Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

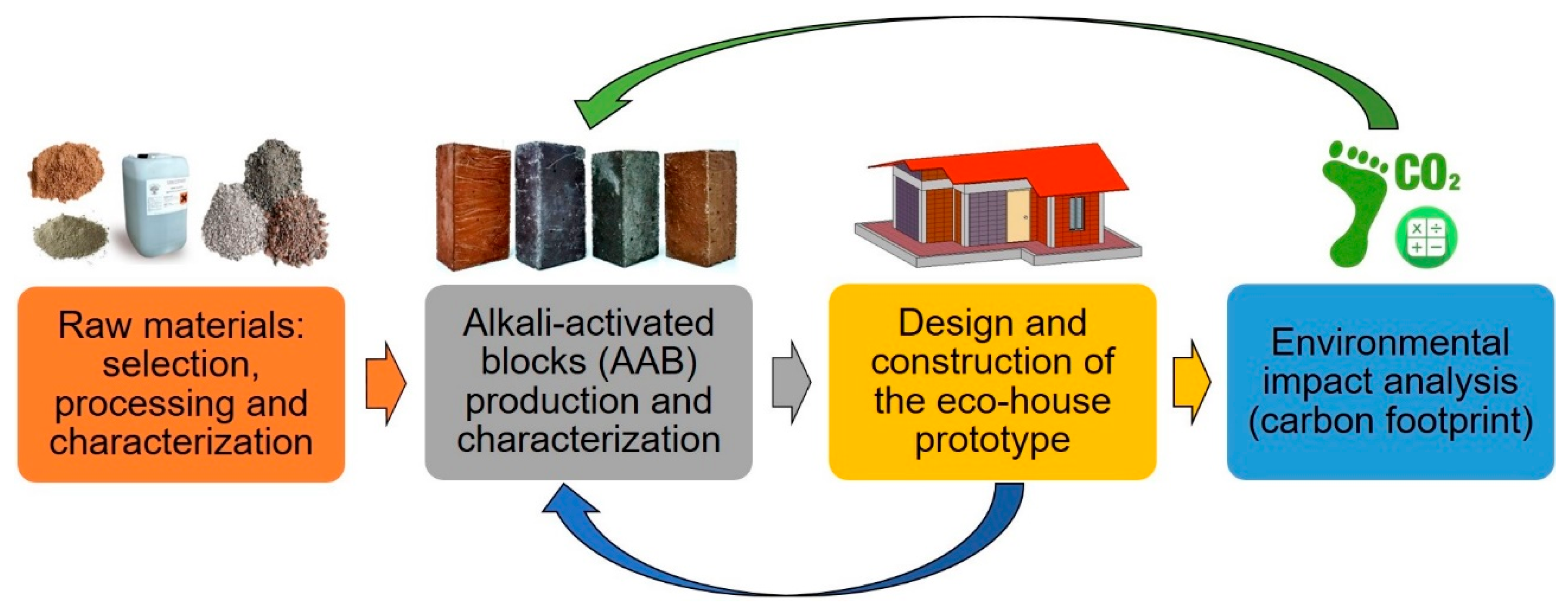

2.2. Methodology

3. Results and Analysis

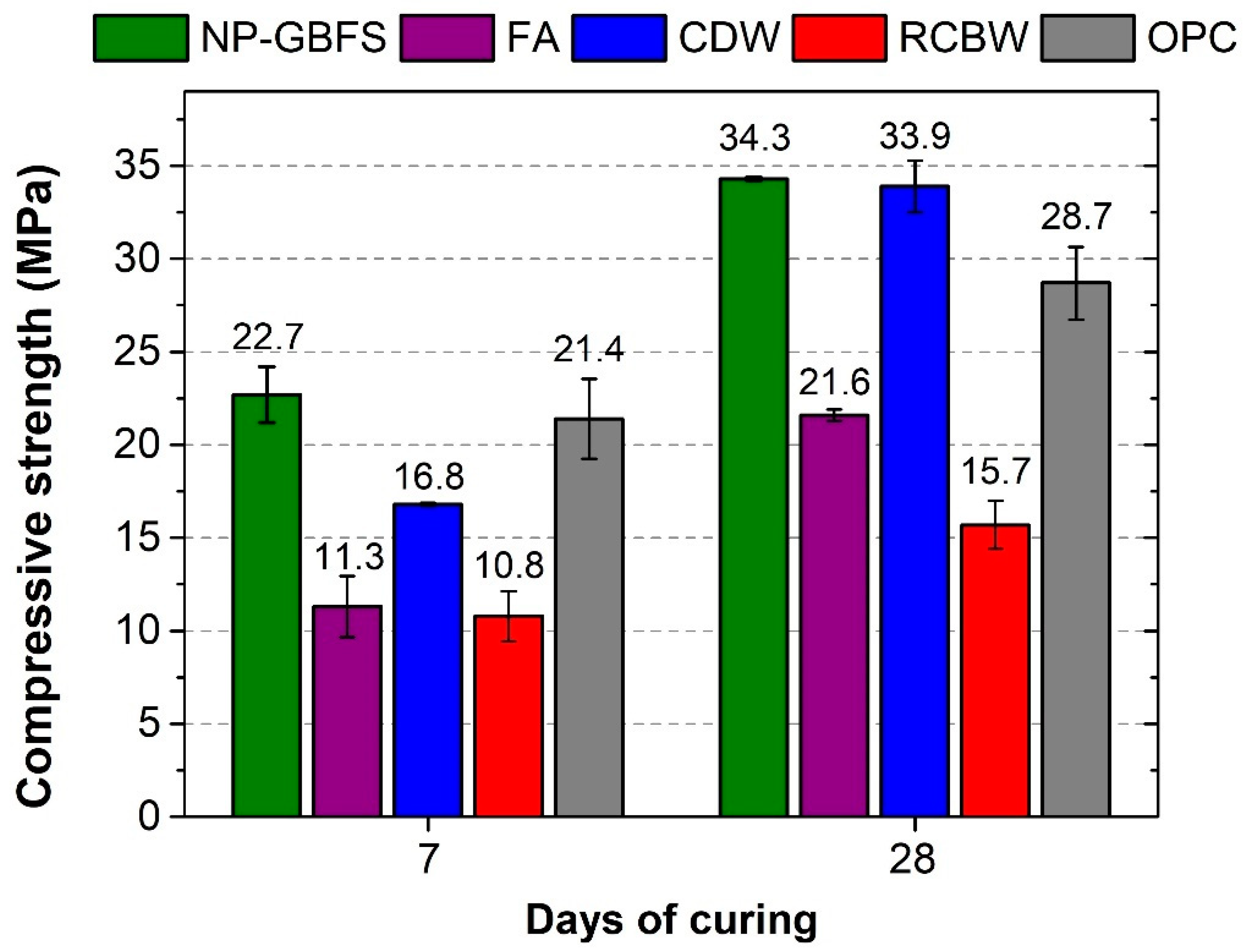

3.1. Mechanical Characterization of the Mixtures

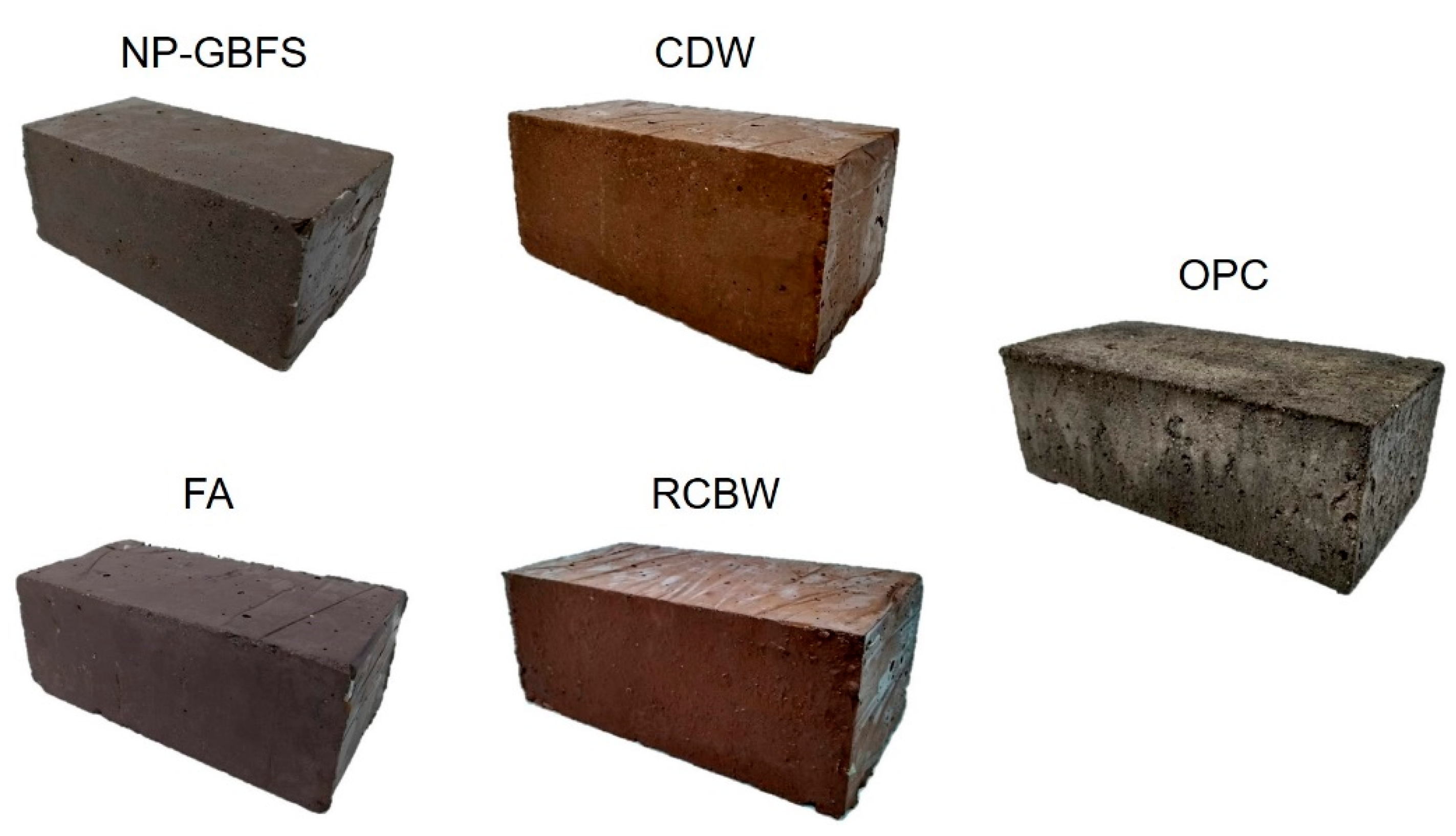

3.2. Alkali-Activated Blocks Production

3.3. Physical-Mechanical Characterization of the Alkali-Activated Blocks

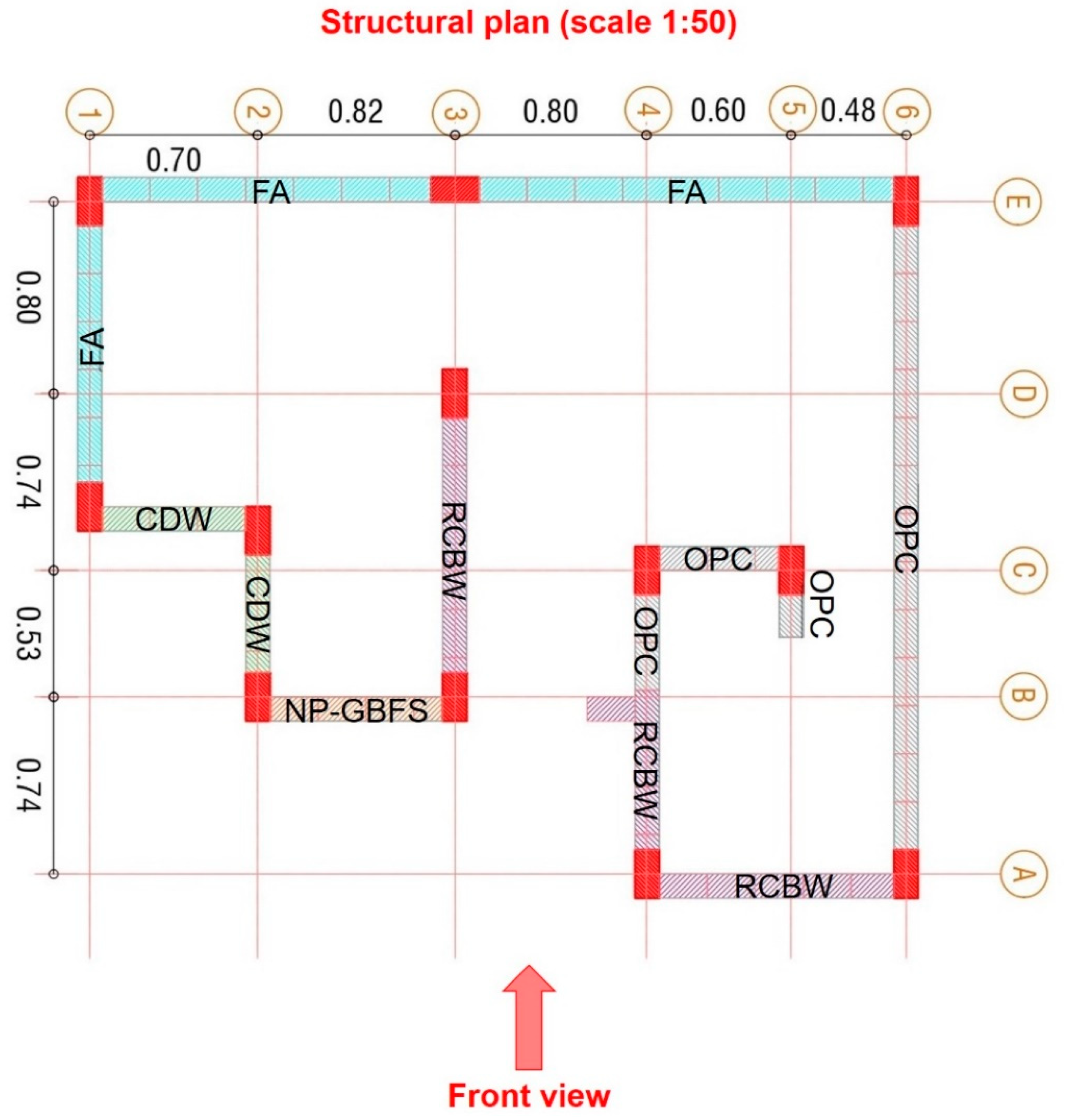

3.4. Design of the Eco-House Prototype

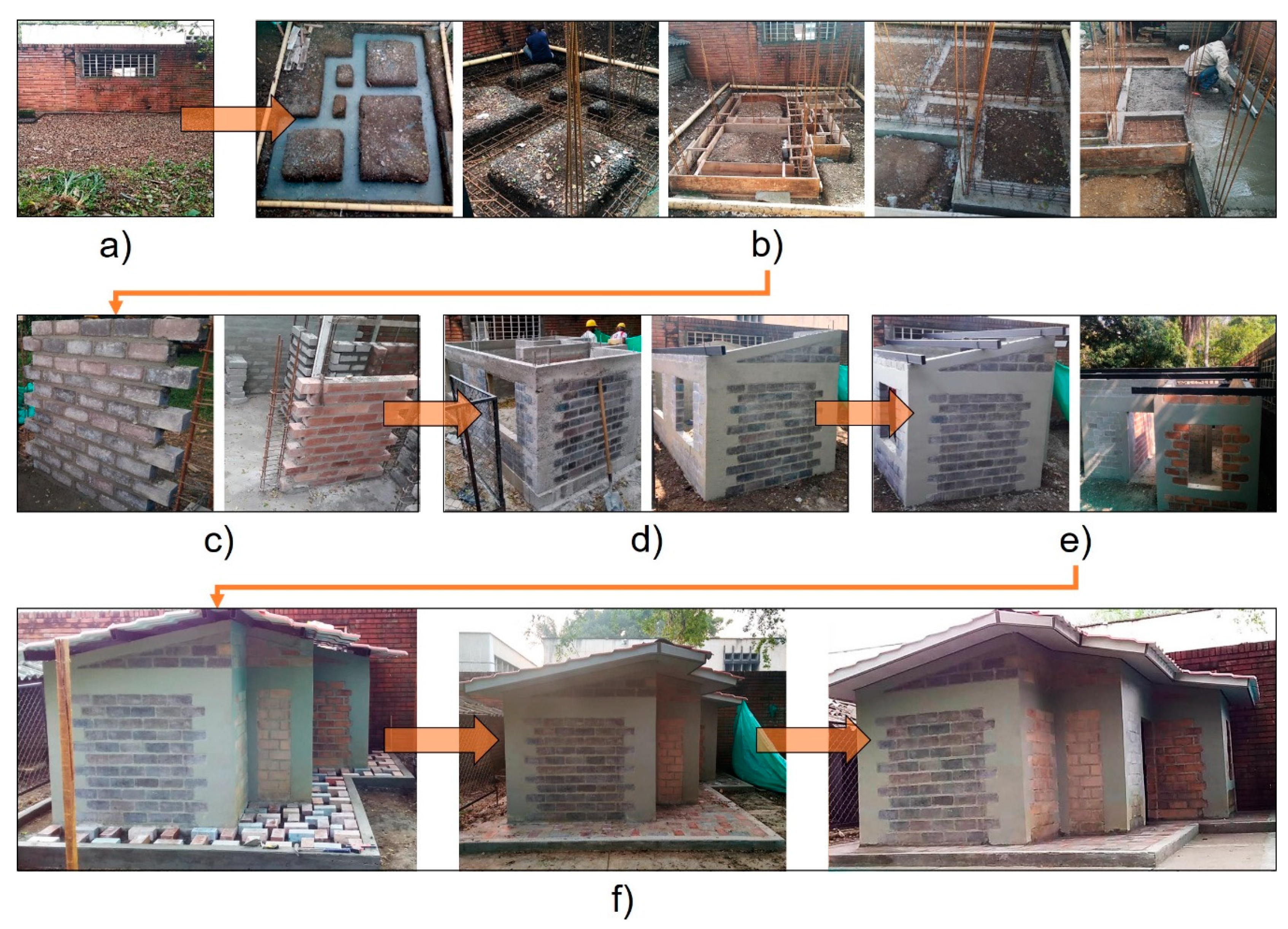

