High Performance NbMoTa–Al2O3 Multilayer Composite Structure Manufacturing by Laser Directed Energy Deposition

Abstract

1. Introduction

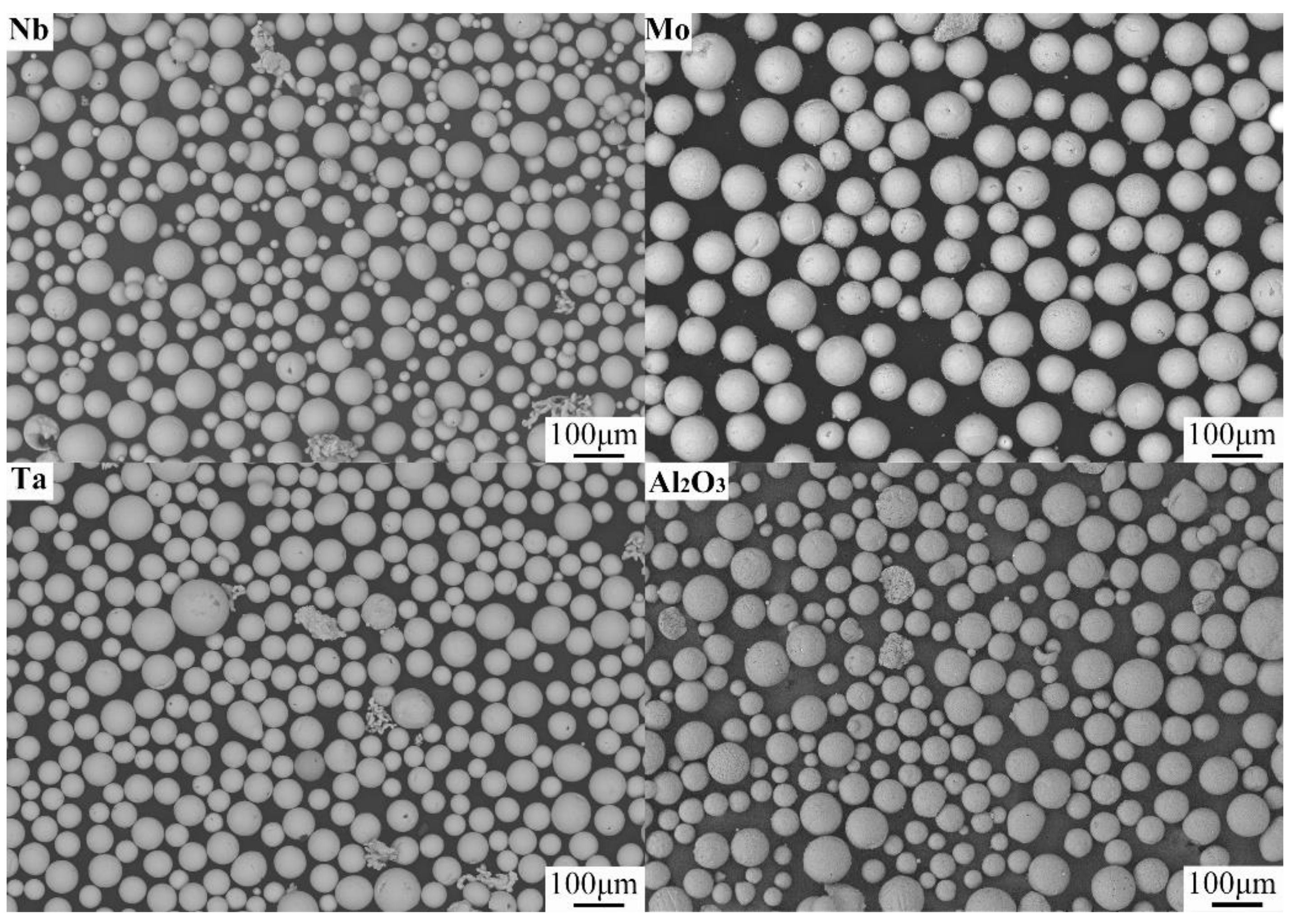

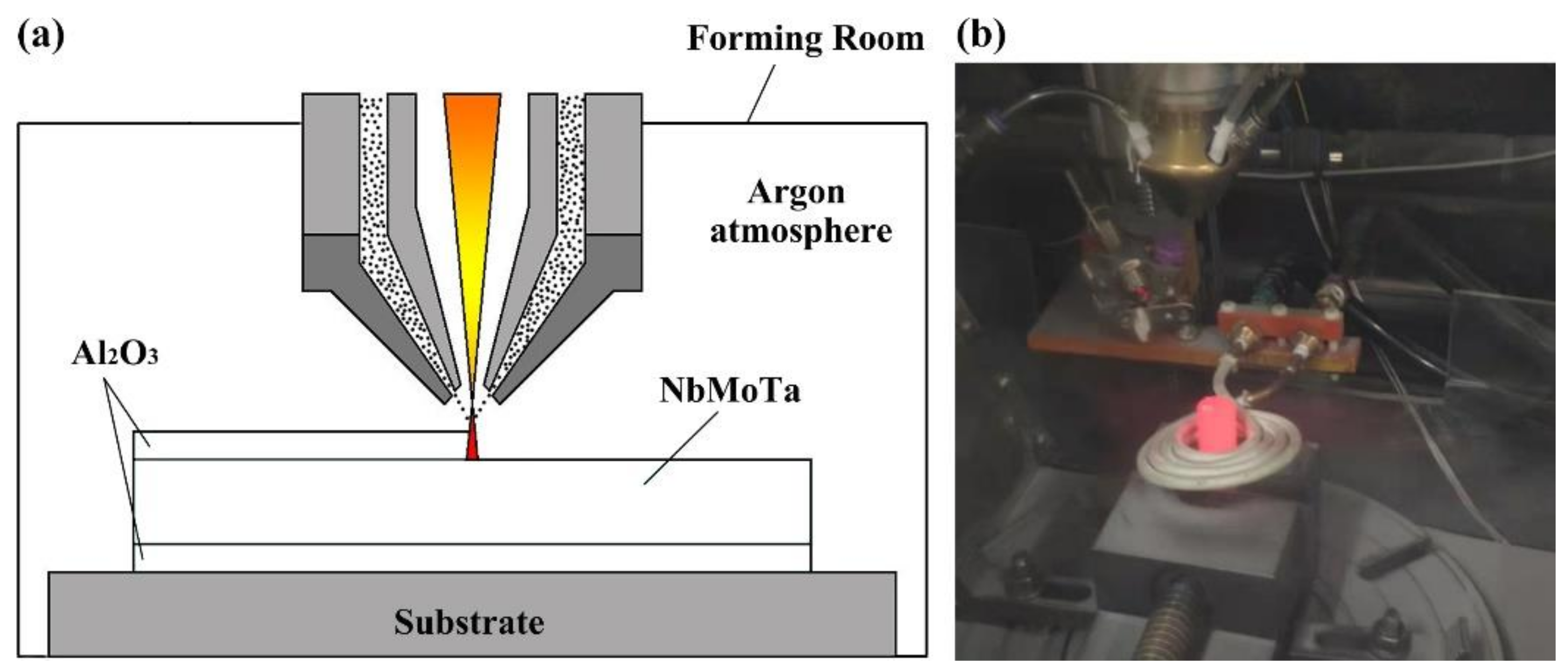

