Deformation Resistance Performance of Carbon Fiber-Reinforced Plastic Machined by Controlling Drilling Area Temperature below the Glass Transition Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. CFRP Laminates Manufacturing

2.2. Glass Transition Temperature of CFRP

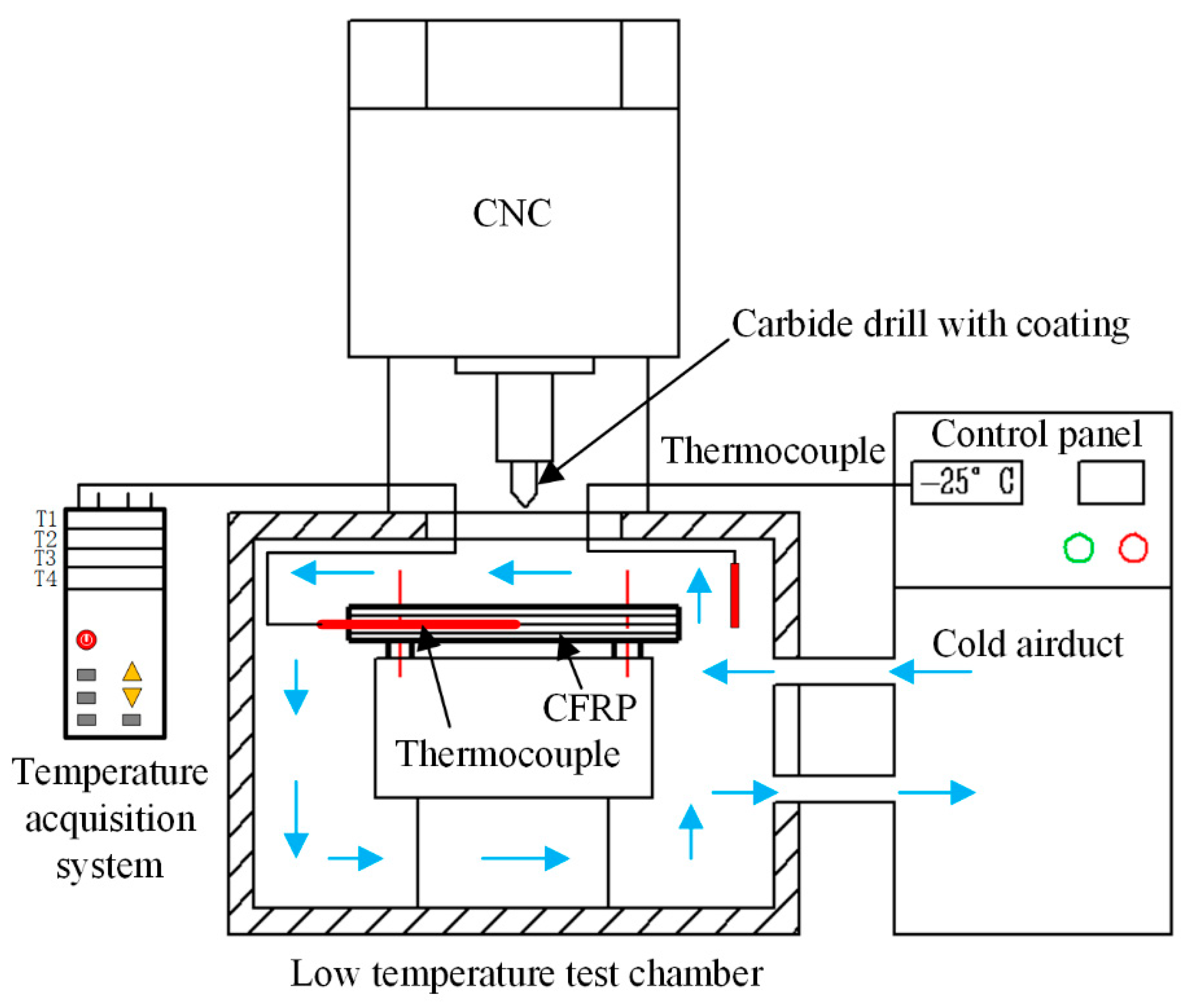

