Effect of Thermal Aging on the Mechanical Properties of High Tenacity Polyester Yarn

Abstract

:1. Introduction

2. Materials and Methods

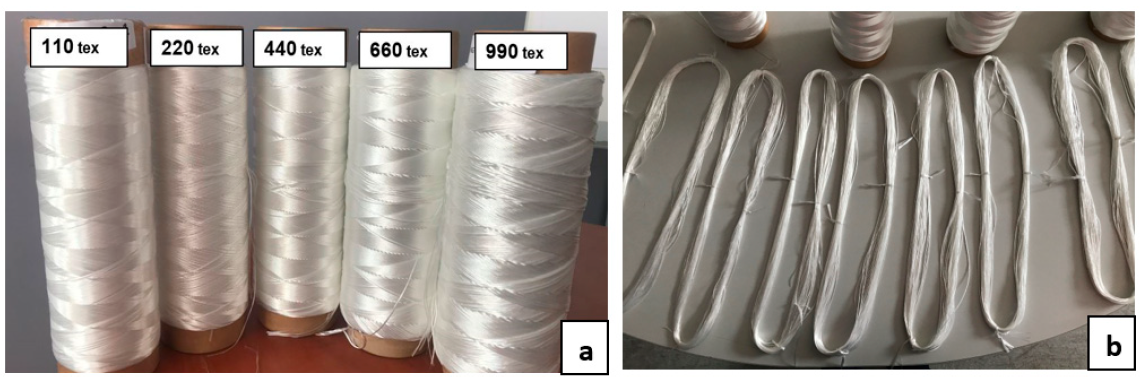

2.1. Materials

2.2. Yarn Aging

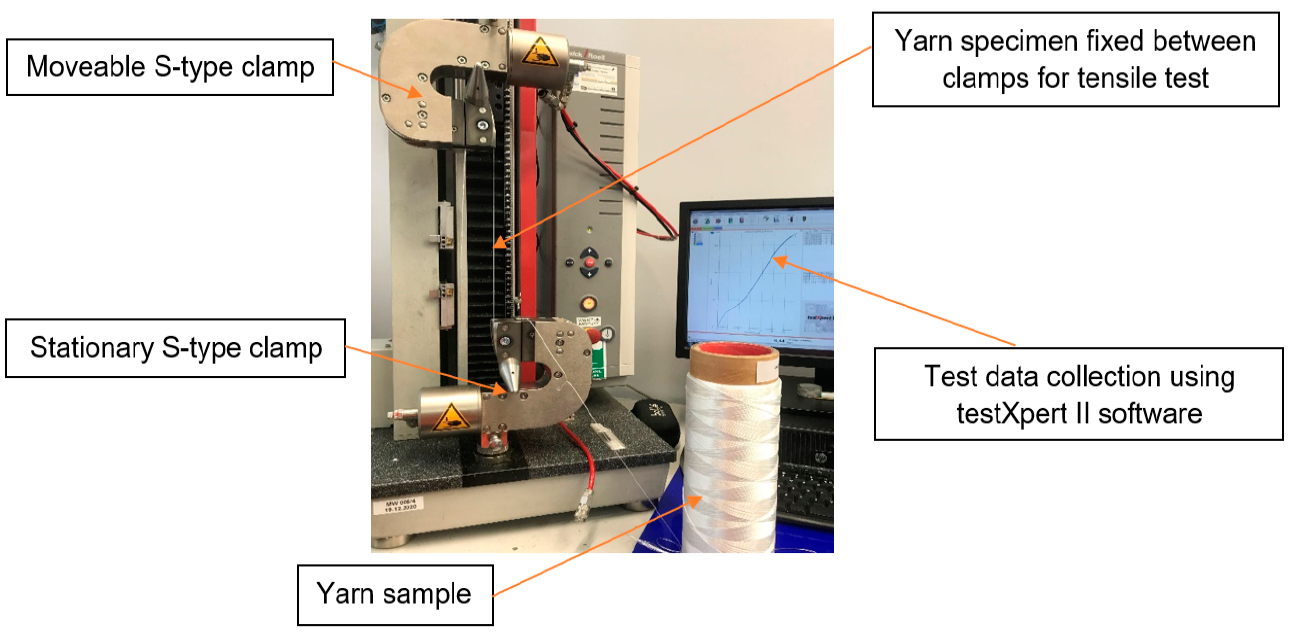

2.3. Tensile Strength Testing

