Automotive Steel with a High Product of Strength and Elongation used for Cold and Hot Forming Simultaneously

Abstract

:1. Introduction

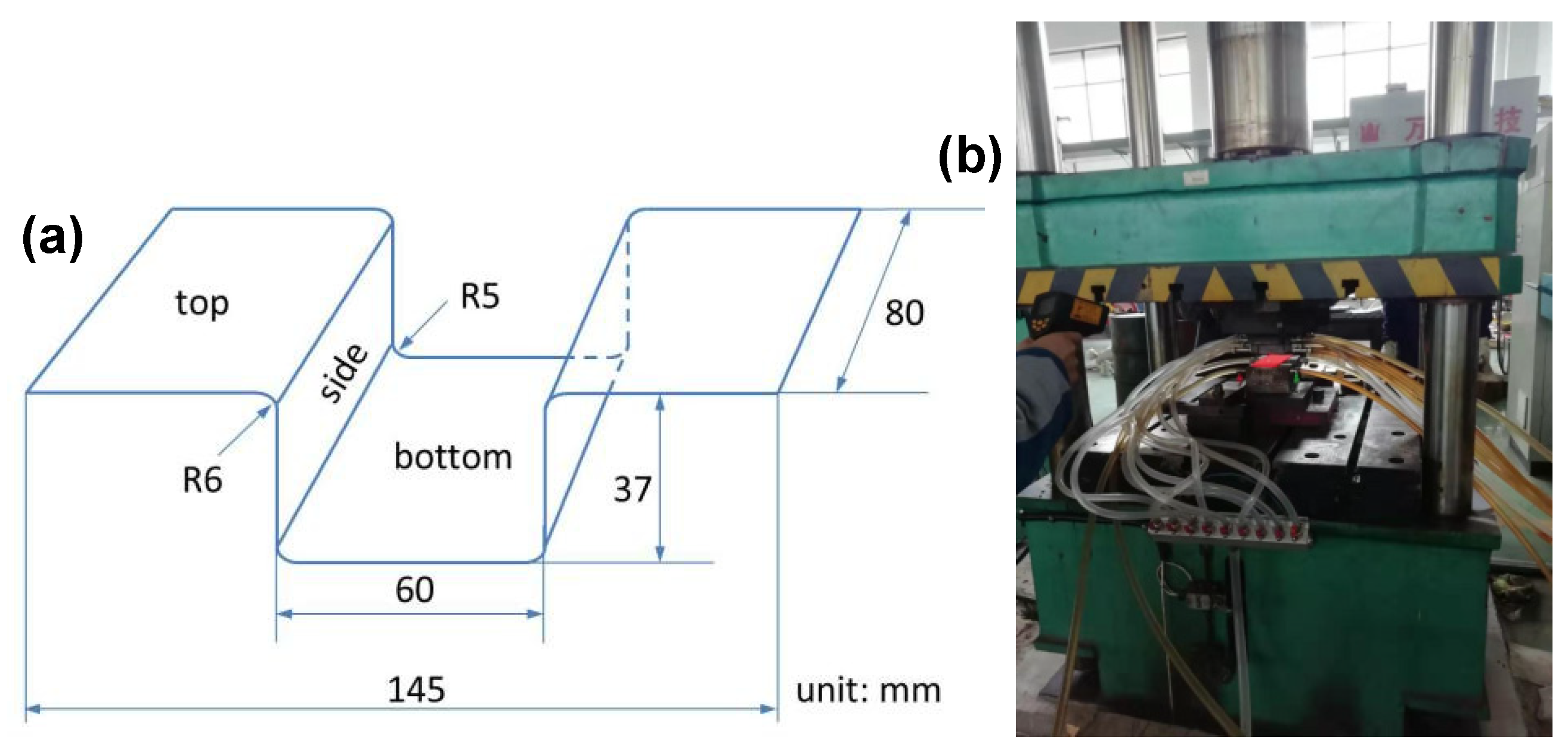

