Effect of Steel Fiber Content on Shear Behavior of Reinforced Expanded-Shale Lightweight Concrete Beams with Stirrups

Abstract

1. Introduction

2. Research Significance

3. Experimental Work

3.1. Production of SFRELC

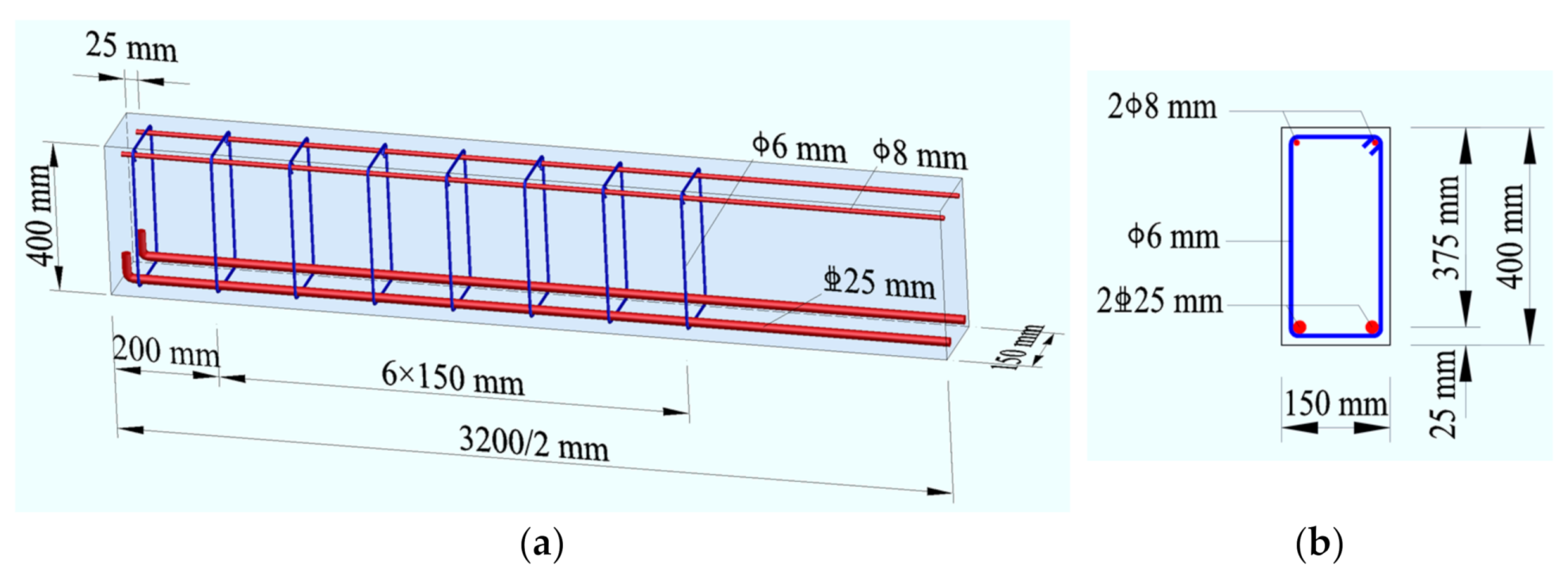

3.2. Design and Fabrication of Test Beams

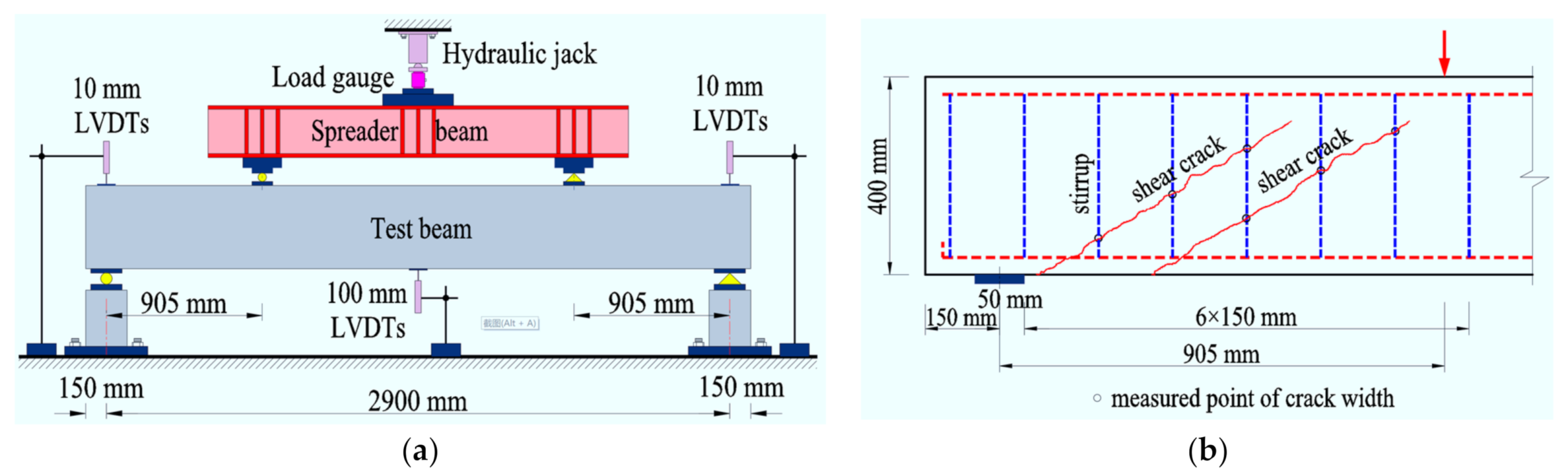

3.3. Test Method

4. Test Results and Analyses

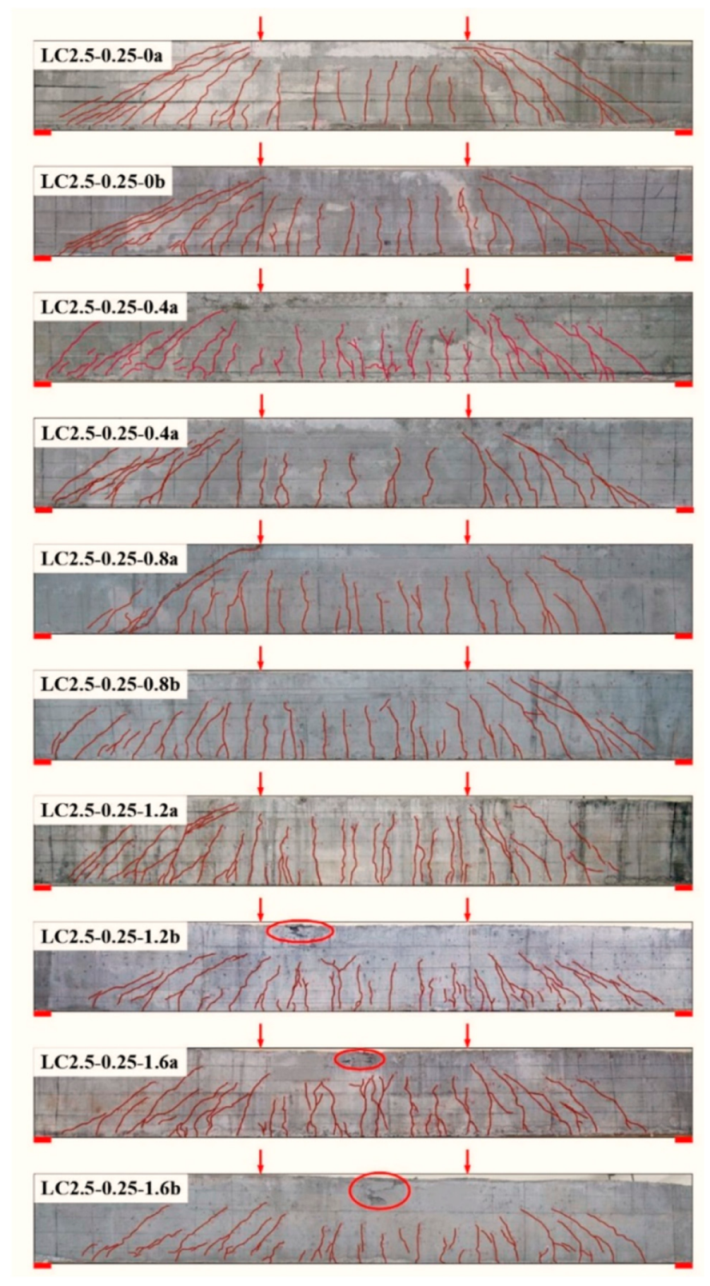

4.1. Patterns of Crack Distribution and Failure

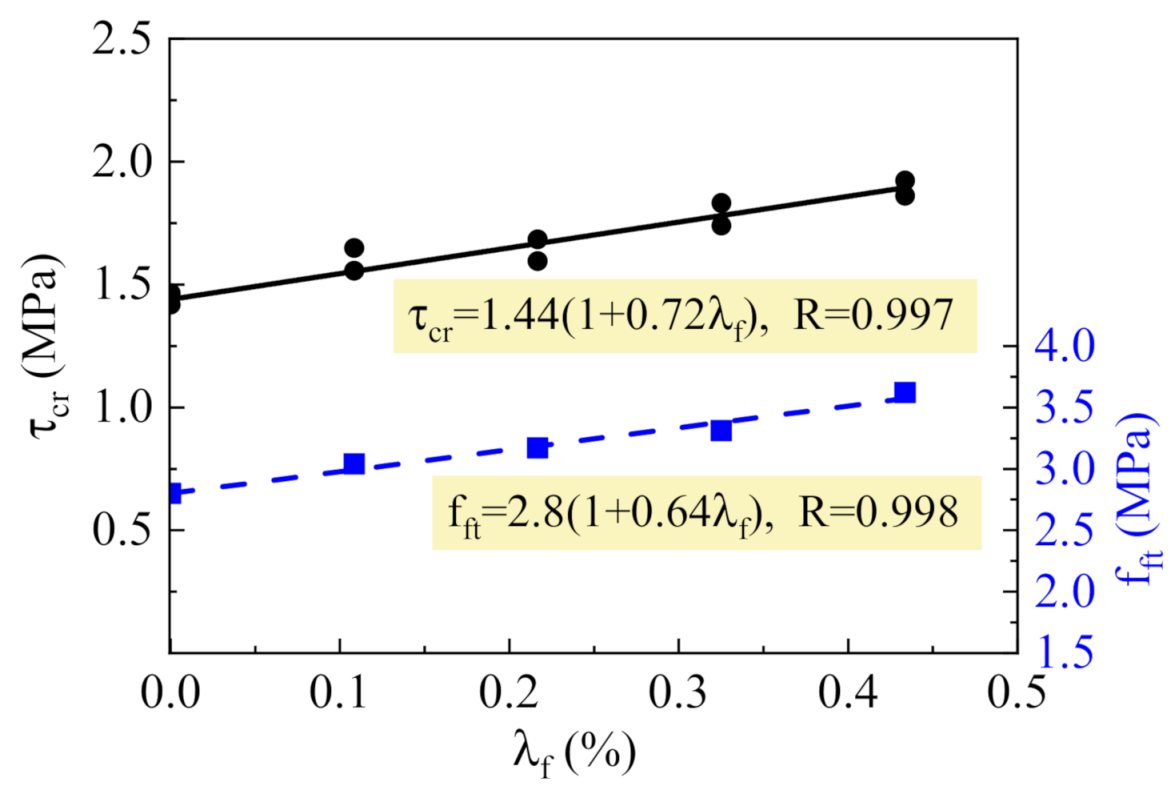

4.2. Shear-Cracking Force

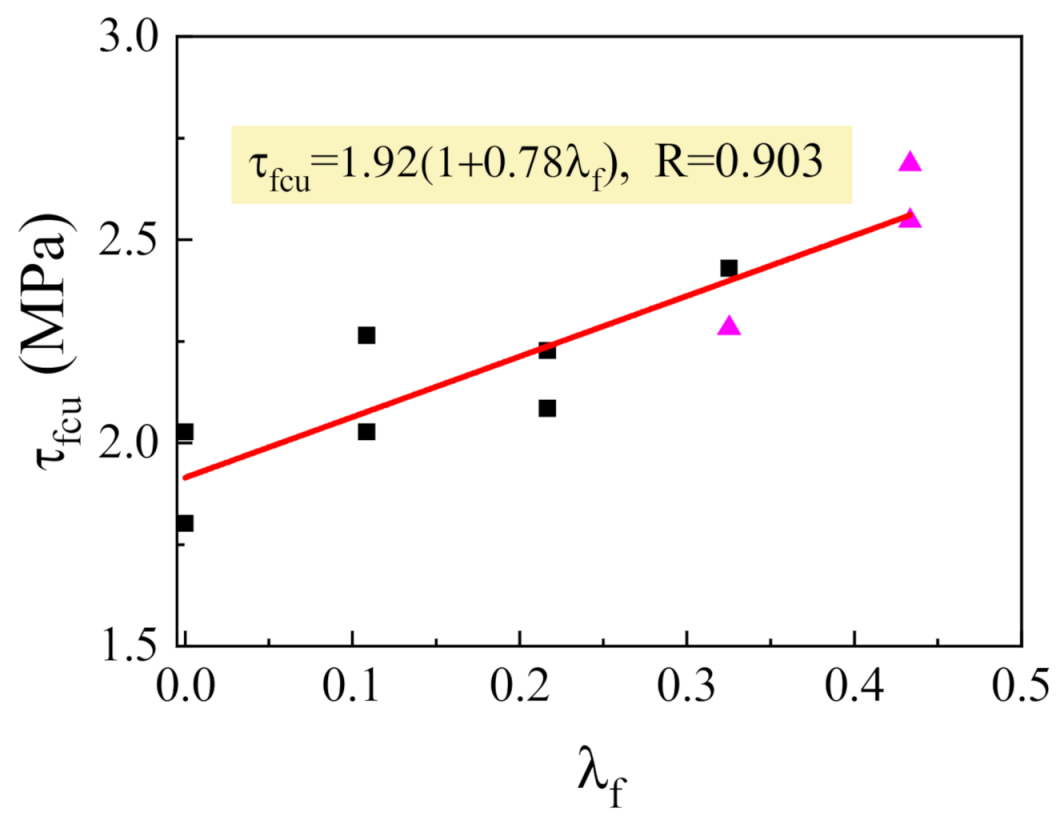

