Evaluation of the Dimensional Stability of Black Poplar Wood Modified Thermally in Nitrogen Atmosphere

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Origin and Preparation of Black Poplar Wood

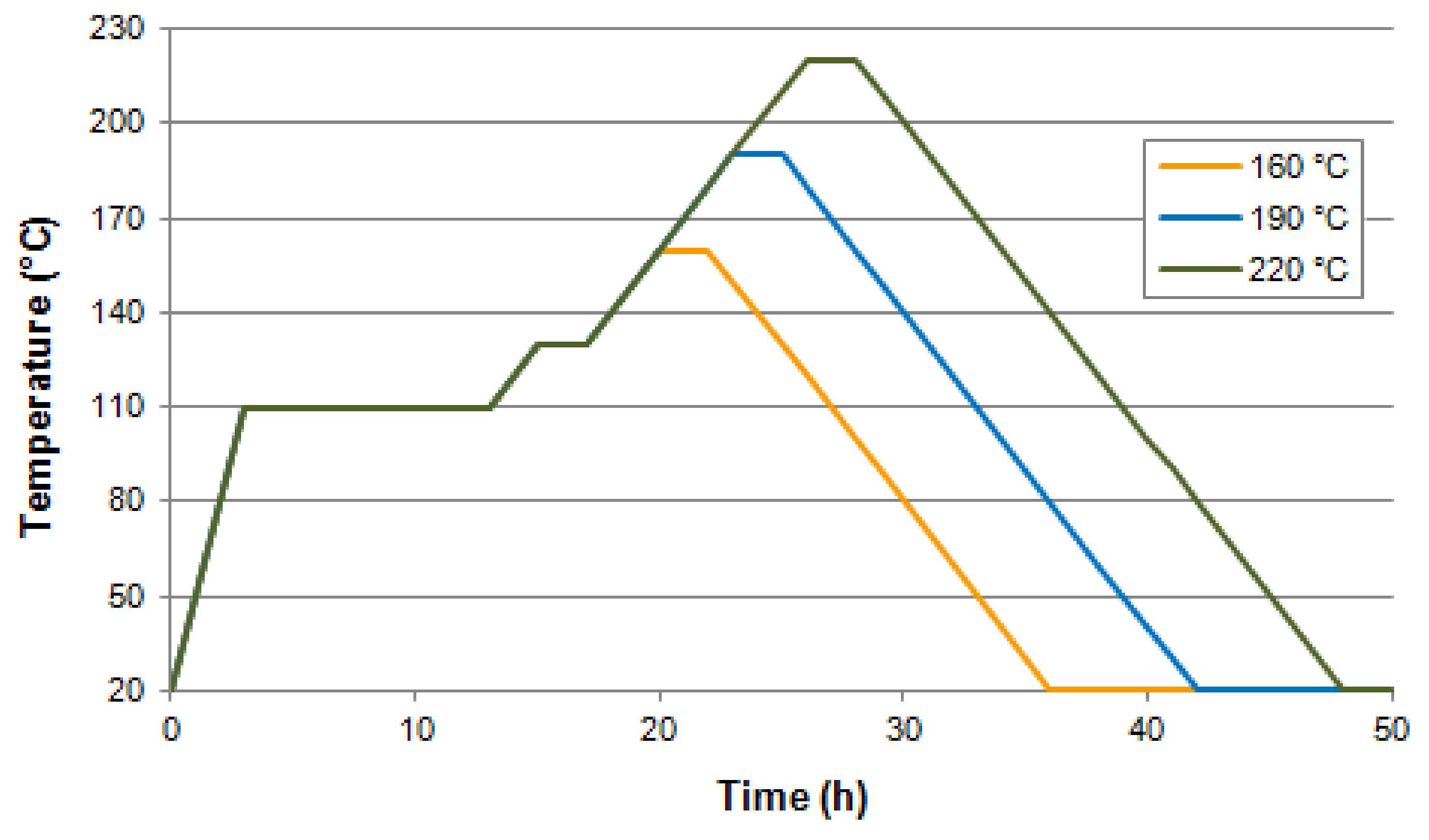

2.2. Thermal Modification in Nitrogen Atmosphere

2.3. Density, Moisture Content and Mass Loss

2.4. Chemical Composition

2.5. Determination of the Equilibrium Moisture Content and Dimensional Changes of Wood

2.6. Determination of Water Absorption and Swelling

2.7. Statistical Analysis

3. Results and Discussion

3.1. Changes in Chemical Composition

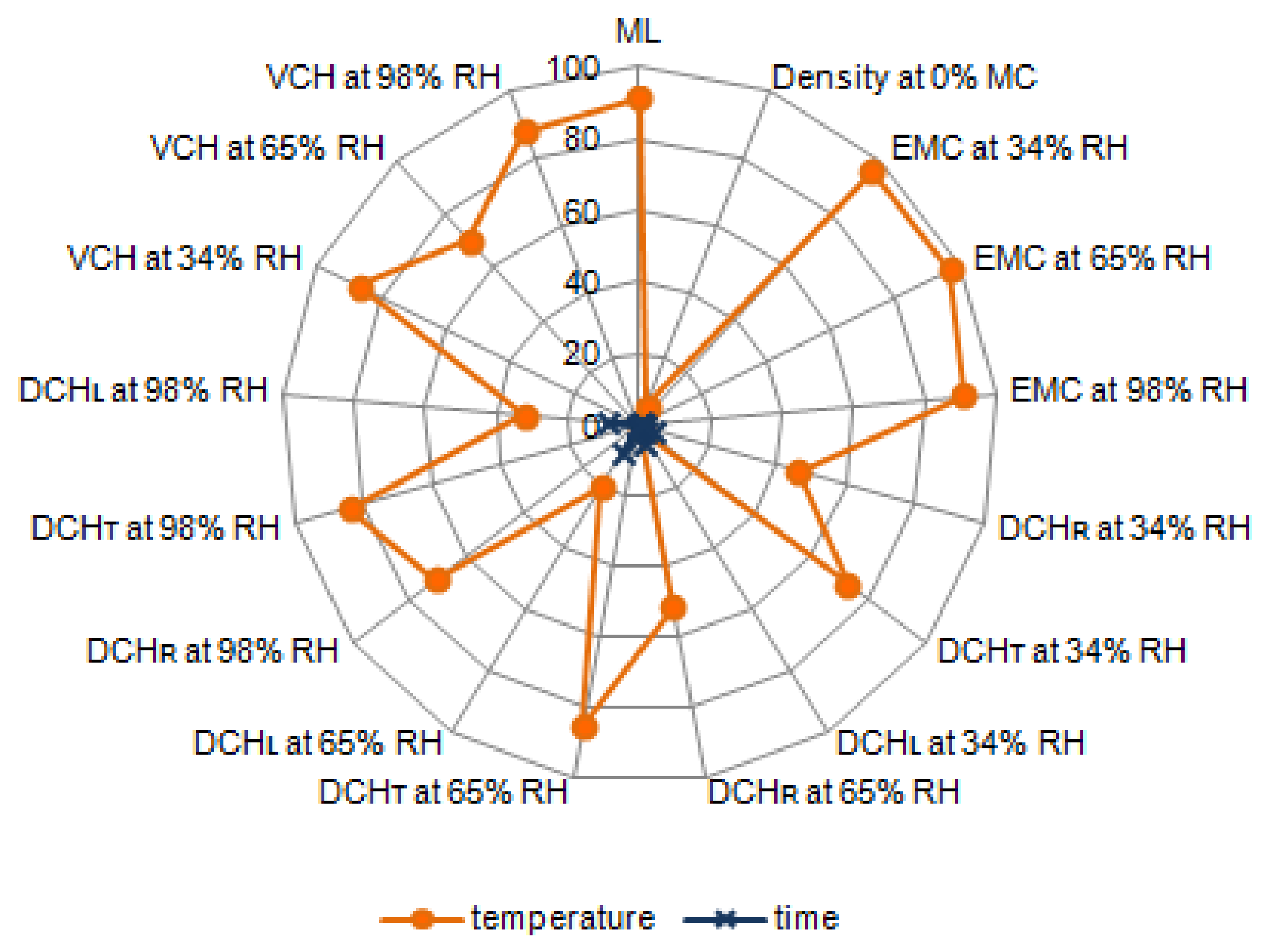

3.2. Mass Loss and Density of Black Poplar Thermally Modified in Nitrogen Atmosphere

3.3. Equilibrium Moisture Content and Dimensional Changes of Black Poplar during Humidification at Different Relative Humidities