2. Materials and Methods

3. Results and Discussion

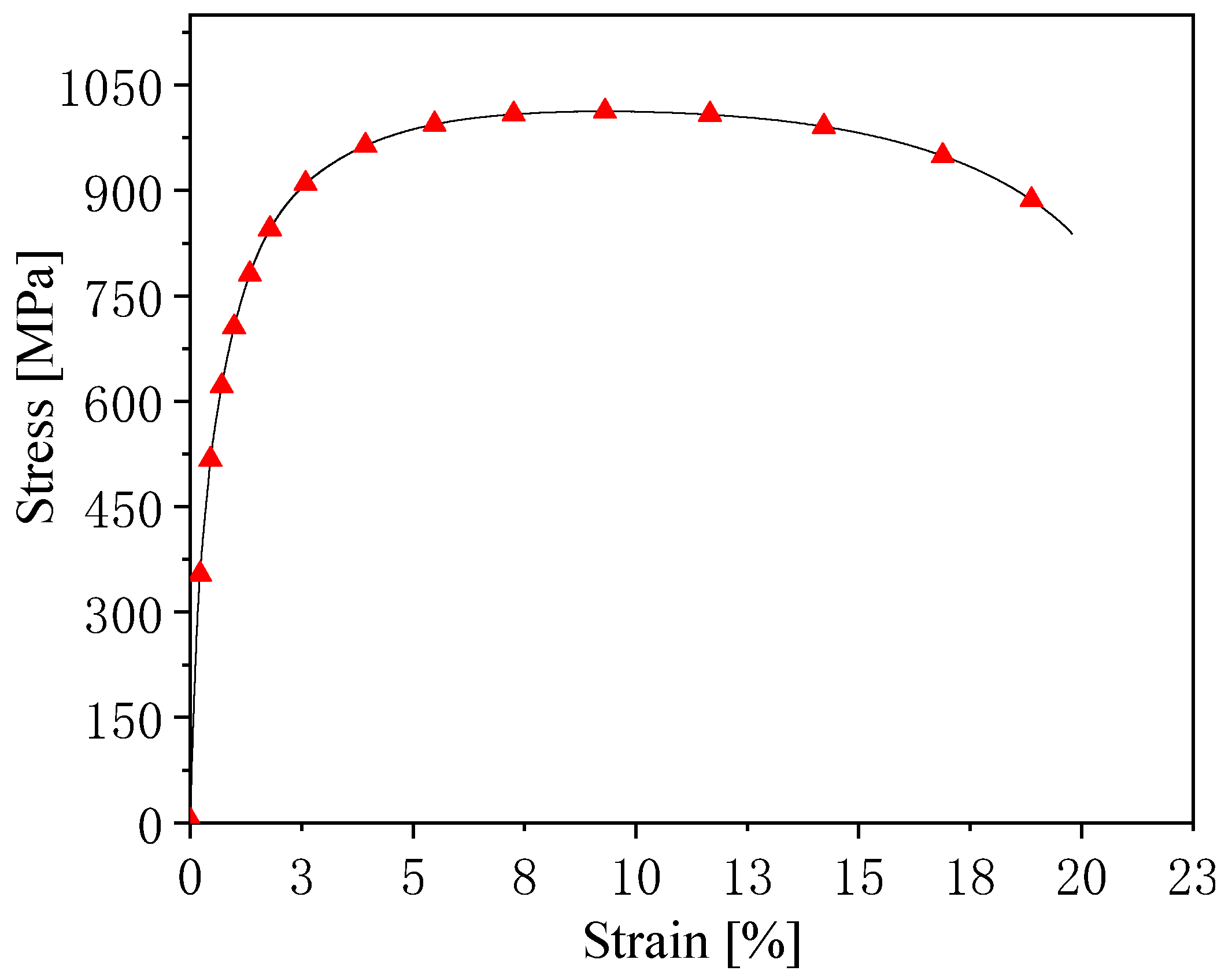

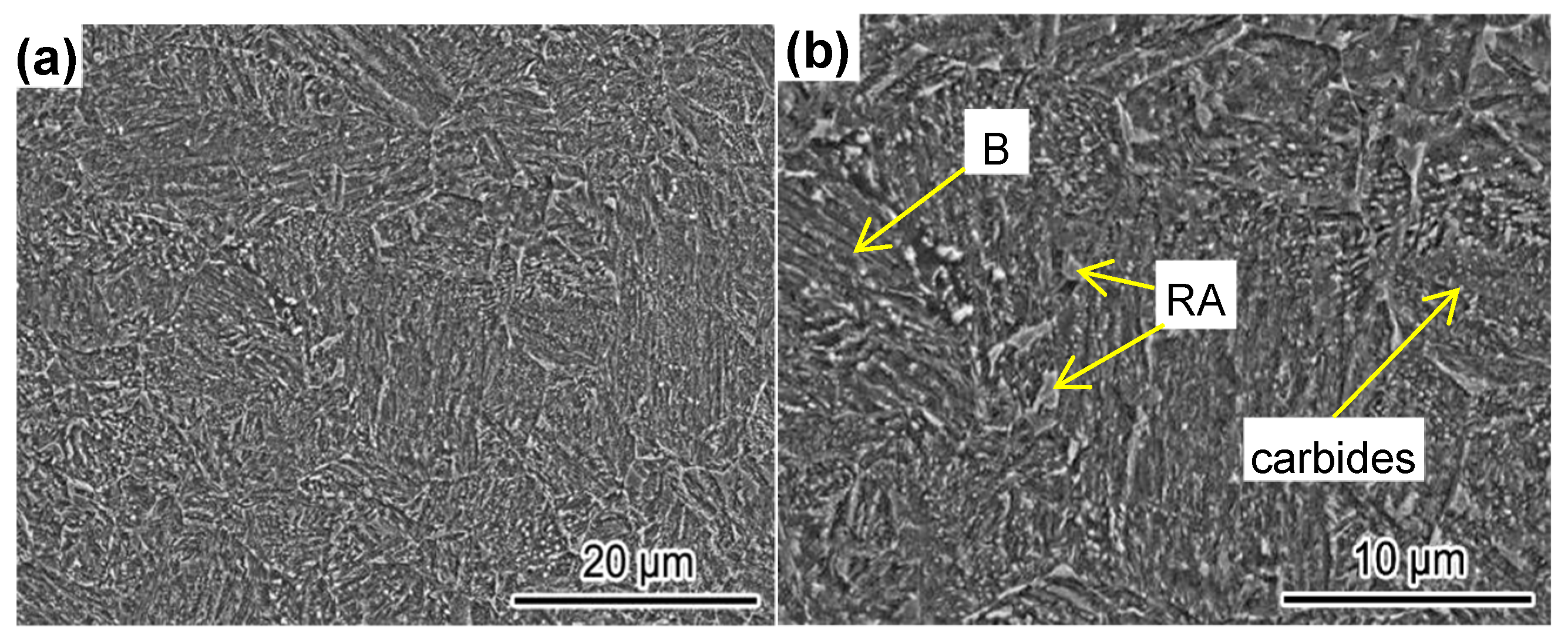

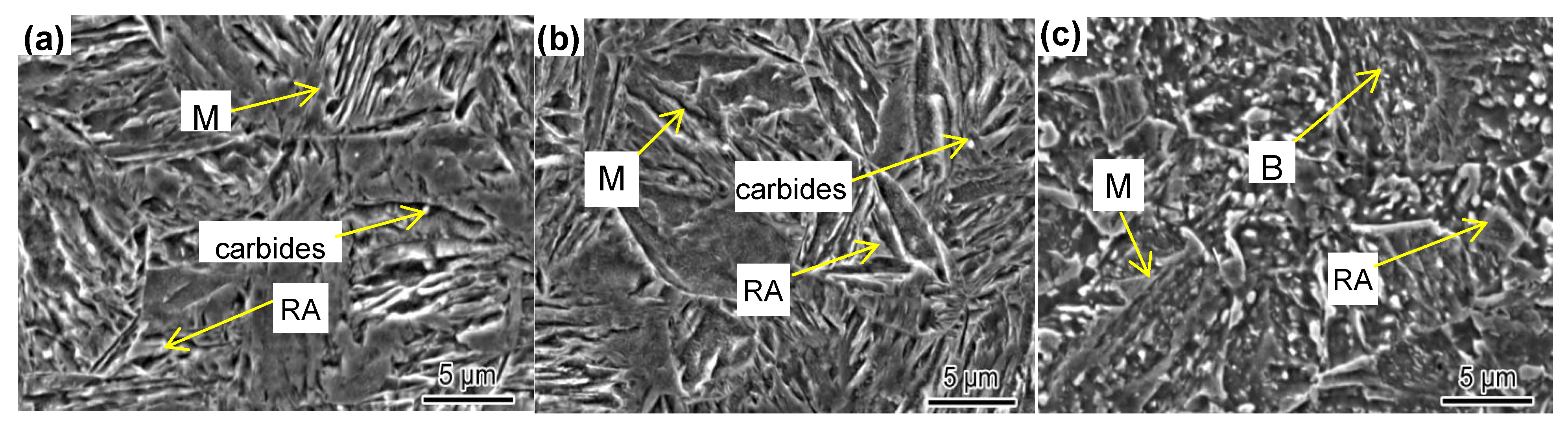

