A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures

Abstract

:1. Introduction

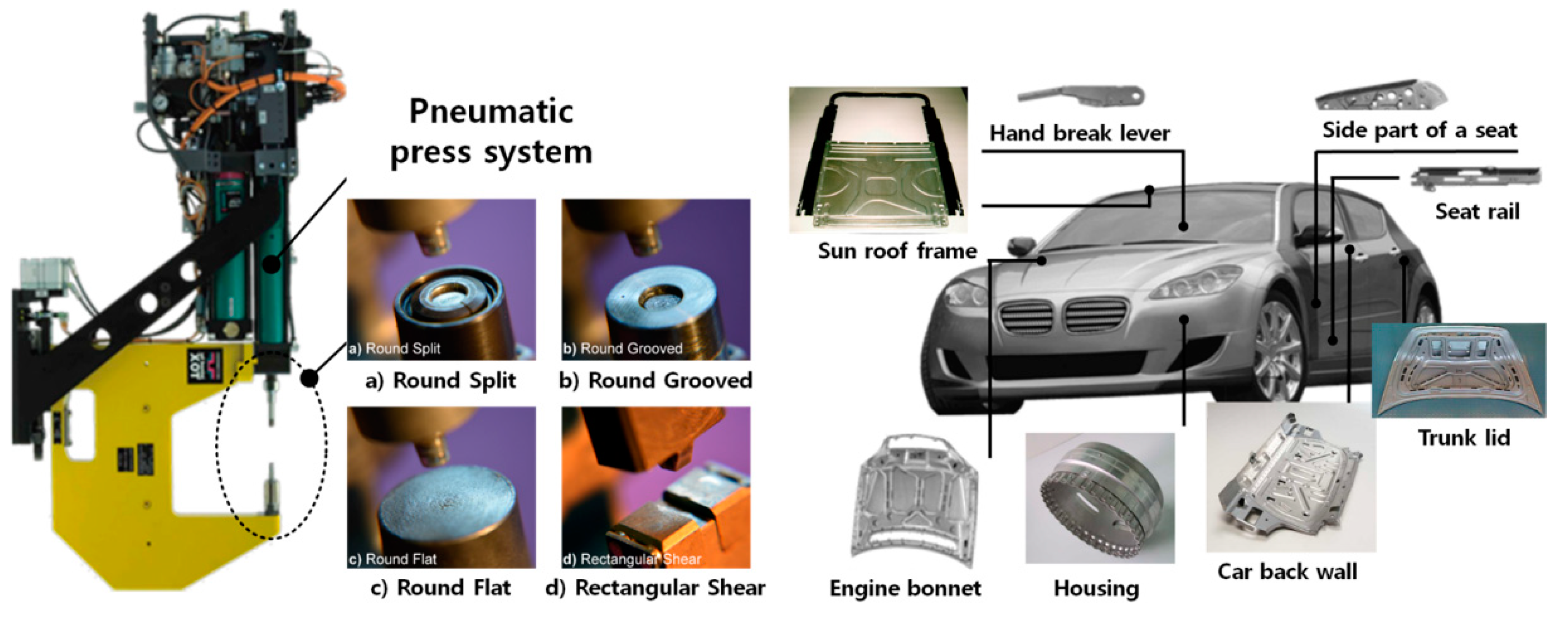

2. Advanced Mechanical Fastening Processes

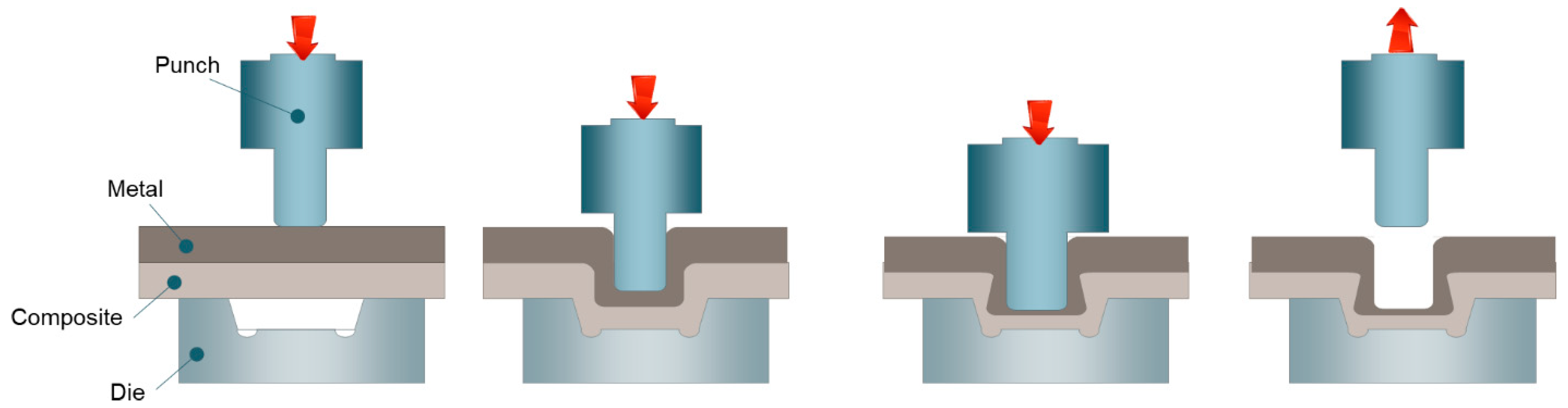

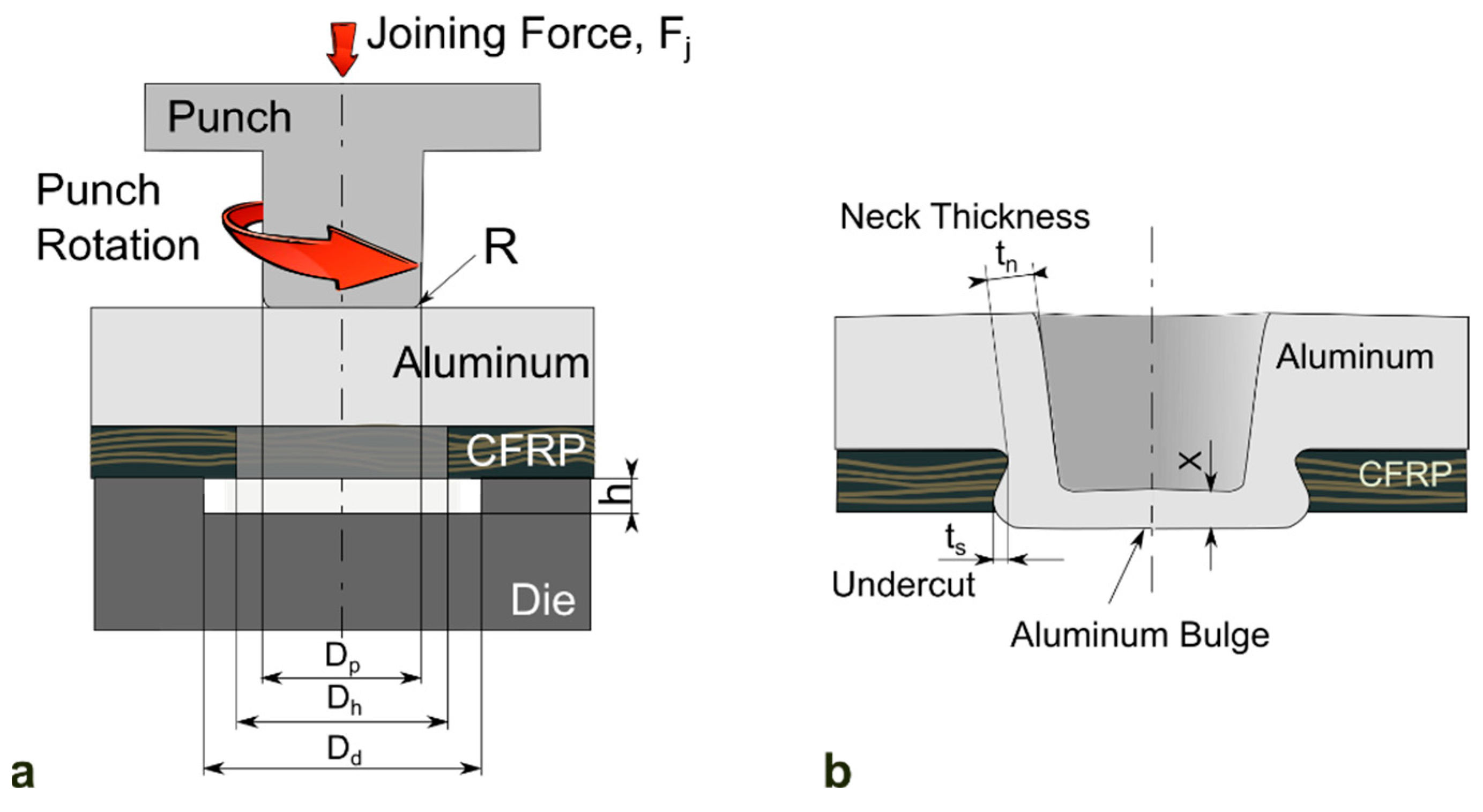

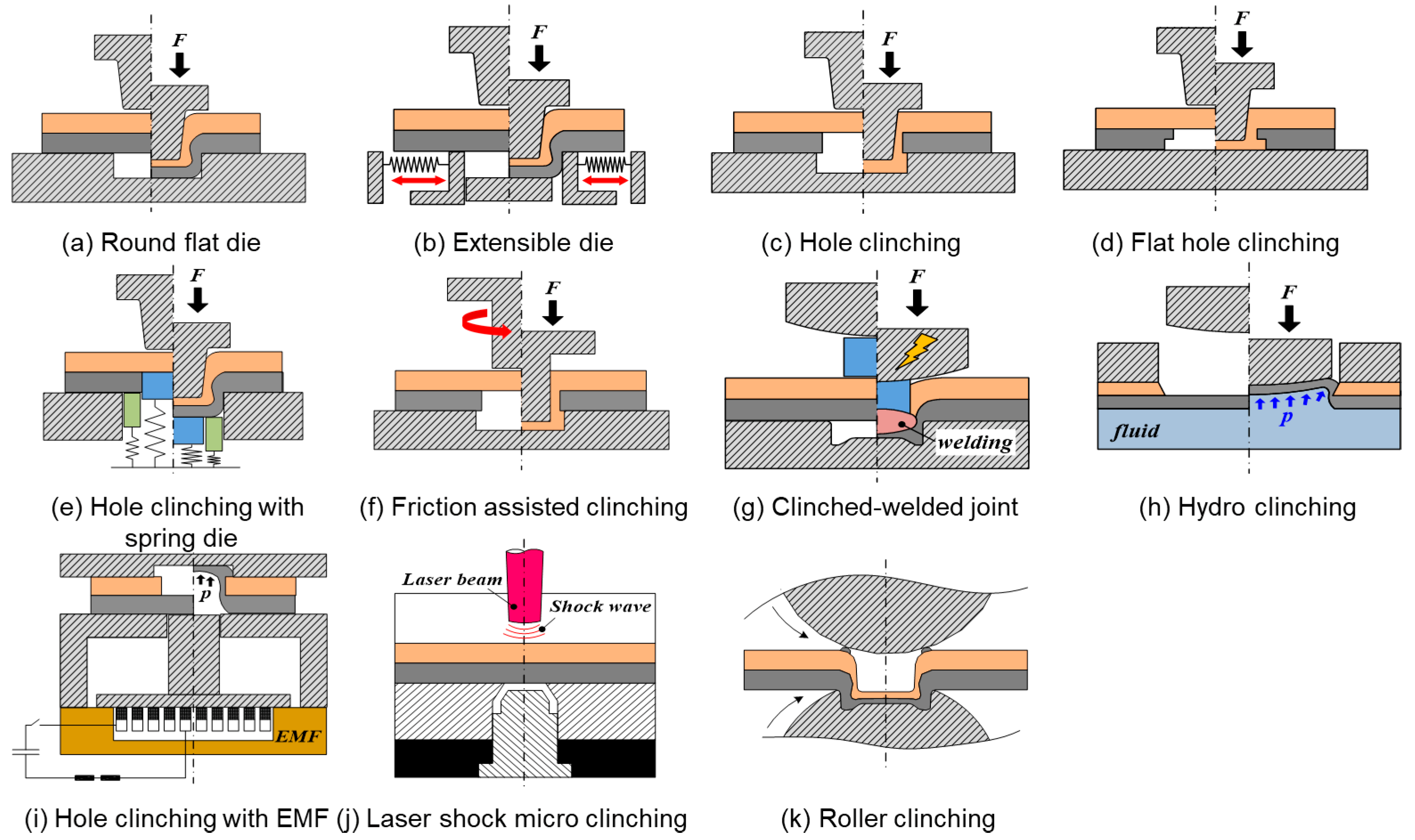

2.1. Mechanical Clinching

