Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W–Ni–Fe Alloy—A Review

Abstract

:1. Introduction

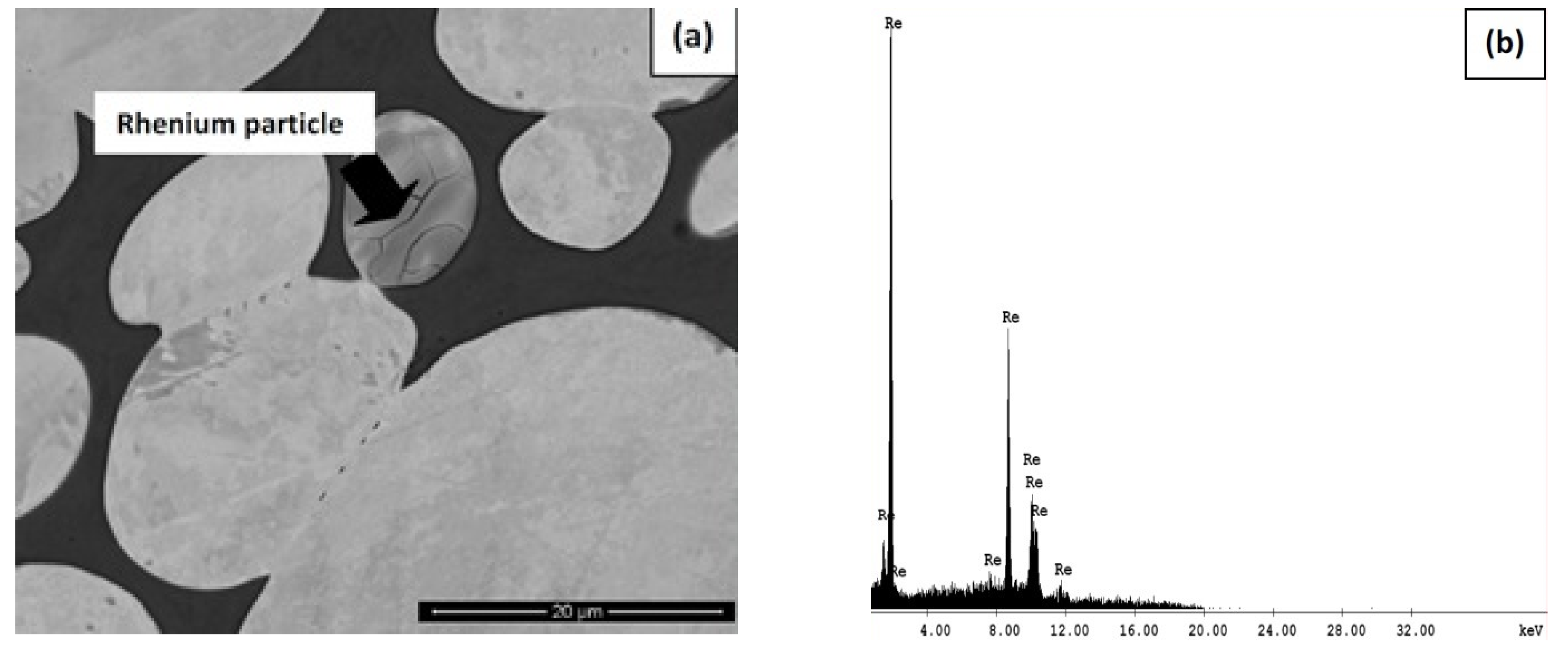

2. Effect of Rhenium and Tantalum on W–Ni–Fe

3. Effect of Molybdenum on W–Ni–Fe

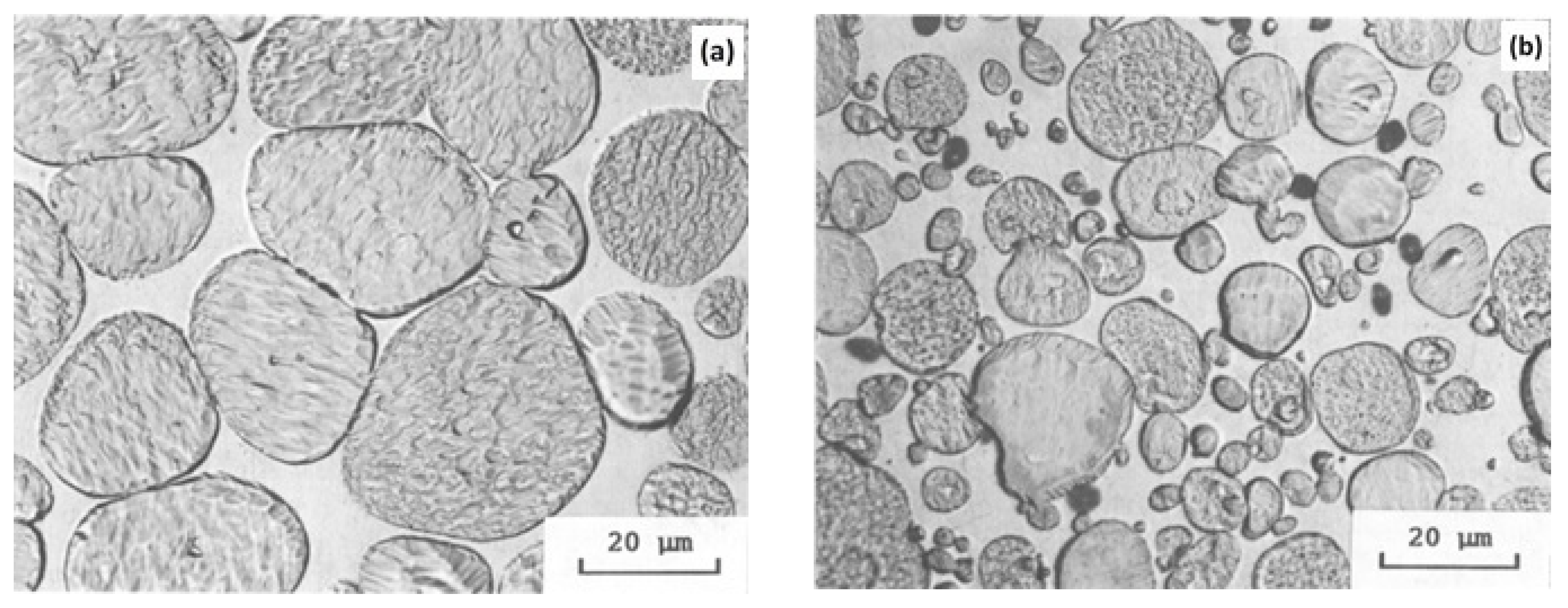

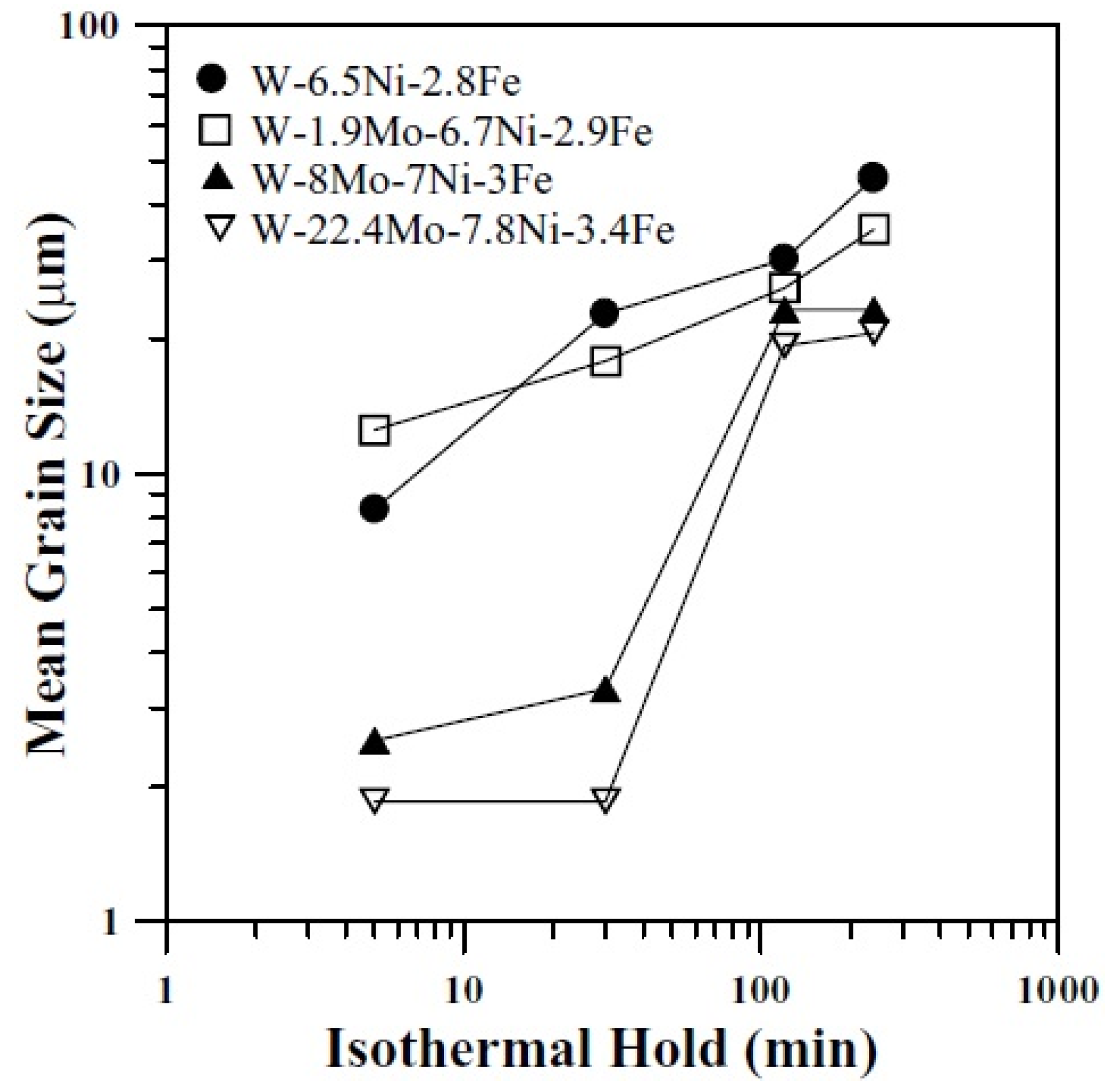