2.4. Scanning Electron Microscope Observation

3. Results and Discussion

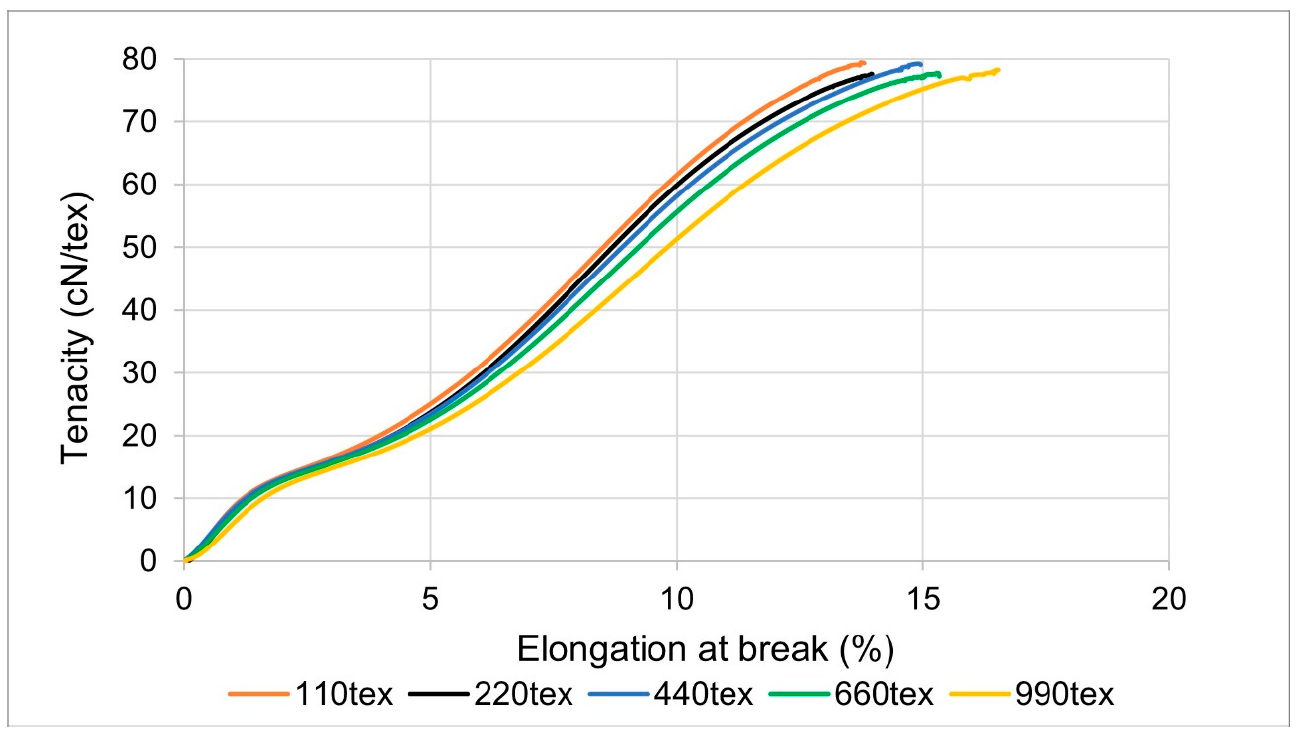

3.1. Unaged High Tenacity Polyester Yarn Tensile Strength Test Results

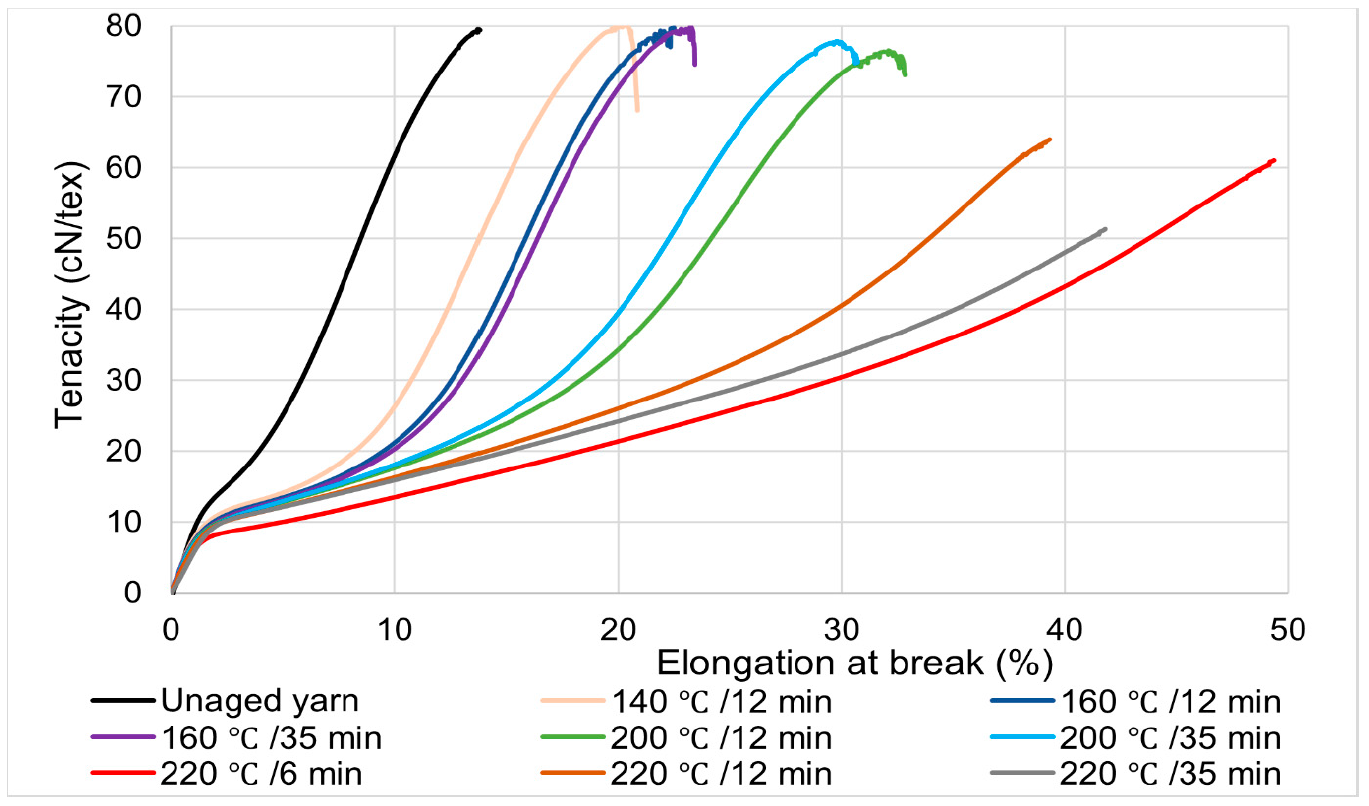

