Study of Interaction Mechanism between Positrons and Ag Clusters in Dilute Al–Ag Alloys at Low Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Characterization Methods

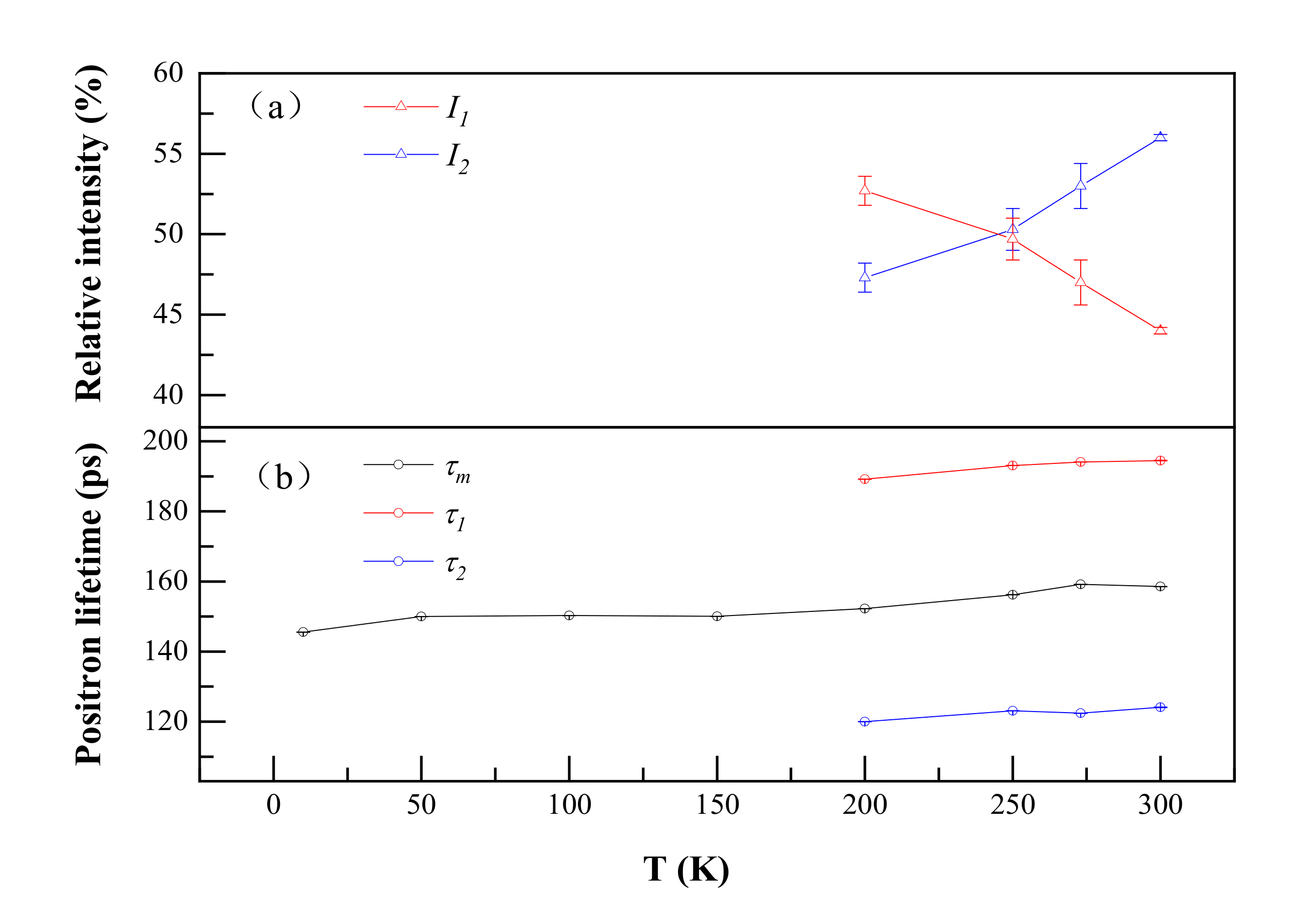

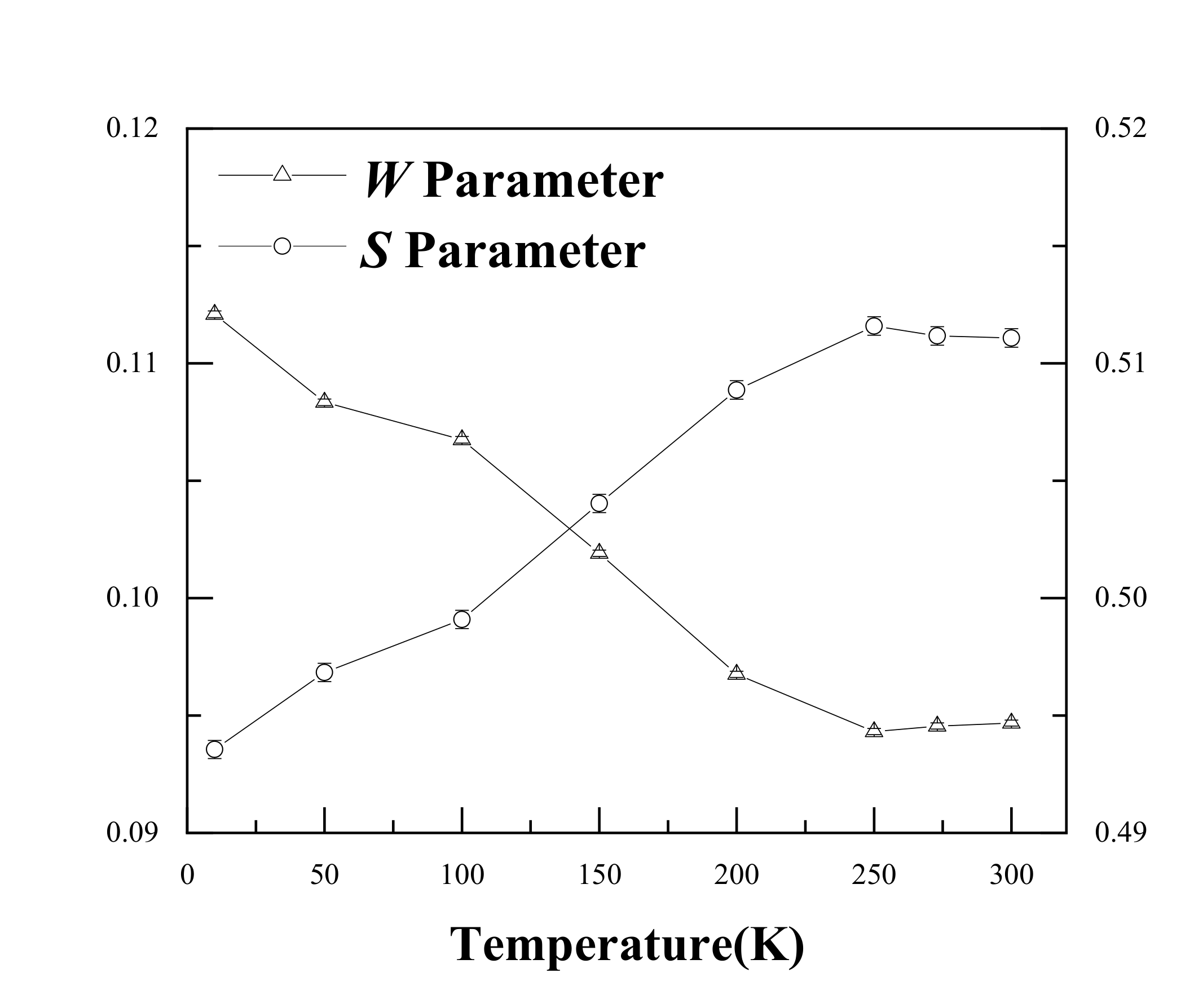

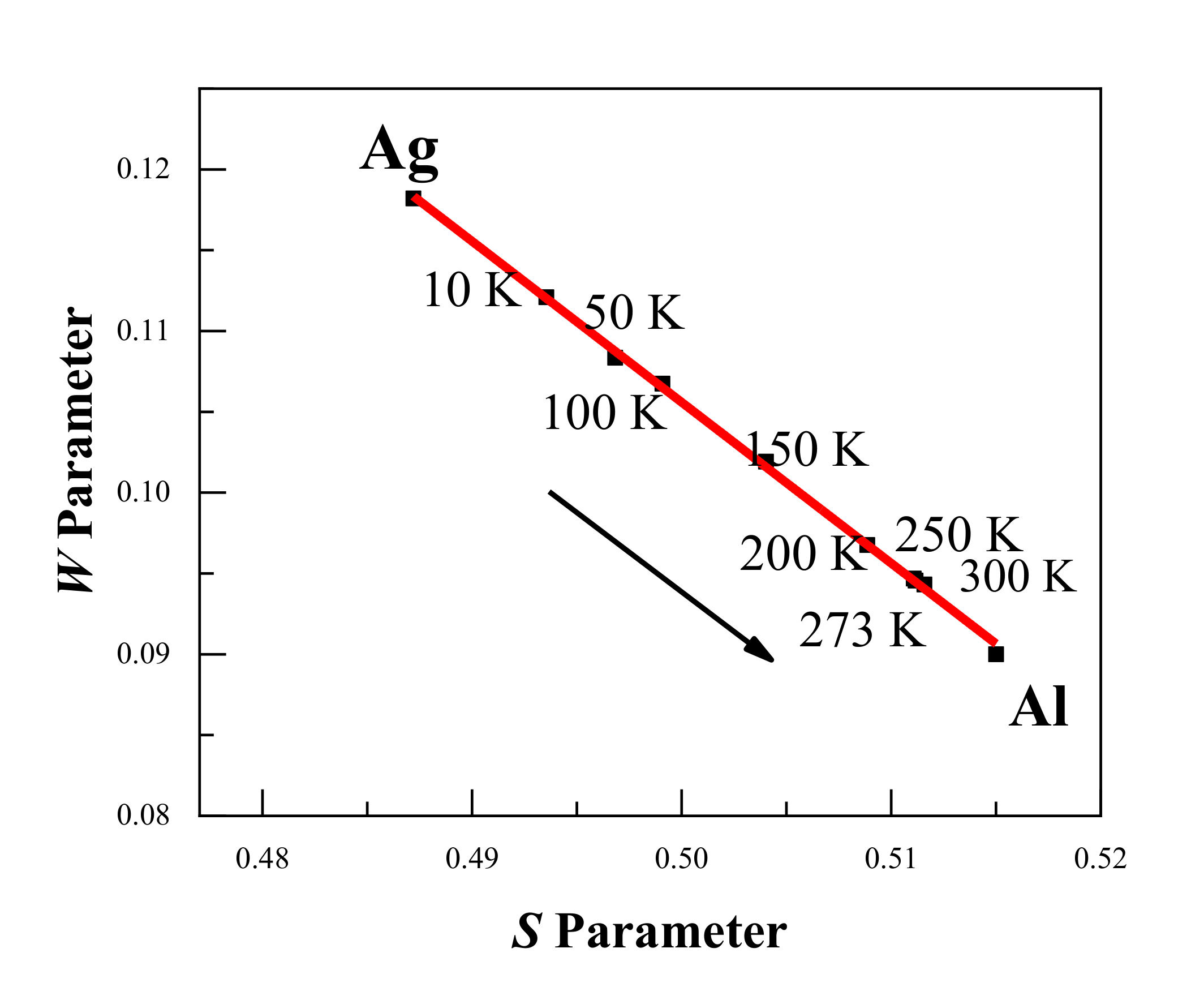

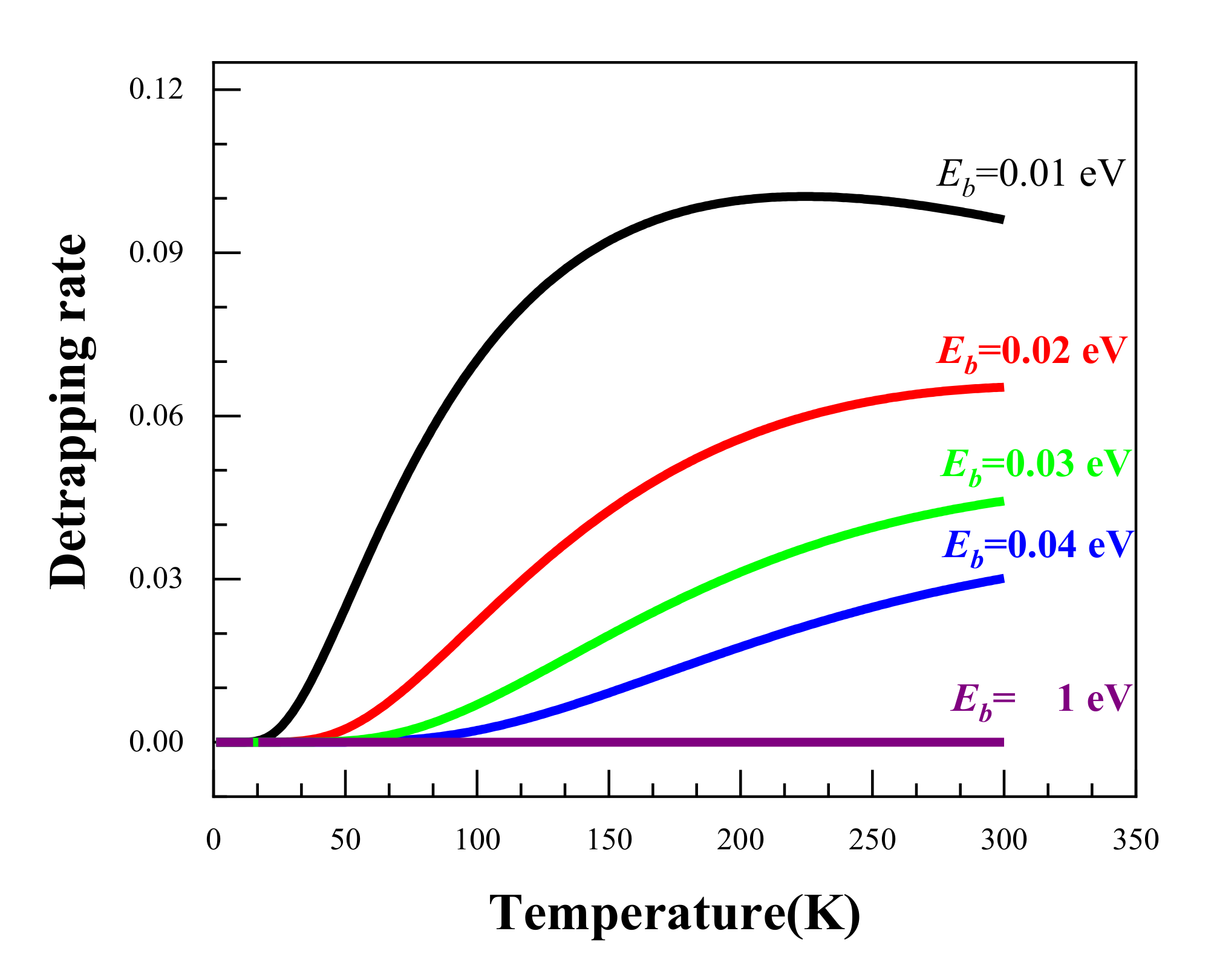

