Creep–Fatigue Experiment and Life Prediction Study of Piston 2A80 Aluminum Alloy

Abstract

:1. Introduction

2. Simulation of Piston Temperature and Stress Field

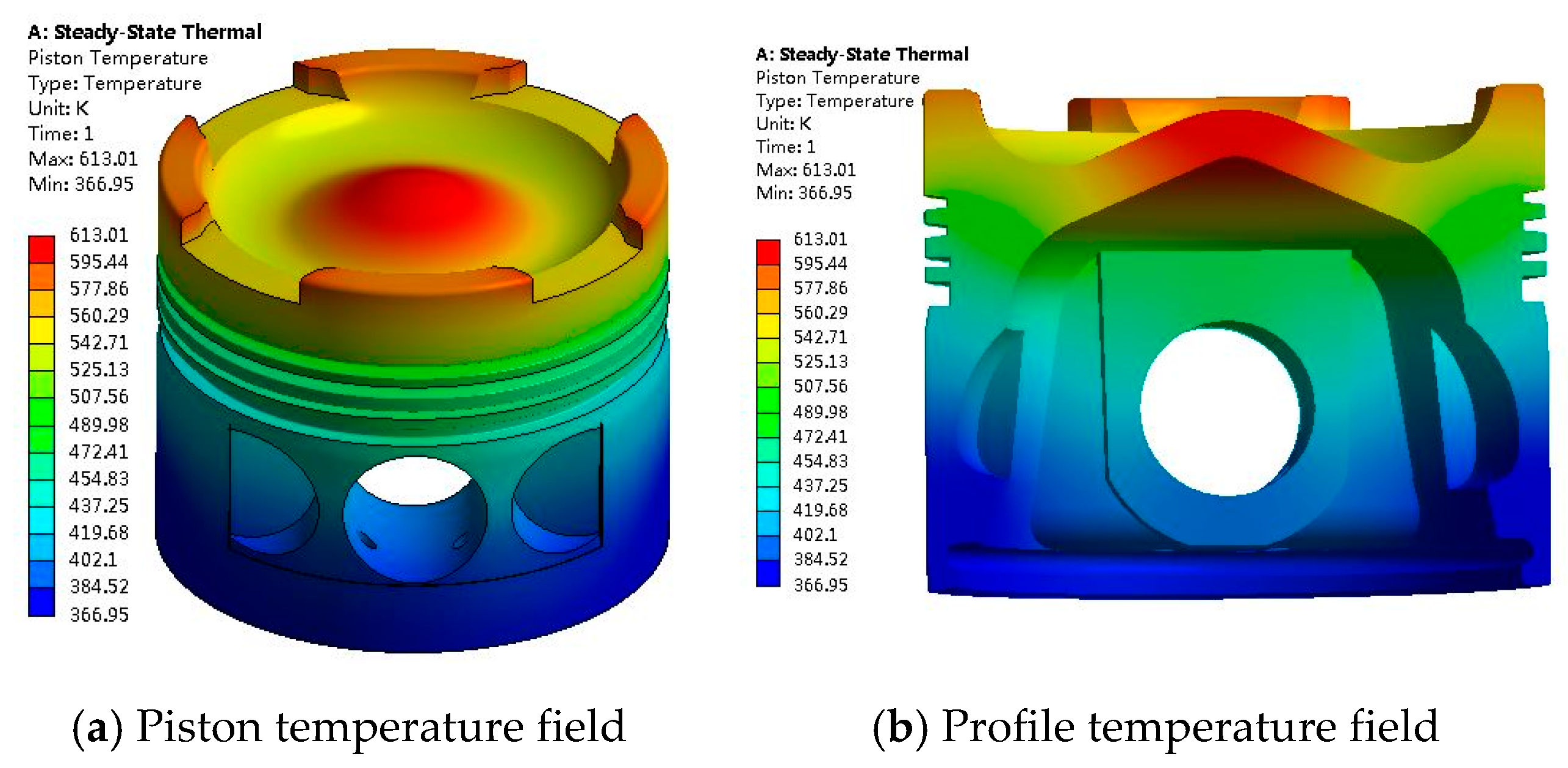

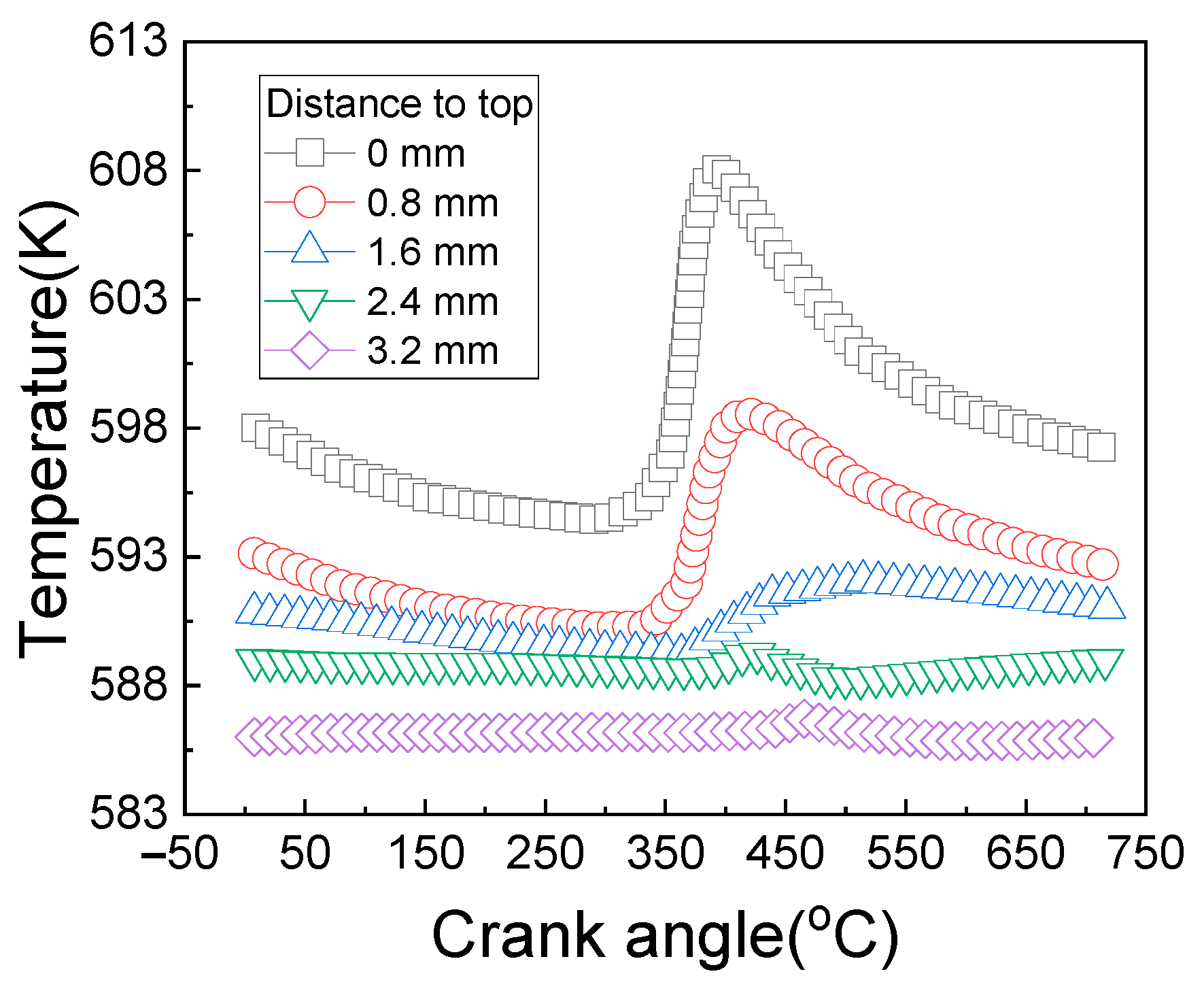

2.1. Temperature Field Analysis

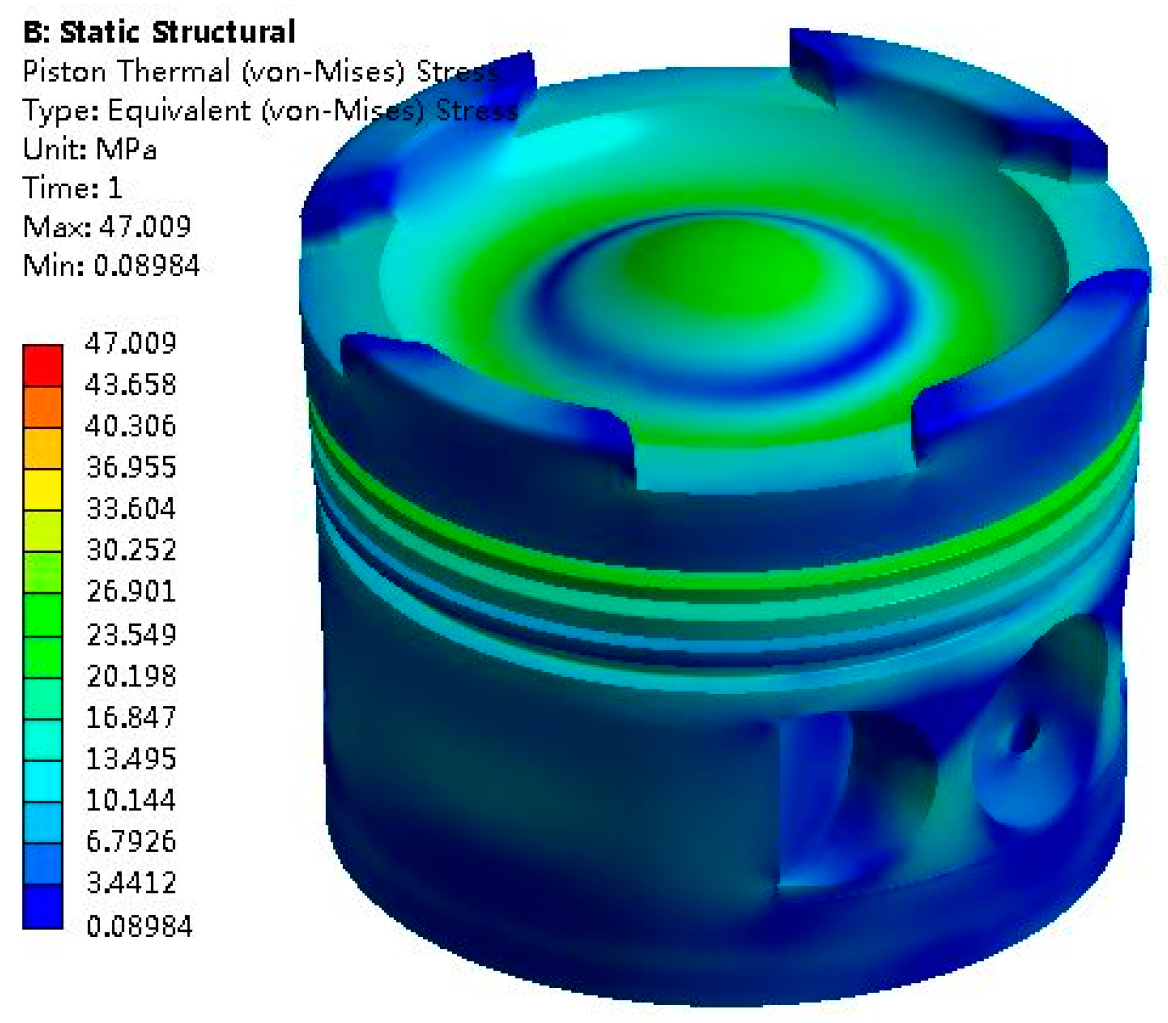

2.2. Thermal Stress Field Analysis

