Optimum Placement of Heating Tubes in a Multi-Tube Latent Heat Thermal Energy Storage

Abstract

:1. Introduction

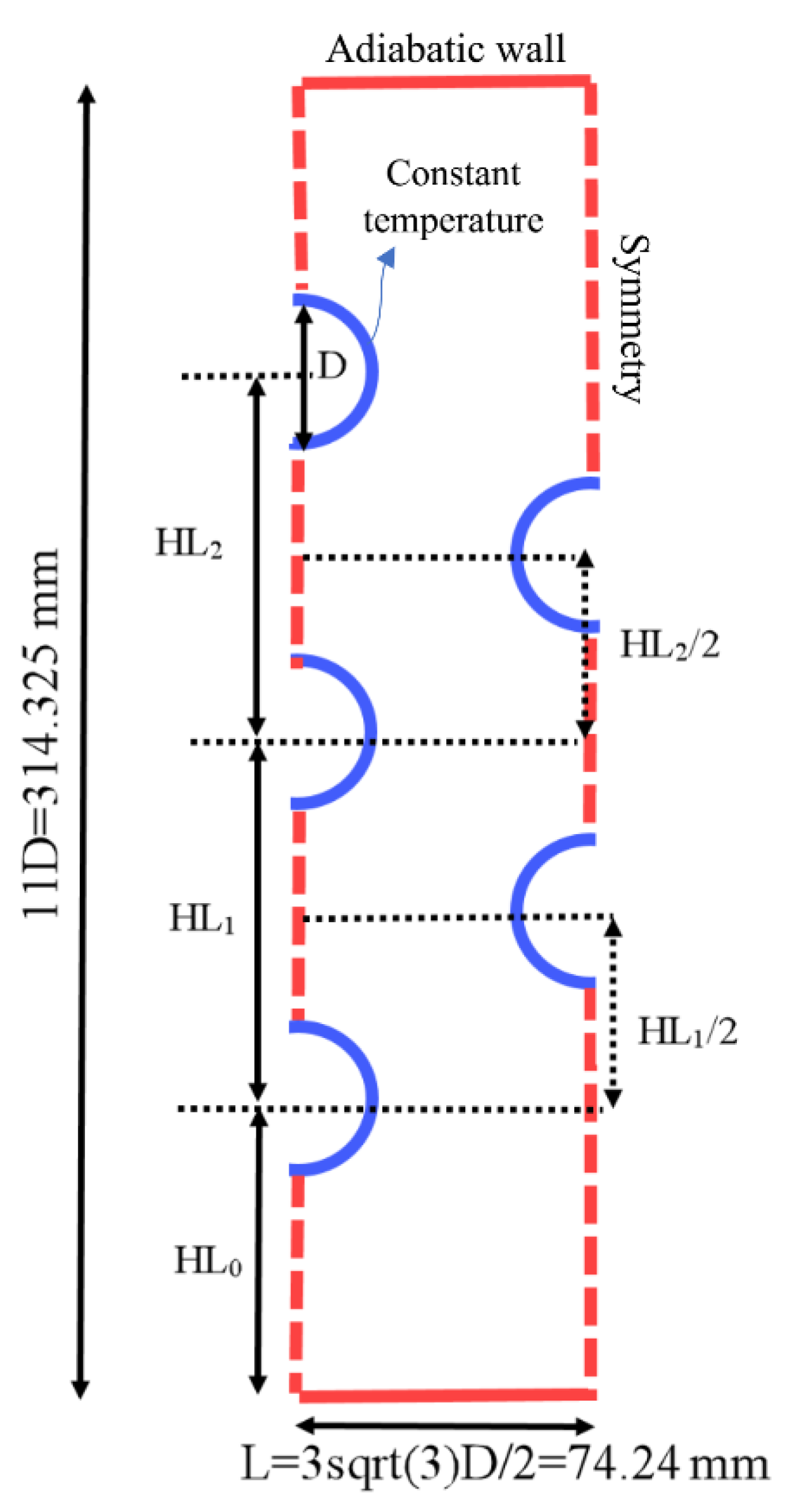

2. Model and Governing Equations

3. Numerical Method, Mesh Study, and Validation

3.1. Numerical Method

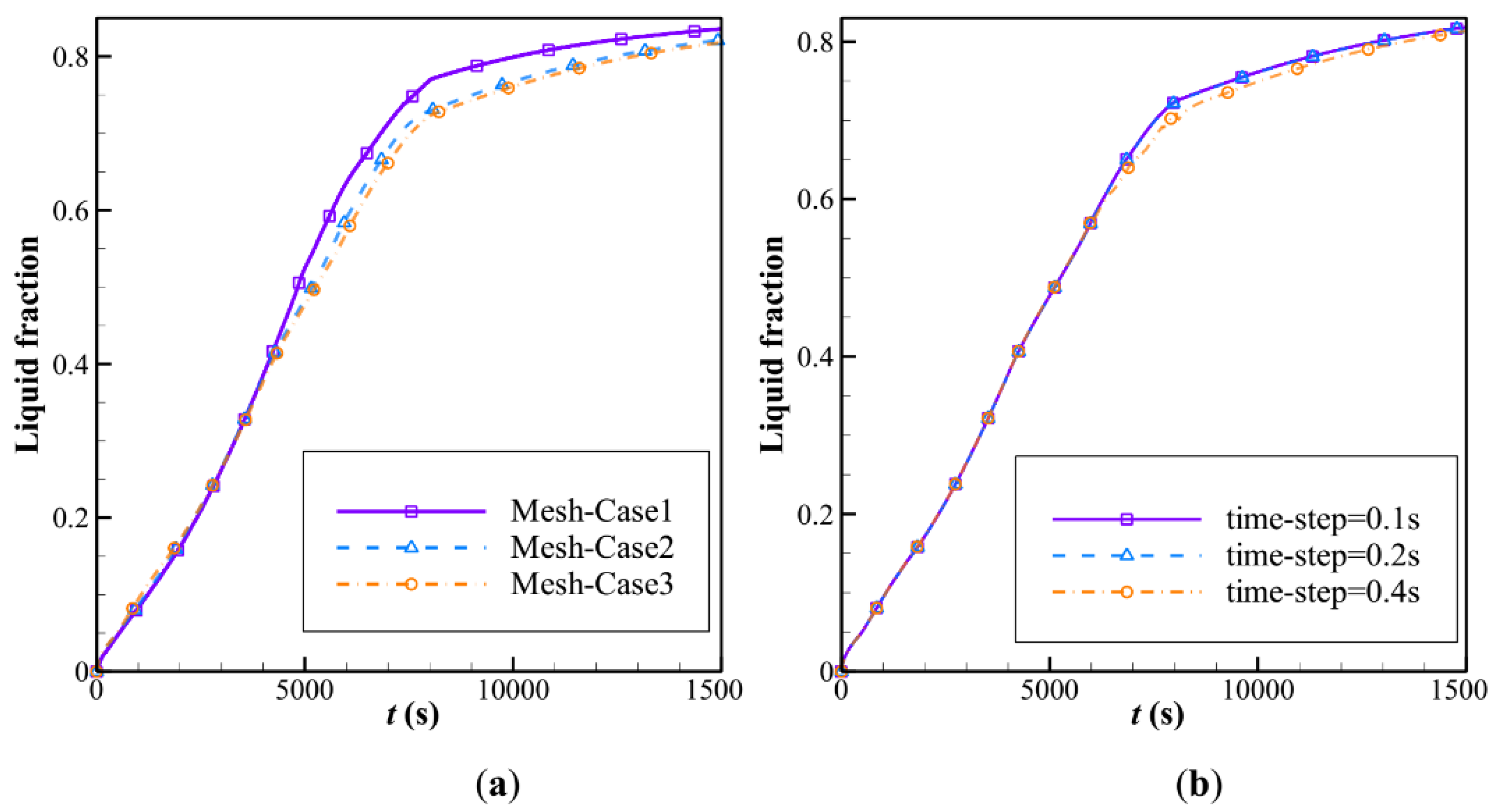

3.2. Mesh and Time-Step Size Study

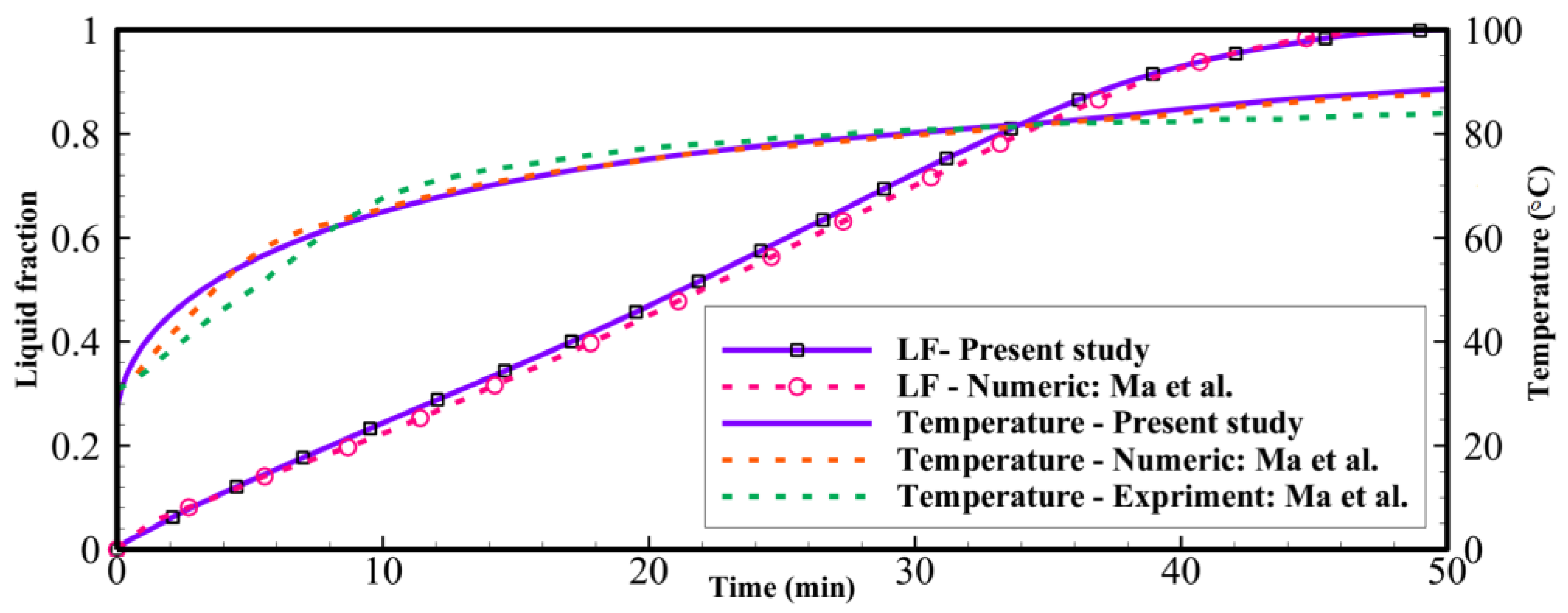

3.3. Validation