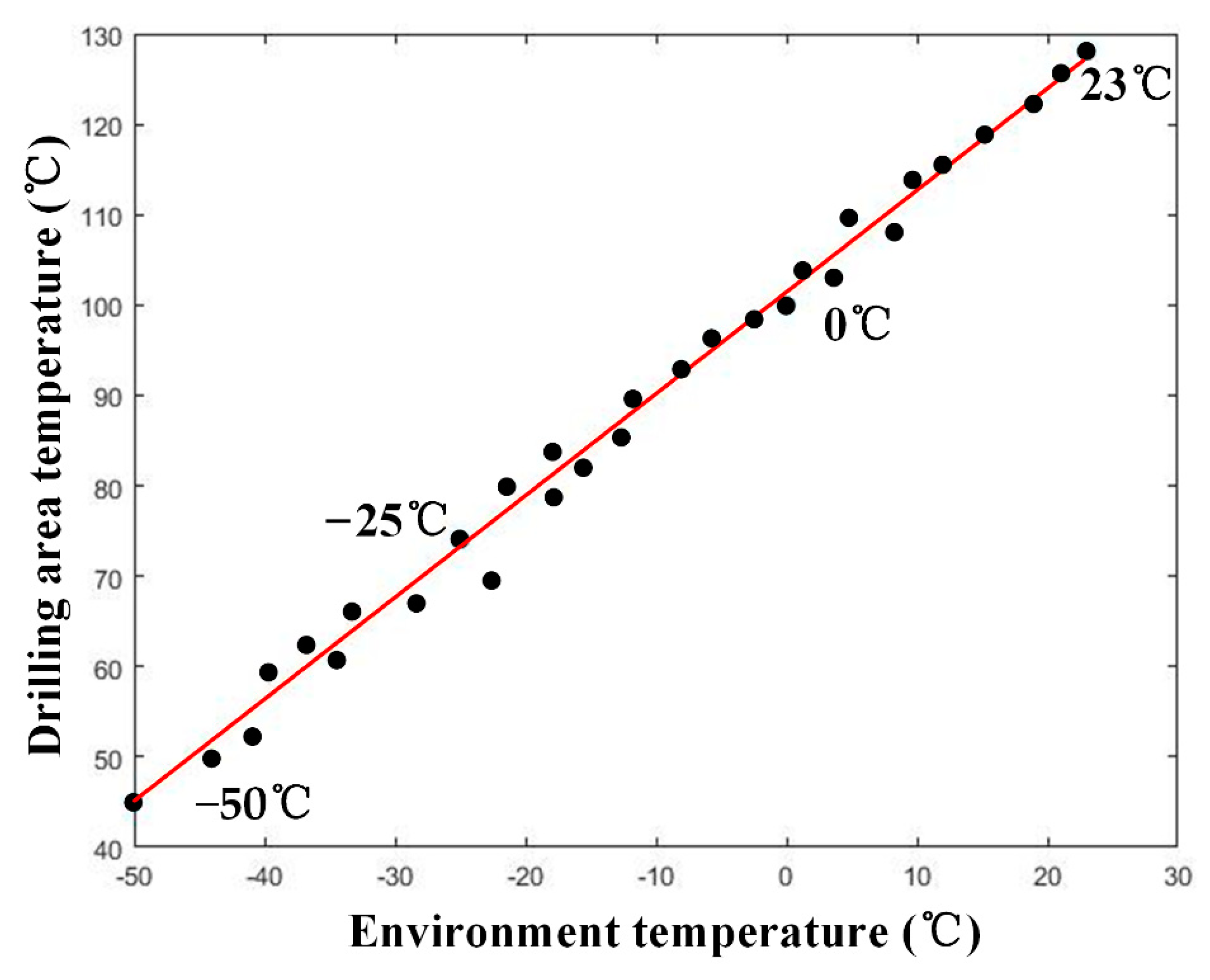

2.3. Experimental Design and Measurement

3. Results and Discussion

3.1. Glass Transition Temperature of CFRP

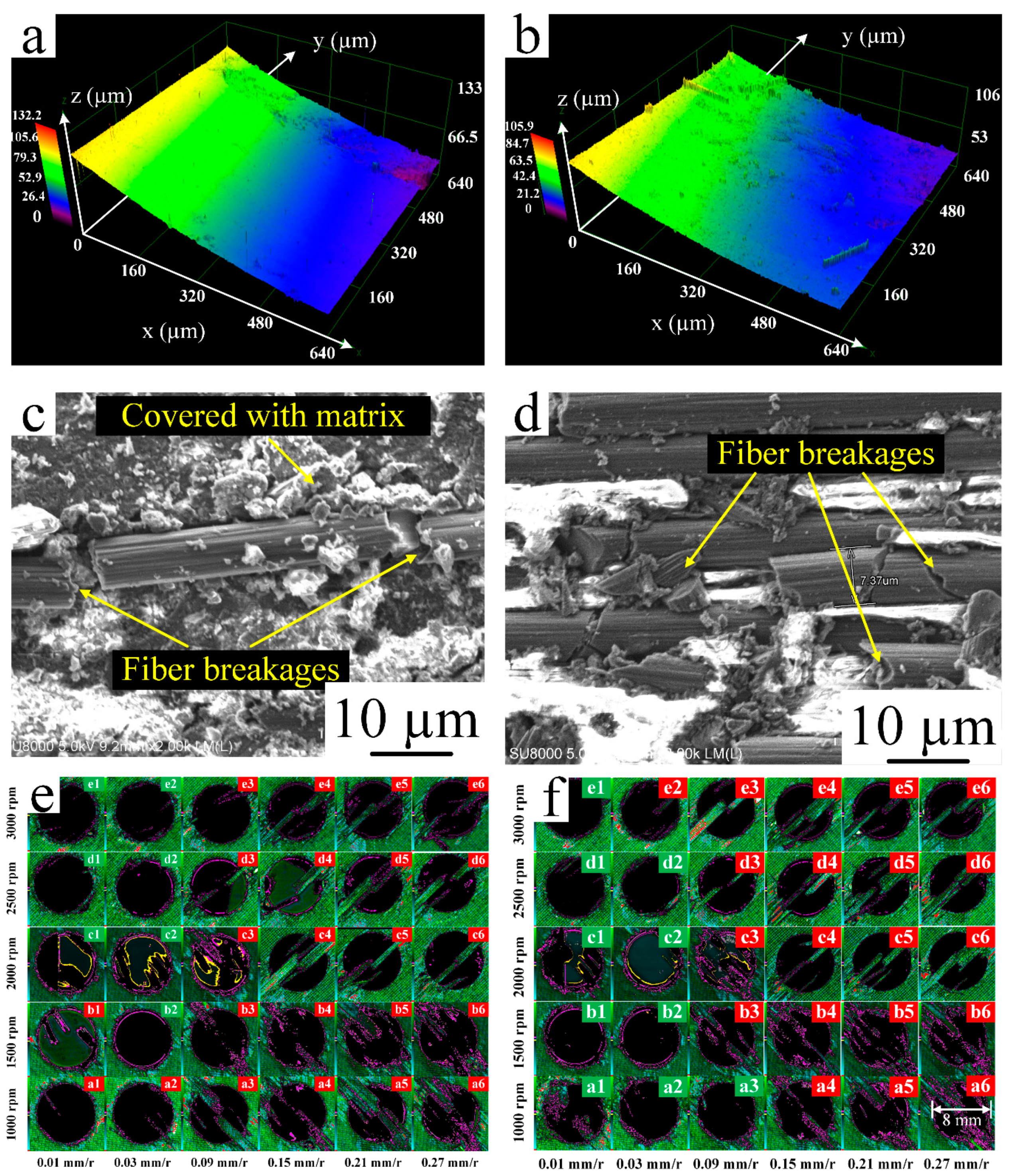

3.2. Drilling Test under Tg

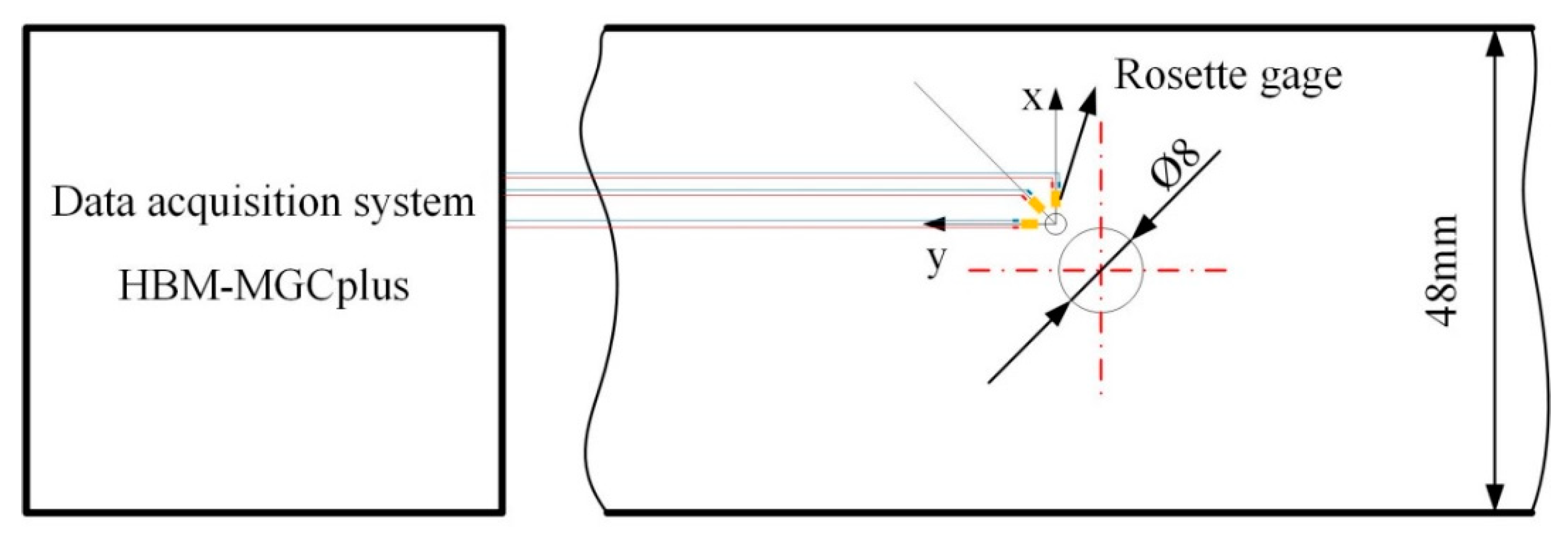

3.3. Analysis of Deformation Resistance Performance

3.4. Analysis of the Difference in Deformation Resistance Performance

4. Conclusions

- Machinability of CFRPs improved when DAT was lower than Tg. The occurrence of damages, such as burr, heat accumulation, etc., decreased due to the cryogenic machining approach.

- Although higher tensile/tensile deformation resistance property was obtained in the cryogenic machining, low compressive/compressive deformation resistance property was obtained simultaneously.

- After ten thousand compressive/compressive fatigue loadings, the residual intensity of specimens under cryogenic treatment was 7.14% lower than those of untreated specimens.