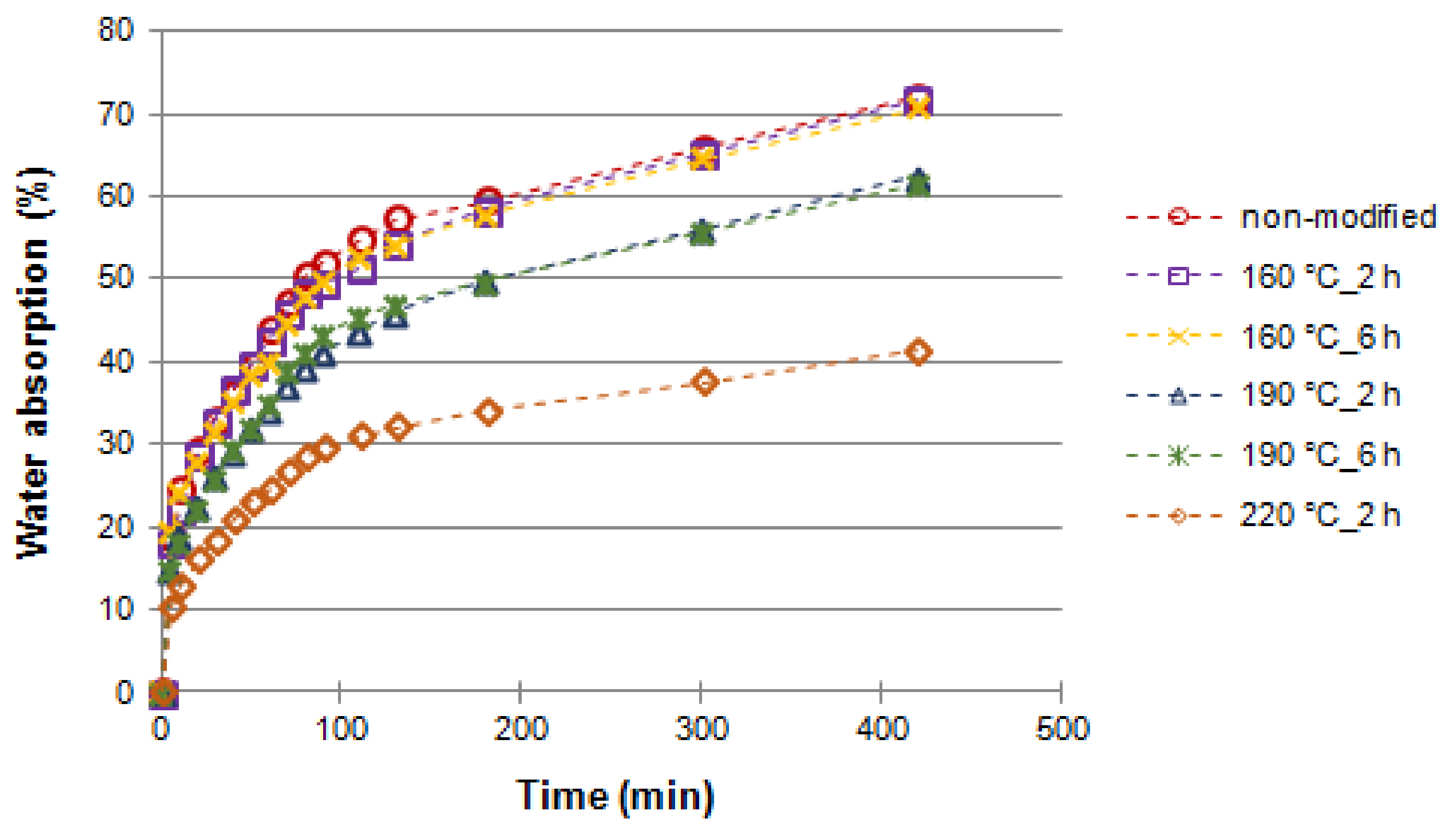

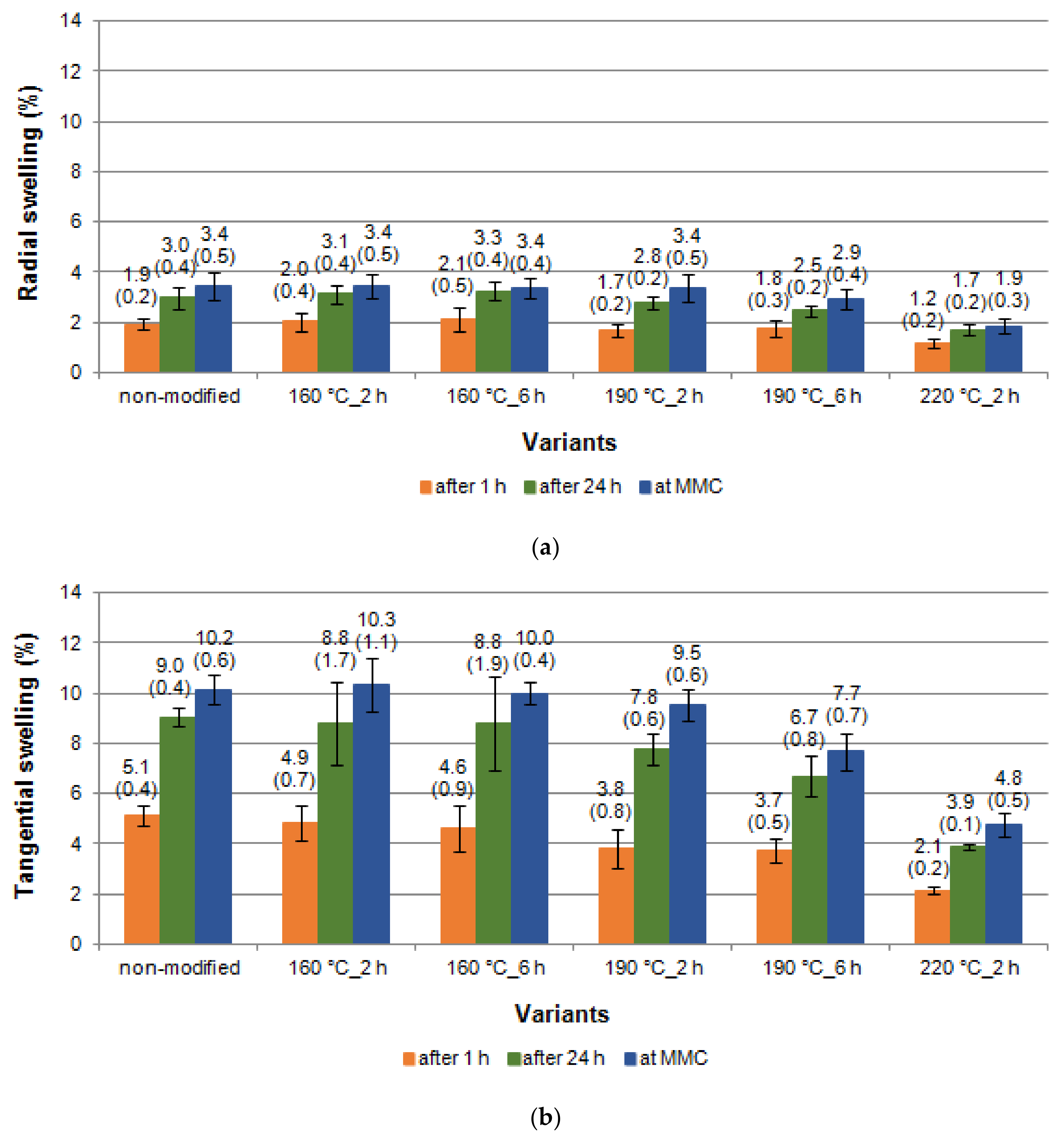

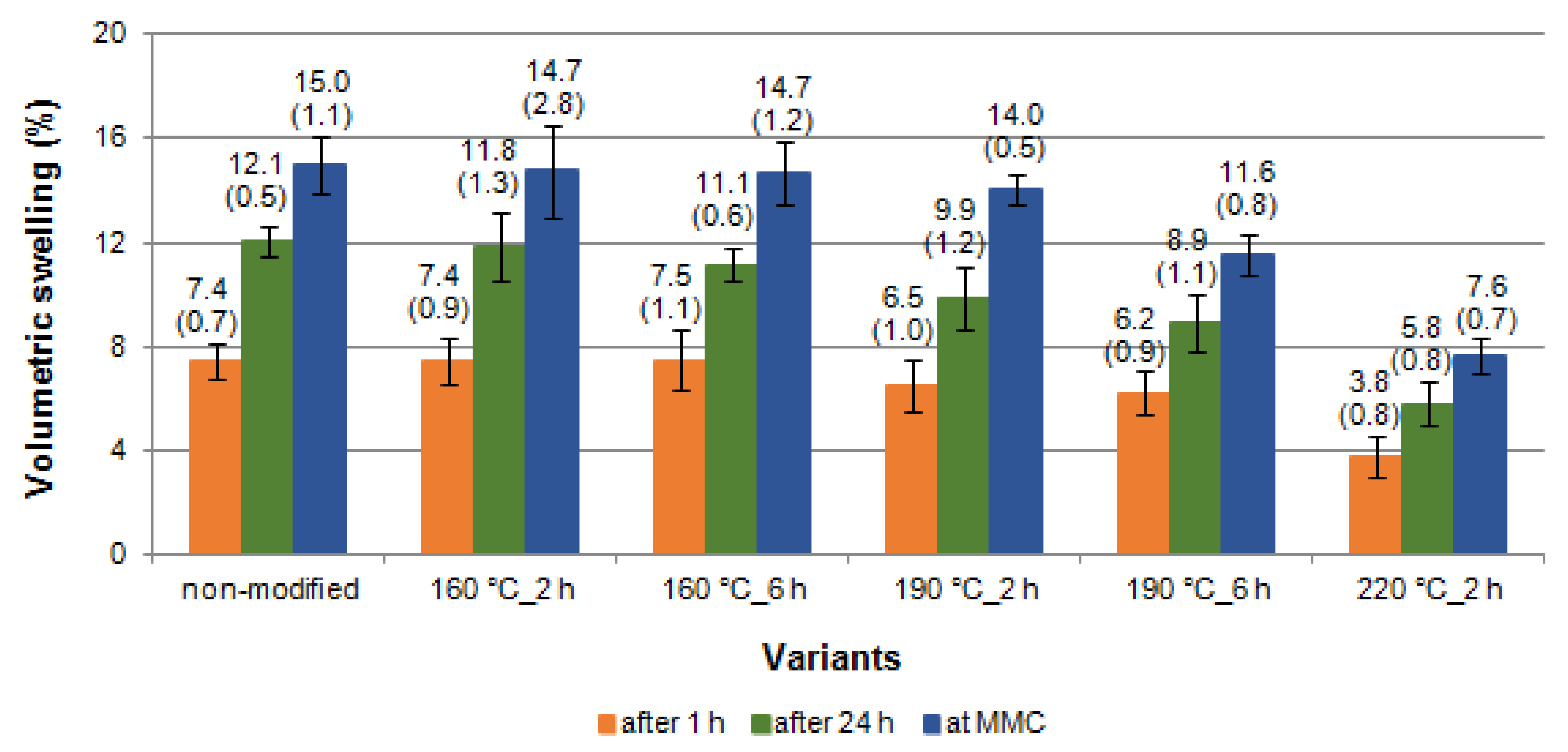

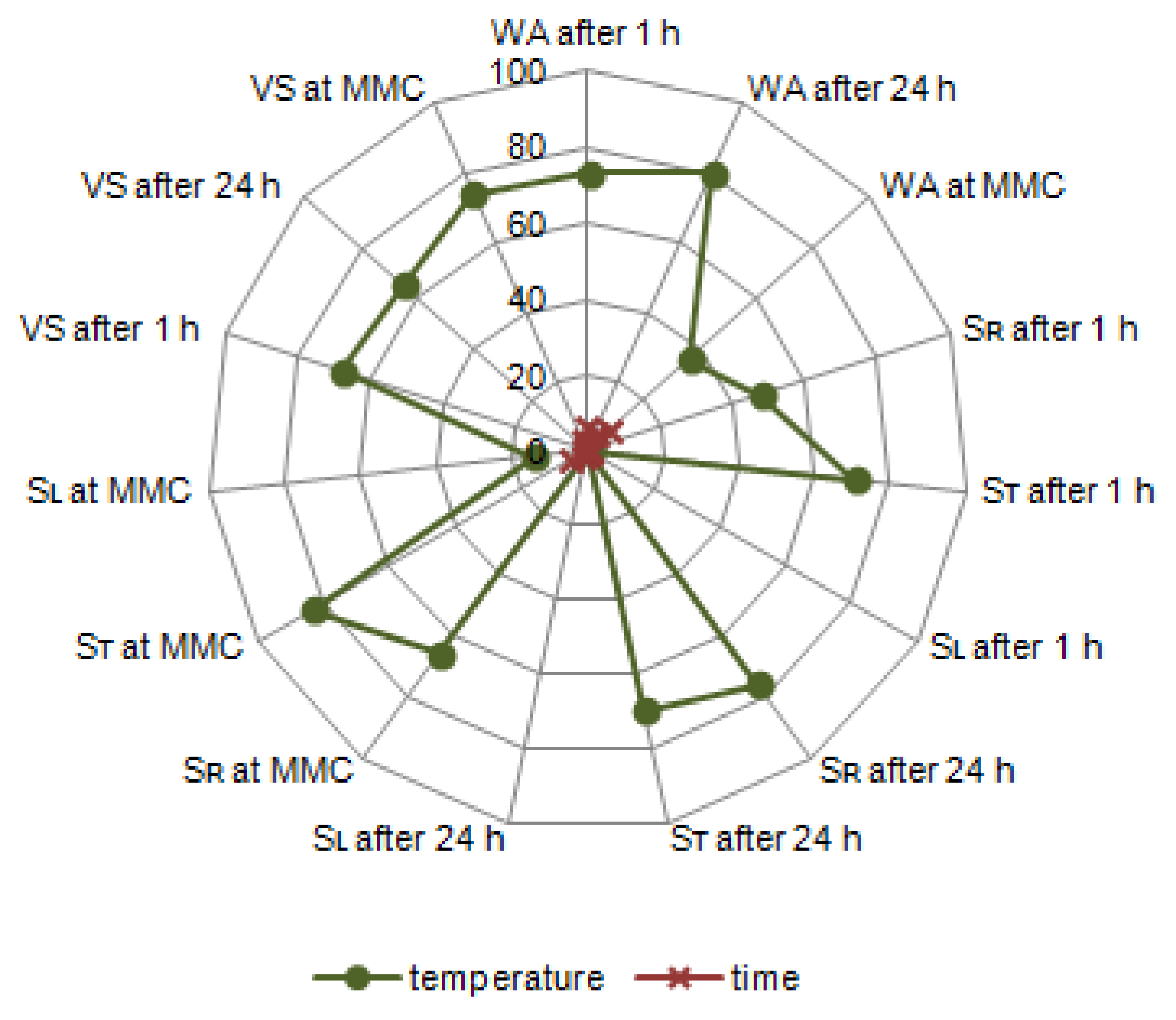

3.4. Dimensional Changes of Black Poplar after Soaking in Water

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brito, J.O.; Silva, F.G.; Leao, M.M.; Almeida, G. Chemical composition changes in eucalyptus and pinus woods submitted to heat treatment. Biores. Technol. 2008, 99, 8545–8548. [Google Scholar] [CrossRef]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Borrega, M.; Karenlampi, P.P. Hygroscopicity of heat-treated Norway spruce (Picea abies) wood. Eur. J. Wood Wood Prod. 2010, 2, 233–235. [Google Scholar] [CrossRef] [Green Version]

- Roszyk, E.; Stachowska, E.; Majka, J.; Mania, P.; Broda, M. Moisture-Dependent Strength Properties of Thermally-Modified Fraxinus excelsior Wood in Compression. Materials 2020, 13, 1647. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schorr, D.; Blanchet, P. Improvement of White Spruce Wood Dimensional Stability by Organosilanes Sol-Gel Impregnation and Heat Treatment. Materials 2020, 13, 973. [Google Scholar] [CrossRef] [Green Version]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef] [Green Version]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. IForest Biogeosci. For. 