4. Results and Discussion

5. Conclusions

- Based on the Taguchi design, the first row of the HTF tubes should be placed at the lowest possible point while the other tubes should be distributed evenly in the enclosure.

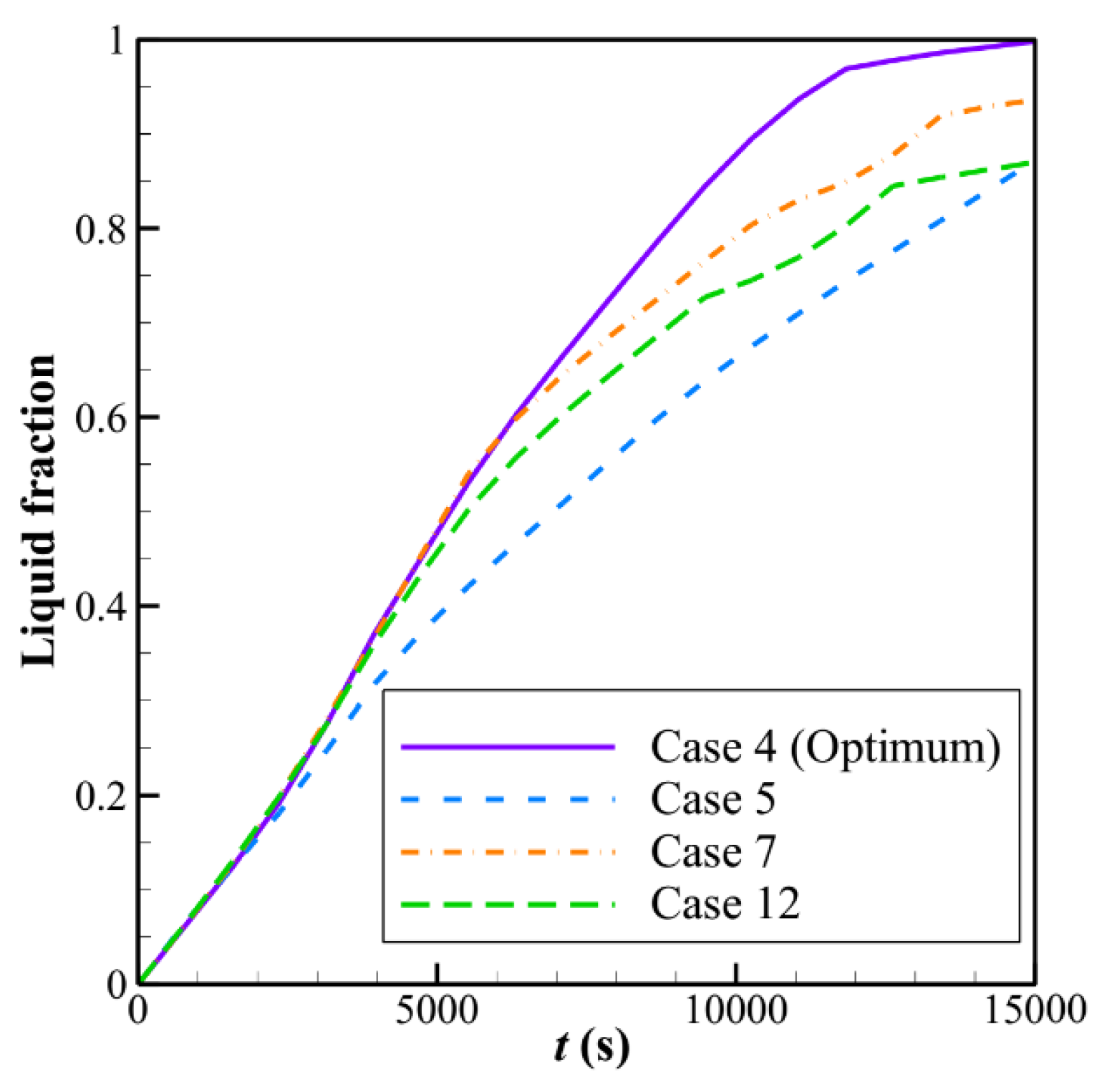

- The charging time of the LHTES unit could be changed by about 76% by just changing the location of tubes in the enclosure.