3.1. Sintering Mechanism of W–Ni–Fe-Mo Alloy

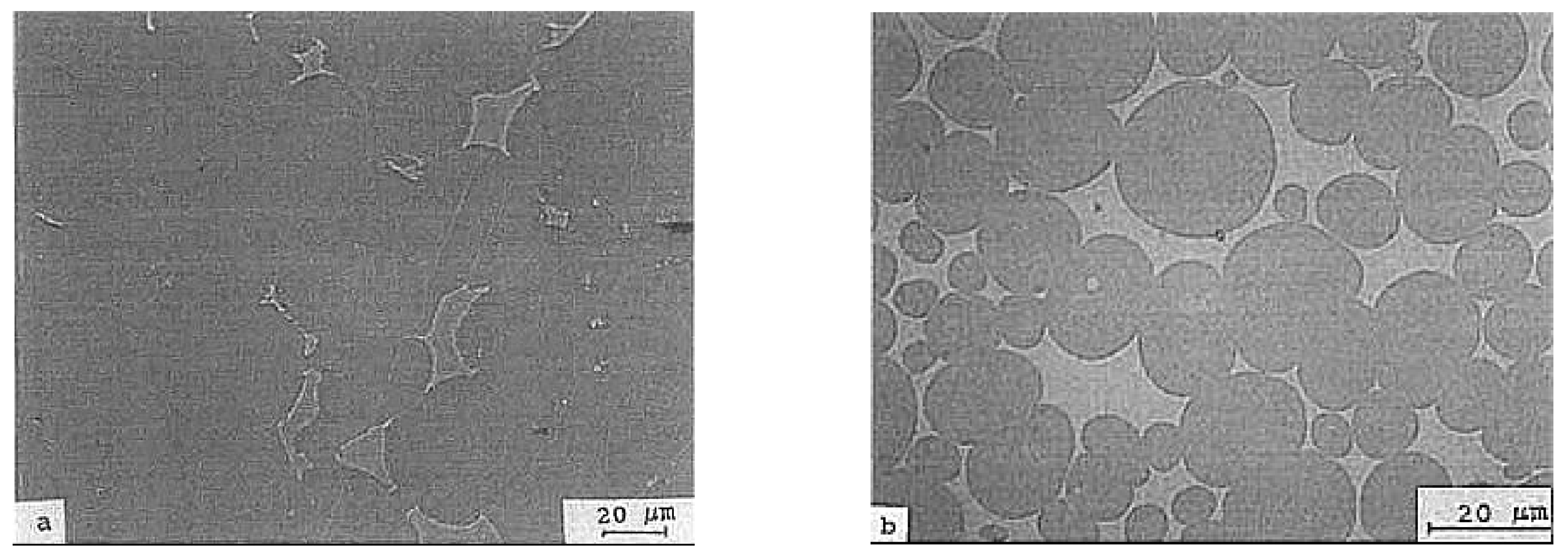

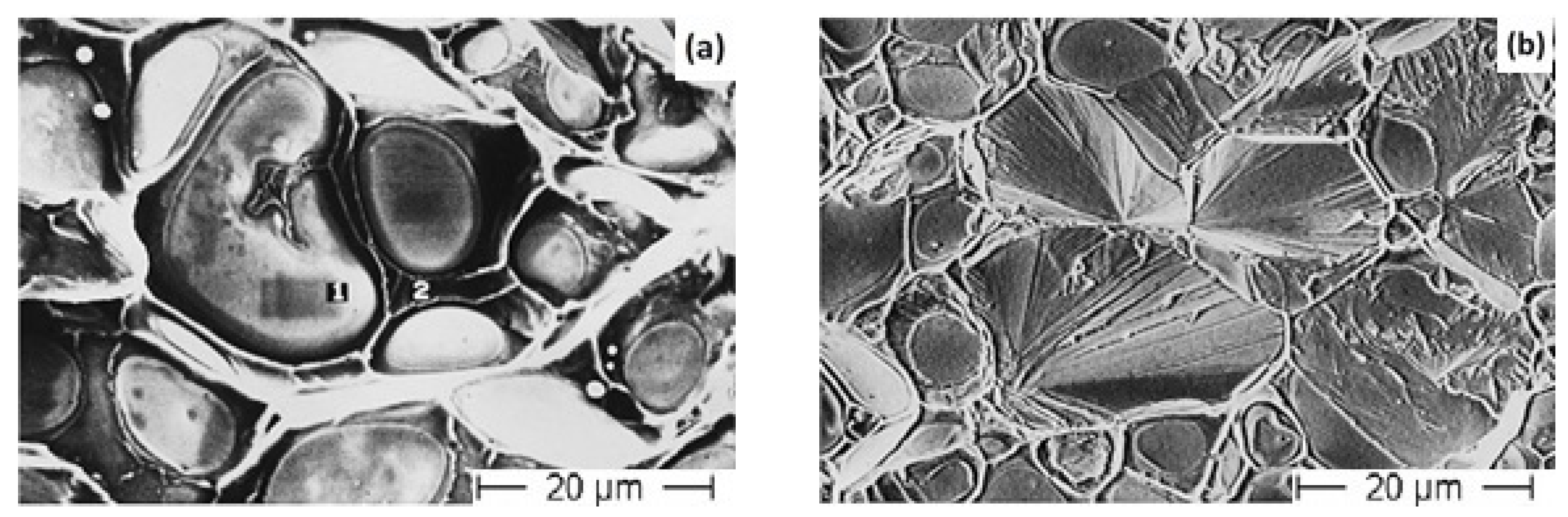

3.2. Microstructural Analysis of W–Ni–Fe-Mo

3.3. Mechanical Properties of W–Ni–Fe-Mo

4. Effect of Oxide Dispersions on WHA