4.3. Shear Capacity

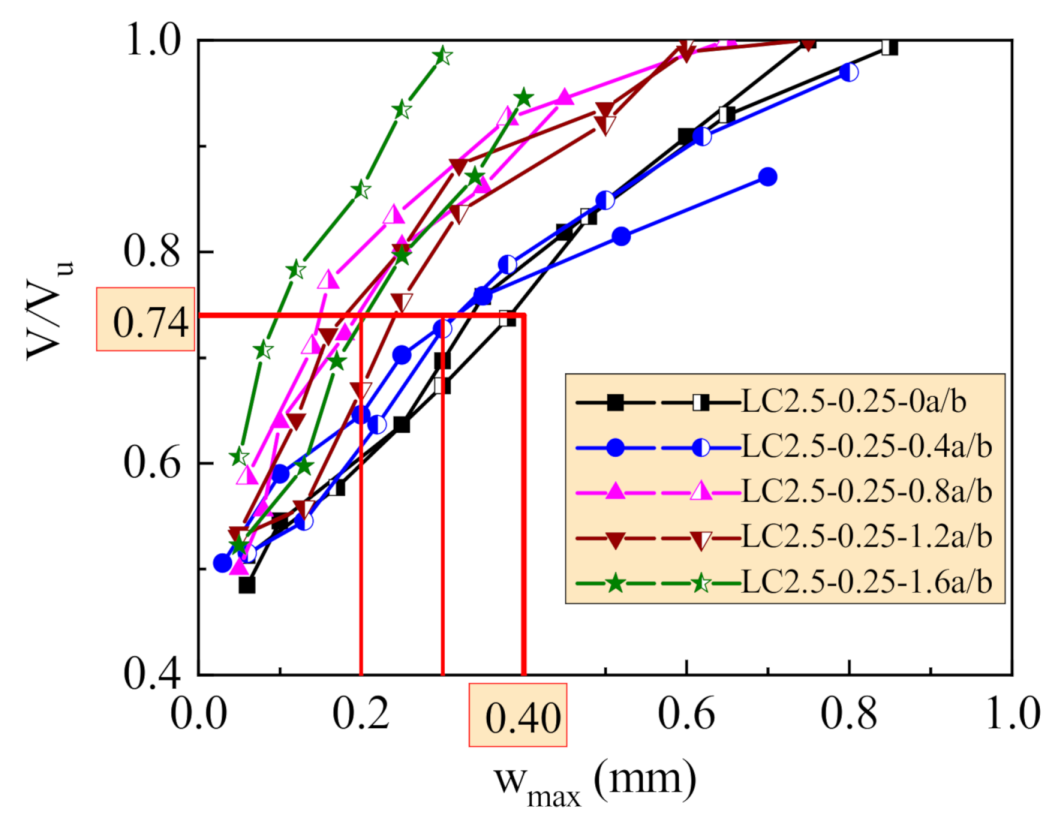

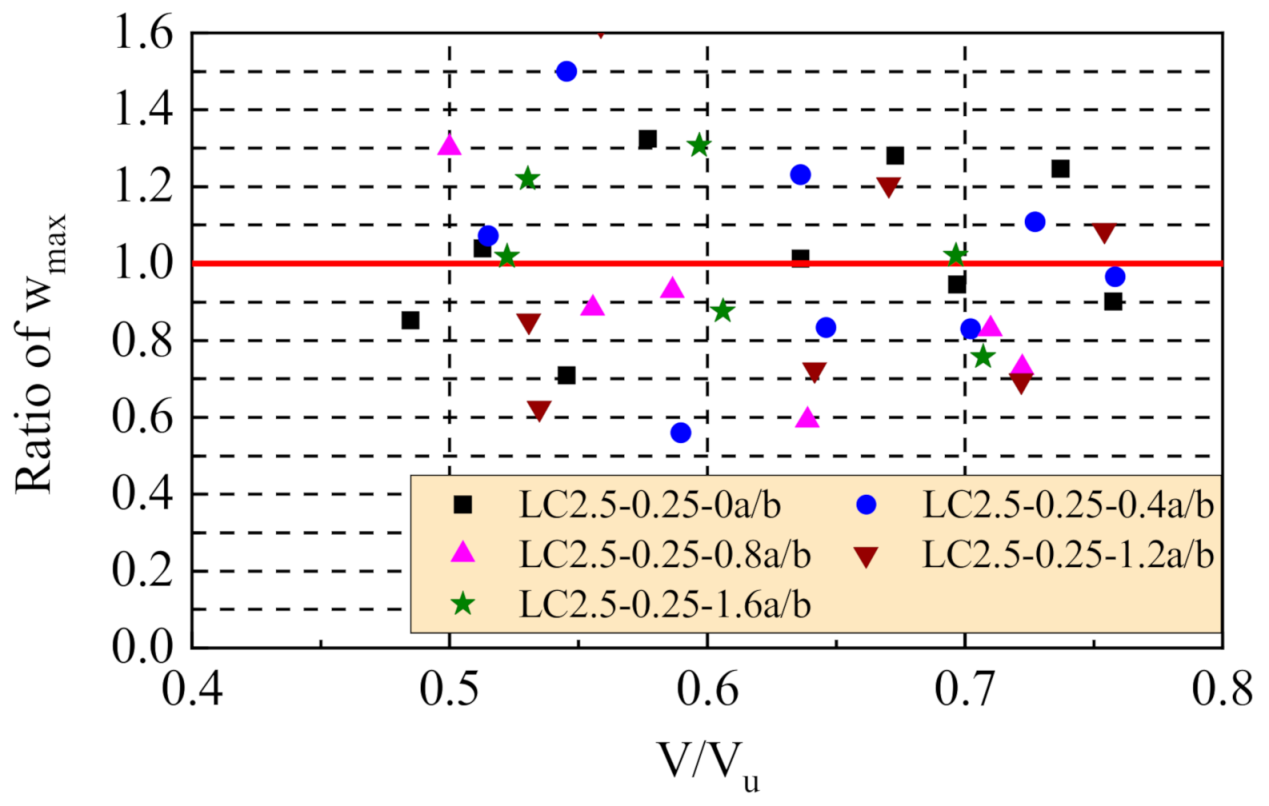

4.4. Shear-Crack Width

5. Conclusions

- (1)

- Steel fiber had a higher strengthening effect coupling with stirrups on the shear-cracking resistance of reinforced SFRELC beams. For simplifying the calculation, the beneficial effect can be neglected to provide a conservative result only considering the strengthening of steel fiber on the tensile strength of SFRELC.

- (2)