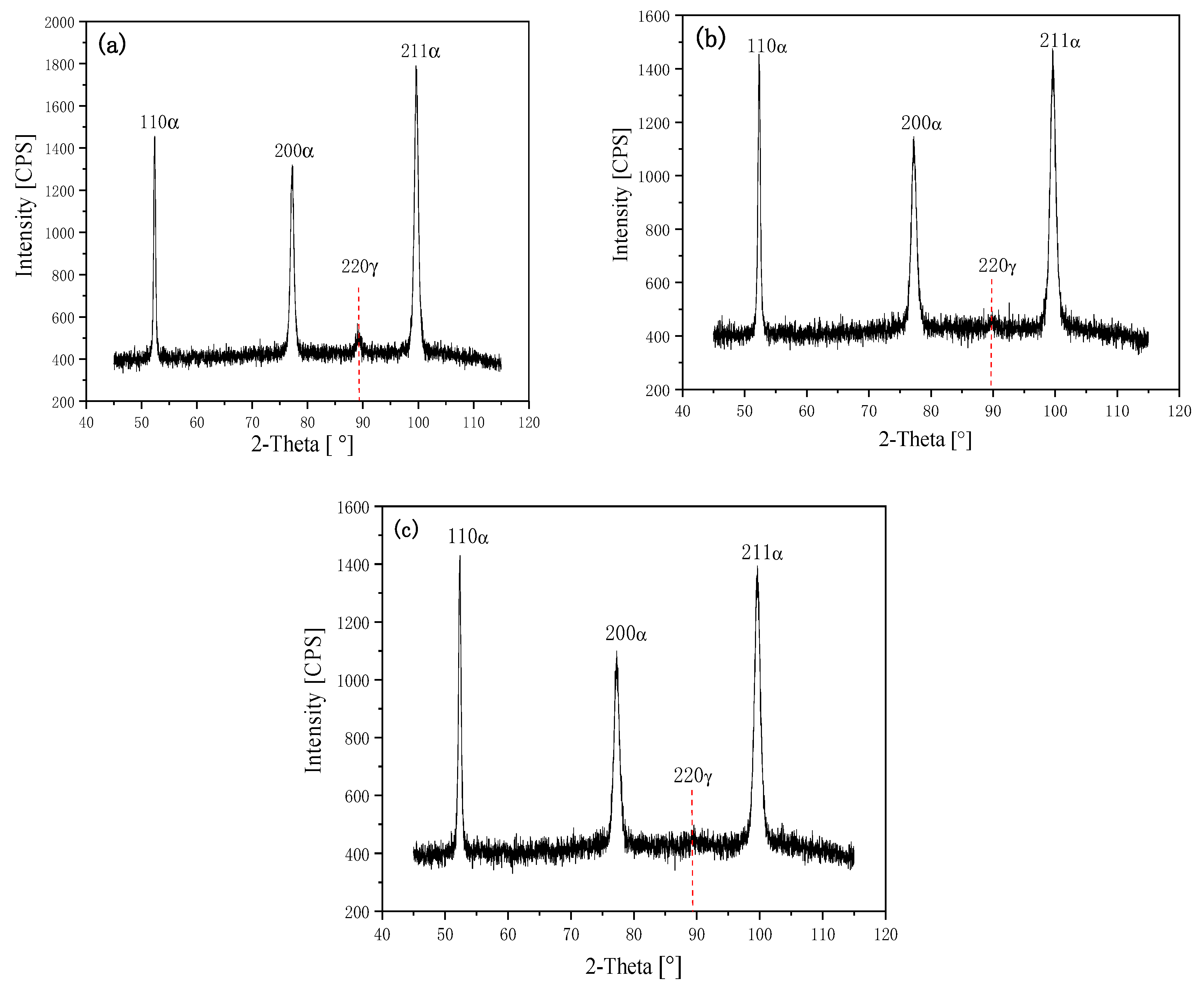

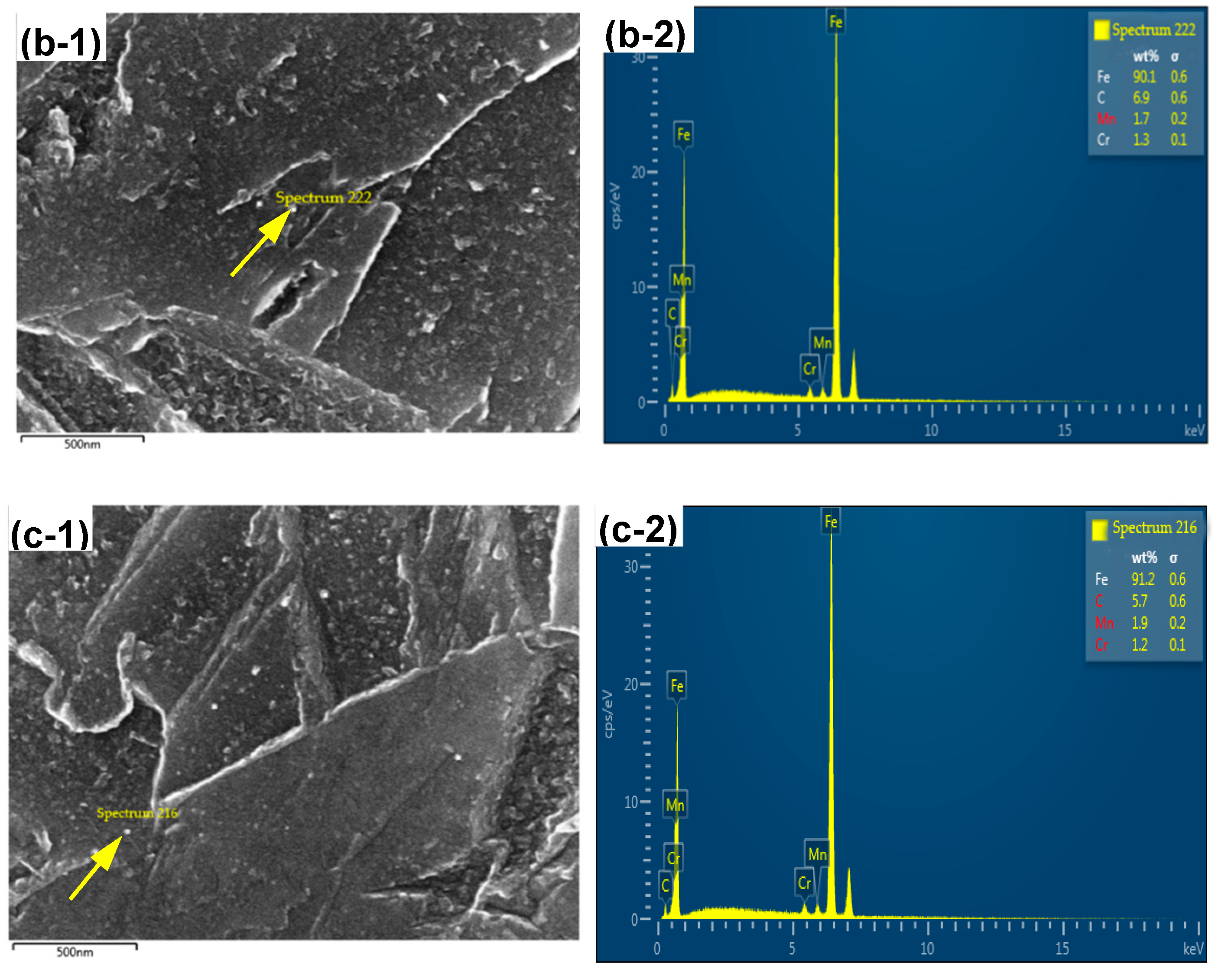

3.1. Microstructure and Properties of Cold-Rolled Sheets after Continuous Annealing

