Technical and Environmental Viability of a Road Bicycle Pedal Part Made of a Fully Bio-Based Composite Material

Abstract

:1. Introduction

2. Materials and Methods

3. Results

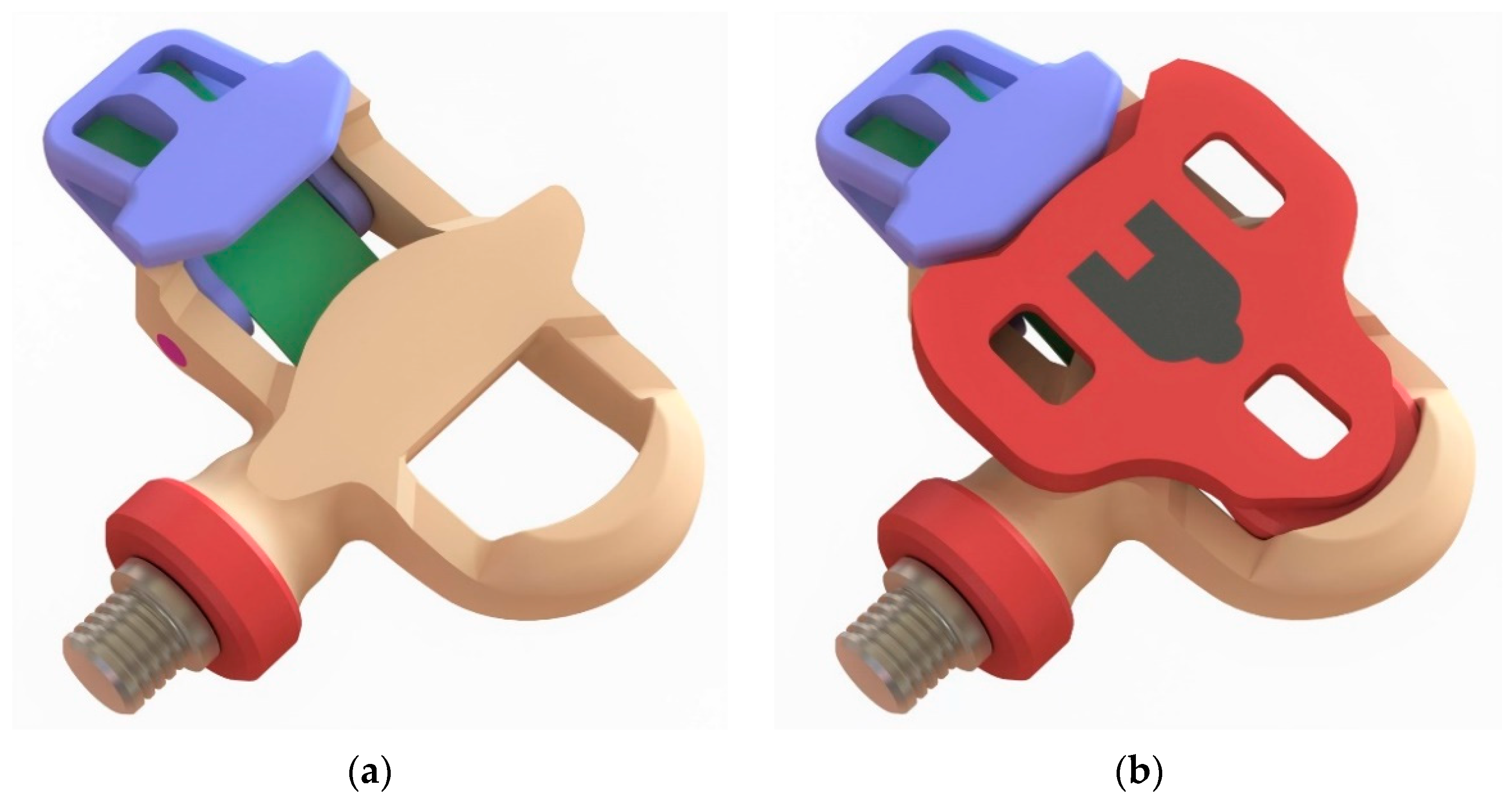

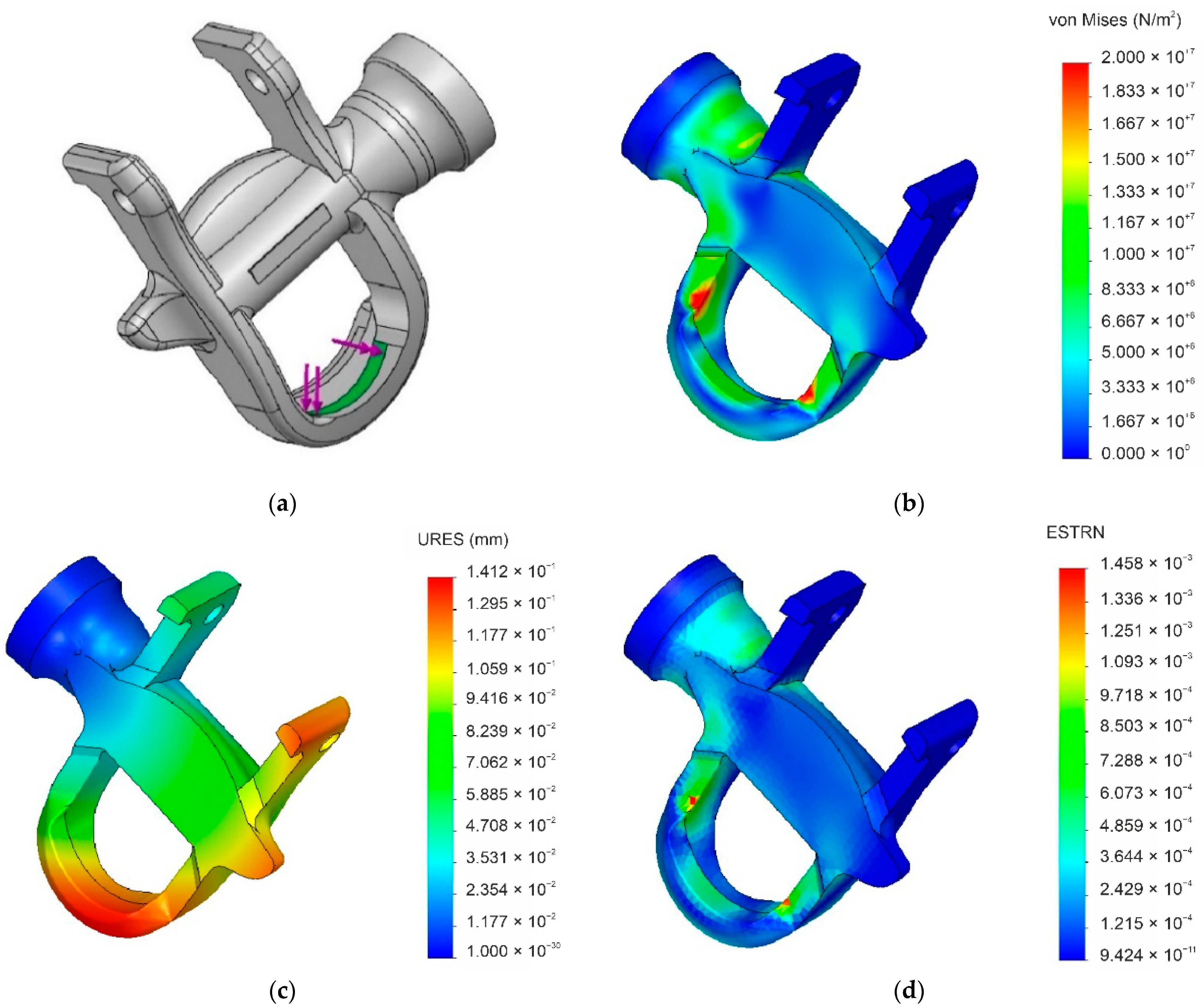

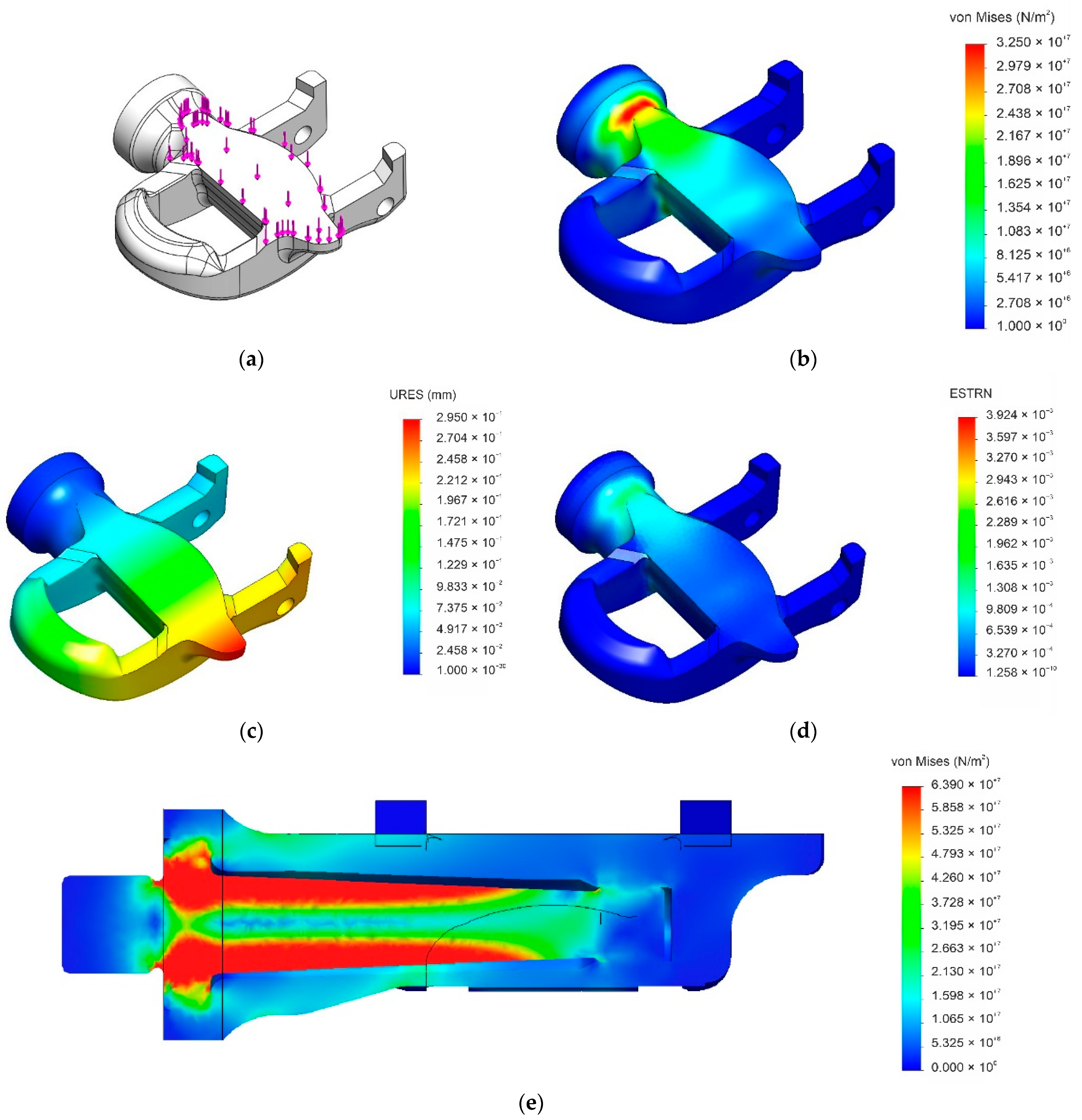

3.1. Definition of the Case Study

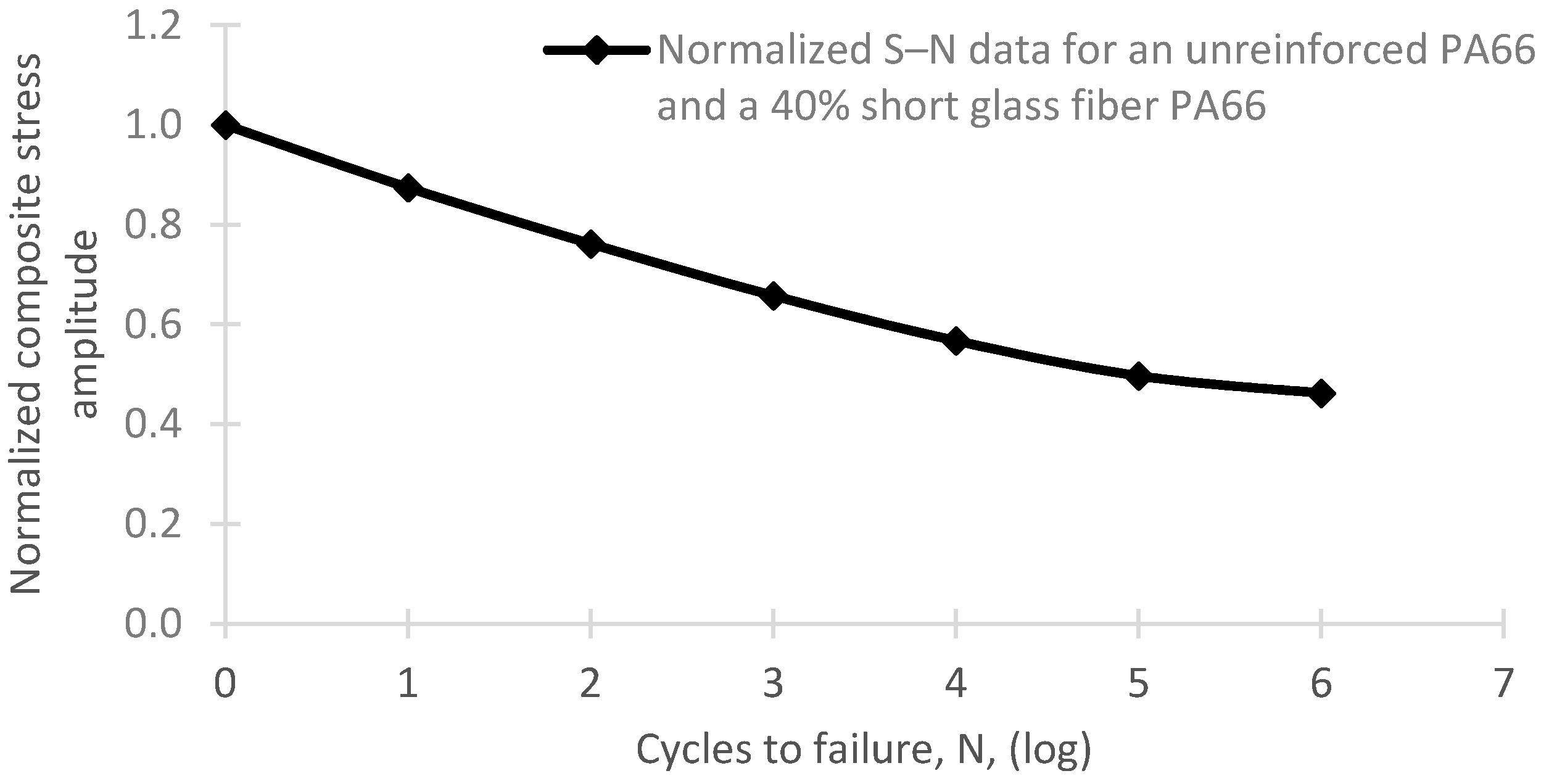

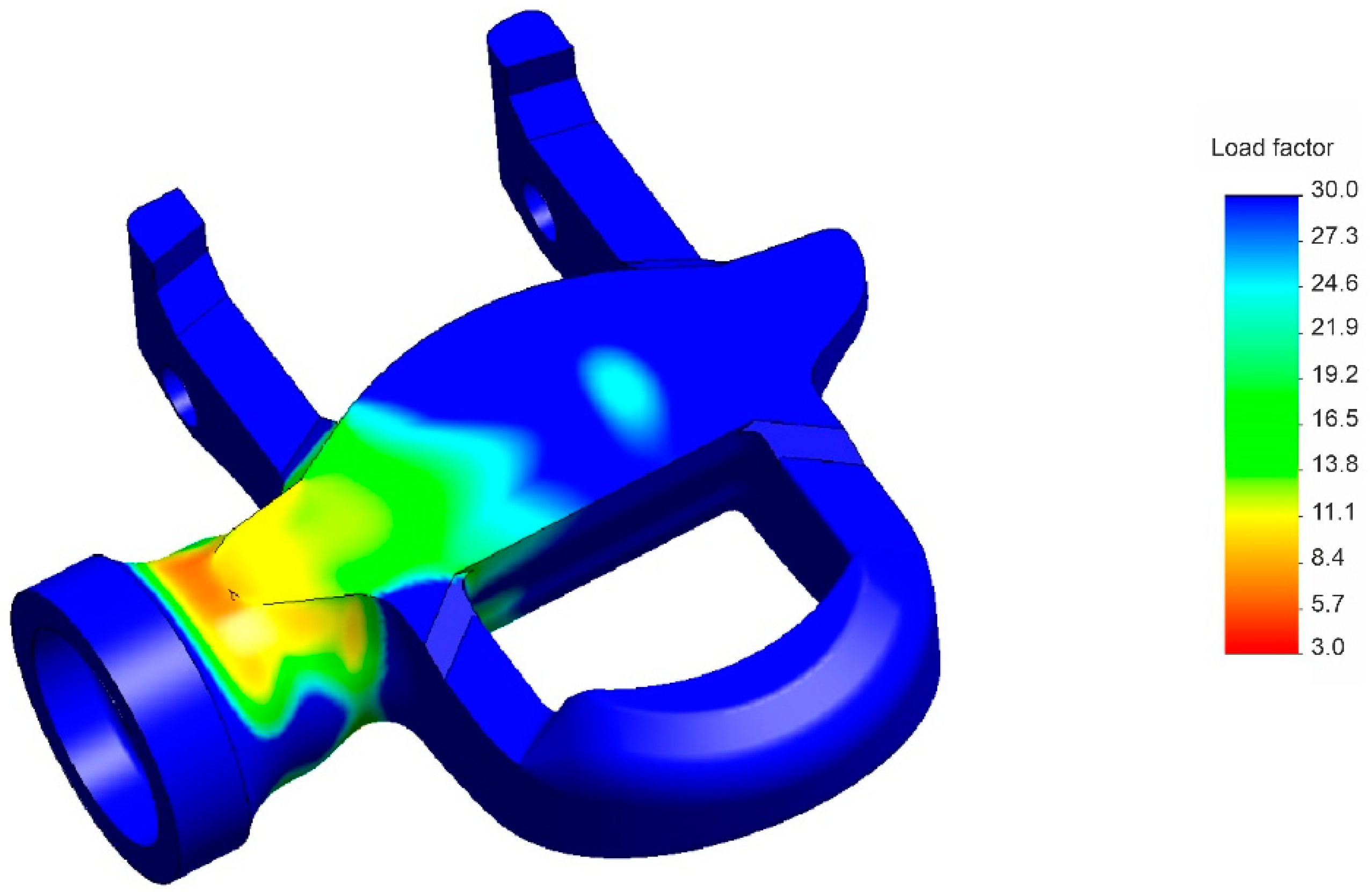

3.2. Analysis of the Test Case

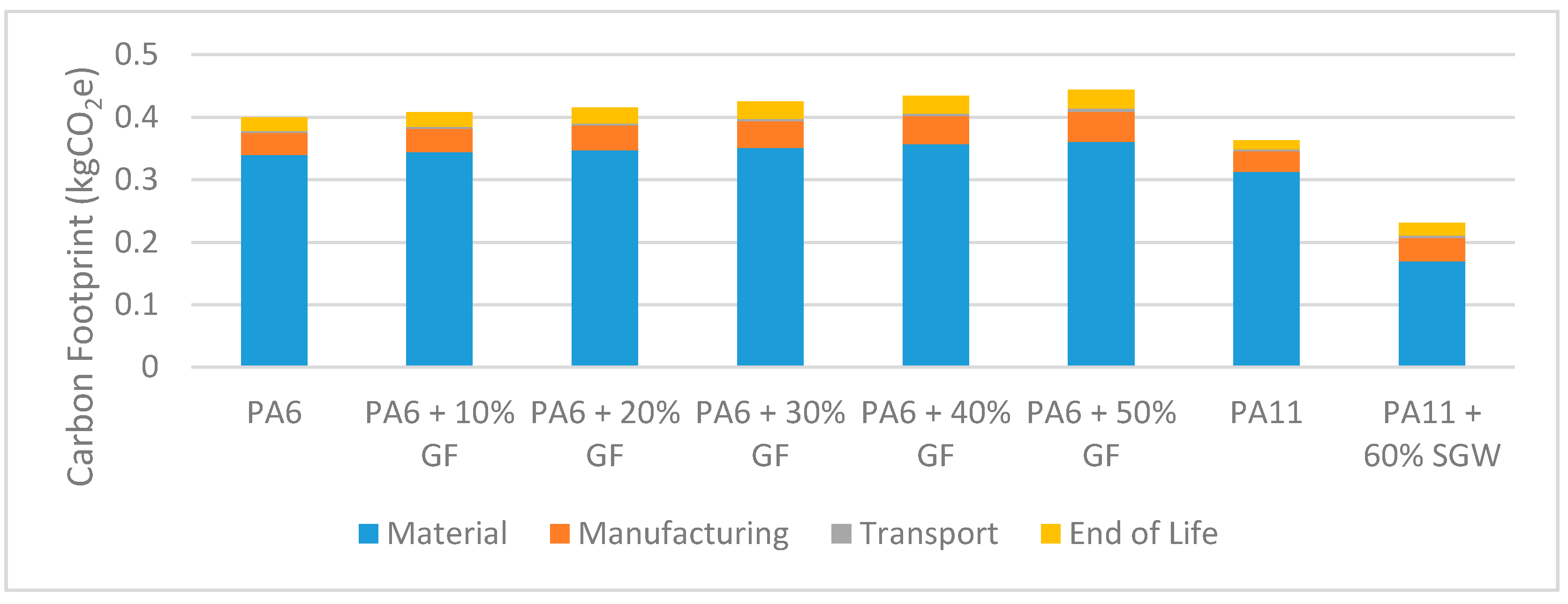

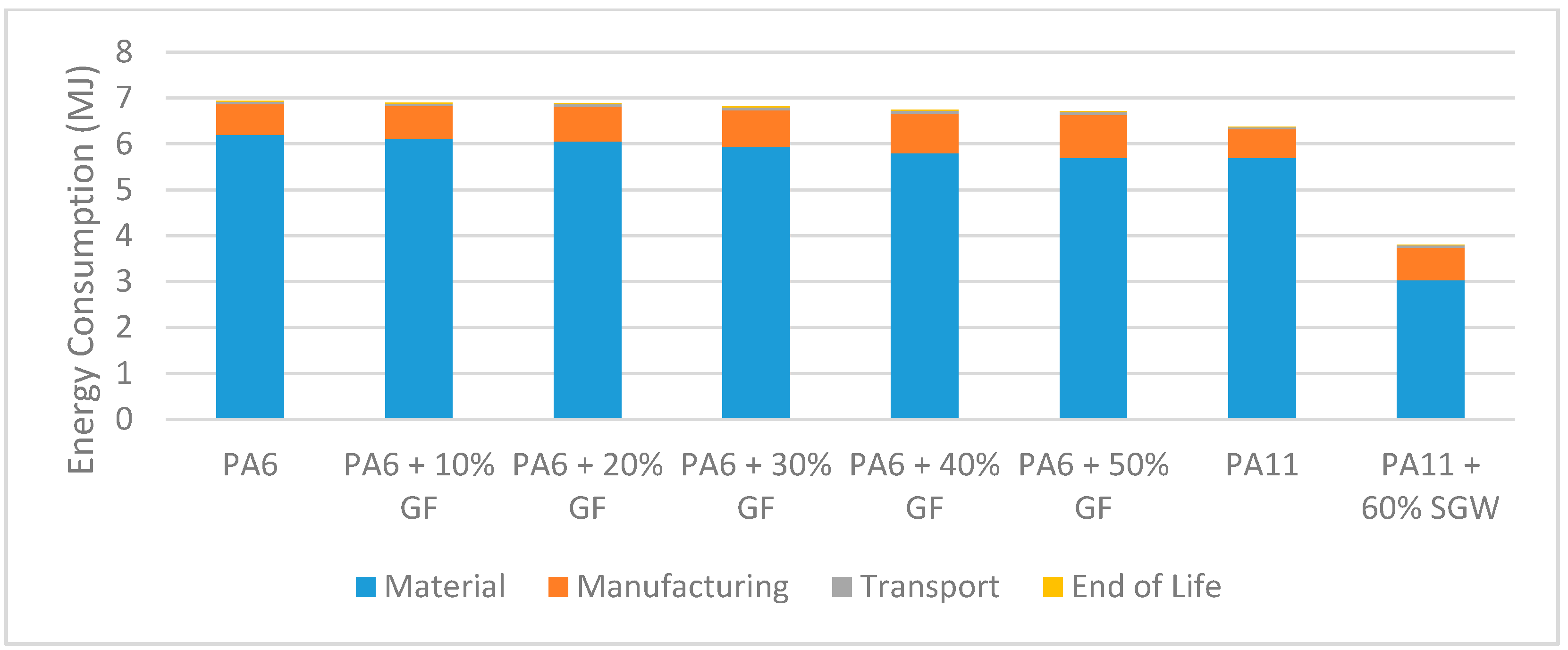

3.3. Life Cycle Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomason, J. Glass fibre sizing: A review. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, M.; Kumar, S.; Mohapatra, S.K. Properties of Glass-Fiber Hybrid Composites: A Review. Polym. Technol. Eng. 2016, 56, 455–469. [Google Scholar] [CrossRef]

