Fatigue Life Improvement of Cracked Aluminum 6061-T6 Plates Repaired by Composite Patches

Abstract

1. Introduction

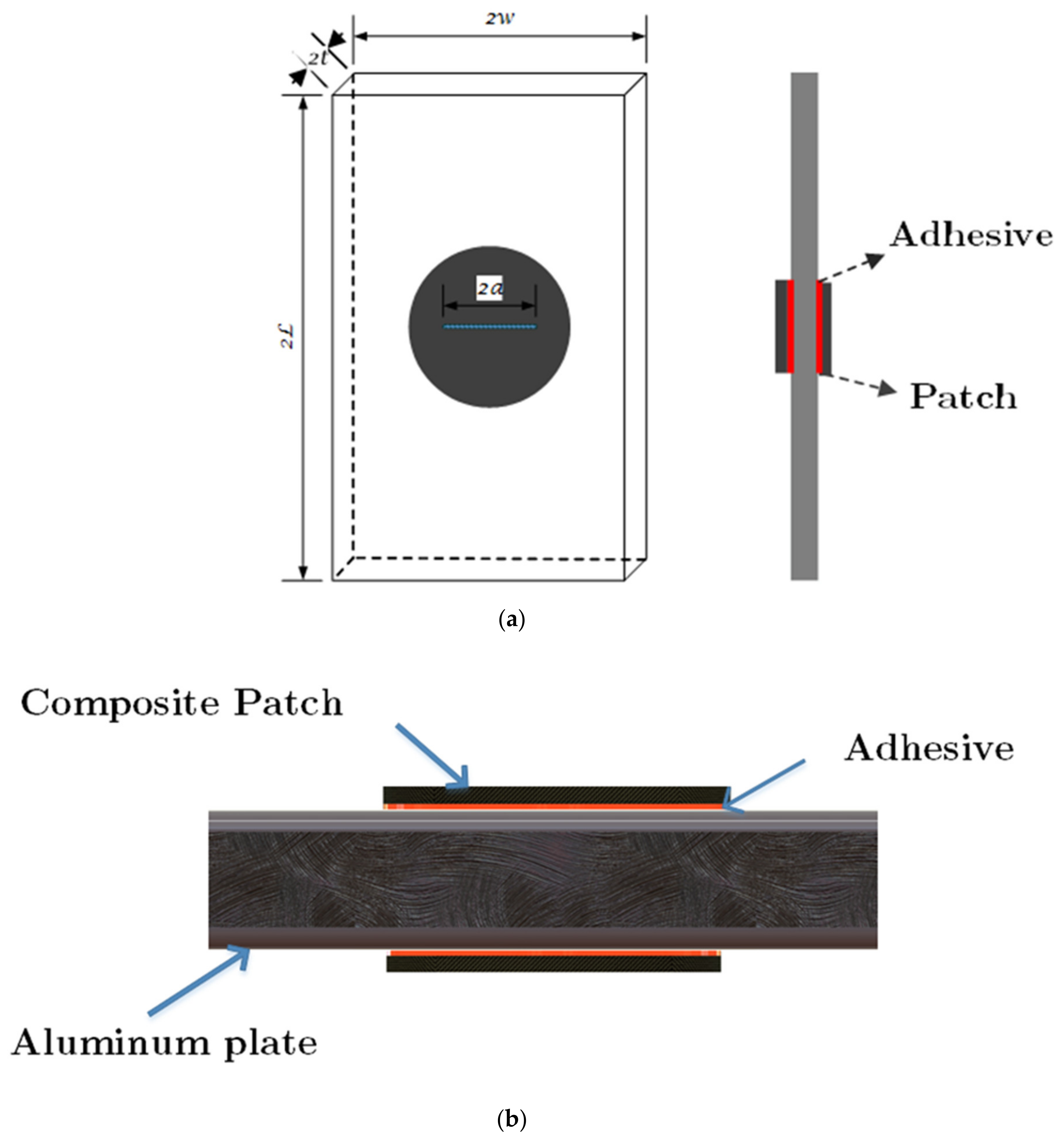

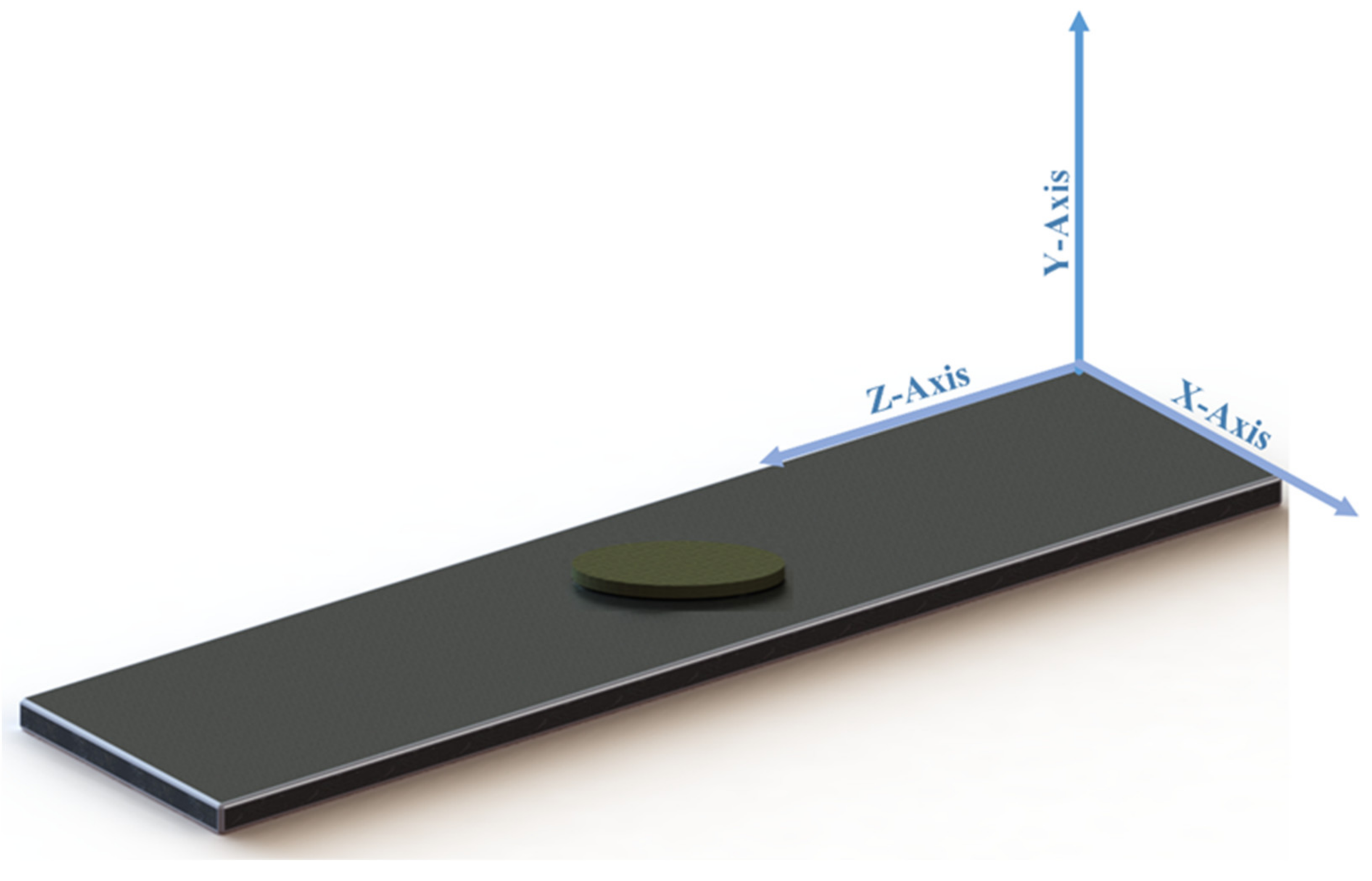

