Exceptional Mechanical Properties and Heat Resistance of Photocurable Bismaleimide Ink for 3D Printing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of BDM-DDM-GMA Oligomer

2.3. Preparation of Photocurable BDM Inks for 3D Printing

2.3.1. Preparation of Photocurable BDM Inks

2.3.2. 3D Printing using Commercial and BDM Inks

2.4. Characterization Techniques

3. Results and Discussion

3.1. Synthesis of the Photosensitive BDM-DDM-GMA Oligomer

3.2. Rheological Characterization

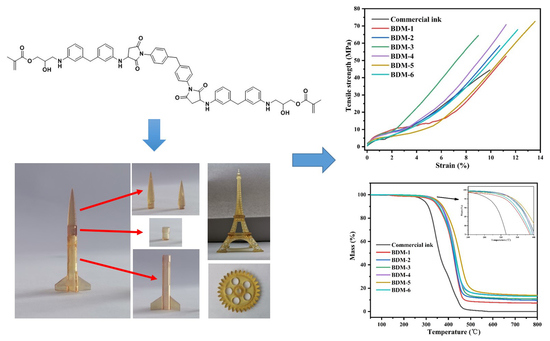

3.3. Mechanical Properties of 3D-Printed Samples

3.4. Thermal Properties of 3D-Printed Samples

3.5. Fabrication of Objects with SLA 3D Printer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of additive manufacturing: Overview of 4D and 3D printed smart and advanced materials and their applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Kang, J.; Shangguan, H.; Deng, C.; Hu, Y.; Yi, J.; Wang, X.; Zhang, X.; Huang, T. Additive manufacturing-driven mold design for castings. Addit. Manuf. 2018, 22, 472–478. [Google Scholar] [CrossRef]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in Polyimide-Based Materials for Space Applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef]

- Egan, P.F. Integrated Design Approaches for 3D Printed Tissue Scaffolds: Review and Outlook. Materials 2019, 12, 2355. [Google Scholar] [CrossRef] [Green Version]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef] [PubMed]

- Tasolamprou, A.C.; Mentzaki, D.; Viskadourakis, Z.; Economou, E.N.; Kafesaki, M.; Kenanakis, G. Flexible 3D Printed Conductive Metamaterial Units for Electromagnetic Applications in Microwaves. Materials 2020, 13, 3879. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Katti, P.; Kumar, S.; Bose, S. Macroporous epoxy-carbon fiber structures with a sacrificial 3D printed polymeric mesh suppresses electromagnetic radiation. Chem. Eng. J. 2019, 357, 384–394. [Google Scholar] [CrossRef]

- Gong, H.; Beauchamp, M.; Perry, S.; Woolley, A.T.; Nordin, G.P. Optical approach to resin formulation for 3D printed microfluidics. RSC Adv. 2015, 5, 106621–106632. [Google Scholar] [CrossRef] [Green Version]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Gurr, M.; Hofmann, D.; Ehm, M.; Thomann, Y.; Kübler, R.; Mülhaupt, R. Acrylic Nanocomposite Resins for Use in Stereolithography and Structural Light Modulation Based Rapid Prototyping and Rapid Manufacturing Technologies. Adv. Funct. Mater. 2008, 18, 2390–2397. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, X.; Lin, G.; Xi, L.; Yang, Y.; Lei, D.; Dong, H.; Su, J.; Cui, Y.; Liu, X. Preparation, Characterization and Application of UV-Curable Flexible Hyperbranched Polyurethane Acrylate. Polymers 2017, 9, 552. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barkane, A.; Platnieks, O.; Jurinovs, M.; Gaidukovs, S. Thermal stability of UV-cured vegetable oil epoxidized acrylate-based polymer system for 3D printing application. Polym. Degrad. Stabil. 2020, 181, 109347. [Google Scholar] [CrossRef]

- Dall’Argine, C.; Hochwallner, A.; Klikovits, N.; Liska, R.; Stampf, J.; Sangermano, M. Hot-Lithography SLA-3D Printing of Epoxy Resin. Macromol. Mater. Eng. 2020, 305, 2000325. [Google Scholar] [CrossRef]

- Duoss, E.B.; Weisgraber, T.H.; Hearon, K.; Zhu, C.; Small, W.; Metz, T.R.; Vericella, J.J.; Barth, H.D.; Kuntz, J.D.; Maxwell, R.S.; et al. Three-Dimensional Printing of Elastomeric, Cellular Architectures with Negative Stiffness. Adv. Funct. Mater. 2014, 24, 4905–4913. [Google Scholar] [CrossRef]