- The residual tensile stress of specimen subjected to cryogenic treatment was lower than those of untreated specimens when using the through-hole drilling method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geier, N.; Davim, J.P.; Szalay, T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105552. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Review on Machinability of Fiber Reinforced Polymers: A Drilling Approach. Silicon 2018, 10, 2295–2305. [Google Scholar] [CrossRef]

- Panchagnula, K.K.; Palaniyandi, K. Drilling on fiber reinforced polymer/nanopolymer composite laminates: A review. J. Mater. Res. Technol. 2018, 7, 180–189. [Google Scholar] [CrossRef]

- Romhány, G.; Kovács, L. Derivation of Ply Specific Stiffness Parameters of Fiber Reinforced Polymer Laminates via Inverse Solution of Classical Laminate Theory. Period. Polytech. Mech. Eng. 2018, 62, 158–164. [Google Scholar]

- Hegde, S.; Satish Shenoy, B.; Chethan, K.N. Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance. Mater. Today Proc. 2019, 19, 658–662. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Damage and dimensional precision on milling carbon fiber-reinforced plastics using design experiments. J. Mater. Process. Technol. 2005, 160, 160–167. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, K.; Cheng, H.; Luo, B.; Hou, G. Force coefficient prediction for drilling of UD-CFRP based on FEM simulation of orthogonal cutting. Int. J. Adv. Manuf. Technol. 2019, 104, 3695–3716. [Google Scholar] [CrossRef]

- Sur, G.; Erkan, Ö. Surface quality optimization of CFRP plates drilled with standard and step drill bits using TAGUCHI, TOPSIS and AHP method. Eng. Comput. 2020. [Google Scholar] [CrossRef]

- Raj, D.S.; Karunamoorthy, L. A new and comprehensive characterisation of tool wear in CFRP drilling using micro-geometry and topography studies on the cutting edge. J. Manuf. Process. 2018, 32, 839–856. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Ren, F. An investigation of drilling high-strength CFRP composites using specialized drills. Int. J. Adv. Manuf. Technol. 2019, 103, 3425–3442. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Zhang, C.; Wang, F.J.; Fu, R.; Chen, C. An investigation of the effects of step drill geometry on drilling induced delamination and burr of Ti/CFRP stacks. Compos. Struct. 2020, 235, 111786. [Google Scholar] [CrossRef]

- Karpat, Y.; DeÄŸer, B.; Bahtiyar, O. Drilling thick fabric woven CFRP laminates with double point angle drills. J. Mater. Process. Technol. 2012, 212, 2117–2127. [Google Scholar] [CrossRef]

- Slamani, M.; Chatelain, J.-F.; Hamedanianpour, H. Comparison of two models for predicting tool wear and cutting force components during high speed trimming of CFRP. Int. J. Mater. Form. 2015, 8, 305–316. [Google Scholar] [CrossRef]

- Sala, G. Composite degradation due to fluid absorption. Compos. Part B Eng. 2000, 31, 357–373. [Google Scholar] [CrossRef]

- Khashaba, U.A. Drilling of polymer matrix composites: A review. J. Compos. Mater. 2012, 47, 1817–1832. [Google Scholar] [CrossRef]

- Weinert, K.; Kempmann, C. Cutting Temperatures and Their Effects on the Machining Behaviour in Drilling Reinforced Plastic Composites. Adv. Eng. Mater. 2004, 6, 684–689. [Google Scholar] [CrossRef]

- Fu, R.; Jia, Z.; Wang, F.; Jin, Y.; Sun, D.; Yang, L.; Cheng, D. Drill-exit temperature characteristics in drilling of UD and MD CFRP composites based on infrared thermography. Int. J. Mach. Tools Manuf. 2018, 135, 24–37. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Paulo Davim, J. On the analysis of temperatures, surface morphologies and tool wear in drilling CFRP/Ti6Al4V stacks under different cutting sequence strategies. Compos. Struct. 2020, 234, 111708. [Google Scholar] [CrossRef]

- Impero, F.; Dix, M.; Squillace, A.; Prisco, U.; Palumbo, B.; Tagliaferri, F. A comparison between wet and cryogenic drilling of CFRP/Ti stacks. Mater. Manuf. Process. 2018, 33, 1354–1360. [Google Scholar] [CrossRef]