- With the increase of steel fiber content, the shear failure could be modified with good ductility and transferred to the flexure. The stirrups improved the distribution of shear cracks with reduced spacing and width. This provided a good condition of SFRELC subjected to shear force to improve the shear capacity provided by SFRELC. Considering the effect of steel fiber reinforcement on the shear capacity of beams provided by SFRELC, the formulas are proposed for the prediction and the design of shear capacity of reinforced SFRELC beams with stirrups.

- (3)

- With the increase of steel fiber content, the maximum width of shear cracks became smaller after shear cracking, and it extended slowly at the same loading level of test beams. The reduction of maximum width of shear cracks promoted the adaptability of reinforced SFRELC beams in a severe environment. Based on the test results, the formula for the prediction of maximum width of shear cracks is proposed.

- (4)

- The study was limited to the changes of steel fiber content in condition of the constant shear span to depth ratio and stirrups ratio. To build a broad recognized method for the design of reinforced SFRELC beams under shear stress, many more systematical research studies need to carried out to identify the effects of multiple factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, M.L.; Zhao, M.S.; Chen, M.H.; Li, J.; Law, D. An experimental study on strength and toughness of steel fiber reinforced expanded-shale lightweight concrete. Constr. Build. Mater. 2018, 183, 493–501. [Google Scholar] [CrossRef]

- Zhao, M.S.; Zhang, B.; Shang, P.R.; Fu, Y. Complete Stress–Strain Curves of Self-Compacting Steel Fiber Reinforced Expanded-Shale Lightweight Concrete under Uniaxial Compression. Materials 2019, 12, 2979. [Google Scholar] [CrossRef]