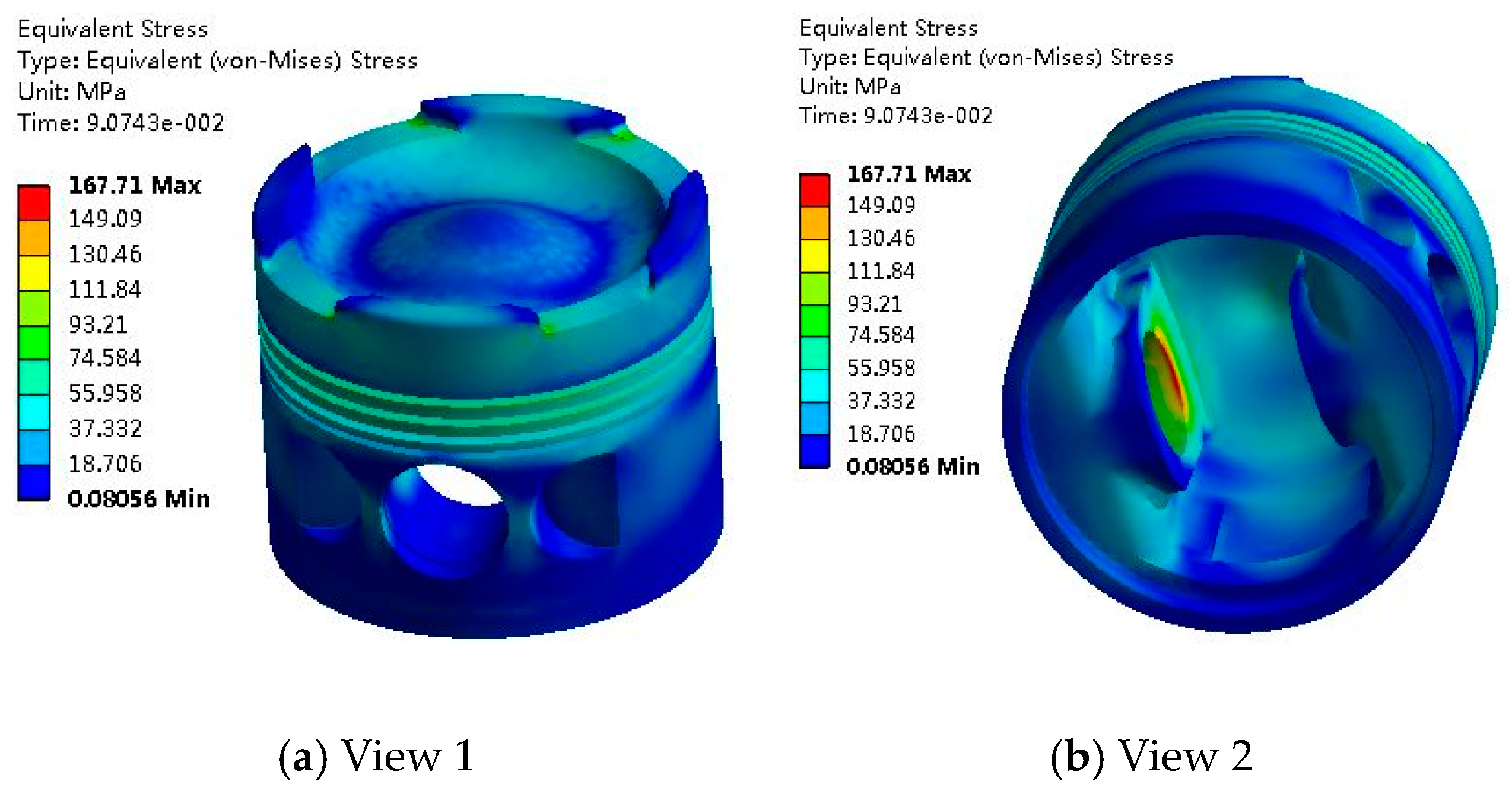

2.3. Thermal–Mechanical Coupling Stress Field

2.4. Brief Summary

3. Creep–Fatigue Test of Aluminum Alloy Materials

3.1. Test Schemes

3.2. Processing of Specimens

3.3. Analysis of Test Results

3.3.1. Overview of Results

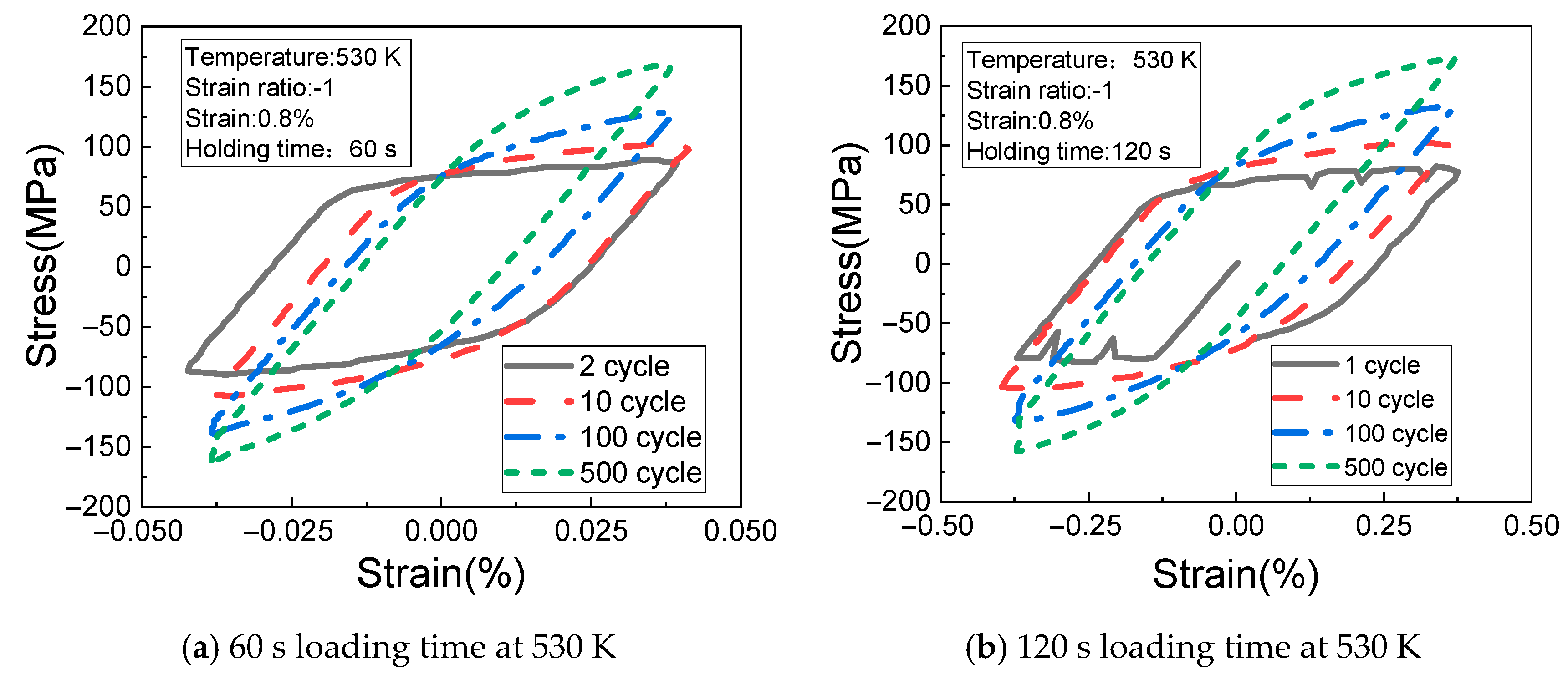