- Chatterjee, A. Thermal degradation analysis of thermoset resins. J. Appl. Polym. Sci. 2009, 114, 1417–1425. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Dang, J.; El Mansori, M.; Ren, F. A Study on Drilling High-Strength CFRP Laminates: Frictional Heat and Cutting Temperature. Materials 2018, 11, 2366. [Google Scholar] [CrossRef] [PubMed]

- Abish, J.; Samal, P.; Narenther, M.S.; Kannan, C.; Balan, A.S.S. Assessment of drilling-induced damage in CFRP under chilled air environment. Mater. Manuf. Process. 2018, 33, 1361–1368. [Google Scholar] [CrossRef]

- John, K.M.; Kumaran, S.T. A feasible strategy to produce quality holes using temperature-assisted drilling on CFRP. Int. J. Adv. Manuf. Technol. 2020, 110, 3113–3127. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Dargusch, M.S. Thermally enhanced machining of hard-to-machine materials—A review. Int. J. Mach. Tools Manuf. 2010, 50, 663–680. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Muñoz-Escalona, P.; Newman, S.T. State-of-the-art cryogenic machining and processing. Int. J. Comput. Integr. Manuf. 2013, 26, 616–648. [Google Scholar] [CrossRef]

- Basmaci, G.; Yoruk, A.S.; Koklu, U.; Morkavuk, S. Impact of Cryogenic Condition and Drill Diameter on Drilling Performance of CFRP. Appl. Sci. 2017, 7, 667. [Google Scholar] [CrossRef]

- Rajkumar, G.M.; Bhardwaj, D.; Kannan, C.; Oyyaravelu, R.; Balan, A.S.S. Effect of chilled air on delamination, induced vibration, burr formation and surface roughness in CFRP drilling: A comparative study. Mater. Res. Express 2018, 6, 035305. [Google Scholar] [CrossRef]

- Samuel Raj, D.; Karunamoorthy, L. Performance of cryogenically treated WC drill using tool wear measurements on the cutting edge and hole surface topography when drilling CFRP. Int. J. Refract. Met. Hard Mater. 2019, 78, 32–44. [Google Scholar] [CrossRef]

- Kumar, D.; Gururaja, S.; Jawahir, I.S. Machinability and surface integrity of adhesively bonded Ti/CFRP/Ti hybrid composite laminates under dry and cryogenic conditions. J. Manuf. Process. 2020, 58, 1075–1087. [Google Scholar] [CrossRef]

- Wang, F.; Qian, B.; Jia, Z.; Cheng, D.; Fu, R. Effects of cooling position on tool wear reduction of secondary cutting edge corner of one-shot drill bit in drilling CFRP. Int. J. Adv. Manuf. Technol. 2018, 94, 4277–4287. [Google Scholar] [CrossRef]

- Ferreira Batista, M.; Basso, I.; de Assis Toti, F.; Roger Rodrigues, A.; Ricardo Tarpani, J. Cryogenic drilling of carbon fibre reinforced thermoplastic and thermoset polymers. Compos. Struct. 2020, 251, 112625. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, X.; Malakooti, M.H.; Sodano, H.A. Novel self-healing CFRP composites with high glass transition temperatures. Compos. Sci. Technol. 2018, 168, 96–103. [Google Scholar] [CrossRef]

- Melo, J.D.D.; Radford, D.W. Time and temperature dependence of the viscoelastic properties of CFRP by dynamic mechanical analysis. Compos. Struct. 2005, 70, 240–253. [Google Scholar] [CrossRef]

- Morkavuk, S.; Köklü, U.; Bağcı, M.; Gemi, L. Cryogenic machining of carbon fiber reinforced plastic (CFRP) composites and the effects of cryogenic treatment on tensile properties: A comparative study. Compos. Part B Eng. 2018, 147, 1–11. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, H.; Zhang, F.; Wang, M.; Zheng, Y. Comparison of the geometric accuracy of holes made in CFRP/Ti laminate by drilling and helical milling. Int. J. Adv. Manuf. Technol. 2021, 112, 3343–3350. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S. An Investigation of burrs, chip formation, hole size, circularity and delamination during drilling operation of GLARE using ANOVA. Compos. Struct. 2017, 159, 745–760. [Google Scholar] [CrossRef]

