Influence of Pulse Current Forward-Reverse Duty Cycle on Structure and Performance of Electroplated W–Cu Composite Coatings

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Effect of Forward Duty Cycle on the Structure of W–Cu Composite Coatings

3.2. Effect of Reverse Duty Cycle on the Structure of W–Cu Composite Coatings

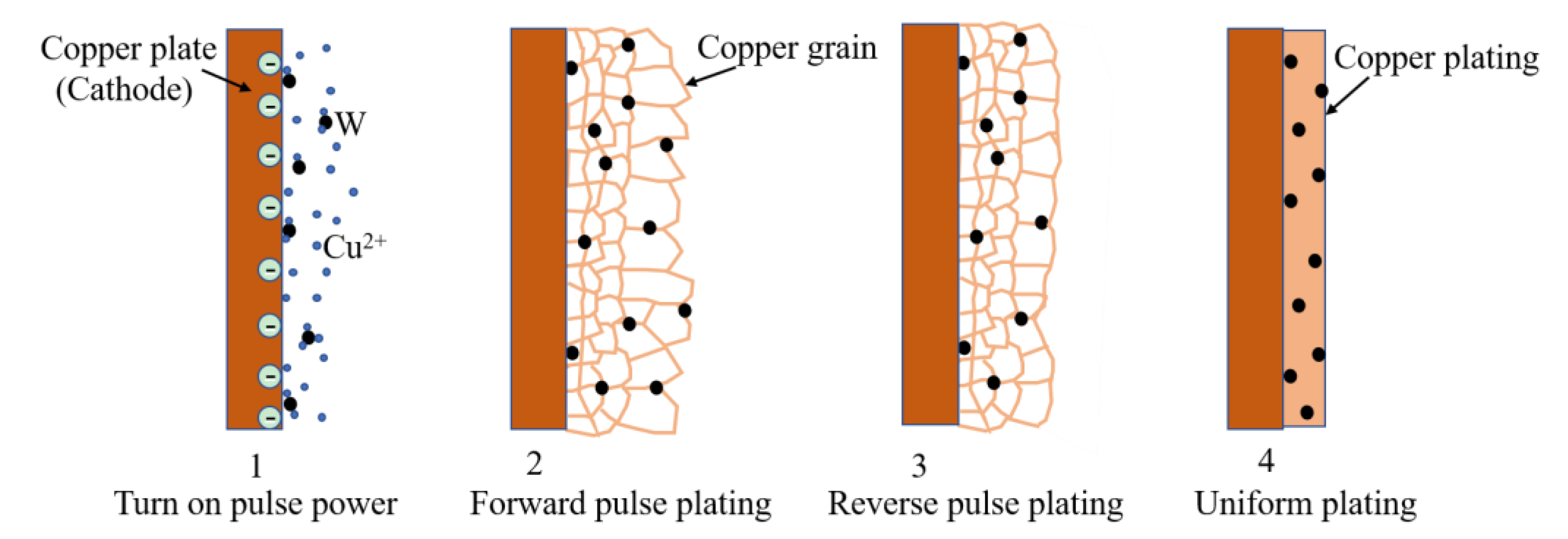

3.3. Densification Mechanism of Pulse Electroplated W–Cu Composites

3.4. Microhardness and Electrical Conductivity of W–Cu Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hou, C.; Song, X.; Tang, F.; Li, Y.; Cao, L.; Wang, J.; Nie, Z. W–Cu composites with submicron- and nanostructures: Progress and challenges. NPG Asia Mater. 2019, 11, 74. [Google Scholar] [CrossRef]

- Dong, L.L.; Ahangarkani, M.; Chen, W.G.; Zhang, Y.S. Recent progress in development of tungsten-copper composites: Fabrication, modification and applications. Int. J. Refract. Met. Hard Mater. 2018, 75, 30–42. [Google Scholar] [CrossRef]

- Chen, P.; Luo, G.; Li, M.; Shen, Q.; Zhang, L. Effects of Zn additions on the solid-state sintering of W–Cu composites. Mater. & Des. (1980–2015) 2012, 36, 108–112. [Google Scholar]