3.5. Construction of the Eco-House Prototype

3.6. Estimation of the Environmental Impact

4. Conclusions

- Alkali activation technology or geopolymerization is a sustainable method that uses various types of aluminosilicates (precursors), including natural pozzolans (NP), granulated blast furnace slag (GBFS), fly ash (FA), construction and demolition waste (CDW) (concrete, ceramics, mortar, and bricks wastes), and red clay brick waste (RCBW). Note that the latter are industrial by-products or waste, considered worldwide as an environmental problem due to their extensive generation and poor management. In this sense, alkaline activation from the use of this type of waste is proposed as a comprehensive alternative and an approach towards the implementation of the “circular economy” in the construction sector.

- The alkali-activated blocks produced met all the physical-mechanical specifications established by the Colombian Technical Standard (NTC) to be classified as concrete units for structural masonry. The compressive strengths (28 days) of the NP–GBFS (31.4 MPa), FA (23.9 MPa), CDW (26.1 MPa), and RCBW (17.0 MPa) blocks and the reference OPC block (22.7 MPa) exceeded the minimum limit established by NTC 4026 (equivalent to ASTM C90) for its structural classification (low class ≥ 8 MPa and high class ≥ 13 MPa).

- The architectural and structural design, as well as the construction process, of the eco-house prototype met all the specifications of the Colombian Regulations for Earthquake Resistant Buildings (NSR-10) for one- and two-story houses.