4.1. Effect of Lanthanum and Lanthanum Oxide on W–Ni–Fe

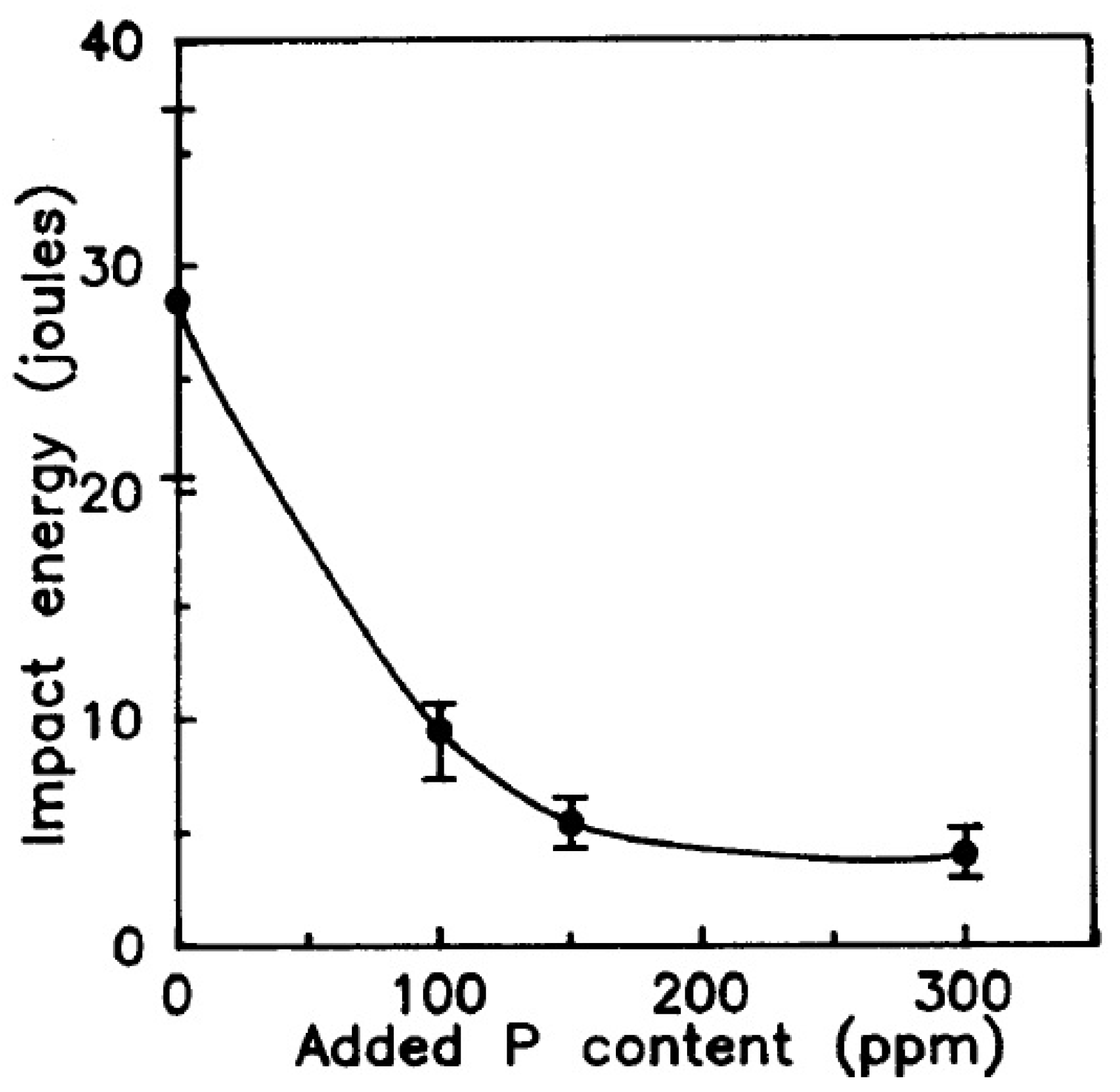

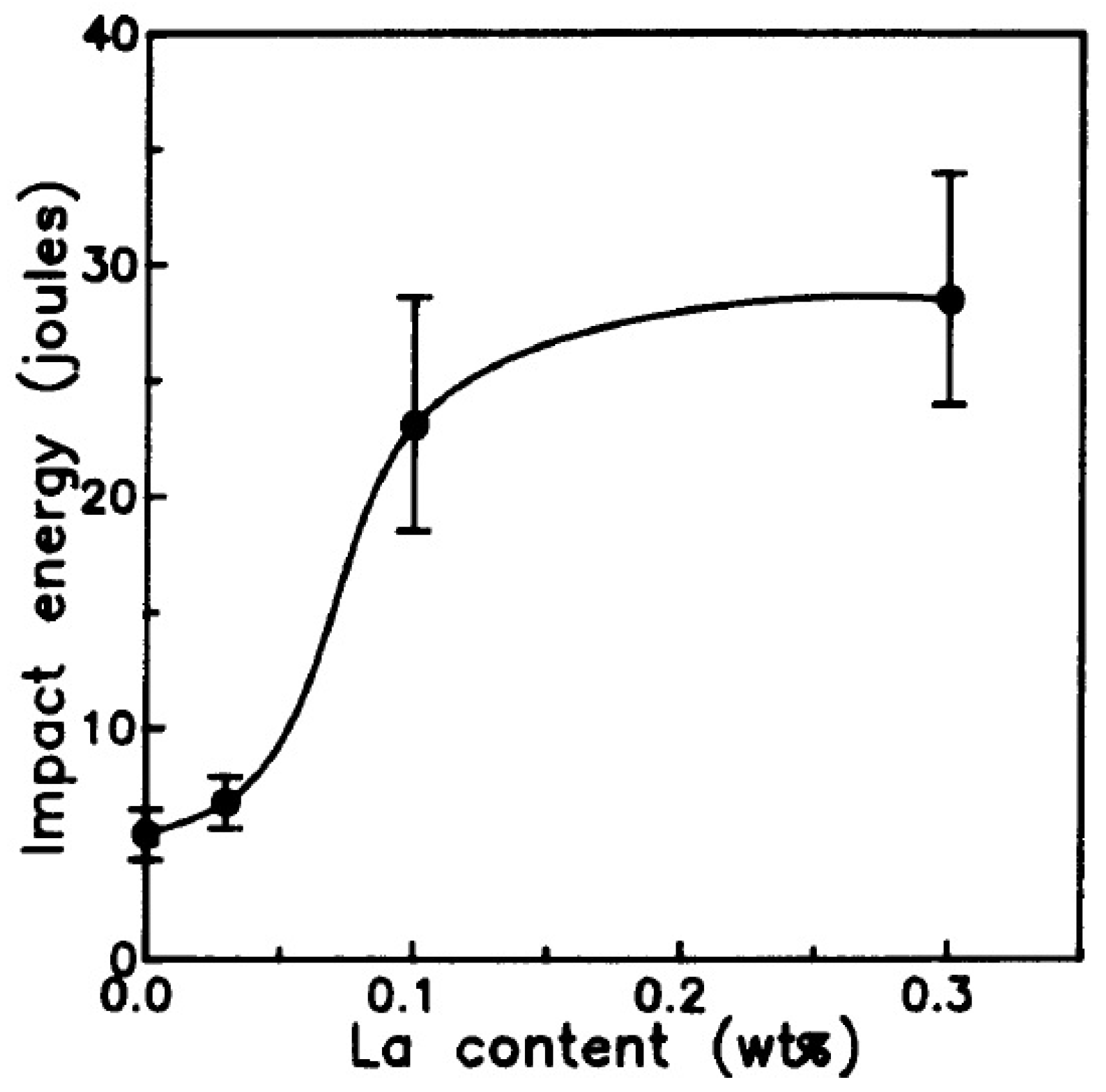

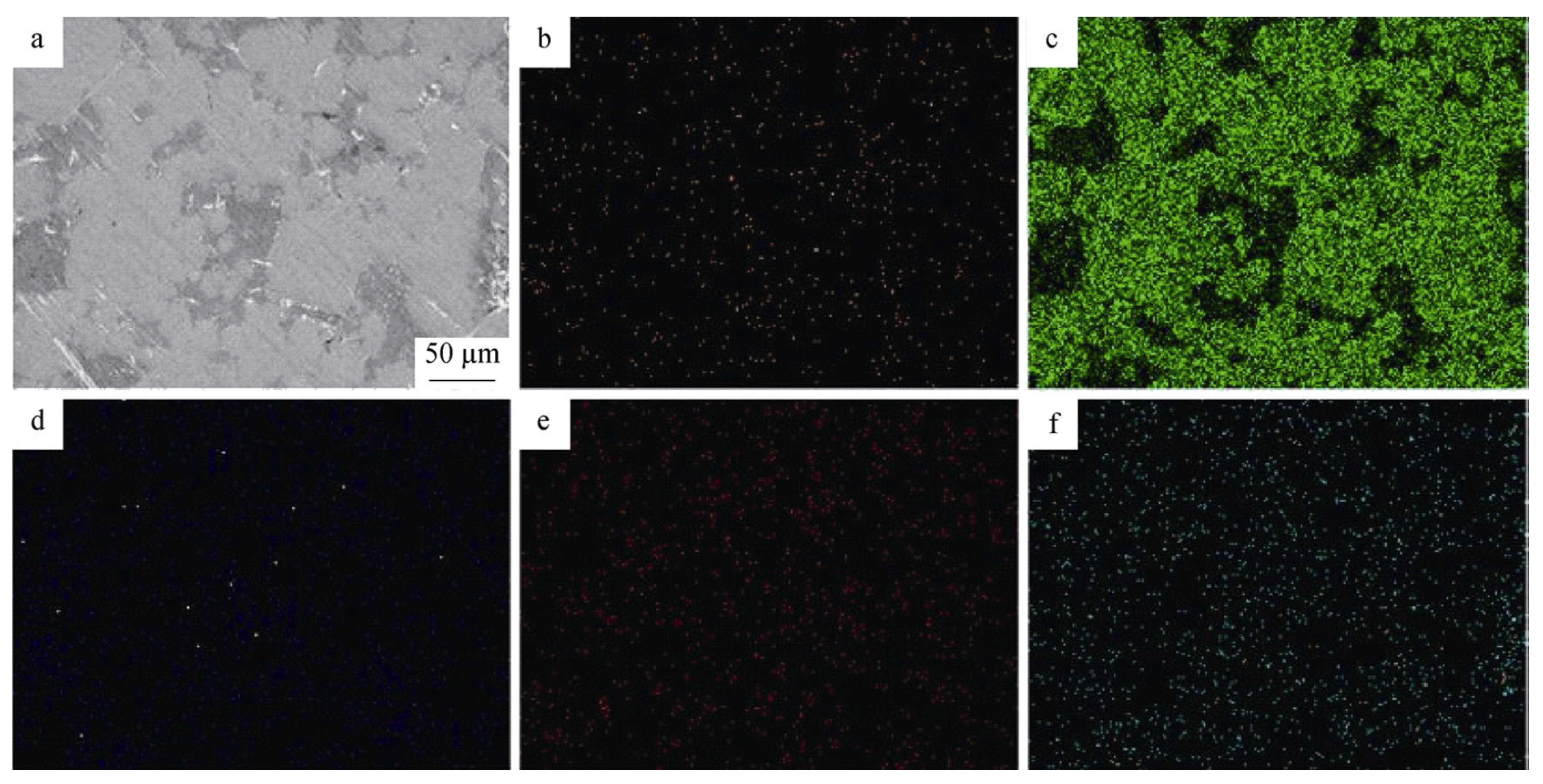

Microstructure Analysis and Mechanical Properties

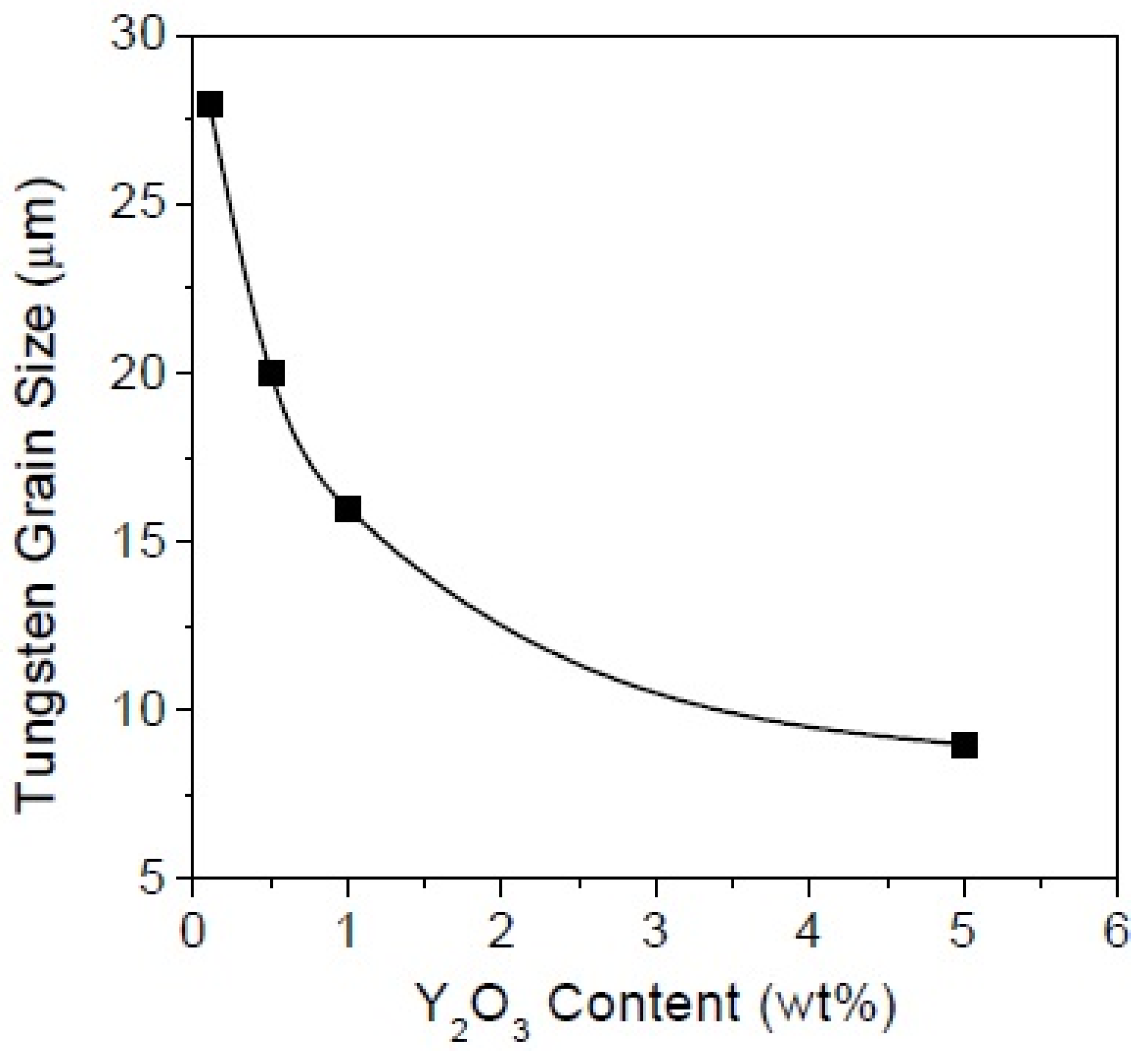

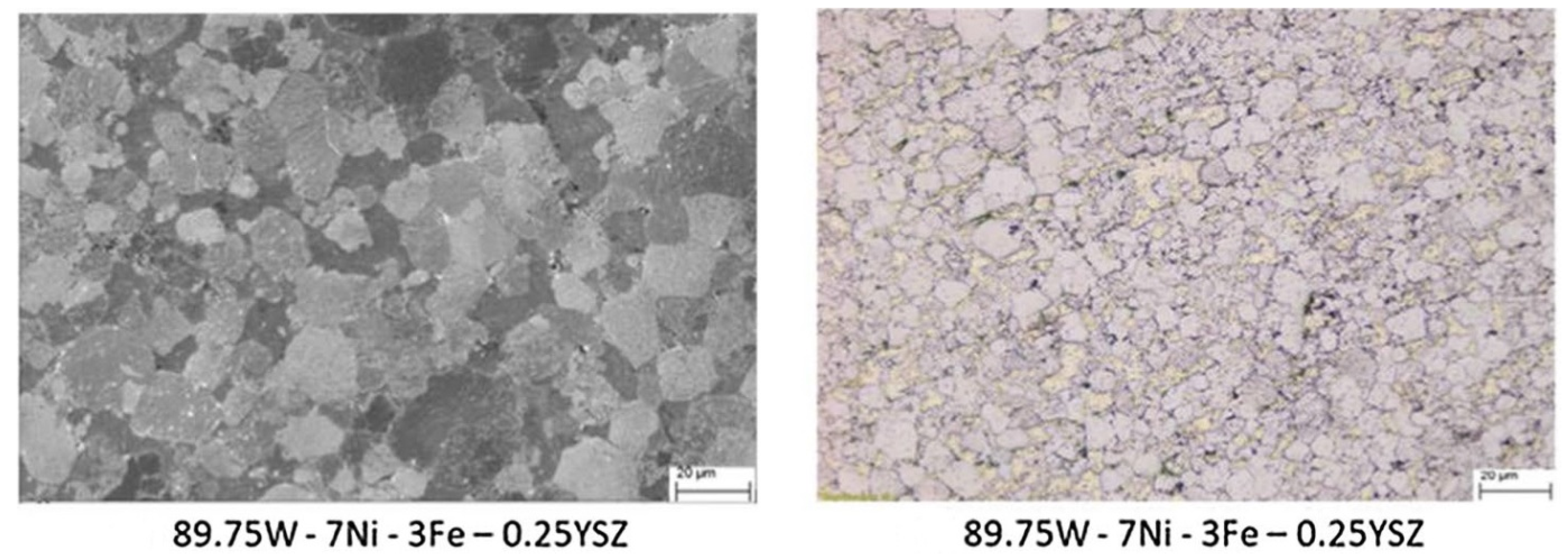

4.2. Effect of Yttrium and Yttrium Oxide on W–Ni–Fe

5. Discussion and Conclusions

- The strength and hardness of tungsten heavy alloys depend on the bonding strength of the W–matrix interface. A W–Ni–Fe alloy with good strength is made possible with the addition of rhenium and molybdenum elements.

