A Fast and Implantation-Free Sample Production Method for Large Scale Electron-Transparent Metallic Samples Destined for MEMS-Based In Situ S/TEM Experiments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Provenance of the Metallic Samples

2.2. Jet Electropolishing (JEP)

2.3. Scanning/Transmission Electron Microscopy (S/TEM)

2.4. MEMS Experiments with In Situ S/TEM

3. Results and Discussion

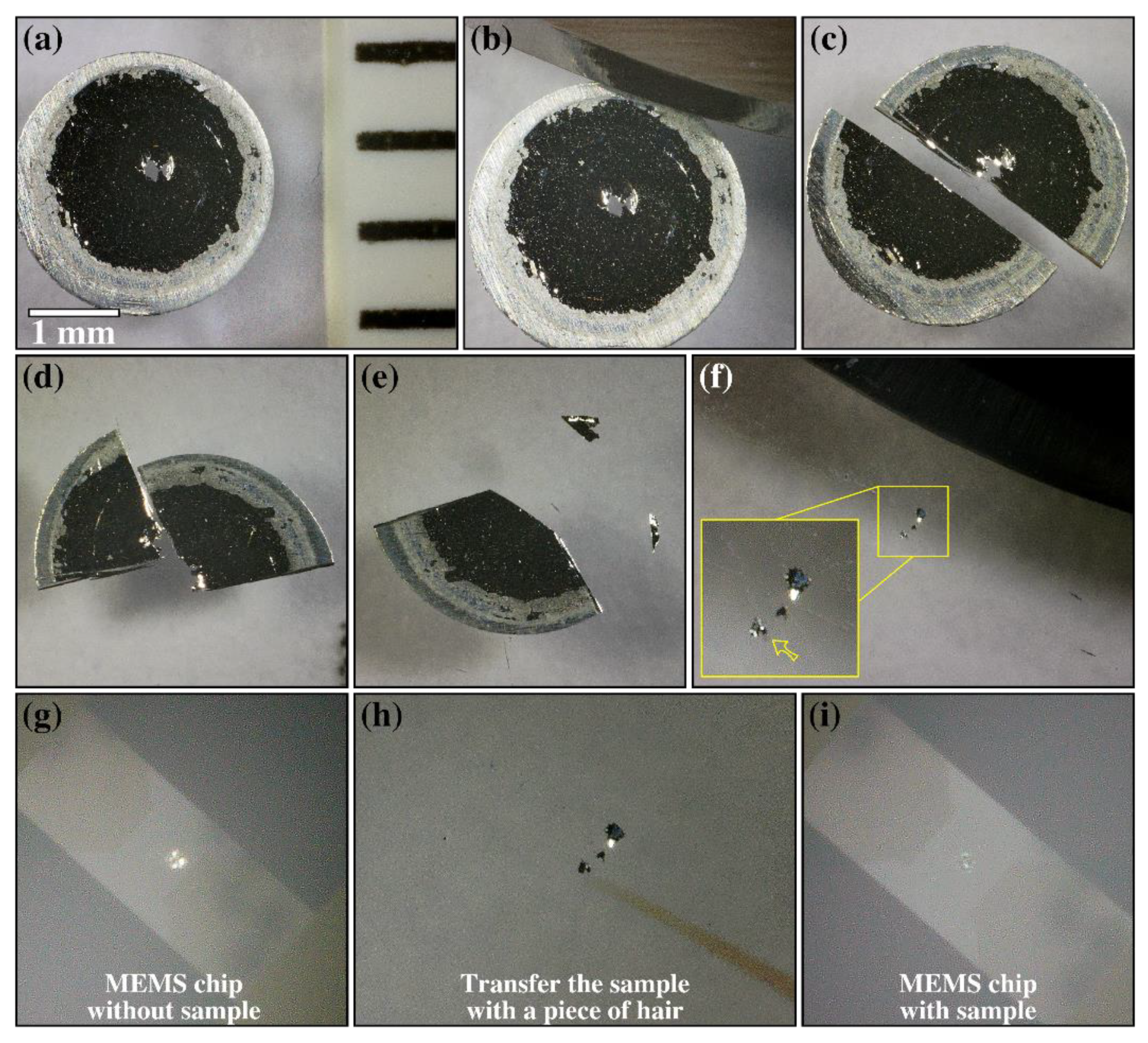

3.1. MEMS Sample Preparation Methodology

