Surface Modification Using Assisting Electrodes in Wire Electrical Discharge Machining for Silicon Wafer Preparation

Abstract

1. Introduction

2. Experiment Procedures and Data Collection

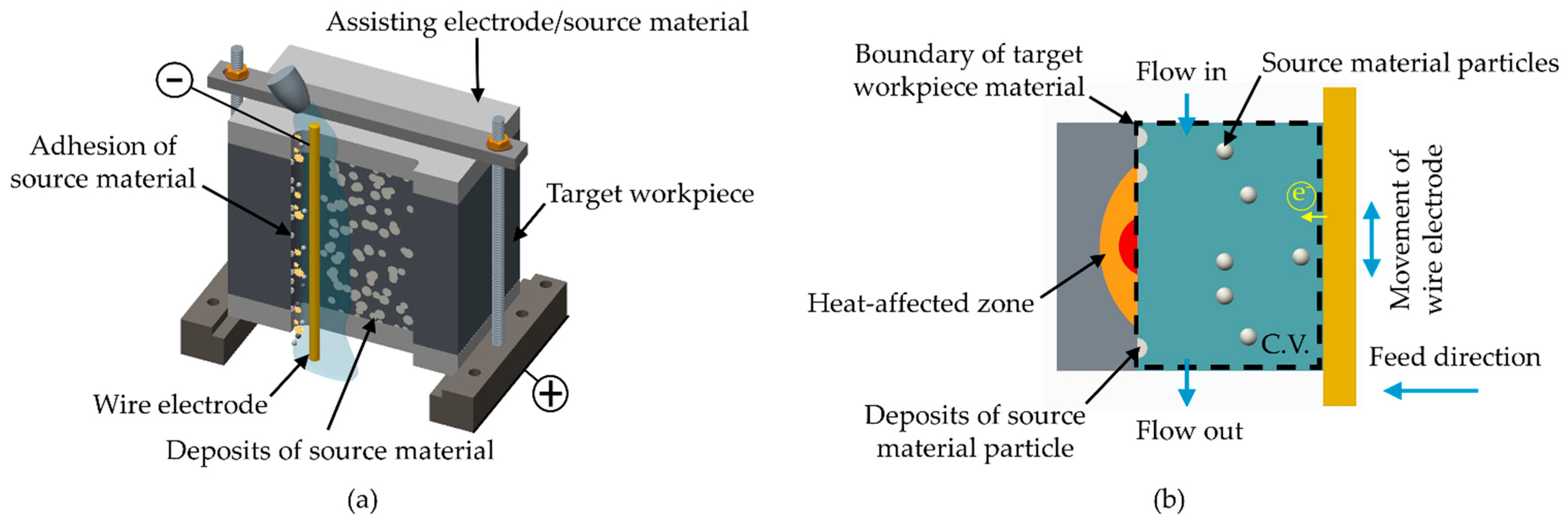

2.1. Machining Strategy and Surface Modification

2.2. Stacked Materials, Wire Electrodes, and Machine Set-Up

| Polycrystalline Silicon [31] | Mo [32] | A6061-T6 [33] | |

|---|---|---|---|

| Density (g/cm3) | 2.33 | 10.3 | 2.7 |