3.2. Comparison of 110 Tex High Tenacity Polyester Yarn Tensile Properties in a Different Aging Time and Temperature

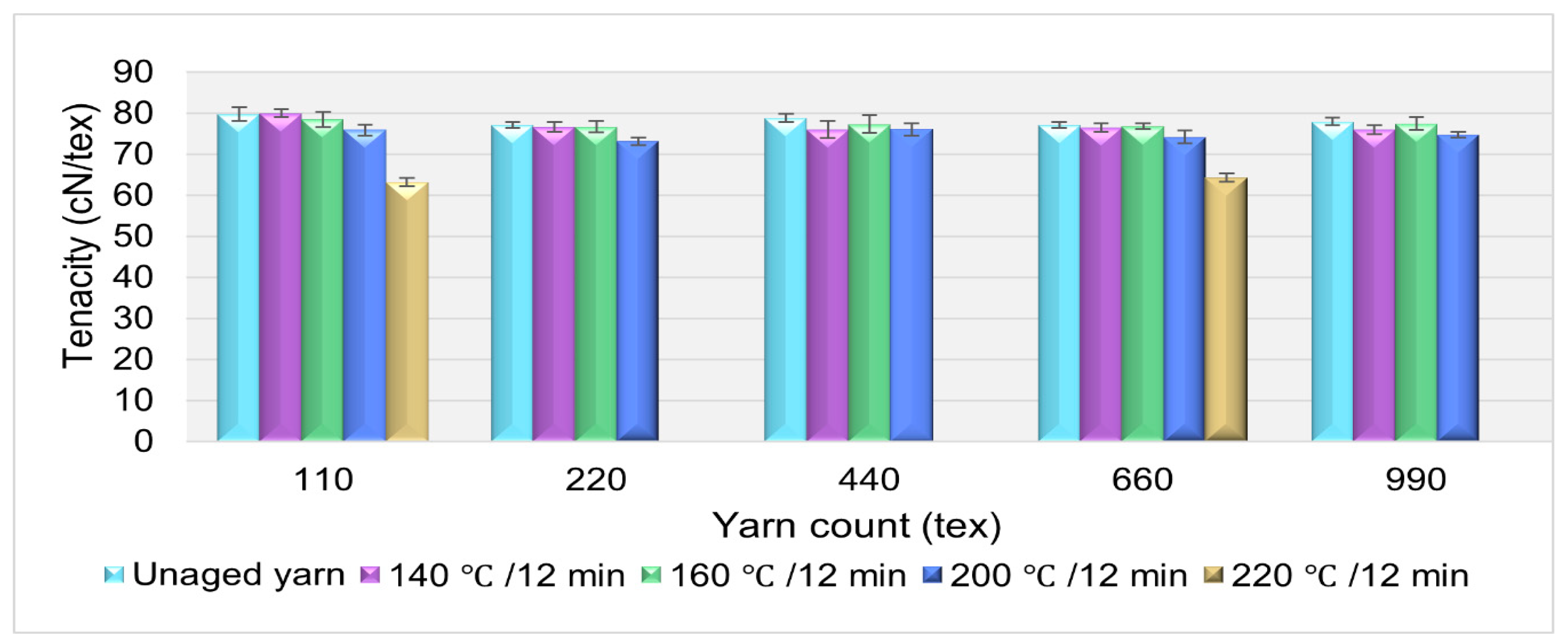

3.3. Effect of Temperature on the Polyester Yarn’s Tenacity

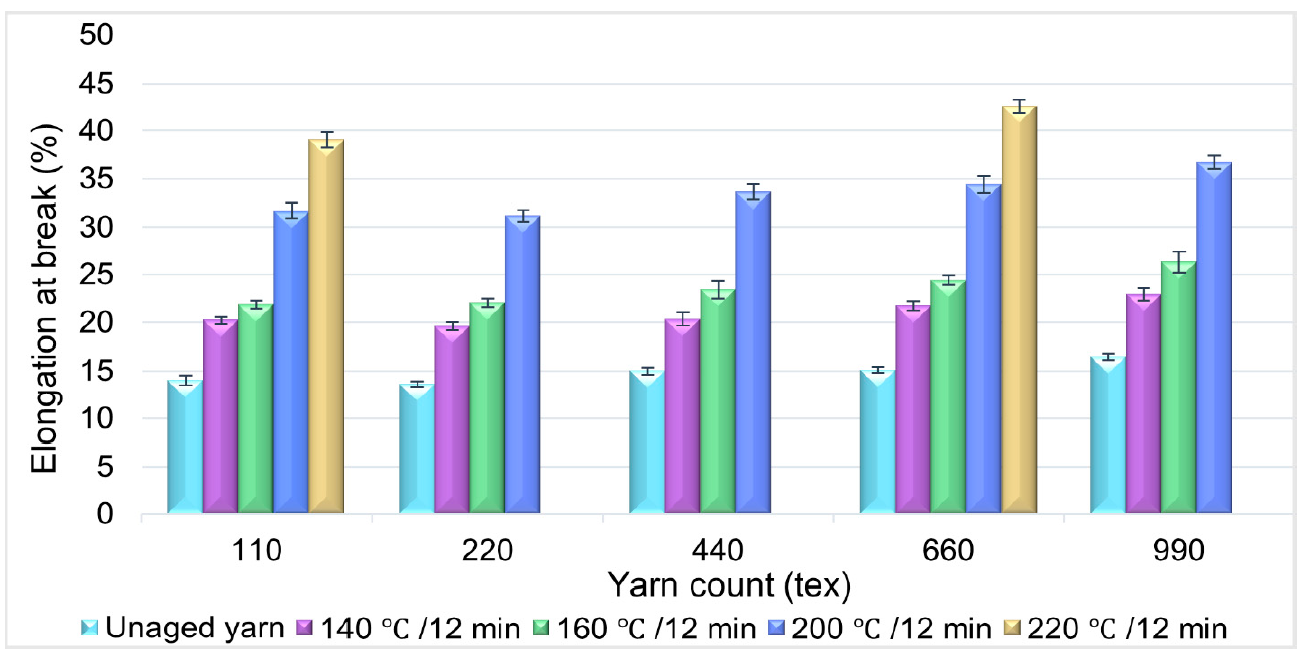

3.4. Effect of Temperature on Percentage Elongation of HT Polyester Yarn