- Zhao, S.B.; Li, C.Y.; Zhao, M.S.; Zhang, X.Y. Experimental Study on Autogenous and Drying Shrinkage of Steel Fiber Reinforced Lightweight-Aggregate Concrete. Adv. Mater. Sci. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Zhao, M.S.; Zhang, X.Y.; Song, W.H.; Li, C.Y.; Zhao, S.B. Development of Steel Fiber-Reinforced Expanded-Shale Lightweight Concrete with High Freeze-Thaw Resistance. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Zhao, M.S.; Zhang, X.Y.; Yan, K.; Fei, T.; Zhao, S.B. Bond performance of deformed rebar in steel fiber reinforced lightweight-aggregate concrete affected by multi-factors. Civ. Eng. J. 2018, 3, 276–290. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhao, S.B.; Chen, H.; Gao, D.Y. Experimental study on flexural capacity of reinforced SFRFLC superposed beams. J. Build. Struct. 2015, 2, 257–264. [Google Scholar]

- Zhao, M.S.; Li, C.Y.; Su, J.; Shang, P.R.; Zhao, S.B. Experimental study and theoretical prediction of flexural behaviors of reinforced SFRELC beams. Constr. Build. Mater. 2019, 208, 454–463. [Google Scholar] [CrossRef]

- Li, C.Y.; Li, Q.; Li, X.K.; Zhang, X.Y.; Zhao, S.B. Elasto-plastic bending behaviors of reinforced SFRELC beams analyzed by nonlinear finite-element method. Case Study Constr. Mater. 2020, 13, e00372. [Google Scholar]

- Qu, F.L.; Li, C.Y.; Peng, C.; Ding, X.X.; Hu, X.; Pan, L.Y. Flexural Fatigue Performance of Steel Fiber Reinforced Expanded-Shales Lightweight Concrete Superposed Beams with Initial Static-Load Cracks. Materials 2019, 12, 3261. [Google Scholar] [CrossRef]

- Li, X.K.; Li, C.Y.; Zhao, M.L.; Yang, H.; Zhou, S.Y. Testing and prediction of shear performance for steel fiber reinforced expanded-shale lightweight concrete beams without web reinforcements. Materials 2019, 12, 1594. [Google Scholar] [CrossRef]

- Nes, L.G.; Øverli, J.A. Structural behaviour of layered beams with fibre-reinforced LWAC and normal density concrete. Mater. Struct. 2015, 49, 689–703. [Google Scholar] [CrossRef]

- Jiao, C.J.; Xu, B.F.; Gao, J.Y.; Wang, L. Experiments on shear resistance of steel fiber reinforced lightweight aggregate concrete beams. J. Civ. Eng. Manag. 2017, 34, 9–13. [Google Scholar]

- Zhao, S.B.; Li, F.L.; Zhao, G.F.; Huang, C.K. Experimental research on shear cracking strength of steel fiber reinforced concrete beams. J. Hydroelectr. Eng. 1997, 4, 18–29. [Google Scholar]

- Zhao, S.B.; Zhao, G.F.; Huang, C.K. Shear-crack width of steel fiber reinforced prestressed concrete beams. J. Dalian Univ. Technol. 1998, 38, 705–710. [Google Scholar]

- Zhao, S.B.; Li, F.L.; Zhao, G.F.; Huang, C.K. Shear resistance of steel fiber reinforced concrete beams. J. Basic Sci. Eng. 1998, 6, 77–82. [Google Scholar]

- Cucchiara, C.; Mendola, L.L.; Papia, M. Effectiveness of stirrups and steel fibers as shear reinforcement. Cem. Concr. Compos. 2004, 26, 777–786. [Google Scholar] [CrossRef]

- You, Z.; Ding, Y.; Niederegger, C. Replacing stirrups of self-compacting concrete beams with steel fibers. Trans. Tianjin Univ. 2010, 16, 411–416. [Google Scholar] [CrossRef]

- Tahenni, T.; Chemrouk, M.; Lecompte, T. Effect of steel fibers on the shear behavior of high strength concrete beams. Constr. Build. Mater. 2016, 105, 14–28. [Google Scholar] [CrossRef]

- Ding, Y.; You, Z.; Jalali, S. The composite effect of steel fibres and stirrups on the shear behaviour of beams using self-consolidating concrete. Eng. Struct. 2011, 33, 107–117. [Google Scholar] [CrossRef]