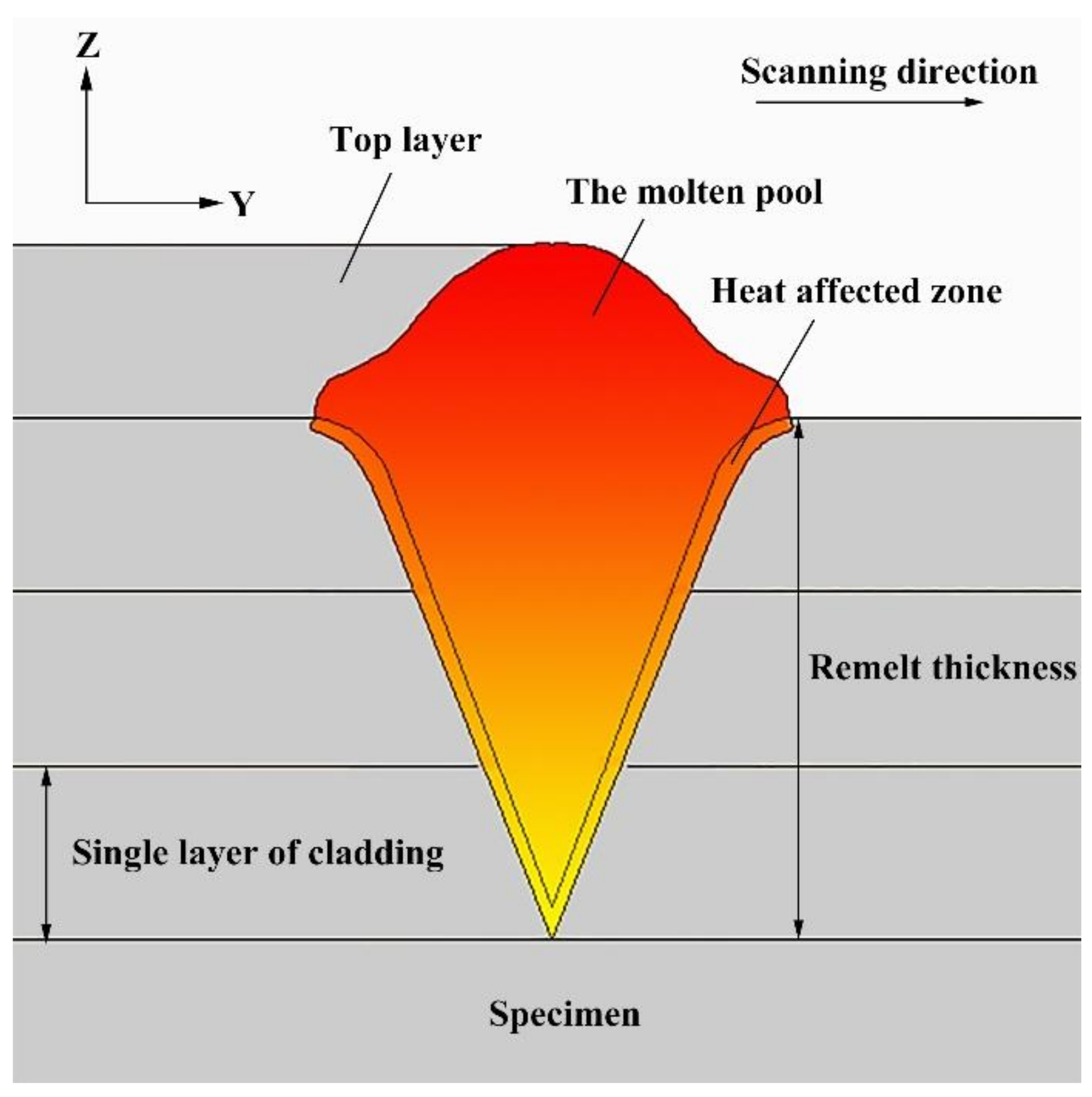

2. Materials and Methods

3. Results and Discussion