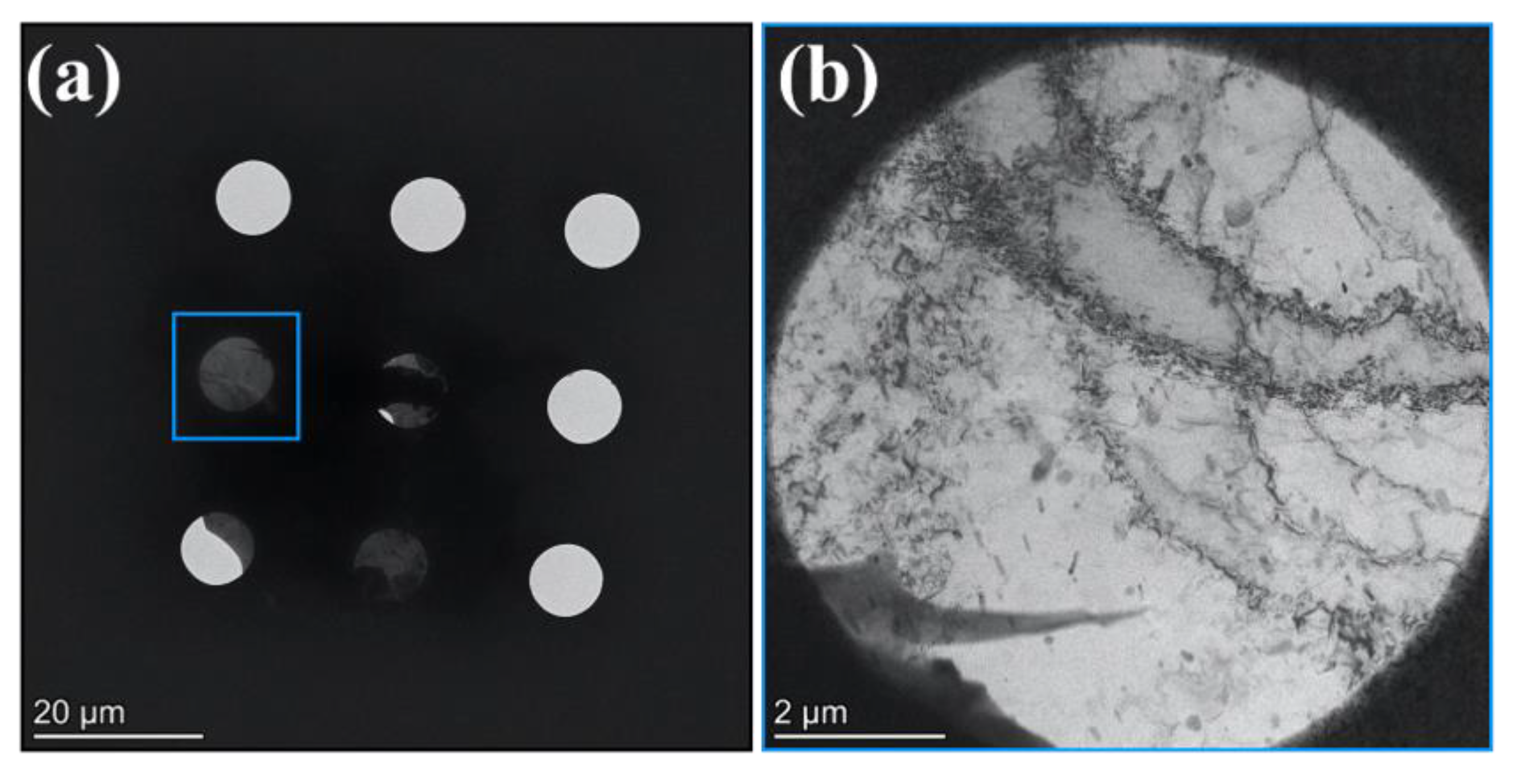

3.2. Characterisation with S/TEM

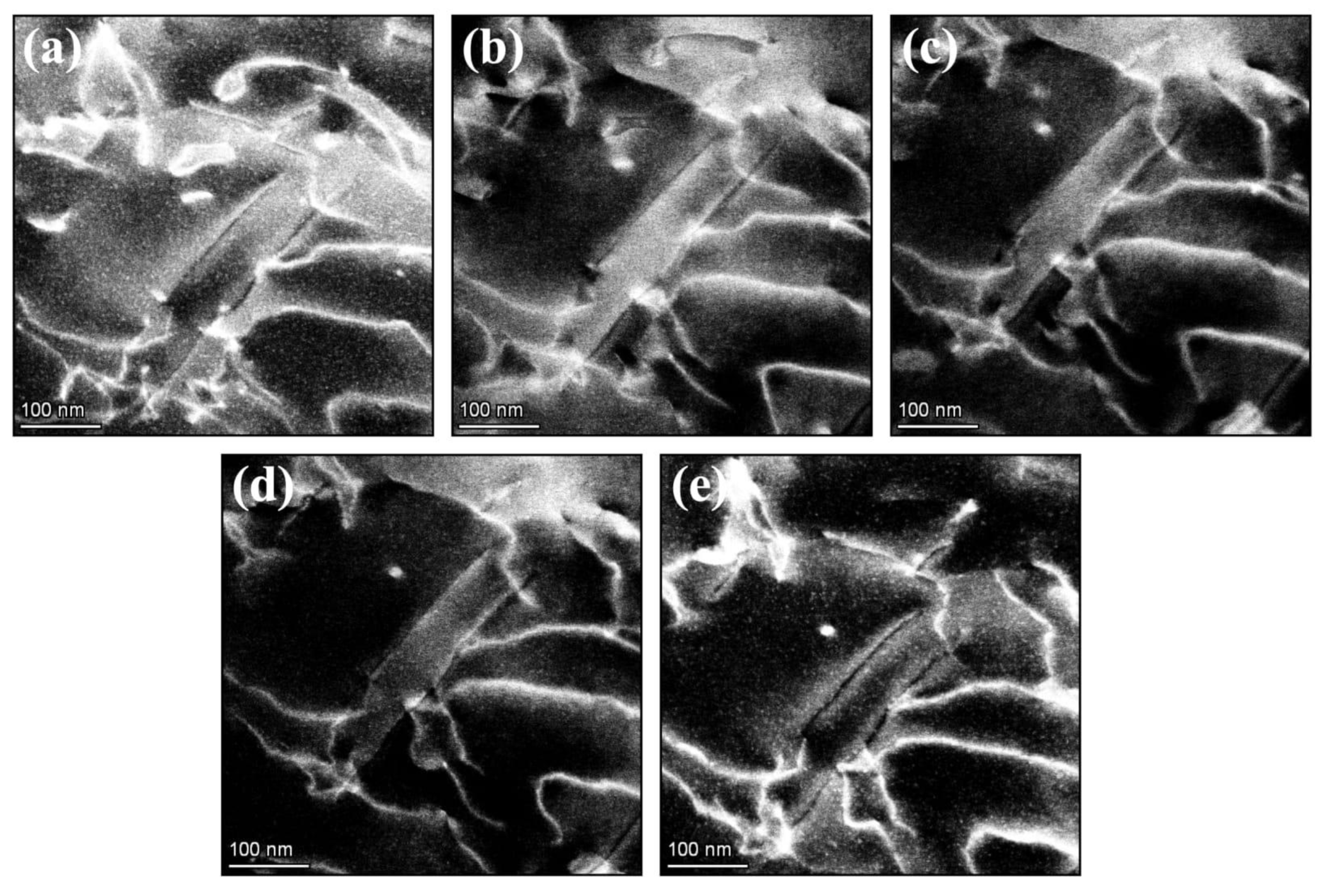

3.3. Paint Bake of AlMgZn(Cu) Alloy within a S/TEM

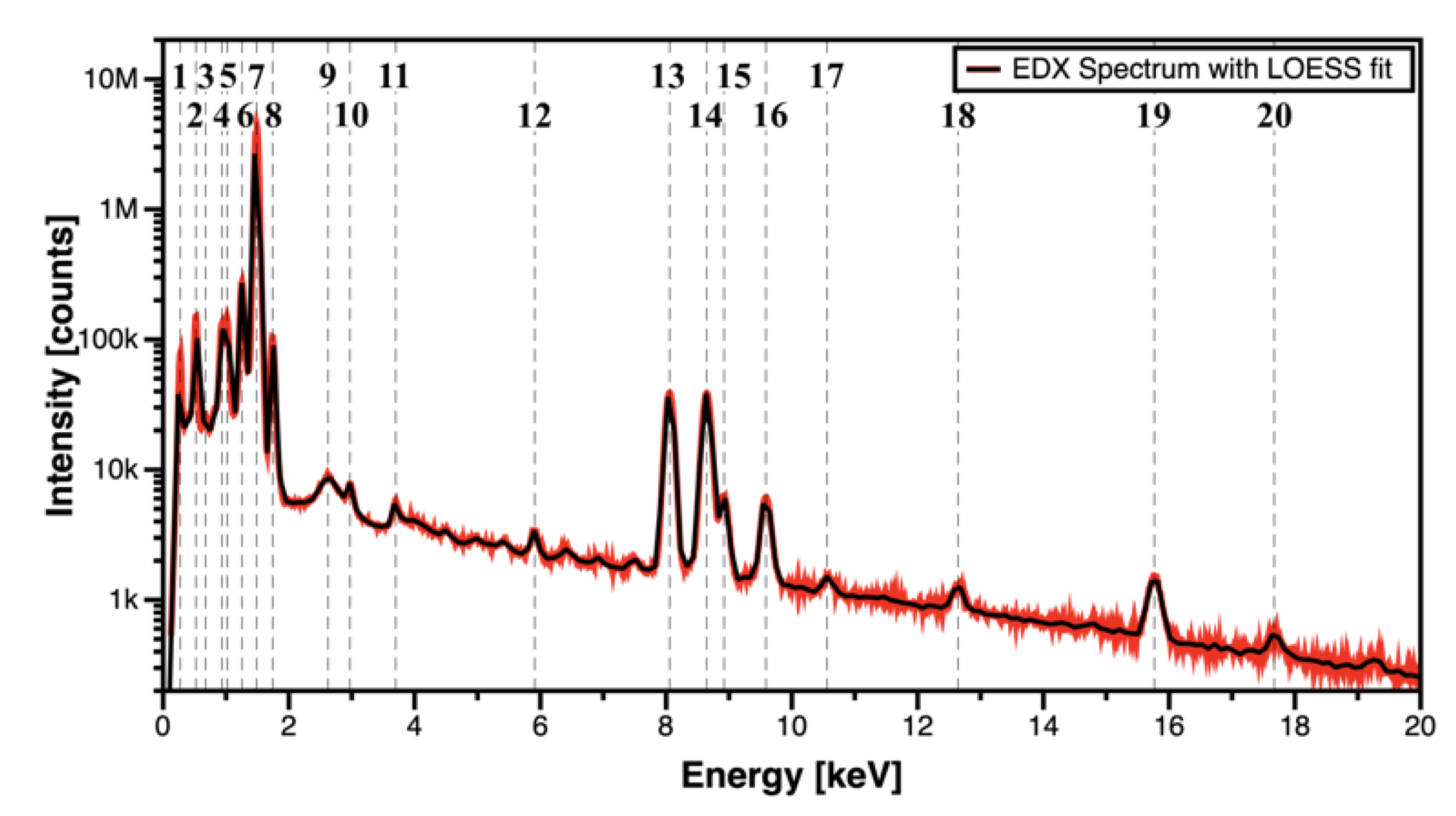

3.4. Post-Experiment Impurity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Noh, K.; Sun, L.; Chen, X.; Wen, J.; Dillon, S. In Situ TEM Characterization of Electrochemical Systems. Microsc. Microanal. 2011, 17, 1572–1573. [Google Scholar] [CrossRef] [Green Version]