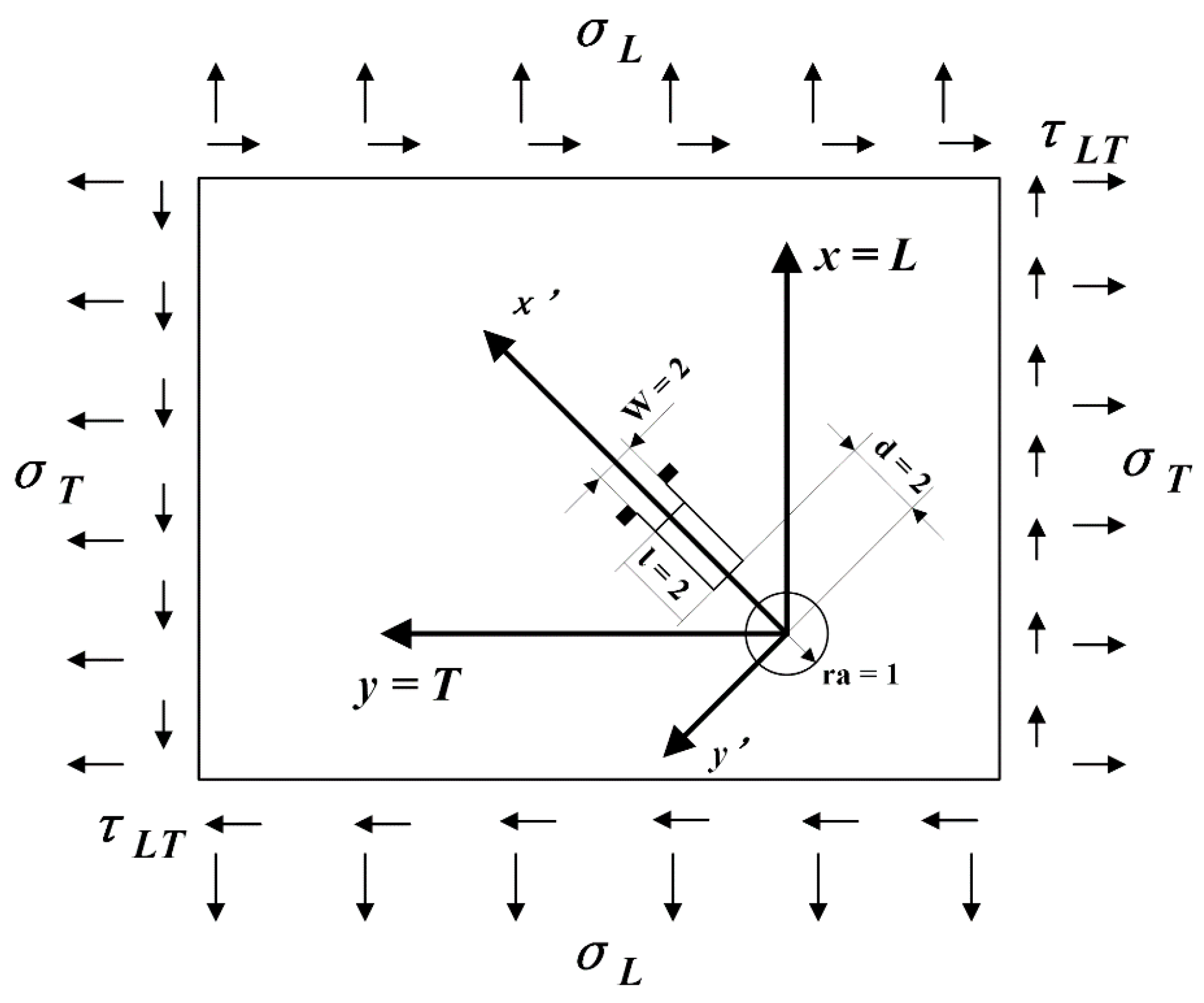

- Pagliaro, P.; Zuccarello, B. Residual Stress Analysis of Orthotropic Materials by the Through-hole Drilling Method. Exp. Mech. 2007, 47, 217–236. [Google Scholar] [CrossRef]