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Vernois, M. Heat treatment of wood in France—State of the art. In Proceedings of the Special Seminar of COST Action E22, Review on Heat Treatments of Wood, Antibes, France, 9 February 2001. [Google Scholar]

- Hofmann, T.; Retfalvi, T.; Albert, L.; Niemz, P. Investigation of the chemical changes in the structure of wood thermally modified with in a nitrogen atmospehere autoclave. Wood Res. 2008, 53, 85–98. [Google Scholar]

- Sandak, J.; Goli, G.; Cetera, P.; Sandak, A.; Cavalli, A.; Todaro, L. Machinability of Minor Wooden Species before and after Modification with Thermo-Vacuum Technology. Materials 2017, 10, 121. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Fan, Y.; Gao, J.; Star, N.M. The effect of heat treatment on the chemical and color change of black locust (Robinia pseudoacacia) wood flour. BioResources 2012, 7, 1157–1170. [Google Scholar] [CrossRef]

- Kol, H.Ş.; Kokten, E.S. Effects of heat treatment in nitrogen atmosphere on swelling properties and color change of oak (Quercus robur) wood. In Proceedings of the IInd International Furniture Congres, Mugla, Turkey, 13–15 October 2016. [Google Scholar]

- Gurleyen, L.; Ayata, U.; Esteves, B.; Cakicier, N. Effects of heat treatment on the adhesion strength, pendulum hardness, surface roughness, color and glossiness of Scots pine laminated parquet with two different types of UV varnish application. Maderas. Cien. Tecnol. 2017, 19, 213–224. [Google Scholar] [CrossRef] [Green Version]

- Candelier, K.; Dumarçay, S.; Pétrissans, A.; Desharnais, L.; Gérardin, P.; Pétrissans, M. Comparison of chemical composition and decay durability of heat treated wood cured under different inert atmospheres: Nitrogen or vacuum. Polym. Degrad. Stab. 2015, 98, 677–681. [Google Scholar] [CrossRef]

- Shaikhutdinova, A.R.; Safin, R.R.; Nazipova, F.V. Thermal modification of mood in production of finishing materials. Solid State Phenom. 2017, 265, 171–176. [Google Scholar] [CrossRef]

- Vanden Broeck, A. European black poplar—Populus nigra. In Technical Guidelines for Genetic Conservation and Use; European Forest Genetic Resources Programme (EUFORGEN): Rome, Italy, 2003. [Google Scholar]

- Agricultural Research Service, National Plant Germplasm System. Germplasm Resources Information Network (GRIN-Taxonomy). 2020. Available online: https://npgsweb.ars-grin.gov/gringlobal/taxon/taxonomysearch.aspx?language=en (accessed on 18 February 2020).

- Wagenführ, R. Holzatlas, 6th ed.; Neu Bearbeitete und Erweiteste Auflage; Fachbuchverlag: Leipzig, Germany, 2007. [Google Scholar]