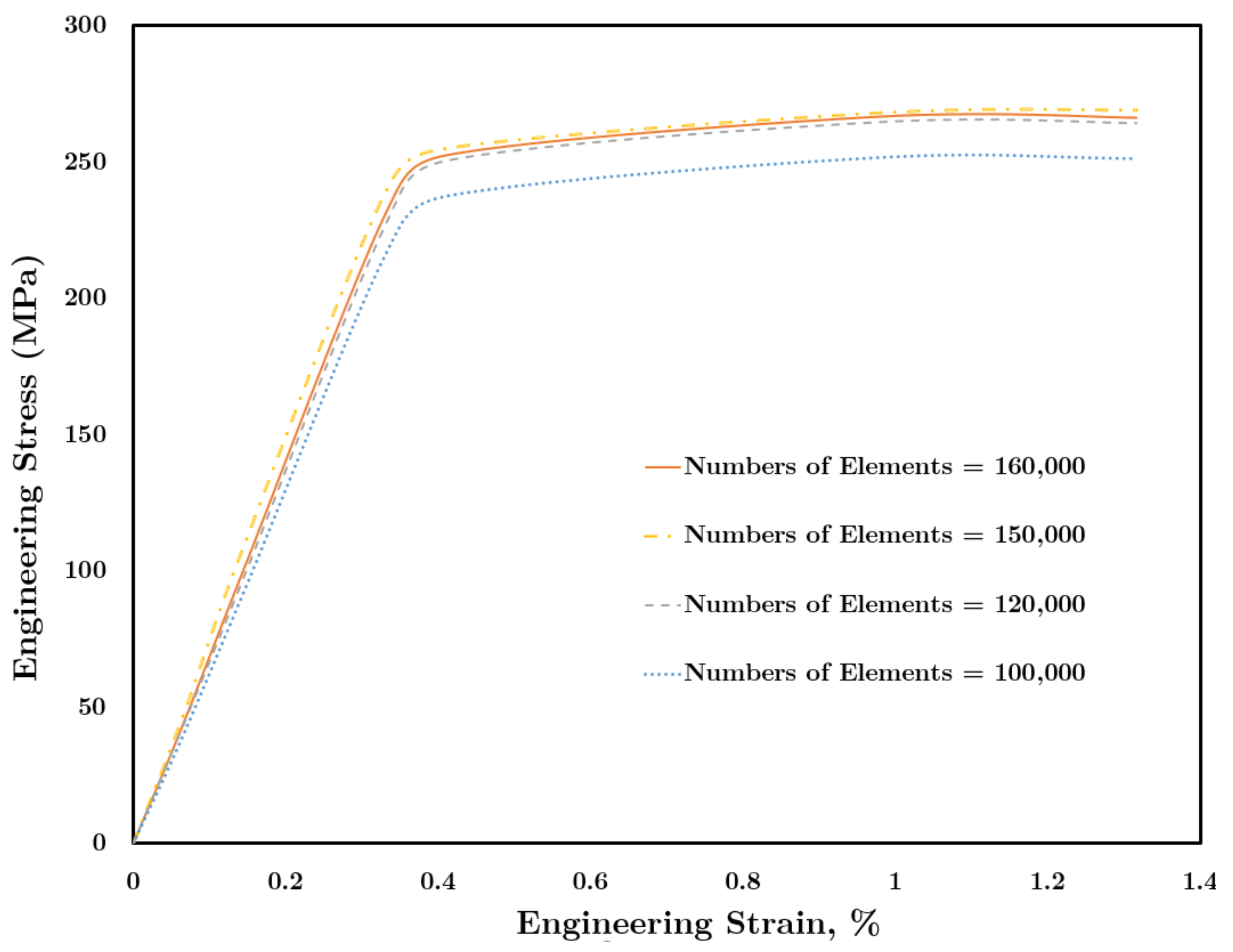

2. Materials and Models

2.1. Numerical Modeling

2.2. Fatigue Life Analysis

3. Results

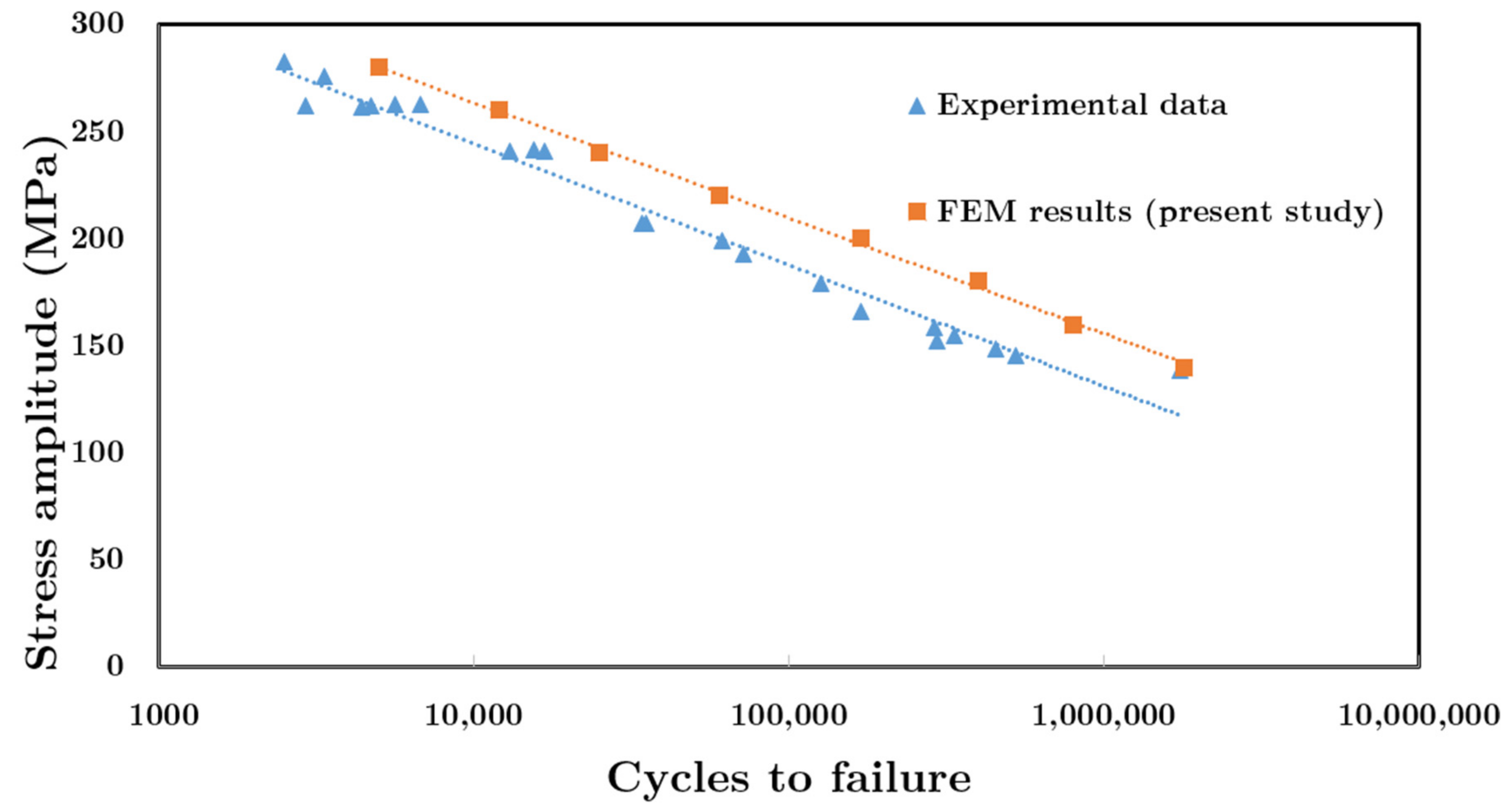