- Kanitkar, Y.M.; Kulkarni, A.P.; Wangikar, K.S. Characterization of Glass Hybrid composite: A Review. Mater. Today Proc. 2017, 4, 9627–9630. [Google Scholar] [CrossRef]

- Tarvainen, K.; Jolanki, R.; Forsman-Grönholm, L.; Estlander, T.; Pfäffli, P.; Juntunen, J.; Kanerva, L. Exposure, skin protection and occupational skin diseases in the glass-fibre-reinforced plastics industry. Contact Dermat. 1993, 29, 119–127. [Google Scholar] [CrossRef]

- Hogan, D.J.; Morrison, M.; Desai, A. Fiberglass, Dusts. In Kanerva’s Occupational Dermatology; Springer International Publishing: New York, NY, USA, 2019; pp. 543–557. [Google Scholar]

- Milton, D.K.; Walters, M.D.; Hammond, K.; Evans, J.S. Worker exposure to endotoxin, phenolic compounds, and formal-dehyde in a fiberglass insulation manufacturing plant. Am. Ind. Hyg. Assoc. J. 1996, 57, 889–896. [Google Scholar] [CrossRef]

- Costa, R.; Orriols, R. Man-Made Mineral Fibers and the Respiratory Tract. Arch. Bronconeumol. 2012, 48, 460–468. [Google Scholar] [CrossRef] [PubMed]

- Baan, R.A.; Grosse, Y. Man-made mineral (vitreous) fibres: Evaluations of cancer hazards by the IARC Monographs Pro-gramme. Mutat. Res. 2004, 553, 43–58. [Google Scholar] [CrossRef]

- Kwak, K.; Paek, D.; Park, J. Occupational exposure to formaldehyde and risk of lung cancer: A systematic review and meta-analysis. Am. J. Ind. Med. 2020, 63, 312–327. [Google