- Nguyen, C.T.; Wagenführ, A.; Phuong, L.X.; Dai, V.H.; Bremer, M.; Fischer, S. The effects of thermal modification on the properties of two Vietnamese bamboo species, Part I: Effects on physical properties. Bioresources 2012, 7, 5355–5366. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Zhang, Y.; Shen, Y.; Li, C.; Wang, Y.; Ma, Z.; Sun, W. New Perspective on Wood Thermal Modification: Relevance between the Evolution of Chemical Structure and Physical-Mechanical Properties, and Online Analysis of Release of VOCs. Polymers 2019, 11, 1145. [Google Scholar] [CrossRef] [Green Version]

- Kubovský, I.; Kačíková, D.; Kačík, F. Structural Changes of Oak Wood Main Components Caused by Thermal Modification. Polymers 2020, 12, 48. [Google Scholar] [CrossRef] [Green Version]

- Esteves, B.; Domingos, I.; Pereira, H. Improvement of technological quality of eucalypt wood by heat treatment in air at 170–200 °C. For. Prod. J. 2007, 57, 47–52. [Google Scholar]

- Yang, T.; Lee, C.; Lee, C.; Cheng, Y. Effects of different thermal modification media on physical and mechanical properties of moso bamboo. Constr. Build. Mater. 2016, 119, 251–259. [Google Scholar] [CrossRef]

- Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests; ISO 13061-2; International Organization for Standardization: Geneva, Switzerland, 2014.

- Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests; ISO 13061-1; International Organization for Standardization: Geneva, Switzerland, 2014.

- Antczak, A.; Radomski, A.; Zawadzki, J. Benzene substitution in wood analysis. Ann. Warsaw Univ. Life Sci. SSGW For. Wood Technol. 2006, 58, 15–19. [Google Scholar]

- Kürschner, K.; Hoffer, A. Ein neues Verfahren zur Bestimmung der Cellulose in Hölzern und Zellstoffen. Tech. Chem. Papier Zellstoff Fabr. 1929, 26, 125–129. [Google Scholar]

- Wise, L.E.; Murphy, M.; D’Addieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap. Trade J. 1946, 122, 35–43. [Google Scholar]

- TAPPI T 222 om-15. Acid-Insoluble Lignin in Wood and Pulp; TAPPI Press: Atlanta, GA, USA, 2015. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluitter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass, Laboratory Analytical Procedure (LAP); (NREL/TP-510-42618); National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2011. [Google Scholar]

- Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 15: Determination of Radial and Tangential Shrinkage; ISO/DIS 13061-13; International Organization for Standardization: Geneva, Switzerland, 2016.

- Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 14: Determination of Volumetric Shrinkage; ISO/DIS 13061-14; International Organization for Standardization: Geneva, Switzerland, 2016.

- Čabalová, I.; Kačík, F.; Lagaňa, R.; Výbohová, E.; Bubeníková, T.; Čaňová, I.; Ďurkovič, J. Effect of thermal treatment on the chemical, physical, and mechanical properties of pedunculate oak (Quercus robur L.) wood. BioResources 2018, 13, 157–170. [Google Scholar] [CrossRef]

- Bremer, M.; Fischer, S.; Nguyen, T.C.; Wagenführ, A.; Phuong, L.X.; Dai, V.H. Effects of Thermal Modification on the Properties of Two Vietnamese Bamboo Species. Part II: Effects on Chemical Composition. Bioresources 2013, 8, 981–993. [Google Scholar] [CrossRef] [Green Version]

- Kollmann, F.; Fengel, D. Änderungen der Chemischen Zusammensetzung von Holz durch Thermische Behandlung. Holz Roh Werks 1965, 23, 461–468. [Google Scholar] [CrossRef]

- Gawron, J. Zmiany Wybranych Właściwości Fizyko-Chemicznych Drewna Jesionu Wyniosłego (Fraxinus excelsior L.) Poddanego Modyfikacji Termicznej (Changes of Selected Physical and Chemical Properties of Ash Wood (Fraxinus excelsior L.) Subjected to thermal Modification). Ph.D. Dissertation, Faculty of Wood Technology, WULS, Warsaw, Poland, 2012. (In Polish). [Google Scholar]

- Kozakiewicz, P.; Drożdżek, M.; Laskowska, A.; Grześkiewicz, M.; Bytner, O.; Radomski, A.; Zawadzki, J. Effects of Thermal Modification on the Selected Physical Properties of Sapwood and Heartwood of Black Poplar (Populus nigra L.). BioResources 2019, 14, 8391–8404. [Google Scholar] [CrossRef]

- Tjeerdsma, B.; Boonstra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Eur. J. Wood Wood Prod. 1998, 56, 149–153. [Google Scholar] [CrossRef]

- Kamdem, D.; Pizzi, A.; Jermannaud, A. Durability of heat-treated wood. Holz Roh Werkst. 2002, 60, 1–6. [Google Scholar] [CrossRef]

- Lee, C.H.; Yang, T.H.; Cheng, Y.W.; Lee, C.J. Effects of thermal modification on the surface and chemical properties of moso bamboo. Constr. Build. Mater. 2018, 178, 59–71. [Google Scholar] [CrossRef]

- Huang, C.X.; He, J.; Min, D.Y.; Lai, C.H.; Yu, S.Y.; Yong, Q. Effect of dilute acid pretreatment on the lignin structure of Moso bamboo inner skin. J. For. Eng. 2016, 1, 55–60. [Google Scholar]

- Huang, C.X.; Lin, W.Q.; Lai, C.H.; Li, X.; Jin, Y.C.; Yong, Q. Coupling the post-extraction process to remove residual lignin and alter the recalcitrant structures for improving the enzymatic digestibility of acid pretreated bamboo residues. Bioresour. Technol. 2019, 285, 121355. [Google Scholar] [CrossRef]

- İmirzi, H.Ö.; Ülker, O.; Burdurlu, E. Effect of densification temperature and some surfacing techniques on the surface roughness of densified Scots pine (Pinus sylvestris L.). BioResources 2014, 9, 191–209. [Google Scholar] [CrossRef]

- Mania, P.; Gąsiorek, M. Acoustic Properties of Resonant Spruce Wood Modified Using Oil-Heat Treatment (OHT). Materials 2020, 13, 1962. [Google Scholar] [CrossRef]

- Srinivasa, K.; Pandey, K. Effect of Heat Treatment on Color Changes, Dimensional Stability, and Mechanical Properties of Wood. J. Wood Chem. Technol. 2012, 32, 304–316. [Google Scholar] [CrossRef]