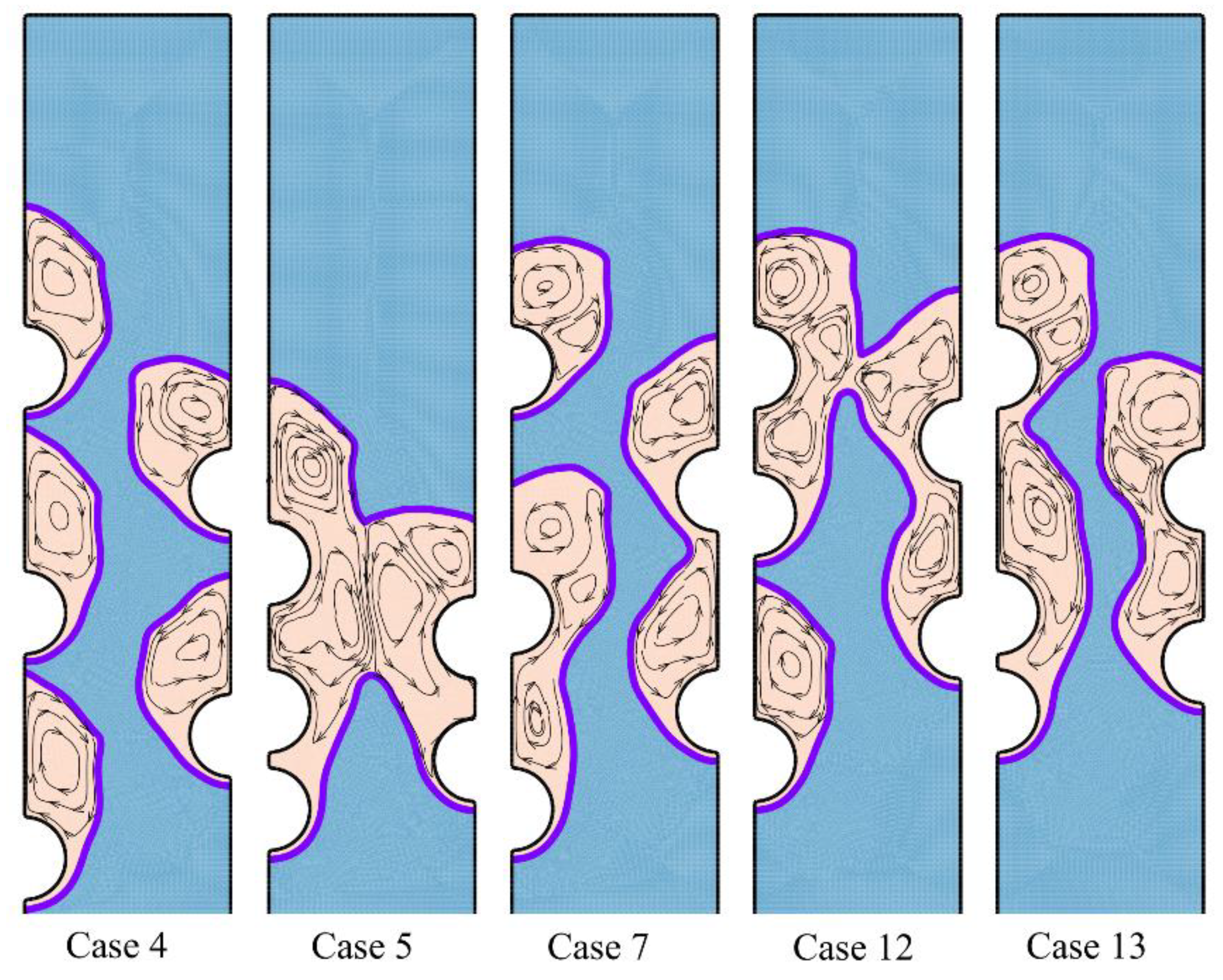

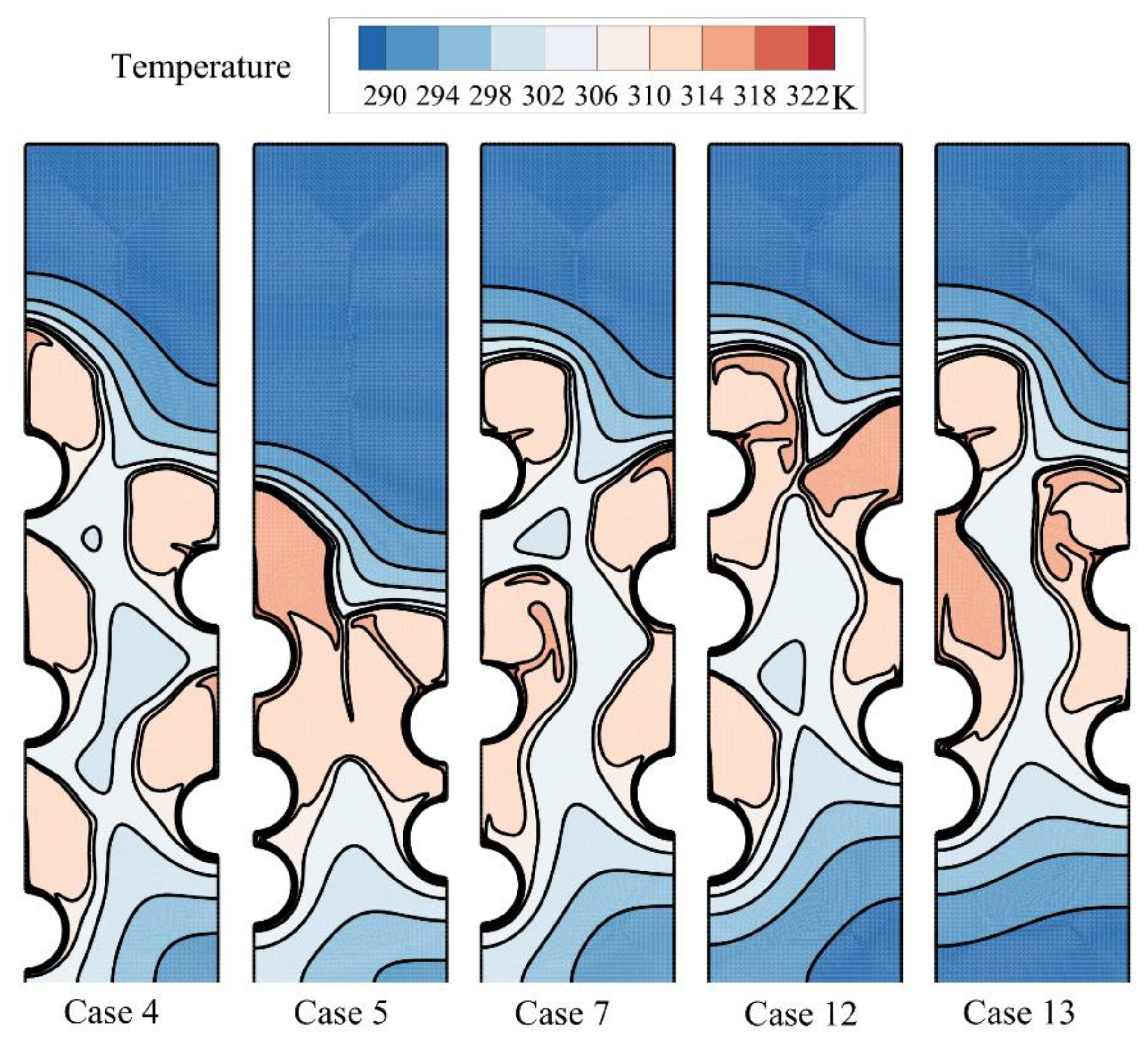

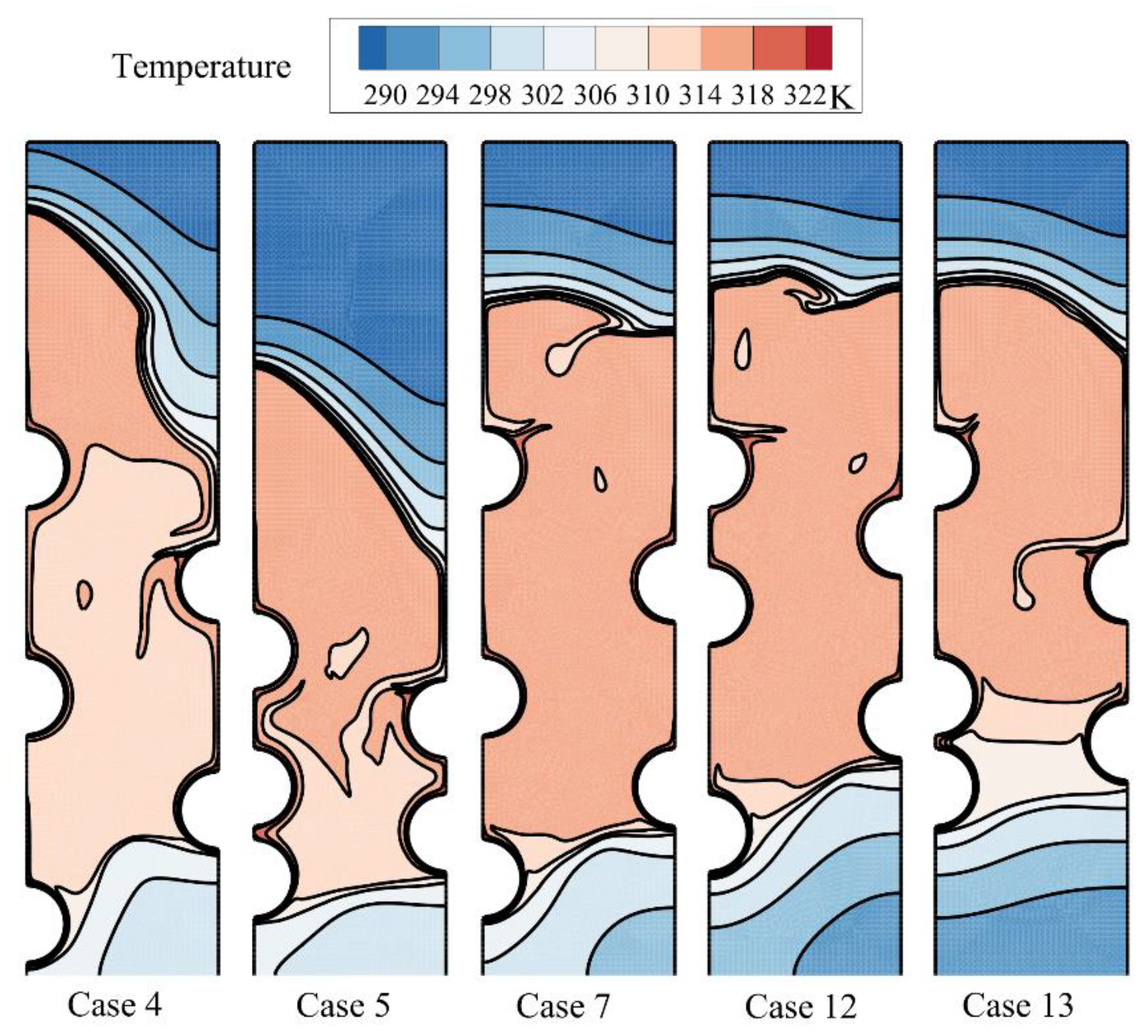

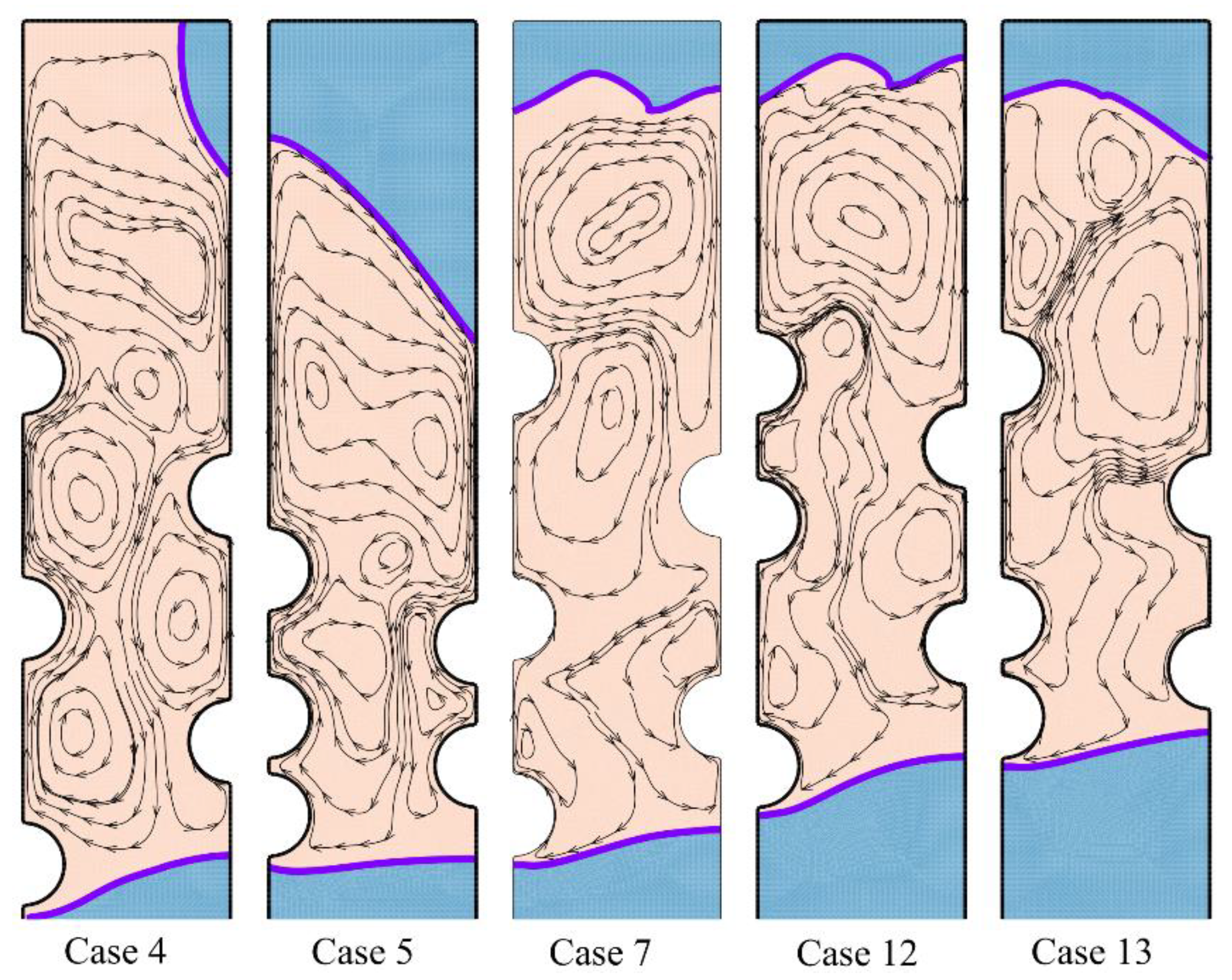

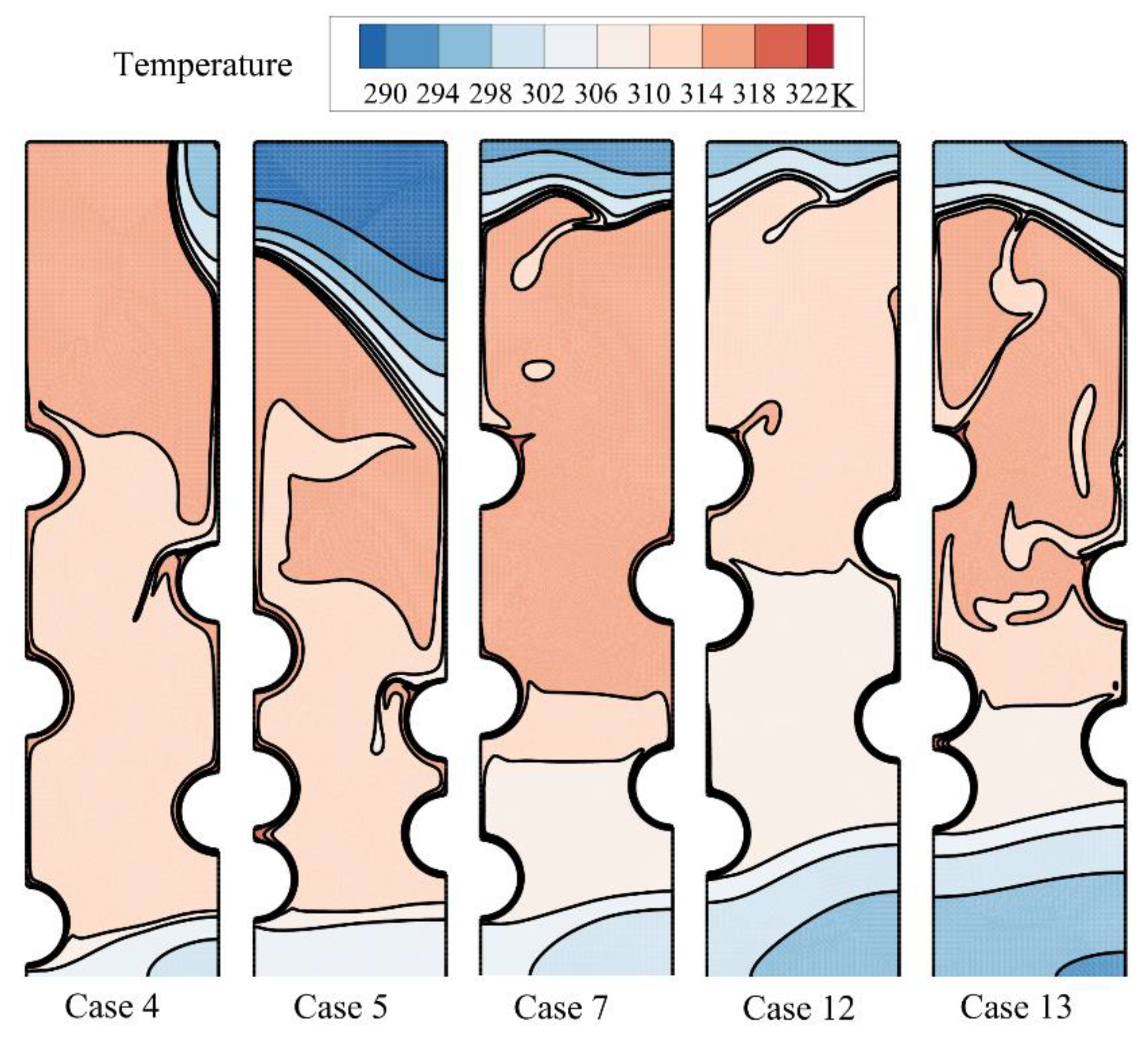

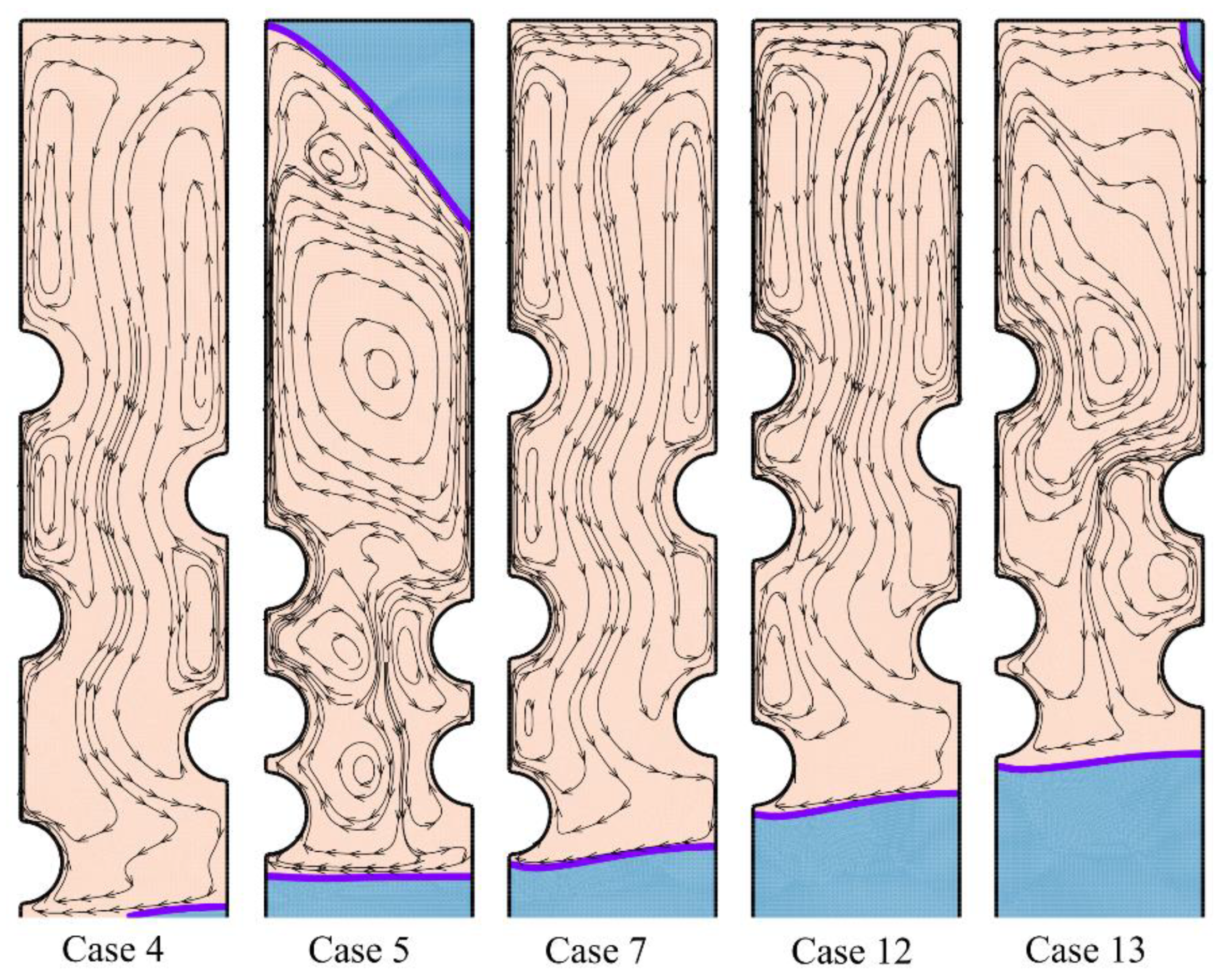

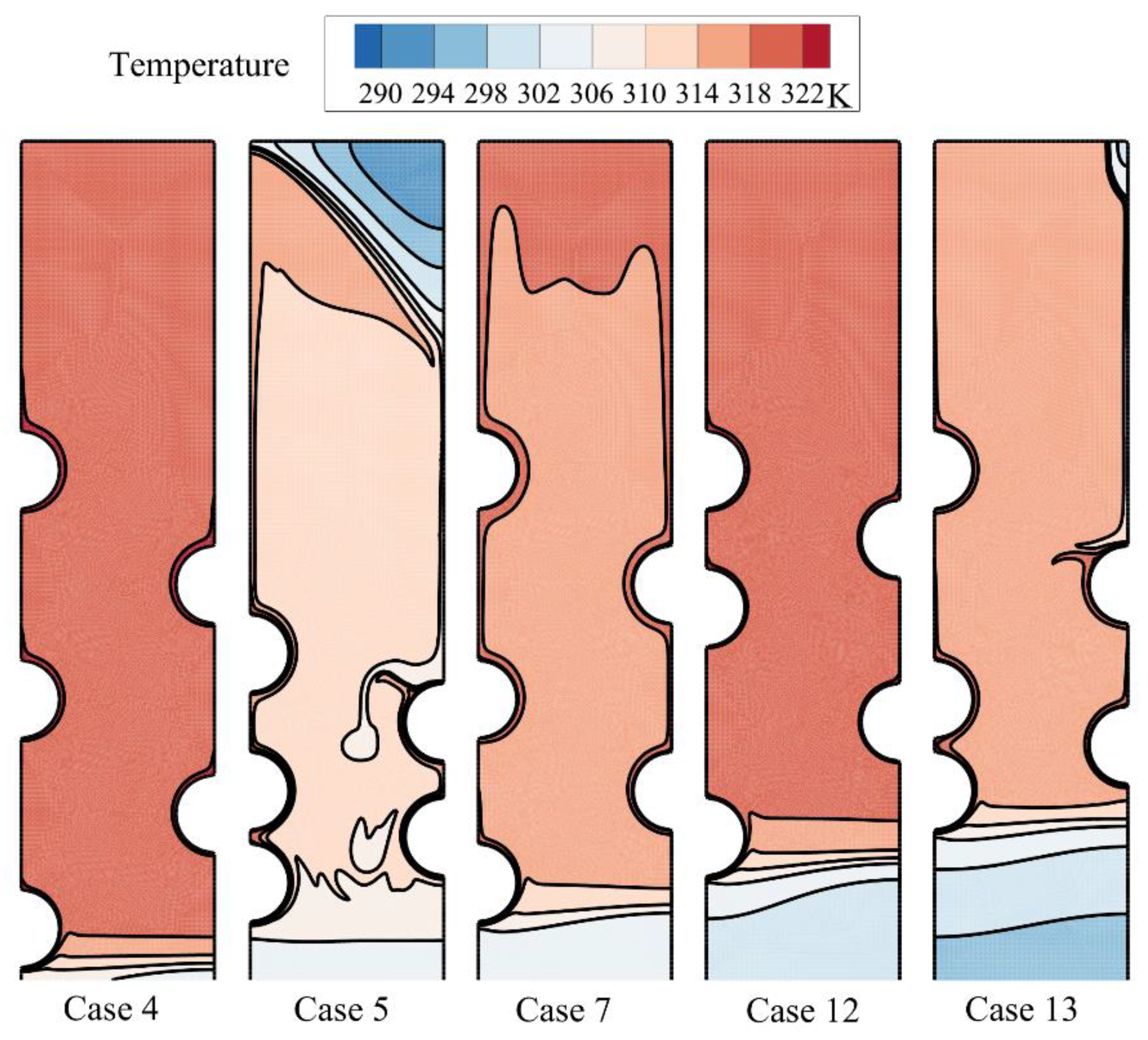

- From the streamlines and melting interfaces, it can be concluded that the formation of streamlines and free-convection flow circulation in each step of the melting process are the key points in the design of LHTES. Special attention should be paid to the streamline at the final stages of the charging process. A general uniform large circulation flow in the enclosure was much better than several small and week circulation flows.

- The Taguchi method could be used to effectively propose the optimum design of an LHTES unit with few simulations. Thus, this approach seems useful in the future design of energy storage systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Am (kg m−3 s−1) | mushy zone constant | tm (s) | melting/solidification time |

