Vegetable Fillers and Rapeseed Oil-Based Polyol as Natural Raw Materials for the Production of Rigid Polyurethane Foams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials for Polyurethane Foams Preparation

2.2. Synthesis of Rigid Polyurethane Foams

2.3. Characterization of Raw Materials and Rigid Polyurethane Foams

3. Results

3.1. Analysis of the Natural Raw Materials and the Processing Parameters of the Used Compositions

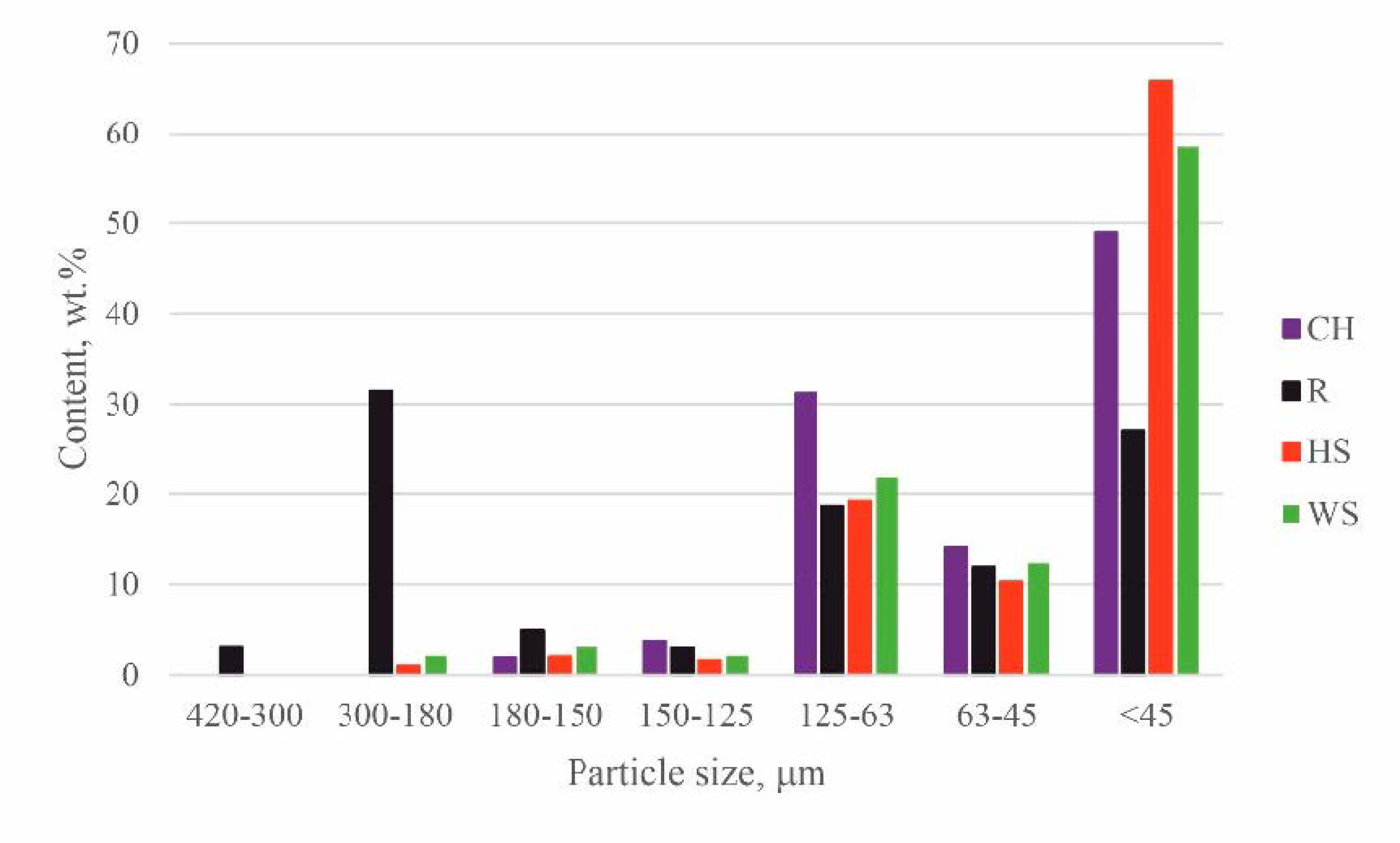

3.1.1. Sieve Analysis of the Natural Fillers

3.1.2. Chemical Composition of the Natural Fillers

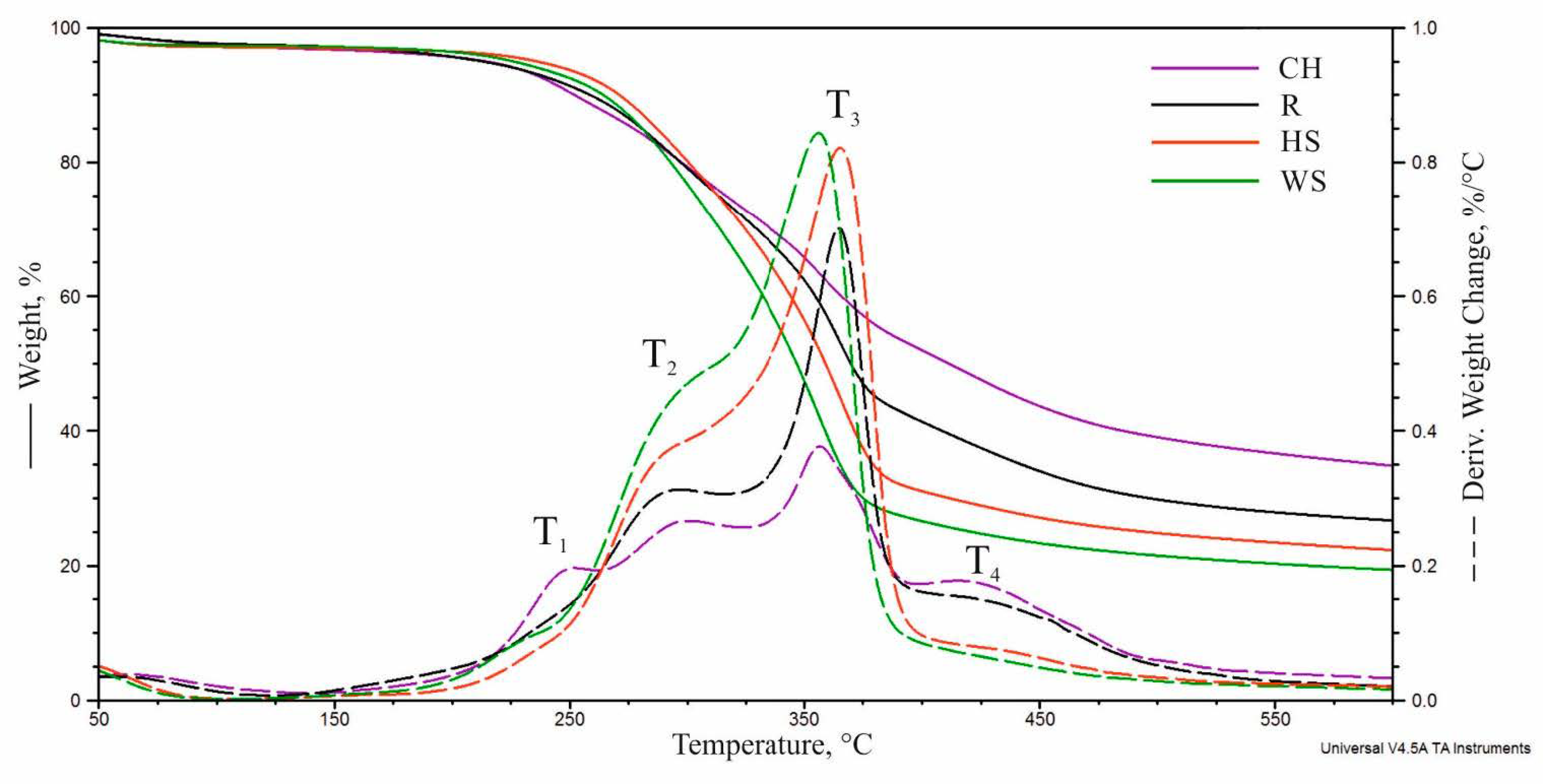

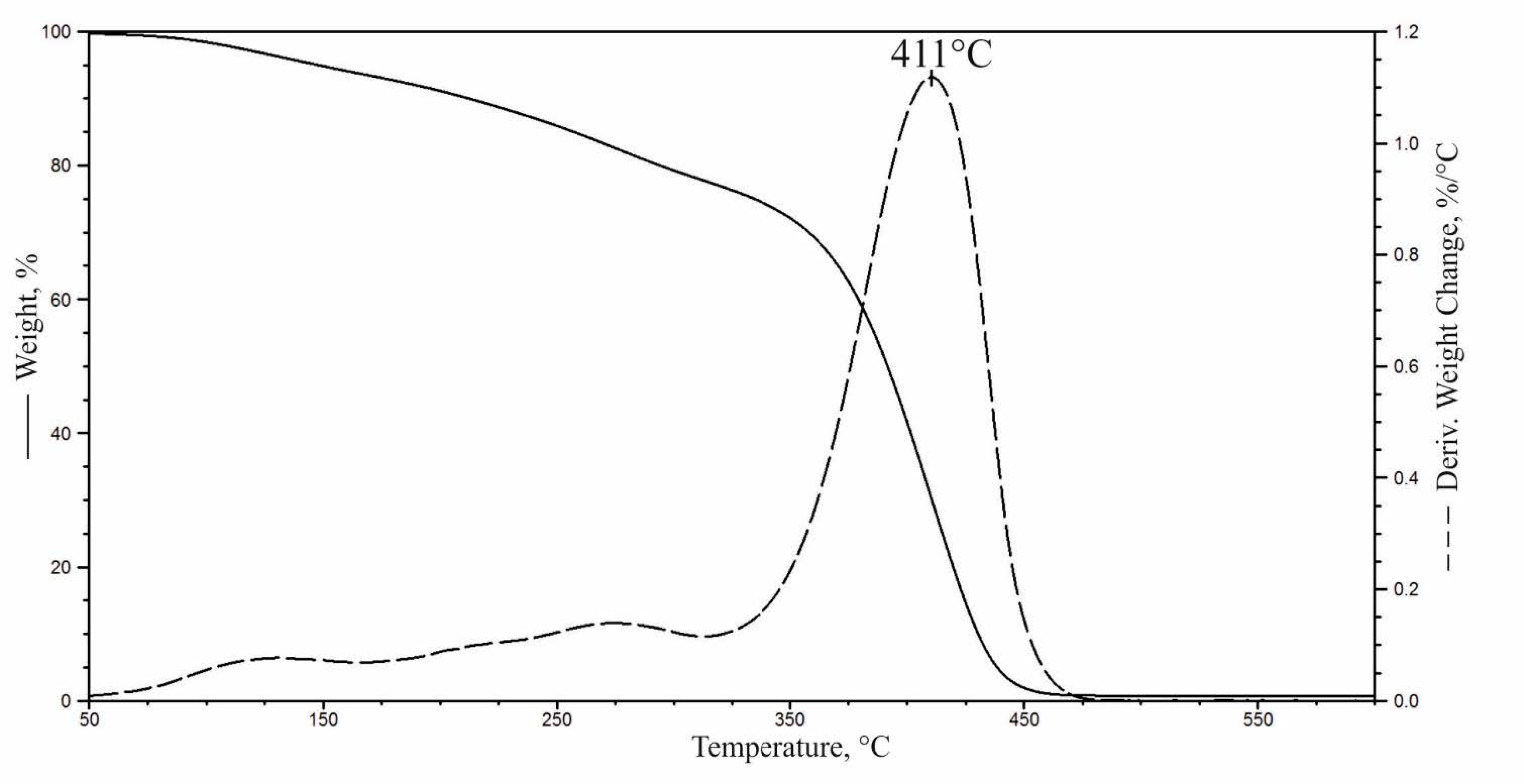

3.1.3. Thermal Analysis of the Natural Fillers

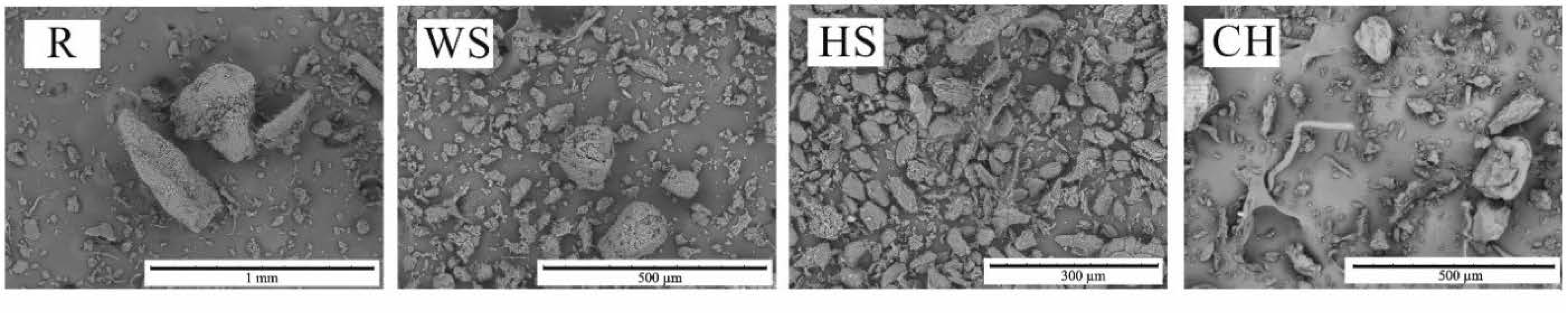

3.1.4. Analysis of the Filler Particles’ Surface Morphology