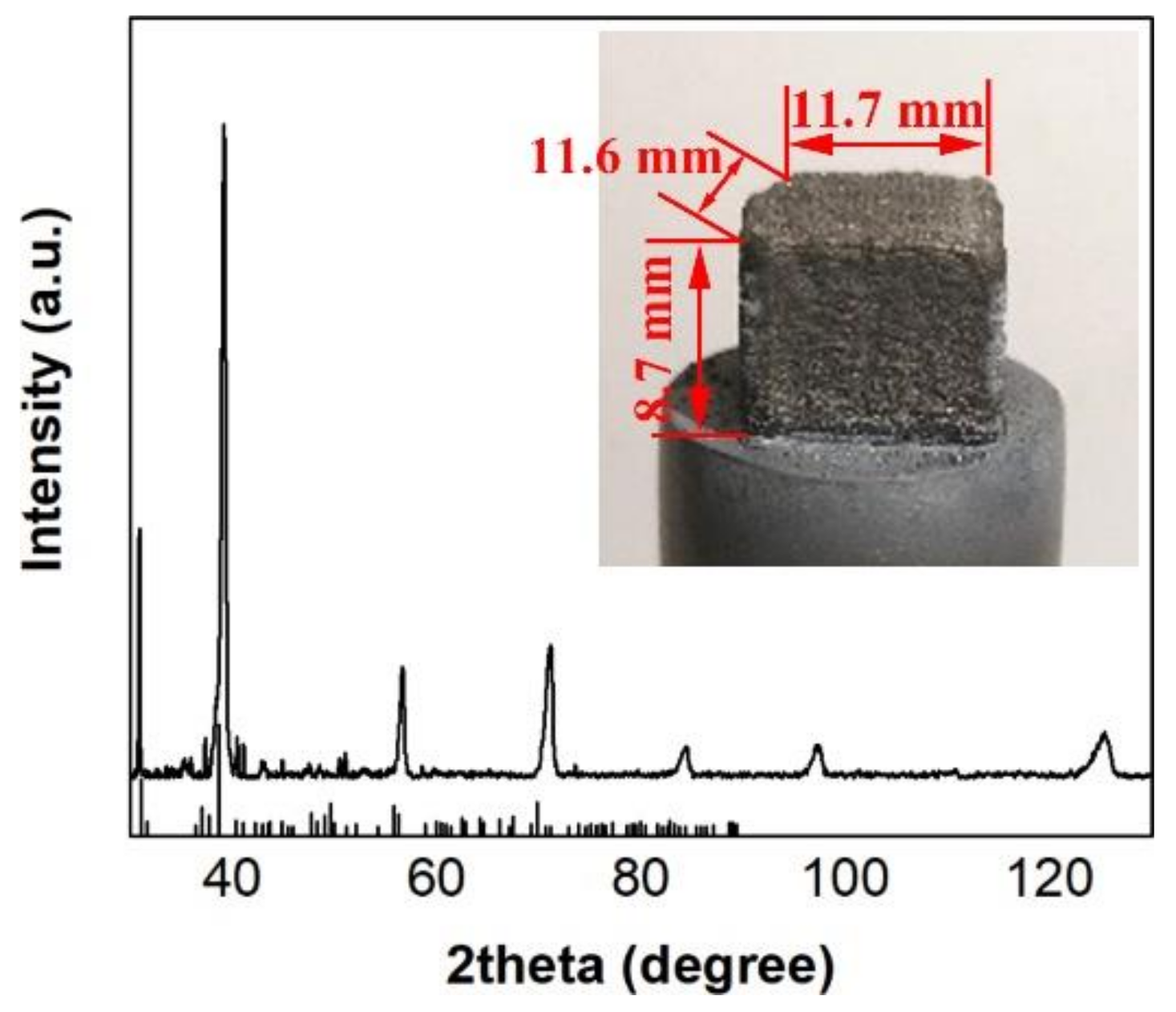

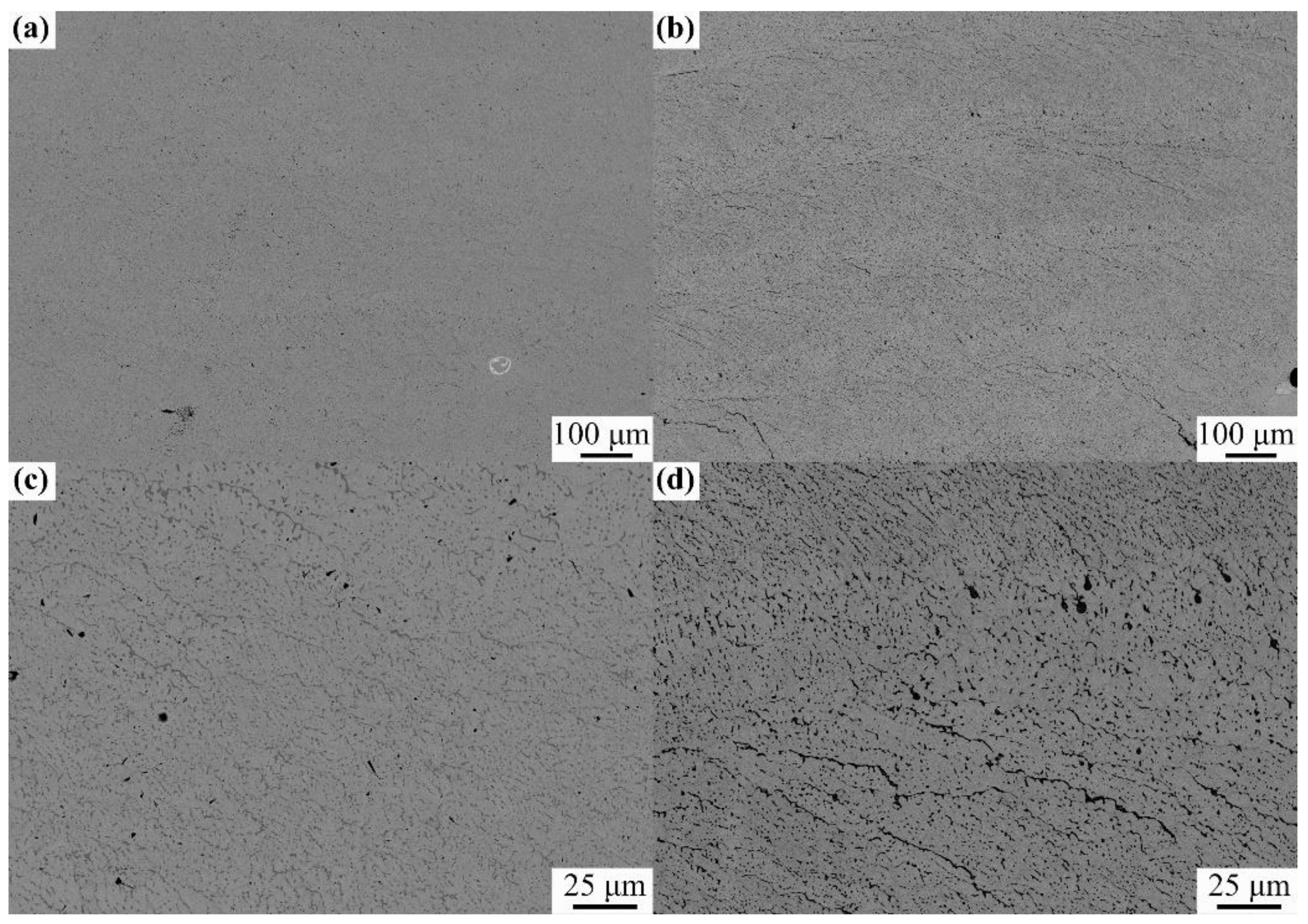

