Conceptual Study and Manufacturing of a Configurable and Weld-Free Lattice Base for Automatic Food Machines

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Selection

- Italian Decree of Ministry of 21 March 1973, with subsequent amendments, regulates packaging, containers, and tools intended to come into contact with food substances or substances for personal use;

- Italian Decree of Ministry of 27 October 2009, n. 176, for stainless steels;

- Italian Decree of Ministry of 21 December 2010, n. 258, for stainless steels;

- Regulation (EC) No. 1935/2004 of the European Parliament and of the Council of 27 October 2004 on materials and articles intended to come into contact with food;

- Commission Regulation (EU) No. 10/2011 of 14 January 2011 on plastic materials and articles intended to come into contact with food;

- EHEDG (European Hygienic Engineering and Design Group) doc. 32—materials of construction for equipment in contact with food.

2.2. PDP Methodology

2.3. Requirements and Constraints Definition

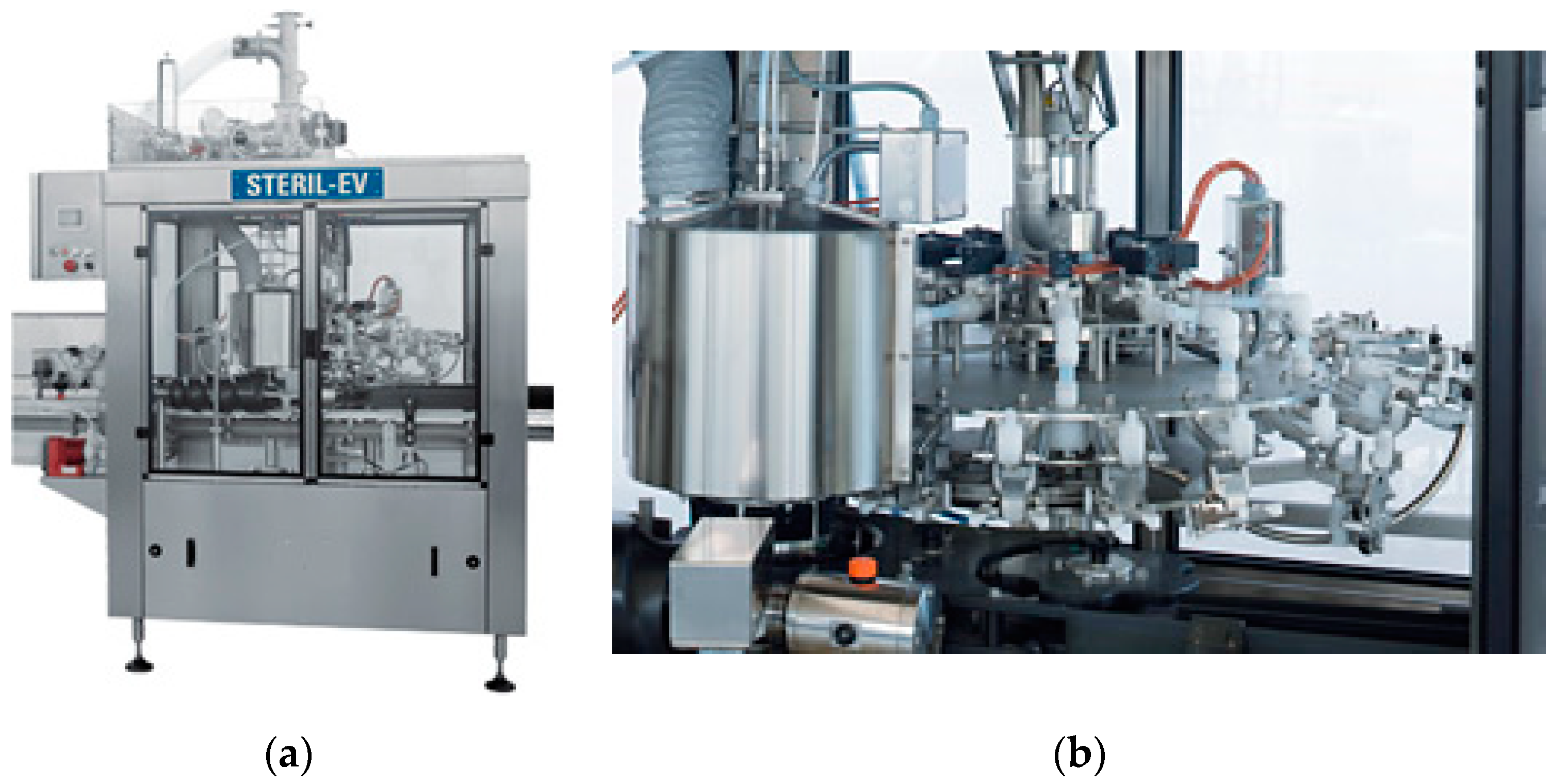

- Sustain suspended masses: the base must give support to the rotating parts of the machine that operate the rinsing/sanitizing and/or filling and/or capping of the beverage container.

- Transfer load to the ground: the base is stand-alone on the ground (i.e., not connected to any other structure) and transfers static and dynamic actions.

- Provide stiffness and vibration damping: the base must sustain masses and transfer loads, providing sufficient stiffness and vibration damping.

- Adaptability: the base must be adaptable to machines of all types (sterilizers, fillers, cappers, and combined groups) and sizes by composing the same items, with minimal dimensional variations of the latter.

- Cleanability: accessibility for maintenance and sanification in compliance with the regulations and directives listed below.

- Peculiar design: creating a completely new design, which differentiates the machine on the market.

3. Results and Discussion

3.1. Functional Decomposition

3.2. Research of Existing Concepts

- to increase the know-how regarding the product to be designed;

- to reduce the time of conceptual study thanks to the know-how acquired;

- to improve any existing solutions;

- to establish design constraints due to existing patents in order to avoid interference.