- Bal, B. A comparative study of some of the mechanical properties of pine wood heat treated in vacuum, nitrogen, and air atmospheres. BioResources 2018, 13, 5504–5511. [Google Scholar]

- Bal, B.C. A comparative study of the physical properties of thermally treated poplar and plane woods. BioResources 2013, 8, 6493–6500. [Google Scholar] [CrossRef]

- Dong, X.; Min, X.; Shi, J.T.; Jian, L. Effect of Thermal Modification on the Physical Properties of Populus ussuriensis. Adv. Mater. Res. 2012, 476–478, 1889–1892. [Google Scholar] [CrossRef]

- Brito, A.F.; Calonego, F.W.; Bond, B.H.; Severo, E.T.D. Color changes, EMC and biological resistance of thermally modified yellow poplar. Wood Fiber Sci. 2018, 50, 439–446. [Google Scholar] [CrossRef]

- Liang, T.; Wang, L. Thermal treatment of poplar hemicelluloses at 180 to 220 °C under nitrogen atmosphere. BioResources 2017, 12, 1128–1135. [Google Scholar] [CrossRef] [Green Version]

- Burmester, A. Zur Dimensionsstabilisierung von Holz. Holz Roh Werkst. 1975, 33, 333–335. [Google Scholar] [CrossRef]

- Miklečić, J.; Jirouš-Rajković, V. Influence of Thermal Modification on Surface Properties and Chemical Composition of Beech Wood (Fagus sylvatica L.). Drv. Ind. 2016, 67, 65–71. [Google Scholar] [CrossRef] [Green Version]

- Chu, T.V. Improvement of Dimensional Stability of Acacia mangium Wood by Heat Treatment: A Case Study of Vietnam. J. For. Environ. Sci. 2013, 29, 109–115. [Google Scholar] [CrossRef]

- Cao, Y.; Lu, J.; Huang, R.; Jiang, J. Increased dimensional stability of Chinese fir through steam-heat Treatment. Eur. J. Wood Wood Prod. 2012, 7, 441–444. [Google Scholar] [CrossRef]

- Kollman, F.; Cote, W.A. Principles of Wood Science and Technology I; Springer: Berlin/Heidelberg, Germany, 1968; p. 204. [Google Scholar]

- Kaar, C. Wood—Water Relations; Springer: Berlin, Germany, 1988. [Google Scholar]

| Saturated Solution of Chemicals | RH (%) | |

|---|---|---|

| MgCl2 6H2O | Magnesium chloride hexahydrate | 34 |

| NaNO2 | Sodium nitrite | 65 |

| K2SO4 | Potassium sulfate anhydrous | 98 |

| Modification Temperature (°C) | Modification Time (h) | Cellulose (%) | Holocellulose (%) | Hemicelluloses (%) | Lignin (%) | Chloroform-Ethanol Extractives (%) |

|---|---|---|---|---|---|---|

| non-modified | - | 52.15 ± 0.49 | 82.11 ± 0.34 | 29.96 ± 0.83 | 24.16 ± 0.48 | 1.80 ± 0.03 |

| 160 | 2 | 54.58 ± 0.01 * | 78.54 ± 0.87 * | 23.96 ± 0.88 * | 25.15 ± 0.17 | 2.04 ± 0.18 |

| 6 | 54.43 ± 0.68 * | 80.78 ± 0.17 * | 26.35 ± 0.86 * | 24.88 ± 0.87 | 2.26 ± 0.33 * | |

| 190 | 2 | 53.82 ± 0.11 * | 77.03 ± 0.44 * | 23.21 ± 0.55 * | 24.85 ± 0.35 | 2.92 ± 0.13 * |

| 6 | 54.81 ± 0.05 * | 73.01 ± 0.38 * | 18.19 ± 0.43 * | 24.81 ± 0.26 | 6.50 ± 0.15 * | |

| 220 | 2 | 61.63 ± 0.25 * | 64.81 ± 0.31 * | 3.18 ± 0.56 * | 25.23 ± 0.54 | 6.59 ± 0.04 * |

| Wood Components | Factor | Sum of Squares | Fisher’s F-test | Significance Level | Factor Influence (%) |

|---|---|---|---|---|---|

| SS | F | p | |||

| Cellulose | Intercept | 39,045.78 | 341,029.2 | 0.000000 | - |

| Temperature (1) | 110.03 | 480.5 | 0.000000 | 98 | |

| Time (2) | 1.41 | 12.4 | 0.004842 | 1 | |

| Error | 1.26 | - | - | 1 | |

| Holocellulose | Intercept | 64,008.36 | 20,544.73 | 0.000000 | - |

| 1 | 404.42 | 64.90 | 0.000001 | 92 | |

| 2 | 3.08 | 0.99 | 0.341417 | 1 | |

| Error | 34.27 | - | - | 7 | |

| Hemicelluloses | Intercept | 3082.142 | 810.4047 | 0.000000 | - |

| 1 | 891.493 | 117.2026 | 0.000000 | 95 | |

| 2 | 7.987 | 2.1001 | 0.175195 | 1 | |

| Error | 41.835 | - | - | 4 | |

| Lignin | Intercept | 7501.667 | 133,683.4 | 0.000000 | - |

| 1 | 0.182 | 1.6 | 0.241368 | 21 | |

| 2 | 0.087 | 1.5 | 0.239712 | 10 | |

| Error | 0.617 | - | - | 69 | |

| Chloroform -Ethanol Extractives | Intercept | 277.3767 | 366.5698 | 0.000000 | - |

| 1 | 53.4715 | 35.3329 | 0.000016 | 74 | |

| 2 | 10.5281 | 13.9136 | 0.003323 | 15 | |

| Error | 8.3235 | - | - | 11 |

| Modification Temperature (°C) | Modification Time (h) | ML(%) | ρ at 0% MC (kg × m−3) | RH (%) | ||