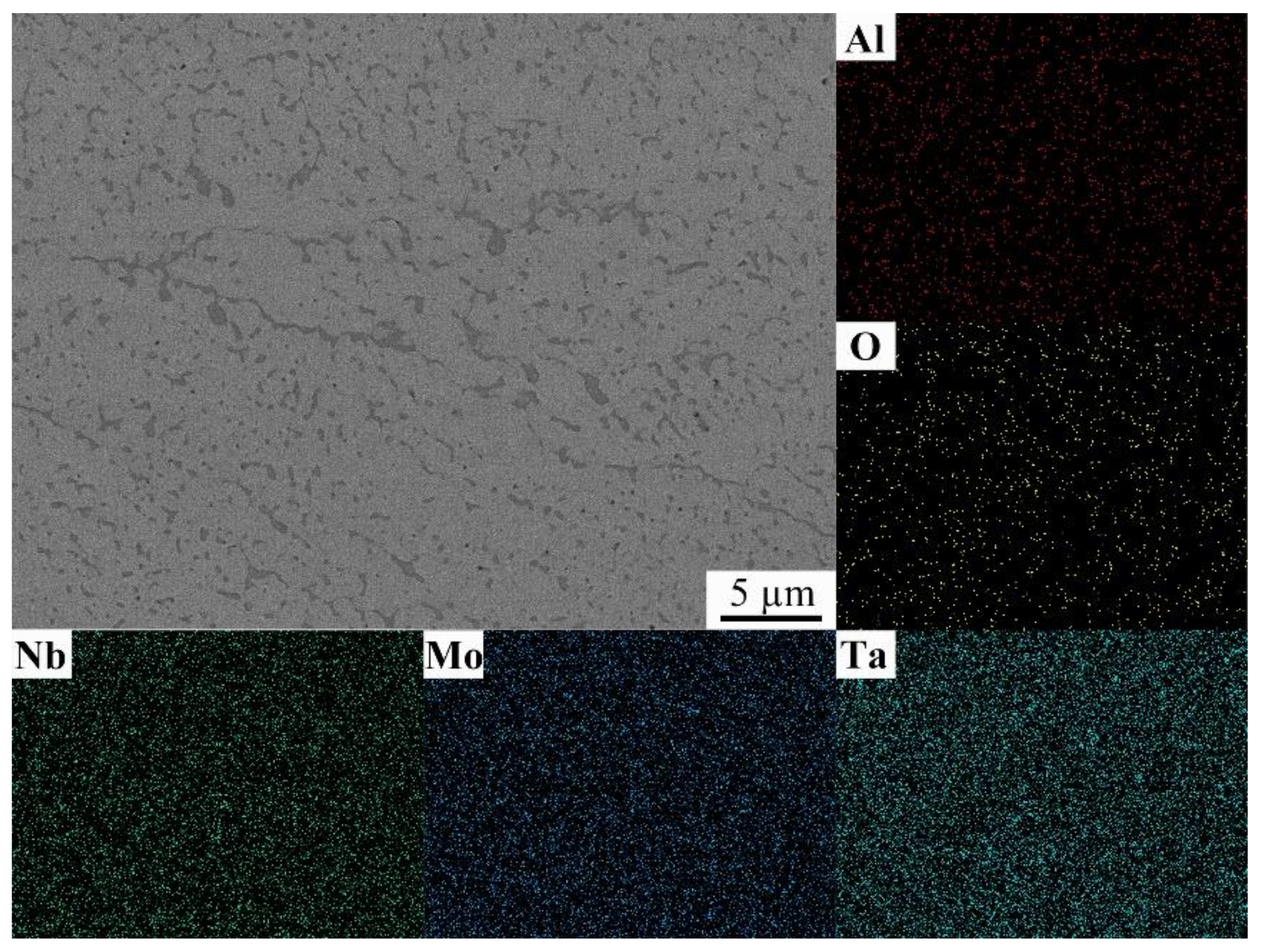

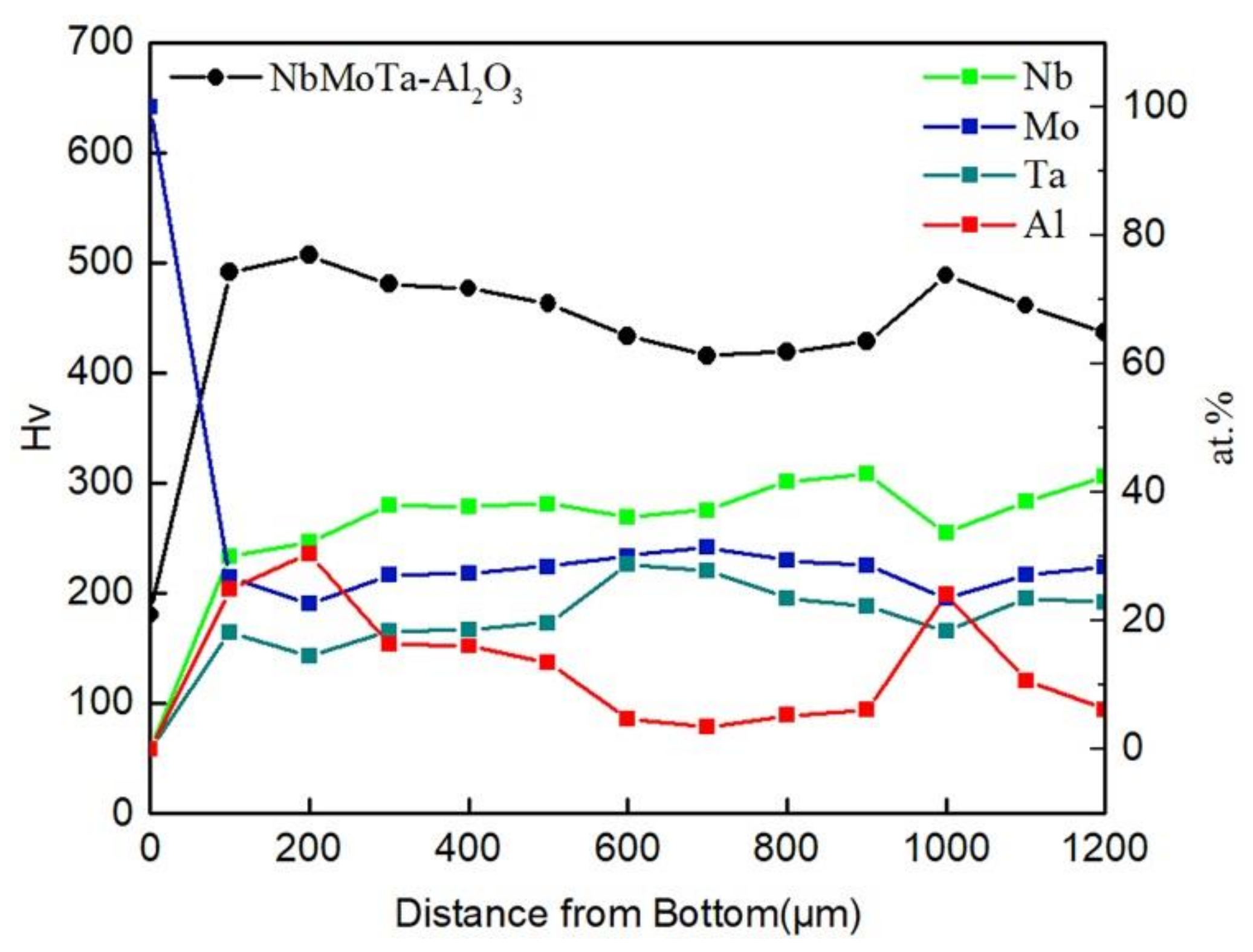

3.1. Microstructure and Composition