Scholar] [CrossRef] [PubMed]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of fiberglass wind turbine blades into reinforced fila-ments for use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Ciocan, C.; Kristova, P.; Annels, C.; Derjean, M.; Hopkinson, L. Glass reinforced plastic (GRP) a new emerging contaminant—First evidence of GRP impact on aquatic organisms. Mar. Pollut. Bull. 2020, 160, 111559. [Google Scholar] [CrossRef]

- Castro, A.C.M.; Carvalho, J.P.; Ribeiro, M.C.S.; Meixedo, J.P.; Silva, F.J.; Fiúza, A.; Dinis, M.D.L. An integrated recycling approach for GFRP pultrusion wastes: Recycling and reuse assessment into new composite materials using Fuzzy Boolean Nets. J. Clean. Prod. 2014, 66, 420–430. [Google Scholar] [CrossRef] [Green Version]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.; Johnson, R.D.J.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent advancement in the natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, S.; Hasan, K.M.F.; Jahid, A.; Mohiuddin, K.; Zhang, R.; Zhu, J. Comprehensive review on plant fiber-reinforced polymeric biocomposites. J. Mater. Sci. 2021, 56, 7231–7264. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and ma-chinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Hernández-Díaz, D.; Villar-Ribera, R.; Espinach, F.X.; Julián, F.; Hernández-Abad, V.; Delgado-Aguilar, M. Impact properties and water uptake behavior of old newspaper recycled fibers-reinforced polypropylene composites. Materials 2020, 13, 1079. [Google Scholar] [CrossRef] [Green Version]