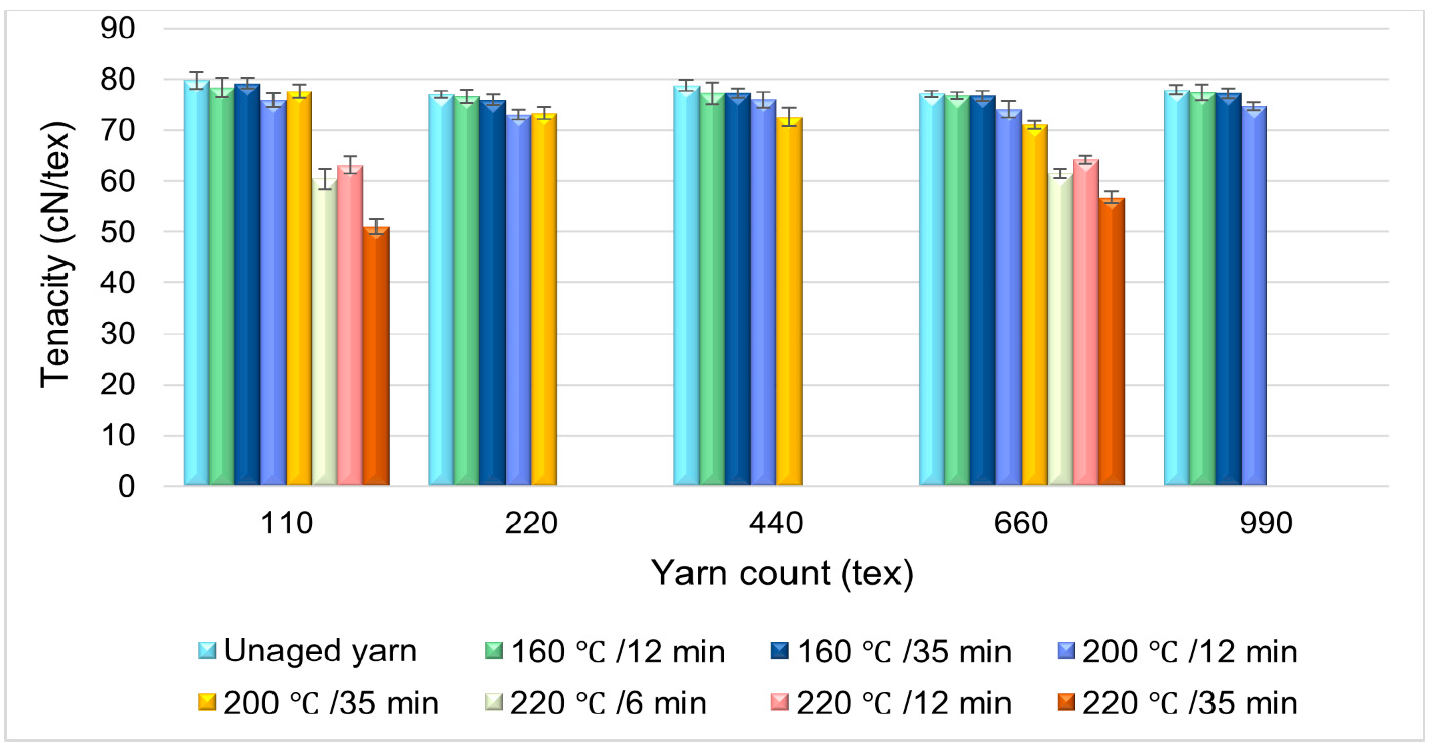

3.5. Effect of Aging Time on the Polyester Yarn’s Tenacity

3.6. Effect of Aging Time on the Elongation of HT Polyester Yarn

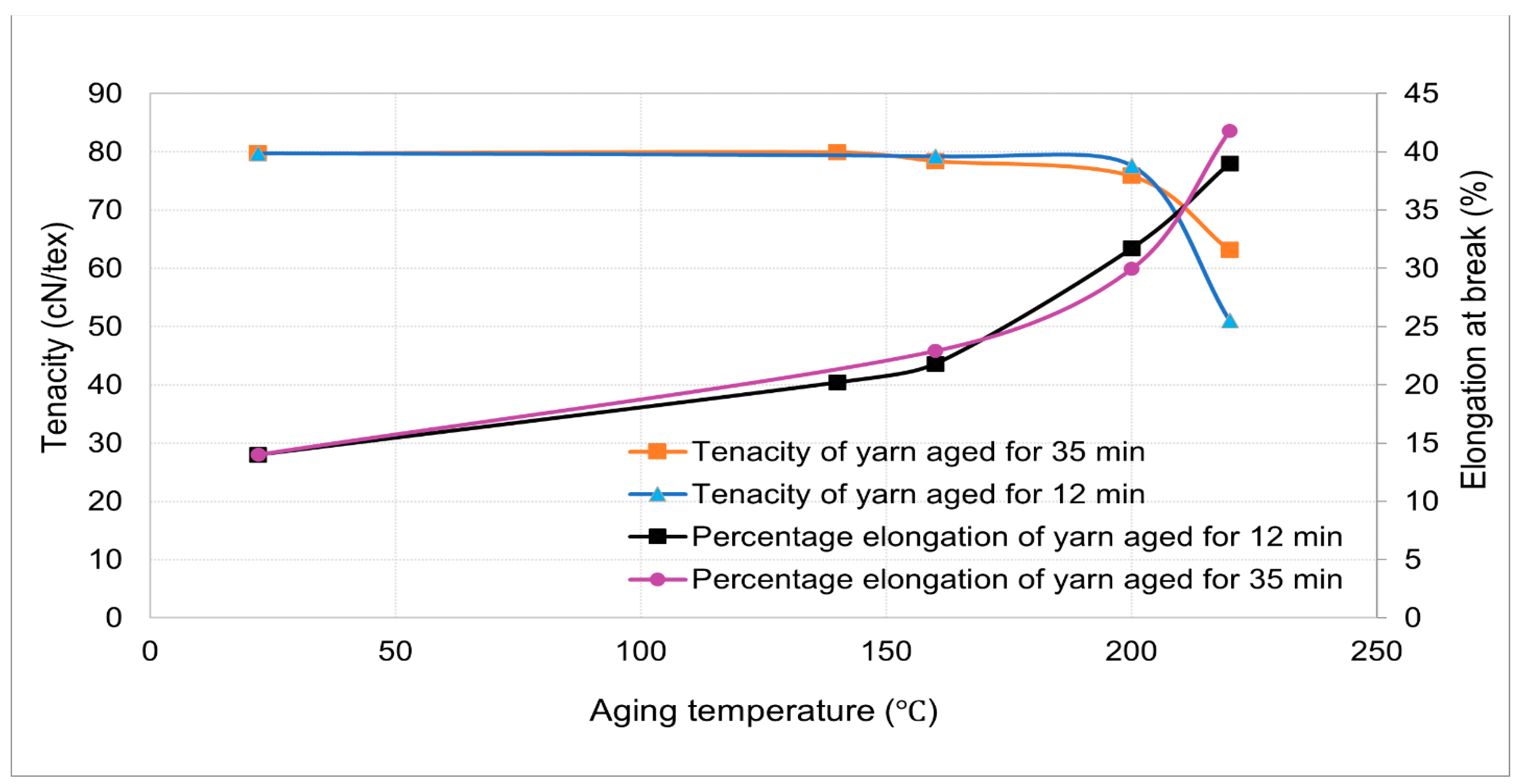