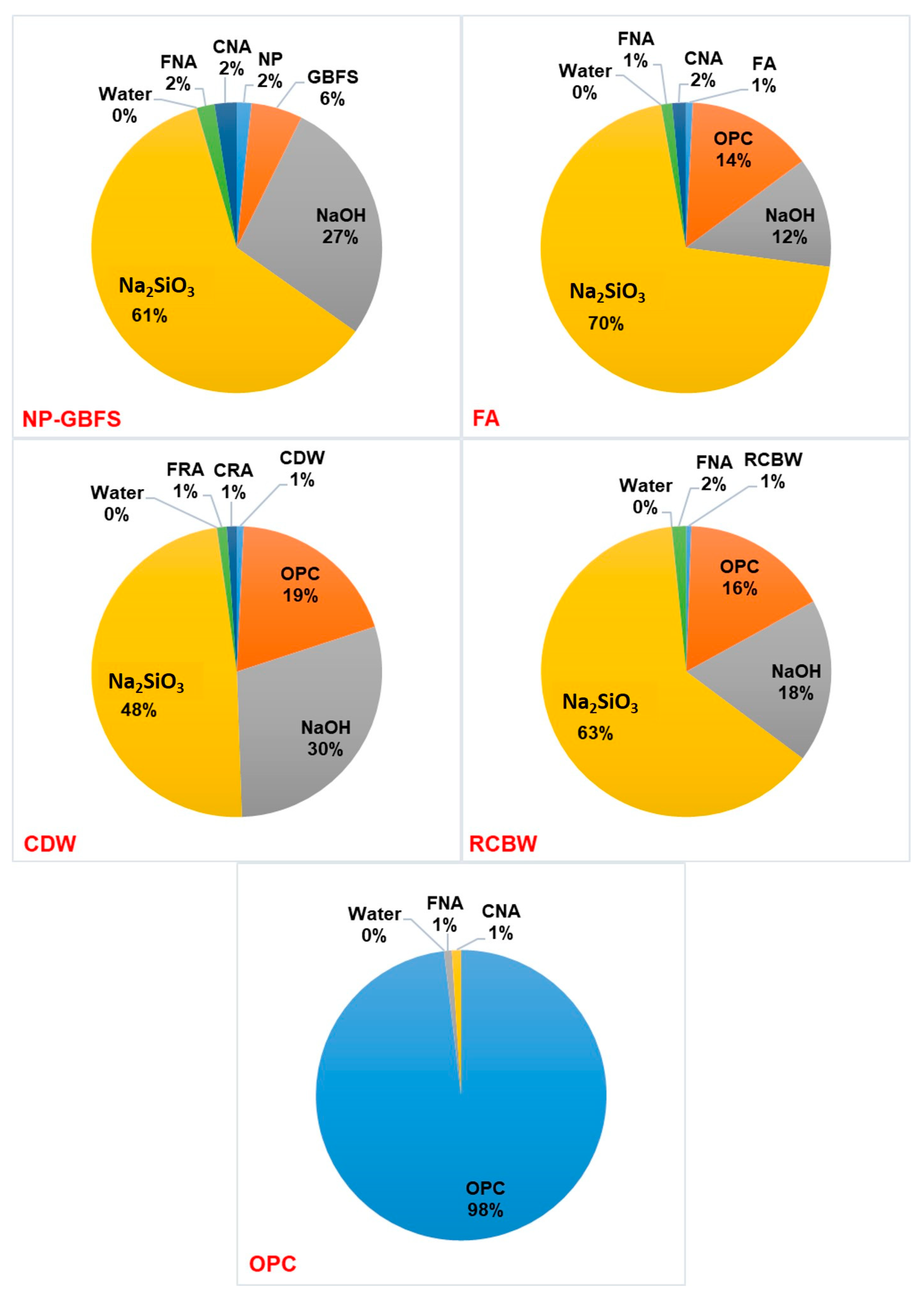

- The results obtained show that NaOH (1.46 × 100 kg∙CO2∙eq), OPC (8.45 × 10−1 kg∙CO2∙eq), and Na2SiO3 (8.12 × 10−1 kg∙CO2∙eq) are, in that order, the raw materials with the highest CO2/kg emissions among all the raw materials used. However, the carbon footprint of alkali-activated blocks ultimately depends on the design of the mixtures or the proportions of these materials. In this sense, the alkali-activated blocks had carbon footprints 25.4–54.7% lower than that of the OPC-based reference blocks. In effect, the global warming potential (GWP) values of the NP–GBFS, FA, CDW, and RCBW mixtures were 155.9, 240.5, 220.0, and 257.0 kg∙CO2∙eq/m3, respectively, compared to the GWP of 344.5 kg∙CO2∙eq/m3 of the OPC mixture. Regarding the masonry units (625 concrete blocks/m3), the GWP values associated with the raw materials of the NP–GBFS, FA, CDW, and RCBW blocks were 0.25, 0.38, 0.35, and 0.41 kg∙CO2∙eq/block, respectively, compared with the 0.55 kg∙CO2∙eq/block produced by the OPC block. By including the transportation of raw materials in the GWP calculation, although the values increase up to 23%, the total GWP of alkali-activated blocks was lower than that of the reference blocks.

- In summary, the study shows the feasibility of making use of industrial by-products and wastes (GBFS, FA, RCBW, RCD) as raw materials to produce alkali-activated blocks with a low environmental footprint and appropriate characteristics for the construction of houses, complying with the specifications of the construction codes. This option is in accordance with the principles of the circular economy. Future studies should focus on evaluating the thermal performance and durability of the prototype.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations (UN). 2030 Agenda for Sustainable Development of the United Nations General Assembly. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 12 September 2020).

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the Construction Industry: A Review of Recent Developments Based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean Production and Properties of Geopolymer Concrete: A Review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, Green Alkali Activated Cementitious Material: Synthesis, Applications and Challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Wang, A.; Zheng, Y.; Zhang, Z.; Liu, K.; Li, Y.; Shi, L.; Sun, D. The Durability of Alkali-Activated Materials in Comparison with Ordinary Portland Cements and Concretes: A Review. Engineering 2020, 6, 695–706. [Google Scholar] [CrossRef]

- Komnitsas, K.A. Potential of Geopolymer Technology towards Green Buildings and Sustainable Cities. Procedia Eng. 2011, 21, 1023–1032. [Google Scholar] [CrossRef] [Green Version]

- Ouellet-Plamondon, C.; Habert, G. Life cycle assessment (LCA) of alkali-activated cements and concretes. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., Labrincha, J.A., Leonelli, C., Palomo, A., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 663–686. ISBN 9781782422761. [Google Scholar]

- Habert, G.; D’Espinose De Lacaillerie, J.B.; Roussel, N. An Environmental Evaluation of Geopolymer Based Concrete Production: Reviewing Current Research Trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New Cements for the 21st Century: The Pursuit of an Alternative to Portland Cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-Activated Materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Gavali, H.R.; Bras, A.; Faria, P.; Ralegaonkar, R.V. Development of Sustainable Alkali-Activated Bricks Using Industrial Wastes. Constr. Build. Mater. 2019, 215, 180–191. [Google Scholar] [CrossRef]

- Deraman, L.M.; Abdullah, M.M.A.; Ming, L.Y.; Ibrahim, W.M.W.; Tahir, M.F.M.; Abdullah, M.M.A.; Ramli, M.M.; Rahim, S.Z.A.; Isa, S.S.M.; Saad, M.N.M.; et al. Mechanical Properties on Geopolymer Brick: A Review. AIP Conf. Proc. 2017, 1885, 20041. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.; Ibrahim, W.M.W.; Tahir, M.F.M. The Properties and Durability of Fly Ash-Based Geopolymeric Masonry Bricks. In Eco-Efficient Masonry Bricks and Blocks; Pacheco-Torgal, F., Lourenço, P.B., Labrincha, J.A., Kumar, S., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 273–287. ISBN 978-1-78242-305-8. [Google Scholar]

