisov, A.A.; Gasanov, M.F.; Zolotov, A.E.; Zheltov, M.A. Nonstationary Electrochemical Response to the Intermittent Portevin–Le Chatelier Deformation in an Aluminum–Magnesium Alloy. Phys. Solid State 2019, 61, 157–162. [Google Scholar] [CrossRef]

- Shibkov, A.A.; Zolotov, A.E.; Zheltov, M.A.; Denisov, A.A. Morphological transition from the Euclidean to the fractal shape of the Lüders band in the aluminum-magnesium alloy AMg6. Phys. Solid State 2011, 53, 887–895. [Google Scholar] [CrossRef]

- Zuo, X.; Tan, Y.; Zhou, Y.; Zhu, H.; Fang, H. Multifractal analysis of three-dimensional surface topographies of GCr15 steel and H70 brass during wear process. Measurement 2018, 125, 196–218. [Google Scholar] [CrossRef]

- Yakimov, B.N.; Gelashvili, D.B.; Zhang, Y.; Markelov, I.N.; Zhang, S.; Ma, K. Quantification of non-power-law diversity scaling with local multifractal analysis. Ecol. Inform. 2018, 48, 48–59. [Google Scholar] [CrossRef]

- Volchuk, V.; Kroviakov, S. Method of material quality estimation with usage of multifractal formalism. Teh. Glas. 2018, 12, 93–97. [Google Scholar] [CrossRef]

- Kanygina, O.N.; Chetverikova, A.G.; Filyak, M.M.; Ogerchuk, A.A. Fractal Approach to the Analysis of Ceramic Surfaces. Glas. Ceram. 2016, 72, 444–448. [Google Scholar] [CrossRef]

- Brun, M.; Casnedi, L.; Pia, G. Bending strength of porous ceramics tiles: Bounds and estimates of effective properties of an Intermingled Fractal Units’ model. Ceram. Int. 2018, 44, 10241–10248. [Google Scholar] [CrossRef]

- Qi, F.; Meng, S.; Song, F.; Guo, H.; Xu, X.; Shao, Y.; Chen, Y. Fractal characterization of ceramic crack patterns after thermal shocks. J. Am. Ceram. Soc. 2018, 102, 3641–3652. [Google Scholar] [CrossRef]

- Vuckovic, V.; Mitić, V.V.; Kocic, L.; Nikolic, V. The fractal nature approach in ceramics materials and discrete field simulation. Sci. Sinter. 2018, 50, 371–385. [Google Scholar] [CrossRef] [Green Version]

- Dan-Ling, W.D.; Juan-Fang, L.I. A Study on the Characteristics of Liquid-vapor Interface by Using Fractal Theory. In Proceedings of the International Symposium on Heat Transfer & Energy Conservation, Guangzhou, China, 11–15 January 2004. [Google Scholar]

- Zhou, J.; Sancaktar, E. Yield Behavior of Moderately Filled Epoxy/Ni Suspensions. J. Adhes. Sci. Technol. 2010, 24, 1929–1948. [Google Scholar] [CrossRef]

- Solov’Yov, I.A.; Solov’Yov, A.V. Simulation of nanofractal dynamics with MBN Explorer. J. Phys. Conf. Ser. 2013, 438, 012006. [Google Scholar] [CrossRef]

- Santillán, J.M.J.; Van Raap, M.F.; Zélis, P.M.; Coral, D.F.; Muraca, D.; Schinca, D.C.; Scaffardi, L.B. Ag nanoparticles formed by femtosecond pulse laser ablation in water: Self-assembled fractal structures. J. Nanoparticle Res. 2015, 17, 17. [Google Scholar] [CrossRef]

- Xiao-Xu, L.; Jing-Hua, Y.; Dao-Bin, S.; Wen-Bin, B.; Wei-Dong, C.; Zhong-Hua, W. Small-Angle X-Ray Scattering Study on Nanostructures of Polyimide Films. Chin. Phys. Lett. 2010, 27, 27. [Google Scholar] [CrossRef]

- Tian, D.; Li, X.; He, J.-H. Self-assembly of macromolecules in a long and narrow tube. Therm. Sci. 2018, 22, 1659–1664. [Google Scholar] [CrossRef]

- Pandey, I.; Chandra, A. Factors affecting fractal patterns obtained by electroless deposition in polymer. Mater. Res. Express 2019, 6, 105307. [Google Scholar] [CrossRef]

- Ritter, J.E.; Huseinovic, A. Adhesion and Reliability of Epoxy/Glass Interfaces. J. Electron. Packag. 2000, 123, 401–404. [Google Scholar] [CrossRef]

- Ji, N.P.; Kaifeng, Z. Fractal Characterization of Uniformity of Discrete Phase in Nanocomposites. J. B. Univ. Aeronaut. Astronaut. 2009, 35, 852–855. [Google Scholar]