| Hardness | 7.0 Mohs | 250 HV | 95 HB500 |

| Specific heat capacity (J/g·K) | 0.71 | 0.25 | 0.896 |

| Thermal conductivity (cal/cm × s × °C) | 0.30 | 0.33 | 0.4 |

| Electrical resistivity (μΩ·m) | 10 | 0.19 | 0.04 |

| Melting point (°C) | 1412 | 2610 | 582–652 |

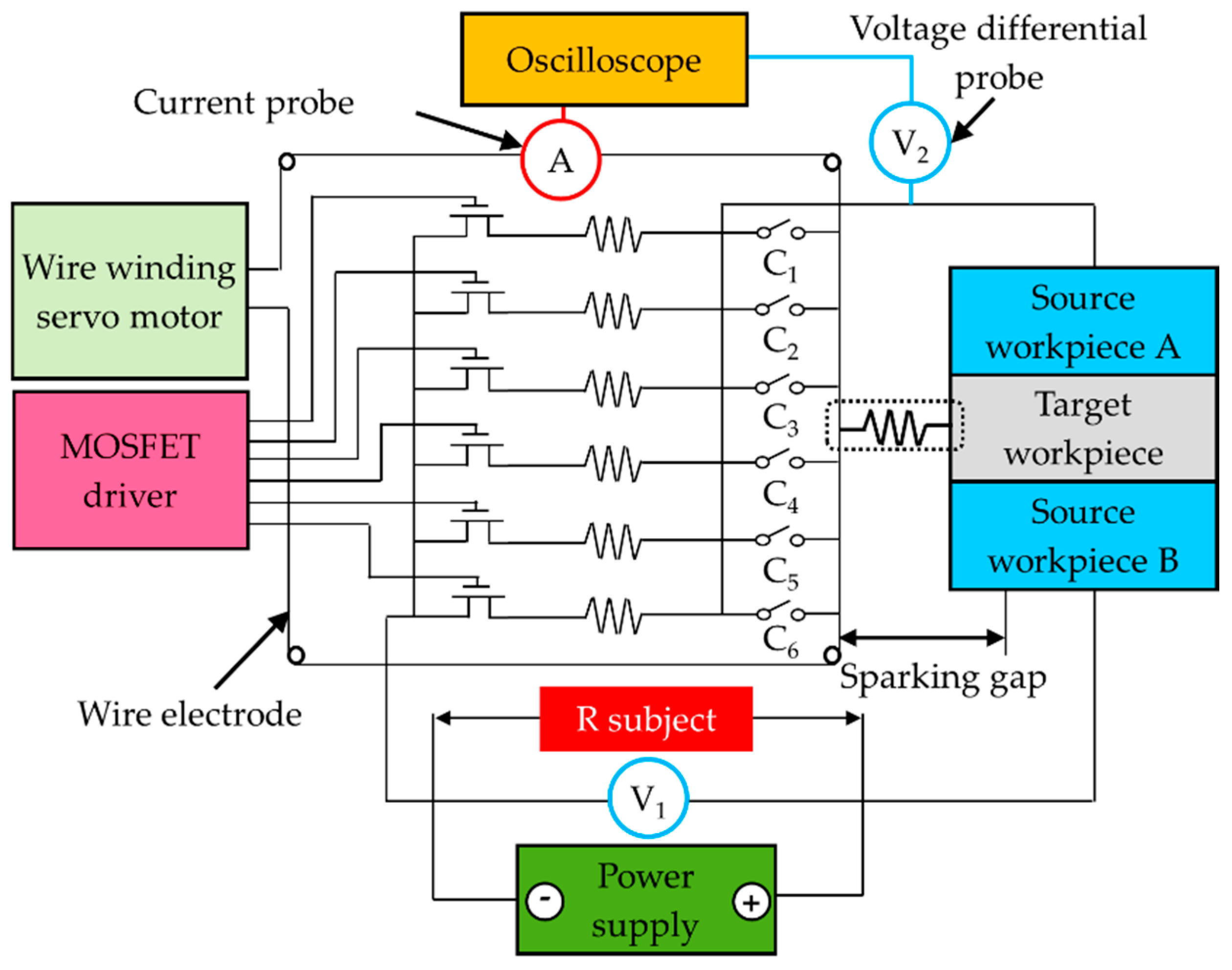

2.3. Designed Discharging Circuit

2.4. Design of the Experiments

2.5. Data Collection

3. Results and Discussion

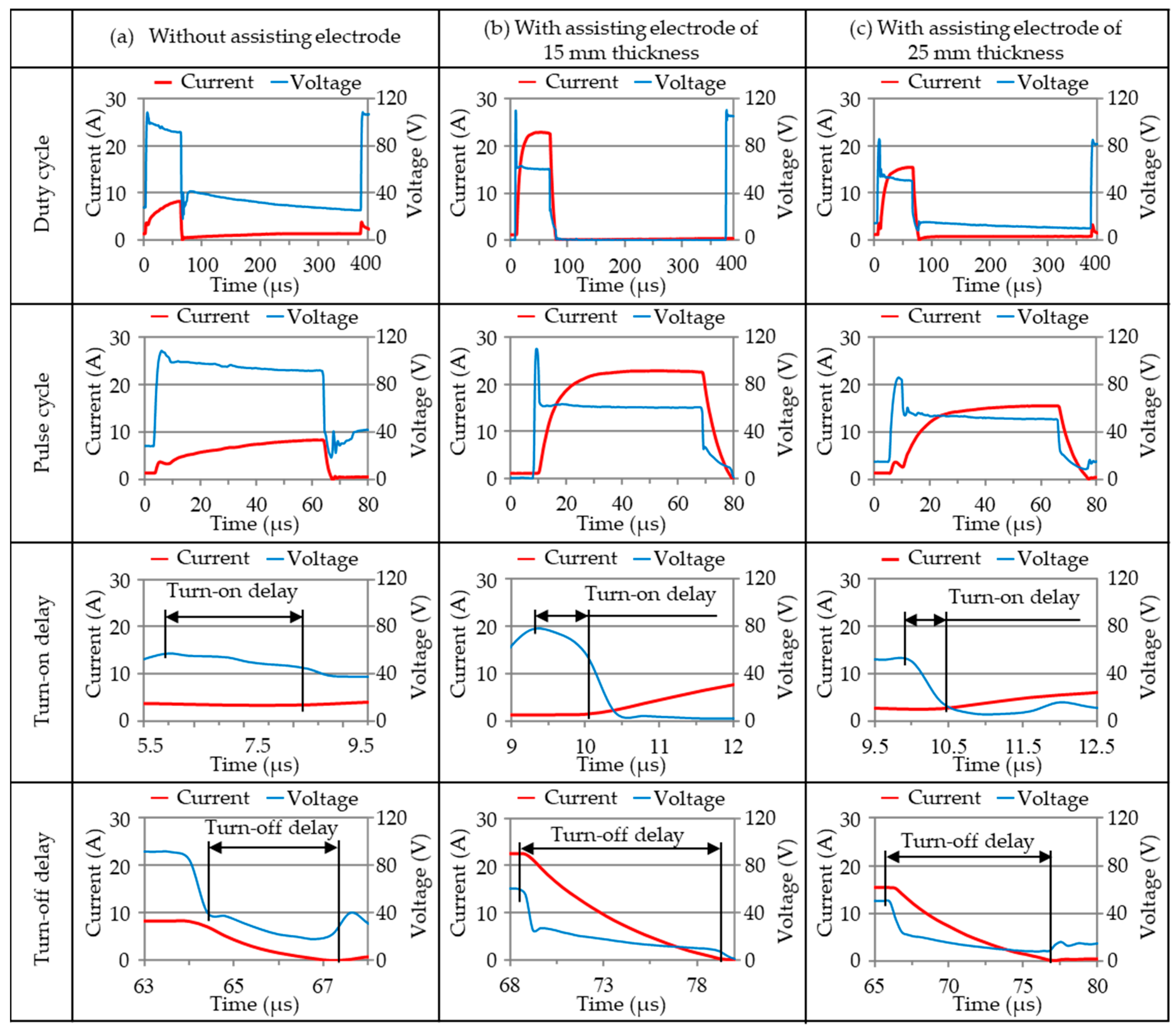

3.1. Analysis of Discharge Voltage and Current Waveforms

