Self-Fluxing Mechanism in Geopolymerization for Low-Sintering Temperature of Ceramic

Abstract

:1. Introduction

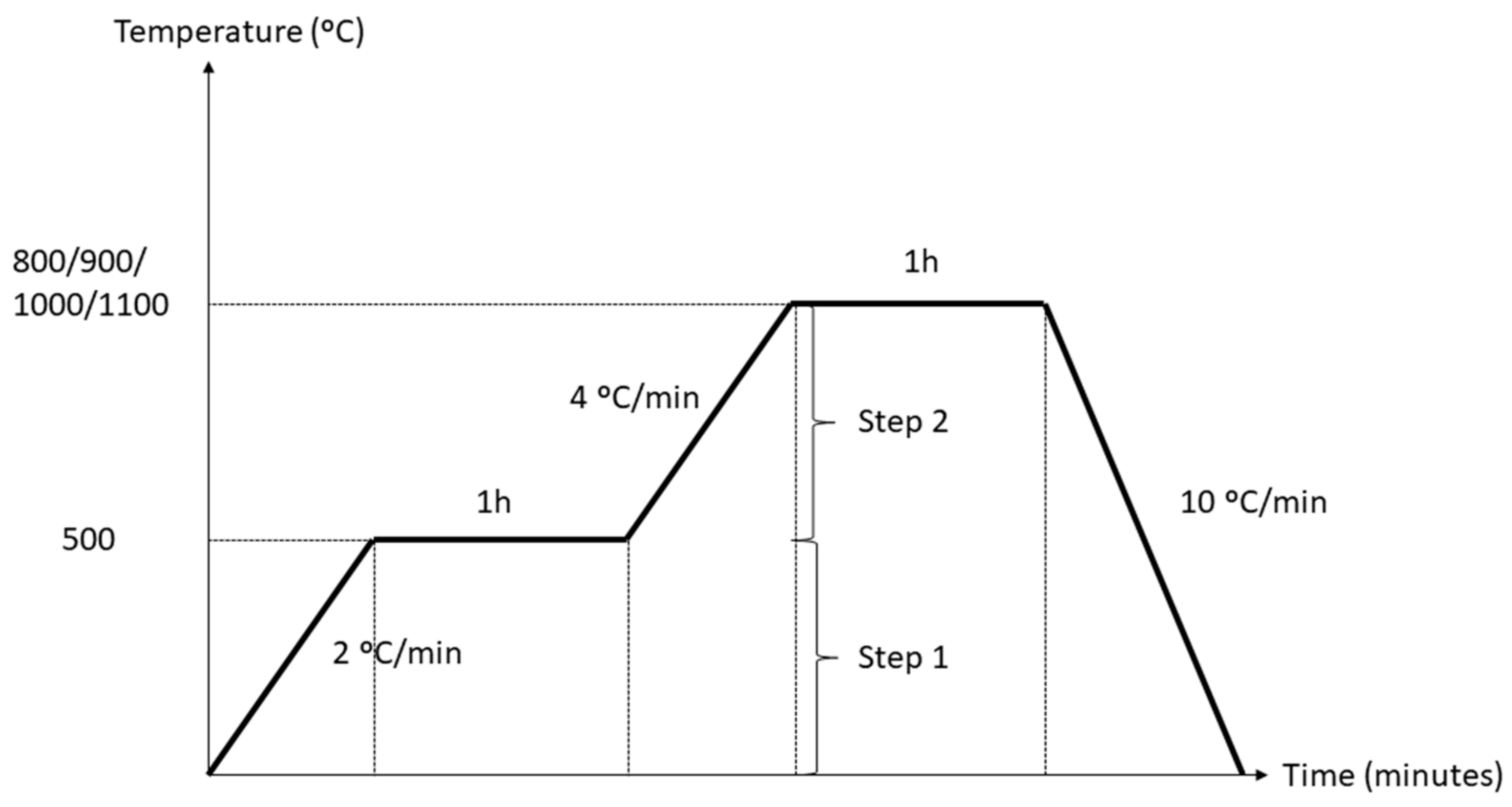

2. Materials and Methods

3. Results

3.1. Compressive Strength

3.2. Phase Transformation Analysis

(Amorphous)(Crystalline)

3.3. Microstructural Evolution at Different Sintering Temperature

3.4. Micro-X-ray Adsorption Analysis

3.5. Thermal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mierzwiński, D.; Łach, M.; Hebda, M.; Walter, J.; Szechyńska-Hebda, M.; Mikuła, J. Thermal phenomena of alkali-activated metakaolin studied with a negative temperature coefficient system. J. Therm. Anal. Calorim. 2019, 138, 4167–4175. [Google Scholar]