- Oh, B.H.; Kim, E.S.; Lim, D.H.; Yoo, S.W. Shear behaviour and shear analysis of reinforced concrete beams containing steel fibres. Mag. Concr. Res. 1998, 50, 283–291. [Google Scholar] [CrossRef]

- Dancygier, A.N.; Savir, Z. Effects of Steel Fibers on Shear Behavior of High-Strength Reinforced Concrete Beams. Adv. Struct. Eng. 2011, 14, 745–761. [Google Scholar] [CrossRef]

- Cucchiara, C.; Fossetti, M.; Papia, M. Steel fibre and transverse reinforcement effects on the behaviour of high strength concrete beams. Struct. Eng. Mech. 2012, 42, 551–570. [Google Scholar] [CrossRef]

- Lim, D.; Oh, B. Experimental and theoretical investigation on the shear of steel fibre reinforced concrete beams. Eng. Struct. 1999, 21, 937–944. [Google Scholar] [CrossRef]

- Amin, A.; Foster, S.J. Shear strength of steel fiber reinforced concrete beams with stirrups. Eng. Struct. 2016, 111, 323–332. [Google Scholar]

- Yoo, D.-Y.; Yuan, T.; Yang, J.-M.; Yoon, Y.-S. Feasibility of replacing minimum shear reinforcement with steel fibers for sustainable high-strength concrete beams. Eng. Struct. 2017, 147, 207–232. [Google Scholar]

- Ranjan, S.D.; Abhimanyu, S. Effect of steel fiber content on behavior of concrete beams with and without stirrups. ACI Struct. J. 2014, 111, 1157–1166. [Google Scholar]

- Kim, C.-G.; Lee, H.; Park, H.-G.; Hong, G.-H.; Kang, S.-M. Effect of Steel Fibers on Minimum Shear Reinforcement of High-Strength Concrete Beams. ACI Struct. J. 2017, 114, 1109–1119. [Google Scholar] [CrossRef]

- Aoude, H.; Belghiti, M.; Cook, W.D.; Mitchell, D. Response of Steel Fiber-Reinforced Concrete Beams with and without Stirrups. ACI Struct. J. 2012, 109, 359–367. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yang, J.-M. Effects of stirrup, steel fiber, and beam size on shear behavior of high-strength concrete beams. Cem. Concr. Compos. 2018, 87, 137–148. [Google Scholar] [CrossRef]

- Di Prisco, M.; Romero, J.A. Diagonal shear in thin-webbed reinforced concrete beams: Fibre and stirrup roles at shear collapse. Mag. Concr. Res. 1996, 48, 59–76. [Google Scholar] [CrossRef]

- Zhao, J.; Liang, J.; Chu, L.; Shen, F. Experimental Study on Shear Behavior of Steel Fiber Reinforced Concrete Beams with High-Strength Reinforcement. Materials 2018, 11, 1682. [Google Scholar] [CrossRef] [PubMed]

- Biolzi, L.; Cattaneo, S. Response of steel fiber reinforced high strength concrete beams: Experiments and code predictions. Cem. Concr. Compos. 2017, 77, 1–13. [Google Scholar] [CrossRef]

- Junior, S.F.; De Hanai, J.B. Shear behavior of fiber reinforced concrete beams. Cem. Concr. Compos. 1997, 19, 359–366. [Google Scholar]

- Turmo, J.; Banthia, N.; Gettu, R.; Barragán, B. Study of the shear behaviour of fibre reinforced concrete beams. Mater. Constr. 2008, 58, 5–13. [Google Scholar]

- Campione, G. Flexural and Shear Resistance of Steel Fiber–Reinforced Lightweight Concrete Beams. J. Struct. Eng. 2014, 140, 04013103. [Google Scholar] [CrossRef]

- Li, C.Y.; Liang, N.; Zhao, M.L.; Yao, K.Q.; Li, J.; Li, X.K. Shear Performance of Reinforced Concrete Beams Affected by Satisfactory Composite-Recycled Aggregates. Materials 2020, 13, 1711. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Lightweight-Aggregate Concrete Structures; JGJ12-2006; China Building Industry Press: Beijing, China, 2006. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Design of Concrete Structures; GB50010-2010; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Design of Steel Fiber Reinforced Concrete Structures; JGJ/T465-2019; China Building Industry Press: Beijing, China, 2020. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Steel Fiber Reinforced Concrete; JG/T472-2015; China Building Industry Press: Beijing, China, 2015. [Google Scholar]

- Canadian Standards Association. Design of Concrete Structures: Structures Design; CSA A23.3-04; Canadian Standards Association: Mississauga, TN, Canada, 2004. [Google Scholar]