| Cp (J kg−1 K−1) | specific heat | T (K) | temperature |

| g (ms−2) | gravity | Te (K) | mean temperature after the phase change process |

| k (W m−1 K−1) | thermal conductivity | Ti (K) | initial temperature |

| Lf (J kg−1) | latent heat of fusion | ||

| LF | the normal total amount of melted phase change mateial | ||

| m (kg) | mass | Greek symbols | |

| P (Pa) | pressure | β (K−1) | expansion coefficient |

| Q (J) | thermal storage/recovery capacity | λ | local liquid fraction |

| (W) | thermal storage/recovery rate | μ (kg m−1 s−1) | dynamic Viscosity |

| TL (K) | liquidus temperature | ρ (kg m−3) | density |

| Ts (K) | solidus temperature | ΔH (J kg−1) | latent heat of fusion |

| (m s−1) | velocity | ||

References

- Dinker, A.; Agarwal, M.; Agarwal, G. Heat storage materials, geometry and applications: A review. J. Energy Inst. 2017, 90, 1–11. [Google Scholar] [CrossRef]

- Dhaidan, N.S.; Khodadadi, J. Melting and convection of phase change materials in different shape containers: A review. Renew. Sustain. Energy Rev. 2015, 43, 449–477. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Liu, Y.; Gao, Q.; Wang, G.; Yan, Z.; Shen, M. Experimental research on thermal characteristics of PCM thermal energy storage units. J. Energy Inst. 2020, 93, 76–86. [Google Scholar] [CrossRef]

- Farah, S.; Liu, M.; Saman, W. Numerical investigation of phase change material thermal storage for space cooling. Appl. Energy 2019, 239, 526–535. [Google Scholar] [CrossRef]

- Shahsavar, A.; Goodarzi, A.; Mohammed, H.I.; Shirneshan, A.; Talebizadehsardari, P. Thermal performance evaluation of non-uniform fin array in a finned double-pipe latent heat storage system. Energy 2020, 193, 116800. [Google Scholar] [CrossRef]

- Memon, Z.Q.; Pao, W.; Hashim, F.M.; Ali, H.M. Experimental investigation of two-phase separation in T-Junction with combined diameter ratio. J. Nat. Gas. Sci. Eng. 2020, 73, 103048. [Google Scholar] [CrossRef]