- Yousefi Oderji, S.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators. J. Clean. Prod. 2019, 225, 1–10. [Google Scholar]

- Li, O.H.; Yun-Ming, L.; Cheng-Yong, H.; Bayuaji, R.; Abdullah, M.M.A.B.; Loong, F.K.; Jin, T.A.; Teng, N.H.; Nabiałek, M.; Jeż, B.; et al. Evaluation of the Effect of Silica Fume on Amorphous Fly Ash Geopolymers Exposed to Elevated Temperature. Magnetochemistry 2021, 7, 9. [Google Scholar]

- Zailani, W.W.A.; Abdullah, M.M.A.B.; Arshad, M.F.; Razak, R.A.; Tahir, M.F.M.; Zainol, R.R.M.A.; Nabialek, M.; Sandu, A.V.; Wysłocki, J.J.; Błoch, K. Characterisation at the Bonding Zone between Fly Ash Based Geopolymer Repair Materials (GRM) and Ordinary Portland Cement Concrete (OPCC). Materials 2021, 14, 56. [Google Scholar]

- Cilla, M.S.; De Melo Cartaxo, J.; Menezes, R.R.; Delima Santana, L.N.; De Araujo Neves, G. Production of fire clay porous structure with no aligned macro porosity from water-based slurry by freeze casting process: A new approach. Ceram. Int. 2016, 42, 9278–9282. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J.; Song, Q. The effect of Na+ and H2O on structural and mechanical properties of coal gangue-based geopolymer: Molecular dynamics simulation and experimental study. Constr. Build. Mater. 2020, 121081. [Google Scholar] [CrossRef]

- Merabtene, M.; Kacimi, L.; Clastres, P. Elaboration of geopolymer binders from poor kaolin and dam sludge waste. Heliyon 2019, 5. [Google Scholar] [CrossRef] [Green Version]

- Papa, E.; Medri, V.; Amari, S.; Manaud, J.; Benito, P.; Vaccari, A.; Landi, E. Zeolite-geopolymer composite materials: Production and characterization. J. Clean. Prod. 2018, 171, 76–84. [Google Scholar] [CrossRef]

- Saha, S.; Rajasekaran, C. Enhancement of the properties of fly ash based geopolymer paste by incorporating ground granulated blast furnace slag. Constr. Build. Mater. 2017, 146, 615–620. [Google Scholar]

- Shoaei, P.; Musaeei, H.R.; Mirlohi, F.; Narimani zamanabadi, S.; Ameri, F.; Bahrami, N. Waste ceramic powder-based geopolymer mortars: Effect of curing temperature and alkaline solution-to-binder ratio. Constr. Build. Mater. 2019, 227, 116686. [Google Scholar]

- Hounsi, A.D.; Lecomte-Nana, G.L.; Djétéli, G.; Blanchart, P. Kaolin-based geopolymers: Effect of mechanical activation and curing process. Constr. Build. Mater. 2013, 42, 105–113. [Google Scholar]

- Tiffo, E.; Batiste, J.; Mbah, B.; Placide, D.; Noel, J.; Djobo, Y.; Elimbi, A. Physical and mechanical properties of unheated and heated kaolin based-geopolymers with partial replacement of aluminium hydroxide. Mater. Chem. Phys. 2020, 239, 122103. [Google Scholar]

- Jamil, N.H.; Abdullah, M.M.A.B.; Pa, F.C.; Mohamad, H.; Ibrahim, W.M.A.W.; Chaiprapa, J. Influences of SiO2, Al2O3, CaO and MgO in phase transformation of sintered kaolin-ground granulated blast furnace slag geopolymer. J. Mater. Res. Technol. 2020, 9, 14922–14932. [Google Scholar]

- Zawrah, M.F.; Abo Sawan, S.E.; Khattab, R.M.; Abdel-Shafi, A.A. Effect of nano sand on the properties of metakaolin-based geopolymer: Study on its low rate sintering. Constr. Build. Mater. 2020, 246, 118486. [Google Scholar]

- Chen, C.Y.; Tuan, W.H. The processing of kaolin powder compact. Ceram. Int. 2001, 27, 795–800. [Google Scholar]

- Lao, X.; Xu, X.; Jiang, W.; Liang, J.; Miao, L.; Wu, Q. Influences of impurities and mineralogical structure of different kaolin minerals on thermal properties of cordierite ceramics for high-temperature thermal storage. Appl. Clay Sci. 2020, 187, 105485. [Google Scholar]

- Rincón, A.; Desideri, D.; Bernardo, E. Functional glass-ceramic foams from ‘inorganic gel casting’ and sintering of glass/slag mixtures. J. Clean. Prod. 2018, 187, 250–256. [Google Scholar]