- Weng, Z.; Zhou, Y.; Lin, W.; Senthil, T.; Wu, L. Structure-property relationship of nano enhanced stereolithography resin for desktop SLA 3D printer. Compos. Part A Appl. Sci. Manuf. 2016, 88, 234–242. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, Y.; Jiao, T.; Lu, G.; Liu, J. Photocurable modification of inorganic fillers and their application in photopolymers for 3D printing. Polym. Chem. UK 2019, 10, 6350–6359. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Enhanced mechanical properties of 3D printed graphene-polymer composite lattices at very low graphene concentrations. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105726. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, R.; Huang, W.; Zhao, W.; Wang, G. Aliphatic silicone-epoxy based hybrid photopolymers applied in stereolithography 3D printing. Polym. Adv. Technol. 2020. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, J.; Wu, L.; Weng, Z.; Zheng, L.; Peng, S.; Zhang, X. High performance POSS filled nanocomposites prepared via UV-curing based on 3D stereolithography printing. Compos. Part A Appl. Sci. Manuf. 2019, 117, 276–286. [Google Scholar] [CrossRef]

- Guo, Y.; Ji, Z.; Zhang, Y.; Wang, X.; Zhou, F. Solvent-free and photocurable polyimide inks for 3D printing. J. Mater. Chem. A 2017, 5, 16307–16314. [Google Scholar] [CrossRef]

- Borrello, J.; Nasser, P.; Iatridis, J.C.; Costa, K.D. 3D printing a mechanically-tunable acrylate resin on a commercial DLP-SLA printer. Addit. Manuf. 2018, 23, 374–380. [Google Scholar] [CrossRef]

- Uzcategui, A.C.; Muralidharan, A.; Ferguson, V.L.; Bryant, S.J.; McLeod, R.R. Understanding and Improving Mechanical Properties in 3D printed Parts Using a Dual-Cure Acrylate-Based Resin for Stereolithography. Adv. Eng. Mater. 2018, 20, 1800876. [Google Scholar] [CrossRef] [PubMed]

- Iredale, R.J.; Ward, C.; Hamerton, I. Modern advances in bismaleimide resin technology: A 21st century perspective on the chemistry of addition polyimides. Prog. Polym. Sci. 2017, 69, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Pham, Q.; Yang, C.; Chern, C.; Musuvadhi Babulal, L.; Seenivasan, M.; Brunklaus, G.; Placke, T.; Hwang, B.; Winter, M. Study of electrochemical performance and thermal property of LiNi0.5Co0.2Mn0.3O2 cathode materials coated with a novel oligomer additive for high-safety lithium-ion batteries. Chem. Eng. J. 2021, 405, 126727. [Google Scholar] [CrossRef]

- Sipaut, C.S.; Padavettan, V.; Rahman, I.A.; Mansa, R.F.; Dayou, J.; Jafarzadeh, M. An optimized preparation of bismaleimide-diamine co-polymer matrices. Polym. Adv. Technol. 2014, 25, 673–683. [Google Scholar] [CrossRef]

- Zhou, X.; Qiu, S.; Liu, J.; Zhou, M.; Cai, W.; Wang, J.; Chu, F.; Xing, W.; Song, L.; Hu, Y. Construction of porous g-C3N4@PPZ tubes for high performance BMI resin with enhanced fire safety and toughness. Chem. Eng. J. 2020, 401, 126094. [Google Scholar] [CrossRef]

- Wu, G.; Kou, K.; Chao, M.; Zhuo, L.; Zhang, J.; Li, N. Preparation and characterization of bismaleimide-triazine/epoxy interpenetrating polymer networks. Thermochim. Acta 2012, 537, 44–50. [Google Scholar] [CrossRef]

- Ji, L.; Gu, A.; Liang, G.; Yuan, L. Novel modification of bismaleimide-triazine resin by reactive hyperbranched polysiloxane. J. Mater. Sci. 2010, 45, 1859–1865. [Google Scholar] [CrossRef]

- Li, Q.; Hu, C.; Ye, W.; Gu, H.; Huang, P. Study on Properties of Phenol Type Epoxy Resin Modified by Bismaleimide. J. Aeronaut. Mater. 2008, 28, 82–86. [Google Scholar]

- Thomas, D.G. Transport characteristics of suspension’: Viii. a note on the viscosity of newtonian suspensions of uniform spherical particles. J. Colloid Sci. 1965, 20, 267–277. [Google Scholar] [CrossRef]