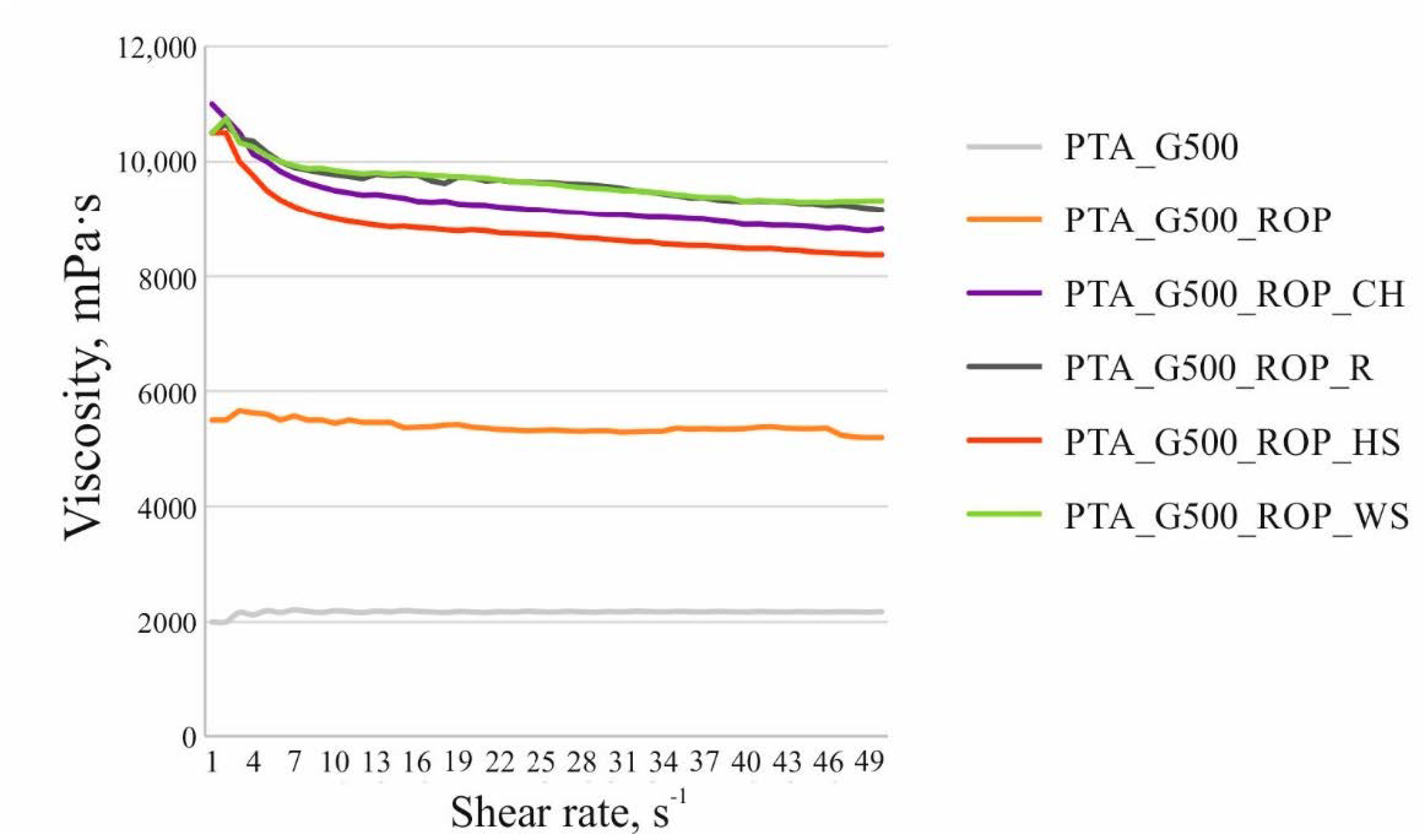

3.1.5. Analysis of Viscosity of the Polyols with the Natural Filler Particles

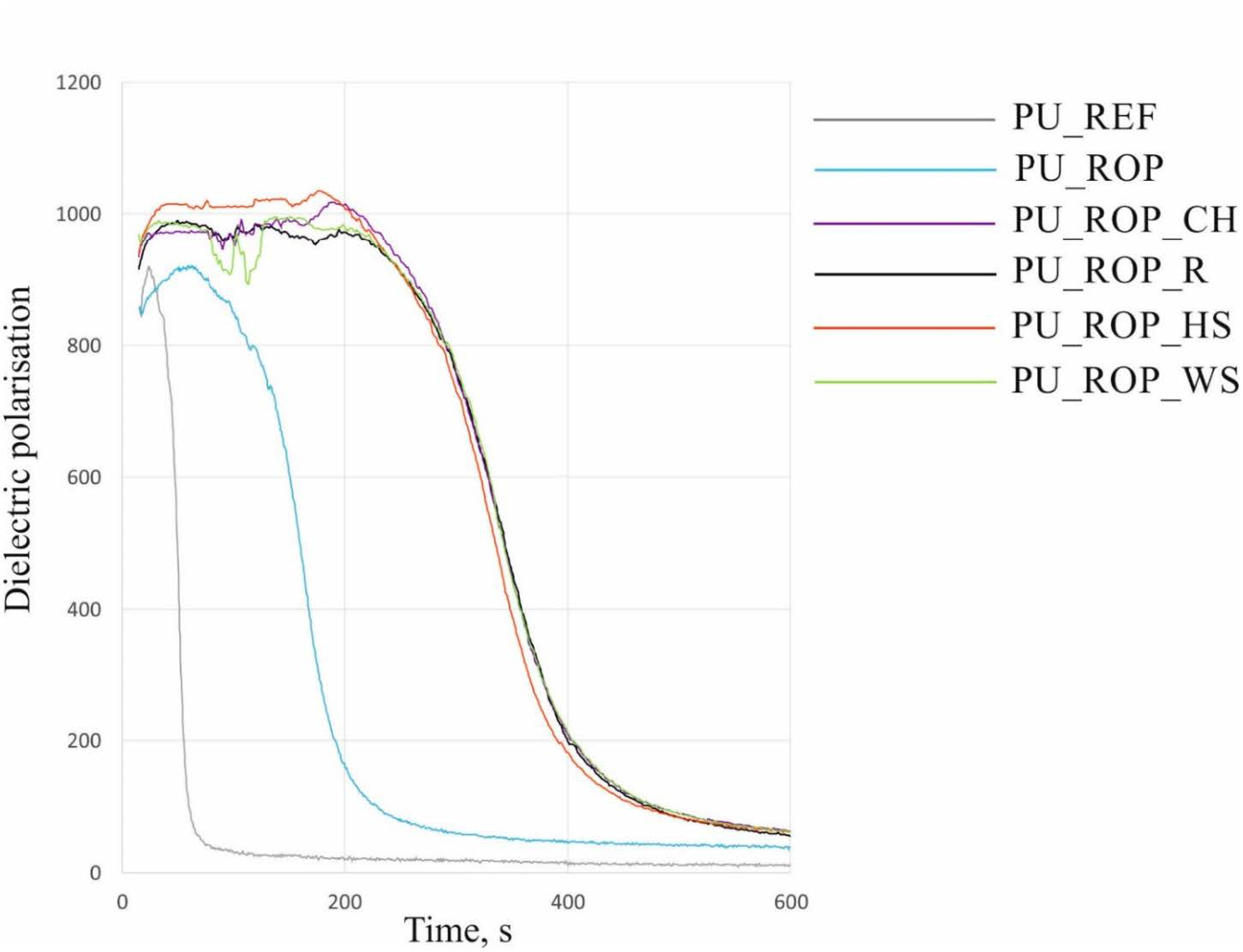

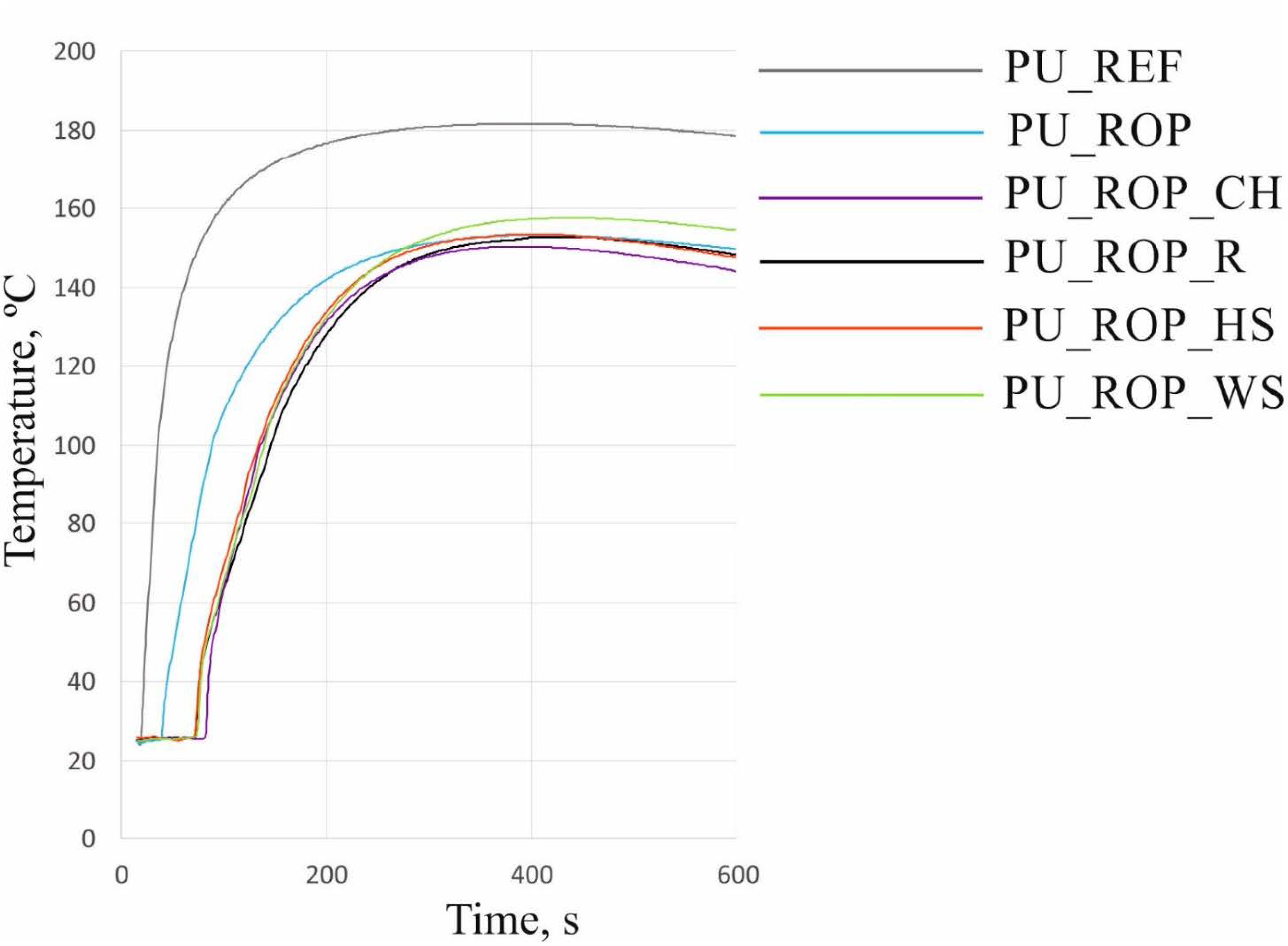

3.1.6. Analysis of the Foaming Process

3.2. Cell Structure and Properties of Rigid Polyurethane Foams

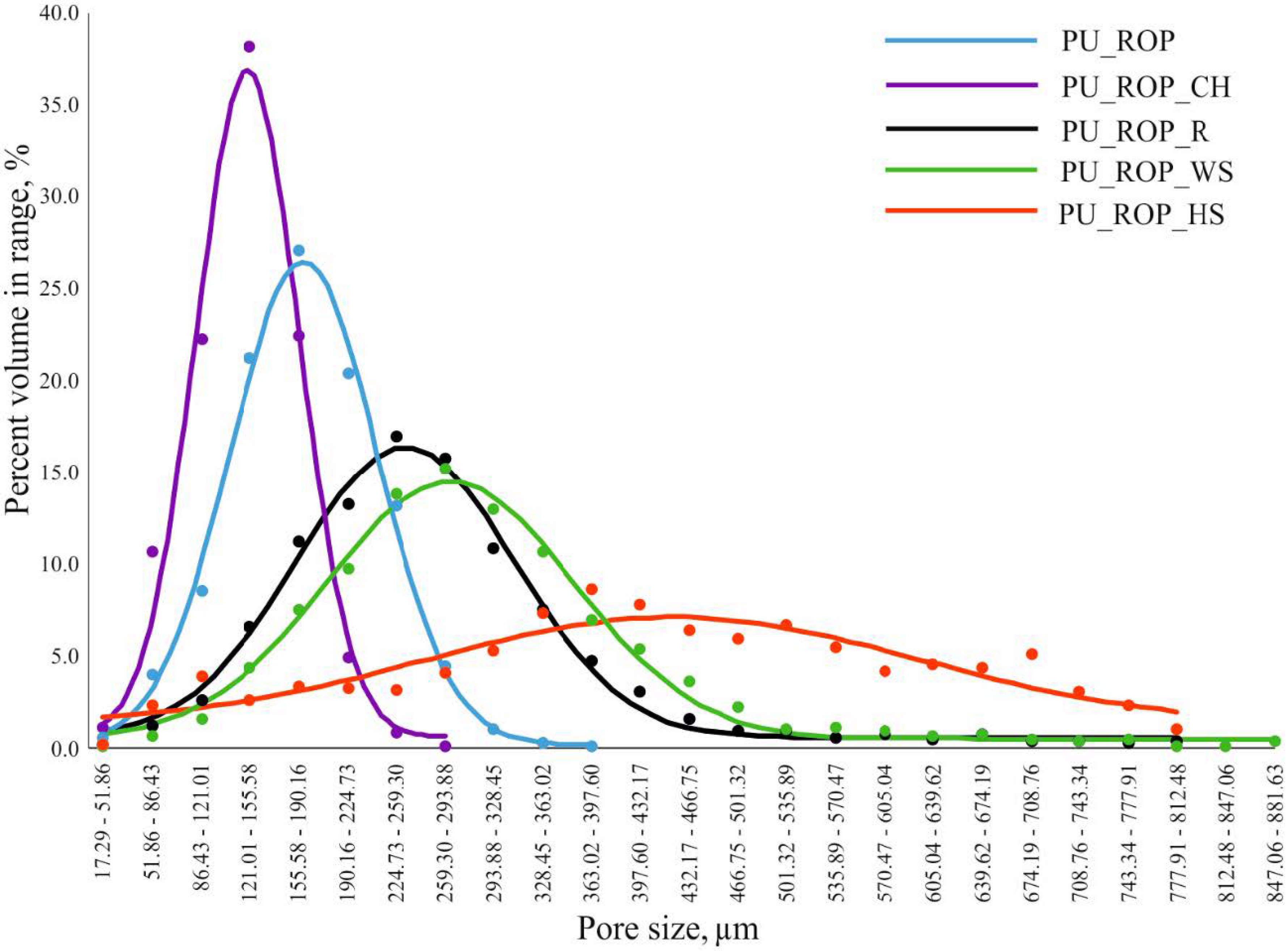

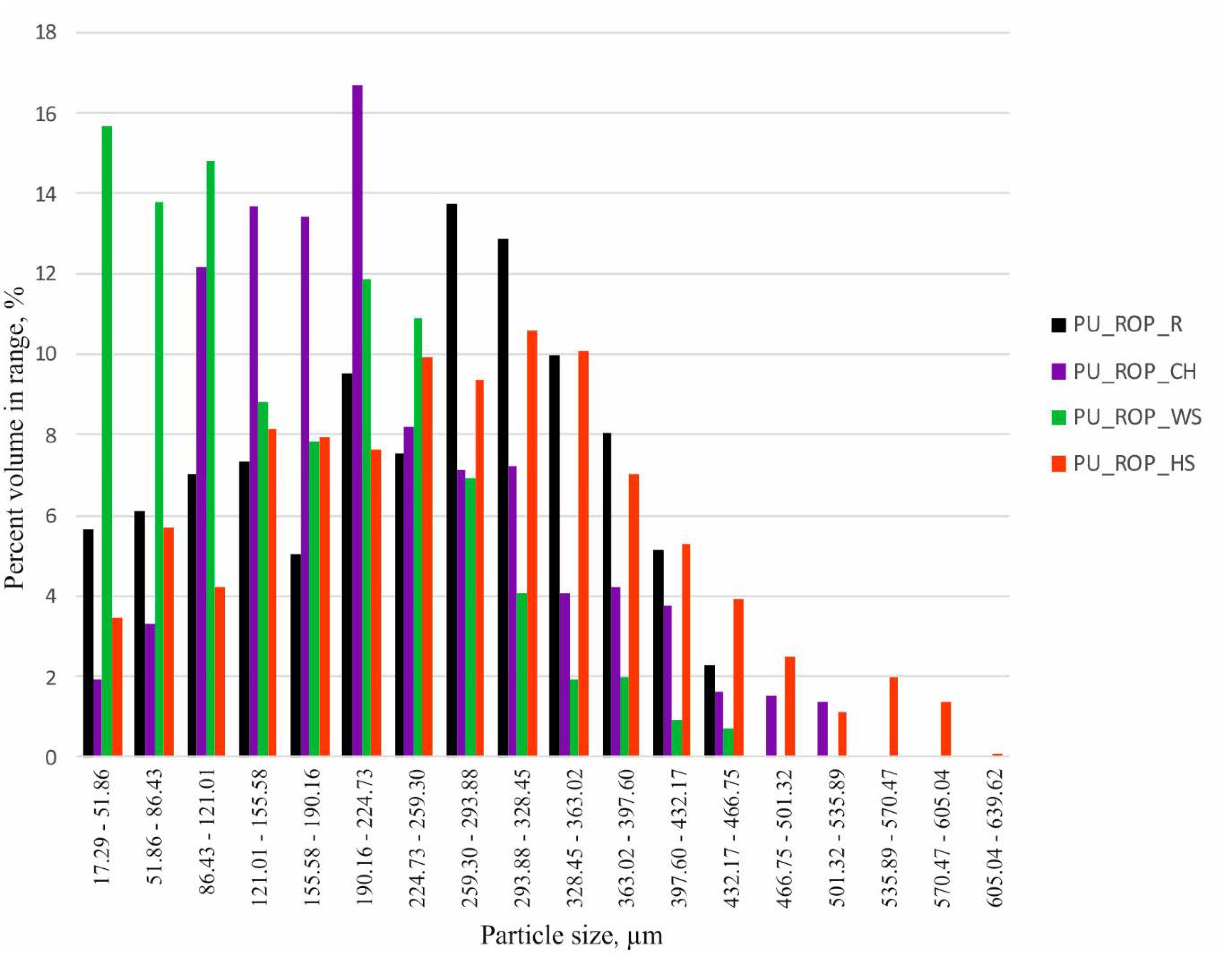

3.2.1. Structure Analysis of the Polyurethane Composites