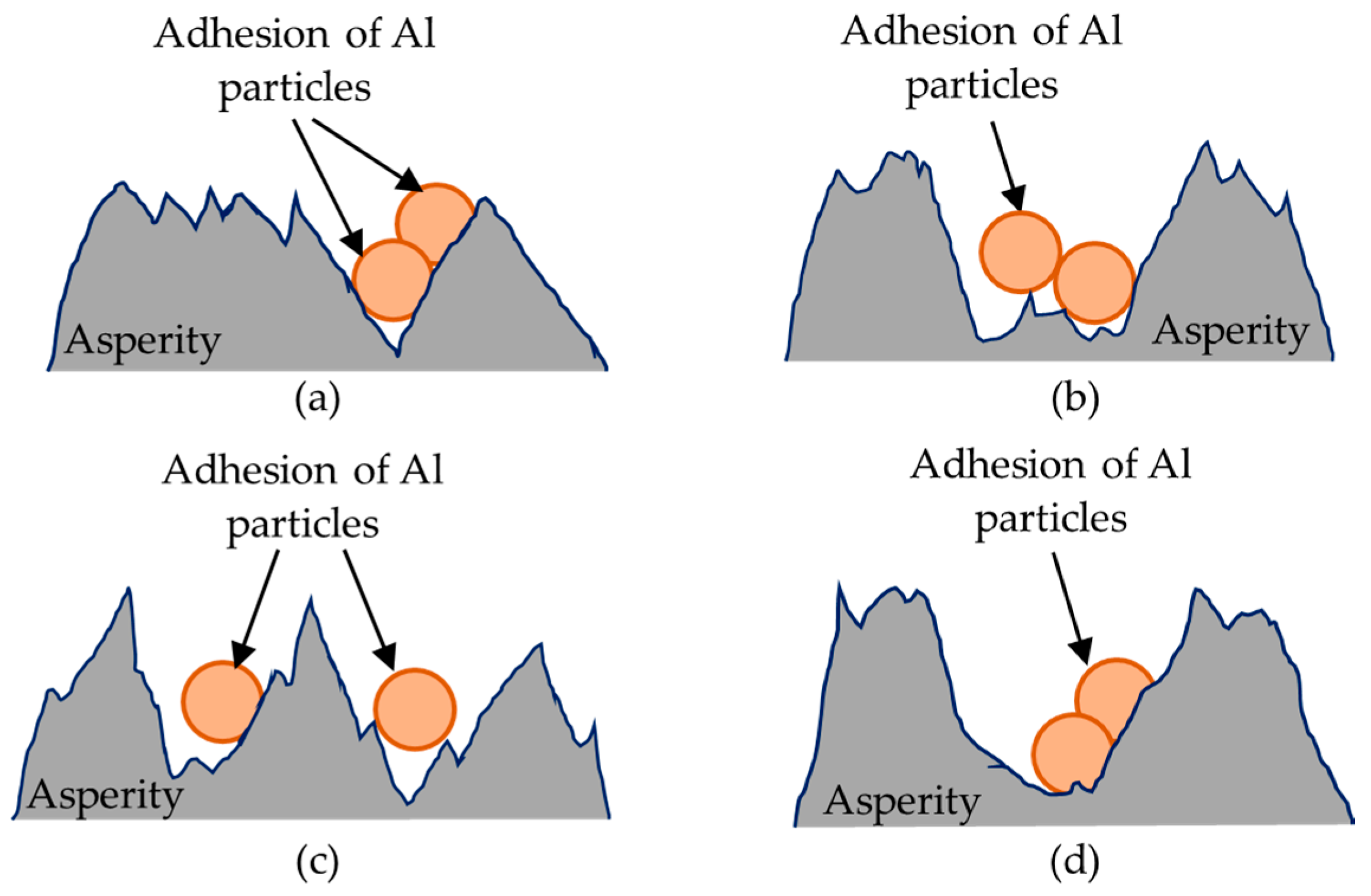

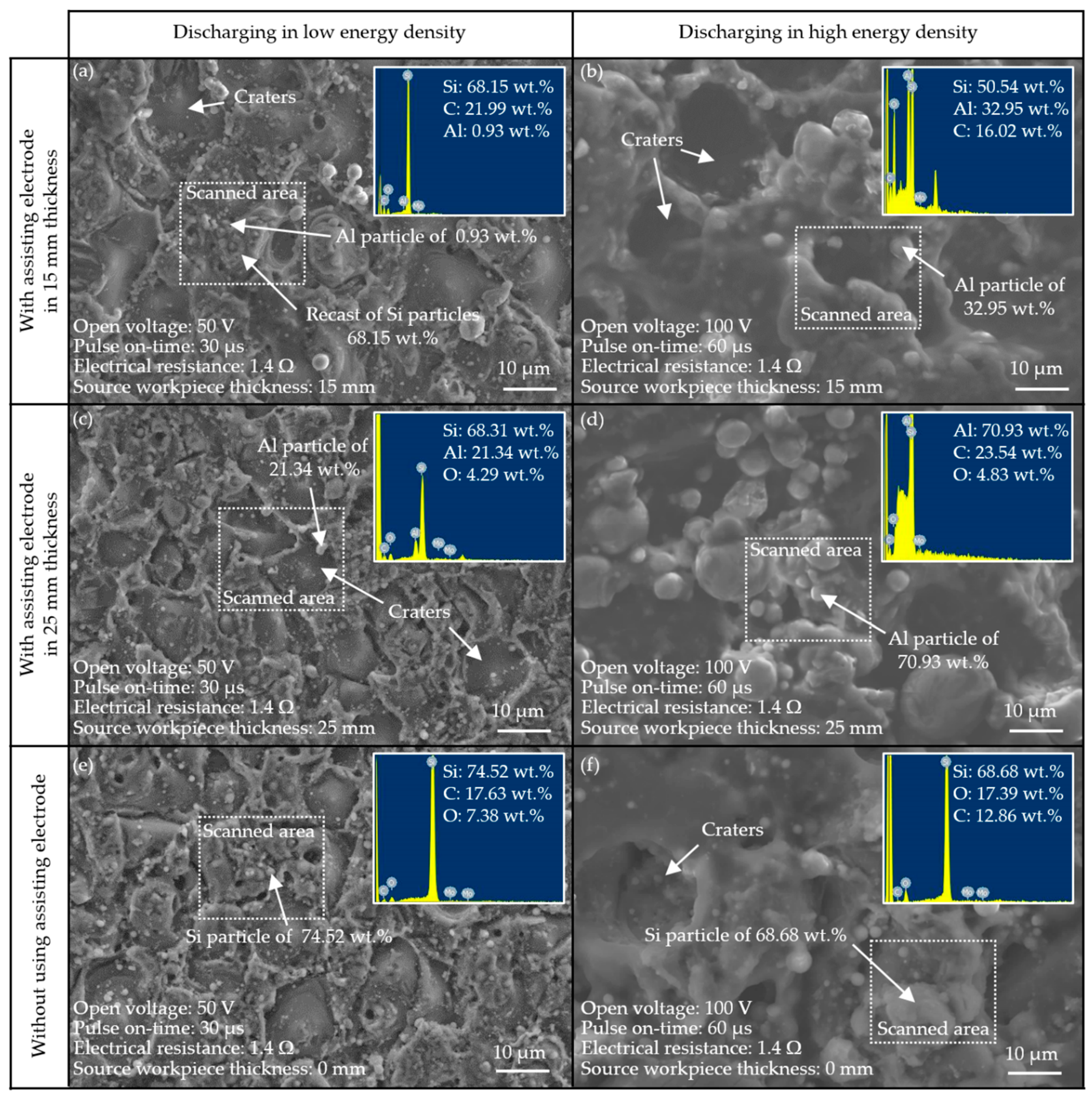

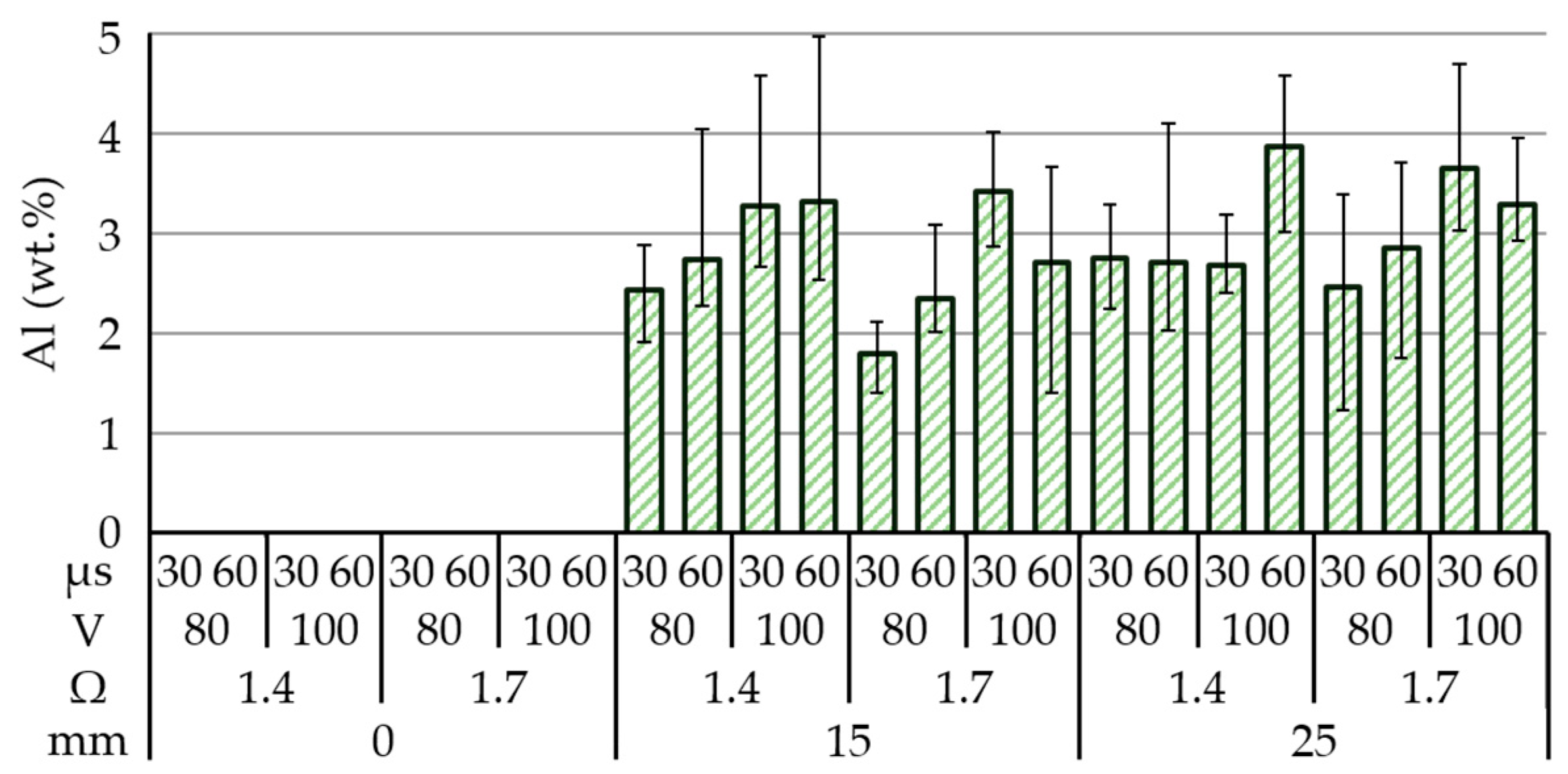

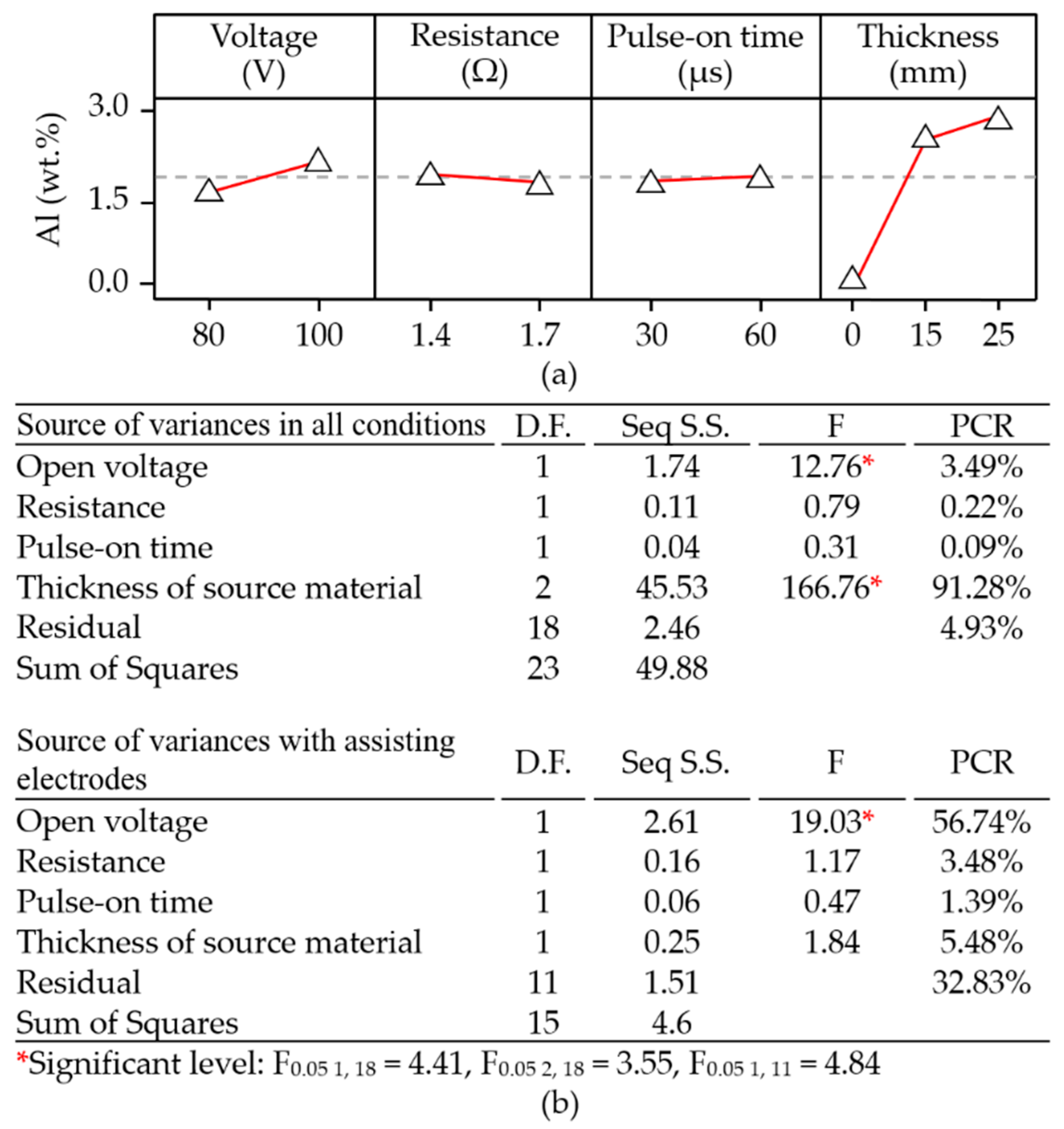

3.2. Surface Modification

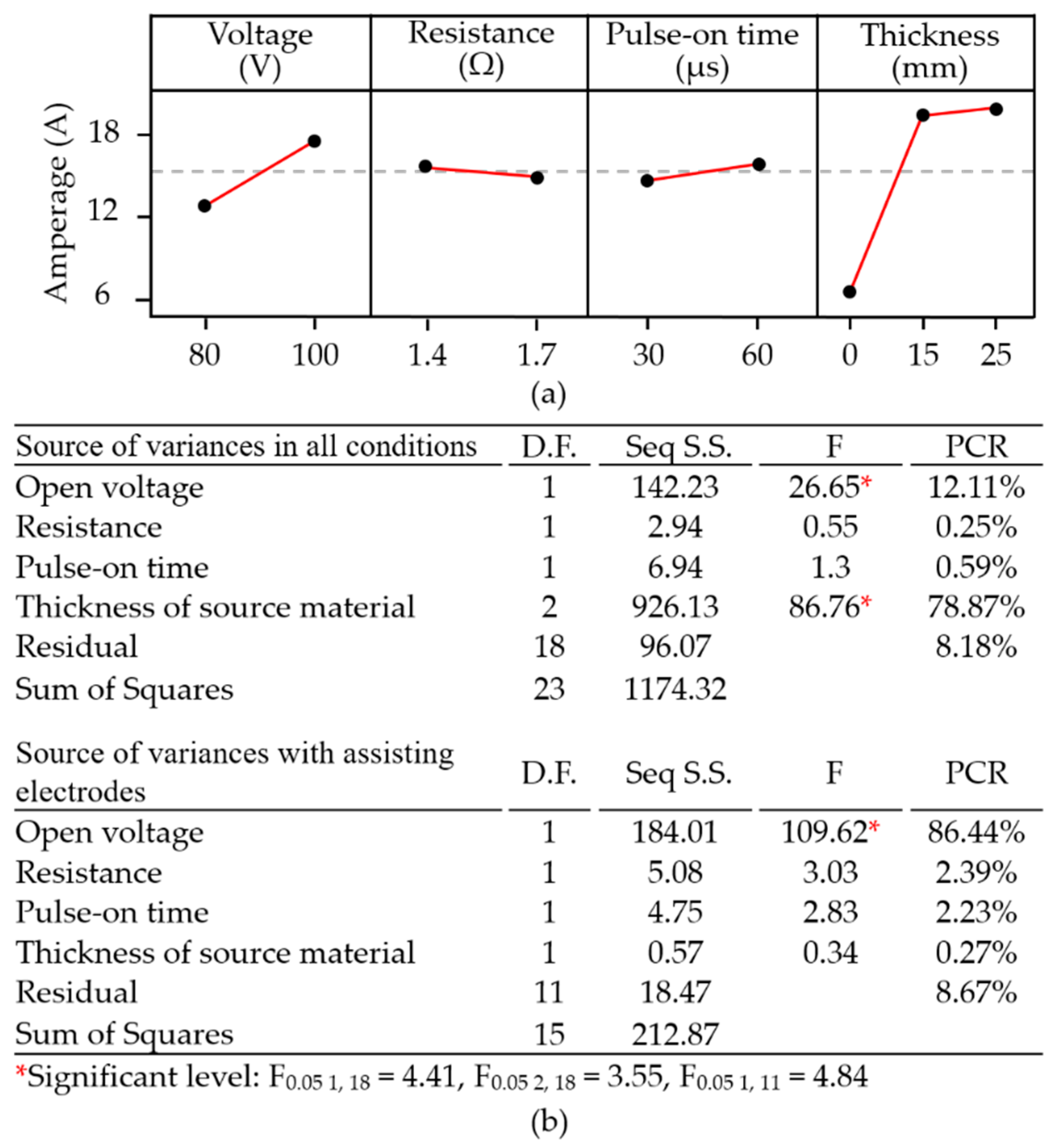

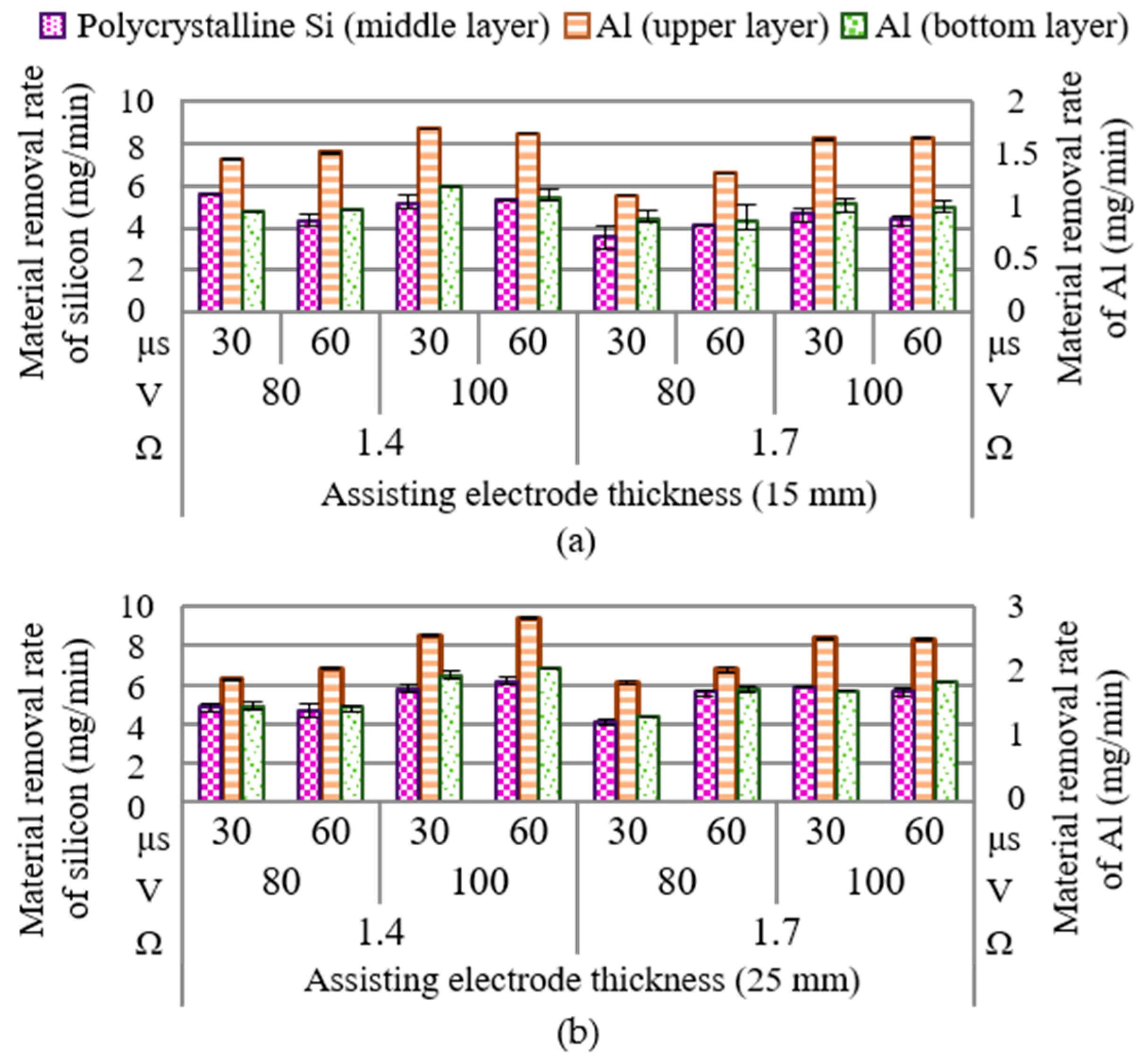

3.3. Material Removal

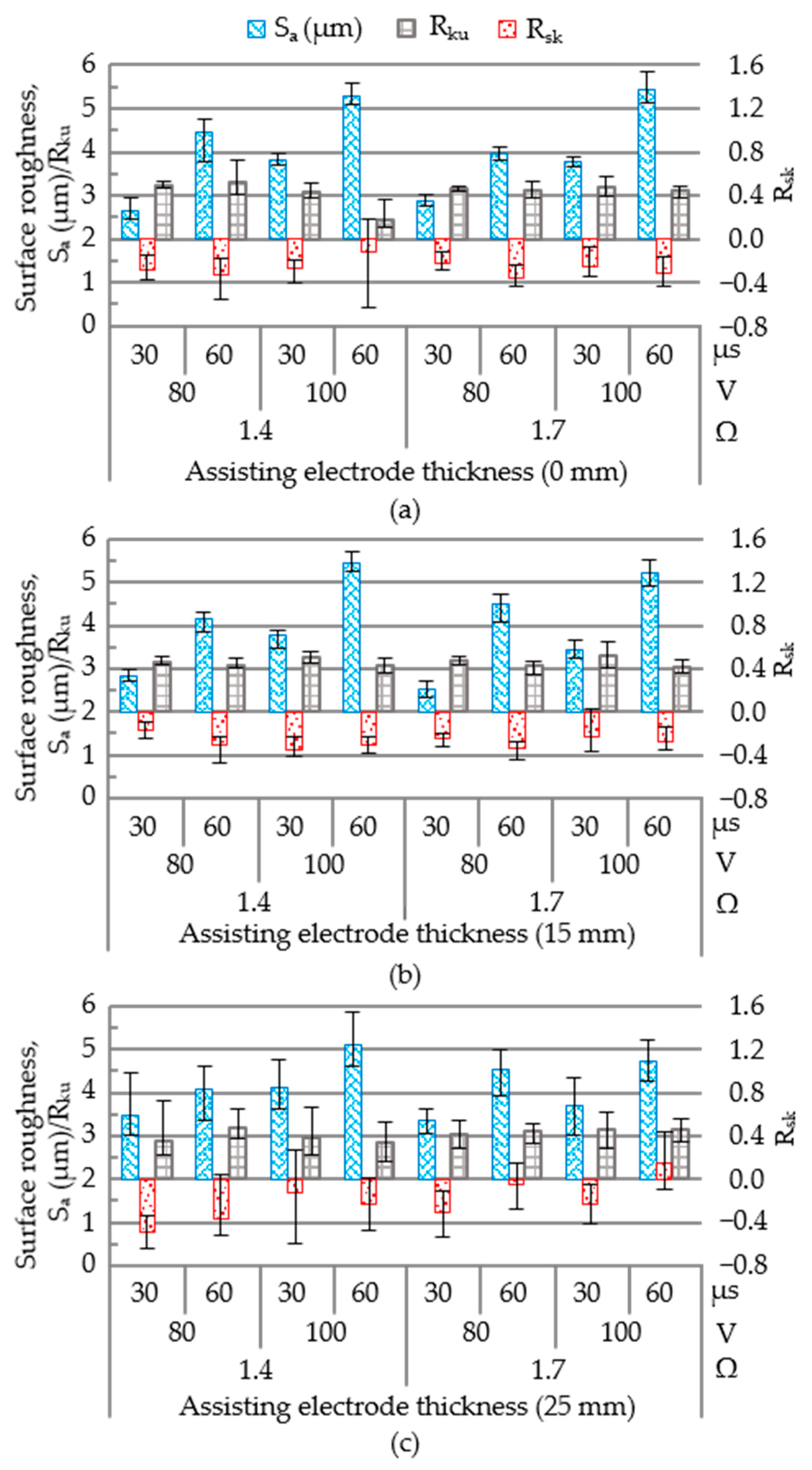

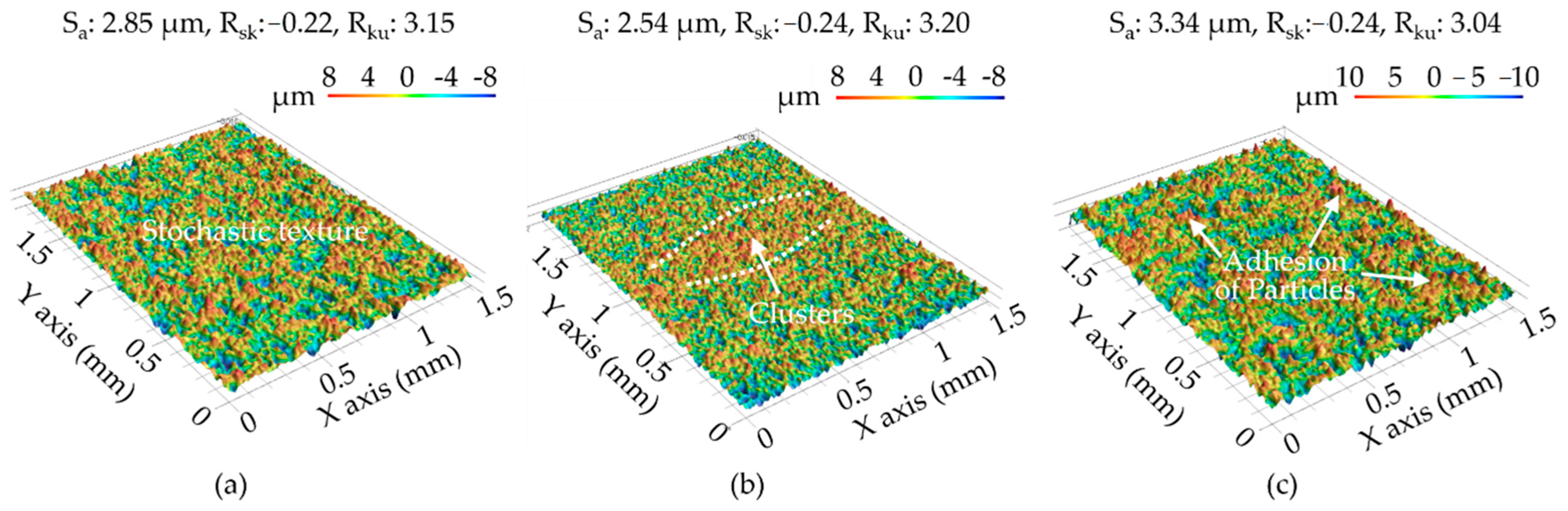

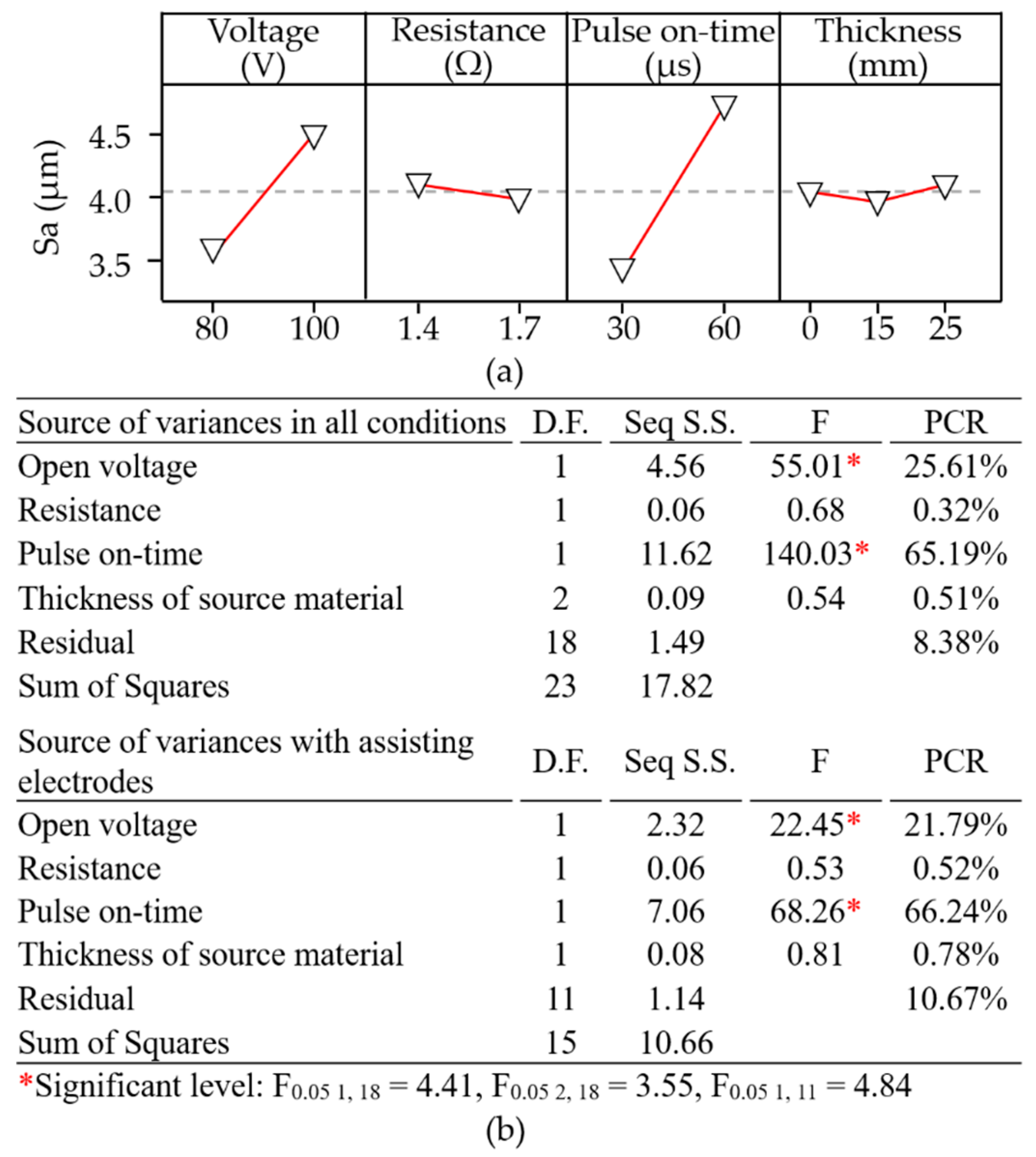

3.4. Surface Roughness