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.Z.; Bourgeois, L.; Rosalie, J.M.; Medhekar, N.V. The bi-layered precipitate phase zeta in the Al-Ag alloy system. Acta Mater. 2017, 132, 525–537. [Google Scholar] [CrossRef]

- Auld, J.H.; Vietz, J.T.; Polmear, I.J. T-phase Precipitation induced by the Addition of Silver to an Aluminium–Copper–Magnesium Alloy. Nature 1966, 209, 703–704. [Google Scholar] [CrossRef]

- Polmear, I.J. A Trace Element Effect in Alloys based on the Aluminium-Zinc-Magnesium System. Nature 1960, 186, 303–304. [Google Scholar] [CrossRef]

- Lumley, R.N.; Polmear, I.J.; Morton, A.J. Development of mechanical properties during secondary aging in aluminium alloys. Mater. Sci. Technol. 2005, 21, 1025–1032. [Google Scholar] [CrossRef]

- Marceau, R.K.W.; Sha, G.; Ferragut, R.; Dupasquier, A.; Ringer, S.P. Solute clustering in Al-Cu-Mg alloys during the early stages of elevated temperature ageing. Acta Mater. 2010, 58, 4923–4939. [Google Scholar] [CrossRef]

- Nakamura, J.; Matsuda, K.; Kawabata, T.; Sato, T.; Nakamura, Y.; Ikeno, S. Effect of Silver Addition on the beta ’-Phase in Al-Mg-Si-Ag Alloy. Mater. Trans. 2010, 51, 310–316. [Google Scholar] [CrossRef]