3.7. Effect of Aging Time and Temperature on the Percentage of Elongation and Tenacity

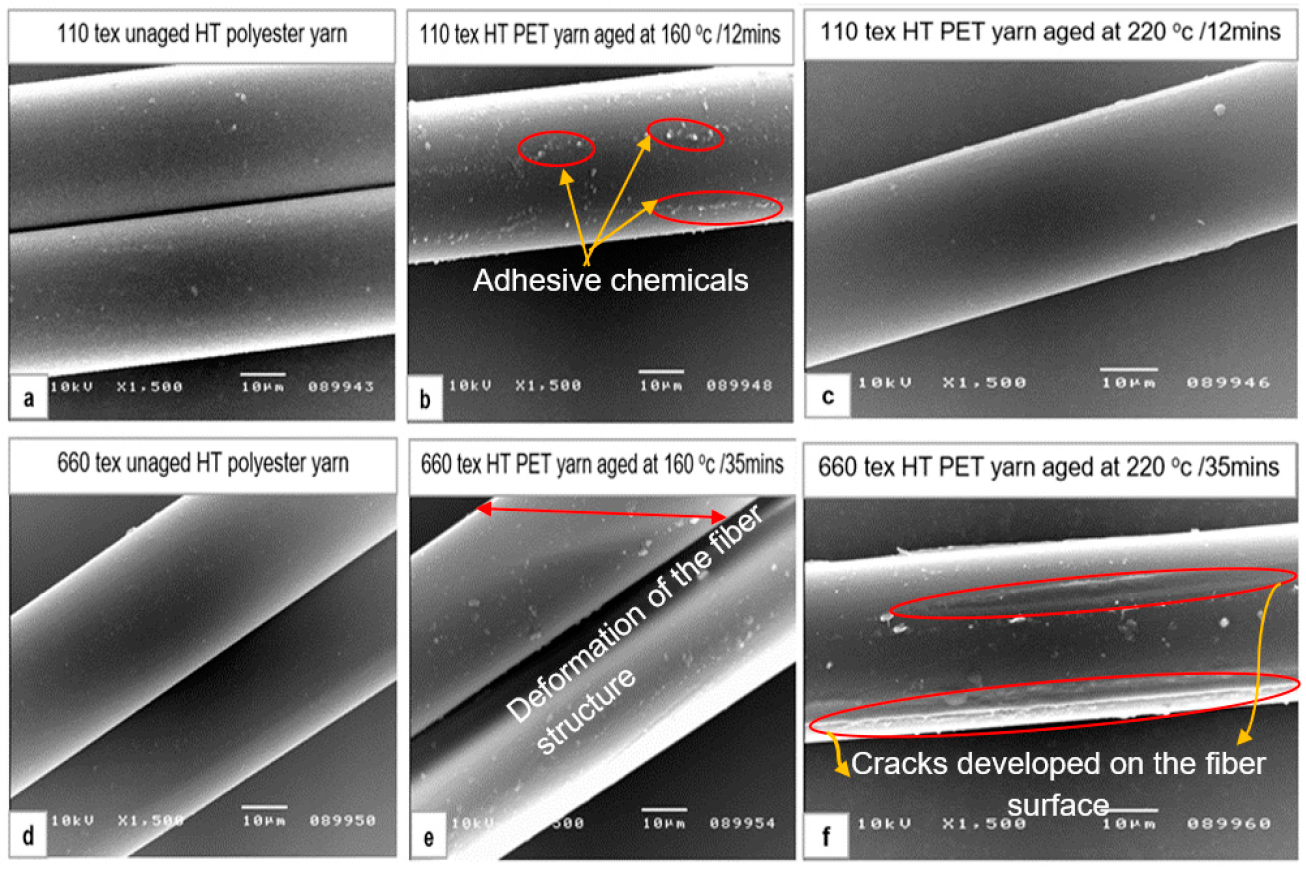

3.8. Structural View of Unaged and Aged HT Polyester Yarn

4. Conclusions

- The stress–strain curve of all polyester samples included in this work shows that the response of the yarns to a given load in an elastic region of the curve is similar regardless of the thermal aging conditions and linear density of the yarn. However, the plastic region characteristics of the curve are reliant on the linear density of the yarn, aging temperature, and aging time.