- British Standards Institution. Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings; Eurocode 2; British Standards Institution: London, UK, 2004. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete; ACI 318-14; ACI: Farmington Hill, MI, USA, 2014. [Google Scholar]

- ACI Committee 544. Design Considerations for Steel Fiber Reinforced Concrete; ACI 544.4R-2009; ACI: Farmington Hill, MI, USA, 2009. [Google Scholar]

| Identifier | b (mm) | h0 (mm) | vf (%) | Strength of SFRELC (MPa) | Computed Shear Force (kN) | ||

|---|---|---|---|---|---|---|---|

| ffc | fft | Vu(1) | Vu(4) | ||||

| LC2.5-0.25-0a | 150 | 362 | 0 | 36.4 | 2.80 | 143 | 177 |

| LC2.5-0.25-0b | 155 | 362 | 0 | 36.4 | 2.80 | 145 | 178 |

| LC2.5-0.25-0.4a | 150 | 362 | 0.4 | 42.4 | 3.04 | 151 | 179 |

| LC2.5-0.25-0.4b | 150 | 362 | 0.4 | 42.4 | 3.04 | 151 | 179 |

| LC2.5-0.25-0.8a | 155 | 362 | 0.8 | 49.2 | 3.17 | 157 | 182 |

| LC2.5-0.25-0.8b | 155 | 362 | 0.8 | 49.2 | 3.17 | 157 | 182 |

| LC2.5-0.25-1.2a | 150 | 362 | 1.2 | 51.6 | 3.31 | 160 | 182 |

| LC2.5-0.25-1.2b | 150 | 362 | 1.2 | 51.6 | 3.31 | 160 | 182 |

| LC2.5-0.25-1.6a | 150 | 362 | 1.6 | 52.3 | 3.62 | 170 | 182 |

| LC2.5-0.25-1.6b | 155 | 364 | 1.6 | 52.3 | 3.62 | 171 | 182 |

| Identifier | Vcr (kN) | Failure Pattern | Vu (kN) | |||

|---|---|---|---|---|---|---|

| Test | Computed | Test | Computed by Formulas (1), (3) and (10) | Computed by Formula (11) | ||

| LC2.5-0.25-0a | 80 | 77.7 | Shear | 165 | 143 | 124 |

| LC2.5-0.25-0b | 80 | 79.8 | Shear | 156 | 145 | 125 |

| LC2.5-0.25-0.4a | 90 | 84.3 | Shear | 178 | 151 | 130 |

| LC2.5-0.25-0.4b | 85 | 84.3 | Shear | 165 | 151 | 130 |

| LC2.5-0.25-0.8a | 90 | 91.8 | Shear | 180 | 160 | 137 |

| LC2.5-0.25-0.8b | 95 | 91.8 | Shear | 172 | 160 | 137 |

| LC2.5-0.25-1.2a | 100 | 90.3 | Shear | 187 | 166 | 141 |

| LC2.5-0.25-1.2b | 95 | 90.3 | Shear-flexural | 179 | 166 | 141 |

| LC2.5-0.25-1.6a | 105 | 100.4 | Flexural | 201 | 173 | 147 |

| LC2.5-0.25-1.6b | 105 | 103.1 | Flexural | 198 | 175 | 149 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhao, M.; Zhang, X.; Li, J.; Li, X.; Zhao, M. Effect of Steel Fiber Content on Shear Behavior of Reinforced Expanded-Shale Lightweight Concrete Beams with Stirrups. Materials 2021, 14, 1107. https://doi.org/10.3390/ma14051107

Li C, Zhao M, Zhang X, Li J, Li X, Zhao M. Effect of Steel Fiber Content on Shear Behavior of Reinforced Expanded-Shale Lightweight Concrete Beams with Stirrups. Materials. 2021; 14(5):1107. https://doi.org/10.3390/ma14051107

Chicago/Turabian StyleLi, Changyong, Minglei Zhao, Xiaoyan Zhang, Jie Li, Xiaoke Li, and Mingshuang Zhao. 2021. "Effect of Steel Fiber Content on Shear Behavior of Reinforced Expanded-Shale Lightweight Concrete Beams with Stirrups" Materials 14, no. 5: 1107. https://doi.org/10.3390/ma14051107

APA StyleLi, C., Zhao, M., Zhang, X., Li, J., Li, X., & Zhao, M. (2021). Effect of Steel Fiber Content on Shear Behavior of Reinforced Expanded-Shale Lightweight Concrete Beams with Stirrups. Materials, 14(5), 1107. https://doi.org/10.3390/ma14051107