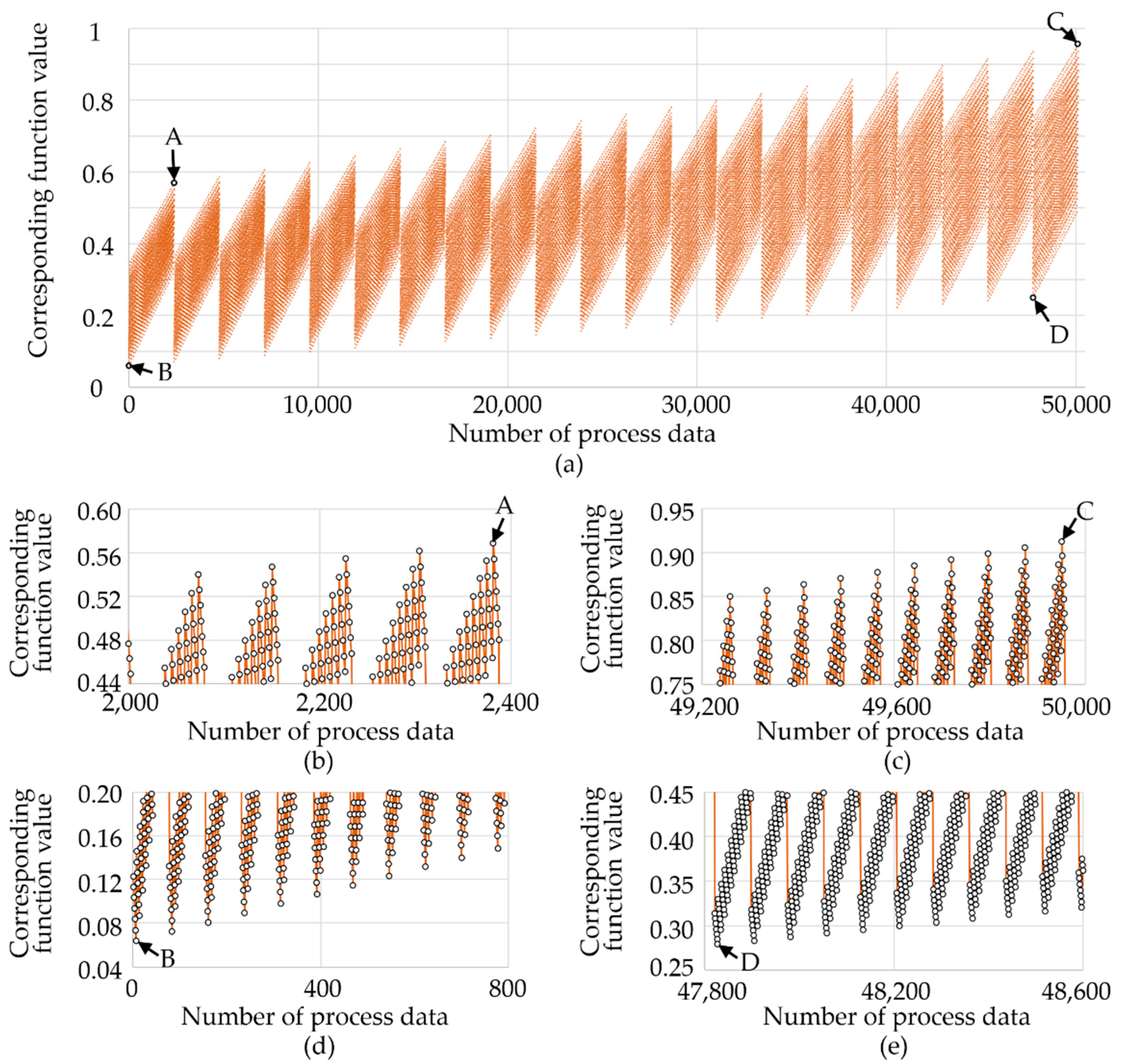

3.5. Multi-Objective Optimization

4. Conclusions

- The modified surface tended to increase conductivity in the discharging region of the polycrystalline silicon workpiece, thereby promoting discharging actions and drawing high currents (~25.35 A). The low conductivity of polycrystalline silicon (~10 μΩ·m) was overcome through application of conductive assisting electrodes (~0.04 μΩ·m) to reduce turn-on delays (~1.4 μs), albeit at the cost of increased turn-off delays (~10.9 μs).

- The deposition of aluminum did not increase proportionally with the thickness of the assisting electrodes, since the drawn current did not increase proportionally with their thickness. There was effective migration of aluminum to the machined surfaces when using assisting electrodes of 15 mm (1.80–3.32 wt %) and 25 mm (2.46–3.86%) over a sample area of 50 × 50 μm2.

- Assisting electrodes are meant to enhance the conductivity of the polycrystalline silicon workpiece when the pulse-on time sufficiently exceeds the recorded turn-on delay interval. When using assisting electrodes (15 or 25 mm), the parameter with the most pronounced effect on material removal was the open voltage (PCR = 78.22%). The optimal parameter combination in terms of material removal rate was as follows: high open voltage (100 V), high electrical resistance (1.4 Ω), long pulse-on time (60 μs), and thick assisting electrodes (25 mm).