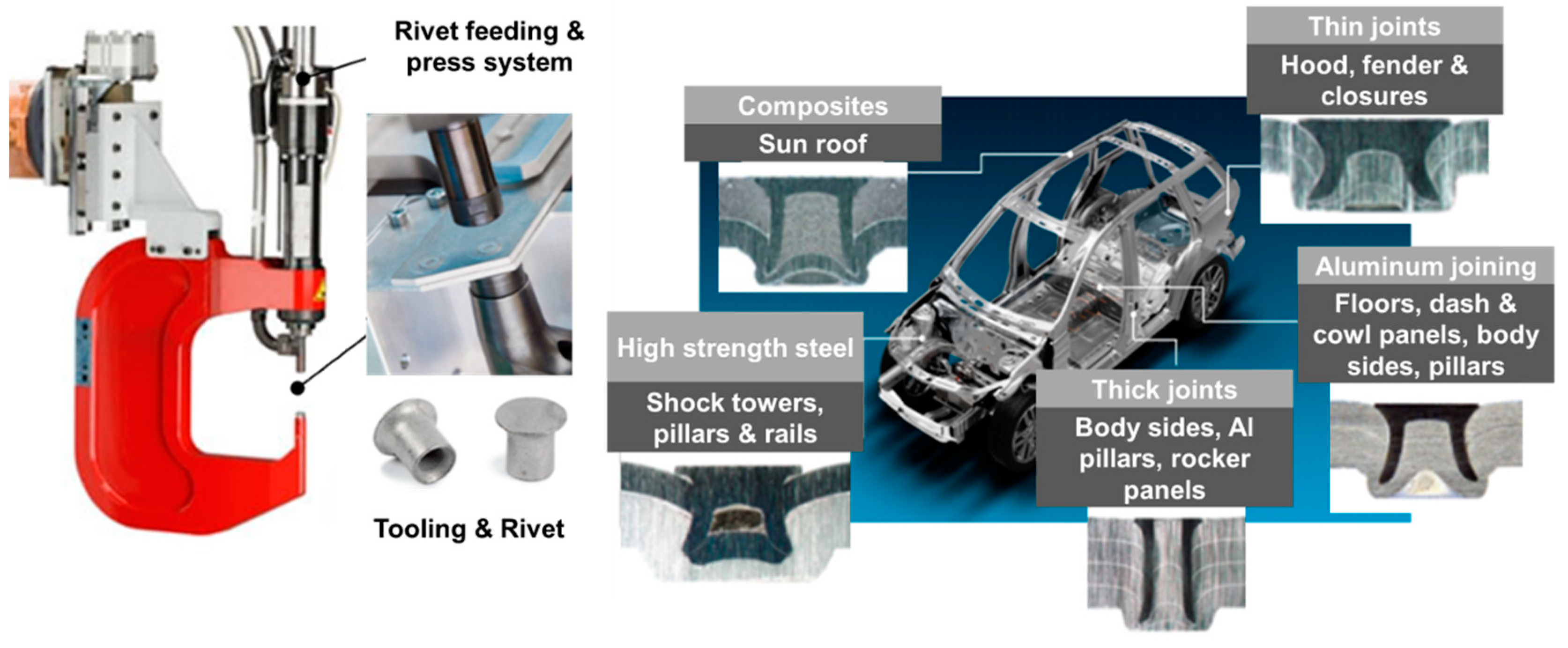

2.2. Self-Pierce Riveting

3. Thermomechanical Interlocking Processes

3.1. Friction Riveting

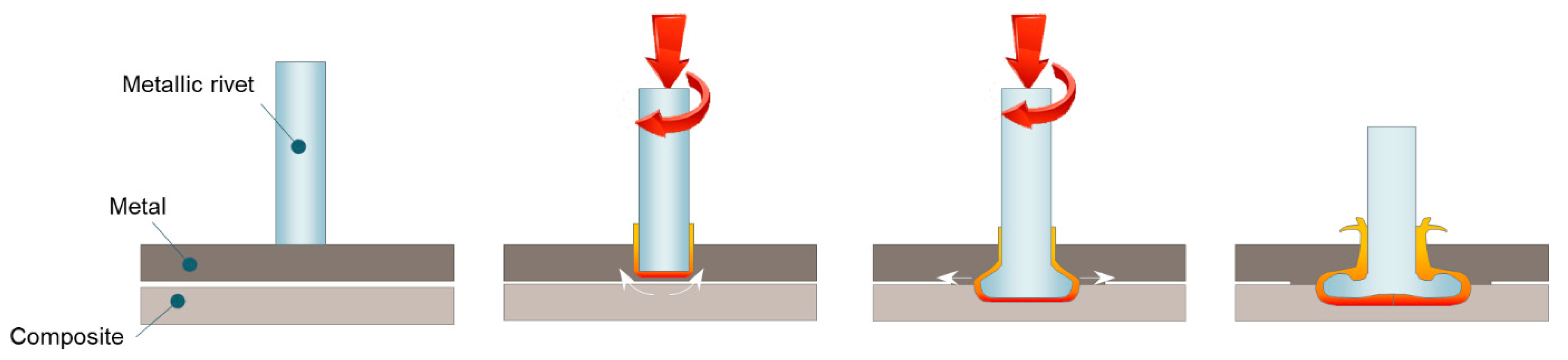

3.2. Friction Self-Riveting

3.3. Injection Clinching Joining

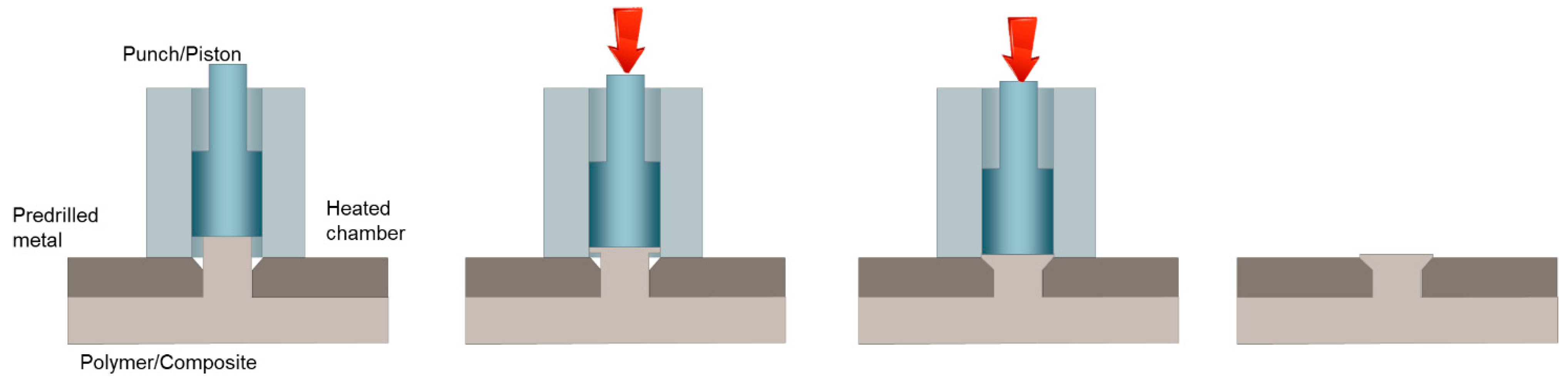

3.4. Friction-Based Filling Stacking