- The correlation between the microstructural parameters and mechanical properties shows that a smaller grain size is an effective factor in improving the strength and ductility of the tungsten heavy alloy. The drop in ductility in a molybdenum-added heavy alloy can be controlled to some extent with the use of a 8/2 ratio of Ni/Fe.

- The oxide dispersion of yttrium with W–Ni–Fe is found to be more effective in obtaining an alloy with good strength and ductility compared with a lanthanum oxide dispersion. A fine-grained alloy with yttrium dispersion leads to a microstructure that can promote adiabatic shear banding, which is a necessary criterion for kinetic energy penetrator applications.

- Processing techniques like spark plasma sintering are observed to produce tungsten heavy alloys with higher yield and tensile strength. The optimum sintering temperature and time are also important factors to be controlled in obtaining an alloy with specific mechanical properties.

- Developments in processing methods like additive manufacturing techniques will help to improve the alloying techniques with tungsten heavy alloys and to produce complex net-shaped parts with higher strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stwertka, A. A Guide to the Elements, 2nd ed.; Oxford University Press: New York, NY, USA, 2002; ISBN 0-19-515026-0. [Google Scholar]

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Yoshida, N.; ASDEX Upgrade Team. Materials for the plasma-facing components of fusion reactors. J. Nucl. Mater. 2004, 329, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.M.; Yan, Q.Z.; Shen, W.P.; Ge, C.C. Explosive consolidation and its application on preparing of ultra-fine grained tungsten plasma facing material. In Advanced Materials Research; Trans Tech Publications Ltd: Bäch SZ, Switzerland, 2011; Volume 181, pp. 842–845. [Google Scholar]

- Yar, M.A.; Wahlberg, S.; Bergqvist, H.; Salem, H.G.; Johnsson, M.; Muhammed, M. Spark plasma sintering of tungsten-yttrium oxide composites from chemically synthesized nanopowders and microstructural characterization. J. Nucl. Mater. 2011, 412, 227–232. [Google Scholar] [CrossRef]

- Cottrell, G.A. A survey of plasma facing materials for fusion power plants. Mater. Sci. Technol. 2006, 22, 869–880. [Google Scholar] [CrossRef]

- Lungu, M.V.; Patroi, D.; Marinescu, V.; Mitrea, S.; Ion, I.; Godeanu, P. Tungsten-copper composites for arcing contact applications in high voltage circuit breakers. Mater. Sci. Res. India 2020, 17, 123. [Google Scholar]

- Lassner, E.; Schubert, W.-D. Tungsten. Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, 1st ed.; Springer: Boston, MA, USA, 1999. [Google Scholar]

- Senthilnathan, N.; Annamalai, R.A.; Venkatachalam, G. Activated sintering of tungsten alloys through conventional and spark plasma sintering process. Mater. Manuf. Process. 2017, 32, 1861–1868. [Google Scholar] [CrossRef]

- Lee, G.; McKittrick, J.; Ivanov, E.; Olevsky, E.A. Densification mechanism and mechanical properties of tungsten powder consolidated by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 61, 22–29. [Google Scholar] [CrossRef] [Green Version]

- Ren, C.; Fang, Z.Z.; Koopman, M.; Butler, B.; Paramore, J.; Middlemas, S. Methods for improving ductility of tungsten—A review. Int. J. Refract. Met. Hard Mater. 2018, 75, 170–183. [Google Scholar] [CrossRef]

- Kharchenko, V.K.; Bukhanovskii, V.V. High-temperature strength of refractory metals, alloys and composite materials based on them. Part 1. Tungsten, its alloys, and composites. Strength Mater. 2012, 44, 512–517. [Google Scholar] [CrossRef]

- Klopp, W.D.; Raffo, P.L.; Witzke, W.R. Mechanical Properties of Dilute Tungsten-Rhenium Alloys; NASA Technical Note TN D-3483; National Aeronautics and Space Administration: Cleveland, OH, USA, 1966.

- Wurster, S.; Gludovatz, B.; Hoffmann, A.; Pippan, R. Fracture behaviour of tungsten-vanadium and tungsten-tantalum alloys and composites. J. Nucl. Mater. 2011, 413, 166–176. [Google Scholar] [CrossRef]

- Patra, A.; Saxena, R.; Karak, S.K. Combined effect of Ni and nano-Y2O3 addition on microstructure, mechanical and high temperature behavior of mechanically alloyed W-Mo. Int. J. Refract. Met. Hard Mater. 2016, 60, 131–146. [Google Scholar] [CrossRef]

- Raghu, T.; Sundaresan, R.; Ramakrishnan, P.; Mohan, T.R. Synthesis of nanocrystalline copper-tungsten alloys by mechanical alloying. Mater. Sci. Eng. A 2001, 304, 438–441. [Google Scholar] [CrossRef]

- Rieth, M.; Dafferner, B. Limitations of W and W—1% La2O3 for use as structural materials. J. Nucl. Mater. 2005, 342, 20–25. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.M.; Hao, T.; Zhou, Y.; Wang, X.P.; Fang, Q.F.; Liu, C.S. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized Yttria dispersion strengthening. J. Nucl. Mater. 2014, 451, 35–39. [Google Scholar] [CrossRef]

- Hu, Y.J.; Shang, S.L.; Wang, Y.; Darling, K.A.; Butler, B.G.; Kecskes, L.J.; Liu, Z.K. Effects of alloying elements and temperature on the elastic properties of W-based alloys by first-principles calculations. J. Alloy. Compd. 2016, 671, 267–275. [Google Scholar] [CrossRef] [Green Version]

- Senthilnathan, N.; Annamalai, A.R.; Venkatachalam, G. Sintering of tungsten and tungsten heavy alloys of W–Ni–Fe and W–Ni–Cu: A review. Trans. Indian Inst. Met. 2017, 70, 1161–1176. [Google Scholar] [CrossRef]

- Yih, S.W.H.; Wang, C.T. Tungsten: Sources, Metallurgy, Properties and Applications; Plenum Press: New York, NY, USA, 1979. [Google Scholar]

- Jain, M.; Skandan, G.; Martin, K.; Cho, K.; Klotz, B.; Dowding, R.; Kapoor, D.; Agrawal, D.K.; Cheng, J. Microwave sintering: A new approach to fine-grain tungsten-I. Int. J. Powder Metall. 2006, 42, 45–50. [Google Scholar]

- Mondal, A.; Upadhyaya, A.; Agrawal, D. Effect of heating mode on sintering of tungsten. Int. J. Refract. Met. Hard Mater. 2010, 28, 597–600. [Google Scholar] [CrossRef]

- Autissier, E.; Richou, M.; Minier, L.; Naimi, F.; Pintsuk, G.; Bernard, F. Spark plasma sintering of pure and doped tungsten as plasma facing material. Phys. Scr. 2014, 159, 014034. [Google Scholar] [CrossRef]

- Ramesh, K.T. On the localization of shearing deformations in tungsten heavy alloys. Mech. Mater. 1994, 17, 165–173. [Google Scholar] [CrossRef]

- Upadhyaya, A. Processing strategy for consolidating tungsten heavy alloys for ordnance applications. Mater. Chem. Phys. 2001, 67, 101–110. [Google Scholar] [CrossRef]

- German, R.M. Critical developments in tungsten heavy alloys. Tungsten Tungsten Alloy. 1992, 1992, 3–13. [Google Scholar]

- Kunčická, L.; Kocich, R.; Klečková, Z. Effects of sintering conditions on structures and properties of sintered tungsten heavy alloy. Materials 2020, 13, 2338. [Google Scholar] [CrossRef] [PubMed]