- Ferone, C.; Colangelo, F.; Cioffi, R.; Montagnaro, F.; Santoro, L. Mechanical Performances of Weathered Coal Fly Ash Based Geopolymer Bricks. Procedia Eng. 2011, 21, 745–752. [Google Scholar] [CrossRef]

- Deraman, L.M.; Abdullah, M.M.A.B.; Liew, Y.M.; Hussin, K.; Yahya, Z. The Strength of Bottom Ash-Based Geopolymer Brick with Inclusion of Fly Ash. Mater. Sci. Forum 2016, 841, 26–29. [Google Scholar] [CrossRef]

- Arıöz, Ö.; Kilinç, K.; Tuncan, M.; Tuncan, A.; Kavas, T. Physical, Mechanical and Micro-Structural Properties of F Type Fly-Ash Based Geopolymeric Bricks Produced by Pressure Forming Process. Adv. Sci. Technol. 2011, 69, 69–74. [Google Scholar] [CrossRef]

- Gavali, H.R.; Ralegaonkar, R.V. Design Development of Sustainable Alkali-Activated Bricks. J. Build. Eng. 2020, 30, 101302. [Google Scholar] [CrossRef]

- Gavali, H.R.; Ralegaonkar, R.V. Design of Eco-Efficient Housing with Sustainable Alkali-Activated Bricks. J. Clean. Prod. 2020, 254, 120061. [Google Scholar] [CrossRef]

- Huynh, T.-P.; Hwang, C.-L.; Lin, K.-L.; Ngo, S.-H. Effect of Residual Rice Husk Ash on Mechanical-Microstructural Properties and Thermal Conductivity of Sodium-Hydroxide-Activated Bricks. Environ. Prog. Sustain. Energy 2018, 37, 1647–1656. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Huynh, T.-P. Evaluation of the Performance and Microstructure of Ecofriendly Construction Bricks Made with Fly Ash and Residual Rice Husk Ash. Adv. Mater. Sci. Eng. 2015, 2015, 891412. [Google Scholar] [CrossRef] [Green Version]

- Maulana, A.; Wardani, N.K.; Syamsidar, D.; Ariani; Nurfadilla; Subaer. Development of Hybrid Composite Rice Husk Ash (RHA)–Geopolymer for Bricks Bearing Buildings. In MATEC Web of Conferences, Proceedings of the International Conference on Engineering Technology (ETIC 2016) Ho Chi Minh City, Vietnam, 5–6 August 2016; Abdullah, M.A.B., Abd Rahim, S.Z., Muhammad Suandi, M.E., Mat Saad, M.N., Ghazali, M.F., Eds.; EDP Sciences: Les Ulis, France, 2017; Volume 97, p. 01009. [Google Scholar]

- Poinot, T.; Laracy, M.E.; Aponte, C.; Jennings, H.M.; Ochsendorf, J.A.; Olivetti, E.A. Beneficial Use of Boiler Ash in Alkali-Activated Bricks. Resour. Conserv. Recycl. 2018, 128, 1–10. [Google Scholar] [CrossRef]

- Venugopal, K.; Radhakrishna; Sasalatti, V. Development of Alkali Activated Geopolymer Masonry Blocks. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 12072. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, B.S.; Liew, M.S.; Alaloul, W.S.; Al-Fakih, A.; Ibrahim, W.; Adamu, M. Development of Rubberized Geopolymer Interlocking Bricks. Case Stud. Constr. Mater. 2018, 8, 401–408. [Google Scholar] [CrossRef]

- Ren, P.; Li, B.; Yu, J.-G.; Ling, T.-C. Utilization of Recycled Concrete Fines and Powders to Produce Alkali-Activated Slag Concrete Blocks. J. Clean. Prod. 2020, 267, 122115. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of Eco-Friendly Bricks from Copper Mine Tailings through Geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Durability and Leaching Behavior of Mine Tailings-Based Geopolymer Bricks. Constr. Build. Mater. 2013, 44, 743–750. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Utilization of Cement Kiln Dust (CKD) to Enhance Mine Tailings-Based Geopolymer Bricks. Constr. Build. Mater. 2013, 40, 1002–1011. [Google Scholar] [CrossRef]

- Chen, C.; Li, Q.; Shen, L.; Zhai, J. Feasibility of Manufacturing Geopolymer Bricks Using Circulating Fluidized Bed Combustion Bottom Ash. Environ. Technol. 2012, 33, 1313–1321. [Google Scholar] [CrossRef] [PubMed]

- Apithanyasai, S.; Supakata, N.; Papong, S. The Potential of Industrial Waste: Using Foundry Sand with Fly Ash and Electric Arc Furnace Slag for Geopolymer Brick Production. Heliyon 2020, 6, e03697. [Google Scholar] [CrossRef]

- Dahmen, J.; Kim, J.; Ouellet-Plamondon, C.M. Life Cycle Assessment of Emergent Masonry Blocks. J. Clean. Prod. 2018, 171, 1622–1637. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía De Gutiérrez, R.; Puertas, F. Alkali-Activated Binary Concrete Based on a Natural Pozzolan: Physical, Mechanical and Microstructural Characterization. Mater. Constr. 2019, 69. [Google Scholar] [CrossRef]

- Valencia-Saavedra, W.; Mejía de Gutiérrez, R.; Gordillo, M. Geopolymeric Concretes Based on Fly Ash with High Unburned Content. Constr. Build. Mater. 2018, 165, 697–706. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Rivera, J.F.; Mejía de Gutiérrez, R. Alkali-Activated Building Materials Made with Recycled Construction and Demolition Wastes. Constr. Build. Mater. 2017, 149, 130–138. [Google Scholar] [CrossRef]