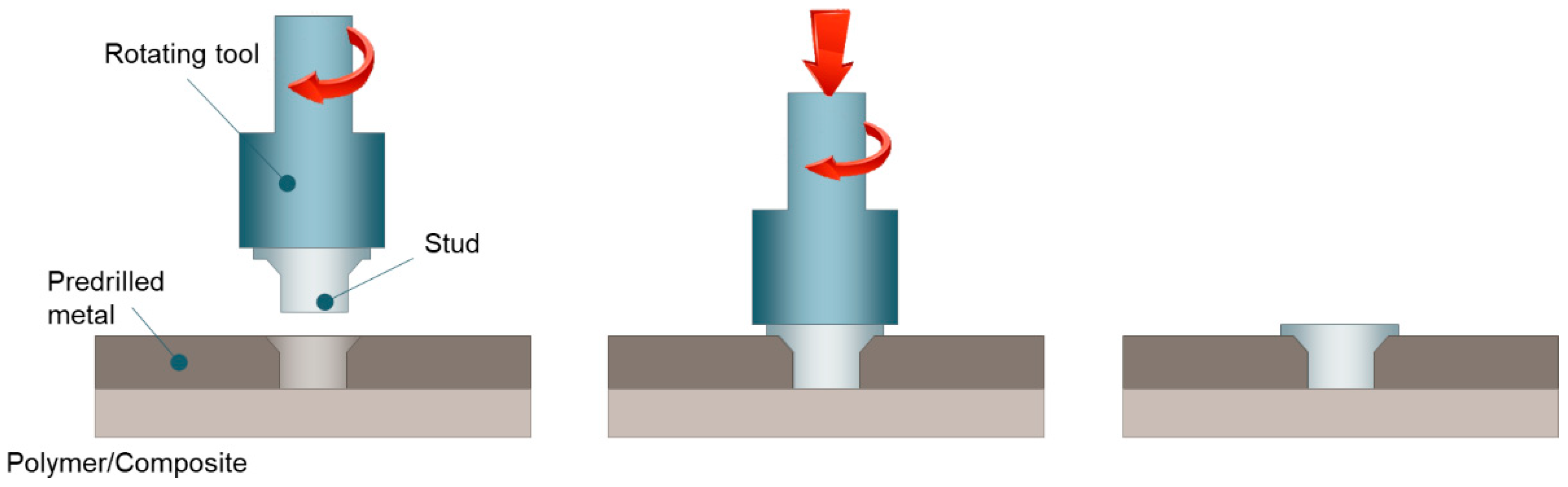

3.5. Friction Stir Lap Welding

4. Thermomechanical Joining Processes

- The surface conditions of the joining partners including the nature of the polymer (polymer matrix), the chemical composition of the metal surface, and the morphology of the metal surface.

