Manufacture of Binary Nanofeatured Polymeric Films Using Nanosphere Lithography and Ultraviolet Roller Imprinting

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials

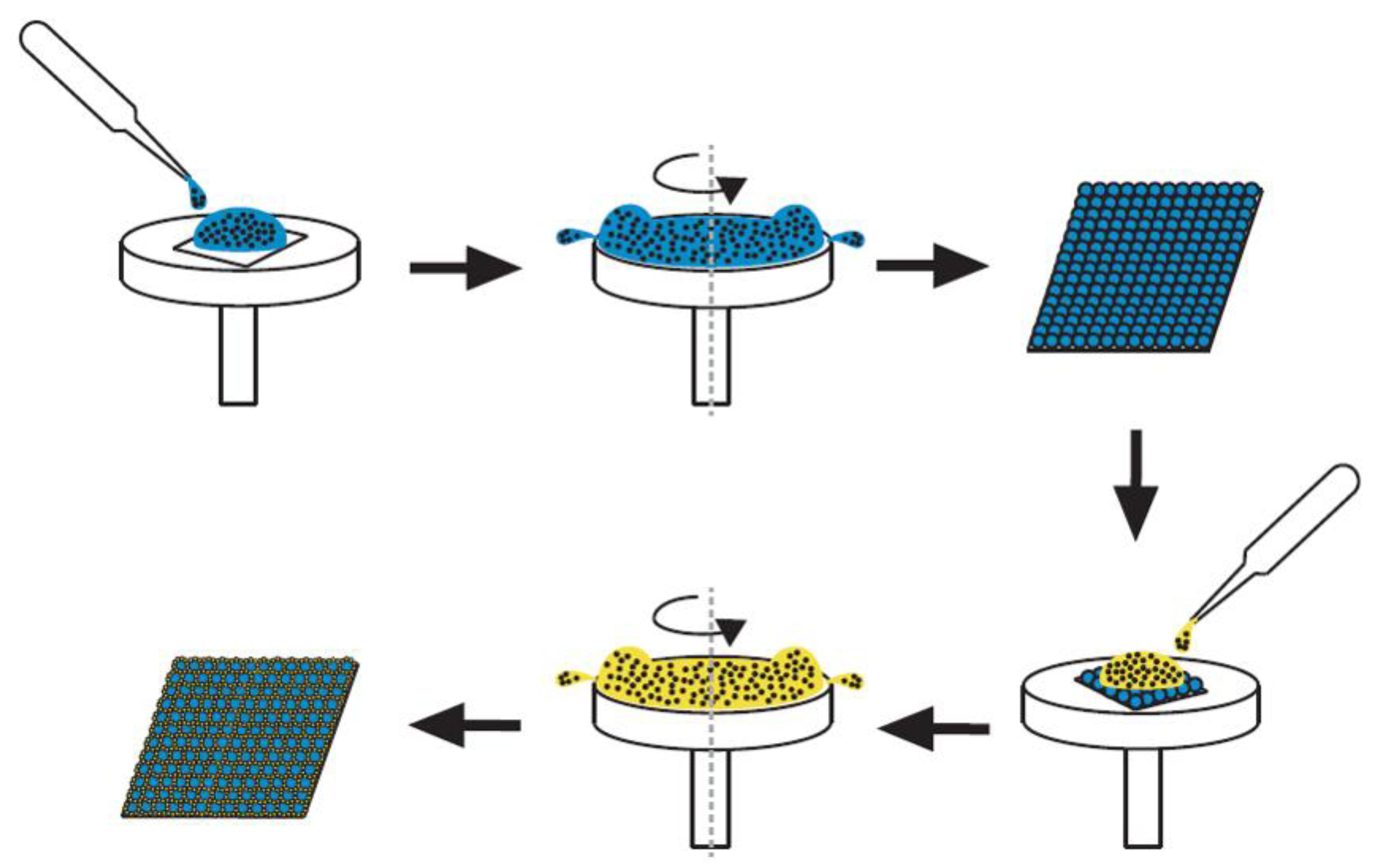

2.2. Prepare the Nanofeatured Template

2.3. Preparation of Soft Mold

2.4. Roller Imprinting of Nanofeatured Films

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rajab, F.H.; Whitehead, D.; Liu, Z.; Li, L. Characteristics of hierarchical micro/nano surface structure formation generated by picosecond laser processing in water and air. Appl. Phys. B 2017, 123, 282. [Google Scholar] [CrossRef]