- Li, B.; Sun, Z.; Hou, G.; Hu, P.; Yuan, F. Fabrication of fine-grained W–Cu composites with high hardness. J. Alloy. Compd. 2018, 766, 204–214. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Luo, G.; Shen, Q.; Zhang, L. Densification and properties investigation of W–Cu composites prepared by electroless-plating and activated sintering. Int. J. Refract. Met. Hard Mater. 2018, 71, 255–261. [Google Scholar] [CrossRef]

- Chen, W.; Dong, L.; Wang, J.; Zuo, Y.; Ren, S.; Fu, Y. Synergistic enhancing effect for mechanical and electrical properties of tungsten copper composites using spark plasma infiltrating sintering of copper-coated graphene. Sci. Rep. 2017, 7, 17836. [Google Scholar] [CrossRef] [PubMed]

- Deng, N.; Zhou, Z.; Li, J.; Wu, Y. W–Cu composites with homogenous Cu-network structure prepared by spark plasma sintering using core-shell powders. Int. J. Refract. Met. Hard Mater. 2019, 82, 310–316. [Google Scholar] [CrossRef]

- Zhou, K.; Chen, W.G.; Wang, J.J.; Yan, G.J.; Fu, Y.Q. W–Cu composites reinforced by copper coated graphene prepared using infiltration sintering and spark plasma sintering: A comparative study. Int. J. Refract. Met. Hard Mater. 2019, 82, 91–99. [Google Scholar] [CrossRef]

- Alizadeh, M.; Safaei, H. Characterization of Ni–Cu matrix, Al2O3 reinforced nano-composite coatings prepared by electrodeposition. Appl. Surf. Sci. 2018, 456, 195–203. [Google Scholar] [CrossRef]

- Song, G.; Sun, L.; Li, S.; Sun, Y.; Fu, Q.; Pan, C. Synergistic effect of Gr and CNTs on preparing ultrathin Cu–(CNTs + Gr) composite foil via electrodeposition. Compos. Part B: Eng. 2020, 187, 107841. [Google Scholar] [CrossRef]

- Sun, H.; Deng, N.; Li, J.; He, G.; Li, J. Highly thermal-conductive graphite flake/Cu composites prepared by sintering intermittently electroplated core-shell powders. J. Mater. Sci. & Technol. 2021, 61, 93–99. [Google Scholar]

- Khorashadizade, F.; Saghafian, H.; Rastegari, S. Effect of electrodeposition parameters on the microstructure and properties of Cu–TiO2 nanocomposite coating. J. Alloy. Compd. 2019, 770, 98–107. [Google Scholar] [CrossRef]

- Xue, Z.; Lei, W.; Wang, Y.; Qian, H.; Li, Q. Effect of pulse duty cycle on mechanical properties and microstructure of nickel-graphene composite coating produced by pulse electrodeposition under supercritical carbon dioxide. Surf. Coat. Technol. 2017, 325, 417–428. [Google Scholar] [CrossRef]

- Vazquez-Arenas, J.; Treeratanaphitak, T.; Pritzker, M. Formation of Co–Ni alloy coatings under direct current, pulse current and pulse-reverse plating conditions. Electrochim. Acta 2012, 62, 63–72. [Google Scholar] [CrossRef]

- Thiemig, D.; Lange, R.; Bund, A. Influence of pulse plating parameters on the electrocodeposition of matrix metal nanocomposites. Electrochim. Acta 2007, 52, 7362–7371. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; He, T.; Fan, Y.; Yang, Q.; Zhan, Y. The influence of pulse plating parameters on microstructure and properties of Ni–W–Si3N4 nanocomposite coatings. Ceram. Int. 2016, 42, 18380–18392. [Google Scholar] [CrossRef]

- Marro, J.B.; Darroudi, T.; Okoro, C.A.; Obeng, Y.S.; Richardson, K.C. The Influence of Pulsed Electroplating Frequency and Duty Cycle on Copper Film Microstructure and Stress State. Thin solid films 2017, 621, 91–97. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Allahyarzadeh, M.H.; Aliofkhazraei, M.; Rouhaghdam, A.R.S.; Torabinejad, V. Structure and wettability of pulsed electrodeposited Ni–W–Cu–(α-alumina) nanocomposite. Surf. Coat. Technol. 2016, 307, 525–533. [Google Scholar] [CrossRef]