- Zhong, X.L.; Schilling, S.; Zaluzec, N.J.; Burke, M.G. Sample Preparation Methodologies for In Situ Liquid and Gaseous Cell Analytical Transmission Electron Microscopy of Electropolished Specimens. Microsc. Microanal. 2016, 22, 1350–1359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Damiano, J.; Nackashi, D.P.; Mick, S.E. A MEMS based Technology Platform for in-situ TEM Heating Studies. Microsc. Microanal. 2008, 14, 1332–1333. [Google Scholar] [CrossRef]

- Novák, L.; Stárek, J.; Vystavěl, T.; Mele, L. MEMS-based Heating Element for in-situ Dynamical Experiments on FIB/SEM Systems. Microsc. Microanal. 2016, 22, 184–185. [Google Scholar] [CrossRef] [Green Version]

- Hattar, K.; Han, J.; Saif, T.; Robertson, I.M. Development and Application of a MEMS-Based In Situ TEM Straining Device for Ultra-Fine Grained Metallic Systems. Microsc. Microanal. 2004, 10, 50–51. [Google Scholar] [CrossRef]

- Tochigi, E.; Sato, T.; Shibata, N.; Fujita, H.; Ikuhara, Y. In situ STEM Mechanical Experiments at Atomic-Resolution Using a MEMS Device. Microsc. Microanal. 2019, 25, 1884–1885. [Google Scholar] [CrossRef] [Green Version]

- Dillon, S.J.; Liu, Y. In-Situ TEM in Complex Environments: Photocatalysis. Microsc. Microanal. 2012, 18, 1072–1073. [Google Scholar] [CrossRef]

- Sun, L. In-situ TEM Study on Solar Cell. Microsc. Microanal. 2020, 26, 3160. [Google Scholar] [CrossRef]

- Li, W.; Li, M.; Wang, X.; Xu, P.; Yu, H.; Li, X. An in-situ TEM microreactor for real-time nanomorphology & physicochemical parameters interrelated characterization. Nano Today 2020, 35, 100932. [Google Scholar]

- Imrich, P.J.; Kirchlechner, C.; Kiener, D.; Dehm, G. In Situ TEM Microcompression of Single and Bicrystalline Samples: Insights and Limitations. JOM 2015, 67, 1704–1712. [Google Scholar] [CrossRef]

- Tuck, K.; Ellis, M.; Geisberger, A.; Skidmore, G.; Foster, P. FIB Prepared TEM Sample Lift-out Using MEMS Grippers. Microsc. Microanal. 2004, 10, 1144–1145. [Google Scholar] [CrossRef]

- Vijayan, S.; Jinschek, J.R.; Kujawa, S.; Greiser, J.; Aindow, M. Focused Ion Beam Preparation of Specimens for Micro-Electro-Mechanical System-based Transmission Electron Microscopy Heating Experiments. Microsc. Microanal. 2017, 23, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Giannuzzi, L.A.; Stevie, F.A. A review of focused ion beam milling techniques for TEM specimen preparation. Micron 1999, 30, 197–204. [Google Scholar] [CrossRef]

- Mayer, J.; Giannuzzi, L.A.; Kamino, T.; Michael, J. TEM Sample Preparation and FIB-Induced Damage. MRS Bull. 2007, 32, 400–407. [Google Scholar] [CrossRef] [Green Version]

- Ernst, A.; Wei, M.; Aindow, M. A Comparison of Ga FIB and Xe-Plasma FIB of Complex Al Alloys. Microsc. Microanal. 2017, 23, 288–289. [Google Scholar] [CrossRef] [Green Version]

- Bender, H.; Franquet, A.; Drijbooms, C.; Parmentier, B.; Clarysse, T.; Vandervorst, W.; Kwakman, L. Surface contamination and electrical damage by focused ion beam: Conditions applicable to the extraction of TEM lamellae from nanoelectronic devices. Semicond. Sci. Technol. 2015, 30, 114015. [Google Scholar] [CrossRef]

- Estivill, R.; Audoit, G.; Barnes, J.-P.; Grenier, A.; Blavette, D. Preparation and Analysis of Atom Probe Tips by Xenon Focused Ion Beam Milling. Microsc. Microanal. 2016, 22, 576–582. [Google Scholar] [CrossRef] [PubMed]