- Oliver-Ortega, H.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M.; Méndez, J.A.; Espinach, F.X. Impact Strength and Water Uptake Behavior of Bleached Kraft Softwood-Reinforced PLA Composites as Alternative to PP-Based Materials. Polymers 2020, 12, 2144. [Google Scholar] [CrossRef]

- Thomason, J.L.; Fernandez, R.; Luis, J.J.F.i.M. A review of the impact performance of natural fiber thermoplastic composites. Frontiers 2018, 5, 60. [Google Scholar] [CrossRef]

- Rozman, H.D.; Lai, C.Y.; Ismail, H.; Ishak, Z.A.M. The effect of coupling agents on the mechanical and physical properties of oil palm empty fruit bunch-polypropylene composites. Polym. Int. 2000, 49, 1273–1278. [Google Scholar] [CrossRef]

- Feng, D.; Caulfield, D.F.; Sanadi, A.R. Effect of compatibilizer on the structure-property relationships of ke-naf-fiber/polypropylene composites. Polym. Compos. 2001, 22, 506–517. [Google Scholar] [CrossRef]

- Clemons, C.; Sanadi, A.R. Instrumented Impact Testing of Kenaf Fiber Reinforced Polypropylene Composites: Effects of Temperature and Composition. J. Reinf. Plast. Compos. 2007, 26, 1587–1602. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Villar, M.A. Thermal and mechanical characterization of linear low-density polyethylene/wood flour composites. J. Appl. Polym. Sci. 2003, 90, 2775–2784. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Ramírez, M.G.L.; Satyanarayana, K.G.; Iwakiri, S.; De Muniz, G.B.; Tanobe, V.; Flores-Sahagun, T.S. Study of the properties of biocomposites. Part I. Cassava starch-green coir fibers from Brazil. Carbohydr. Polym. 2011, 86, 1712–1722. [Google Scholar] [CrossRef] [Green Version]

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Borowski, G.; Szczypiński, M.; Klepka, T.; Thakur, V.K. Recent progress in bi-odegradable polymers and nanocomposite-based packaging materials for sustainable environment. Int. J. Polym. Anal. Charact. 2018, 23, 383–395. [Google Scholar] [CrossRef]

- Nakajima, H.; Dijkstra, P.; Loos, K. The recent developments in biobased polymers toward general and engineering appli-cations: Polymers that are upgraded from biodegradable polymers, analogous to petroleum-derived polymers, and newly developed. Polymers 2017, 9, 523. [Google Scholar]

- Sadasivuni, K.K.; Saha, P.; Adhikari, J.; Deshmukh, K.; Ahamed, M.B.; Cabibihan, J.J. Recent advances in mechanical prop-erties of biopolymer composites: A review. Polym. Compos. 2020, 41, 32–59. [Google Scholar] [CrossRef]

- Sampath, U.G.T.M.; Ching, Y.C.; Chuah, C.H.; Sabariah, J.J.; Lin, P.-C. Fabrication of Porous Materials from Natu-ral/Synthetic Biopolymers and Their Composites. Materials 2016, 9, 991. [Google Scholar] [CrossRef] [Green Version]

- Torres, F.G.; Rodriguez, S.; Saavedra, A.C. Green Composite Materials from Biopolymers Reinforced with Agroforestry Waste. J. Polym. Environ. 2019, 27, 2651–2673. [Google Scholar] [CrossRef]

- George, A.; Sanjay, M.; Srisuk, R.; Parameswaranpillai, J.; Siengchin, S. A comprehensive review on chemical properties and applications of biopolymers and their composites. Int. J. Biol. Macromol. 2020, 154, 329–338. [Google Scholar] [CrossRef]

- Lalit, R.; Mayank, P.; Ankur, K. Natural Fibers and Biopolymers Characterization: A Future Potential Composite Material. Stroj. Časopis J. Mech. Eng. 2018, 68, 33–50. [Google Scholar] [CrossRef] [Green Version]

- Corbière-Nicollier, T.; Gfeller Laban, B.; Lundquist, L.; Leterrier, Y.; Månson, J.A.E.; Jolliet, O. Life cycle assessment of bio-fibres replacing glass fibres as reinforcement in plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.P.; Suh, S.; Weidema, B.P.; Pen-nington, D.W. Life cycle assessment Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Henton, D.; Gruber, P.; Lunt, J.; Randall, J. Polylactic Acid Technology. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005; pp. 527–577. [Google Scholar]

- Weber, C.; Werner, H.; Deubel, T. A different view on Product Data Management/Product Life-Cycle Management and its future potentials. J. Eng. Des. 2003, 14, 447–464. [Google Scholar] [CrossRef]

- Buchert, T.; Neugebauer, S.; Schenker, S.; Lindow, K.; Stark, R. Multi-criteria Decision Making as a Tool for Sustainable Product Development—Benefits and Obstacles. Procedia CIRP 2015, 26, 70–75. [Google Scholar] [CrossRef] [Green Version]

- Ren, J.; Manzardo, A.; Mazzi, A.; Zuliani, F.; Scipioni, A. Prioritization of bioethanol production pathways in China based on life cycle sustainability assessment and multicriteria decision-making. Int. J. Life Cycle Assess. 2015, 20, 842–853. [Google Scholar] [CrossRef]

- Zarte, M.; Pechmann, A.; Nunes, I.L. Decision support systems for sustainable manufacturing surrounding the product and production life cycle—A literature review. J. Clean. Prod. 2019, 219, 336–349. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarres, Q.; Ardanuy, M.; Mutjé, P. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Kagan, V.A.; McPherson, R.; Chung, J.S. An Advanced High Modulus (HMG) Short Glass-Fiber Reinforced Nylon 6: Part I—Role and Kinetic of Fiber-Glass Reinforcements. J. Reinf. Plast. Compos. 2003, 22, 1035–1044. [Google Scholar] [CrossRef]

- MatWeb.com Matweb—The Online Materials Information Resource. Available online: http://www.matweb.com/Search/MaterialGroupSearch.aspx?GroupID=17 (accessed on 4 January 2021).