3.3. Concept Generation of a Structural Node for an Orientable Lattice Structure

- The first two exploit the components of the structure of Figure 6, but replace the L-shape structural node with a circular plate to obtain different angles between tubulars.

- The third, in addition to replacing the L-shape structural node with a plate, exploits the idea of a pivoting wheel using a double cylindrical hinge for connection with inclined rods.

3.4. Concept Selection

3.5. Detail Design

3.6. Virtual and Physical Prototyping

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Cagnon, T.; Méry, A.; Chalier, P.; Guillaume, C.; Gontard, N. Fresh food packaging design: A requirement driven approach applied to strawberries and agro-based materials. Innov. Food Sci. Emerg. Technol. 2013, 20, 288–298. [Google Scholar] [CrossRef]

- Khan, Z.H.; Khalid, A.; Iqbal, J. Towards realizing robotic potential in future intelligent food manufacturing systems. Innov. Food Sci. Emerg. Technol. 2018, 48, 11–24. [Google Scholar] [CrossRef] [Green Version]

- Lucera, A.; Costa, C.; Mastromatteo, M.; Conte, A.; Del Nobile, M.A. Influence of different packaging systems on fresh-cut zucchini (Cucurbita pepo). Innov. Food Sci. Emerg. Technol. 2010, 11, 361–368. [Google Scholar] [CrossRef]

- Pańcikiewicz, K.; Świerczyńska, A.; Hućko, P.; Tumidajewicz, M. Laser Dissimilar Welding of AISI 430F and AISI 304 Stainless Steels. Materials 2020, 13, 4540. [Google Scholar] [CrossRef] [PubMed]

- Landowski, M.; Świerczyńska, A.; Rogalski, G.; Fydrych, D. Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels. Materials 2020, 13, 2930. [Google Scholar] [CrossRef] [PubMed]

- EHEDG (European Hygienic Engineering Design Group). Doc 9—Welding Stainless Steel to Meet Hygienic Requirements; EHEDG: Brussels, Belgium, 1993. [Google Scholar]

- Pahl, G.; Beitz, W. Engineering Design: A Systematic Approach; Springer: London, UK, 1996. [Google Scholar]

- Ulrich, K. The role of product architecture in the manufacturing firm. Res. Policy 1995, 24, 419–440. [Google Scholar] [CrossRef] [Green Version]

- Malmqvist, J. Improved function-means trees by inclusion of design history information. J. Eng. Des. 1997, 8, 107–117. [Google Scholar] [CrossRef]

- Shimomura, Y.; Yoshioka, M.; Takeda, H.; Umeda, Y.; Tomiyama, T. Representation of design object based on the functional evolution process model. J. Mech. Des. 1998, 120, 221–229. [Google Scholar] [CrossRef]