- The polyester yarn samples subjected to thermal aging at the temperature of 140 °C and 160 °C at 12 min and 35 min have not shown any tenacity difference compared to the unaged yarn sample. Nevertheless, the tenacity of the polyester yarn was lowered as the temperature rose above 200 °C. Compared to the unaged yarn sample, the tenacity of the yarns aged at 200 °C and 220 °C for 12 min dropped by 4.28% and 18.45%, respectively. Moreover, the yarn aged at 220 °C for 35 min displayed, on average, a 30.97% lower tenacity compared to the unaged yarn.

- The elongation of the polyester yarn samples increased with the increase in temperature, aging time, and the yarn’s linear density, and an almost five times higher elongation was obtained for the yarn aged at 220 °C for 6 min compared to the unaged yarn.

- The fiber’s surface structure was also affected as the yarn underwent thermal aging at a higher temperature (220 °C) for a longer aging time (35 min).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaffe, M.; Easts, A.J.; Feng, X. Polyester fibers. In Thermal Analysis of Textiles and Fibers; Jaffe, M., Joseph, D.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 133–149. ISBN 978-0-08-100572-9. [Google Scholar]

- Textile Exchange. Preferred Fiber & Materials Market Report 2019. Available online: https://store.textileexchange.org/wp-content/uploads/woocommerce_uploads/2019/11/Textile-Exchange_Preferred-Fiber-Material-Market-Report_2019.pdf (accessed on 2 October 2020).

- Militky, J. Tensile failure of polyester fibers. In Handbook of Properties of Textile and Technical Fibres, 2nd ed.; Bunsel, A.R., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 66, pp. 421–513. ISBN 978-0-08-101272-7. [Google Scholar]

- Samui, B.K.; Prakasan, M.P.; Ramesh, C.; Chakrabarty, D.; Mukhopadhyay, R. Structure–property relationship of different types of polyester industrial yarns. J. Text. Inst. 2013, 104, 35–45. [Google Scholar] [CrossRef]

- Samui, B.K.; Dasgupta, S.; Mukhopadhyay, R.; Ramesh, C.; Chakrabarty, D. Studies on the static and dynamic properties of different types of polyester industrial yarns. J. Text. Inst. 2016, 107, 1175–1184. [Google Scholar] [CrossRef]

- Martin, R.T.; Garth, L.W. Physical Aging Studies of Semicrystalline Poly(ethylene Terephthalate). J. Appl. Polym. Sci. 1979, 26, 2813–2825. [Google Scholar]

- Jing, L.; Shanyuan, W. Analysis and discussion of the modulus-strain curves of poly(ethylene terephthalate) and polyamide industrial yarns. J. Appl. Polym. Sci. 2005, 95, 859–862. [Google Scholar] [CrossRef]

- Farhoodi, M.; Mousavi, S.M.; Sotudeh-Gharebagh, R.; Emam-Djomeh, Z.; Oromiehie, A.; Mansour, H. A Study on Physical Aging of Semicrystalline Polyethylene Terephthalate below the Glass Transition Point. J. Appl. Res. Technol. 2012, 10, 698–702. [Google Scholar] [CrossRef]

- Chen, K.; Yu, J.; Liu, Y.; Song, M.; Jiang, Q.; Ji, H.; Zou, J.; Zhang, Y.; Wang, H. Creep deformation and its correspondence to the microstructure of different polyester industrial yarns at room temperature. Polym. Int. 2019, 68, 555–563. [Google Scholar] [CrossRef]

- Prevorsek, D.C.; Tirpak, G.A.; Harget, P.J.; Reimschuessel, A.C. Effects of thermal contraction on structure and properties of PET fibers. J. Macromol. Sci. Part B 1974, 9, 733–759. [Google Scholar] [CrossRef]

- Chen, K.; Liu, Y.; Ji, H.; Zhang, Y.; Song, M.; Jiang, Q.; Zhang, Y.; Wang, H. The evaluation of structure and properties of high-strength polyester industrial fibers with different polycondensation processes. J. Text. Inst. 2020, 1–6. [Google Scholar] [CrossRef]