- Rezaei-Sameti, M.; Nadali, S.; Rajabi, J.; Rakhshi, M. The effects of pulse electrodeposition parameters on morphology, hardness and wear behavior of nano-structure Cr–WC composite coatings. J. Mol. Struct. 2012, 1020, 23–27. [Google Scholar] [CrossRef]

- Wei, X.; Tang, J.; Ye, N.; Zhuo, H. A novel preparation method for W–Cu composite powders. J. Alloy. Compd. 2016, 661, 471–475. [Google Scholar] [CrossRef]

- Pandey, R.N.; Srivastava, A.K.; Bapat, M.G. Behaviour of some copper(ii) salts in propylene carbonate: Standard electrode potential of the Cu2+/Cu system at 25 °C. J. Electroanal. Chem. Interfacial Electrochem. 1988, 245, 123–130. [Google Scholar] [CrossRef]

- Feng, Y.; McGuire, G.E.; Shenderova, O.A.; Ke, H.; Burkett, S.L. Fabrication of copper/carbon nanotube composite thin films by periodic pulse reverse electroplating using nanodiamond as a dispersing agent. Thin solid films 2016, 615, 116–121. [Google Scholar] [CrossRef]

- Kamnerdkhag, P.; Free, M.L.; Shah, A.A.; Rodchanarowan, A. The effects of duty cycles on pulsed current electrodeposition of Zn Ni Al2O3 composite on steel substrate: Microstructures, hardness and corrosion resistance. Int. J. Hydrog. Energy 2017, 42, 20783–20790. [Google Scholar] [CrossRef]

| Conditions | Parameters |

|---|---|

| Current density (J) | 2 A/dm2 |

| Frequency (f) | 1500 Hz |

| Forward pulse duty cycle (df) | 20–60% |

| Reverse pulse duty cycle (dr) | 5–15% |

| Temperature | 30 ℃ |

| Plating time | 2 h |

| Properties | Cu | W | W–Cu Composite (J = 2 A/dm2, f = 1500 Hz, df = 40%) | ||

|---|---|---|---|---|---|

| dr = 5% | dr = 10% | dr = 15% | |||

| Vickers hardness (HV) | 85 | 300–650 1 | 90 (SD 2 = 1.75) | 127 (SD = 0.84) | 103 (SD = 1.21) |

| Electrical conductivity (MS/m) | 57.1 | 17.7 | 48.0 (SD = 2.05) | 53.7 (SD = 0.75) | 56.5 (SD = 0.85) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Ye, N.; Zhuo, H.; Wei, C.; Zhou, W.; Mao, J.; Tang, J. Influence of Pulse Current Forward-Reverse Duty Cycle on Structure and Performance of Electroplated W–Cu Composite Coatings. Materials 2021, 14, 1233. https://doi.org/10.3390/ma14051233

Zhao Y, Ye N, Zhuo H, Wei C, Zhou W, Mao J, Tang J. Influence of Pulse Current Forward-Reverse Duty Cycle on Structure and Performance of Electroplated W–Cu Composite Coatings. Materials. 2021; 14(5):1233. https://doi.org/10.3390/ma14051233

Chicago/Turabian StyleZhao, Yuchao, Nan Ye, Haiou Zhuo, Chaolong Wei, Weiwei Zhou, Jie Mao, and Jiancheng Tang. 2021. "Influence of Pulse Current Forward-Reverse Duty Cycle on Structure and Performance of Electroplated W–Cu Composite Coatings" Materials 14, no. 5: 1233. https://doi.org/10.3390/ma14051233

APA StyleZhao, Y., Ye, N., Zhuo, H., Wei, C., Zhou, W., Mao, J., & Tang, J. (2021). Influence of Pulse Current Forward-Reverse Duty Cycle on Structure and Performance of Electroplated W–Cu Composite Coatings. Materials, 14(5), 1233. https://doi.org/10.3390/ma14051233