- Guinier, A. The mechanism of precipitation in aluminium-silver alloy crystals during structural hydrogenation. C. R. Hebd. Seances Acad. Sci. 1942, 214, 34–37. [Google Scholar]

- Dubey, P.A.; Schonfeld, B.; Kostorz, G. Shape and internal structure of guinier-preston zones in Al-Ag. Acta Metall. Mater. 1991, 39. [Google Scholar] [CrossRef]

- Baur, R.; Gerold, V. Existence of a metastable miscibility gap in aluminium-silver alloys. Acta Metall. 1962, 10, 637–645. [Google Scholar] [CrossRef]

- Nagai, Y.; Toyama, T.; Tang, Z.; Inoue, K.; Chiba, T.; Hasegawa, M.; Hirosawa, S.; Sato, T. Interactions between Fermi surfaces and Brillouin zone boundaries and phase stability of embedded metallic nanoparticles. Phys. Rev. B 2009, 79, 21405. [Google Scholar] [CrossRef]

- Zou, B.; Qi, N.; Liu, Z.W.; Chen, Z.Q.; Liu, H.Q.; Yi, D.Q.; Tang, Z. Enhanced positron trapping by Ag nanoclusters at low temperatures: A challenge of positron sensitivity to quantum dots. J. Appl. Phys. 2017, 121, 125103. [Google Scholar] [CrossRef]

- Alkassab, T.; Haasen, P. Early stages of precipitation in dilute Al-Ag alloys. Z. Met. 1993, 84, 248–250. [Google Scholar]

- Nicholson, R.B.; Nutting, J. The metallography of precipitation in an A1-16% Ag alloy. Acta Metall. 1961, 9, 332–343. [Google Scholar] [CrossRef]

- Wang, C.; Ma, B.; Cao, X.Z.; He, S.; Han, J.B.; Wei, M.; Evans, D.G.; Duan, X. Bridge-type interface optimization on a dual-semiconductor heterostructure toward high performance overall water splitting. J. Mater. Chem. A 2018, 6, 7871–7876. [Google Scholar] [CrossRef]

- Ning, X.; Cao, X.Z.; Li, C.; Li, D.M.; Zhang, P.; Gong, Y.H.; Xia, R.; Wang, B.Y.; Wei, L. Modification of source contribution in PALS by simulation using Geant4 code. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 2017, 397, 75–81. [Google Scholar] [CrossRef]

- Cao, X.Z.; Zhu, T.; Jin, S.X.; Kuang, P.; Zhang, P.; Lu, E.Y.; Gong, Y.H.; Guo, L.P.; Wang, B.Y. Detection of helium in irradiated Fe9Cr alloys by coincidence Doppler broadening of slow positron annihilation. Appl. Phys. A Mater. Sci. Process. 2017, 123, 177. [Google Scholar] [CrossRef]

- Nagai, Y.; Takadate, K.; Tang, Z.; Ohkubo, H.; Sunaga, H.; Takizawa, H.; Hasegawa, M. Positron annihilation study of vacancy-solute complex evolution in Fe-based alloys. Phys. Rev. B 2003, 67, 224202. [Google Scholar] [CrossRef]

- Iakubov, I.T.; Pogosov, V.V. Positron binding energy in monovacancy of metals and work functions in stabilized jellium model. In Positron Annihilation Icpa-10, Pts 1 and 2; He, Y.J., Cao, B.S., Jean, Y.C., Eds.; Transtec Publications Ltd.: Zurich-Uetikon, Switzerland, 1995; Volume 175, pp. 169–172. [Google Scholar] [CrossRef]

- Smedskjaer, L.C.; Manninen, M.; Fluss, M.J. An alternative interpretation of positron-annihilation in dislocations. J. Phys. F Metal Phys. 1980, 10, 2237–2249. [Google Scholar] [CrossRef]

- Hidalgo, C.; Linderoth, S.; Dediego, N. Positron-trapping mechanism at dislocations in Zn. Phys. Rev. B 1987, 36, 6740–6745. [Google Scholar] [CrossRef] [PubMed]

- Riceevans, P.; Hlaing, T.; Chaglar, I. Evidence for Temperature Dependence of Positron Trapping Rate in Plastically Deformed Copper. Phys. Rev. Lett. 1976, 37, 1415–1418. [Google Scholar] [CrossRef]