- Kim, Y.C.; Hong, S.; Sun, H.; Kim, M.G.; Choi, K.; Cho, J.; Choi, H.R.; Koo, J.C.; Moon, H.; Byun, D.; et al. UV-curing kinetics and performance development of in situ curable 3D printing materials. Eur. Polym. J. 2017, 93, 140–147. [Google Scholar] [CrossRef]

- Mireya Matos Ruiz, J.Y.C.A. New waterborone epoxy coatings based on cellulose nanofillers. Macromol. Symp. 2001, 169, 211–222. [Google Scholar] [CrossRef]

- Ding, R.; Du, Y.; Goncalves, R.B.; Francis, L.F.; Reineke, T.M. Sustainable near UV-curable acrylates based on natural phenolics for stereolithography 3D printing. Polym. Chem. UK 2019, 10, 1067–1077. [Google Scholar] [CrossRef]

- Chen, J.; Ober, C.K.; Poliks, M.D.; Zhang, Y.; Wiesner, U.; Cohen, C. Controlled degradation of epoxy networks: Analysis of crosslink density and glass transition temperature changes in thermally reworkable thermosets. Polymer 2004, 45, 1939–1950. [Google Scholar] [CrossRef]

- Cheng, Q.; Zheng, Y.; Wang, T.; Sun, D.; Lin, R. Yellow resistant photosensitive resin for digital light processing 3D printing. J. Appl. Polym. Sci. 2020, 137, 48369. [Google Scholar] [CrossRef]

- Ramírez-Soria, E.; Bonilla-Cruz, J.; Flores-Amaro, M.G.; García, V.J.; Lara-Ceniceros, T.E.; Longoria-Rodríguez, F.E.; Elizondo, P.; Advincula, R.C. On the Effect of Ultralow Loading of Microwave-Assisted Bifunctionalized Graphene Oxide in Stereolithographic 3D-Printed Nanocomposites. ACS Appl. Mater. Inter. 2020, 12, 49061–49072. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zheng, L.; Peng, S.; Miao, J.; Zhong, J.; Wu, L.; Weng, Z. Structure-Property Relationship of Stereolithography Resins Containing Polysiloxane Core-Shell Nanoparticles. ACS Appl. Mater. Inter. 2020, 12, 4917–4926. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Li, L.; Yan, B.; Bao, J.; Zhang, A. Acrylate-based photosensitive resin for stereolithographic three-dimensional printing. J. Appl. Polym. Sci. 2019, 136, 47487. [Google Scholar] [CrossRef]

| Materials | Commercial Ink | BDM-1 | BDM-2 | BDM-3 | BDM-4 | BDM-5 | BDM-6 |

|---|---|---|---|---|---|---|---|

| BDM-DDM-GMA, wt% | - | 5.0 | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 |

| YYUV-5, wt% | 30.0 | 27.5 | 25.0 | 22.5 | 20.0 | 17.5 | 15.0 |

| YYUV-4, wt% | 30.0 | 27.5 | 25.0 | 22.5 | 20.0 | 17.5 | 15.0 |

| YYUV-3, wt% | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| YYUV-2, wt% | 13.0 | 13.0 | 13.0 | 13.0 | 13.0 | 13.0 | 13.0 |

| YYUV-1, wt% | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| HEMA, wt% | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| HPMA, wt% | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| TPO, wt% | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Irgacure 184, wt% | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Solvents and Active Diluents | DMF | Toluene | THF | HEMA | HPMA | CTFA | TMPTA | IBOA |

|---|---|---|---|---|---|---|---|---|

| Solubility a | ++ | ++ | ++ | +- | +- | +- | +- | +- |

| Samples | Tensile Strength (MPa) | Elongation at Break (%) | Flexural Strength (MPa) | Flexural Modulus (MPa) | Strain (%) |

|---|---|---|---|---|---|

| Commercial ink | 44.3 ± 0.5 | 9.9 ± 0.6 | 50.1 ± 1.2 | 1265.7 ± 57.5 | 2.4 ± 0.2 |

| BDM-1 | 52.5 ± 0.7 | 11.2 ± 1.1 | 56.9 ± 2.2 | 1569.3 ± 45.3 | 1.8 ± 0.2 |

| BDM-2 | 58.6 ± 0.3 | 10.7 ± 0.4 | 80.3 ± 1.7 | 2998.9 ± 99.2 | 2.8 ± 0.1 |

| BDM-3 | 64.5 ± 2.2 | 9.0 ± 0.5 | 84.7 ± 0.9 | 3227.6 ± 76.1 | 2.1 ± 0.3 |

| BDM-4 | 70.9 ± 1.0 | 11.2 ± 0.7 | 115.5 ± 3.3 | 3634.5 ± 102.0 | 4.2 ± 0.3 |

| BDM-5 | 72.6 ± 1.3 | 13.6 ± 1.4 | 117.4 ± 4.1 | 4468.8 ± 62.7 | 4.0 ± 0.4 |

| BDM-6 | 67.9 ± 0.9 | 12.2 ± 0.9 | 101.6 ± 2.6 | 3466.2 ± 120.9 | 5.5 ± 0.2 |

| Samples | Tg (°C) | E′ at 35 °C (MPa) | E′ at Tg + 50 °C (MPa) | νe (× 102 mol m−3) |