3.1. Validation

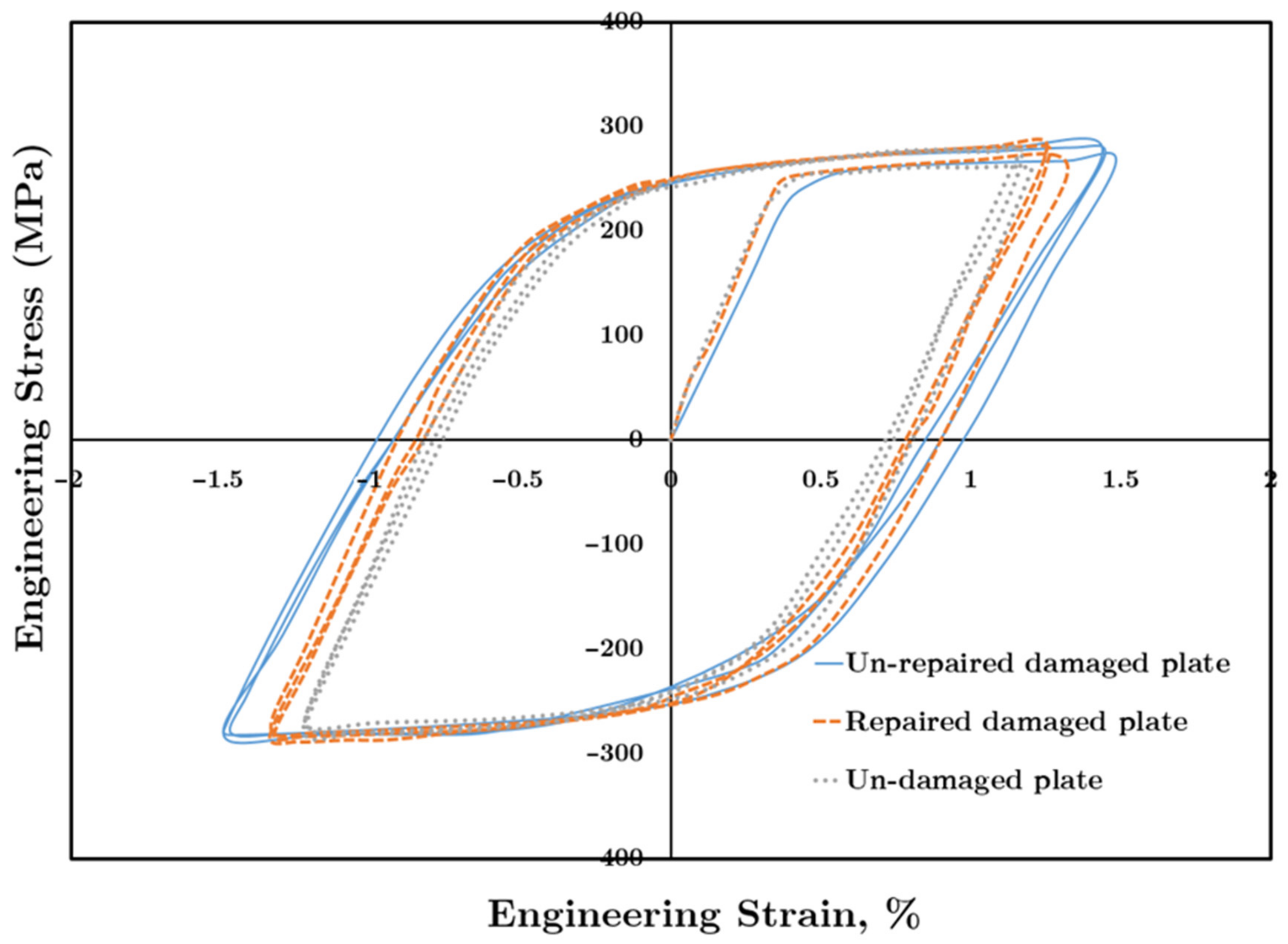

3.2. Hysteresis Loop

3.3. Fatigue Life Prediction

4. Conclusions

- The aluminum plate repaired by composite patches has a narrower hysteresis loop in the strain direction compared to the unrepaired damaged plate. Therefore, the plastic strain amplitude of the repaired plate is lower than the unrepaired plate. For example, at MPa, the plastic strain amplitude of the repaired plate becomes 50.3% less than the plastic strain amplitude of the unrepaired damaged plate.