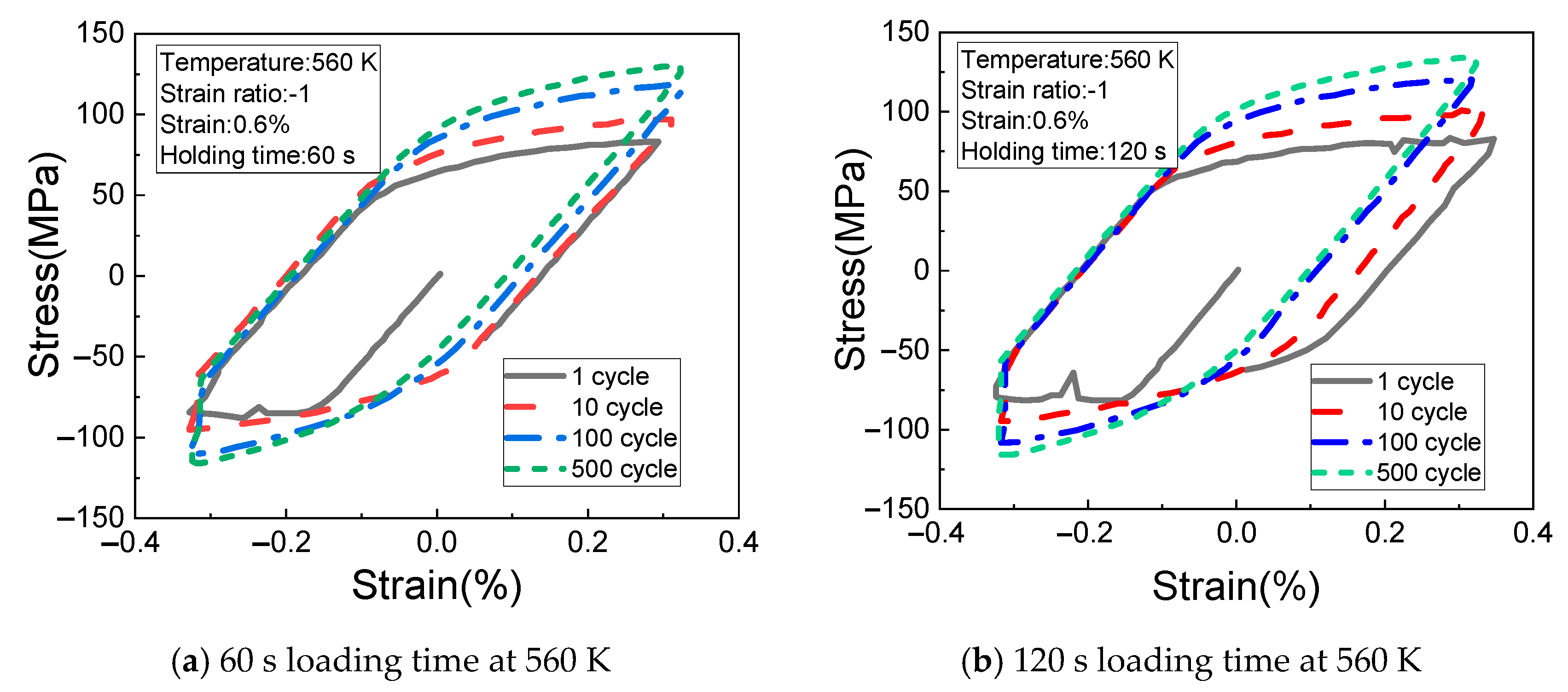

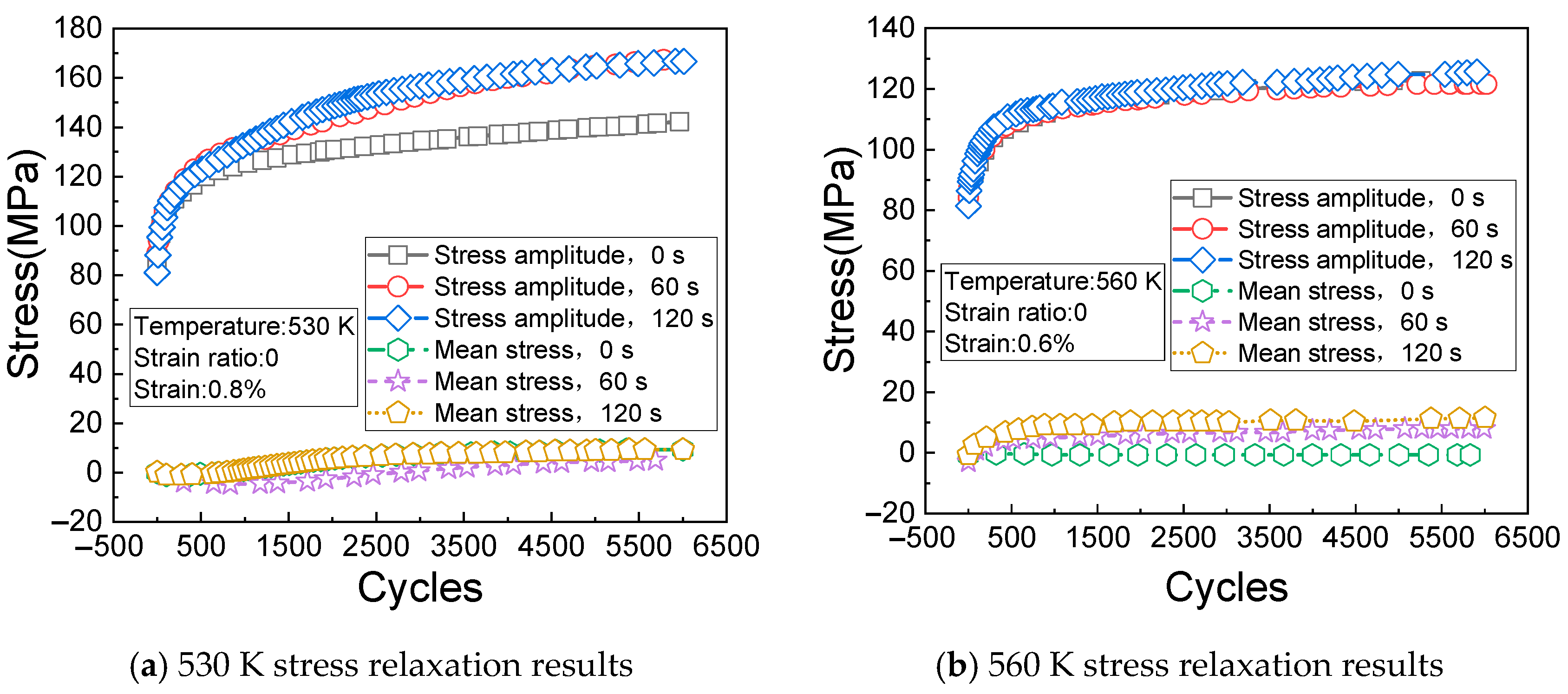

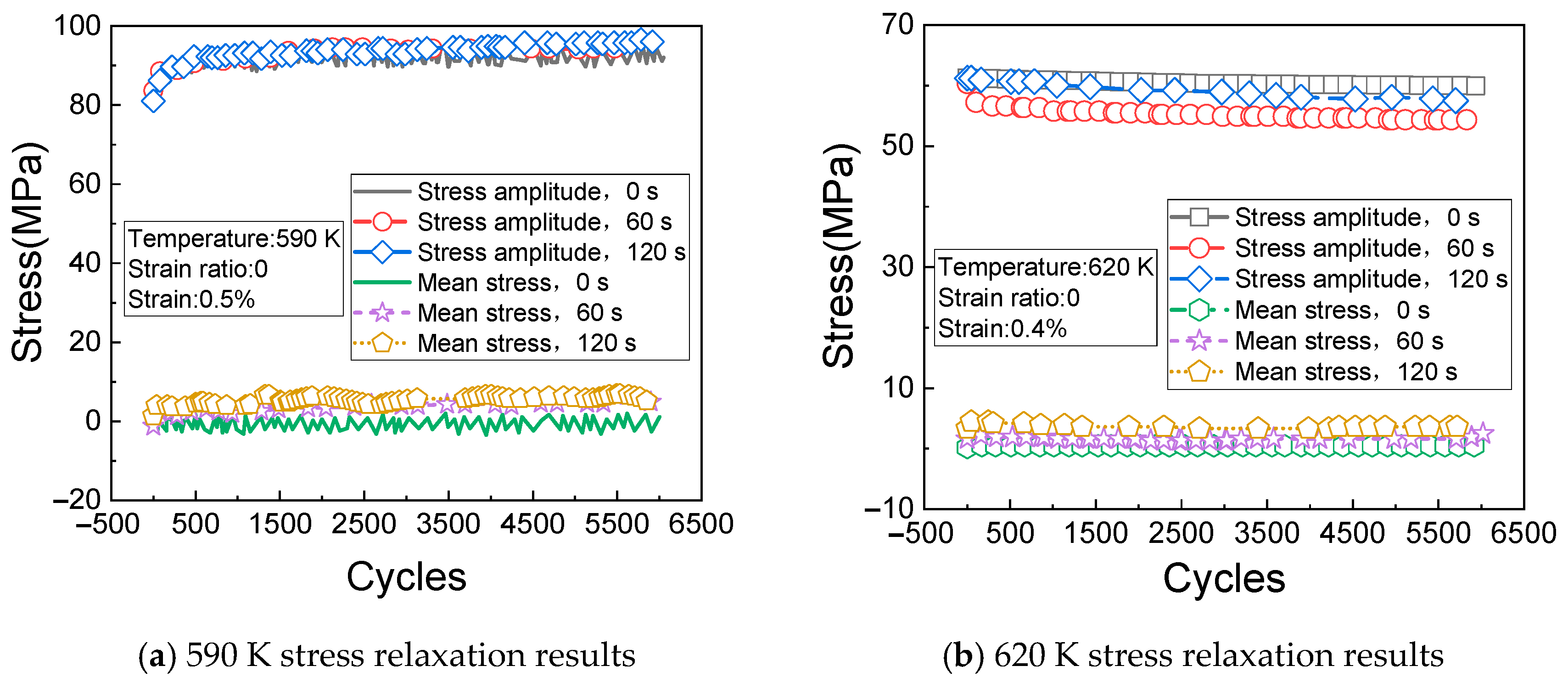

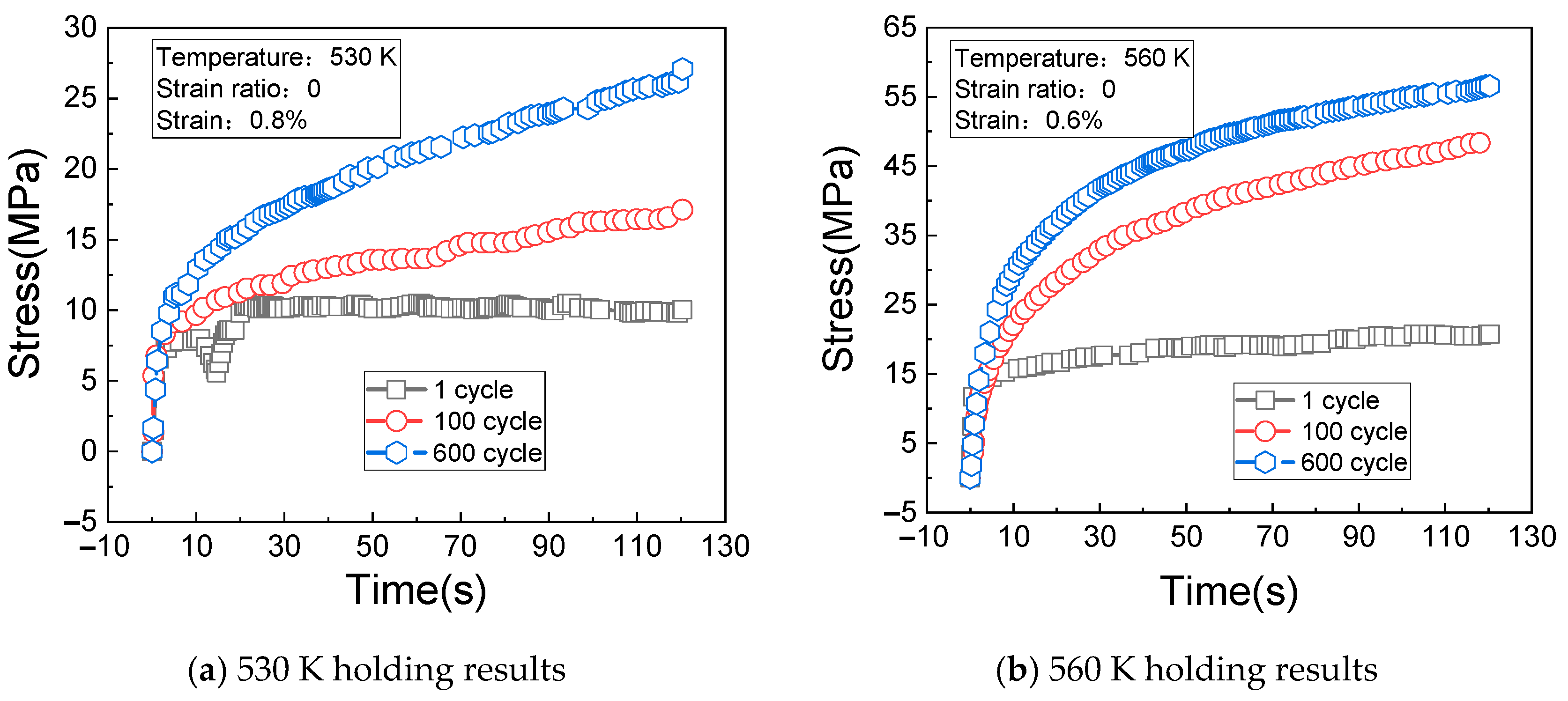

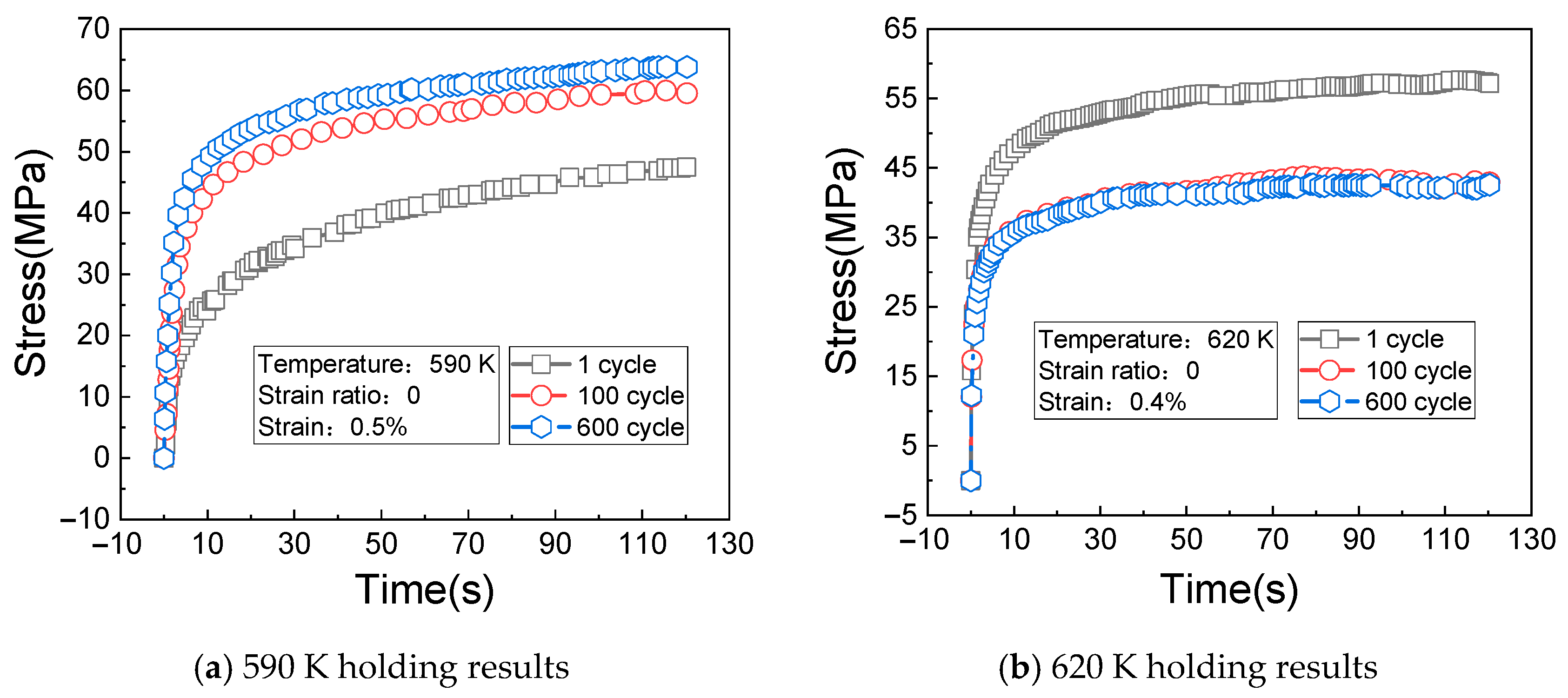

3.3.2. Creep–Fatigue Stress Relaxation

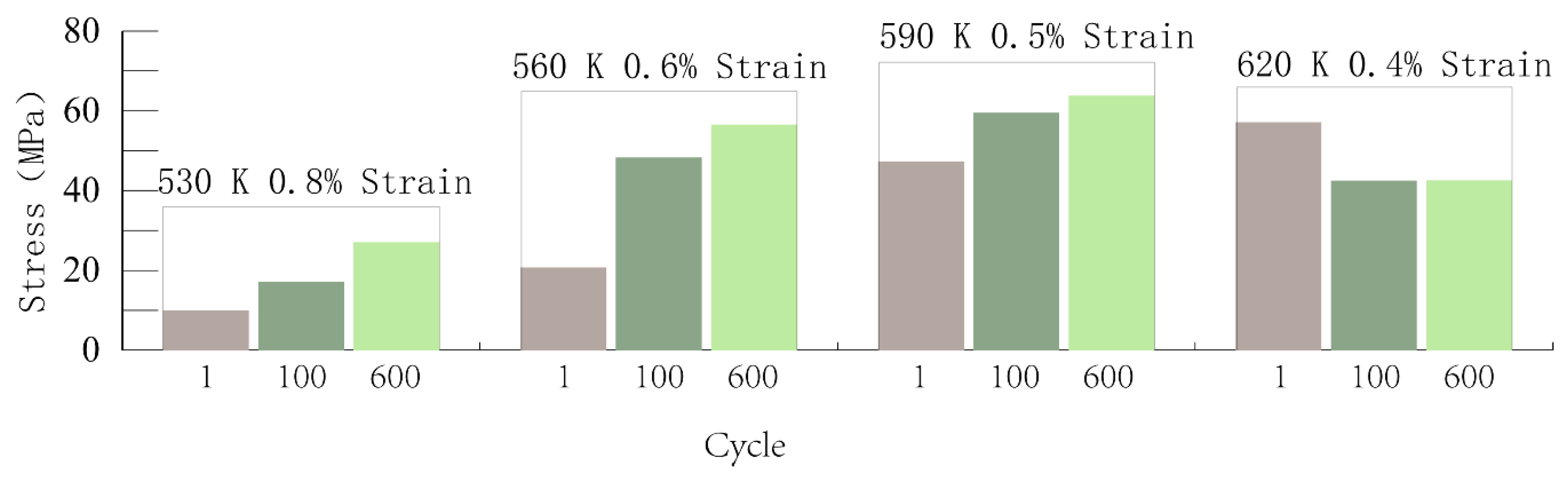

3.3.3. Impacts of Holding Time

3.4. Brief Summary

- Under the creep–fatigue loading conditions, a certain degree of stress relaxation occurs in all temperature ranges. With the increase of temperature, the stress relaxation amplitude of material increases obviously, which indicates the important impact of temperature conditions on the creep stress relaxation;

- At lower temperatures, the material experiences the phenomenon of cyclic hardening and stress relaxation. With the increase of temperature, the degree of cyclic hardening decreases obviously, but the stress relaxation amplitude increases gradually;

- With the increase of temperature and the extension of holding time, the cyclic stress response of the material increases gradually.