- Yu, T.; Yassine, A.A.; Goldberg, D.E. An information theoretic method for developing modular architectures using genetic algorithms. Res. Eng. Des. 2007, 18, 91–109. [Google Scholar] [CrossRef]

- Sanaei, R.; Otto, K.N.; Hölttä-Otto, K.; Wood, K.L. An algorithmic approach to system modularization under constraints. In Proceedings of the 19th International DSM Conference, Helsinki, Finland, 11–13 September 2017; Aalto University Design Factory: Aalto, Finland, 2017. [Google Scholar]

- Stone, R.B.; Wood, K.L.; Crawford, R.H. A heuristic method for identifying modules for product architectures. Des. Stud. 2000, 21, 5–31. [Google Scholar] [CrossRef]

- Hospido, A.; Vazquez, M.E.; Cuevas, A.; Feijoo, G.; Moreira, M.T. Environmental assessment of canned tuna manufacture with a life-cycle perspective. Resour. Conserv. Recycl. 2006, 47, 56–72. [Google Scholar] [CrossRef]

- Davis, S.; Casson, J.W.; Masey, R.J.M.; King, M.; Gray, J.O.; Caldwell, D.G. Robot prototyping in the design of food processing machinery. Ind. Robot. 2007, 34, 135–141. [Google Scholar] [CrossRef]

- Dai, J.S.; Caldwell, D.G. Origami-based robotic paper-and-board packaging for food industry. Trends Food Sci. Technol. 2010, 21, 153–157. [Google Scholar] [CrossRef]

- Mahalik, N.P.; Nambiar, A.N. Trends in food packaging and manufacturing systems and technology. Trends Food Sci. Technol. 2010, 21, 117–128. [Google Scholar] [CrossRef]

- Bigliardi, B.; Galati, F. Models of adoption of open innovation within the food industry. Trends Food Sci. Technol. 2013, 30, 16–26. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E.; Galati, F. Open innovation and supply chain management in food machinery supply chain: A case study. Int. J. Eng. Sci. Tech. 2010, 2, 244–255. [Google Scholar] [CrossRef] [Green Version]

- Formentini, G.; Favi, C.; Pirondi, A.; Giuliese, G. Engineering design in food-packaging industry: The case study of a tuna canning machine. Procedia CIRP 2021, in press. [Google Scholar]

- Toma, G.; Vettori, M.; Pirondi, A.; Moroni, F.; Zerbini, G.; Rocchi, F. Concezione e realizzazione di un basamento innovativo per una macchina sterilizzatrice bottiglie. In Proceedings of the Atti Convegno AIAS 2011, Palermo, Italia, 7–10 September 2011. [Google Scholar]

- UNI EN 1672-2. Machines for the Food Industry—Basic Concepts—Safety and Hygiene Requirements; Ente Italiano di Normazione: Milan, Italy, 2009. [Google Scholar]

- UNI EN ISO 14159. Safety of Machinery—Requirements Relating to Hygiene for the Design of Machinery; Ente Italiano di Normazione: Milan, Italy, 2002. [Google Scholar]

- Pirondi, A.; Dazzi, F.; Zomparelli, L. Adhesive joint use and aging in food machinery: A case-study on beverage filling systems. Int. J. Adhes. Adhes. 2021. [Google Scholar] [CrossRef]

- Rocchi, F.; Pirondi, A.; Moroni, F.; Vettori, M. Operating Machine. Patent EP2565126A1-ITGE20110098A1, 9 February 2011. [Google Scholar]

- Ulrich, K.T.; Eppinger, S.D. Product Design and Development, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2011. [Google Scholar]

- Chakrabarti, A.; Morgenstern, S.; Knaab, H. Identification and application of requirements and their impact on the design process: A protocol study. Res. Eng. Des. 2004, 15, 22–39. [Google Scholar] [CrossRef]

- European Patent Office. Available online: www.epo.org (accessed on 18 February 2021).

- Sistema Vestrut. Available online: https://www.vestrut.it/it/sistema-vestrut (accessed on 18 February 2021).