- Chang, H.W.; Tsai, Y.C.; Cheng, C.W.; Lin, C.Y.; Lin, Y.W.; Wu, T.M. Nanostructured Ag surface fabricated by femtosecond laser for surface-enhanced Raman scattering. J. Colloid Interface Sci. 2011, 360, 305–308. [Google Scholar] [CrossRef]

- Maksoud, M.I.A.A.; Fahim, R.A.; Shalan, A.E.; Abd Elkodous, M.; Olojede, S.O.; Osman, A.I.; Farrell, C.; Al-Muhtaseb, A.H.; Awed, A.S.; Ashour, A.H.; et al. Advanced materials and technologies for supercapacitors used in energy conversion and storage: A review. Environ. Chem. Lett. 2020. [Google Scholar] [CrossRef]

- Cao, X.; Tan, C.; Sindoro, M.; Zhang, H. Hybrid micro-/nano-structures derived from metal—Organic frameworks: Preparation and applications in energy storage and conversion. Chem. Soc. Rev. 2017, 46, 2660–2677. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Zhong, M.; Zhang, H.; Xie, Y.; Lin, C. Superhydrophobic and colorful copper surfaces fabricated by picosecond laser induced periodic nanostructures. Appl. Surf. Sci. 2014, 311, 461–467. [Google Scholar] [CrossRef]

- Long, J.; Pan, L.; Fan, P.; Gong, D.; Jiang, D.; Zhang, H.; Li, L.; Zhong, M. Cassie-state stability of metallic superhydrophobic surfaces with various micro/nanostructures produced by a Femtosecond laser. Langmuir 2016, 32, 1065–1072. [Google Scholar] [CrossRef] [PubMed]

- Jagdheesh, R. Fabrication of a superhydrophobic Al2O3 surface using picosecond laser pulses. Langmuir 2014, 30, 12067–12073. [Google Scholar] [CrossRef] [PubMed]

- Prakash, J.; Khan, S.; Chauhan, S.; Biradar, A.M. Metal oxide-nanoparticles and liquid crystal composites: A review of recent progress. J. Mol. Liq. 2020, 297, 112052. [Google Scholar] [CrossRef]

- Limongi, T.; Tirinato, L.; Pagliari, F.; Giugni, A.; Allione, M.; Perozziello, G.; Candeloro, P.; Fabrizio, E. Fabrication and applications of micro/nanostructured devices for tissue engineering. Nano-Micro Lett. 2017, 9, 1. [Google Scholar] [CrossRef] [Green Version]

- Zouani, O.F.; Chanseau, C.; Brouillaud, B.; Bareille, R.; Deliane, F.; Foulc, M.-P.; Mehdi, A.; Durrie, M.-C. Altered nanofeature size dictates stem cell differentiation. J. Cell. Sci. 2012, 125, 1217–1224. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Calderon, M.; Manso-Silvan, M.; Rodriguez, A.; Gomez-Aranzadi, M.; Garcia-Ruiz, J.P.; Olaizola, S.M.; Martin-Palma, R.J. Surface micro- and nano-texturing of stainless steel by femtosecond laser for the control of cell migration. Sci. Rep. 2016, 6, 36296. [Google Scholar] [CrossRef] [PubMed]

- Abasian, P.; Ghanavati, S.; Rahebi, S.; Khorasani, S.N.; Khaliki, S. Polymeric nanocarriers in targeted drug delivery systems: A review. Polym. Adv. Tech. 2020, 31, 2939–2954. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef] [Green Version]

- Leitgeb, M.; Nees, D.; Ruttloff, S.; Palfinger, U.; Gotz, J.; Liska, R.; Belegratis, M.R.; Stadlober, B. Multilength scale patterning of functional layers by roll-to-roll ultraviolet-light assisted nanoimprint lithography. ACS Nano 2016, 10, 4926–4941. [Google Scholar] [CrossRef] [PubMed]

- Yi, P.; Wu, H.; Zhang, C.; Peng, L. Roll-to-roll UV imprinting lithography for micro/nanostructures. J. Vas. Sci. Technol. B 2015, 33, 060801. [Google Scholar] [CrossRef]