4. Fatigue Life Prediction Models of Aluminum Alloy Materials

4.1. Creep Fatigue Life Prediction Model Based on Energy Dissipation Criteria

4.1.1. Overview

4.1.2. Cyclic Hysteresis Energy of Low Cycle Fatigue

4.1.3. Cyclic Hysteresis Energy of Creep–Fatigue

4.2. Creep–Fatigue Life Prediction Model Based on the Twin Support Vector Machine

4.2.1. Support Vector Machine

4.2.2. Nonlinear Support Vector Regression Machine

4.2.3. Nonlinear Least-Square Twin Support Vector Regression Machine

4.2.4. Data Normalization and Cross-Validation Methods

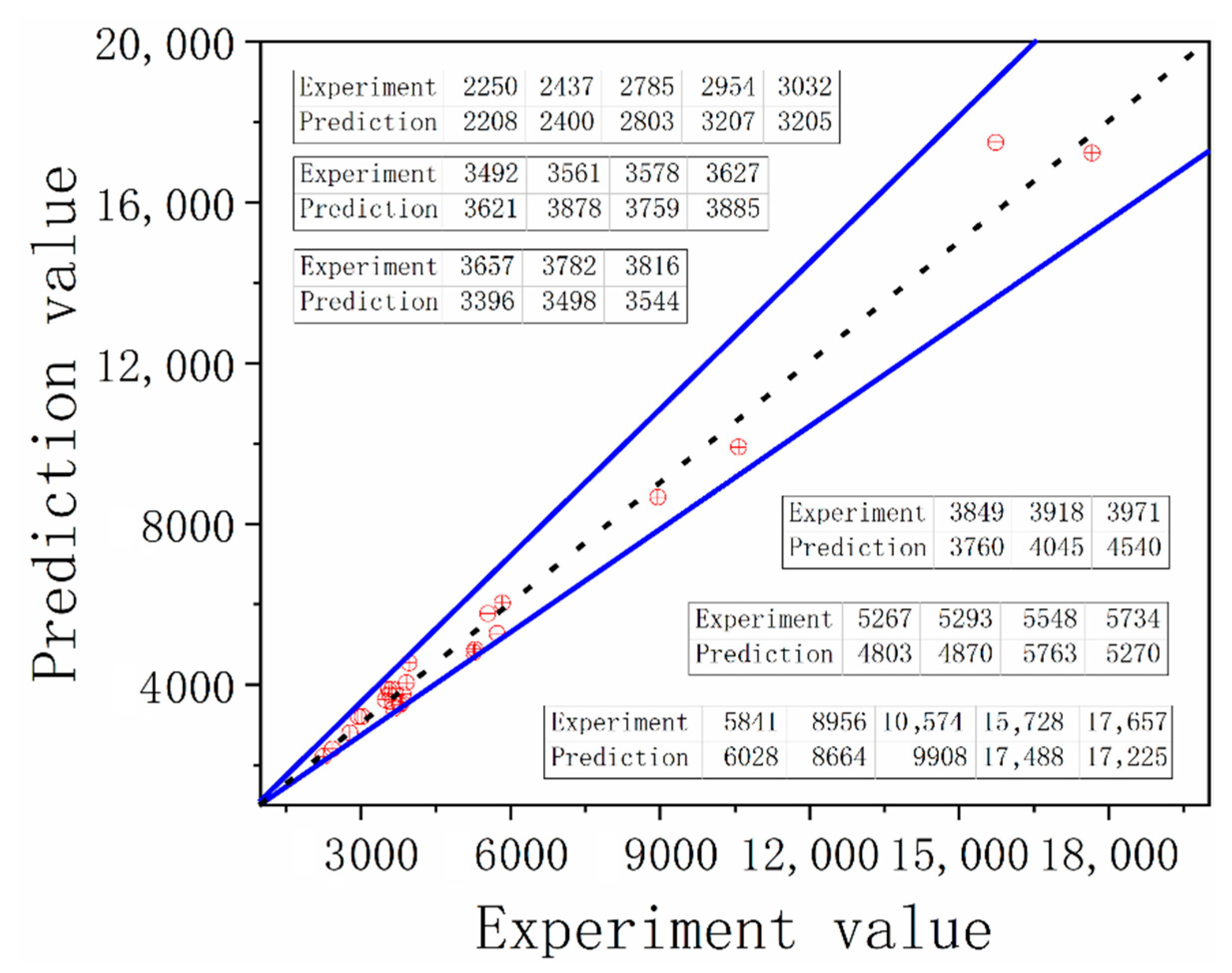

4.3. Result Analysis

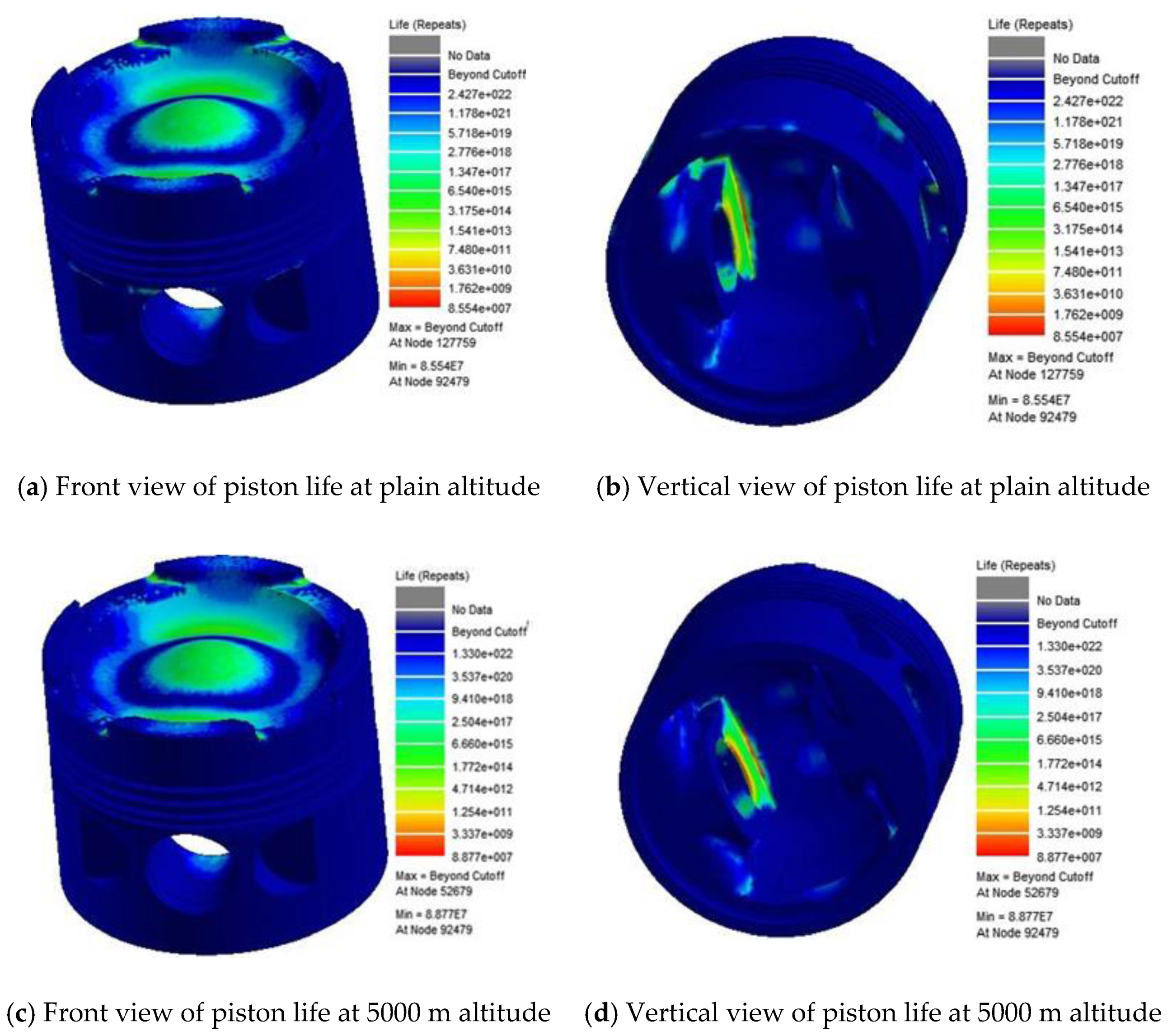

5. Fatigue Life Prediction Analysis of Piston

6. Conclusions

- The temperature field, thermal stress field, and thermo–mechanical coupling stress of the piston are calculated and analyzed with the finite element method; results show that the piston highest temperature is 613.01 K, the maximum thermal stress is 47.009 MPa, the maximum thermo-mechanical coupling stress is 167.71 MPa, and the areas with heavy thermal and mechanical loads are mainly concentrated in the center of the top piston, the inlet and exhaust valve grooves, piston pin seat, etc. If the diesel engine works for a long time under the working conditions of high speed and large load, the creep–fatigue failure will occur easily;