- Ali, H.M. Recent advancements in PV cooling and efficiency enhancement integrating phase change materials based systems–A comprehensive review. Sol. Energy 2020, 197, 163–198. [Google Scholar] [CrossRef]

- Sajawal, M.; Rehman, T.-u.; Ali, H.M.; Sajjad, U.; Raza, A.; Bhatti, M.S. Experimental thermal performance analysis of finned tube-phase change material based double pass solar air heater. Case Stud. Therm. Eng. 2019, 15, 100543. [Google Scholar] [CrossRef]

- Sardari, P.T.; Grant, D.; Giddings, D.; Walker, G.S.; Gillott, M. Composite metal foam/PCM energy store design for dwelling space air heating. Energy Convers. Manag. 2019, 201, 112151. [Google Scholar] [CrossRef]

- Singh, R.P.; Kaushik, S.; Rakshit, D. Melting phenomenon in a finned thermal storage system with graphene nano-plates for medium temperature applications. Energy Convers. Manag. 2018, 163, 86–99. [Google Scholar] [CrossRef]

- Hassan, A.; Wahab, A.; Qasim, M.A.; Janjua, M.M.; Ali, M.A.; Ali, H.M.; Jadoon, T.R.; Ali, E.; Raza, A.; Javaid, N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew. Energy 2020, 145, 282–293. [Google Scholar] [CrossRef]