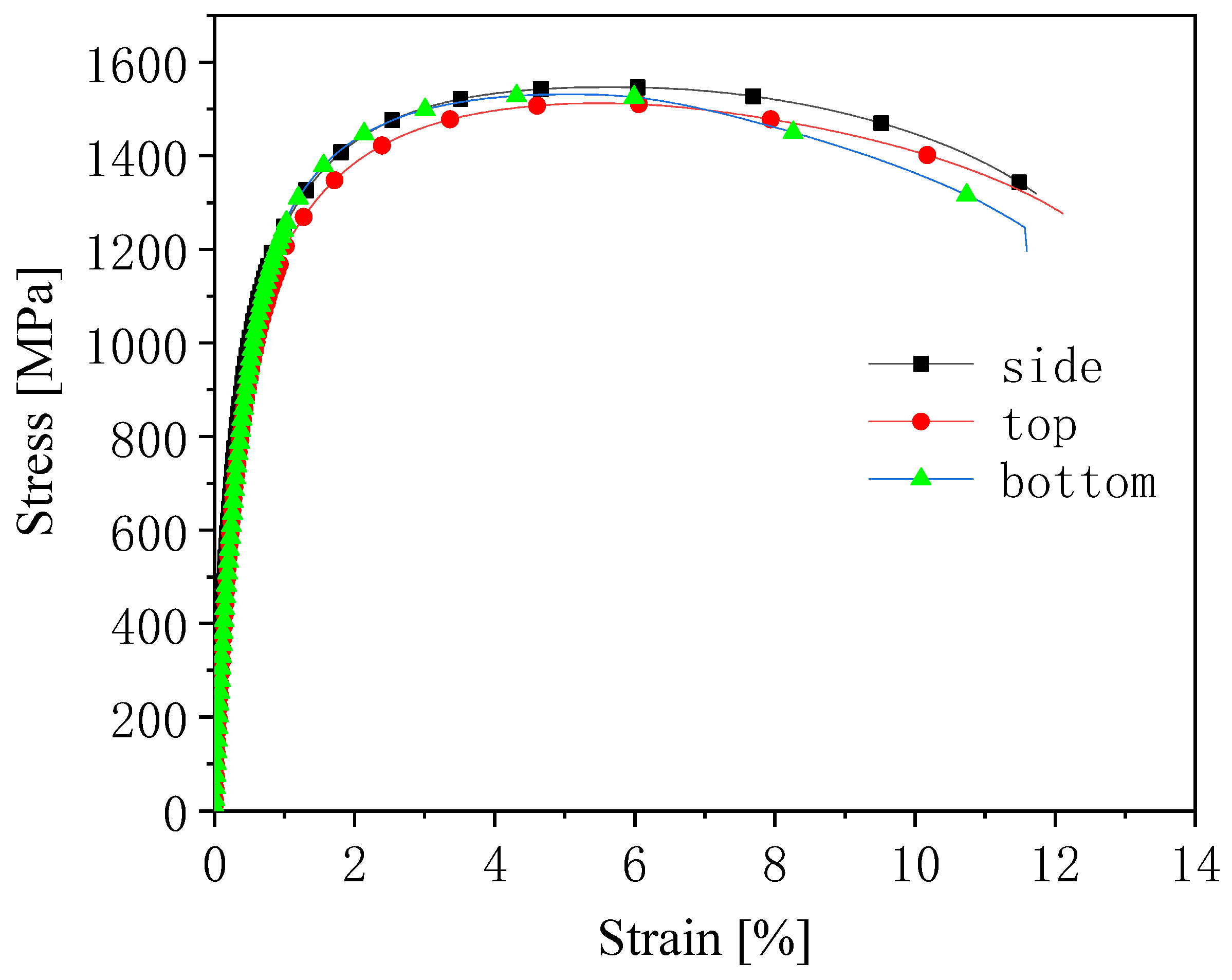

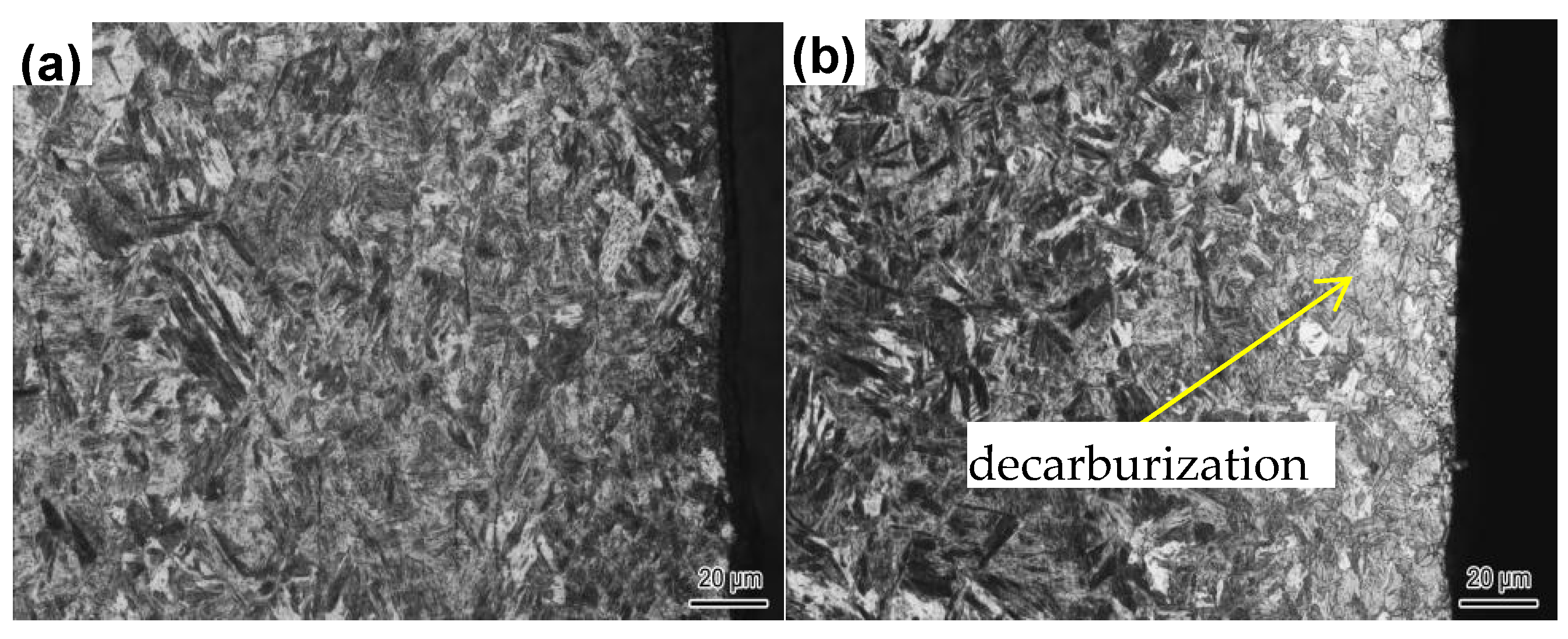

3.2. Microstructure and Properties of Hot-Formed Parts

4. Conclusions

- (1)

- A high product of strength and elongation was obtained for the automotive steels designed, allowing for both cold forming and hot forming using a multiphase, multidimensional reinforced plasticization concept. The products of strength and elongation for cold-formed and hot-formed steel were 20 and 18 GPa·% respectively, while the tensile strengths were more than 1000 and 1500 MPa, respectively.