- Using the composite patch improves the logarithmic fatigue life significantly (at MPa, by 100% and at , by 55%).

- The higher the applied load level, the higher the effect of applying a double-sided composite patch is on the damaged aluminum plate’s fatigue life improvement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, P.; Shinde, P.S.; Bhoyar, G. Fracture Toughness and Shear Strength of the Bonded Interface Between an Aluminium Alloy Skin and a FRP Patch. J. Inst. Eng. Ser. C 2018, 100, 779–789. [Google Scholar] [CrossRef]

- Kwon, Y.; Hall, B. Analyses of cracks in thick stiffened plates repaired with single-sided composite patch. Compos. Struct. 2015, 119, 727–737. [Google Scholar] [CrossRef]

- Kumar, S.A.; Rajesh, R.; Pugazhendhi, S. A review of stress concentration studies on fibre composite panels with holes/cutouts. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1461–1472. [Google Scholar] [CrossRef]

- Ayatollahi, M.; Hashemi, R. Mixed mode fracture in an inclined center crack repaired by composite patching. Compos. Struct. 2007, 81, 264–273. [Google Scholar] [CrossRef]

- Ayatollahi, M.; Hashemi, R. Computation of stress intensity factors (KI, KII) and T-stress for cracks reinforced by composite patching. Compos. Struct. 2007, 78, 602–609. [Google Scholar] [CrossRef]

- De Finis, R.; Palumbo, D.; Serio, L.M.; De Filippis, L.A.C.; Galietti, U. Correlation between Thermal Behaviour of AA5754-H111 during Fatigue Loading and Fatigue Strength at Fixed Number of Cycles. Materials 2018, 11, 719. [Google Scholar] [CrossRef] [PubMed]

- Makwana, A.H.; Shaikh, A.A.; Bakare, A.K.; Chitturi, S. Investigation of patch hybridization effect on the composite patch repair of a cracked aluminum plate: A pragmatic approach. Mech. Adv. Mater. Struct. 2018, 26, 1458–1468. [Google Scholar] [CrossRef]

- Dai, J.; Zhao, P.; Su, H.; Wang, Y. Mechanical Behavior of Single Patch Composite Repaired Al Alloy Plates: Experimental and Numerical Analysis. Materials 2020, 13, 2740. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wu, J.; Xi, J.; Yu, Z. Bonded Repair Optimization of Cracked Aluminum Alloy Plate by Microwave Cured Carbon-Aramid Fiber/Epoxy Sandwich Composite Patch. Materials 2019, 12, 1655. [Google Scholar] [CrossRef]

- Hedayati, R.; Khouzani, S.G.; Jahanbakhshi, M. Investigation of debonding propagation in aluminum/composite joints under fatigue loading. J. Adhes. Sci. Technol. 2015, 29, 59–73. [Google Scholar] [CrossRef]

- Baker, A.A.; Rose, L.F.; Jones, R. Advances in the Bonded Composite Repair of Metallic Aircraft Structure; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Rasane, A.R.; Kumar, P.; Khond, M.P. Optimizing the size of a CFRP patch to repair a crack in a thin sheet. J. Adhes. 2016, 93, 1064–1080. [Google Scholar] [CrossRef]

- Seo, D.-C.; Lee, J.-J. Fatigue crack growth behavior of cracked aluminum plate repaired with composite patch. Compos. Struct. 2002, 57, 323–330. [Google Scholar] [CrossRef]

- Ergun, E.; Taşgetiren, S.; Topçu, M. Fatigue and fracture analysis of aluminum plate with composite patches under the hygrothermal effect. Compos. Struct. 2010, 92, 2622–2631. [Google Scholar] [CrossRef]