- Van Huis, M.A.; van Veen, A.; Schut, H.; Falub, C.V.; Eijt, S.W.H.; Mijnarends, P.E.; Kuriplach, J. Positron confinement in embedded lithium nanoclusters. Phys. Rev. B 2002, 65, 085416. [Google Scholar] [CrossRef]

- Puska, M.J.; Lanki, P.; Nieminen, R.M. Positron affinities for elemental metals. J. Phys. Condes. Matter 1989, 1, 6081–6093. [Google Scholar] [CrossRef]

- Hugenschmidt, C.; Pikart, P.; Stadlbauer, M.; Schreckenbach, K. High elemental selectivity to Sn submonolayers embedded in Al using positron annihilation spectroscopy. Phys. Rev. B 2008, 77. [Google Scholar] [CrossRef]

- Kansy, J. Microcomputer program for analysis of positron annihilation lifetime spectra. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1996, 374, 235–244. [Google Scholar] [CrossRef]

- Alexander, K.B.; Legoues, F.K.; Aaronson, H.I.; Laughlin, D.E. Faceting of GP zones in an Al-Ag alloy. Acta Metall. 1984, 32, 2241–2249. [Google Scholar] [CrossRef]

- Nagai, Y.; Honma, T.; Tang, Z.; Hono, K.; Hasegawa, M. Coincidence Doppler broadening study of the pre-precipitation stage of an Al-Cu-Mg-Ag alloy. Philos. Mag. A Phys. Condens. Matter Struct. Defects Mech. Prop. 2002, 82, 1559–1572. [Google Scholar] [CrossRef]

- Raju, P.; Gupta, R.; Siegel, W. Annihilation of a positron in a vacancy in aluminum. Phys. Rev. B 1980, 22, 4572–4589. [Google Scholar] [CrossRef]

- Zhang, S.S.; Yao, Z.J.; Kong, X.S.; Chen, L.; Qin, J.Y. First-principles calculations of solute-vacancy interactions in aluminum. Chin. Physics. B 2020, 29. [Google Scholar] [CrossRef]

- Maury, F.; Lucasson, A.; Lucasson, P.; Dimitrov, C. Mixed-interstitial recovery in AlTi and AlAg dilute alloys. J. Phys. F Metal Phys. 1988, 18, 657–675. [Google Scholar] [CrossRef]

- Folegati, P.; Makkonen, I.; Ferragut, R.; Puska, M.J. Analysis of electron-positron momentum spectra of metallic alloys as supported by first-principles calculations. Phys. Rev. B 2007, 75, 054201. [Google Scholar] [CrossRef]

- Nagai, Y.; Tang, Z.; Ohkubo, H.; Takadate, K.; Hasegawa, M. Elemental analysis of positron affinitive site in materials by coincidence Doppler broadening spectroscopy. Radiat. Phys. Chem. 2003, 68, 381–386. [Google Scholar] [CrossRef]

- Seeger, A. Study of defects in crystals by positron-annihilation. Appl. Phys. 1974, 4, 183–199. [Google Scholar] [CrossRef]

- Brandt, W.; Paulin, R. Positron diffusion in solids. Phys. Rev. B Solid State 1972, 5, 2430–2435. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, P.; Wang, B.; Cao, X.; Jin, S.; Yu, R. Study of Interaction Mechanism between Positrons and Ag Clusters in Dilute Al–Ag Alloys at Low Temperature. Materials 2021, 14, 1451. https://doi.org/10.3390/ma14061451

Liu X, Zhang P, Wang B, Cao X, Jin S, Yu R. Study of Interaction Mechanism between Positrons and Ag Clusters in Dilute Al–Ag Alloys at Low Temperature. Materials. 2021; 14(6):1451. https://doi.org/10.3390/ma14061451

Chicago/Turabian StyleLiu, Xiaoshuang, Peng Zhang, Baoyi Wang, Xingzhong Cao, Shuoxue Jin, and Runsheng Yu. 2021. "Study of Interaction Mechanism between Positrons and Ag Clusters in Dilute Al–Ag Alloys at Low Temperature" Materials 14, no. 6: 1451. https://doi.org/10.3390/ma14061451

APA StyleLiu, X., Zhang, P., Wang, B., Cao, X., Jin, S., & Yu, R. (2021). Study of Interaction Mechanism between Positrons and Ag Clusters in Dilute Al–Ag Alloys at Low Temperature. Materials, 14(6), 1451. https://doi.org/10.3390/ma14061451