- Sistema Cubotto. Available online: https://www.vestrut.it/it/sistema-cubotto (accessed on 18 February 2021).

| Lap Shear Strength * | Tensile Strength ** | Young’s Modulus |

|---|---|---|

| 23 | 32 | 1718 |

| Module | Design Option 1 | Design Option 2 | Design Option 3 |

|---|---|---|---|

| Module 1 | Plate | Lattice | Skin + stringers |

| Module 2 | Monobloc | Lattice | Monocoque |

| Concept Name | Concept Sketch | Concept Description |

|---|---|---|

| (A) |  | Joint consisting of a perforated circular base that acts as a guide for two rotating sliders. Once the sliders have reached the positions to form the desired opening angle, they are fixed, each with two pins/fasteners, to the base of the node. |

| (B) |  | Evolution of the previous solution. The circular base is no longer perforated, but equipped with a rail that is also circular, on which two cursors can rotate to reach the desired opening angle. The fastening takes place by means of pins, which bind the sliders to the guide, which is drilled in the radial direction. |

| (C) |  | The solution provides a base plate on which two further plates are fixed by means of pins and screws, connected in turn to the rods. An additional element is fixed to the pin to hook the inclined rods. This last solution for hooking the inclined rods can be easily extended to concepts A and B. |

| Concept Name | Concept Sketch | Concept Description |

|---|---|---|

| (A) |  | The solution provides a cube on which seats are manufactured to host several ball joints, which allow any shape of the base of the structure and inclination of the rods. The ball joint is fixed as in Figure 6 by a flange fastened to the cube and/or bonded with a structural adhesive. |

| (B) |  | It consists of a cylindrical block with semicircular grooves where spheres (in red) are positioned. The locking of the spheres on the groove takes place by means of a casing. The casing has also the function of sealing the inside and making the joint more hygienic. The ring is closed at the ends by two plates. With respect to the patent PR2013A000019 shown in Appendix A, the spheres are kept in position by adhesive bonding or welding. |

| (C) |  | It consists of three overlapping machined plates with hemispherical seats for commercial spheres with a threaded hole to insert a stud. The plates have cavities that accommodate a sphere for connection with both the horizontal and the inclined rods. The entire system of plates and spheres is enclosed within a casing that seals the node. |

| Criterion | Ref. Concept (Figure 6) | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|

| Adaptability | 0 | + | + | + | + | + | + |

| Modularity | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Cleanability | 0 | 0 | 0 | 0 | + | + | + |

| Design | 0 | 0 | 0 | 0 | 0 | + | + |

| Manufacturing | 0 | 0 | 0 | 0 | + | − | − |

| Assembly | 0 | 0 | 0 | + | − | − | + |

| Total + | 0 | 1 | 1 | 2 | 3 | 3 | 4 |

| Total 0 | 5 | 5 | 5 | 4 | 2 | 1 | 1 |

| Total − | 0 | 0 | 0 | 0 | 1 | 2 | − |

| Sum | 0 | 1 | 1 | 2 | 2 | 1 | 3 |

| Ranking | 6 | 4 | 4 | 2 | 3 | 5 | 1 |

| Criterion | Weight | C | D | F |

|---|---|---|---|---|

| Cleanability | 0.3 | 3 | 4 | 4 |

| Design | 0.1 | 3 | 4 | 5 |

| Manufacturing | 0.2 | 3 | 4 | 2 |

| Assembly | 0.4 | 3 | 2 | 3 |

| Sum | 1 | 3 | 3.1 | 3.2 |

| Ranking | - | 3 | 2 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pirondi, A.; Liberini, A.; Rocchi, F. Conceptual Study and Manufacturing of a Configurable and Weld-Free Lattice Base for Automatic Food Machines. Materials 2021, 14, 1692. https://doi.org/10.3390/ma14071692

Pirondi A, Liberini A, Rocchi F. Conceptual Study and Manufacturing of a Configurable and Weld-Free Lattice Base for Automatic Food Machines. Materials. 2021; 14(7):1692. https://doi.org/10.3390/ma14071692

Chicago/Turabian StylePirondi, Alessandro, Andrea Liberini, and Flavio Rocchi. 2021. "Conceptual Study and Manufacturing of a Configurable and Weld-Free Lattice Base for Automatic Food Machines" Materials 14, no. 7: 1692. https://doi.org/10.3390/ma14071692

APA StylePirondi, A., Liberini, A., & Rocchi, F. (2021). Conceptual Study and Manufacturing of a Configurable and Weld-Free Lattice Base for Automatic Food Machines. Materials, 14(7), 1692. https://doi.org/10.3390/ma14071692