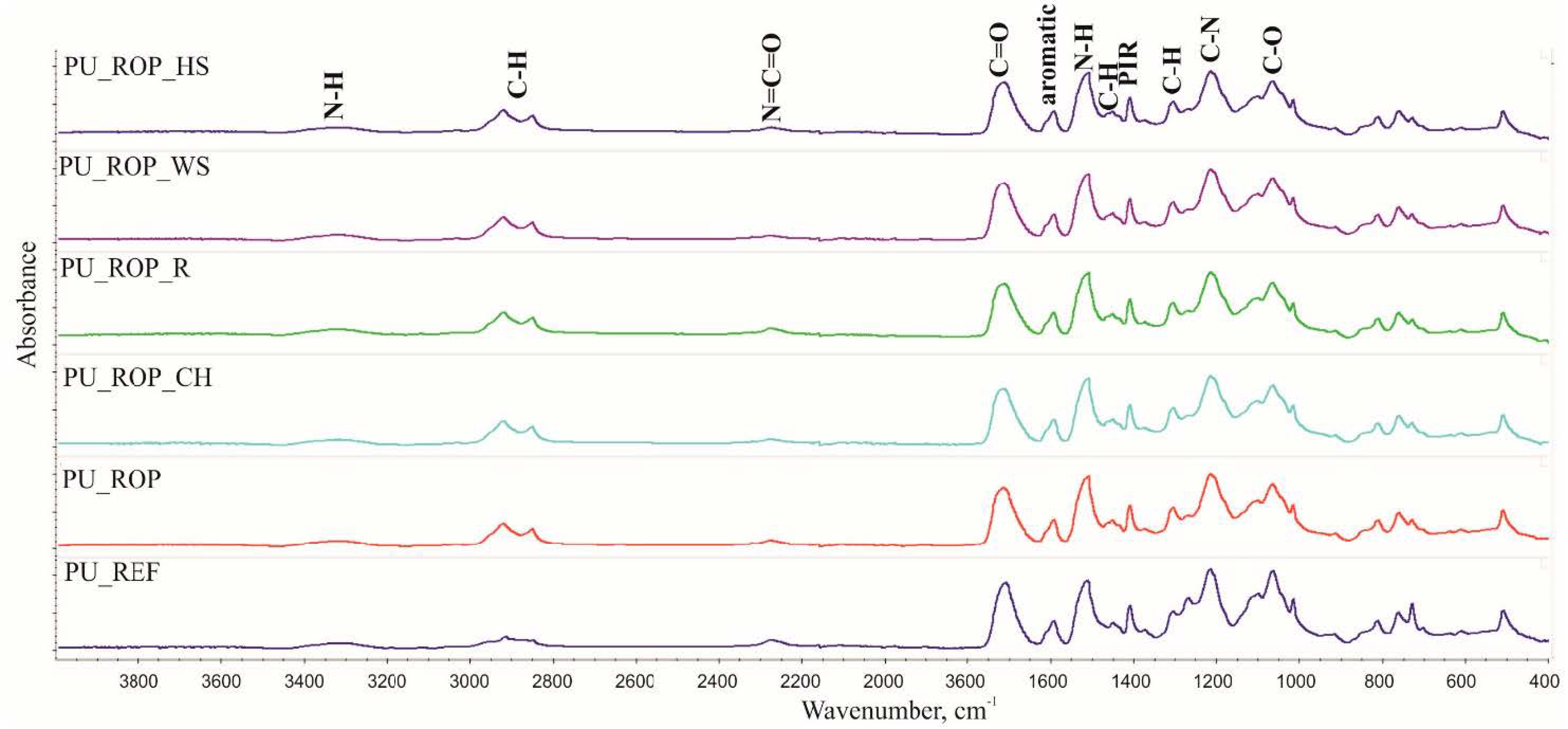

3.2.2. Analysis of the Chemical Composition of the Foams

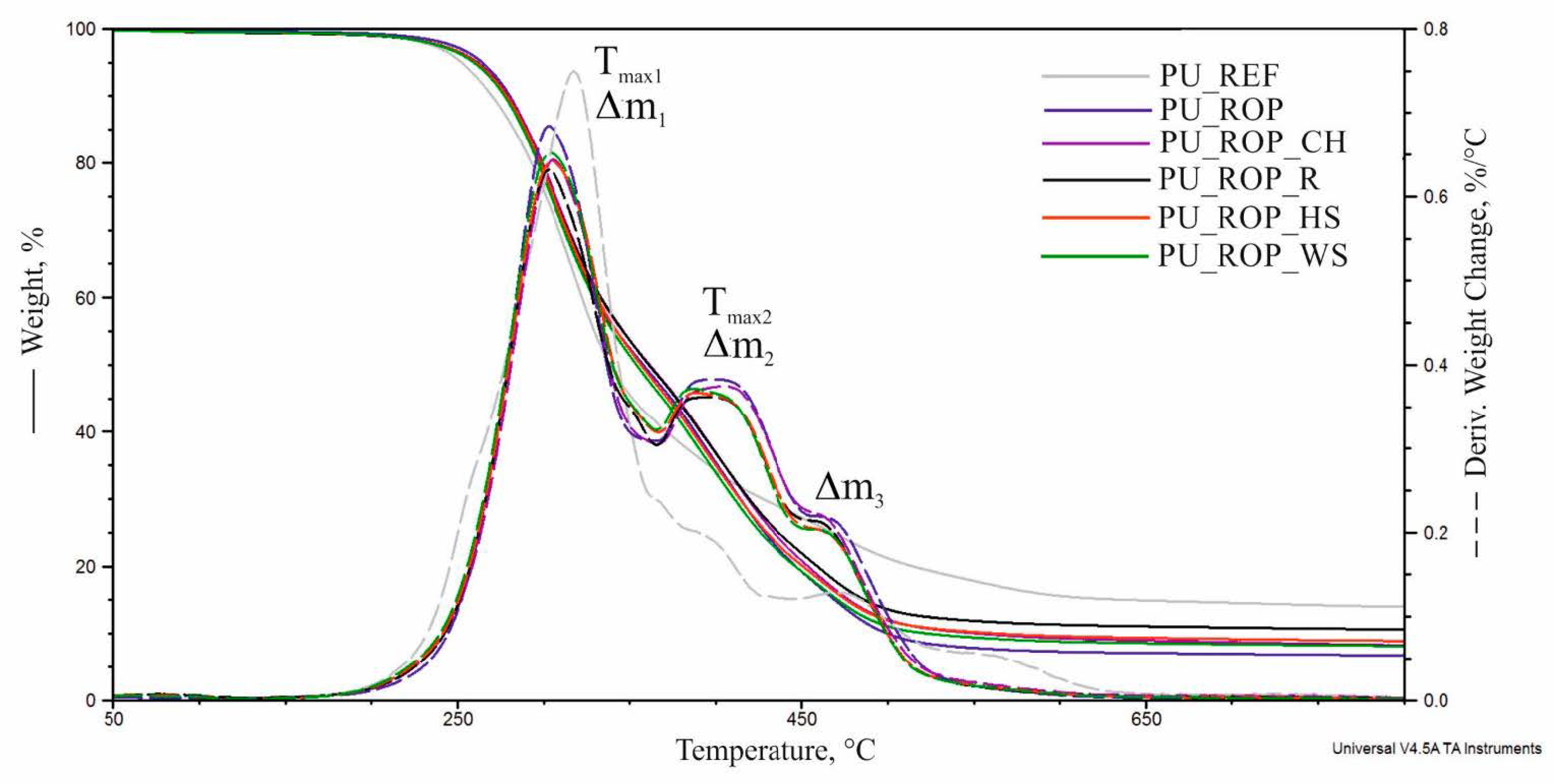

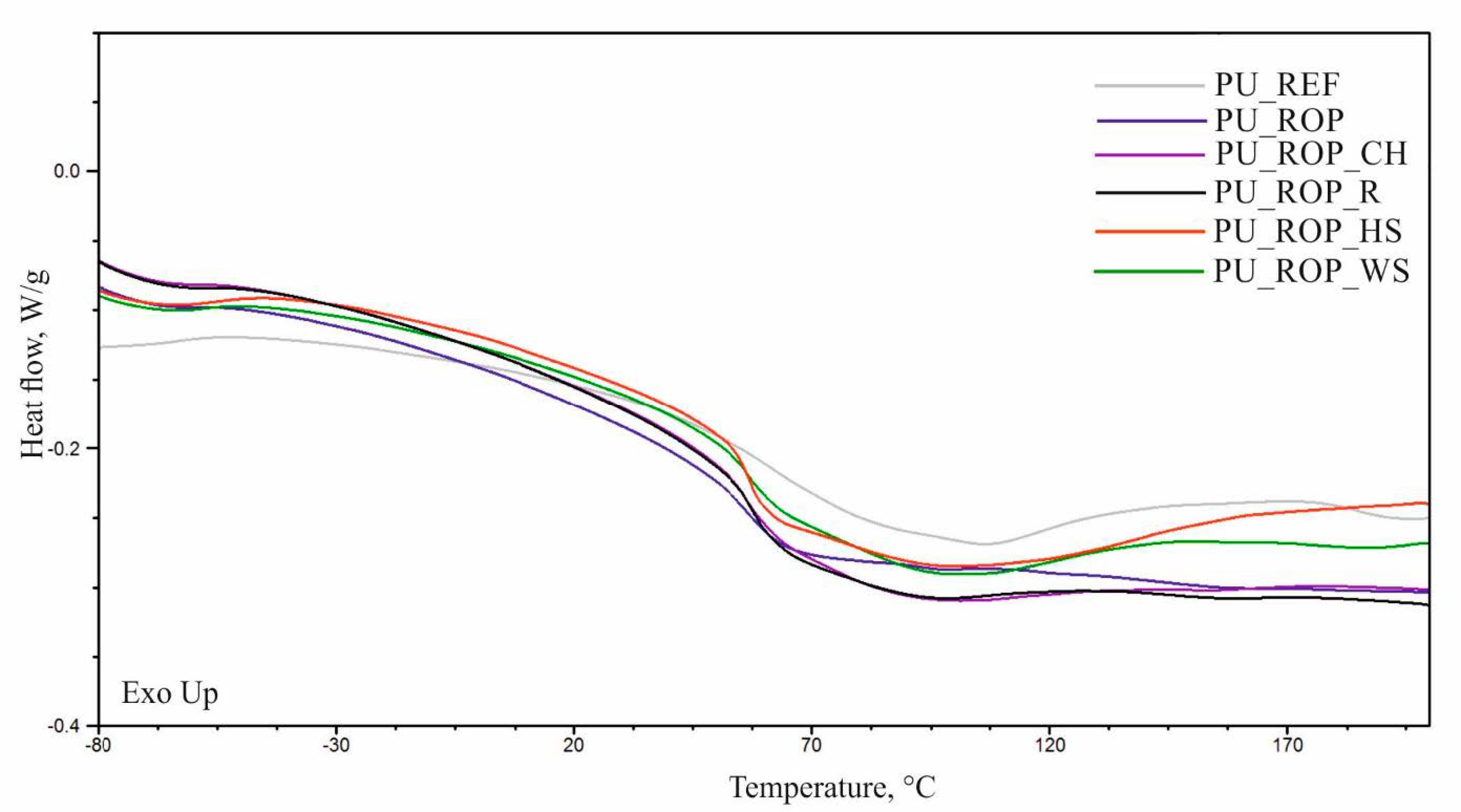

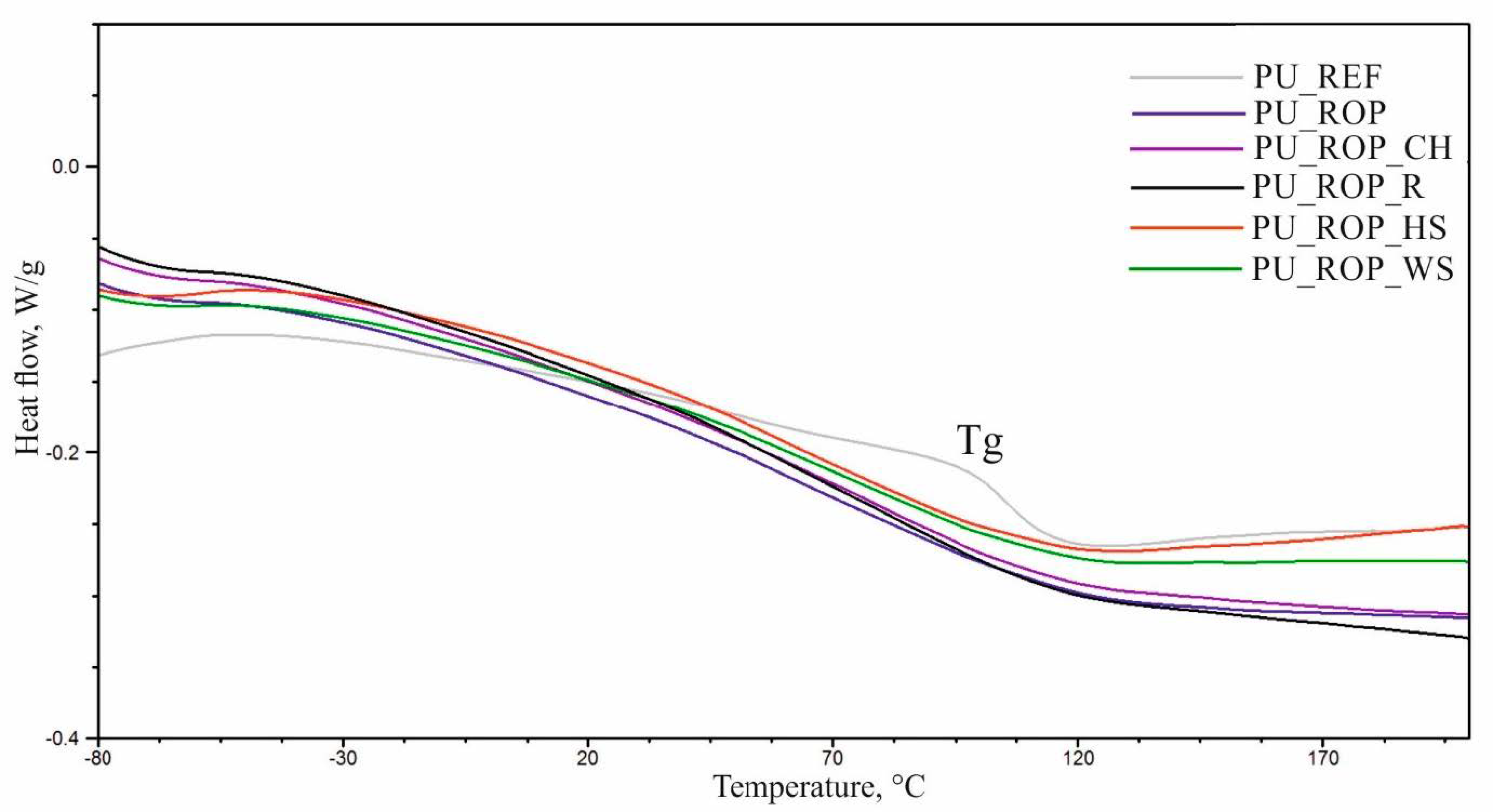

3.2.3. Thermal Analysis of the Rigid Polyurethane Foams

3.2.4. Analysis of the Physicomechanical Properties of the Foams

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kijeński, J. Polymeric materials in sustainable development—from the need to use to the need for wear. Part I. There is no turning back from plastics. Polimery 2019, 64, 725–739. [Google Scholar] [CrossRef]

- Chavarro Gomez, J.; Zakaria, R.; Aung, M.M.; Mokhtar, M.N.; Yunus, R.B. Characterization of novel rigid-foam polyurethanes from residual palm oil and algae oil. J. Mater. Res. Technol. 2020, 9, 16303–16316. [Google Scholar] [CrossRef]

- Global Polyurethane Market Outlook 2020–2030: Focus on Coatings, Adhesives & Sealants, Flexible & Rigid Foams, Elastomers, and More. Available online: https://www.globenewswire.com/news-release/2020/02/24/1989158/0/en/Global-Polyurethane-Market-Outlook-2020-2030-Focus-on-Coatings-Adhesives-Sealants-Flexible-Rigid-Foams-Elastomers-and-More.html (accessed on 14 February 2020).