- Stemper, L.; Tunes, M.A.; Dumitraschkewitz, P.; Mendez-Martin, F.; Tosone, R.; Marchand, D.; Curtin, W.A.; Uggowitzer, P.J.; Pogatscher, S. Giant hardening response in AlMgZn(Cu) alloys. Acta Mater. 2021, 206, 116617. [Google Scholar] [CrossRef]

- Isabell, T.C.; Fischione, P.E.; O’Keefe, C.; Guruz, M.U.; Dravid, V.P. Plasma Cleaning and Its Applications for Electron Microscopy. Microsc. Microanal. 1999, 5, 126–135. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Peak Index | Measured (keV) | Expected (keV) | Relative‡ (%) | Identified Element |

|---|---|---|---|---|

| 1† | 0.273 | 0.280 | 1.60 | C K |

| 2 | 0.521 | 0.524 | 3.20 | O K |

| 3† | 0.675 | - | 0.61 | Multi. Elements |

| 4 | 0.933 | 0.929 | 2.89 | Cu L |

| 5 | 1.018 | 1.012 | 3.34 | Zn L |

| 6 | 1.253 | 1.254 | 6.34 | Mg K |

| 7 | 1.487 | 1.487 | 100 | Al K |

| 8 | 1.742 | 1.742 | 2.31 | Si K |

| 9† | 2.623 | - | 0.21 | Multi. Elements |

| 10† | 2.971 | - | 0.18 | Multi. Elements |

| 11† | 3.699 | 3.691 | 0.13 | Ca K |

| 12† | 5.910 | - | 0.08 | Multi. Elements |

| 13 | 8.055 | 8.048 | 0.09 | Cu K |

| 14 | 8.644 | 8.639 | 0.09 | Zn K |

| 15 | 8.921 | 8.907 | 0.14 | Cu K |

| 16 | 9.587 | 9.574 | 0.14 | Zn K |

| 17† | 10.558 | - | 0.04 | Multi. Elements |

| 18† | 12.643 | - | 0.03 | Multi. Elements |

| 19† | 15.764 | 15.775 | 0.04 | Zr K |

| 20† | 17.671 | 17.667 | 0.01 | Zr K |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tunes, M.A.; Quick, C.R.; Stemper, L.; Coradini, D.S.R.; Grasserbauer, J.; Dumitraschkewitz, P.; Kremmer, T.M.; Pogatscher, S. A Fast and Implantation-Free Sample Production Method for Large Scale Electron-Transparent Metallic Samples Destined for MEMS-Based In Situ S/TEM Experiments. Materials 2021, 14, 1085. https://doi.org/10.3390/ma14051085

Tunes MA, Quick CR, Stemper L, Coradini DSR, Grasserbauer J, Dumitraschkewitz P, Kremmer TM, Pogatscher S. A Fast and Implantation-Free Sample Production Method for Large Scale Electron-Transparent Metallic Samples Destined for MEMS-Based In Situ S/TEM Experiments. Materials. 2021; 14(5):1085. https://doi.org/10.3390/ma14051085

Chicago/Turabian StyleTunes, Matheus A., Cameron R. Quick, Lukas Stemper, Diego S. R. Coradini, Jakob Grasserbauer, Phillip Dumitraschkewitz, Thomas M. Kremmer, and Stefan Pogatscher. 2021. "A Fast and Implantation-Free Sample Production Method for Large Scale Electron-Transparent Metallic Samples Destined for MEMS-Based In Situ S/TEM Experiments" Materials 14, no. 5: 1085. https://doi.org/10.3390/ma14051085

APA StyleTunes, M. A., Quick, C. R., Stemper, L., Coradini, D. S. R., Grasserbauer, J., Dumitraschkewitz, P., Kremmer, T. M., & Pogatscher, S. (2021). A Fast and Implantation-Free Sample Production Method for Large Scale Electron-Transparent Metallic Samples Destined for MEMS-Based In Situ S/TEM Experiments. Materials, 14(5), 1085. https://doi.org/10.3390/ma14051085