- Orban, R.L. New research directions in powder metallurgy. Rom. Rep. Phys. 2004, 56, 505–516. [Google Scholar]

- Gurwell, W.E.; Nelson, R.G.; Dudder, G.B.; Davis, N.C. Fabrication and Properties of Tungsten Heavy Metal Alloys Containing 30% to 90% Tungsten; Pacific Northwest Lab.: Richland, WA, USA, 1984. [Google Scholar]

- Ćirović, N.; Spasojević, P.; Ribić-Zelenović, L.; Maričič, A.; Spasojević, M. Synthesis, structure and properties of nickel-iron-tungsten alloy electrodeposits part II: Effect of microstructure on hardness, electrical and magnetic properties. Sci. Sinter. 2016, 48, 34. [Google Scholar] [CrossRef]

- Chausse, C.; Nardou, F. Evolution of the microstructure in a W alloy during sintering before the formation of a liquid phase. Mater. High Temp. 1999, 16, 37–41. [Google Scholar] [CrossRef]

- Johnson, J.L.; Upadhyaya, A.; German, R.M. Microstructural effects on distortion and solid-liquid segregation during liquid phase sintering under microgravity conditions. Metall. Mater. Trans. B 1998, 29, 857–866. [Google Scholar] [CrossRef]

- Liu, J.; Upadhyaya, A.; German, R.M. Application of percolation theory in predicting shape distortion during liquid-phase sintering. Metall. Mater. Trans. A 1999, 30, 2209–2220. [Google Scholar] [CrossRef]

- Mondal, A.; Upadhyaya, A.; Agrawal, D. Microwave and conventional sintering of 90W-7Ni-3Cu alloys with premixed and prealloyed binder phase. Mater. Sci. Eng. A 2010, 527, 6870–6878. [Google Scholar] [CrossRef]

- Senthilnathan, N.; Annamalai, R.A.R.; Venkatachalam, G. Effect of cobalt addition on the morphology and mechanical properties of W–Ni–Cu-Co alloy. Emerg. Mater. Res. 2019, 8, 558–566. [Google Scholar] [CrossRef]

- Mondal, A.; Upadhyaya, A.; Agrawal, D. Effect of heating mode and sintering temperature on the consolidation of 90W-7Ni-3Fe alloys. J. Alloy. Compd. 2011, 509, 301–310. [Google Scholar] [CrossRef]

- Senthilnathan, N.; Annamalai, A.R.; Venkatachalam, G. Microstructure and mechanical properties of spark plasma sintered tungsten heavy alloys. Mater. Sci. Eng. A 2018, 710, 66–73. [Google Scholar] [CrossRef]

- Anderson, K.R.; Groza, J.R.; Fendorf, M.; Echer, C.J. Surface oxide debonding in field assisted powder sintering. Mater. Sci. Eng. A 1999, 270, 278–282. [Google Scholar] [CrossRef]

- Fan, J.L.; Huang, B.Y.; Qu, X.H. Distortion prediction and control of injection molded tungsten heavy alloys. J. Adv. Mater. 2004, 36, 72–74. [Google Scholar]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of metal matrix composites by metal injection molding—A review. J. Mater. Process. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.Y.; Gu, S.N.; Yang, S. Microstructure and properties of tungsten heavy alloys fabricated by laser direct deposition. Mater. Sci. Technol. 2017, 33, 415–420. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Ma, S.; Yang, X.; Li, J.; Zhou, Y.; Liu, X.; Tang, J.; Wang, X.; Le, G. Densification, microstructural evolutions of 90W-7Ni-3Fe tungsten heavy alloys during laser melting deposition process. Int. J. Refract. Met. Hard Mater. 2020, 10, 105254. [Google Scholar] [CrossRef]

- Iveković, A.; Montero-Sistiaga, M.L.; Vanmeensel, K.; Kruth, J.P.; Vleugels, J. Effect of processing parameters on microstructure and properties of tungsten heavy alloys fabricated by SLM. Int. J. Refract. Met. Hard Mater. 2019, 82, 23–30. [Google Scholar] [CrossRef]

- Kotoban, D.V.; Nazarov, A.P.; Shishkovsky, I.V. Comparative study of selective laser melting and direct laser metal deposition of Ni3Al intermetallic alloy. In Materials Science Forum; Trans Tech Publications Ltd: Back SZ, Switzerland, 2015; Volume 834, pp. 103–111. [Google Scholar]

- Das, J.; Rao, G.A.; Pabi, S.K. Microstructure and mechanical properties of tungsten heavy alloys. Mater. Sci. Eng. A 2010, 527, 7841–7847. [Google Scholar] [CrossRef]

- Islam, S.H.; Qu, X.H.; Akhtar, F.; Feng, P.Z.; He, X.B. Microstructure and tensile properties of tungsten heavy alloys. In Materials Science Forum; Trans Tech Publications Ltd: Bach SZ, Switzerland, 2007; Volume 534, pp. 561–564. [Google Scholar]

- Prabhu, G.; Kumar, N.A.; Sankaranarayana, M.; Nandy, T.K. Tensile and impact properties of microwave sintered tungsten heavy alloys. Mater. Sci. Eng. A 2014, 607, 63–70. [Google Scholar] [CrossRef]

- German, R.M.; Bose, A.; Kemp, P.B.; Zhang, H. Additive Effects on the Microstructure and Properties of Tungsten Heavy-Alloy Composites; No. AD-A-218540/3/XAB; Rensselaer Polytechnic Inst.: Troy, NY, USA, 1989. [Google Scholar]

- German, R.M.; Bose, A.; Jerman, G. Rhenium Alloying of Tungsten Heavy Alloys; No. AD-A-211099/7/XAB; Rensselaer Polytechnic Inst.: Troy, NY, USA, 1989. [Google Scholar]

- Liu, W.; Ma, Y.; Huang, B. Influence of minor elements additions on microstructure and properties of 93W-4.9Ni-2.1Fe alloys. Bull. Mater. Sci. 2008, 31, 1–6. [Google Scholar] [CrossRef]

- Kiran, U.R.; Panchal, A.; Kumar, M.P.; Sankaranarayana, M.; Rao, G.N.; Nandy, T.K. Refractory metal alloying: A new method for improving mechanical properties of tungsten heavy alloys. J. Alloy. Compd. 2017, 709, 609–619. [Google Scholar] [CrossRef]

- Bose, A.; German, R.M. Microstructural refinement of W–Ni–Fe heavy alloys by alloying additions. Metall. Trans. A 1988, 19, 3100–3103. [Google Scholar] [CrossRef]

- Livramento, V.; Nunes, D.; Correia, J.B.; Carvalho, P.A.; Mateus, R.; Hanada, K.; Shohoji, N.; Fernandes, H.; Silva, C.; Alves, E. Tungsten-tantalum composites for plasma facing components. Mater. Energy 2010, 5, 4–8. [Google Scholar]

- Rieth, M.; Dudarev, S.L.; De Vicente, S.G.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef] [Green Version]

- Massalski, T.B.; Murray, J.L.; Bennett, L.H.; Baker, H. Binary Alloy Phase Diagrams; American Society for Metals: Metals Park, OH, USA, 1987; Volume I, p. 1100. [Google Scholar]

- Moffatt, W.G. The Handbook of Binary Phase Diagrams; Genium: Schenectady, NY, USA, 1986; Volume III. [Google Scholar]

- Kemp, P.B.; German, R.M. Grain growth in liquid-phase-sintered W-Mo-Ni-Fe alloys. J. Less Common Met. 1991, 175, 353–368. [Google Scholar] [CrossRef]

- Gummeson, P.V.; Gustofson, D.A. Modern Developments in Powder Metallurgy, Proceedings of the International Powder Metallurgy Conference, Orlando, FL, USA, 5–10 June 1988; Metal Powders Industries Federation: Princeton, NJ, USA, 1988; Volume 19, pp. 139–153. [Google Scholar]

- Lin, K.H.; Hsu, C.S.; Lin, S.T. Precipitation of an intermetallic phase in Mo-alloyed tungsten heavy alloys. Mater. Trans. 2003, 44, 358–366. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.S.; Lin, S.T. Effect of molybdenum on grain growth of W-Mo-Ni-Fe heavy alloys. J. Mater. Sci. 2003, 38, 1543–1549. [Google Scholar] [CrossRef]

- Hsu, C.S.; Lin, K.H.; Lin, S.T. Precipitation mechanisms of intermetallic compounds in W-Mo-Ni-Fe alloys. Int. J. Refract. Met. Hard Mater. 2005, 23, 175–182. [Google Scholar] [CrossRef]