|---|---|---|---|---|---|---|

| 34 | 65 | 98 | ||||

| EMC (%) | ||||||

| non-modified | - | - | 375 ± 38 | 5.8 ± 0.1 | 10.0 ± 0.2 | 27.0 ± 0.9 |

| 160 | 2 | 0.9 ± 0.5 | 374 ± 34 | 5.4 ± 0.1 * | 9.1 ± 0.1 * | 26.1 ± 1.3 |

| 6 | 0.7 ± 0.4 | 374 ± 36 | 5.0 ± 0.2 * | 9.3 ± 0.1 * | 25.9 ± 1.4 | |

| 190 | 2 | 0.8 ± 0.4 | 373 ± 37 | 4.1 ± 0.1 * | 8.3 ± 0.3 * | 23.7 ± 1.2 * |

| 6 | 2.1 ± 0.7* | 366 ± 37 | 4.1 ± 0.2 * | 7.9 ± 0.2 * | 22.7 ± 1.0 * | |

| 220 | 2 | 6.8 ± 0.9* | 349 ± 34 * | 2.9 ± 0.2 * | 5.4 ± 0.1 * | 16.0 ± 0.6 * |

| Modification Temperature (°C) | Modification Time (h) | RH (%) | |||||

|---|---|---|---|---|---|---|---|

| 34 | 65 | 98 | |||||

| Dimensional Changes (%) | |||||||

| DCHR | DCHT | DCHR | DCHT | DCHR | DCHT | ||

| non-modified | - | 0.9 ± 0.1 | 1.4 ± 0.2 | 1.0 ± 0.2 | 2.8 ± 0.3 | 2.9 ± 0.2 | 8.6 ± 0.4 |

| 160 | 2 | 0.7 ± 0.1 * | 1.4 ± 0.1 | 1.1 ± 0.2 | 2.5 ± 0.2 | 2.9 ± 0.4 | 8.1 ± 0.7 |

| 6 | 0.6 ± 0.1 * | 1.4 ± 0.3 | 1.1 ± 0.1 | 2.6 ± 0.3 | 2.7 ± 0.4 | 8.2 ± 0.4 | |

| 190 | 2 | 0.6 ± 0.1 * | 1.0 ± 0.1 * | 1.0 ± 0.1 | 2.2 ± 0.1 * | 2.5 ± 0.3 | 7.3 ± 0.7 * |

| 6 | 0.6 ± 0.1 * | 1.0 ± 0.2 * | 1.0 ± 0.2 | 2.3 ± 0.2 * | 2.5 ± 0.2 | 6.5 ± 0.4 * | |

| 220 | 2 | 0.5 ± 0.1 * | 0.6 ± 0.1 * | 0.6 ± 0.2 * | 1.2 ± 0.2 * | 1.4 ± 0.3 * | 4.4 ± 0.6 * |

| Modification Temperature (°C) | Modification Time (h) | RH (%) | |||||

|---|---|---|---|---|---|---|---|

| 34 | 65 | 98 | |||||

| Dimensional Changes (%) | |||||||

| DCHL | VCH | DCHL | VCH | DCHL | VCH | ||

| non-modified | - | 0.2 ± 0.1 | 2.4 ± 0.2 | 0.3 ± 0.1 | 4.0 ± 0.8 | 0.4 ± 0.1 | 11.9 ± 0.5 |

| 160 | 2 | 0.2 ± 0.1 | 2.4 ± 0.3 | 0.3 ± 0.1 | 3.9 ± 0.4 | 0.5 ± 0.1 | 11.6 ± 1.1 |

| 6 | 0.2 ± 0.1 | 2.4 ± 0.3 | 0.3 ± 0.1 | 3.9 ± 0.6 | 0.4 ± 0.1 | 11.6 ± 0.5 | |

| 190 | 2 | 0.2 ± 0.1 | 1.7 ± 0.2 * | 0.2 ± 0.1 * | 3.3 ± 0.2 | 0.4 ± 0.1 | 10.6 ± 0.8 * |

| 6 | 0.2 ± 0.1 | 1.8 ± 0.3 * | 0.2 ± 0.1 * | 3.5 ± 0.3 | 0.4 ± 0.1 | 10.3 ± 0.7 * | |

| 220 | 2 | 0.2 ± 0.1 | 0.8 ± 0.1 * | 0.2 ± 0.1 * | 2.2 ± 0.4 * | 0.3 ± 0.1 | 6.3 ± 0.5 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bytner, O.; Laskowska, A.; Drożdżek, M.; Kozakiewicz, P.; Zawadzki, J. Evaluation of the Dimensional Stability of Black Poplar Wood Modified Thermally in Nitrogen Atmosphere. Materials 2021, 14, 1491. https://doi.org/10.3390/ma14061491

Bytner O, Laskowska A, Drożdżek M, Kozakiewicz P, Zawadzki J. Evaluation of the Dimensional Stability of Black Poplar Wood Modified Thermally in Nitrogen Atmosphere. Materials. 2021; 14(6):1491. https://doi.org/10.3390/ma14061491

Chicago/Turabian StyleBytner, Olga, Agnieszka Laskowska, Michał Drożdżek, Paweł Kozakiewicz, and Janusz Zawadzki. 2021. "Evaluation of the Dimensional Stability of Black Poplar Wood Modified Thermally in Nitrogen Atmosphere" Materials 14, no. 6: 1491. https://doi.org/10.3390/ma14061491

APA StyleBytner, O., Laskowska, A., Drożdżek, M., Kozakiewicz, P., & Zawadzki, J. (2021). Evaluation of the Dimensional Stability of Black Poplar Wood Modified Thermally in Nitrogen Atmosphere. Materials, 14(6), 1491. https://doi.org/10.3390/ma14061491