- The joining parameters used during the operation.

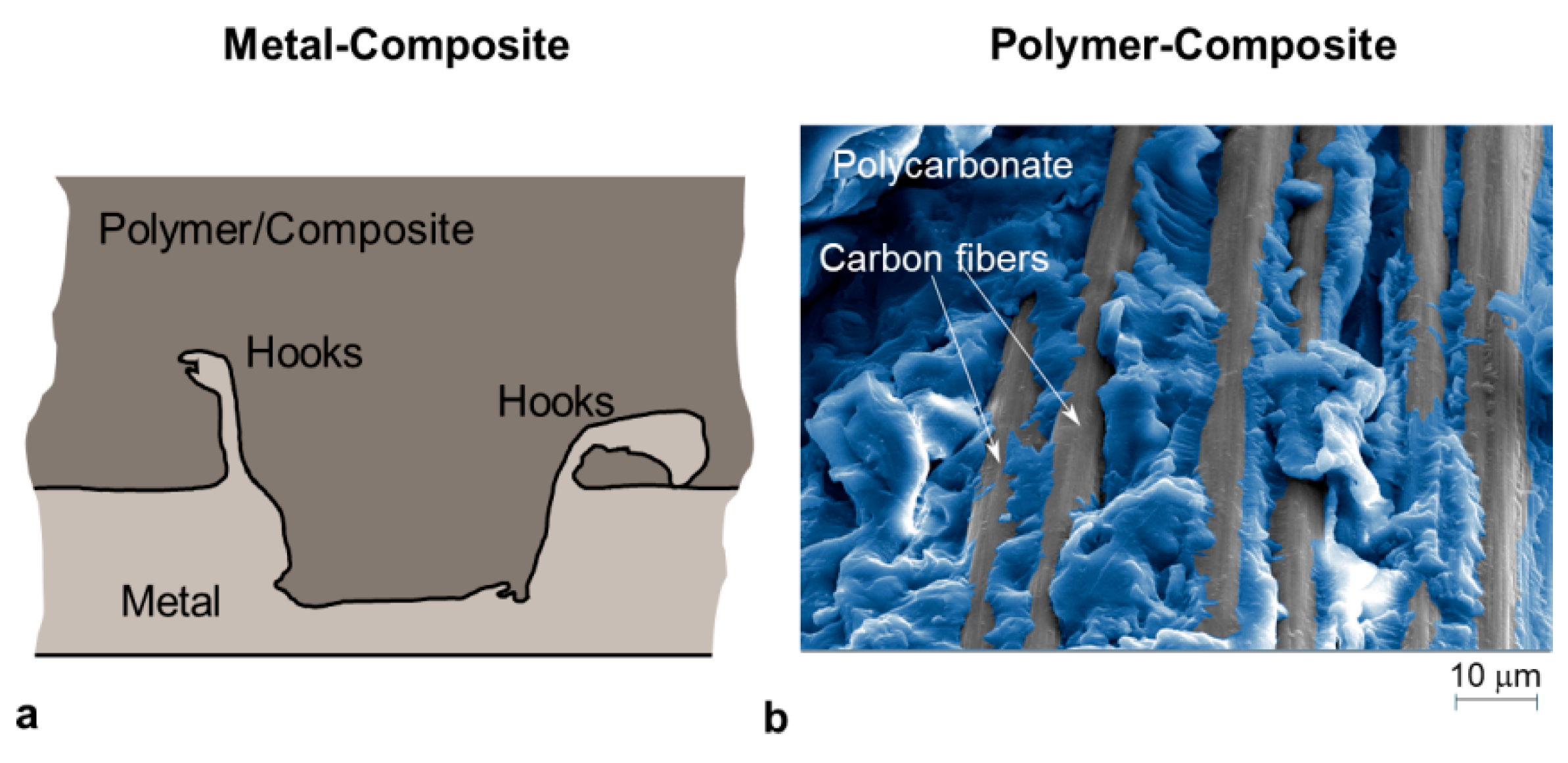

4.1. The Surfaces of the Joining Partners

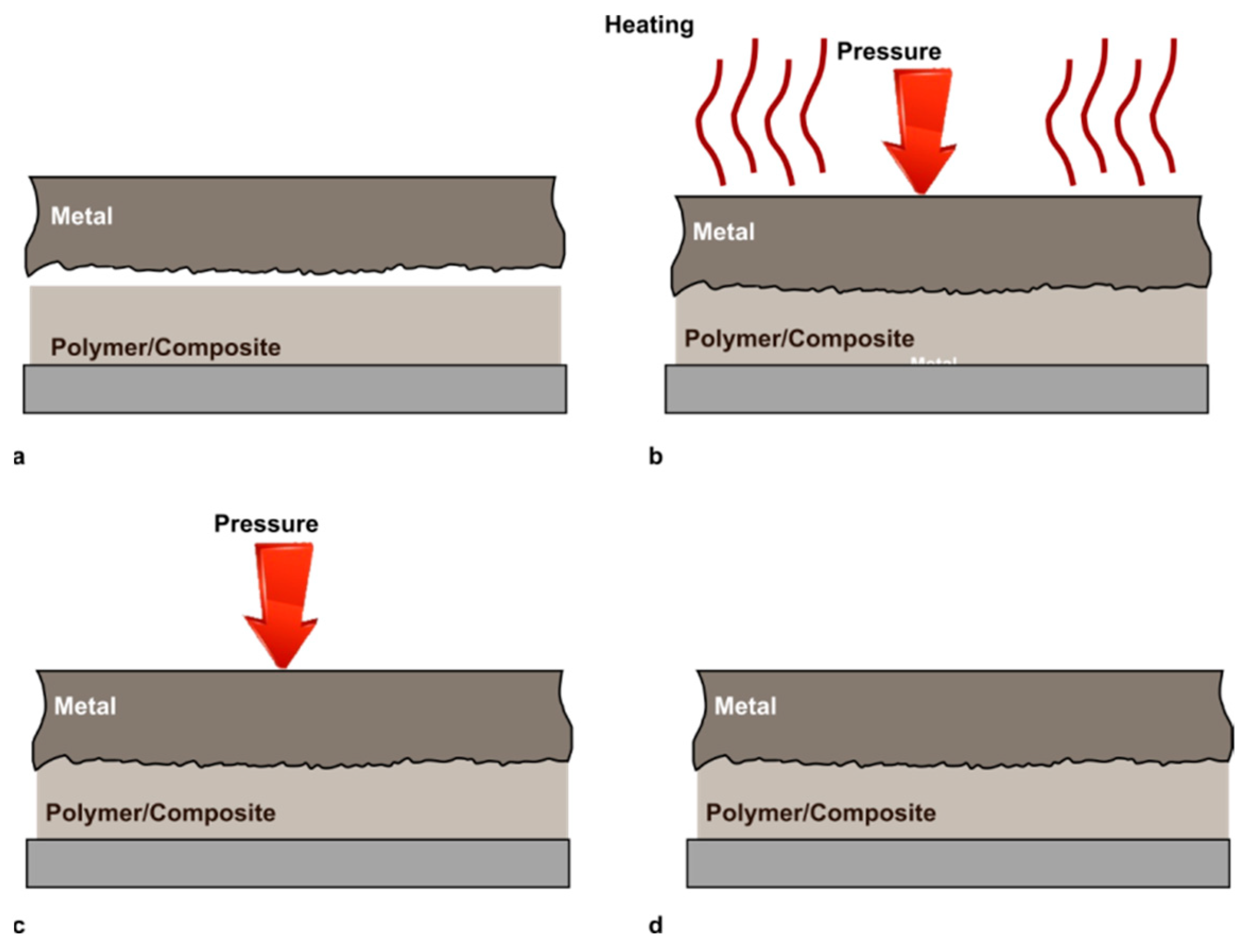

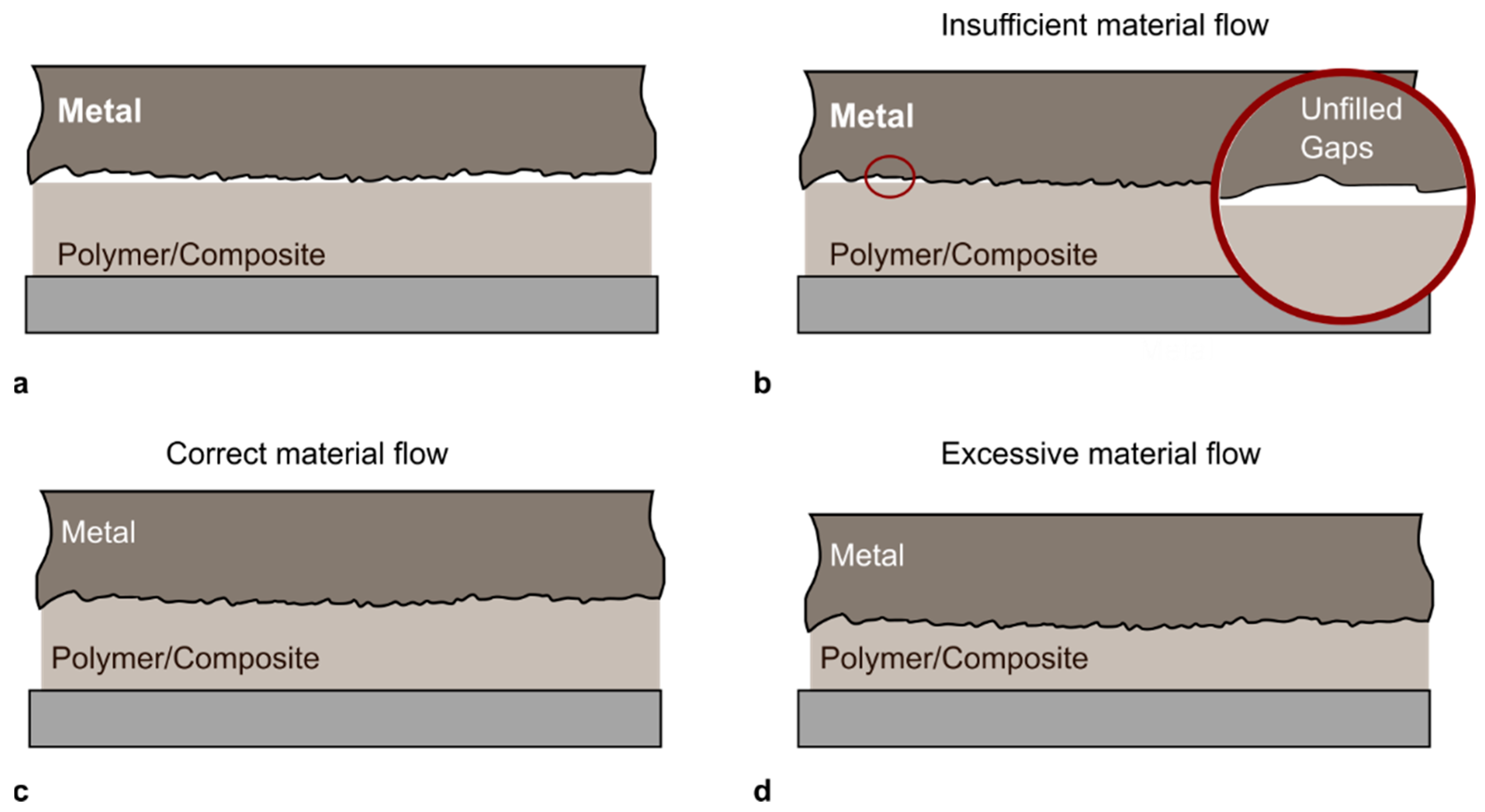

4.2. The Processing Conditions

- TMJPs can complete rapidly while adhesive bonding needs a long curing time.

- No autoclave is necessary.

- No additional thermoset interlayer. This may solve numerous issues, including weight increase, cost, and storage.

- Thermoplastics are commonly tougher as compared to thermosets.

- Damaged thermoplastic joints could be restored by applying TMJP without the need to disassembling the structure.