- (2)

- The good mechanical properties, with regard to cold and hot forming, of this new automotive steel were due to an optimized alloy design. With the proposed methodology, a multiphase, grain-refined, and multidimensional microstructure of bainite, martensite, and nanosecond phase particles could be obtained under simple production process conditions.

- (3)

- This new automotive steel is characterized by its low-alloy design, simple production process, and good oxidation resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kang, Y.L.; Zhu, G.M. Development trend of china’s automobile industry and the opportunities and challenges of steels for automobiles. Iron Steel 2014, 12, 1–7. [Google Scholar]

- Choudhary, S.K.; Ghosh, A. Mathematical model for prediction of composition of inclusions formed during solidification of liquid steel. ISIJ Int. 2009, 49, 1819–1827. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.Y.; Zhang, M.D.; Xu, H.F.; Dong, H.; Cao, W.Q. Research and application of high performance automobile steel. Iron Steel 2016, 51, 511–519. [Google Scholar]

- Kang, Y.L. Current status, demand and development tendency of automobile steel plate abroad. China Metall. 2003, 6, 18–23. [Google Scholar]

- Wang, C.Y.; Yang, J.; Chang, Y.; Cao, W.Q.; Dong, H. Development trend and challenge of advanced high strength automobile steels. Iron Steel 2019, 54, 1–6. [Google Scholar]

- Li, G.J.; Liu, X.L. Literature review on research and development of automotive lightweight technology. Mater. Sci. Technol. 2020, 28, 47–61. [Google Scholar]

- Ohjoon, K.; Lee, K.Y.; Kim, G.S.; Chin, K.G. New trends in advanced high strength steel developments for automotive application. Mater. Sci. Forum 2010, 884, 136–141. [Google Scholar]

- Dong, H.; Cao, W.Q.; Shi, J.; Wang, C.Y.; Wang, M.Q.; Weng, Y.Q. Microstructure and performance control technology of the 3rd generation auto sheet steels. Iron Steel 2011, 46, 1–11. [Google Scholar]

- Liu, A.M.; Feng, Y.; Zhao, Y.; Ma, M.T.; Lu, H.Z. Effect of Niobium and Vanadium Micro-alloying on Microstructure and Property of 22MnB5 Hot Press Forming Steel. Mater. Mechancial Eng. 2019, 43, 34–37. [Google Scholar]

- Chen, Y. Study of High Strength Auto-Steel Sheets and Stamping Parts Based on Lightweight Evaluation. Ph.D. Thesis, Central Iron and Steel Research Institute, Beijing, China, 2017. [Google Scholar]

- Liang, J.T. Strengthen-toughening Mechanism and Application Technology of 2000MPa Grade Hot Stamping Steel. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2019. [Google Scholar]

- Liu, J.; Zhu, G.H.; Mao, W.; Subramanian, S.V. Modeling of critical grain size for shifting plasticity enhancement to decrease by refining grain size. Mater. Sci. Eng. A 2014, 607, 302–306. [Google Scholar] [CrossRef]

- Wang, M.M.; Zhang, X.Y.; Xiao, Y.R.; Xu, L.B.; Hou, S.X.; Li, Y.G. One of the key research progress of steels with high product of strength and elongation for automobiles: Research progress of Q&P steel. Trans. Mater. Heat Treat. 2019, 40, 11–19. [Google Scholar]

- Zhang, Z.Q.; Huang, W.; Gao, Z.F. Progress on research and development of 3rd generation of advanced high-strength steel for car. Spec. Steel 2013, 34, 16–21. [Google Scholar]

- Han, H.N.; Oh, C.S.; Kim, G.; Kwon, O. Design method for TRIP aided multiphase steel based on a microstructure-based modelling for transformation-induced plasticity and mechanically induced martensitic transformation. Mater. Sci. Eng. A. 2009, 499, 462–468. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; de Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 512, 611–622. [Google Scholar] [CrossRef]

- Liu, T.; Zhu, Z.Q. Research status of medium manganese steel for the 3rd gernation automobile sheet. Ordnance Mater. Sci. Eng. 2019, 42, 102–108. [Google Scholar]

- Diao, K.S.; Jiang, H.M.; Chen, X.P. Research and typical application of QP980 steel produced by BaoSteel based on formability. Forg. Stamp. Technol. 2012, 37, 113–115, 121. [Google Scholar]

- Zhu, G.H.; Ding, H.L.; Wang, X.N.; Wang, Y.Q.; Chen, Q.W. Research and Development of the Third Generation Steels for Automobile with Ultra-High Strength and Product of Strength and Elongation Based on Strength and Plasticity Enhancement by Multi-Dimensions Mechanisms. Mater. China 2018, 37, 826–836. [Google Scholar]