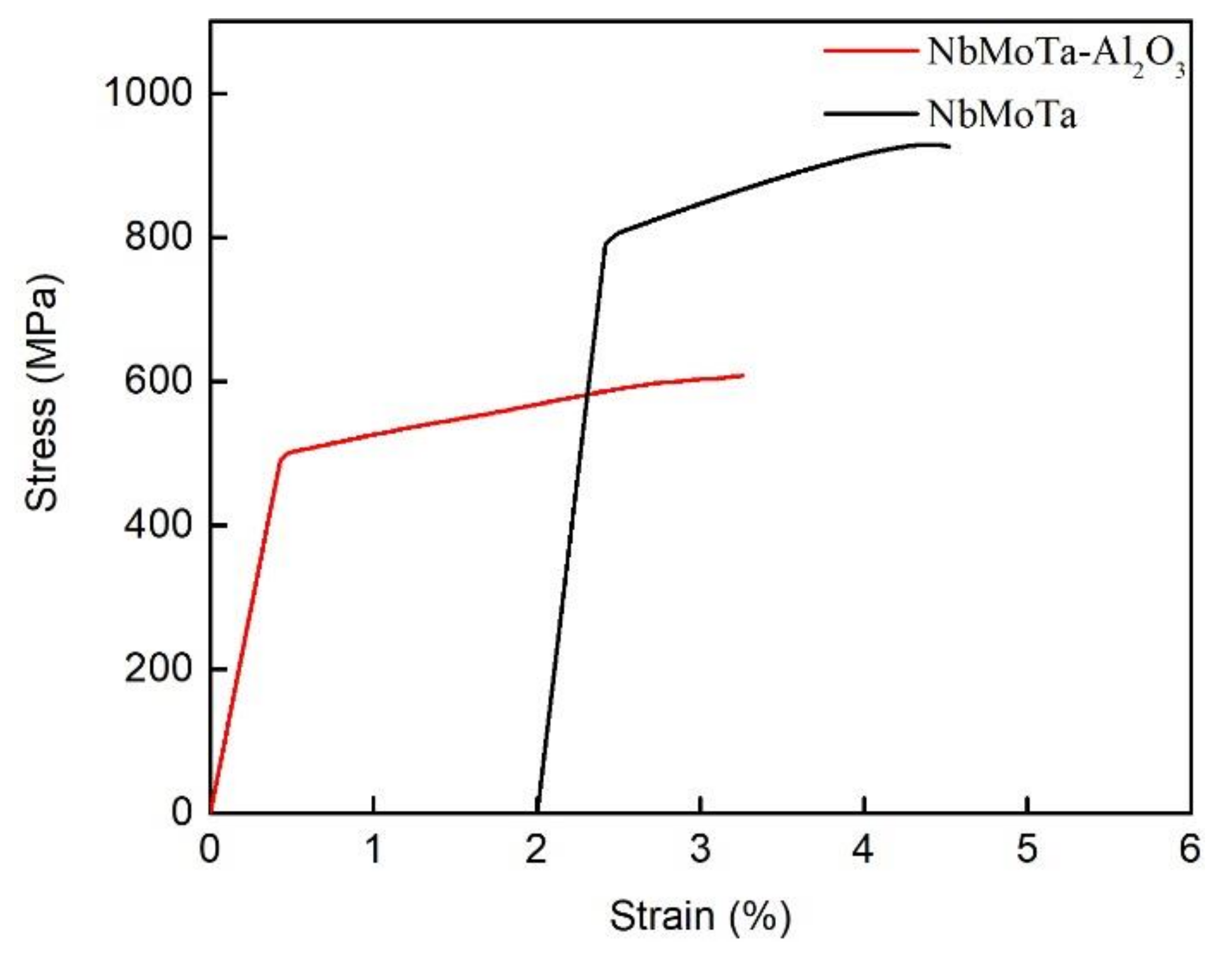

3.2. Mechanical Properties

4. Conclusions

- (1)