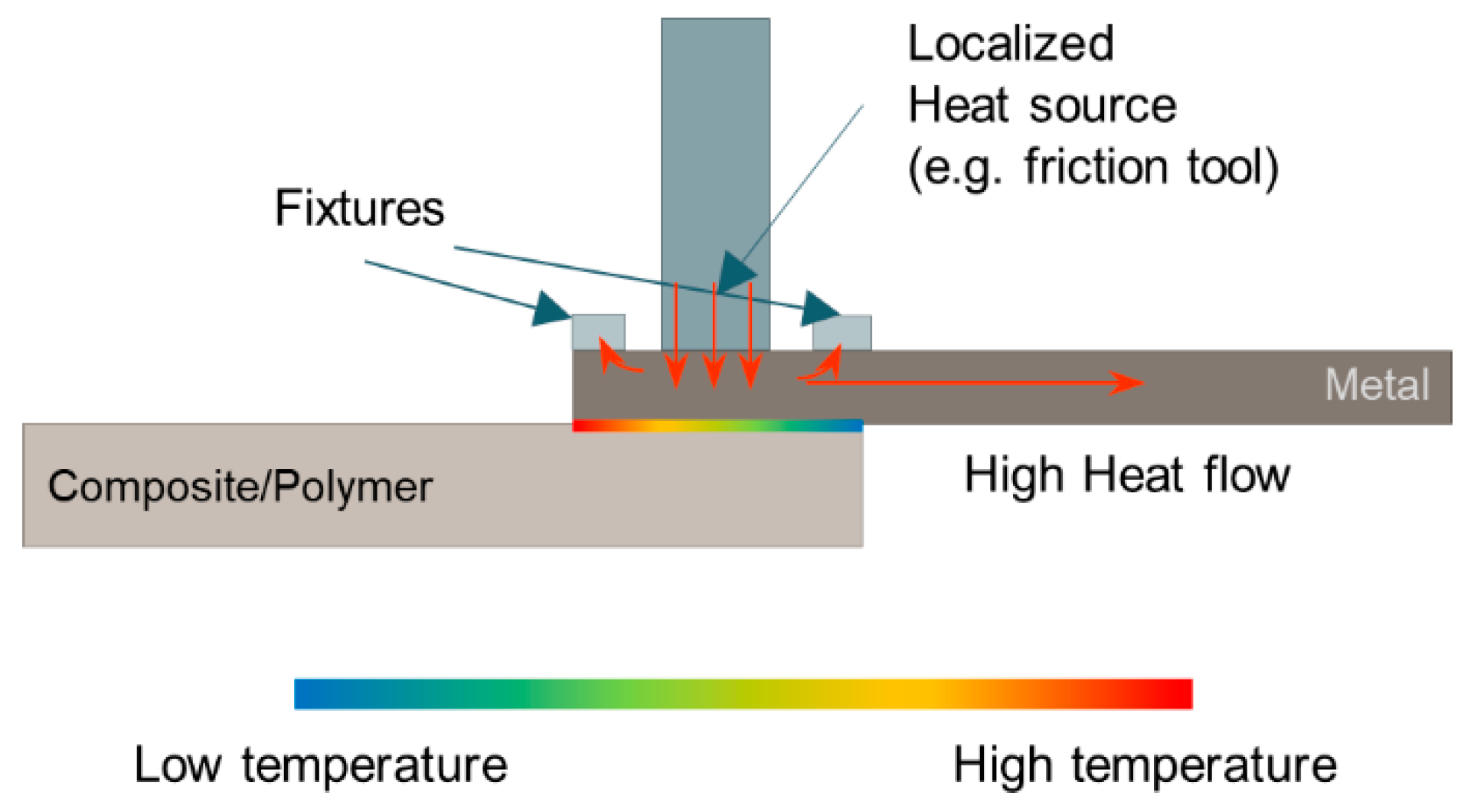

- a limited dimension of the heating source on the metal component surface;

- the presence of clamping equipment that promotes localized heat exchanges and

- the limited contact interface between the metal and the underlying polymer/composite.

5. Discussion

6. Conclusions

- Advanced mechanical fastening: the joining is achieved through mechanical interlocking, which is produced through plastic deformation (generally at room temperature) of the joining partners. These processes produce a significant alteration at both sides of the connection (protrusions, defects, etc.) Some processes do not require hole drilling as well as external connecting elements.

- Thermomechanical interlocking: the joining is mainly developed through macro-mechanical interlocking and high thermoplastic deformation of the joining partners. These joining processes damaged the appearance of at least one joining partner due to the high degree of thermoplastic deformation as well as the adoption of protruding elements in many cases. These joining processes can be used to produce either spot or continuous joints.

- Thermomechanical joining processes: the joining is achieved through the application of heating (different heating media are available) and compression pressure at the joint interface. Different joining mechanisms can be activated including chemical bonding, physical bonding, and micro-mechanical interlocking. These processes can guarantee better joint appearance since high degree of plastic deformation of the joining partners can be avoided during the joining. These processes can also be used to produce either continuous or spot joints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Trask, R.S.; Hallett, S.R.; Helenon, F.M.M.; Wisnom, M.R. Influence of process induced defects on the failure of composite T-joint specimens. Compos. Part A Appl. Sci. Manuf. 2012, 43, 748–757. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Anders, D.; Weinberg, K. Influence of strain rate on fracture behavior of sandwich composite T-joints. Eur. J. Mech. A Solids 2019, 78, 103821. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, R.; Ai, S.; He, R.; Pei, Y.; Fang, D. Load distribution in threads of porous metal–ceramic functionally graded composite joints subjected to thermomechanical loading. Compos. Struct. 2015, 134, 680–688. [Google Scholar] [CrossRef] [Green Version]

- Zhou, W.; Ai, S.; Chen, M.; Zhang, R.; He, R.; Pei, Y.; Fang, D. Preparation and thermodynamic analysis of the porous ZrO2/(ZrO2 + Ni) functionally graded bolted joint. Compos. Part B Eng. 2015, 82, 13–22. [Google Scholar] [CrossRef]

- Lambiase, F.; Durante, M. Mechanical behavior of punched holes produced on thin glass fiber reinforced plastic laminates. Compos. Struct. 2017, 173, 25–34. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Xie, Y.; Li, J.; Guan, M.; Wan, L.; Dong, Z.; Cao, J. Friction self-riveting welding between polymer matrix composites and metals. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105624. [Google Scholar] [CrossRef]

- Blaga, L.; Bancilă, R.; dos Santos, J.F.; Amancio-Filho, S.T. Friction Riveting of glass–fibre-reinforced polyetherimide composite and titanium grade 2 hybrid joints. Mater. Des. 2013, 50, 825–829. [Google Scholar] [CrossRef] [Green Version]

- Ozlati, A.; Movahedi, M.; Tamizi, M.; Tartifzadeh, Z.; Alipour, S. An alternative additive manufacturing-based joining method to make Metal/Polymer hybrid structures. J. Manuf. Process. 2019, 45, 217–226. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Li, J.; Si, X.; Fan, Q. Improving mechanical properties of composite/metal friction stir lap welding joints via a taper-screwed pin with triple facets. J. Mater. Process. Technol. 2019, 268, 80–86. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Li, J.; Wan, L. Joining of carbon fiber reinforced thermoplastic and metal via friction stir welding with co-controlling shape and performance. Compos. Part A Appl. Sci. Manuf. 2018, 112, 328–336. [Google Scholar] [CrossRef]

- Abibe, A.B.; Amancio-Filho, S.T.; Dos Santos, J.F.; Hage, E. Mechanical and failure behaviour of hybrid polymer–metal staked joints. Mater. Des. 2013, 46, 338–347. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Upadhyay, P.; Reza-E-Rabby, M.; Li, X.; Li, L.; Soulami, A.; Kappagantula, K.S.; Whalen, S. Joining of thermoset carbon fiber reinforced polymer and AZ31 magnesium alloy sheet via friction stir interlocking. Int. J. Adv. Manuf. Technol. 2020, 109, 689–698. [Google Scholar] [CrossRef]

- Wang, T.; Li, L.; Pallaka, M.R.; Das, H.; Whalen, S.; Soulami, A.; Upadhyay, P.; Kappagantula, K.S. Mechanical and microstructural characterization of AZ31 magnesium‑carbon fiber reinforced polymer joint obtained by friction stir interlocking technique. Mater. Des. 2021, 198, 109305. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Li, J.; Wan, L. New technique of friction-based filling stacking joining for metal and polymer. Compos. Part B Eng. 2019, 163, 217–223. [Google Scholar] [CrossRef]

- Katayama, S. Handbook of Laser Welding Technologies; Woodhead Publishing: Cambridge, UK; Sawston, UK, 2013. [Google Scholar]

- Lambiase, F.; Genna, S. Experimental analysis of Laser assisted joining of Al-Mg aluminium alloy with Polyetheretherketone (PEEK). Int. J. Adhes. Adhes. 2018, 84, 265–274. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Laser assisted joining of AA5053 aluminum alloy with polyvinyl chloride (PVC). Opt. Laser Technol. 2018, 107, 80–88. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Kant, R. Optimization of laser-assisted joining through an integrated experimental-simulation approach. Int. J. Adv. Manuf. Technol. 2018, 97, 2655–2666. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Leone, C.; Paoletti, A. Laser-assisted direct-joining of carbon fibre reinforced plastic with thermosetting matrix to polycarbonate sheets. Opt. Laser Technol. 2017, 94, 45–58. [Google Scholar] [CrossRef]

- Schricker, K.; Samfaß, L.; Grätzel, M.; Ecke, G.; Bergmann, J.P. Bonding mechanisms in laser-assisted joining of metal-polymer composites. J. Adv. Join. Process. 2020, 1, 100008. [Google Scholar] [CrossRef]

- Staab, F.; Liesegang, M.; Balle, F. Local shear strength distribution of ultrasonically welded hybrid Aluminium to CFRP joints. Compos. Struct. 2020, 248, 112481. [Google Scholar] [CrossRef]