- Based on the finite element calculation results, the creep–fatigue test is carried out for the material 2A80 aluminum alloy of the piston, and the results show that the influence of temperature conditions on creep stress relaxation is very significant. With the increase of temperature, the degree of cyclic hardening decreases gradually, but the stress relaxation amplitude increases. With the increase of temperature and the extension of holding time, the cyclic stress of the material increases gradually;

- According to the above simulation and test results, the fatigue life prediction models of aluminum alloy materials are proposed with two methods—the creep–fatigue life prediction model based on energy dissipation criteria and the fatigue life prediction model based on twin support vector regression machine. These two methods are verified based on the test results, and the results show that the fatigue life prediction model based on the twin support vector regression machine is more accurate in predicting the life of the creep–fatigue on aluminum alloy materials;

- The fatigue life prediction model based on the twin support vector regression machine is used to predict the piston fatigue life under the actual service conditions, and the results show that the minimum fatigue life of the piston is 2113.6 h in the plain conditions, and is 1425.7 h at the altitude of 5000 m;

- Limitations of the research: Firstly, the conditions of the experiment in this research were limited because of our limited budget, and hence we could not obtain the explicit response characteristics of the alloy. Secondly, the study of creep–fatigue prediction model based on the energy dissipation criteria was not enough, and there was still room to improve its prediction accuracy and computational speed. Last but not least, there was no prediction verification for the fatigue life of piston as a result of the limitation of budget and experiment technology;

- Future work: Firstly, more experiments focused on the response characteristic of alloy should be conducted in the temperature range of 470–650 K, the strain range of 0.3–1.5%, and the loading speed of 0.2–20 cpm. Secondly, the study for creep–fatigue prediction model based on the energy dissipation criteria should receive more attention to investigate the core parameters in predicting the fatigue life of alloy. Lastly, the verification experiment for the actual fatigue life should be conducted if conditions such as the budget and experiment technology allow.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Subbarao, R.; Vart Gupta, S. Thermal and structural analyses of an internal combustion engine piston with suitable different super alloys. Mater. Today Proc. 2020, 22, 2950–2956. [Google Scholar] [CrossRef]

- Prakash Varma, P.S.; Venkata Subbaiah, K. A review on thermal and CFD analysis of 3 different piston bowl geometry’s. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Huang, F.; Kong, W. Experimental investigation of operating characteristics and thermal balance of a miniature free-piston linear engine. Appl. Therm. Eng. 2020, 178, 115608. [Google Scholar] [CrossRef]

- Reddy Anugu, A.; Vishnu Tej Reddy, N.; Venkateswarlu, D. Theoritical modelling and finite element analysis of automobile piston. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Zhaoju, Q.; Yingsong, L.; Zhenzhong, Y.; Junfa, D.; Lijun, W. Diesel engine piston thermo-mechanical coupling simulation and multidisciplinary design optimization. Case Stud. Therm. Eng. 2019, 15, 100527. [Google Scholar] [CrossRef]

- Ye, W.; Zhang, T.; Wang, X.; Liu, Y.; Chen, P. Parametric study of gamma-type free piston stirling engine using nonlinear thermodynamic-dynamic coupled model. Energy 2020, 211, 118458. [Google Scholar] [CrossRef]

- Yao, Z.; Qian, Z. Thermal analysis of Nano ceramic coated piston used in natural gas engine. J. Alloy Compd. 2018, 768, 441–450. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, J.; Liu, Y.; Qiao, X.; Zhang, X.; Jin, Y.; Zhang, S.; Wang, T.; Kang, Q. A RBFNN & GACMOO-Based Working State Optimization Control Study on Heavy-Duty Diesel Engine Working in Plateau Environment. Energies 2020, 13, 279. [Google Scholar] [CrossRef] [Green Version]

- Kalyana Kumar, M.; Sudersanan, P.D. A study on thermomechanical properties of zirconium di oxide coated piston material of various thickness and its comparison with uncoated material. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Satyanarayana, K.; Mohan Rao, P.V.J.; Kumar, I.N.N.; Prasad, V.V.S.; Hanumantha Rao, T.V. Some Studies on Stress Analysis of A Sundry Variable Compression Ratio Diesel Engine Piston. Mater. Today Proc. 2018, 5, 18251–18259. [Google Scholar] [CrossRef]

- Chen, W.; Kitamura, T.; Feng, M. Creep and fatigue behavior of 316L stainless steel at room temperature: Experiments and a revisit of a unified viscoplasticity model. Int. J. Fatigue 2018, 112, 70–77. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Creep and fatigue behaviors of High-Density Polyethylene (HDPE): Effects of temperature, mean stress, frequency, and processing technique. Int. J. Fatigue 2020, 141, 105871. [Google Scholar] [CrossRef]

- Sun, L.; Bao, X.G.; Guo, S.J.; Wang, R.Z.; Zhang, X.C.; Tu, S.T. The creep-fatigue behavior of a nickel-based superalloy: Experiments study and cyclic plastic analysis. Int. J. Fatigue 2021, 147. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, X.; Lan, K.-C.; Lee, H.; Tsang, D.K.L.; Stubbins, J.F. On the biaxial thermal creep-fatigue behavior of Ni-base Alloy 617 at 950 °C. Int. J. Fatigue 2020, 139, 105787. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, W.; Liang, J.; Li, X. Creep–fatigue interaction behavior of nickel-based single crystal superalloy at high temperature by in-situ SEM observation. Int. J. Fatigue 2020, 141, 105879. [Google Scholar] [CrossRef]

- Hamidi Ghaleh Jigh, B.; Hosseini-Toudeshky, H.; Farsi, M.A. Low cycle fatigue analyses of open-celled aluminum foam under compression–compression loading using experimental and microstructure finite element analysis. J. Alloy Compd. 2019, 797, 231–236. [Google Scholar] [CrossRef]

- Bartošák, M.; Španiel, M.; Doubrava, K. Unified viscoplasticity modelling for a SiMo 4.06 cast iron under isothermal low-cycle fatigue-creep and thermo-mechanical fatigue loading conditions. Int. J. Fatigue 2020, 136, 105566. [Google Scholar] [CrossRef]

- Tang, B.; Zhang, M.; Yang, R.; Chen, W.; Kou, H.; Li, J. Microplasticity behavior study of equiaxed near-β titanium alloy under high-cycle fatigue loading: Crystal plasticity simulations and experiments. J. Mater. Res. Technol. 2019, 8, 6146–6157. [Google Scholar] [CrossRef]

- Yuan, G.-J.; Wang, R.-Z.; Gong, C.-Y.; Zhang, X.-C.; Tu, S.-T. Investigations of micro-notch effect on small fatigue crack initiation behaviour in nickel-based alloy GH4169: Experiments and simulations. Int. J. Fatigue 2020, 136, 105578. [Google Scholar] [CrossRef]

- Zhao, B.; Xie, L.; Wang, L.; Hu, Z.; Zhou, S.; Bai, X. A new multiaxial fatigue life prediction model for aircraft aluminum alloy. Int. J. Fatigue 2021, 143, 105993. [Google Scholar] [CrossRef]

- Chen, S.; Wei, D.; Wang, J.; Wang, Y.; Jiang, X. A new fatigue life prediction model considering the creep-fatigue interaction effect based on the Walker total strain equation. Chin. J. Aeronaut. 2020, 33, 2382–2394. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, X.; Ji, Y.; Zhang, W.; Hassan, T.; Gong, J. P92 steel creep-fatigue interaction responses under hybrid stress-strain controlled loading and a life prediction model. Int. J. Fatigue 2020, 140, 105837. [Google Scholar] [CrossRef]