- The suitable layer distribution ratio of NbMoTa and Al2O3 was determined to be 3:1. The multilayer composite structure prepared by LDED has no macro cracks or holes. With the addition of Al2O3, the grain size of the NbMoTa–Al2O3 composite structure was smaller and more uniform than the NbMoTa multi-principal alloy;

- (2)

- Precipitated phases exist on the grain boundaries, and the test results show that it may be that during the process of NbMoTa deposition, Ta and the remelted Al2O3 underwent a complex chemical reaction, and finally AlTaO4 was formed;

- (3)

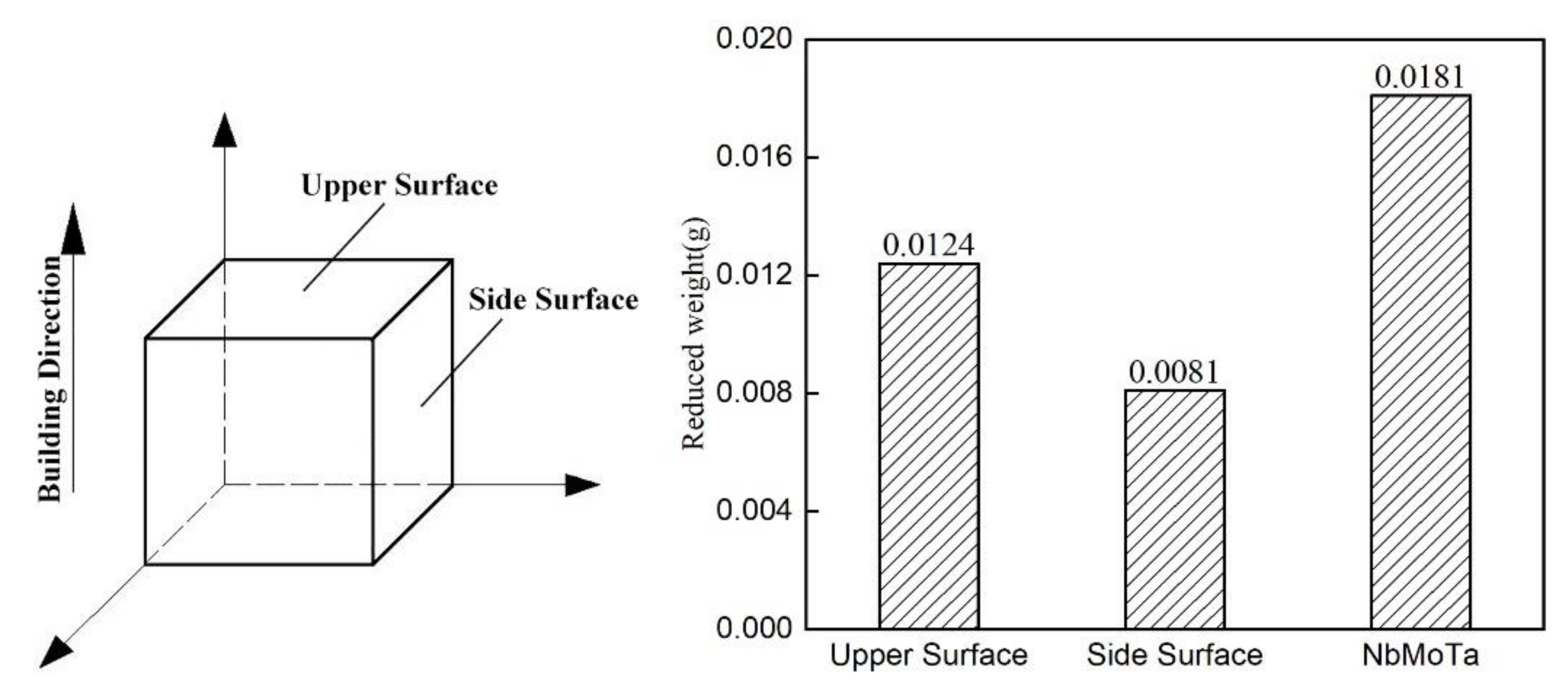

- Al2O3, as a strengthening particle, improved the wear resistance of the sample, which was higher than that of the NbMoTa multi-principal alloy formed by LDED. The resistivity of the specimens was 1.55 × 10−5 Ω × m in the parallel forming direction and 1.29 × 10−7 Ω × m in the perpendicular forming direction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Pavlov, M.; Novichenko, D.; Doubenskaia, M. Optical diagnostics of deposition of metal matrix composites by Laser Cladding. Phys. Procedia 2011, 12, 674–682. [Google Scholar] [CrossRef]

- Warren, R. Ceramic-matrix composites. Composites 1987, 18, 86–87. [Google Scholar] [CrossRef]