- Yeh, R.-Y.; Hsu, R.-Q. Development of ultrasonic direct joining of thermoplastic to laser structured metal. Int. J. Adhes. Adhes. 2016, 65, 28–32. [Google Scholar] [CrossRef]

- Lionetto, F.; Balle, F.; Maffezzoli, A. Hybrid ultrasonic spot welding of aluminum to carbon fiber reinforced epoxy composites. J. Mater. Process. Technol. 2017, 247, 289–295. [Google Scholar] [CrossRef]

- Junior, W.S.; Handge, U.A.; dos Santos, J.F.; Abetz, V.; Amancio-Filho, S.T. Feasibility study of friction spot welding of dissimilar single-lap joint between poly(methyl methacrylate) and poly(methyl methacrylate)-SiO2 nanocomposite. Mater. Des. 2014, 64, 246–250. [Google Scholar] [CrossRef]

- Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. Friction Spot Joining of aluminum AA2024/carbon-fiber reinforced poly(phenylene sulfide) composite single lap joints: Microstructure and mechanical performance. Mater. Des. 2014, 54, 196–206. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Bueno, C.; dos Dos Santos, J.F.; Huber, N.; Hage, E. On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater. Sci. Eng. A 2011, 528, 3841–3848. [Google Scholar] [CrossRef] [Green Version]

- Goushegir, S.M.; Dos Santos, J.F.; Amancio-Filho, S.T. Influence of process parameters on mechanical performance and bonding area of AA2024/carbon-fiber-reinforced poly(phenylene sulfide) friction spot single lap joints. Mater. Des. 2015, 83, 431–442. [Google Scholar] [CrossRef] [Green Version]

- Jiang, M.; Chen, K.; Chen, B.; Wang, M.; Hua, X.; Zhang, L.; Shan, A. Friction spot joining of TC4 alloy and ultra-high molecular weight polyethylene: Focused on temperature-force relationship. Mater. Des. 2020, 188, 108419. [Google Scholar] [CrossRef]

- Liu, F.C.; Dong, P.; Pei, X. A high-speed metal-to-polymer direct joining technique and underlying bonding mechanisms. J. Mater. Process. Technol. 2020, 280, 116610. [Google Scholar] [CrossRef]

- Liu, F.C.; Liao, J.; Nakata, K. Joining of metal to plastic using friction lap welding. Mater. Des. 2014, 54, 236–244. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Durante, M. Mechanism of bonding of AA7075 aluminum alloy and CFRP during Friction Assisted Joining. Compos. Struct. 2021, 261, 113593. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A. Friction Assisted Joining of titanium and polyetheretherketone (PEEK) sheets. Thin-Walled Struct. 2018, 130, 254–261. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Grossi, V.; Genna, S. Improving energy efficiency in friction assisted joining of metals and polymers. J. Mater. Process. Technol. 2017, 250, 379–389. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Kant, R. A procedure for calibration and validation of FE modelling of laser-assisted metal to polymer direct joining. Opt. Laser Technol. 2018, 98, 363–372. [Google Scholar] [CrossRef]

- Lambiase, F.; di Ilio, A.; Paoletti, A. Hybrid numerical modeling of Friction Assisted Joining. J. Manuf. Process. 2020, 57, 233–243. [Google Scholar] [CrossRef]

- Tolephih, M.H.; Abood, A.N.; Saad, H.M. Hot Press Bonding of Aluminum Alloy AA6061-T6 to Polyamide and Polyamide Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012029. [Google Scholar] [CrossRef]

- Szallies, K.; Bielenin, M.; Schricker, K.; Bergmann, J.P.; Neudel, C. Single-side resistance spot joining of polymer-metal hybrid structures. Weld. World 2019, 63, 1145–1152. [Google Scholar] [CrossRef]

- Li, X.; Xu, D.; Gong, N.; Xu, Z.; Wang, L.; Dong, W. Improving the strength of injection molded aluminum/polyphenylene sulfide lap joints dependence on surface microstructure and composition. Mater. Des. 2019, 179, 107875. [Google Scholar] [CrossRef]

- Li, X.; Liu, F.; Gong, N.; Yang, C.; Wang, B. Surface topography induced high injection joining strength of polymer-metal composite and fracture mechanism. Compos. Struct. 2018, 184, 545–553. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Dos Santos, J.F. Joining of polymers and polymer-metal hybrid structures: Recent developments and trends. Polym. Eng. Sci. 2009, 49, 1461–1476. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Eshtayeh, M.M.; Hrairi, M.; Mohiuddin, A.K.M. Clinching process for joining dissimilar materials: State of the art. Int. J. Adv. Manuf. Technol. 2015, 82, 179–195. [Google Scholar] [CrossRef]

- Lambiase, F.; Balle, F.; Blaga, L.-A.; Liu, F.; Amancio-Filho, S.T. Friction-based processes for hybrid multi-material joining. Compos. Struct. 2021, 113828. [Google Scholar] [CrossRef]

- He, X. Clinching for sheet materials. Sci. Technol. Adv. Mater. 2017, 18, 381–405. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Shan, H.; Li, Y.; Guo, J.; Luo, Z.; Ma, C.Y. Joining aluminum alloy 5052 sheets via novel hybrid resistance spot clinching process. Mater. Des. 2017, 118, 36–43. [Google Scholar] [CrossRef]

- Zhao, L.; He, X.C.; Lu, Y. Study on Clinching of Titanium Alloy. Appl. Mech. Mater. 2014, 633–634, 86–89. [Google Scholar] [CrossRef]

- Osten, J.; Söllig, P.; Reich, M.; Kalich, J.; Füssel, U.; Keßler, O. Softening of High-Strength Steel for Laser Assisted Clinching. Adv. Mater. Res. 2014, 966–967, 617–627. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A. Friction-assisted clinching of Aluminum and CFRP sheets. J. Manuf. Process. 2018, 31, 812–822. [Google Scholar] [CrossRef]

- Lambiase, F.; di Ilio, A. Joining Aluminum with Titanium alloy sheets by mechanical clinching. J. Manuf. Process. 2018, 35, 457–465. [Google Scholar] [CrossRef]

- Lee, C.J.; Kim, B.M.; Kang, B.S.; Song, W.J.; Ko, D.C. Improvement of joinability in a hole clinching process with aluminum alloy and carbon fiber reinforced plastic using a spring die. Compos. Struct. 2017, 173, 58–69. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, C.J.; Kim, B.H.; Ahn, M.S.; Kim, B.M.; Ko, D.C. Effect of Tool Shape on Hole Clinching for CFRP with Steel and Aluminum Alloy Sheet. Key Eng. Mater. 2014, 622–623, 476–483. [Google Scholar] [CrossRef]

- Varis, J. Economics of clinched joint compared to riveted joint and example of applying calculations to a volume product. J. Mater. Process. Technol. 2006, 172, 130–138. [Google Scholar] [CrossRef]

- Pressotechnik, T. Available online: https://us.tox-pressotechnik.com/ (accessed on 1 February 2021).