- Shaoqun, Z.; Jun, H.; Wei, X.; Guangwei, C.; Yangjun, L.; Wei, S.; Jiaxiong, Y. Fracture Features and the Relationship between Wood Shear Strength and Fractal Dimension. Sci. Silvae Sin. 2015, 51, 127–134. [Google Scholar]

- Wang, C.; Smith, L.M.; Wang, G.; Shi, S.Q.; Cheng, H.; Zhang, S. Characterization of interfacial interactions in bamboo pulp fiber/high-density polyethylene composites treated by nano CaCO3 impregnation modification using fractal theory and dynamic mechanical analysis. Ind. Crop. Prod. 2019, 141, 111712. [Google Scholar] [CrossRef]

- Starodubtseva, M.; Starodubtsev, I.E.; Starodubtsev, E.G. Novel fractal characteristic of atomic force microscopy images. Micron 2017, 96, 96–102. [Google Scholar] [CrossRef]

- Gabibov, I.A.; Dyshin, O.A.; Rustamova, K.B. Formation of the properties of the structure of disperse-filled polymer composites. Plast. Massy 2019, 23–26. [Google Scholar] [CrossRef]

- Xue, M.G.; Wang, S.F. The Analysis of Relationships between Surface Porosity and Air Permeability of Paper (board). Adv. Mater. Res. 2011, 396–398, 1426–1429. [Google Scholar] [CrossRef]

- Campano, C.; Balea, A.; Ángeles, B.; Negro, C. A reproducible method to characterize the bulk morphology of cellulose nanocrystals and nanofibers by transmission electron microscopy. Cellulose 2020, 27, 4871–4887. [Google Scholar] [CrossRef]

- Ferreira, W.H.; Dahmouche, K.; Andrade, C.T. Dispersion of reduced graphene oxide within thermoplastic starch/poly(lactic acid) blends investigated by small-angle X-ray scattering. Carbohydr. Polym. 2019, 208, 124–132. [Google Scholar] [CrossRef]

- Codou, A.; Misra, M.; Andrzejewski, J. Sustainable biocomposites from Nylon 6 and polypropylene blends and biocarbon—Studies on tailored morphologies and complex composite structures. Compos. Part. A Appl. Sci. Manuf. 2020, 129, 105680. [Google Scholar] [CrossRef]

- Xian, Y.; Wang, C.; Wang, G.; Smith, L.; Cheng, H. Fractal dimension analysis of interface and impact strength in core–shell structural bamboo plastic composites. Iran. Polym. J. 2017, 26, 169–178. [Google Scholar] [CrossRef]

- Wei, F.; Wang, W.; Zhang, J. Fractal Characterization of Section Impact Strength of Polypropylene Compound Packaging Materials. Packag. Eng. 2016, 37, 61–65. [Google Scholar]

- Zhang, C. Tensile Strength and Fractal Characteristics of SiC Filled PP/FA Composites. Packag. Eng. 2017. [Google Scholar] [CrossRef]

- Lu, D.R.; He, C.X. Quantitative Analysis of Microcracks in Nano-ALN /PTFE Composites Based on Fractal Theory. In Proceedings of the 10th Sino-Japanese Composite Materials Academic Conference, Chengdu, China, 8 September 2012; pp. 136–139. [Google Scholar]

- Chen, Y.; Deng, Z.; Cheng, Q. Thermal conductivity of Si/Ge nanocomposites with fractal tree-shaped networks by considering the phonon interface scattering. Int. J. Heat Mass Transf. 2015, 88, 572–578. [Google Scholar] [CrossRef]

- Minakova, N.N.; Ushakov, V.Y. Application of Texture Analysis to Assess the Operability of Filled Polymers at High Temperatures. Russ. Phys. J. 2016, 58, 1627–1634. [Google Scholar] [CrossRef]

- Wu, C.; Liu, C.; Chen, Z.; Liang, J. Fractal Quantitative Characterization of Disperse Effect of Glass Beads in Filled Polypropylene Composites. Eng. Plast. Appl. 2016, 44, 92–97. [Google Scholar]

- Zhu, Q.; Zhang, C.; Yang, W. The Influence of permeability on the ablation process for an ablative material. Fractals 2019, 27, 27. [Google Scholar] [CrossRef]

- Jelčič, Ž.; Holjevac-Grguric, T.; Rek, V. Mechanical properties and fractal morphology of high-impact polystyrene/poly(styrene-b-butadiene-b-styrene) blends. Polym. Degrad. Stab. 2005, 90, 295–302. [Google Scholar] [CrossRef]

- Devakul, T.; You, Y.; Burnell, F.J.; Sondhi, S. Fractal Symmetric Phases of Matter. SciPost Phys. 2019, 6, 007. [Google Scholar] [CrossRef] [Green Version]