- Vásquez, A.; Cárdenas, V.; Robayo-Salazar, R.; Mejia de Gutierrez, R. Geopolymer Based on Concrete Demolition Waste. Adv. Powder Technol. 2016, 27, 1173–1179. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejia de Gutierrez, R.; Mulford-Carvajal, A. Production of Building Elements Based on Alkali-Activated Red Clay Brick Waste. Rev. Fac. Ing. 2016, 25, 21–30. [Google Scholar]

- Robayo-Salazar, R.A.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept. Sustainability 2020, 12, 5775. [Google Scholar] [CrossRef]

- Robayo, R.A.; Mulford, A.; Munera, J.; Mejía de Gutiérrez, R. Alternative Cements Based on Alkali-Activated Red Clay Brick Waste. Constr. Build. Mater. 2016, 128, 163–169. [Google Scholar] [CrossRef]

- Universidad del Valle (“University of Valle”) Grupo Materiales Compuestos (“Composites Materials Group”). Available online: http://investigaciongmc.univalle.edu.co/index.html (accessed on 12 September 2020).

- ASTM C33-18, Standard Specification for Concrete Aggregates; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- ASTM C127-15, Standard Test. Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2015.

- ASTM C128-15, Standard Test. Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2015.

- ASTM C29-17, Standard Test. Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2017.

- ASTM C136-19, Standard Test. Method for Sieve Analysis of Fine and Coarse Aggregates; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2019.

- ASTM C131-20, Standard Test. Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2020.

- ASTM C39-18, Standard Test. Method for Compressive Strength of Cylindrical Concrete Specimens; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018.

- NTC 4026, Unidades (Bloques y Ladrillos de Concreto, Para Mampostería Estructural (“Loadbearing Concrete Mansonry Units”); Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC): Bogotá, Colombia, 1997.

- ASTM C90-16, Standard Specification for Loadbearing Concrete Masonry Units; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016.

- NSR-10, Reglamento Colombiano de Construcción Sismo Resistente (“Colombian Regulations for Earthquake Resistant Construction”); Ministerio de Ambiente Vivienda y Desarrollo Territorial: Bogotá, Colombia, 2020.

- ISO 14040:2006, Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ACI Committee 211. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete (ACI 211.1-91); American Concrete Institute (ACI): Farmington Hills, MI, USA, 2002. [Google Scholar]

- Robayo-Salazar, R.A.; Mejia de Gutierrez, R.; Puertas, F. Study of Synergy between a Natural Volcanic Pozzolan and a Granulated Blast Furnace Slag in the Production of Geopolymeric Pastes and Mortars. Constr. Build. Mater. 2017, 157, 151–160. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Mejía-Arcila, J.M.; Mejía de Gutiérrez, R. Eco-Efficient Alkali-Activated Cement Based on Red Clay Brick Wastes Suitable for the Manufacturing of Building Materials. J. Clean. Prod. 2017, 166, 242–252. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of Geopolymer Concrete for a Cleaner and Sustainable Environment—A Review of Mechanical Properties and Microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Rizzuto, J.P.; Kamal, M.; Elsayad, H.; Bashandy, A.; Etman, Z.; Aboel Roos, M.N.; Shaaban, I.G. Effect of Self-Curing Admixture on Concrete Properties in Hot Climate Conditions. Constr. Build. Mater. 2020, 261, 119933. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-08); American Concrete Institute (ACI): Farmington Hills, MI, USA, 2008. [Google Scholar]

- Resolución No. 0472 de 2017, Reglamento Para La Gestión Integral de Los Residuos Generados En Las Actividades de Construcción y Demolición—RCD (“Regulation for the Management of Wastes Generated in Construction and Demolition Activities”); Ministerio del Ambiente y Desarrollo Sostenible: Bogotá, Colombia, 2017.

- Swiss Centre for Life Cycle Inventories Ecoinvent OpenLCA Database Version 3.6. Available online: https://www.ecoinvent.org/database.html (accessed on 31 August 2020).

- De Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-Stone Biomass Ash (OBA): An Alternative Alkaline Source for the Blast Furnace Slag Activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef] [Green Version]

- Kamseu, E.; Beleuk à Moungam, L.M.; Cannio, M.; Billong, N.; Chaysuwan, D.; Melo, U.C.; Leonelli, C. Substitution of Sodium Silicate with Rice Husk Ash-NaOH Solution in Metakaolin Based Geopolymer Cement Concerning Reduction in Global Warming. J. Clean. Prod. 2017, 142, 3050–3060. [Google Scholar] [CrossRef]

- Mejía, J.M.; Mejía de Gutiérrez, R.; Montes, C. Rice Husk Ash and Spent Diatomaceous Earth as a Source of Silica to Fabricate a Geopolymeric Binary Binder. J. Clean. Prod. 2016, 118, 133–139. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M. Use of Glass Waste as an Activator in the Preparation of Alkali-Activated Slag. Mechanical Strength and Paste Characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Villaquirán-Caicedo, M.A.; Mejía de Gutiérrez, R.; Sulekar, S.; Davis, C.; Nino, J.C. Thermal Properties of Novel Binary Geopolymers Based on Metakaolin and Alternative Silica Sources. Appl. Clay Sci. 2015, 118, 276–282. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | MgO | K2O | LOI | SiO2/Al2O3 Molar Ratio | Particle Size (µm) | Density (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NP | 62.0 | 15.5 | 7.3 | 5.2 | 4.1 | 2.5 | 1.6 | 0.5 | 6.8 | 20.6 | 2780 |