- Ouinas, D.; Sahnoune, M.; Benderdouche, N.; Bouiadjra, B.B. Stress intensity factor analysis for notched cracked structure repaired by composite patching. Mater. Des. 2009, 30, 2302–2308. [Google Scholar] [CrossRef]

- Hosseini-Toudeshky, H.; Sadighi, M.; Vojdani, A. Effects of curing thermal residual stresses on fatigue crack propagation of aluminum plates repaired by FML patches. Compos. Struct. 2013, 100, 154–162. [Google Scholar] [CrossRef]

- Albedah, A.; Mohammed, S.M.K.; Bouiadjra, B.B.; Bouiadjra, B.A.B.; Benyahia, F. Effect of the patch length on the effectiveness of one-sided bonded composite repair for aluminum panels. Int. J. Adhes. Adhes. 2018, 81, 83–89. [Google Scholar] [CrossRef]

- Mohammadi, S. Parametric investigation of one-sided composite patch efficiency for repairing crack in mixed mode considering different thicknesses of the main plate. J. Compos. Mater. 2020, 54, 3067–3079. [Google Scholar] [CrossRef]

- Yousefi, A.; Mashhadi, M.M.; Safarabadi, M. Numerical analysis of cracked aluminum plate repaired with multi-scale reinforcement composite patches. J. Compos. Mater. 2020, 54, 4341–4357. [Google Scholar] [CrossRef]

- Palumbo, D.; De Finis, R.; Ancona, F.; Galietti, U. Damage monitoring in fracture mechanics by evaluation of the heat dissipated in the cyclic plastic zone ahead of the crack tip with thermal measurements. Eng. Fract. Mech. 2017, 181, 65–76. [Google Scholar] [CrossRef]

- Ancona, F.; Palumbo, D.; De Finis, R.; Demelio, G.; Galietti, U. Automatic procedure for evaluating the Paris Law of martensitic and austenitic stainless steels by means of thermal methods. Eng. Fract. Mech. 2016, 163, 206–219. [Google Scholar] [CrossRef]

- Hosseini, K.; Safarabadi, M.; Ganjiani, M.; Mohammadi, E. Experimental and numerical fatigue life study of cracked AL plates reinforced by glass/epoxy composite patches in different stress ratios. Mech. Based Des. Struct. Mach. 2020, 1–17. [Google Scholar] [CrossRef]

- Mohammed, S.M.K.; Mhamdia, R.; Albedah, A.; Bouiadjra, B.A.B.; Bouiadjra, B.B.; Benyahia, F. Fatigue crack growth in aluminum panels repaired with different shapes of single-sided composite patches. Int. J. Adhes. Adhes. 2021, 105, 102781. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Peauril, J.; Salih, C.; Reddy, K.R.; Yu, P.; Schubel, P.; Heyer, T. Testing and modelling the fatigue behaviour of GFRP composites—Effect of stress level, stress concentration and frequency. Eng. Sci. Technol. Int. J. 2020, 23, 1223–1232. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Yu, P.; Salih, C.; Abousnina, R.; Heyer, T.; Schubel, P. Tensile Fatigue Behavior of Polyester and Vinyl Ester Based GFRP Laminates—A Comparative Evaluation. Polymers 2021, 13, 386. [Google Scholar] [CrossRef]

- Fernandes, T.A.; Campilho, R.D.; Banea, M.D.; Da Silva, L.F.M. Adhesive Selection for Single Lap Bonded Joints: Experimentation and Advanced Techniques for Strength Prediction. J. Adhes. 2015, 91, 841–862. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Akram, S.; Jaffery, S.H.I.; Khan, M.; Fahad, M.; Mubashar, A.; Ali, L. Numerical and experimental investigation of Johnson–Cook material models for aluminum (Al 6061-T6) alloy using orthogonal machining approach. Adv. Mech. Eng. 2018, 10, 1–14. [Google Scholar] [CrossRef]