- Dorel, S.; Couturier, A.; Lacour, J.R.; Vandewalle, H.; Hautier, C.; Hug, F. Force-velocity relationship in cycling revisited: Benefit of two-dimensional pedal forces analysis. Med. Sci. Sports Exerc. 2010, 42, 1174–1183. [Google Scholar] [CrossRef]

- Bini, R.; Hume, P.; Croft, J.; Kilding, A. Pedal force effectiveness in cycling: A review of constraints and training effects. J. Sci. Cycl. 2013, 2, 11–24. [Google Scholar]

- Alvarez, G.; Vinyolas, J. A New Bicycle Pedal Design for On-Road Measurements of Cycling Forces. J. Appl. Biomech. 1996, 12, 130–142. [Google Scholar] [CrossRef]

- Mornieux, G.; Stapelfeldt, B.; Gollhofer, A.; Belli, A. Effects of Pedal Type and Pull-Up Action during Cycling. Int. J. Sports Med. 2008, 29, 817–822. [Google Scholar] [CrossRef] [Green Version]

- Turpin, N.A.; Watier, B. Cycling Biomechanics and Its Relationship to Performance. Appl. Sci. 2020, 10, 4112. [Google Scholar] [CrossRef]

- Vogt, S.; Schumacher, Y.; Roecker, K.; Dickhuth, H.-H.; Schoberer, U.; Schmid, A.; Heinrich, L. Power Output during the Tour de France. Int. J. Sports Med. 2007, 28, 756–761. [Google Scholar] [CrossRef]

- Dorel, S.; Hautier, C.A.; Rambaud, O.; Rouffet, D.; Van Praagh, E.; Lacour, J.-R.; Bourdin, M. Torque and Power-Velocity Relationships in Cycling: Relevance to Track Sprint Performance in World-Class Cyclists. Int. J. Sports Med. 2005, 26, 739–746. [Google Scholar] [CrossRef] [PubMed]

- Vogt, S.; Roecker, K.; Schumacher, Y.; Pottgießer, T.; Dickhuth, H.-H.; Schmid, A.; Heinrich, L. Cadence-Power-Relationship during Decisive Mountain Ascents at the Tour de France. Int. J. Sports Med. 2008, 29, 244–250. [Google Scholar] [CrossRef]

- Vogt, S.; Schumacher, Y.O.; Blum, A.; Roecker, K.; Dickhuth, H.-H.; Schmid, A.; Heinrich, L. Cycling power output produced during flat and mountain stages in the Giro d’Italia: A case study. J. Sports Sci. 2007, 25, 1299–1305. [Google Scholar] [CrossRef] [PubMed]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modeling of short fiber reinforced polymer composites: A literature review. Int. J. Fatigue 2015, 70, 297–321. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B.; Mai, Y.-W. Chapter 12—Creep and fatigue of short fibre composites. In Science and Engineering of Short Fibre-Reinforced Polymer Composites, 2nd ed.; Fu, S.-Y., Lauke, B., Mai, Y.-W., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 411–435. [Google Scholar]

- Mandell, J.F.; McGarry, F.J.; Huang, D.D.; Li, C.G. Some effects of matrix and interface properties on the fatigue of short fiber-reinforced thermoplastics. Polym. Compos. 1983, 4, 32–39. [Google Scholar] [CrossRef]

- McKeen, L.W. Chapter 8—Polyamides (Nylons). In Fatigue and Tribological Properties of Plastics and Elastomers, 2nd ed.; McKeen, L.W., Ed.; William Andrew Publishing: Oxford, UK, 2010; pp. 175–228. [Google Scholar]

- Salazar, A.; Rico, A.; Rodriguez, J.; Escudero, J.S.; Seltzer, R.; Cutillas, F.M.D.L.E. Monotonic loading and fatigue response of a bio-based polyamide PA11 and a petrol-based polyamide PA12 manufactured by selective laser sintering. Eur. Polym. J. 2014, 59, 36–45. [Google Scholar] [CrossRef]

- Madan, J.; Mani, M.; Lee, J.H.; Lyons, K.W. Energy performance evaluation and improvement of unit-manufacturing processes: Injection molding case study. J. Clean. Prod. 2015, 105, 157–170. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. In Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; pp. 623–628. [Google Scholar]

- Iwko, J.; Wroblewski, R.; Steller, R. Experimental study on energy consumption in the plasticizing unit of the injection molding machine. Polimers 2018, 63, 362–371. [Google Scholar] [CrossRef]

- Hesser, F.; Mihalic, M.; Paichl, B.J.; Wagner, M. Injection moulding unit process for LCA: Energy intensity of manufacturing different materials at different scales. J. Reinf. Plast. Compos. 2016, 36, 338–346. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Kawada, J.; Kitou, M.; Mouri, M.; Kato, Y.; Katagiri, Y.; Matsushita, M.; Ario, T.; Kitou, O.; Usuki, A. Super impact absorbing bio-alloys from inedible plants. Green Chem. 2017, 19, 4503–4508. [Google Scholar] [CrossRef] [Green Version]