- Machined surface quality in terms of skewness (Rsk = −0.49–0.15) and kurtosis (Rku = 2.45–3.30) depended on the deposition of molten aluminum particles in the form of aggregate and clusters; however, the deposition of aluminum did not adversely affect the average surface roughness. The parameter combination used to obtain the optimal surface roughness (Sa 2.54 μs) was as follows: open voltage (80 V), electrical resistance (1.7 Ω), pulse-on time (30 μs), and electrode thickness (15 mm).

- In the multiple objective optimization, the preferred parameter combination (open voltage = 80 V, resistance = 1.4 Ω, pulse-on time = 60 μs, and assisting electrode thickness = 25 mm) achieved the following results: surface modification (3.26 ± 0.61 wt %), material removal rate (7.08 ± 2.2 mg/min), and surface roughness (Sa = 4.3 ± 1.67 μm).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chung, C.; Nhat, L.V. Generation of diamond wire sliced wafer surface based on the distribution of diamond grits. Int. J. Precis. Eng. Manuf. 2014, 15, 789–796. [Google Scholar] [CrossRef]

- Lee, H.; Lee, D.; Jeong, H. Mechanical aspects of the chemical mechanical polishing process: A review. Int. J. Precis. Eng. Manuf. 2016, 17, 525–536. [Google Scholar] [CrossRef]

- Wang, Y.-G.; Chen, Y.; Zhao, Y.-W. Chemical mechanical planarization of silicon wafers at natural pH for green manufacturing. Int. J. Precis. Eng. Manuf. 2015, 16, 2049–2054. [Google Scholar] [CrossRef]

- Salvatori, S.; Pettinato, S.; Piccardi, A.; Sedov, V.; Voronin, A.; Ralchenko, V. Thin Diamond Film on Silicon Substrates for Pressure Sensor Fabrication. Materials 2020, 13, 3697. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Tian, Y.; Teng, C.; Cao, H. Recent Advances in Barrier Layer of Cu Interconnects. Materials 2020, 13, 5049. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Gao, Y.; Yin, Y.; Wang, L.; Pu, T. Experiment and theoretical prediction for surface roughness of PV polycrystalline silicon wafer in electroplated diamond wire sawing. J. Manuf. Process. 2020, 49, 82–93. [Google Scholar] [CrossRef]

- Gao, Y.; Ge, P.; Zhang, L.; Bi, W. Material removal and surface generation mechanisms in diamond wire sawing of silicon crystal. Mater. Sci. Semicond. Process. 2019, 103, 104462. [Google Scholar] [CrossRef]

- Yin, Y.; Gao, Y.; Li, X.; Pu, T.; Wang, L. Experimental study on slicing photovoltaic polycrystalline silicon with diamond wire saw. Mater. Sci. Semicond. Process. 2020, 106, 104779. [Google Scholar] [CrossRef]

- Chen, W.; Liu, X.; Li, M.; Yin, C.; Zhou, L. On the nature and removal of saw marks on diamond wire sawn multicrystalline silicon wafers. Mater. Sci. Semicond. Process. 2014, 27, 220–227. [Google Scholar] [CrossRef]

- Ozturk, S.; Aydin, L.; Celik, E. A comprehensive study on slicing processes optimization of silicon ingot for photovoltaic applications. Sol. Energy 2018, 161, 109–124. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, H.; Yu, N.; Liang, R.; Tong, Z.; Chen, Z.; Wang, J. Evaluation of fixed abrasive diamond wire sawing induced subsurface damage of solar silicon wafers. J. Mater. Process. Technol. 2019, 273, 116267. [Google Scholar] [CrossRef]

- Takino, H.; Ichinohe, T.; Tanimoto, K.; Yamaguchi, S.; Nomura, K.; Kunieda, M. Cutting of polished single-crystal silicon by wire electrical discharge machining. Precis. Eng. 2004, 28, 314–319. [Google Scholar] [CrossRef]

- Saleh, T.; Rasheed, A.N.; Muthalif, A.G.A. Experimental study on improving μ-WEDM and μ-EDM of doped silicon by temporary metallic coating. Int. J. Adv. Manuf. Technol. 2015, 78, 1651–1663. [Google Scholar] [CrossRef]

- Yeh, C.-C.; Wu, K.-L.; Lee, J.-W.; Yan, B.-H. Study on surface characteristics using phosphorous dielectric on wire electrical discharge machining of polycrystalline silicon. Int. J. Adv. Manuf. Technol. 2013, 69, 71–80. [Google Scholar] [CrossRef]

- Dongre, G.; Zaware, S.; Dabade, U.; Joshi, S.S. Multi-objective optimization for silicon wafer slicing using wire-EDM process. Mater. Sci. Semicond. Process. 2015, 39, 793–806. [Google Scholar] [CrossRef]

- Punturat, J.; Tangwarodomnukun, V.; Dumkum, C. Surface characteristics and damage of monocrystalline silicon induced by wire-EDM. Appl. Surf. Sci. 2014, 320, 83–92. [Google Scholar] [CrossRef]

- Pei, Z.J. A study on surface grinding of 300 mm silicon wafers. Int. J. Mach. Tools Manuf. 2002, 42, 385–393. [Google Scholar] [CrossRef]

- Xie, J.; Zhuo, Y.W.; Tan, T.W. Experimental study on fabrication and evaluation of micro pyramid-structured silicon surface using a V-tip of diamond grinding wheel. Precis. Eng. 2011, 35, 173–182. [Google Scholar] [CrossRef]

- Young, H.T.; Liao, H.T.; Huang, H.Y. Surface integrity of silicon wafers in ultra precision machining. Int. J. Adv. Manuf. Technol. 2006, 29, 372–378. [Google Scholar] [CrossRef]

- Gao, S.; Kang, R.; Dong, Z.; Zhang, B. Edge chipping of silicon wafers in diamond grinding. Int. J. Mach. Tools Manuf. 2013, 64, 31–37. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, P.; An, T.; Dai, Y.; Qin, F. Analytical prediction for depth of subsurface damage in silicon wafer due to self-rotating grinding process. Curr. Appl. Phys. 2019, 19, 570–581. [Google Scholar] [CrossRef]

- Huijun, P.; Zhidong, L.; Lian, G.; Mingbo, Q.; Zongjun, T. Study of small holes on monocrystalline silicon cut by WEDM. Mater. Sci. Semicond. Process. 2013, 16, 385–389. [Google Scholar] [CrossRef]

- Dongre, G.G.; Vesivkar, C.; Singh, R.; Joshi, S.S. Modeling of silicon ingot slicing process by wire–electrical discharge machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1664–1678. [Google Scholar] [CrossRef]

- Tian, Y.; Qiu, M.; Liu, Z.; Tian, Z.; Huang, Y. Discharge cutting technology for specific crystallographic planes of monocrystalline silicon. Mater. Sci. Semicond. Process. 2014, 27, 546–552. [Google Scholar] [CrossRef]

- Ge, M.; Liu, Z.; Shen, L.; Ding, H.; Chen, H.; Tian, Z. Thickness measurement of deterioration layer of monocrystalline silicon by specific crystallographic plane cutting of wire electrical discharge machining. J. Mater. Sci. Mater. Electron. 2016, 27, 9107–9114. [Google Scholar] [CrossRef]

- Reynaerts, D.; Heeren, P.-H.; Van Brussel, H. Microstructuring of silicon by electro-discharge machining (EDM)—Part I: Theory. Sens. Actuators A Phys. 1997, 60, 212–218. [Google Scholar] [CrossRef]

- Peng, W.Y.; Liao, Y.S. Study of electrical discharge machining technology for slicing silicon ingots. J. Mater. Process. Technol. 2003, 140, 274–279. [Google Scholar] [CrossRef]

- Lee, H.G.; Simao, J.; Aspinwall, D.K.; Dewes, R.C.; Voice, W. Electrical discharge surface alloying. J. Mater. Process. Technol. 2004, 149, 334–340. [Google Scholar] [CrossRef]

- Takino, H.; Ichinohe, T.; Tanimoto, K.; Yamaguchi, S.; Nomura, K.; Kunieda, M. High-quality cutting of polished single-crystal silicon by wire electrical discharge machining. Precis. Eng. 2005, 29, 423–430. [Google Scholar] [CrossRef]

- Kuo, C.; Kao, H.; Wang, H. Novel design and characterisation of surface modification in wire electrical discharge machining using assisting electrodes. J. Mater. Process. Technol. 2017, 244, 136–149. [Google Scholar] [CrossRef]

- Sedky, S.; Fiorini, P.; Caymax, M.; Loreti, S.; Baert, K.; Hermans, L.; Mertens, R. Structural and mechanical properties of polycrystalline silicon germanium for micromachining applications. J. Microelectromech. Syst. 1999, 7, 365–372. [Google Scholar] [CrossRef]

- Turnlund, J.R.; Friberg, L.T. Molybdenum. In Handbook on the Toxicology of Metals, 3rd ed.; Nordberg, G.F., Fowler, B.A., Nordberg, M., Friberg, L.T., Eds.; Academic Press: Burlington, MA, Canada, 2007; Chapter 34; pp. 731–741. [Google Scholar]

- Metals Handbook; American Society for Metals: Russell Township, OH, USA, 1990; Volume 2.