- Devireddy, S.B.R.; Biswas, S. Effect of Fiber Geometry and Representative Volume Element on Elastic and Thermal Properties of Unidirectional Fiber-Reinforced Composites. J. Compos. 2014, 2014, 1–12. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Tozaki, Y.; Nakashima, Y.; Shimizu, T. Fatigue behaviour of dissimilar friction stir spot welds between A6061-T6 and low carbon steel sheets welded by a scroll grooved tool without probe. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 581–591. [Google Scholar] [CrossRef]

- Fatemi, A.; Plaseied, A.; Khosrovaneh, A.; Tanner, D. Application of bi-linear log–log S–N model to strain-controlled fatigue data of aluminum alloys and its effect on life predictions. Int. J. Fatigue 2005, 27, 1040–1050. [Google Scholar] [CrossRef]

- Badaruddin, M.; Supriadi, H. Low Cycle Fatigue Properties of Extruded 6061-T6 Aluminum Alloy. J. Physics: Conf. Ser. 2019, 1198, 032002. [Google Scholar] [CrossRef]

- Scott-Emuakpor, O.; George, T.; Cross, C.; Shen, M.-H.H. Hysteresis-loop representation for strain energy calculation and fatigue assessment. J. Strain Anal. Eng. Des. 2010, 45, 275–282. [Google Scholar] [CrossRef]

| Materials | Materials Behavior | Elastic Modulus (MPa) | Poisson’s Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|

| Araldite 2015 | elastic isotropic | 1850 | 0.33 | 21.63 |

| Aluminum 6061-T6 | elastic-plastic | 72,000 | 0.35 | 311 |

| A (MPa) | B (MPa) | C0 | n | m0 |

|---|---|---|---|---|

| 250 | 79.7 | 0.0249 | 0.499 | 1.499 |

| Fiber Volume Fraction (%) | E1 (GPa) | E2 (GPa) | E3 (GPa) | V12 | V13 | V23 | G12 (GPa) | G13 (GPa) | G23 (GPa) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Glass Fiber /Epoxy | 60 | 45 | 12 | 12 | 0.28 | 0.28 | 0.4 | 5 | 5 | 5.6 |

| Plane | Z = 0 | Y = 0 | X = 0 | Z = 2L |

|---|---|---|---|---|

| Boundary Condition | Uz = 0 | Uy = 0 | Ux = 0 | Uz = cyclic displacement |

| Materials Constant | Aluminum 6061-T6 |

|---|---|

| Fatigue Ductility Coefficient, (mm/mm) | 0.77 |

| Fatigue Ductility Exponent, c | −1.01 |

| Fatigue Strength Coefficient, (MPa) | 386 |

| Fatigue Strength Exponent, b | −0.036 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousefi, A.; Jolaiy, S.; Hedayati, R.; Serjouei, A.; Bodaghi, M. Fatigue Life Improvement of Cracked Aluminum 6061-T6 Plates Repaired by Composite Patches. Materials 2021, 14, 1421. https://doi.org/10.3390/ma14061421

Yousefi A, Jolaiy S, Hedayati R, Serjouei A, Bodaghi M. Fatigue Life Improvement of Cracked Aluminum 6061-T6 Plates Repaired by Composite Patches. Materials. 2021; 14(6):1421. https://doi.org/10.3390/ma14061421

Chicago/Turabian StyleYousefi, Armin, Saman Jolaiy, Reza Hedayati, Ahmad Serjouei, and Mahdi Bodaghi. 2021. "Fatigue Life Improvement of Cracked Aluminum 6061-T6 Plates Repaired by Composite Patches" Materials 14, no. 6: 1421. https://doi.org/10.3390/ma14061421

APA StyleYousefi, A., Jolaiy, S., Hedayati, R., Serjouei, A., & Bodaghi, M. (2021). Fatigue Life Improvement of Cracked Aluminum 6061-T6 Plates Repaired by Composite Patches. Materials, 14(6), 1421. https://doi.org/10.3390/ma14061421