- Feraldi, R.; Sauer, B.; Cashman, S. Life Cycle Inventory of Plastic Fabrication Processes: Injection Molding and Thermoforming; Franklin Associates: Baton Rouge, LA, USA, 2011; pp. 20–40. [Google Scholar]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Vallero, D. Chapter 31—Controlling Air Pollution from Sources. In Fundamentals of Air Pollution, 5th ed.; Vallero, D., Ed.; Academic Press: Boston, MC, USA, 2014; pp. 881–925. [Google Scholar]

| Material | Tensile Properties | Flexural Properties | ||||

|---|---|---|---|---|---|---|

| (MPa) | (GPa) | |||||

| PA6 | 71.2 | 2.58 | 68.2 | 80.3 | 2.28 | 6.84 |

| PA6 + 10% GF | 92.6 | 4.76 | 5.02 | 140 | 4.2 | - |

| PA6 + 20% GF | 101 | 5.13 | 5.41 | 155 | 4.92 | 6.05 |

| PA6 + 30% GF | 138 | 7.92 | 4.32 | 207 | 7.41 | 4.86 |

| PA6 + 40% GF | 166 | 10.1 | 3.74 | 245 | 9.4 | 4.65 |

| PA6 + 50% GF | 195 | 13.9 | 3.06 | 303 | 12.9 | 3.79 |

| PA11 | 38.3 | 1.4 | 25.0 | 40.0 | 0.9 | 7.4 |

| PA11 + 60% SGW | 59.6 | 5.8 | 2.8 | 102.7 | 4.1 | 3.2 |

| Material | Tensile Properties | Flexural Properties | ||

|---|---|---|---|---|

| n1 | n1 | |||

| PA6 + 10% GF | 54 | 51.7–170 | 167 | 13.8–300 |

| PA6 + 20% GF | 90 | 60–195 | 348 | 50–300 |

| PA6 + 30% GF | 211 | 50–193 | 676 | 40–800 |

| PA6 + 40% GF | 259 | 65–470 | 214 | 115–352 |

| PA6 + 50% GF | 202 | 90–605 | 168 | 175–840 |

| Property | Density (g/cm3) | Weight (g) | Resin Volume (%) | Fibre Volume (%) |

|---|---|---|---|---|

| PA6 | 1.12 | 33.17 | 100 | - |

| PA6 + 10% GF | 1.18 | 35.09 | 95.22 | 4.78 |

| PA6 + 20% GF | 1.26 | 37.25 | 89.86 | 10.14 |

| PA6 + 30% GF | 1.34 | 39.70 | 83.78 | 16.22 |

| PA6 + 40% GF | 1.43 | 42.49 | 76.86 | 23.14 |

| PA6 + 50% GF | 1.54 | 45.70 | 68.89 | 31.11 |

| PA11 | 1.03 | 30.50 | 100 | - |

| PA11 + 60% SGW | 1.20 | 35.42 | 46.45 | 53.50 |

| Stage | PA6 | PA6 + 10% GF | PA6 + 20% GF | PA6 + 30% GF | PA6 + 40% GF | PA6 + 50% GF | PA11 | PA11 + 60% SGW |

|---|---|---|---|---|---|---|---|---|

| Material | 0.340 | 0.344 | 0.347 | 0.351 | 0.357 | 0.361 | 0.313 | 0.170 |

| Manufacture | 0.035 | 0.038 | 0.040 | 0.043 | 0.045 | 0.048 | 0.033 | 0.038 |

| Transport | 0.003 | 0.003 | 0.004 | 0.004 | 0.004 | 0.004 | 0.003 | 0.004 |

| End of life | 0.022 | 0.023 | 0.025 | 0.027 | 0.028 | 0.030 | 0.014 | 0.020 |

| Total | 0.400 | 0.408 | 0.415 | 0.425 | 0.434 | 0.443 | 0.363 | 0.231 |

| Stage | PA6 | PA6 + 10% GF | PA6 + 20% GF | PA6 + 30% GF | PA6 + 40% GF | PA6 + 50% GF | PA11 | PA11 + 60% SGW |

|---|---|---|---|---|---|---|---|---|

| Material | 6.200 | 6.117 | 6.058 | 5.933 | 5.800 | 5.700 | 5.700 | 3.036 |

| Manufacture | 0.673 | 0.712 | 0.756 | 0.805 | 0.862 | 0.927 | 0.619 | 0.702 |

| Transport | 0.046 | 0.049 | 0.052 | 0.056 | 0.060 | 0.064 | 0.043 | 0.052 |

| End of life | 0.017 | 0.018 | 0.019 | 0.020 | 0.022 | 0.022 | 0.011 | 0.012 |

| Total | 6.936 | 6.896 | 6.885 | 6.814 | 6.744 | 6.713 | 6.373 | 3.802 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Díaz, D.; Villar-Ribera, R.; Serra-Parareda, F.; Weyler-Pérez, R.; Sánchez-Romero, M.; Rojas-Sola, J.I.; Julián, F. Technical and Environmental Viability of a Road Bicycle Pedal Part Made of a Fully Bio-Based Composite Material. Materials 2021, 14, 1399. https://doi.org/10.3390/ma14061399

Hernández-Díaz D, Villar-Ribera R, Serra-Parareda F, Weyler-Pérez R, Sánchez-Romero M, Rojas-Sola JI, Julián F. Technical and Environmental Viability of a Road Bicycle Pedal Part Made of a Fully Bio-Based Composite Material. Materials. 2021; 14(6):1399. https://doi.org/10.3390/ma14061399

Chicago/Turabian StyleHernández-Díaz, David, Ricardo Villar-Ribera, Ferran Serra-Parareda, Rafael Weyler-Pérez, Montserrat Sánchez-Romero, José Ignacio Rojas-Sola, and Fernando Julián. 2021. "Technical and Environmental Viability of a Road Bicycle Pedal Part Made of a Fully Bio-Based Composite Material" Materials 14, no. 6: 1399. https://doi.org/10.3390/ma14061399

APA StyleHernández-Díaz, D., Villar-Ribera, R., Serra-Parareda, F., Weyler-Pérez, R., Sánchez-Romero, M., Rojas-Sola, J. I., & Julián, F. (2021). Technical and Environmental Viability of a Road Bicycle Pedal Part Made of a Fully Bio-Based Composite Material. Materials, 14(6), 1399. https://doi.org/10.3390/ma14061399