- Sadeghi, H.M.; Babayan, M.; Chamkha, A. Investigation of using multi-layer PCMs in the tubular heat exchanger with periodic heat transfer boundary condition. Int. J. Heat Mass Transf. 2020, 147, 118970. [Google Scholar] [CrossRef]

- Ren, H.; Lin, W.; Ma, Z.; Fan, W.; Wang, X. Thermal performance evaluation of an integrated photovoltaic thermal-phase change material system using Taguchi method. Energy Procedia 2017, 121, 118–125. [Google Scholar] [CrossRef]

- Mosaffa, A.; Talati, F.; Tabrizi, H.B.; Rosen, M. Analytical modeling of PCM solidification in a shell and tube finned thermal storage for air conditioning systems. Energy Build. 2012, 49, 356–361. [Google Scholar] [CrossRef]

- Niu, X.; Xiao, F.; Ma, Z. Investigation on capacity matching in liquid desiccant and heat pump hybrid air-conditioning systems. Int. J. Refrig. 2012, 35, 160–170. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S. Energy efficient hybrid nanocomposite-based cool thermal storage air conditioning system for sustainable buildings. Energy 2013, 59, 194–214. [Google Scholar] [CrossRef]

- Rastogi, M.; Chauhan, A.; Vaish, R.; Kishan, A. Selection and performance assessment of Phase Change Materials for heating, ventilation and air-conditioning applications. Energy Convers. Manag. 2015, 89, 260–269. [Google Scholar] [CrossRef]

- Redhwan, A.; Azmi, W.; Najafi, G.; Sharif, M.; Zawawi, N. Application of response surface methodology in optimization of automotive air-conditioning performance operating with SiO 2/PAG nanolubricant. J. Therm. Anal. Calorim. 2019, 135, 1269–1283. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Lohrasbi, S.; Nsofor, E.C. Hybrid heat transfer enhancement for latent-heat thermal energy storage systems: A review. Int. J. Heat Mass Transf. 2019, 137, 630–649. [Google Scholar] [CrossRef]

- Yamaha, M.; Misaki, S. The evaluation of peak shaving by a thermal storage system using phase-change materials in air distribution systems. Hvac&R Res. 2006, 12, 861–869. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. Numerical analysis of a shell-and-tube latent heat storage unit with fins for air-conditioning application. Appl. Energy 2015, 138, 381–392. [Google Scholar] [CrossRef]

- Dolado, P.; Lazaro, A.; Marin, J.M.; Zalba, B. Characterization of melting and solidification in a real scale PCM-air heat exchanger: Numerical model and experimental validation. Energy Convers. Manag. 2011, 52, 1890–1907. [Google Scholar] [CrossRef]

- Waqas, A.; Kumar, S. Phase change material (PCM)-based solar air heating system for residential space heating in winter. Int. J. Green Energy 2013, 10, 402–426. [Google Scholar] [CrossRef]

- Diarce, G.; Campos-Celador, Á.; Sala, J.; García-Romero, A. A novel correlation for the direct determination of the discharging time of plate-based latent heat thermal energy storage systems. Appl. Therm. Eng. 2018, 129, 521–534. [Google Scholar] [CrossRef]

- Amin, N.A.M.; Belusko, M.; Bruno, F.; Liu, M. Optimising PCM thermal storage systems for maximum energy storage effectiveness. Sol. Energy 2012, 86, 2263–2272. [Google Scholar] [CrossRef]

- Saman, W.; Bruno, F.; Halawa, E. Thermal performance of PCM thermal storage unit for a roof integrated solar heating system. Sol. Energy 2005, 78, 341–349. [Google Scholar] [CrossRef]

- Wang, M.-H.; Huang, M.-L.; Zhan, Z.-Y.; Huang, C.-J. Application of the extension Taguchi method to optimal capability planning of a stand-alone power system. Energies 2016, 9, 174. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Mo, Y.; Li, J.; Chu, Y.; Liu, L.; Liao, S. Study on the energy charging process of a plate-type latent heat thermal energy storage unit and optimization using Taguchi method. Appl. Therm. Eng. 2020, 164, 114528. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Y.; Li, C.-Q.; Lin, Y.; Yang, W.; Zhang, G. Optimization of a new phase change material integrated photovoltaic/thermal panel with the active cooling technique using taguchi method. Energies 2019, 12, 1022. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.; Ma, Z.; Ren, H.; Gschwander, S.; Wang, S. Multi-objective optimisation of thermal energy storage using phase change materials for solar air systems. Renew. Energy 2019, 130, 1116–1129. [Google Scholar] [CrossRef]

- Harshita, B.; Reddy, K.D.; Venkataramaiah, P. Optimization of Parameters in Thermal Energy Storage System. Int. J. Appl. Eng. Res. 2018, 13, 15278–15283. [Google Scholar]

- Zalba, B.; Sánchez-valverde, B.; Marín, J.M. An experimental study of thermal energy storage with phase change materials by design of experiments. J. Appl. Stat. 2005, 32, 321–332. [Google Scholar] [CrossRef]

- GmbH, R.T. RT35 Data Sheet. Available online: https://www.rubitherm.eu/en/index.php/productcategory/organische-pcm-rt (accessed on 10 November 2020).

- Talebizadeh Sardari, P.; Walker, G.S.; Gillott, M.; Grant, D.; Giddings, D. Numerical modelling of phase change material melting process embedded in porous media: Effect of heat storage size. Proc. Inst. Mech. Eng. Part A J. Power Energy 2020, 243, 365–383. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Nsofor, E.C. Melting enhancement in triplex-tube latent heat energy storage system using nanoparticles-metal foam combination. Appl. Energy 2017, 191, 22–34. [Google Scholar] [CrossRef]

- Mat, S.; Al-Abidi, A.A.; Sopian, K.; Sulaiman, M.Y.; Mohammad, A.T. Enhance heat transfer for PCM melting in triplex tube with internal–external fins. Energy Convers. Manag. 2013, 74, 223–236. [Google Scholar] [CrossRef]

- Ye, W.-B.; Zhu, D.-S.; Wang, N. Numerical simulation on phase-change thermal storage/release in a plate-fin unit. Appl. Therm. Eng. 2011, 31, 3871–3884. [Google Scholar] [CrossRef]

- Assis, E.; Katsman, L.; Ziskind, G.; Letan, R. Numerical and experimental study of melting in a spherical shell. Int. J. Heat Mass Transf. 2007, 50, 1790–1804. [Google Scholar] [CrossRef]

- Al-Abidi, A.A.; Mat, S.; Sopian, K.; Sulaiman, M.Y.; Mohammad, A.T. Internal and external fin heat transfer enhancement technique for latent heat thermal energy storage in triplex tube heat exchangers. Appl. Therm. Eng. 2013, 53, 147–156. [Google Scholar] [CrossRef]