- Wang, H.; Duan, Y.; Abulizi, D.; Zhang, X. Design optimization of CFRP stacking sequence using a multi-island genetic algorithms under low-velocity impact loads. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2017, 32, 720–725. [Google Scholar] [CrossRef]

- Ahci, E.; Talreja, R. Characterization of viscoelasticity and damage in high temperature polymer matrix composites. Compos. Sci. Technol. 2006, 66, 2506–2519. [Google Scholar] [CrossRef]

| Parameters | Specimen 1 | Specimen 2 | Specimen 3 |

|---|---|---|---|

| Length (mm) | 60.4 | 60.3 | 59.62 |

| Width (mm) | 10.9 | 11.42 | 11.38 |

| Thickness (mm) | 3.34 | 3.3 | 3.28 |

| Parameters | Above Tg (40 °C) | Below Tg (−30 °C) |

|---|---|---|

| Roundness (tensile/tensile fatigue test) | 0.02525 | 0.01068 |

| Roundness (compressive/compressive fatigue test) | 0.01324 | 0.0233 |

| Parameters | Above Tg | Below Tg |

|---|---|---|

| Residual intensity (tensile/tensile fatigue test) (MPa) | 485.91 | 486.05 |

| Residual intensity (compressive/compressive fatigue test) (MPa) | 161.65 | 150.1 |

| Elastic Property | Value | Damage Properties | Value |

|---|---|---|---|

| () | 137,000 | () | 2000 |

| () | 9000 | () | 1150 |

| () | 9000 | () | 60 |

| 0.28 | () | 152 | |

| 0.28 | () | 75 | |

| 0.4 | () | 76 | |

| () | 3780 | – | – |

| () | 6000 | – | – |

| () | 6000 | – | – |

| () | 1.79 × 10−9 | – | – |

| Temperature | (µm) | (µm) | (µm) |

|---|---|---|---|

| 40 °C | −741 | −554 | −72 |

| −30 °C | −438 | −234 | −57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhang, X.; Duan, Y.; Xia, Y.; Ming, Y.; Zhu, Y. Deformation Resistance Performance of Carbon Fiber-Reinforced Plastic Machined by Controlling Drilling Area Temperature below the Glass Transition Temperature. Materials 2021, 14, 1394. https://doi.org/10.3390/ma14061394

Zhang C, Zhang X, Duan Y, Xia Y, Ming Y, Zhu Y. Deformation Resistance Performance of Carbon Fiber-Reinforced Plastic Machined by Controlling Drilling Area Temperature below the Glass Transition Temperature. Materials. 2021; 14(6):1394. https://doi.org/10.3390/ma14061394

Chicago/Turabian StyleZhang, Chenping, Xiaohui Zhang, Yugang Duan, Yu Xia, Yueke Ming, and Yansong Zhu. 2021. "Deformation Resistance Performance of Carbon Fiber-Reinforced Plastic Machined by Controlling Drilling Area Temperature below the Glass Transition Temperature" Materials 14, no. 6: 1394. https://doi.org/10.3390/ma14061394

APA StyleZhang, C., Zhang, X., Duan, Y., Xia, Y., Ming, Y., & Zhu, Y. (2021). Deformation Resistance Performance of Carbon Fiber-Reinforced Plastic Machined by Controlling Drilling Area Temperature below the Glass Transition Temperature. Materials, 14(6), 1394. https://doi.org/10.3390/ma14061394