- Członka, S.; Strąkowska, A.; Kairytė, A.; Kremensas, A. Nutmeg filler as a natural compound for the production of polyurethane composite foams with antibacterial and anti-aging properties. Polym. Test. 2020, 86, 106479. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [Green Version]

- Zieleniewska, M.; Leszczyński, M.K.; Kurańska, M.; Prociak, A.; Szczepkowski, L.; Krzyzowska, M.; Ryszkowska, J. Preparation and characterisation of rigid polyurethane foams using a rapeseed oil-based polyol. Ind. Crops Prod. 2015, 74, 887–897. [Google Scholar] [CrossRef]

- Kurańska, M.; Pinto, J.A.; Salach, K.; Barreiro, M.F.; Prociak, A. Synthesis of thermal insulating polyurethane foams from lignin and rapeseed based polyols: A comparative study. Ind. Crops Prod. 2020, 143, 111882. [Google Scholar] [CrossRef]

- Ribeiro Da Silva, V.; Mosiewicki, M.A.; Yoshida, M.I.; Coelho Da Silva, M.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash II: Mechanical characterization. Polym. Test. 2013, 32, 665–672. [Google Scholar] [CrossRef]

- Ji, D.; Fang, Z.; He, W.; Luo, Z.; Jiang, X.; Wang, T.; Guo, K. Polyurethane rigid foams formed from different soy-based polyols by the ring opening of epoxidised soybean oil with methanol, phenol, and cyclohexanol. Ind. Crops Prod. 2015, 74, 76–82. [Google Scholar] [CrossRef]

- Kurańska, M.; Leszczyńska, M.; Malewska, E.; Prociak, A.; Ryszkowska, J. Implementation of circular economy principles in the synthesis of polyurethane foams. Polymers 2020, 12, 2068. [Google Scholar] [CrossRef]

- Kurańska, M.; Leszczyńska, M.; Kubacka, J.; Prociak, A.; Ryszkowska, J. Effects of Modified Used Cooking Oil on Structure and Properties of Closed-Cell Polyurethane foams. J. Polym. Environ. 2020, 28, 2780–2788. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Daver, F.; Ivanova, E.P.; Adhikari, B. Polyurethanes from seed oil-based polyols: A review of synthesis, mechanical and thermal properties. Ind. Crops Prod. 2019, 142, 111841. [Google Scholar] [CrossRef]

- Kattiyaboot, T.; Thongpin, C. Effect of Natural Oil Based Polyols on the Properties of Flexible Polyurethane Foams Blown by Distilled Water. Energy Procedia 2016, 89, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Dhaliwal, G.S.; Anandan, S.; Chandrashekhara, K.; Lees, J.; Nam, P. Development and characterization of polyurethane foams with substitution of polyether polyol with soy-based polyol. Eur. Polym. J. 2018, 107, 105–117. [Google Scholar] [CrossRef]

- Kirpluks, M.; Kalnbunde, D.; Benes, H.; Cabulis, U. Natural oil based highly functional polyols as feedstock for rigid polyurethane foam thermal insulation. Ind. Crops Prod. 2018, 122, 627–636. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaur, R.; Walia, R.S.S. PU foam derived from renewable sources: Perspective on properties enhancement: An overview. Eur. Polym. J. 2017, 95, 255–274. [Google Scholar] [CrossRef]

- Kopik, M. Powstawanie i Zagospodarowanie Odpadów Generowanych w Rolnictwie i Przemyśle Rolno-Spożywczym—Stan Obecny i Perspektywy; Europejska Agencja Rozwoju Sp. J. Kopik i wspólnicy: Kielce, Poland, 2019. (In Polish) [Google Scholar]

- Ryszkowska, J. Materiały Poliuretanowe Wytwarzane z Zastosowaniem Surowców Odnawialnych; Oficyna Wydawnicza Politechniki Warszawskiej: Warsaw, Poland, 2019. (In Polish) [Google Scholar]

- Li, H.; Liang, Y.; Li, P.; He, C. Conversion of biomass lignin to high-value polyurethane: A review. J. Bioresour. Bioprod. 2020, 5, 163–179. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Czupryński, B.; Borowicz, M.; Liszkowska, J. Nowe tworzywa poliuretanowe z udziałem bionapełniacza. Polimery 2015, 60, 586–591. [Google Scholar]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L. Rigid polyurethane foam composites with nut shells. Polimery 2020, 65, 728–737. [Google Scholar] [CrossRef]

- Jonjaroen, V.; Ummartyotin, S.; Chittapun, S. Algal cellulose as a reinforcement in rigid polyurethane foam. Algal Res. 2020, 51, 102057. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Strzelec, K. Kompozyty polimerowe zawierające włókna roślinne—zynniki wpływające na wytrzymałość mechaniczną. Technol. i jakość Wyr. 2018, 63, 45–54. [Google Scholar]

- Septevani, A.A.; Evans, D.A.C.; Martin, D.J.; Annamalai, P.K. Hybrid polyether-palm oil polyester polyol based rigid polyurethane foam reinforced with cellulose nanocrystal. Ind. Crops Prod. 2018, 112, 378–388. [Google Scholar] [CrossRef]

- Salasinska, K.; Ryszkowska, J. Natural fibre composites from polyethylene waste and hazelnut shell: Dimensional stability, physical, mechanical and thermal properties. Compos. Interfaces 2012, 19, 321–332. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Banik, I.; Sain, M.M. Water Blown Soy Polyol-Based Polyurethane Foams of Different Rigidities. J. Reinf. Plast. Compos. 2008, 27, 357–373. [Google Scholar] [CrossRef]

- Prociak, A.; Rokicki, G.; Ryszkowska, J. Materiały Poliuretanowe; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2014. [Google Scholar]

- Leszczyńska, M.; Ryszkowska, J.; Szczepkowski, L.; Kurańska, M.; Prociak, A.; Leszczyński, M.K.; Gloc, M.; Antos-Bielska, M.; Mizera, K. Cooperative effect of rapeseed oil-based polyol and egg shells on the structure and properties of rigid polyurethane foams. Polym. Test. 2020, 90, 106696. [Google Scholar] [CrossRef]

- Leszczyńska, M.; Ryszkowska, J.; Leszczyński, M.; Szczepkowski, L.; Przekurat, S.; Przekurat, A. Application of Raspberry Seeds as Filler Material for Production of Polyurethane Foam Biocomposites; The Patent Office of the Republic of Poland: Warsaw, Poland, 2020; p. PL234693. [Google Scholar]

- Leszczyńska, M.; Ryszkowska, J.; Leszczyński, M.; Szczepkowski, L.; Przekurat, S.; Przekurat, A. Application of Chokeberry Pomace as Filler Material for Production of Polyurethane Foam Biocomposites; The Patent Office of the Republic of Poland: Warsaw, Poland, 2019; p. PL233444. [Google Scholar]

- Krutul, D. Ćwiczenia z Chemii Drewna oraz Wybranych Zagadnień Chemii Organicznej; WULS: Warsaw, Poland, 2002. (In Polish) [Google Scholar]

- Sałasińska, K. Kompozyty Polimerowe z Napełniaczami Pochodzenia Roślinnego Otrzymywane z Materiałów Odpadowych. Ph.D. Thesis, Warsaw University of Technology, Warsaw, Poland, 2014. (In Polish). [Google Scholar]

- Kurańska, M.; Prociak, A. The influence of rapeseed oil-based polyols on the foaming process of rigid polyurethane foams. Ind. Crops Prod. 2016, 89, 182–187. [Google Scholar] [CrossRef]

- Tan, S.; Abraham, T.; Ference, D.; MacOsko, C.W. Rigid polyurethane foams from a soybean oil-based Polyol. Polymer 2011, 52, 2840–2846. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Marcovich, N.E.E.; Kurańska, M.; Prociak, A.; Malewska, E.; Kulpa, K. Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind. Crops Prod. 2017, 102, 88–96. [Google Scholar] [CrossRef]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer (Guildf) 2020, 190, 216–225. [Google Scholar] [CrossRef]