|---|---|---|---|---|

| Commercial ink | 75 | 1107.6 | 94.9 | 0.96 |

| BDM-1 | 119 | 1835.6 | 119.7 | 1.09 |

| BDM-2 | 125 | 2464.2 | 133.1 | 1.19 |

| BDM-3 | 133 | 2931.1 | 160.7 | 1.41 |

| BDM-4 | 140 | 3570.5 | 197.9 | 1.71 |

| BDM-5 | 155 | 3625.0 | 216.5 | 1.82 |

| BDM-6 | 138 | 3133.3 | 180.9 | 1.57 |

| Samples | T-5% (°C) | T-50% (°C) | Tmax (°C) | CR (%) |

|---|---|---|---|---|

| Commercial ink | 287.5 | 357.6 | 342.5 | 0 |

| BDM-1 | 329.7 | 421.7 | 426.7 | 7.3 |

| BDM-2 | 346.4 | 423.7 | 424.5 | 9.7 |

| BDM-3 | 348.3 | 431.5 | 434.0 | 10.9 |

| BDM-4 | 348.8 | 430.9 | 429.4 | 13.4 |

| BDM-5 | 351.5 | 449.6 | 451.9 | 14.0 |

| BDM-6 | 336.9 | 429.4 | 426.9 | 13.1 |

| Samples | Tensile Strength (MPa) | Elongation at Break (%) | T-5% (°C) | Tmax (°C) | CR (%) | Reference |

|---|---|---|---|---|---|---|

| Polyimide | 24.9 | 5.4 | 351.2 | 434.6 | 25.2 | [22] |

| Calcium sulfate whiskers filling | 29.0 | 4.8 | 133.7 | 138.6 | 77.2 | [18] |

| Aliphatic silicone-epoxy | 32.9 | 6.0 | 359.4 | 418.6 | 7.5 | [20] |

| Aromatic polyurethane acrylates | 33.2 | - | 264.7 | 450.3 | 4.2 | [37] |

| Hyperbranched polyurethane acrylate | 9.6 | 8.4 | 225.6 | 330.7 | 0 | [13] |

| Graphene oxide filling | 61.9 | 7.2 | 234.1 | - | - | [38] |

| Epoxy-based resin | 55.0 | 12.1 | - | - | - | [39] |

| SiO2 filling | 53.8 | 2.7 | - | - | - | [17] |

| Acrylate-based photosensitive resin | 44.9 | 5.5 | - | - | - | [40] |

| BDM-5 | 72.6 | 13.6 | 351.5 | 451.9 | 14.0 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, W.; Lin, Q.; Qu, B.; Zheng, Y.; Liu, X.; Li, W.; Zhao, X.; Chen, S.; Zhuo, D. Exceptional Mechanical Properties and Heat Resistance of Photocurable Bismaleimide Ink for 3D Printing. Materials 2021, 14, 1708. https://doi.org/10.3390/ma14071708

Hua W, Lin Q, Qu B, Zheng Y, Liu X, Li W, Zhao X, Chen S, Zhuo D. Exceptional Mechanical Properties and Heat Resistance of Photocurable Bismaleimide Ink for 3D Printing. Materials. 2021; 14(7):1708. https://doi.org/10.3390/ma14071708

Chicago/Turabian StyleHua, Wenqiang, Qilang Lin, Bo Qu, Yanyu Zheng, Xiaoying Liu, Wenjie Li, Xiaojing Zhao, Shaoyun Chen, and Dongxian Zhuo. 2021. "Exceptional Mechanical Properties and Heat Resistance of Photocurable Bismaleimide Ink for 3D Printing" Materials 14, no. 7: 1708. https://doi.org/10.3390/ma14071708

APA StyleHua, W., Lin, Q., Qu, B., Zheng, Y., Liu, X., Li, W., Zhao, X., Chen, S., & Zhuo, D. (2021). Exceptional Mechanical Properties and Heat Resistance of Photocurable Bismaleimide Ink for 3D Printing. Materials, 14(7), 1708. https://doi.org/10.3390/ma14071708