- Cho, D.H.; Yu, W.-R.; Youk, J.H.; Yoo, J.H. Formation of micro-crystals in poly(ethylene terephthalate) fiber by a short heat treatment and their influence on the mechanical properties. Eur. Polym. J. 2007, 43, 3562–3572. [Google Scholar] [CrossRef]

- Liu, Y.; Yin, L.; Zhao, H.; Song, G.; Tang, F.; Wang, L.; Shao, H.; Zhang, Y. Lamellar and fibrillar structure evolution of poly(ethylene terephthalate) fiber in thermal annealing. Polymer 2016, 105, 157–166. [Google Scholar] [CrossRef]

- Aytaç, A.; Yilmaz, B.; Deniz, V. Effects of linear density and twist level on the mechanical properties of nylon 6.6 tyre cords. Fibers Polym. 2010, 11, 309–315. [Google Scholar] [CrossRef]

- Lechat, C.; Bunsell, A.R.; Davies, P.; Piant, A. Mechanical behaviour of polyethylene terephthalate & polyethylene naphthalate fibers under cyclic loading. J. Mater. Sci. 2006, 41, 1745–1756. [Google Scholar] [CrossRef]

- Soares, A.P. Method of production of industrial polyester yarns. J. Chem. Inf. Model. 2013, 53, 1689–1699. [Google Scholar]

- Barburski, M. Analysis of the mechanical properties of conveyor belts on the three main stages of production. J. Ind. Text. 2014, 45, 1322–1334. [Google Scholar] [CrossRef]

- Barburski, M. Analysis of the pipe conveyor belt pressure on the rollers on its circuit. J. Ind. Text. 2016, 45, 1619–1634. [Google Scholar] [CrossRef]

- Barburski, M.; Góralczyk, M.; Snycerski, M. Analysis of changes in the internal structure of PA6.6/PET fabrics of different weave patterns under heat treatment. Fibres Text. East. Eur. 2015, 23, 46–51. [Google Scholar] [CrossRef]

- ISO. Textiles—Yarns from Packages—Determination of Single-End Breaking Force and Elongation at Break Using Constant Rate of Extension (CRE) Tester; ISO 2062:2009; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Pirzadeh, E.; Zadhoush, A.; Haghighat, M. Hydrolytic and thermal degradation of PET fibers and PET granule: The effects of crystallization, temperature, and humidity. J. Appl. Polym. Sci. 2007, 106, 1544–1549. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Kikutani, T. Melt-spun fibers for textile applications. Materials 2020, 13, 4298. [Google Scholar] [CrossRef]

- Gupta, V.B. The Nature of Coupling between the Crystalline and Amorphous Phases and its Effect on the Properties of Heat-set Poly(ethylene terephthalate) Fibres. J. Text. Inst. 1995, 86, 299–313. [Google Scholar] [CrossRef]

- Ma, J.; Yu, L.; Chen, S.; Chen, W.; Wang, Y.; Guang, S.; Zhang, X.; Lu, W.; Wang, Y.; Bao, J. Structure—Property Evolution of Poly(ethylene terephthalate) Fibers in Industrialized Process under Complex Coupling of Stress and Temperature Field. Macromolecules 2018, 52, 565–574. [Google Scholar] [CrossRef]

- Sardag, S.; Ozdemir, O.; Kara, I. The effects of heat-setting on the properties of polyester/viscose blended yarns. Fibres Text. East. Eur. 2007, 15, 50–53. [Google Scholar]

| Yarn Type | Property | ||||

|---|---|---|---|---|---|

| Linear Density (tex) | Breaking Force (N) | Breaking Tenacity (cN/tex) | Elongation at Break (%) | Hot Air Shrinkage (%) | |

| High Tenacity Polyester | 110 | 89.9 | 81.0 | 13.5 | 5.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemmi, T.S.; Barburski, M.; Kabziński, A.; Frukacz, K. Effect of Thermal Aging on the Mechanical Properties of High Tenacity Polyester Yarn. Materials 2021, 14, 1666. https://doi.org/10.3390/ma14071666

Lemmi TS, Barburski M, Kabziński A, Frukacz K. Effect of Thermal Aging on the Mechanical Properties of High Tenacity Polyester Yarn. Materials. 2021; 14(7):1666. https://doi.org/10.3390/ma14071666

Chicago/Turabian StyleLemmi, Tsegaye Sh., Marcin Barburski, Adam Kabziński, and Krzysztof Frukacz. 2021. "Effect of Thermal Aging on the Mechanical Properties of High Tenacity Polyester Yarn" Materials 14, no. 7: 1666. https://doi.org/10.3390/ma14071666

APA StyleLemmi, T. S., Barburski, M., Kabziński, A., & Frukacz, K. (2021). Effect of Thermal Aging on the Mechanical Properties of High Tenacity Polyester Yarn. Materials, 14(7), 1666. https://doi.org/10.3390/ma14071666