- Sutthi, R.; Kaewwinud, N.; Chindaprasirt, P.; Mutoh, Y.; Laonapakul, T. Effect of curing temperature and time on the mechanical properties of hydroxyapatite/calcined kaolin. ScienceAsia 2018, 44, 397–402. [Google Scholar]

- Heah, C.Y.; Kamarudin, H.; Al Bakri, A.M.; Bnhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Liew, Y.M. Effect of curing profile on kaolin-based geopolymers. Phys. Procedia 2011, 22, 305–311. [Google Scholar]

- Liu, H.; Lu, H.; Chen, D.; Wang, H.; Xu, H.; Zhang, R. Preparation and properties of glass-ceramics derived from blast-furnace slag by a ceramic-sintering process. Ceram. Int. 2009, 35, 3181–3184. [Google Scholar]

- Liu, J.; Yu, Q.; Zuo, Z.; Yang, F.; Han, Z.; Qin, Q. Reactivity and performance of dry granulation blast furnace slag cement. Cem. Concr. Compos. 2019, 95, 19–24. [Google Scholar]

- Li, Z.; Zhang, W.; Wang, R.; Chen, F.; Jia, X.; Cong, P. Effects of reactive MgO on the reaction process of geopolymer. Materials 2019, 12, 526. [Google Scholar]

- Ye, J.; Zhang, W.; Shi, D. Effect of elevated temperature on the properties of geopolymer synthesized from calcined ore-dressing tailing of bauxite and ground-granulated blast furnace slag. Constr. Build. Mater. 2014, 69, 41–48. [Google Scholar]

| Chemical Composition (%) | Kaolin | GGBS |

|---|---|---|

| CaO | N/A | 50.37 |

| SiO2 | 54.0 | 30.4 |

| Al2O3 | 31.7 | 10.5 |

| Fe2O3 | 4.89 | 0.53 |

| MgO | N/A | 3.2 |

| TiO2 | 1.41 | 0.98 |

| K2O | 6.05 | N/A |

| ZrO2 | 0.10 | 0.05 |

| MnO2 | 0.11 | 0.71 |

| LOI | 1.74 | 0.32 |

| Sintering Temperature (°C) | 800 | 900 | 1000 | 1100 |

|---|---|---|---|---|

| Q: Quartz (SiO2) | 77% | 4% | 4% | - |

| AL: Albite (heat treated) Na(AlSi3O8) | - | 74% | 95% | 47% |

| A: Akermanite (Ca2Mg(Si2O7) | - | 10% | 1% | - |

| N: Nepheline (Si-rich) Na7 (Al6Si10O32) | - | 13% | - | - |

| M: Magnetite (Fe3O4) | 23% | - | - | - |

| AN: Anorthite (CaAl2Si2O8) | - | - | - | 53% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamil, N.H.; Abdullah, M.M.A.B.; Pa, F.C.; Mohamad, H.; Ibrahim, W.M.A.W.; Amonpattaratkit, P.; Gondro, J.; Sochacki, W.; Ibrahim, N. Self-Fluxing Mechanism in Geopolymerization for Low-Sintering Temperature of Ceramic. Materials 2021, 14, 1325. https://doi.org/10.3390/ma14061325

Jamil NH, Abdullah MMAB, Pa FC, Mohamad H, Ibrahim WMAW, Amonpattaratkit P, Gondro J, Sochacki W, Ibrahim N. Self-Fluxing Mechanism in Geopolymerization for Low-Sintering Temperature of Ceramic. Materials. 2021; 14(6):1325. https://doi.org/10.3390/ma14061325

Chicago/Turabian StyleJamil, Noorina Hidayu, Mohd. Mustafa Al Bakri Abdullah, Faizul Che Pa, Hasmaliza Mohamad, Wan Mohd Arif W. Ibrahim, Penphitcha Amonpattaratkit, Joanna Gondro, Wojciech Sochacki, and Norfadhilah Ibrahim. 2021. "Self-Fluxing Mechanism in Geopolymerization for Low-Sintering Temperature of Ceramic" Materials 14, no. 6: 1325. https://doi.org/10.3390/ma14061325

APA StyleJamil, N. H., Abdullah, M. M. A. B., Pa, F. C., Mohamad, H., Ibrahim, W. M. A. W., Amonpattaratkit, P., Gondro, J., Sochacki, W., & Ibrahim, N. (2021). Self-Fluxing Mechanism in Geopolymerization for Low-Sintering Temperature of Ceramic. Materials, 14(6), 1325. https://doi.org/10.3390/ma14061325