- Yang, L.-T.; Zhao, C.-S.; Dai, C.-L.; Fu, L.-Y.; Lin, S.-Q. Thermal and Mechanical Properties of Polyurethane Rigid Foam Based on Epoxidized Soybean Oil. J. Polym. Environ. 2012, 20, 230–236. [Google Scholar] [CrossRef]

- Prociak, A.; Kurańska, M.; Cabulis, U.; Ryszkowska, J.; Leszczyńska, M.; Uram, K.; Kirpluks, M. Effect of bio-polyols with different chemical structures on foaming of polyurethane systems and foam properties. Ind. Crops Prod. 2018, 120, 262–270. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Czuprynski, B.; Liszkowska, J. Composites of rigid polyurethane-polyisocyanurate foams with oak bark. Polimery 2017, 62, 666–672. [Google Scholar] [CrossRef]

- Gu, R.; Sain, M.M.; Konar, S.K. A feasibility study of polyurethane composite foam with added hardwood pulp. Ind. Crops Prod. 2013, 42, 273–279. [Google Scholar] [CrossRef]

- Silva, M.C.; Takahashi, A.; Chaussy, D.; Belgacem, M.N.; Silva, G.G. Composites of rigid polyurethane foam and cellulose fiber residue. J. Appl. Polym. Sci. 2010, 117, 3665–3672. [Google Scholar] [CrossRef]

- Prociak, A.; Kuranska, M.; Malewska, E. Porous polyurethane plastics synthetized using bio-polyols from renewable raw materials. Polimery 2017, 62, 353–363. [Google Scholar] [CrossRef]

- Hejna, A.; Haponiuk, J.; Piszczyk, Ł.; Klein, M.; Formela, K. Performance properties of rigid polyurethane-polyisocyanurate/brewers’ spent grain foamed composites as function of isocyanate index. E-Polymers 2017, 17, 427–437. [Google Scholar] [CrossRef]

| Sample | PU_REF | PU_ROP | PU_ROP_CH | PU_ROP_R | PU_ROP_WS | PU_ROP_HS |

|---|---|---|---|---|---|---|

| Raw Materials | Composition (pbw) | |||||

| Natural filler | - | - | 15 | 15 | 15 | 15 |

| Polios® 420 PTA | 75 | 18.75 | 18.75 | 18.75 | 18.75 | 18.75 |

| Rokopol® G500 | 25 | 6.25 | 6.25 | 6.25 | 6.25 | 6.25 |

| ROP | 0 | 75 | 75 | 75 | 75 | 75 |

| Jeffcat® DPA | 1 | 1 | 1 | 1 | 1 | 1 |

| Jeffcat® ZF-10 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Distilled water | 1.35 | 1.30 | 1.01 | 1.03 | 1.00 | 1.00 |

| Tegostab® B4900 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 |

| Ongronat® TR 4040 | Isocyanate index 110 | |||||

| Apparent density kg/m3 | 84 ± 4 | 62 ± 2 | 65 ± 2 | 69 ± 1 | 70 ± 4 | 72 ± 3 |

| Natural Filler | Hemicellulose, % | Cellulose, % | Lignin, % | Raw fat, % |

|---|---|---|---|---|

| CH | 21.7 | 20.6 | 58.0 | 7.3 |

| R | 38.5 | 28.0 | 42.3 | 12.2 |

| HS | 20.3 | 37.8 | 38.7 | 1.5 |

| WS | 28.6 | 34.7 | 37.3 | 5.5 |

| Sample | Closed Cell Content, % | Total Porosity, % |

|---|---|---|

| PU_REF | 84 ± 1 | - |

| PU_ROP | 89 ± 0 | 92 |

| PU_ROP_CH | 91 ± 0 | 89 |

| PU_ROP_R | 90 ± 0 | 95 |

| PU_ROP_WS | 89 ± 1 | 97 |

| PU_ROP_HS | 89 ± 1 | 94 |

| Sample | T5%, °C | Tmax1/(Vmax1), °C/%/°C | Δm1, % | Tmax2/ Vmax2, °C/%/ °C | Δm2, % | Δm3, % | R (800 °C), % |

|---|---|---|---|---|---|---|---|

| PU_REF | 252 | 317/0.75 | 72 | - | - | 12 | 14 |

| PU_ROP | 264 | 303/0.68 | 52 | 399/0.38 | 28 | 12 | 7 |

| PU_ROP_CH | 261 | 306/0.64 | 50 | 403/0.37 | 28 | 12 | 8 |

| PU_ROP_R | 261 | 303/0.63 | 52 | 397/0.36 | 27 | 11 | 11 |

| PU_ROP_WS | 259 | 304/0.65 | 53 | 386/0.37 | 27 | 11 | 8 |

| PU_ROP_HS | 261 | 305/0.64 | 52 | 388/0.37 | 27 | 11 | 9 |

| Sample | Tg, °C |

|---|---|

| PU_REF | 105 ± 0 |

| PU_ROP | 84 ± 1 |

| PU_ROP_CH | 94 ± 1 |

| PU_ROP_R | 95 ± 2 |

| PU_ROP_WS | 90 ± 1 |

| PU_ROP_HS | 87 ± 2 |

| Material | Friability, % | Dimensional Stability in Water, Thickness (24 h, 40 °C), % | Dimensional Stability in Water, Width (24 h, 40 °C), % | Dimensional Stability in Water, Length (24 h, 40 °C), % | Water Absorption (24 h, 40 °C), % |

|---|---|---|---|---|---|

| PU_REF | 2.09 ± 0.8 | −0.93 ± 0.02 | −0.35 ± 0.49 | −0.59 ± 0.23 | 2.68 ± 1.65 |

| PU_ROP | 0.31 ± 0.1 | −0.07 ± 0.01 | 0.39 ± 0.33 | 0.47 ± 0.27 | 0.95 ± 0.14 |

| PU_ROP_CH | 1.41 ± 0.2 | −0.22 ± 0.05 | −0.21 ± 0.95 | −0.25 ± 0.58 | 0.79 ± 0.18 |

| PU_ROP_R | 1.61± 0.2 | 0.04 ± 0.16 | −0.28 ± 0.08 | 0.06 ± 0.14 | 0.74 ± 0.13 |

| PU_ROP_WS | 1.79 ± 0.3 | −0.07 ± 0.06 | −0.45 ± 0.49 | 0.42 ± 0.43 | 0.97 ± 0.09 |

| PU_ROP_HS | 1.94 ± 0.4 | −0.12 ± 0.08 | −0.28 ± 0.51 | 0.49 ± 0.75 | 0.91 ± 0.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leszczyńska, M.; Malewska, E.; Ryszkowska, J.; Kurańska, M.; Gloc, M.; Leszczyński, M.K.; Prociak, A. Vegetable Fillers and Rapeseed Oil-Based Polyol as Natural Raw Materials for the Production of Rigid Polyurethane Foams. Materials 2021, 14, 1772. https://doi.org/10.3390/ma14071772

Leszczyńska M, Malewska E, Ryszkowska J, Kurańska M, Gloc M, Leszczyński MK, Prociak A. Vegetable Fillers and Rapeseed Oil-Based Polyol as Natural Raw Materials for the Production of Rigid Polyurethane Foams. Materials. 2021; 14(7):1772. https://doi.org/10.3390/ma14071772

Chicago/Turabian StyleLeszczyńska, Milena, Elżbieta Malewska, Joanna Ryszkowska, Maria Kurańska, Michał Gloc, Michał K. Leszczyński, and Aleksander Prociak. 2021. "Vegetable Fillers and Rapeseed Oil-Based Polyol as Natural Raw Materials for the Production of Rigid Polyurethane Foams" Materials 14, no. 7: 1772. https://doi.org/10.3390/ma14071772

APA StyleLeszczyńska, M., Malewska, E., Ryszkowska, J., Kurańska, M., Gloc, M., Leszczyński, M. K., & Prociak, A. (2021). Vegetable Fillers and Rapeseed Oil-Based Polyol as Natural Raw Materials for the Production of Rigid Polyurethane Foams. Materials, 14(7), 1772. https://doi.org/10.3390/ma14071772