- Zhang, Y.; Bandyopadhyay, A. Direct fabrication of compositionally graded Ti-Al2O3 multi-material structures using Laser Engineered Net Shaping. Addit. Manuf. 2018, 21, 104–111. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W.; Shun, T.T.; Chen, S.K. Multi-principal-element alloys with improved oxidation and wear resistance for Thermal Spray Coating. Adv. Eng. Mater. 2004, 6, 74–78. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.W. Alloy design strategies and future trends in high-entropy alloys. J. Miner. Met. Mater. Soc. 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Li, D.; Chen, Z.; Huang, S.; Lu, Z.; Yan, H. WxNbMoTa refractory high-entropy alloys fabricated by Laser Cladding Deposition. Materials 2019, 12, 533. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D metal printing Technology. IFAC PapersOnLine 2016, 49, 103–110. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the use of X-ray computed tomography in assessment of 3D-Printed components. J. Nondestruct. Eval. 2020, 39. [Google Scholar] [CrossRef]

- Gadagi, B.; Lekurwale, R. A review on advances in 3D metal printing. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Li, D.; He, J.; Tian, X.; Liu, Y.; Zhang, A.; Lian, Q.; Lu, B. Additive manufacturing: Integrated fabrication of macro/microstructures. J. Mech. Eng. 2013, 49, 129–135. [Google Scholar] [CrossRef]

- Kattire, P.; Paul, S.; Singh, R.; Yan, W. Experimental characterization of laser cladding of CPM 9V on H13 tool steel for die repair applications. J. Manuf. Process. 2015, 20, 492–499. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Lin, P.; Liu, H. Microstructure and mechanical properties of functionally graded TiCp/Ti6Al4V composite fabricated by laser melting deposition. Ceram. Int. 2018, 43, 16638–16651. [Google Scholar] [CrossRef]

- Gualtieri, T.; Bandyopadhyay, A. Additive manufacturing of compositionally gradient metal-ceramic structures: Stainless steel to vanadium carbide. Mater. Des. 2018, 139, 419–428. [Google Scholar] [CrossRef]

- Sahasrabudhe, H.; Bose, S.; Bandyopadhyay, A. Laser processed calcium phosphate reinforced CoCrMo for load-bearing applications: Processing and wear induced damage evaluation. Acta Biomater. 2018, 66, 118–128. [Google Scholar] [CrossRef]

- Roy, M.; Krishna, B.V.; Bandyopadhyay, A.; Bose, S. Laser processing of bioactive tricalcium phosphate coating on titanium for load-bearing implants. Acta Biomater. 2008, 4, 324–333. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Dittrick, S.; Gualtieri, T.; Wu, J.; Bose, S. Calcium phosphate–titanium composites for articulating surfaces of load-bearing implants. J. Mech. Behav. Biomed. Mater. 2016, 57, 280–288. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Li, D.; Chen, Z.; Wang, F.; Wu, M. Comparative study of the microstructures and mechanical properties of laser metal deposited and vacuum arc melted refractory NbMoTa medium-entropy alloy. Int. J. Refract. Met. Hard Mater. 2020, 88, 105195. [Google Scholar] [CrossRef]

- Nurminen, J.; Näkki, J.; Vuoristo, P. Microstructure and properties of hard and wear resistant MMC coatings deposited by laser cladding. Int. J. Refract. Met. Hard Mater. 2009, 27, 472–478. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shahabi, H.S.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Nd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

| Materials | Laser Power (W) | Scanning Speed (mm/s) | Z-Axis Single Layer Travel (mm) | Overlap Rate (%) | Powder Mass Flows (g/min) | Volume Flow of Auxiliary Gas (L/min) | Volume Flow of ProTective Gas (L/min) |

|---|---|---|---|---|---|---|---|

| NbMoTa | 550 | 8 | 0.08 | 50 | 2.96 | 5.0 | 4.0 |

| Al2O3 | 200 | 8 | 0.08 | 50 | 1.47 | 4.0 | 4.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Chen, Z.; He, Y.; Guo, X.; Li, Q.; Ji, S.; Zhao, Y.; Li, D. High Performance NbMoTa–Al2O3 Multilayer Composite Structure Manufacturing by Laser Directed Energy Deposition. Materials 2021, 14, 1685. https://doi.org/10.3390/ma14071685

Zhang H, Chen Z, He Y, Guo X, Li Q, Ji S, Zhao Y, Li D. High Performance NbMoTa–Al2O3 Multilayer Composite Structure Manufacturing by Laser Directed Energy Deposition. Materials. 2021; 14(7):1685. https://doi.org/10.3390/ma14071685

Chicago/Turabian StyleZhang, Hang, Zihao Chen, Yaoyao He, Xin Guo, Qingyu Li, Shaokun Ji, Yizhen Zhao, and Dichen Li. 2021. "High Performance NbMoTa–Al2O3 Multilayer Composite Structure Manufacturing by Laser Directed Energy Deposition" Materials 14, no. 7: 1685. https://doi.org/10.3390/ma14071685

APA StyleZhang, H., Chen, Z., He, Y., Guo, X., Li, Q., Ji, S., Zhao, Y., & Li, D. (2021). High Performance NbMoTa–Al2O3 Multilayer Composite Structure Manufacturing by Laser Directed Energy Deposition. Materials, 14(7), 1685. https://doi.org/10.3390/ma14071685