- Jin, Y.; Cao, S.; Zhu, J.; Liu, H.; Chen, B.; Xu, H. Gradient structure induced by molybdenum in 90W–Ni–Fe heavy alloy. Int. J. Refract. Met. Hard Mater. 2014, 43, 141–146. [Google Scholar] [CrossRef]

- Bose, A.; German, R.M. Matrix composition effects on the tensile properties of tungsten-molybdenum heavy alloys. Metall. Trans. A 1990, 21, 1325–1327. [Google Scholar] [CrossRef]

- Ding, L.; Xiang, D.P.; Li, Y.Y.; Zhao, Y.W.; Li, J.B. Phase, microstructure and properties evolution of fine-grained W-Mo-Ni-Fe alloy during spark plasma sintering. Mater. Des. 2012, 37, 8–12. [Google Scholar] [CrossRef]

- Muthuchamy, A.; Yadev, D.; Agrawal, D.K.; Annamalai, R. Structure-property correlations of W–Ni–Fe-Mo heavy alloys consolidated using spark plasma sintering. Mater. Res. Express 2018, 6, 026545. [Google Scholar] [CrossRef]

- Prasad, B.S.L.; Annamalai, R. A study of molybdenum addition on W–Ni–Fe based heavy alloys sintered with spark plasma sintering. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 2–7. [Google Scholar]

- Hong, S.H.; Kang, S.J.L.; Yoon, D.N.; Baek, W.H. The reduction of the interfacial segregation of phosphorus and its embrittlement effect by lanthanum addition in a W–Ni–Fe heavy alloy. Metall. Trans. A 1991, 22, 2969–2974. [Google Scholar] [CrossRef]

- Yoon, H.K.; Lee, S.H.; Kang, S.J.; Yoon, D.N. Effect of vacuum-treatment on mechanical properties of W–Ni–Fe heavy alloy. J. Mater. Sci. 1983, 18, 1374–1380. [Google Scholar] [CrossRef]

- Seah, M.P. Chemistry of solid-solid interfaces—A review of its characterization, theory, and relevance to materials science. J. Vac. Sci. Technol. 1980, 17, 16–24. [Google Scholar] [CrossRef]

- Garcia, C.I.; Ratz, G.A.; Burke, M.G.; DeArdo, A.J. Reducing temper embrittlement by lanthanide additions. JOM 1985, 37, 22–28. [Google Scholar] [CrossRef]

- Wu, G.C.; You, Q.; Wang, D. Influence of the addition of Lanthanum on a W-Mo-Ni-Fe heavy alloy. Int. J. Refract. Met. Hard Mater. 1999, 17, 299–304. [Google Scholar] [CrossRef]

- Garrison, W.M. Ultrahigh-strength steels for aerospace applications. JOM 1990, 42, 20–24. [Google Scholar] [CrossRef]

- Wilson, W.G.; Kay, D.A.R.; Vahed, A. The use of thermodynamics and phase equilibria to predict the behavior of the rare earth elements in steel. JOM 1974, 26, 14–23. [Google Scholar] [CrossRef]

- Wesemann, I.; Spielmann, W.; Heel, P.; Hoffmann, A. Fracture strength and microstructure of ODS tungsten alloys. Int. J. Refract. Met. Hard Mater. 2010, 28, 687–691. [Google Scholar] [CrossRef]

- AyyappaRaj, M.; Yadav, D.; Agrawal, D.K.; Rajan, R.A.A. Microstructure and mechanical properties of spark plasma-sintered La2O3 dispersion-strengthened W–Ni–Fe alloy. Rare Metals 2020, 30, 1–7. [Google Scholar] [CrossRef]

- Liu, R.; Zhou, Y.; Hao, T.; Zhang, T.; Wang, X.P.; Liu, C.S.; Fang, Q.F. Microwave synthesis and properties of fine-grained oxides dispersion strengthened tungsten. J. Nucl. Mater. 2012, 424, 171. [Google Scholar] [CrossRef]

- Mabuchi, M.; Okamoto, K.; Saito, N.; Asahina, T.; Igarashi, T. Deformation behavior and strengthening mechanisms at intermediate temperatures in W-La2O3. Mater. Sci. Eng. A 1997, 237, 241. [Google Scholar] [CrossRef]

- Ishiwata, Y.; Itoh, Y.; Kashiwaya, H. Hot isostatic pressing and sintering behavior of yttrium oxide dispersed tungsten. In Hot Isostatic Pressing—Theory and Applications; Springer: Dordrecht, The Netherlands, 1992; pp. 433–437. [Google Scholar]

- Itoh, Y.; Ishiwata, Y. Strength properties of yttrium-oxide-dispersed tungsten alloy. JSME Int. J. Ser. A Mech. Mater. Eng. 1996, 39, 429–434. [Google Scholar] [CrossRef] [Green Version]

- Ryu, H.J.; Hong, S.H. Fabrication and properties of mechanically alloyed oxide-dispersed tungsten heavy alloys. Mater. Sci. Eng. A 2003, 363, 179–184. [Google Scholar] [CrossRef]

- Annavarapu, S.; Doherty, R.D. Inhibited coarsening of solid-liquid microstructures in spray casting at high volume fractions of solid. Acta Metall. Mater. 1995, 43, 3207–3230. [Google Scholar] [CrossRef]

- Jing-Lian, F.; Tao, L.; Hui-Chao, C.; Deng-Long, W. Preparation of fine grain tungsten heavy alloy with high properties by mechanical alloying and yttrium oxide addition. J. Mater. Process. Technol. 2008, 208, 463–469. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.; Ding, F. Tensile mechanical properties and fracture behavior of tungsten heavy alloys at 25–1100 °C. Mater. Sci. Eng. A 2015, 646, 315–321. [Google Scholar] [CrossRef]

- Chen, C.L. The Effect of Mo and dispersoids on microstructure, sintering behavior, and mechanical properties of W-Mo-Ni-Fe-Co heavy tungsten alloys. Metals 2019, 9, 111. [Google Scholar] [CrossRef] [Green Version]

- Magnes, L.S. Ballistic and instrumented mechanical testing of long rod kinetic energy penetrator materials. In Proceedings of the 4th International Conference on Tungsten, Refractory Metals and Alloys: Processing, Properties and Applications, Metal Powder Industries Federation in Cooperation with the Refractory Metals Association and APMI International, Lake Buena Vista, FL, USA, 17–19 November 1997; pp. 41–58. [Google Scholar]

- Hogwood, M.C.; Bentley, A.R. The Development of High Strength and Toughness Fibrous Microstructures in Tungsten-Nickel-Iron Alloys for Kinetic Energy Penetrator Applications, Proceedings of the 1994 International Conference on Tungsten and Refractory Metals; Bose, A., Dowding, R.J., Eds.; Metal Powder Industries Federation: Princeton, NJ, USA, 1995; pp. 37–45. [Google Scholar]

- Gong, X.; Fan, J.L.; Huang, B.Y.; Tian, J.M. Microstructure characteristics and a deformation mechanism of fine-grained tungsten heavy alloy under high strain rate compression. Mater. Sci. Eng. A 2010, 527, 7565–7570. [Google Scholar] [CrossRef]

- Wei, Q.; Schuster, B.E.; Mathaudhu, S.N.; Hartwig, K.T.; Kecskes, L.J.; Dowding, R.J.; Ramesh, K.T. Dynamic behaviors of body-centered cubic metals with ultrafine grained and nanocrystalline microstructures. Mater. Sci. Eng. A 2008, 493, 58–64. [Google Scholar] [CrossRef]

- Muthuchamy, A.; Boggupalli, L.P.; Yadav, D.R.; Kumar, N.N.; Agrawal, D.K.; Annamalai, A.R. Particulate-reinforced tungsten heavy alloy/yttria-stabilized zirconia composites sintered through spark plasma sintering. Arab. J. Sci. Eng. 2020, 18, 1–9. [Google Scholar] [CrossRef]

- Kim, J.Y.; Jang, D.; Greer, J.R. Tensile and compressive behavior of tungsten, molybdenum, tantalum and niobium at the nanoscale. Acta Mater. 2010, 58, 2355–2363. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Takacs, L. Self-sustaining reactions induced by ball milling. Prog. Mater. Sci. 2002, 47, 355–414. [Google Scholar] [CrossRef]