- Silva, F.; Gonçalves, L.; Fereira, D.; Rebello, J. Characterization of failure mechanism in composite materials through fractal analysis of acoustic emission signals. Chaos Solitons Fractals 2005, 26, 481–494. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Jiang, M.; Lu, Z.; Liu, G.; Song, S.; Yang, B. Characterization of Structure and Properties of Para-Phenylene Terephthalamide Paper-Based Composites by Fractal Dimension. Polym. Mater. Sci. Eng. 2015, 31, 96–101. [Google Scholar]

- Liu, G.; Zhang, M.; Ridgway, C.J.; Gane, P.A.C. Spontaneous Inertial Imbibition in Porous Media Using a Fractal Representation of Pore Wall Rugosity. Transp. Porous Media 2014, 104, 231–251. [Google Scholar] [CrossRef]

- Jian-Chao, C.; Yu, B.; Mao-Fei, M.; Liang, L. Capillary Rise in a Single Tortuous Capillary. Chin. Phys. Lett. 2010, 27, 054701. [Google Scholar] [CrossRef]

- Onda, T.; Shibuichi, S.; Satoh, A.N.; Tsujii, K. Super-Water-Repellent Fractal Surfaces. Langmuir 1996, 12, 2125–2127. [Google Scholar] [CrossRef]

- Cai, J.; Sun, S. Fractal Analysis of Fracture Increasing Spontaneous Imbibition in Porous Media with Gas-Saturated. Int. J. Mod. Phys. C 2013, 24. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, X.; Jiang, G.; Long, G.; Wang, W.; Zhang, Y.; Liu, G. Kozeny–Carman constant for gas flow through fibrous porous media by fractal-monte carlo simulations. Fractals 2019, 27, 1950062. [Google Scholar] [CrossRef]

- Li, X. Research on Porous Media Seepage Based on Directional Random Walking Method. Master’s Thesis, Yangzhou University, Yangzhou, China, 2018. [Google Scholar]

- Kosmidis, K.; Macheras, P. On the Dilemma of Fractal or Fractional Kinetics in Drug Release Studies: A Comparison Between Weibull and Mittag-Leffler Functions. Int. J. Pharm. 2018, 543, 269–273. [Google Scholar] [CrossRef] [Green Version]

- Su, W. Construction of Fractal Calculus. Sci. Sin. Math. 2015, 45, 1587–1598. [Google Scholar] [CrossRef]

- Aln, Q.T.; He, J.H. On Two-Scale Dimension and Its Applications. Therm Sci. 2019, 23, 1707–1712. [Google Scholar] [CrossRef] [Green Version]

- Coronel-Escamilla, A.; Gomez-Aguilar, J.F.; Torres, L.; Escobar-Jimenez, R.F. A Numerical Solution for a Variable-Order Reaction-Diffusion Model by Using Fractional Derivatives with Non-Local and Non-Singular Kernel. Phys. A 2018, 491, 406–424. [Google Scholar] [CrossRef]

- Gomez-Aguilar, J.F. Chaos in a nonlinear Bloch System with Atangana-Baleanu Fractional Derivatives. Numer Meth. Part. D E 2018, 34, 1716–1738. [Google Scholar] [CrossRef]

- Coronel-Escamilla, A.; Gomez-Aguilar, J.F.; Baleanu, D.; Cordova-Fraga, T.; Escobar-Jimenez, R.F.; Olivares-Peregrino, V.H.; Al Qurashi, M.M. Bateman-Feshbach Tikochinsky and Caldirola-Kanai Oscillators with New Fractional Differentiation. Entropy 2017, 19, 55. [Google Scholar] [CrossRef] [Green Version]

- Aguilar, J.F.G.; Cordova-Fraga, T.; Torres-Jimenez, J.; Escobar-Jimenez, R.F.; Olivares-Peregrino, V.H.; Guerrero-Ramirez, G.V. Nonlocal Transport Processes and the Fractional Cattaneo-Vernotte Equation. Math. Probl. Eng. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Q.; An, J.; Mao, H.; Liang, D.; Li, H.; Wang, S.; Huang, C. Review about the Application of Fractal Theory in the Research of Packaging Materials. Materials 2021, 14, 860. https://doi.org/10.3390/ma14040860

Duan Q, An J, Mao H, Liang D, Li H, Wang S, Huang C. Review about the Application of Fractal Theory in the Research of Packaging Materials. Materials. 2021; 14(4):860. https://doi.org/10.3390/ma14040860

Chicago/Turabian StyleDuan, Qingshan, Jiejie An, Hanling Mao, Dongwu Liang, Hao Li, Shuangfei Wang, and Chongxing Huang. 2021. "Review about the Application of Fractal Theory in the Research of Packaging Materials" Materials 14, no. 4: 860. https://doi.org/10.3390/ma14040860