- Colson, P.; Henrist, C.; Cloots, R. Nanosphere lithography: A powerful method for the controlled manufacturing of nanomaterials. J. Nanomat. 2013, 2013. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.A.; Chen, I.T.; Chang, C.H. Recent progress in near-field nanolithography using light interactions with colloidal particles: From nanospheres to three-dimensional nanostructures. Nanotechnology 2019, 30, 352002. [Google Scholar] [CrossRef]

- Cara, E.; Lupe, F.F.; Fretto, M.; de Leo, N.; Tortello, M.; Gonnelli, R.; Sparnacci, K.; Boarino, L. Directed self-assembly of polystyrene nanospheres by direct laser-writing lithography. Nanomaterials 2020, 10, 280. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Whitesides, G.M. Soft lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Liu, S.J.; Chang, Y.C. A novel soft-mold roller embossing method for the rapid fabrication of micro-blocks onto glass substrates. J. Micromech. Microeng. 2007, 17, 172–179. [Google Scholar] [CrossRef]

- Lee, D.; Tang, Y.L.; Liu, S.J. Fast fabrication of nanostructured films using nanocolloid lithography and UV soft mold roller embossing: Effects of processing parameters. Polymers 2021, 13, 405. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Song, C.; Li, Q.; Xiang, X.; Yang, H.; Wang, X.; Gao, J. Hybrid nanostructured antireflection coating by self-assembled nanosphere lithography. Coatings 2019, 9, 453. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.Y.; Lin, K.Y.; Tsai, H.P.; He, Y.X.; Yang, H. Self-assembled dual-sided hemispherical nano-dimple-structured broadband antireflection coatings. Appl. Phys. Lett. 2017, 109, 221601. [Google Scholar] [CrossRef]

- Kang, Y.H.; Oh, S.S.; Kim, Y.S.; Choi, C.G. Fabrication of antireflection nanostructures by hybrid nano-patterning lithography. Microelectron. Eng. 2010, 87, 125–128. [Google Scholar] [CrossRef]

- Xiu, Y.; Zhang, S.; Yelundur, V.; Rohatgi, A.; Hess, D.W.; Wong, C.P. Superhydrophobic and low light reflectivity silicon surfaces fabricated by Hierarchical etching. Langmuir 2008, 24, 10421–10426. [Google Scholar] [CrossRef]

- Tan, X.; Tao, Z.; Yu, M.; Wu, H.; Li, H. Anti-reflectance investigation of a micro-nano hybrid structure fabricated by dry/wet etching methods. Sci. Rep. 2018, 8, 7863. [Google Scholar] [CrossRef] [PubMed]

| Step | Nanosphere Size (nm) | DI Water:Ethanol | Surfactant:PS Sphere | Dispersant (%) | Spin Speed (Spin Time) rpm (s) |

|---|---|---|---|---|---|

| One | 900 | 1:1 | 1:2 | 5 | 500 (30) 1500 (30) 2000 (60) |

| Two | 300 | 10 | 3000 (30) |

| Solar Cell | Vmax (V) | Imax(mA/cm2) | VOC (V) | ISC (mA/cm2) | FF (%) | Eff (%) |

|---|---|---|---|---|---|---|

| Flat film | 0.69 | 1.128 | 0.710 | 1.323 | 0.57 | 5.38 |

| 900/300 nm nanofeature | 0.62 | 1.008 | 0.741 | 1.396 | 0.63 | 6.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Hsu, M.-Y.; Tang, Y.-L.; Liu, S.-J. Manufacture of Binary Nanofeatured Polymeric Films Using Nanosphere Lithography and Ultraviolet Roller Imprinting. Materials 2021, 14, 1669. https://doi.org/10.3390/ma14071669

Lee D, Hsu M-Y, Tang Y-L, Liu S-J. Manufacture of Binary Nanofeatured Polymeric Films Using Nanosphere Lithography and Ultraviolet Roller Imprinting. Materials. 2021; 14(7):1669. https://doi.org/10.3390/ma14071669

Chicago/Turabian StyleLee, Demei, Ming-Yi Hsu, Ya-Ling Tang, and Shih-Jung Liu. 2021. "Manufacture of Binary Nanofeatured Polymeric Films Using Nanosphere Lithography and Ultraviolet Roller Imprinting" Materials 14, no. 7: 1669. https://doi.org/10.3390/ma14071669