- Antony, J.; Antony, F.J. Teaching the Taguchi method to industrial engineers. Work Study 2001, 50, 141–149. [Google Scholar] [CrossRef]

| Property | ρ (kg m−3) | Lf (kJ kg−1) | Cp (kJ kg−1 K) | k (W m−1 K) | μ (N s m−2) | TL (°C) | TS (°C) | β (1 K−1) |

|---|---|---|---|---|---|---|---|---|

| Values | 815 | 170 | 2.0 | 0.2 | 0.023 | 35 | 29 | 0.0006 |

| Factors | Description | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|---|

| A | HL0/D (height of the first tube) | 1.2 | 1.8 | 2.4 | 3.0 |

| B | HL1/D (height of the second tube) | 1.2 | 1.8 | 2.4 | 3.0 |

| C | HL2/D (height of the fourth tube) | 1.2 | 1.8 | 2.4 | 3.0 |

| Experiment Number | Design Parameters | Time (s) for LF = 0.75 | Signal-to-Noise (S/N) Ratio | ||

|---|---|---|---|---|---|

| HL0/D | HL1/D | HL2/D | |||

| 1 | 1.2 | 1.2 | 1.2 | 13,633 | −82.6918 |

| 2 | 1.2 | 1.8 | 1.8 | 13,613 | −82.6791 |

| 3 | 1.2 | 2.4 | 2.4 | 9025 | −79.1089 |

| 4 | 1.2 | 3.0 | 3.0 | 8205 | −78.2816 |

| 5 | 1.8 | 1.2 | 1.8 | 11,977 | −81.5670 |

| 6 | 1.8 | 1.8 | 1.2 | 13,850 | −82.8290 |

| 7 | 1.8 | 2.4 | 3.0 | 9161 | −79.2389 |

| 8 | 1.8 | 3.0 | 2.4 | 9206 | −79.2814 |

| 9 | 2.4 | 1.2 | 2.4 | 14,742 | −83.3711 |

| 10 | 2.4 | 1.8 | 3.0 | 9374 | −79.4385 |

| 11 | 2.4 | 2.4 | 1.2 | 11,096 | −80.9033 |

| 12 | 2.4 | 3.0 | 1.8 | 10,332 | −80.2837 |

| 13 | 3.0 | 1.2 | 3.0 | 12,603 | −82.0095 |

| 14 | 3.0 | 1.8 | 2.4 | 10,710 | −80.5958 |

| 15 | 3.0 | 2.4 | 1.8 | 12,379 | −81.8537 |

| 16 | 3.0 | 3.0 | 1.2 | 10,104 | −80.0899 |

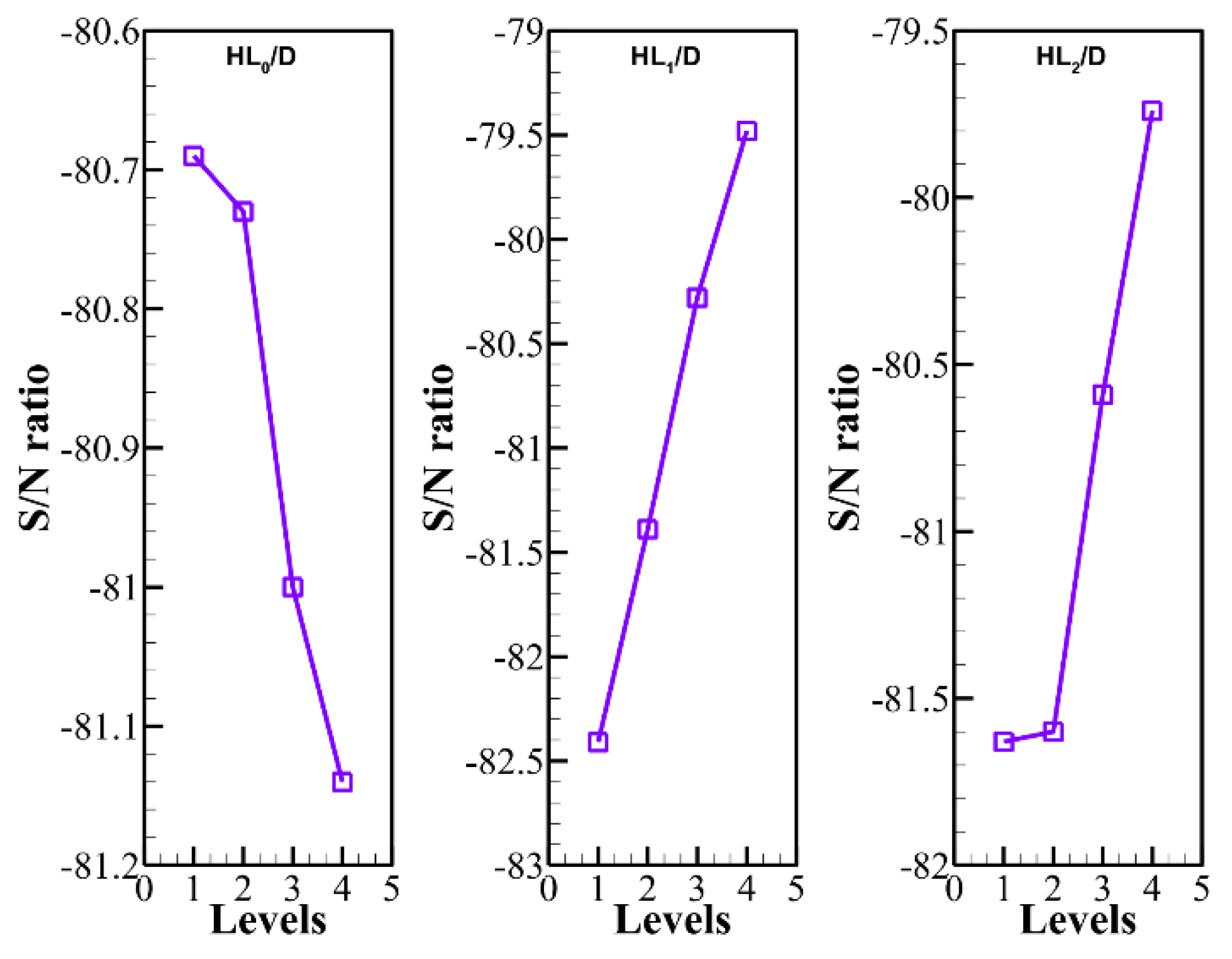

| Level | HL0/D | HL1/D | HL2/D |

|---|---|---|---|

| 1 | −80.69 | −82.41 | −81.63 |

| 2 | −80.73 | −81.39 | −81.60 |

| 3 | −81.00 | −80.28 | −80.59 |

| 4 | −81.14 | −79.48 | −79.74 |

| Delta | 0.45 | 2.93 | 1.89 |

| Rank | 3 | 1 | 2 |

| Optimum Factors | Charging Time of LF = 0.75 | |||

|---|---|---|---|---|

| HL0/D | HL1/D | HL2/D | Taguchi Prediction | Tested Case |

| 1.2 | 3.0 | 3.0 | 7915 | 8205 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghalambaz, M.; Mohammed, H.I.; Naghizadeh, A.; Islam, M.S.; Younis, O.; Mahdi, J.M.; Chatroudi, I.S.; Talebizadehsardari, P. Optimum Placement of Heating Tubes in a Multi-Tube Latent Heat Thermal Energy Storage. Materials 2021, 14, 1232. https://doi.org/10.3390/ma14051232

Ghalambaz M, Mohammed HI, Naghizadeh A, Islam MS, Younis O, Mahdi JM, Chatroudi IS, Talebizadehsardari P. Optimum Placement of Heating Tubes in a Multi-Tube Latent Heat Thermal Energy Storage. Materials. 2021; 14(5):1232. https://doi.org/10.3390/ma14051232

Chicago/Turabian StyleGhalambaz, Mohammad, Hayder I. Mohammed, Ali Naghizadeh, Mohammad S. Islam, Obai Younis, Jasim M. Mahdi, Ilia Shojaeinasab Chatroudi, and Pouyan Talebizadehsardari. 2021. "Optimum Placement of Heating Tubes in a Multi-Tube Latent Heat Thermal Energy Storage" Materials 14, no. 5: 1232. https://doi.org/10.3390/ma14051232

APA StyleGhalambaz, M., Mohammed, H. I., Naghizadeh, A., Islam, M. S., Younis, O., Mahdi, J. M., Chatroudi, I. S., & Talebizadehsardari, P. (2021). Optimum Placement of Heating Tubes in a Multi-Tube Latent Heat Thermal Energy Storage. Materials, 14(5), 1232. https://doi.org/10.3390/ma14051232