- Wu, Z.; Liang, Y.; Fu, E.; Du, J.; Wang, P.; Fan, Y.; Zhao, Y. Effect of ball milling parameters on the refinement of tungsten powder. Metals 2018, 8, 281. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.H.; Ryu, H.J.; Korea Advanced Institute of Science and Technology KAIST. Processes for Making Oxide Dispersion-Strengthened Tungsten Heavy Alloy by Mechanical Alloying. U.S. Patent 6,368,376, 9 April 2002. [Google Scholar]

- Hu, K.; Li, X.; Ai, X.; Qu, S.; Li, Y. Fabrication, characterization, and mechanical properties of 93W-4.9 Ni-2.1 Fe/95W-2.8 Ni-1.2 Fe-1Al2O3 heavy alloy composites. Mater. Sci. Eng. A 2015, 636, 452–458. [Google Scholar] [CrossRef]

| Alloy Type | Tungsten Grain Size (µm) | Matrix Volume Fraction (%) | Contiguity | Dihedral Angle (°) |

|---|---|---|---|---|

| Conventional | 25 ± 11 | 17 ± 3 | 0.36 ± 0.07 | 58 ± 1 |

| Milled | 18 ± 6 | 19 ± 1 | 0.27 ± 0.06 | 42 ± 2 |

| Alloy | Sintering Process | Hardness (HRA) | Tensile Strength (MPa) | Elongation (%) | Reference |

|---|---|---|---|---|---|

| W–8Ni–2Fe–6Re | Sintering at 1500 °C for 60 min | — | 1180 | 13 | [49] |

| W–4.9Ni–2.1Fe | Ball milled for 50 h Sintered at 1490 °C for 90 min | — | 997 | 26.4 | [50] |

| W–4.9Ni–2.1Fe–0.2Re | — | 1050 | 26 | ||

| W–4.9Ni–2.1Fe–0.4Re | — | 1090 | 25 | ||

| W–7Ni–3Fe–1Re | Sintering at 1480 °C for 120 min followed by heat treatment | — | 890 | 14 | [51] |

| W–7Ni–3Fe–1Re | W–Re milled for 5 h followed by 48 h of milling of the whole mixture. Sintering at 1480 °C for 120 min followed by heat treatment | — | 952 | 23 | |

| W–7Ni–3Fe | Sintering at 1500 °C for 30 min and heat treated at 1100 °C for one hour | 62.8 | 925 | 31 | [52] |

| W–7Ni–3Fe–5Ta | 69 | 1025 | 3 |

| Alloy | Sintering Process | Hardness (HRA) | Tensile Strength (MPa) | Elongation (%) | Reference |

|---|---|---|---|---|---|

| W–7Ni–3Fe | Conventional sintering 1500 °C for 30 min Heat treated at 1100 °C for 1 h and water-quenched | 62.8 | 923 | 30 | [63] |

| W–8Ni–2Fe | 63.8 | 918 | 36 | ||

| W–4Mo–8Ni–2Fe | 63.8 | 947 | 31 | ||

| W–8Mo–8Ni–2Fe | 65.9 | 1048 | 24 | ||

| W–12Mo–8Ni–2Fe | 67.4 | 1119 | 14 | ||

| W–16Mo–8Ni–2Fe | 68.4 | 1150 | 10 | ||

| W–2Mo–7Ni–3Fe | Conventional sintering 1500 °C for 30 min Heat treated at 1100 °C for 1 h and water-quenched | 63 | 948 | 28 | [57] |

| W–4Mo–7Ni–3Fe | 64 | 980 | 24 | ||

| W–8Mo–7Ni–3Fe | 68 | 1030 | 20 | ||

| W–12Mo–7Ni–3Fe | 68 | 1100 | 10 | ||

| W–2Mo–7Ni–3Fe | SPS 1000–1250 °C For 8 min at 50 MPa 100 °C/min | 63.9 at 1250 °C | 390 bending strength at 1150 °C | — | [64] |

| W–7Ni–3Fe–4Mo | SPS 1100 °C For 8 min at 50 MPa 100 °C/min | 286 HV | 993 | 24 | [65] |

| W–7Ni–3Fe–8Mo | 336 HV | 1050 | 20 | ||

| W–7Ni–3Fe–12Mo | 354 HV | 1120 | 10 | ||

| W–7Ni–3Fe–16Mo | 372 HV | 1150 | 7 | ||

| W–8Ni–2Fe–0Mo | High-energy ball milling for 40 h and SPS-sintered at 1000 °C for 8 min at 30 MPa and 100 °C/min | 63 | 975 | 28 | [66] |

| W–8Ni–2Fe–6Mo | 65 | 1025 | 22 | ||

| W–8Ni–2Fe–12Mo | 68 | 1120 | 14 | ||

| W–8Ni–2Fe–18Mo | 72 | 1160 | 05 | ||

| W–8Ni–2Fe–24Mo | 75 | 1250 | 02 |

| Alloy | Sintering Process | Hardness (HRC) | Tensile Strength (MPa) | Elongation % | Reference |

|---|---|---|---|---|---|

| W–17.1Mo–2.5Ni-2Fe–0.2La–0.2Mn | Conventional sintering at 1510 °C for 90 min under a hydrogen atmosphere | 34 | 650 | 2.2 | [67] |

| W–16.9Mo–2.5Ni–2Fe–0.4La–0.2Mn | Conventional sintering at 1510 °C for 90 min under a hydrogen atmosphere | 30 | 903 | 4.7 | [67] |

| 90W–7Ni–3Fe | Spark plasma sintering at 1100 °C for 5 min in a vacuum with a heating rate of 100 °C/min | 138 | 475 | 0.64 | [75] |

| W–7Ni–3Fe-0.50La2O3 | Spark plasma sintering at 1100 °C for 5 min in a vacuum with a heating rate of 100 °C/min | 370 | 822 | 0.95 | [75] |

| W–7Ni–3Fe-1.00La2O3 | Spark plasma sintering at 1100 °C for 5 min in a vacuum with a heating rate of 100 °C/min | 533 | 1110 | 0.64 | [75] |

| Alloy | Sintering Process | Hardness (HRB) | Tensile Strength (MPa) | Compression Strength (MPa) | Elongation (%) | Reference |

|---|---|---|---|---|---|---|

| W–5.6Ni–1.4Fe-00.1Y2O3 | Sintering at 1485 °C for 60 min | — | 828 | — | 14.6 | [80] |

| W–5.6Ni–1.4Fe–0.1Y2O3 | Sintering at 1485 °C for 120 min in a hydrogen atmosphere | — | 883 | — | 18.4 | [80] |

| W–7Ni–3Fe (Fine grained alloy) | Sintering at 1480 °C for 30 min in a hydrogen atmosphere | — | 923 | 8 | — | [82] |

| W–7Ni–3Fe–0.04Y2O3 (Fine grained alloy) | — | 1050 | 30.8 | — | [82] | |

| W–4.9Ni–2.1Fe (Coarse grained) | Pre-sintering at 900 °C for 120 min and sintering at 1460 °C for 90 min in a hydrogen atmosphere | — | 580 at 600 °C 330 at 800 °C | — | — | [83] |

| W–4.9Ni–2.1Fe–0.03Y (Fine grained) | — | 620 at 600 °C 460 at 800 °C | — | — | [83] | |

| W–7Ni–3Fe | Spark plasma sintering at 1100 °C with 30 MPa | 68 | 586 | — | 0.64 | [89] |

| W–7Ni–3Fe–0.25YSZ | 109 | 892 | — | 1.83 | ||

| W–7Ni–3Fe–1YSZ | 105 | 658 | — | 2.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natarajan, S.; Gopalan, V.; Rajan, R.A.A.; Jen, C.-P. Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W–Ni–Fe Alloy—A Review. Materials 2021, 14, 1660. https://doi.org/10.3390/ma14071660

Natarajan S, Gopalan V, Rajan RAA, Jen C-P. Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W–Ni–Fe Alloy—A Review. Materials. 2021; 14(7):1660. https://doi.org/10.3390/ma14071660

Chicago/Turabian StyleNatarajan, Senthilnathan, Venkatachalam Gopalan, Raja Annamalai Arunjunai Rajan, and Chun-Ping Jen. 2021. "Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W–Ni–Fe Alloy—A Review" Materials 14, no. 7: 1660. https://doi.org/10.3390/ma14071660

APA StyleNatarajan, S., Gopalan, V., Rajan, R. A. A., & Jen, C.-P. (2021). Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W–Ni–Fe Alloy—A Review. Materials, 14(7), 1660. https://doi.org/10.3390/ma14071660