- Li, H.Z.; Wu, X.; Li, G.Y. Prediction of forming limit diagrams for 22MnB5 in hot stamping process. J. Mater. Sci. Eng. Perform. 2013, 222, 131–140. [Google Scholar] [CrossRef]

- Guo, R. Research on Some Basic Properties of 22MnB5 Hot-Formed Steel for Automotive Applications and its Applications. Master’s Thesis, Dalian University of Technology, Dalian, China, 2012. [Google Scholar]

- Xu, F.Y.; Hu, S.B.; Chen, Y. Quenching and partitioning process of hot stamping steel 22MnB5. J. Mater. Sci. Eng. 2013, 31, 365–371. [Google Scholar]

- Naderi, M.; Durrenberger, L.; Molinari, A.; Bleck, W. Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperatures. Mater. Sci. Eng. A 2008, 478, 130–139. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, S.; Hong, J.; Li, J. Development research on 22MnB5 hot stamping steel. Forg. Stamp. Technol. 2014, 39, 1–5, 10. [Google Scholar]

- Cheng, J.Y.; Zhao, A.M.; Chen, Y.L.; Jin, H.L.; Gao, X.T.; Li, Z. Effect of low-temperature inter critical annealing time on microstructure and properties of 22MnB5 steel. Mater. Sci. Technol. 2012, 4, 38–44, 48. [Google Scholar]

- Huang, F.; Chen, J.; Zhang, Q.G.; Li, J.L.; Wang, Y.Q. Effect of Heat Treatment on Microstructure and Mechanical Properties of New Cold-Rolled Automotive Steels. Metals 2020, 10, 1414. [Google Scholar] [CrossRef]

- Ding, H.L.; Zhu, G.H.; Xiang, C.C.; Pei, F.J.; Chen, J.; Wang, Y.Q.; Chen, Q.W. Excellent combination of plasticity and ultra-high strength in a low-alloy automotive steel treated by conventional continuous annealing. Mater. Sci. Eng. A 2020, 791, 139694. [Google Scholar] [CrossRef]

- Jiang, C.; Shan, Z.D.; Zhuang, B.L.; Rong, W.J.; Zhang, M. Microstructure and properties of hot stamping 22MnB5 steel. Trans. Mater. Heat Treat. 2012, 33, 78–81. [Google Scholar]

| Specimen | C | Mn | Cr | Nb | Si | Ti | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 20Mn2Cr | 0.21 | 1.69 | 1.30 | 0.009 | 0.04 | 0.002 | 0.005 | 0.007 | Balance |

| Specimen | Rm [MPa] | Rp0.2 [MPa] | A [%] | Rm × A [GPa·%] |

|---|---|---|---|---|

| 20Mn2Cr | 1013 | 726 | 20.0 | 20.3 |

| Specimen | Position | Rm [MPa] | Rp0.2 [MPa] | A [%] | Rm × A [GPa·%] |

|---|---|---|---|---|---|

| 20Mn2Cr | Top | 1513 | 1190 | 12.0 | 18.2 |

| Side | 1547 | 1285 | 11.5 | 17.8 | |

| Bottom | 1532 | 1280 | 11.5 | 17.6 |

| Position | RA (XRD)/% | Grain Size (EBSD)/μm |

|---|---|---|

| Top | 4.26 | 3.08 |

| Side | 2.18 | 2.95 |

| Bottom | 1.61 | 3.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, F.; Chen, Q.; Ding, H.; Wang, Y.; Mou, X.; Chen, J. Automotive Steel with a High Product of Strength and Elongation used for Cold and Hot Forming Simultaneously. Materials 2021, 14, 1121. https://doi.org/10.3390/ma14051121

Huang F, Chen Q, Ding H, Wang Y, Mou X, Chen J. Automotive Steel with a High Product of Strength and Elongation used for Cold and Hot Forming Simultaneously. Materials. 2021; 14(5):1121. https://doi.org/10.3390/ma14051121

Chicago/Turabian StyleHuang, Fei, Qiwei Chen, Hanlin Ding, Yongqiang Wang, Xiuting Mou, and Jian Chen. 2021. "Automotive Steel with a High Product of Strength and Elongation used for Cold and Hot Forming Simultaneously" Materials 14, no. 5: 1121. https://doi.org/10.3390/ma14051121

APA StyleHuang, F., Chen, Q., Ding, H., Wang, Y., Mou, X., & Chen, J. (2021). Automotive Steel with a High Product of Strength and Elongation used for Cold and Hot Forming Simultaneously. Materials, 14(5), 1121. https://doi.org/10.3390/ma14051121