- Shimada, T.; Tokuda, K.; Yoshida, K.; Ohno, N.; Sasaki, T. Creep-Fatigue Life Prediction of 316H Stainless Steel by Utilizing Non-Unified Constitutive Model. Procedia Struct. Integr. 2018, 13, 1873–1878. [Google Scholar] [CrossRef]

- Wang, R.-Z.; Zhang, X.-C.; Tu, S.-T.; Zhu, S.-P.; Zhang, C.-C. A modified strain energy density exhaustion model for creep–fatigue life prediction. Int. J. Fatigue 2016, 90, 12–22. [Google Scholar] [CrossRef]

- Li, K.-S.; Wang, R.-Z.; Yuan, G.-J.; Zhu, S.-P.; Zhang, X.-C.; Tu, S.-T.; Miura, H. A crystal plasticity-based approach for creep-fatigue life prediction and damage evaluation in a nickel-based superalloy. Int. J. Fatigue 2021, 143, 106031. [Google Scholar] [CrossRef]

- Li, J.; Chang, Y.; Xiu, Z.; Liu, H.; Xue, A.; Chen, G.; Xu, L.; Sheng, L. A local stress-strain approach for fatigue damage prediction of subsea wellhead system based on semi-decoupled model. Appl. Ocean Res. 2020, 102, 102306. [Google Scholar] [CrossRef]

- Zhu, S.-P.; Liao, D.; Liu, Q.; Correia, J.A.F.O.; De Jesus, A.M.P. Nonlinear fatigue damage accumulation: Isodamage curve-based model and life prediction aspects. Int. J. Fatigue 2019, 128, 105185. [Google Scholar] [CrossRef]

- Yeratapally, S.R.; Leser, P.E.; Hochhalter, J.D.; Leser, W.P.; Ruggles, T.J. A digital twin feasibility study (Part I): Non-deterministic predictions of fatigue life in aluminum alloy 7075-T651 using a microstructure-based multi-scale model. Eng. Fract. Mech. 2020, 228, 106888. [Google Scholar] [CrossRef]

- Tao, Y.; Stevens, C.A.; Bilotti, E.; Peijs, T.; Busfield, J.J.C. Fatigue of carbon cord-rubber composites: Effect of frequency, R ratio and life prediction using constant life models. Int. J. Fatigue 2020, 135, 105558. [Google Scholar] [CrossRef]

- Liu, X.; Liang, S.; Li, G.; Godbole, A.; Lu, C. An improved dynamic stall model and its effect on wind turbine fatigue load prediction. Renew. Energy 2020, 156, 117–130. [Google Scholar] [CrossRef]

- Choi, J.; Quagliato, L.; Lee, S.; Shin, J.; Kim, N. Multiaxial fatigue life prediction of polychloroprene rubber (CR) reinforced with tungsten nano-particles based on semi-empirical and machine learning models. Int. J. Fatigue 2021, 145, 106136. [Google Scholar] [CrossRef]

- Bao, H.; Wu, S.; Wu, Z.; Kang, G.; Peng, X.; Withers, P.J. A machine-learning fatigue life prediction approach of additively manufactured metals. Eng. Fract. Mech. 2021, 242, 107508. [Google Scholar] [CrossRef]

- Zhan, Z.; Li, H. Machine learning based fatigue life prediction with effects of additive manufacturing process parameters for printed SS 316L. Int. J. Fatigue 2021, 142, 105941. [Google Scholar] [CrossRef]

- Hu, D.; Su, X.; Liu, X.; Mao, J.; Shan, X.; Wang, R. Bayesian-based probabilistic fatigue crack growth evaluation combined with machine-learning-assisted GPR. Eng. Fract. Mech. 2020, 229, 106933. [Google Scholar] [CrossRef]

- Yan, W.; Deng, L.; Zhang, F.; Li, T.; Li, S. Probabilistic machine learning approach to bridge fatigue failure analysis due to vehicular overloading. Eng. Struct. 2019, 193, 91–99. [Google Scholar] [CrossRef]

- Mortazavi, S.N.S.; Ince, A. An artificial neural network modeling approach for short and long fatigue crack propagation. Comput. Mater. Sci. 2020, 185, 109962. [Google Scholar] [CrossRef]

- Ma, J.; Luo, D.; Liao, X.; Zhang, Z.; Huang, Y.; Lu, J. Tool wear mechanism and prediction in milling TC18 titanium alloy using deep learning. Measurement 2020, 108554. [Google Scholar] [CrossRef]

- Alqahtani, H.; Bharadwaj, S.; Ray, A. Classification of fatigue crack damage in polycrystalline alloy structures using convolutional neural networks. Eng. Fail. Anal. 2021, 119, 104908. [Google Scholar] [CrossRef]

- Mohanty, J.R.; Mahanta, T.K.; Mohanty, A.; Thatoi, D.N. Prediction of constant amplitude fatigue crack growth life of 2024 T3 Al alloy with R-ratio effect by GP. Appl. Soft Comput. 2015, 26, 428–434. [Google Scholar] [CrossRef]

- Pezda, J.; Jezierski, J. Non-Standard T6 Heat Treatment of the Casting of the Combustion Engine Cylinder Head. Materials 2020, 13, 4114. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, X.; Xiang, P.; Dong, D. Analysis of thermal temperature fields and thermal stress under steady temperature field of diesel engine piston. Appl. Therm. Eng. 2017, 113, 796–812. [Google Scholar] [CrossRef]

- Wu, M.; Wang, J.; Li, P.; Hu, C.; Tian, X.; Song, J. Research Progress on the Anti-Disproportionation of the ZrCo Alloy by Element Substitution. Materials 2020, 13, 3977. [Google Scholar] [CrossRef] [PubMed]

- Alsmadi, Z.Y.; Murty, K.L. High-temperature effects on creep-fatigue interaction of the Alloy 709 austenitic stainless steel. Int. J. Fatigue 2021, 143, 105987. [Google Scholar] [CrossRef]

- Feng, E.S.; Wang, X.G.; Jiang, C. A new multiaxial fatigue model for life prediction based on energy dissipation evaluation. Int. J. Fatigue 2019, 122, 1–8. [Google Scholar] [CrossRef]

- Hasni, H.; Alavi, A.H.; Jiao, P.; Lajnef, N. Detection of fatigue cracking in steel bridge girders: A support vector machine approach. Arch. Civ. Mech. Eng. 2017, 17, 609–622. [Google Scholar] [CrossRef]

- Okabe, T.; Otsuka, Y. Proposal of a Validation Method of Failure Mode Analyses based on the Stress-Strength Model with a Support Vector Machine. Reliab. Eng. Syst. Saf. 2021, 205, 107247. [Google Scholar] [CrossRef]

- Khemchandani, R.; Goyal, K.; Chandra, S. TWSVR: Regression via Twin Support Vector Machine. Neural Netw. 2016, 74, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Gerber, F.; Nychka, D.W. Parallel cross-validation: A scalable fitting method for Gaussian process models. Comput. Stat. Data Anal. 2021, 155, 107113. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Liu, J.; Liu, Y.; Li, H.; Zhang, X.; Hu, X. Creep–Fatigue Experiment and Life Prediction Study of Piston 2A80 Aluminum Alloy. Materials 2021, 14, 1403. https://doi.org/10.3390/ma14061403

Dong Y, Liu J, Liu Y, Li H, Zhang X, Hu X. Creep–Fatigue Experiment and Life Prediction Study of Piston 2A80 Aluminum Alloy. Materials. 2021; 14(6):1403. https://doi.org/10.3390/ma14061403

Chicago/Turabian StyleDong, Yi, Jianmin Liu, Yanbin Liu, Huaying Li, Xiaoming Zhang, and Xuesong Hu. 2021. "Creep–Fatigue Experiment and Life Prediction Study of Piston 2A80 Aluminum Alloy" Materials 14, no. 6: 1403. https://doi.org/10.3390/ma14061403