- Kuo, C.; Jeng, J.Y. The Methodology of Cutting Semi/Non-conductive Material Using WEDM. R.O.C. Patent I571339, 21 February 2017. [Google Scholar]

- Kuo, C.; Jeng, J.Y. The Methodology of Cutting Semi/Non-conductive Material Using WEDM. Japan Patent 6568451, 28 August 2019. [Google Scholar]

| Method | Surface Roughness (μm) | Material Remove Rate (mm3/min) | Challenges | Reference |

|---|---|---|---|---|

| Wire-saw slicing | Ra 0.14–4.23 [6,7,8,9,10,11] | 28.7–94.4 [10,11] | Collapse pits [6,7,8,9,11] Fragmentation [7,8] Chipping-off [8] Scratching groove [6,7,8,9,10,11] | [6,7,8,9,10,11] |

| Diamond grinding | Ra 0.07–3.35 [12,13] | N/A | Grinding mark [12,14] Pitting [12,14] Crack [12,14,15] Chipping-off [16] | [12,13,14,15,16] |

| WEDM | Ra 2.31–6.3 [17,18,19,20] | 0.8–22.3 [17,18,20,21] | Chipping-off [17] Crack [17,18,19] Crater [19,20,21] Bump [21] | [17,18,19,20,21] |

| Test No. | Tsource workpiece (mm) | Electrical Resistance (Ω) | Open Voltage (V) | Pulse-on Time (μs) | Calculated Energy (mJ) |

|---|---|---|---|---|---|

| 1 | 15 | 1.7 | 100 | 30 | 65.79 |

| 2 | 25 | 1.4 | 100 | 30 | 75.76 |

| 3 | 15 | 1.7 | 80 | 30 | 42.11 |

| 4 | 0 | 1.7 | 100 | 30 | 65.79 |

| 5 | 0 | 1.4 | 80 | 30 | 48.48 |

| 6 | 25 | 1.4 | 80 | 60 | 96.97 |

| 7 | 25 | 1.7 | 100 | 30 | 65.79 |

| 8 | 15 | 1.7 | 80 | 60 | 84.21 |

| 9 | 15 | 1.4 | 100 | 30 | 75.76 |

| 10 | 25 | 1.4 | 80 | 30 | 48.48 |

| 11 | 15 | 1.7 | 100 | 60 | 131.58 |

| 12 | 0 | 1.4 | 100 | 30 | 75.76 |

| 13 | 0 | 1.7 | 80 | 30 | 42.11 |

| 14 | 0 | 1.4 | 100 | 60 | 151.52 |

| 15 | 15 | 1.4 | 80 | 60 | 96.97 |

| 16 | 0 | 1.7 | 80 | 60 | 84.21 |

| 17 | 15 | 1.4 | 100 | 60 | 151.52 |

| 18 | 25 | 1.7 | 80 | 30 | 42.11 |

| 19 | 25 | 1.7 | 100 | 60 | 131.58 |

| 20 | 0 | 1.7 | 100 | 60 | 131.58 |

| 21 | 25 | 1.7 | 80 | 60 | 84.21 |

| 22 | 15 | 1.4 | 80 | 30 | 48.48 |

| 23 | 25 | 1.4 | 100 | 60 | 151.52 |

| 24 | 0 | 1.4 | 80 | 60 | 33.74 |

| Objective | Optimal Combination | Regression Equation | |||

|---|---|---|---|---|---|

| x | y | z | k | ||

| Surface modification (wt %) | 100 | 1.4 | 60 | 25 | fsurface modification (x, y, z, k) = −0.1 − 0.007·x − 1.13·y + 0.070·z − 0.022·k + 0.0199·x·y − 0.000383·x·z + 0.00152·x·k − 0.0239·y·z − 0.0020·y·k + 0.000334·z·k |

| Material removal rate (mg/min) | 100 | 1.4 | 60 | 15 | fMRR (x, y, z, k) = 4.63 + 0.033·x − 0.49·y + 0.0841·z − 0.318·k − 0.0025·x·y − 0.000164·x·z + 0.003614·x·k − 0.0301·y·z + 0.0105·y·k − 0.000401·z·k |

| Surface roughness (μm) | 80 | 1.7 | 30 | 15 | fSa (x, y, z, k) = −6.91 + 0.1097·x + 2.61·y + 0.0139·z + 0.1364·k − 0.0393·x·y + 0.000186·x·z − 0.001016·x·k + 0.0158·y·z − 0.0077·y·k − 0.000652·z·k |

| Weighting Factor | Regression Equation | Parameters for Extreme Values | ||||

|---|---|---|---|---|---|---|

| x | y | z | k | Group | ||

| Surface modification: 33.33% Material removal rate: 33.33% Surface roughness: 33.33% | Fmulti-objective (x, y, z, k) = −0.7854 + 0.0448·x + 0.3267·y + 0.0305·z − 0.0527·k − 0.0072·x·y +0.0001·x·z + 0.0014·x·k − 0.0126·y·z + 0.0002·y·k − 0.0002·z·k | 80 | 1.4 | 60 | 25 | A |

| 80 | 1.7 | 30 | 0 | B | ||

| 90 | 1.4 | 60 | 25 | C | ||

| 90 | 1.65 | 30 | 0 | D | ||

| Objective | Experiment Results for Single Objective | Modelling Value in Multi-Objective Equation | Deviation | Interval of Deviation |

|---|---|---|---|---|

| Group A | ||||

| Surface modification (wt %) | 3.87 | 3.26 | −16% | (−24, 63) |

| Material removal rate (mg/min) | 9.28 | 7.08 | −24% | |

| Surface roughness (μm) | 2.63 | 4.3 | 63% | |

| Group B | ||||

| Surface modification (wt %) | 3.87 | 0.09 | −98% | (−98, 0) |

| Material removal rate (mg/min) | 9.28 | 6.69 | −28% | |

| Surface roughness (μm) | 2.63 | 2.63 | 0% | |

| Group C | ||||

| Surface modification (wt %) | 3.87 | 3.62 | −6% | (−12, 79) |

| Material removal rate (mg/min) | 9.28 | 8.18 | −12% | |

| Surface roughness (μm) | 2.63 | 4.71 | 79% | |

| Group D | ||||

| Surface modification (wt %) | 3.87 | 0.24 | −94% | (−94, 19) |

| Material removal rate (mg/min) | 9.28 | 7.01 | −24% | |

| Surface roughness (μm) | 2.63 | 3.13 | 19% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.; Nien, Y.; Chiang, A.; Hirata, A. Surface Modification Using Assisting Electrodes in Wire Electrical Discharge Machining for Silicon Wafer Preparation. Materials 2021, 14, 1355. https://doi.org/10.3390/ma14061355

Kuo C, Nien Y, Chiang A, Hirata A. Surface Modification Using Assisting Electrodes in Wire Electrical Discharge Machining for Silicon Wafer Preparation. Materials. 2021; 14(6):1355. https://doi.org/10.3390/ma14061355

Chicago/Turabian StyleKuo, Chunliang, Yupang Nien, Anchun Chiang, and Atsushi Hirata. 2021. "Surface Modification Using Assisting Electrodes in Wire Electrical Discharge Machining for Silicon Wafer Preparation" Materials 14, no. 6: 1355. https://doi.org/10.3390/ma14061355

APA StyleKuo, C., Nien, Y., Chiang, A., & Hirata, A. (2021). Surface Modification Using Assisting Electrodes in Wire Electrical Discharge Machining for Silicon Wafer Preparation. Materials, 14(6), 1355. https://doi.org/10.3390/ma14061355