| GBFS | 37.7 | 15.7 | 1.8 | 40.3 | 0.2 | 1.3 | 0.4 | - | 4.1 | 26.4 | 2918 |

| FA | 59.0 | 23.9 | 5.9 | 0.74 | 0.2 | 0.3 | 1.2 | 6.3 | 4.2 | 24.9 | 2396 |

| CDW | 47.6 | 11.2 | 5.9 | 21.2 | 0.6 | 1.1 | 1.1 | 9.1 | 7.2 | 92.1 | 2690 |

| RCBW | 65.9 | 20.1 | 9.1 | 0.7 | 0.4 | 0.9 | 1.0 | - | 5.6 | 24.2 | 2560 |

| OPC | 17.9 | 3.9 | 4.8 | 62.3 | 0.2 | 1.8 | 0.3 | 4.1 | - | 21.6 | 3121 |

| Characteristics | Standard | FNA | FRA | CNA | CRA |

|---|---|---|---|---|---|

| Density (kg/m3) | ASTM C127 [42] | 2580 | 2029 | 2540 | 2326 |

| Absorption (%) | ASTM C128 [43] | 1.9 | 12.1 | 2.0 | 9.2 |

| Unit weight (kg/m3) | ASTM C29 [44] | 1630 | 1240 | 1470 | 1211 |

| Maximum size (mm) | ASTM C136 [45] | N/A | 25.4 | 25.4 | |

| Fineness modulus | 2.6 | 3.0 | N/A | ||

| Resistance to degradation, % | ASTM C131 [46] | N/A | 16.4 | 33.6 | |

| Material | Types of Mixes | ||||

|---|---|---|---|---|---|

| NP–GBFS | FA | CDW | RCBW | OPC | |

| NP | 280.0 | - | - | - | - |

| GBFS | 120.0 | - | - | - | - |

| FA | - | 360.0 | - | - | - |

| CDW | - | - | 450.0 | - | - |

| RCBW | - | - | - | 450.0 | - |

| OPC | - | 40.0 | 50.0 | 50.0 | 400.0 |

| NaOH | 29.3 | 20.2 | 44.4 | 32.0 | - |

| Na2SiO3 | 116.6 | 207.8 | 131.0 | 200.0 | - |

| Water | 103 | 60.8 | 151.2 | 100.0 | 260.0 |

| FNA | 761.6 | 722.6 | - | 1000.0 | 707.8 |

| FRA | - | - | 604.8 | - | - |

| CNA | 930.9 | 883.2 | - | - | 865.1 |

| CRA | - | - | 604.8 | - | - |

| Total (kg/m3) | 2341.4 | 2294.6 | 2036.2 | 1832.0 | 2232.8 |

| Class | Minimum Compressive Strength (28 days) | Maximum Water Absorption (%) According to the Weight (Density) (kg/m3) | ||

|---|---|---|---|---|

| Low Weight (<1680 kg/m3) | Medium Weight (1680–2000 kg/m3) | Normal Weight (≥2000 kg/m3) | ||

| High | 13 | 15 | 12 | 9 |

| Low | 8 | 18 | 15 | 12 |

| Properties (28 days) | Type of Block | ||||

|---|---|---|---|---|---|

| Alkali-Activated | OPC | ||||

| NP–GBFS | FA | CDW | RCBW | ||

| Compressive strength (MPa) | 31.4 | 23.9 | 26.1 | 17.0 | 22.7 |

| Modulus of rupture (MPa) | 4.8 | 4.6 | 3.6 | 1.5 | 5.2 |

| Density (kg/m3) | 1902.2 | 2295.2 | 1925.8 | 1535.8 | 2084.5 |

| Absorption (%) | 8.3 | 7.5 | 14.4 | 11.2 | 10.6 |

| Porosity (%) | 15.6 | 17.2 | 27.7 | 17.2 | 22.2 |

| Structural block class | High | High | Low | High | Low |

| Raw Materials | GWP (kg∙CO2∙eq) | |

|---|---|---|

| Cement | OPC | 8.45 × 10−1 |

| Precursors | NP | 9.10 × 10−3 |

| GBFS | 7.42 × 10−2 | |

| FA * | 5.26 × 10−3 | |

| CDW | 3.80 × 10−3 | |

| RCBW | 3.27 × 10−3 | |

| Alkaline Activators | NaOH | 1.46 × 100 |

| Na2SiO3 | 8.12 × 10−1 | |

| Water | H2O | 2.10 × 10−4 |

| Fine Aggregates | FNA | 4.11 × 10−3 |

| FRA | 3.98 × 10−3 | |

| Coarse Aggregates | CNA | 4.11 × 10−3 |

| CRA | 3.98 × 10−3 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robayo-Salazar, R.A.; Valencia-Saavedra, W.; Ramírez-Benavides, S.; Mejía de Gutiérrez, R.; Orobio, A. Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact. Materials 2021, 14, 1275. https://doi.org/10.3390/ma14051275

Robayo-Salazar RA, Valencia-Saavedra W, Ramírez-Benavides S, Mejía de Gutiérrez R, Orobio A. Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact. Materials. 2021; 14(5):1275. https://doi.org/10.3390/ma14051275

Chicago/Turabian StyleRobayo-Salazar, Rafael A., William Valencia-Saavedra, Sandra Ramírez-Benavides, Ruby Mejía de Gutiérrez, and Armando Orobio. 2021. "Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact" Materials 14, no. 5: 1275. https://doi.org/10.3390/ma14051275

APA StyleRobayo-Salazar, R. A., Valencia-Saavedra, W., Ramírez-Benavides, S., Mejía de Gutiérrez, R., & Orobio, A. (2021). Eco-House Prototype Constructed with Alkali-Activated Blocks: Material Production, Characterization, Design, Construction, and Environmental Impact. Materials, 14(5), 1275. https://doi.org/10.3390/ma14051275