- Lambiase, F. Mechanical behaviour of polymer–metal hybrid joints produced by clinching using different tools. Mater. Des. 2015, 87, 606–618. [Google Scholar] [CrossRef]

- Varis, J. Ensuring the integrity in clinching process. J. Mater. Process. Technol. 2006, 174, 277–285. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Kato, T. Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J. Mater. Process. Technol. 2012, 212, 884–889. [Google Scholar] [CrossRef]

- Oudjene, M.; Ben-Ayed, L.; Delamézière, A.; Batoz, J.L. Shape optimization of clinching tools using the response surface methodology with Moving Least-Square approximation. J. Mater. Process. Technol. 2009, 209, 289–296. [Google Scholar] [CrossRef]

- de Paula, A.A.; Aguilar, M.T.P.; Pertence, A.E.M.; Cetlin, P.R. Finite element simulations of the clinch joining of metallic sheets. J. Mater. Process. Technol. 2007, 182, 352–357. [Google Scholar] [CrossRef]

- Jayasekara, V.; Min, K.H.; Noh, J.H.; Kim, M.T.; Seo, J.M.; Lee, H.Y.; Hwang, B.B. Rigid-plastic and elastic-plastic finite element analysis on the clinching joint process of thin metal sheets. Metals Mater. Int. 2010, 16, 339–347. [Google Scholar] [CrossRef]

- Lee, C.-J.; Kim, J.-Y.; Lee, S.-K.; Ko, D.-C.; Kim, B.-M. Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J. Mech. Sci. Technol. 2010, 24, 123–126. [Google Scholar] [CrossRef]

- Lambiase, F.; di Ilio, A. Damage analysis in mechanical clinching: Experimental and numerical study. J. Mater. Process. Technol. 2016, 230, 109–120. [Google Scholar] [CrossRef]

- Varis, J.P.; Lepistö, J. A simple testing-based procedure and simulation of the clinching process using finite element analysis for establishing clinching parameters. Thin-Walled Struct. 2003, 41, 691–709. [Google Scholar] [CrossRef]

- Lee, C.-J.; Kim, J.-Y.; Lee, S.-K.; Ko, D.-C.; Kim, B.-M. Design of mechanical clinching tools for joining of aluminium alloy sheets. Mater. Des. 2010, 31, 1854–1861. [Google Scholar] [CrossRef]

- Coppieters, S.; Lava, P.; Baes, S.; Sol, H.; van Houtte, P.; Debruyne, D. Analytical method to predict the pull-out strength of clinched connections. Thin-Walled Struct. 2012, 52, 42–52. [Google Scholar] [CrossRef]

- Zhao, S.D.; Xu, F.; Guo, J.H.; Han, X.L. Experimental and numerical research for the failure behavior of the clinched joint using modified Rousselier model. J. Mater. Process. Technol. 2014, 214, 2134–2145. [Google Scholar] [CrossRef]

- Song, Y.; Yang, L.; Zhu, G.; Hua, L.; Liu, R. Numerical and experimental study on failure behavior of steel-aluminium mechanical clinched joints under multiple test conditions. Int. J. Lightweight Mater. Manuf. 2019, 2, 72–79. [Google Scholar] [CrossRef]

- Mucha, J. Clinching technology in the automotive industry. Arch. Automot. Eng. 2017, 76. [Google Scholar] [CrossRef]

- Babalo, V.; Fazli, A.; Soltanpour, M. Electro-Hydraulic Clinching: A novel high speed joining process. J. Manuf. Process. 2018, 35, 559–569. [Google Scholar] [CrossRef]

- Lambiase, F. Influence of process parameters in mechanical clinching with extensible dies. Int. J. Adv. Manuf. Technol. 2012, 66, 2123–2131. [Google Scholar] [CrossRef]

- Neugebauer, R.; Kraus, C.; Dietrich, S. Advances in mechanical joining of magnesium. CIRP Ann. 2008, 57, 283–286. [Google Scholar] [CrossRef]

- Busse, S.; Merklein, M.; Roll, K.; Ruther, M.; Zürn, M. Development of a mechanical joining process for automotive body-in-white production. Int. J. Mater. Form. 2010, 3, 1059–1062. [Google Scholar] [CrossRef]

- Lee, C.-J.; Lee, J.-M.; Ryu, H.-Y.; Lee, K.-H.; Kim, B.-M.; Ko, D.-C. Design of hole-clinching process for joining of dissimilar materials—Al6061-T4 alloy with DP780 steel, hot-pressed 22MnB5 steel, and carbon fiber reinforced plastic. J. Mater. Process. Technol. 2014, 214, 2169–2178. [Google Scholar] [CrossRef]

- Wen, T.; Wang, H.; Yang, C.; Liu, L.T. On a reshaping method of clinched joints to reduce the protrusion height. Int. J. Adv. Manuf. Technol. 2014, 71, 1709–1715. [Google Scholar] [CrossRef]

- Shi, C.; Yi, R.; Chen, C.; Peng, H.; Ran, X.; Zhao, S. Forming mechanism of the repairing process on clinched joint. J. Manuf. Process. 2020, 50, 329–335. [Google Scholar] [CrossRef]

- He, X.; Pearson, I.; Young, K. Self-pierce riveting for sheet materials: State of the art. J. Mater. Process. Technol. 2008, 199, 27–36. [Google Scholar] [CrossRef]

- B. Group. Available online: https://www.boellhoff.com (accessed on 1 February 2021).

- Fastening, S.E. Available online: https://www.stanleyengineeredfastening.com (accessed on 1 February 2021).

- Li, D.; Han, L.; Thornton, M.; Shergold, M. Influence of edge distance on quality and static behaviour of self-piercing riveted aluminium joints. Mater. Des. 2012, 34, 22–31. [Google Scholar] [CrossRef]

- Li, D.; Chrysanthou, A.; Patel, I.; Williams, G. Self-piercing riveting-a review. Int. J. Adv. Manuf. Technol. 2017, 92, 1777–1824. [Google Scholar] [CrossRef] [Green Version]

- Porcaro, R.; Hanssen, A.G.; Langseth, M.; Aalberg, A. Self-piercing riveting process: An experimental and numerical investigation. J. Mater. Process. Technol. 2006, 171, 10–20. [Google Scholar] [CrossRef]

- Xie, Z.; Yan, W.; Yu, C.; Mu, T.; Song, L. Tensile capacity of self-piercing rivet connections in thin-walled steel structures. J. Constr. Steel Res. 2018, 144, 211–220. [Google Scholar] [CrossRef]

- Hou, W.; Mangialardi, E.; Hu, S.J.; Wang, P.C.; Menass, R. Characterization for quality monitoring of a self-piercing riveting process. In Proceedings of the Sheet Metal Welding conference XI, Sterling Hieights, Detroit, MI, USA, 11–14 May 2004. [Google Scholar]

- Borba, N.Z.; Blaga, L.; Dos Santos, J.F.; Amancio-Filho, S.T. Direct-Friction Riveting of polymer composite laminates for aircraft applications. Mater. Lett. 2018, 215, 31–34. [Google Scholar] [CrossRef]

- Borba, N.Z.; Kötter, B.; Fiedler, B.; Dos Santos, J.F.; Amancio-Filho, S.T. Mechanical integrity of friction-riveted joints for aircraft applications. Compos. Struct. 2020, 232, 111542. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Beyer, M.; Dos Santos, J.F. Method of Connecting a Metallic Bolt to a Plastic Workpiece. U.S. Patent 7,575,149, 18 August 2009. [Google Scholar]

- Amancio-Filho, S.T.; Blaga, L.-A. Joining of Polymer-Metal Hybrid Structures: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Gagliardi, F.; Conte, R.; Ciancio, C.; Simeoli, G.; Pagliarulo, V.; Ambrogio, G.; Russo, P. Joining of thermoplastic structures by Friction Riveting: A mechanical and a microstructural investigation on pure and glass reinforced polyamide sheets. Compos. Struct. 2018, 204, 268–275. [Google Scholar] [CrossRef]

- Hynes, N.R.J.; Vignesh, N.J.; Velu, P.S. Low-speed friction riveting: A new method for joining polymer/metal hybrid structures for aerospace applications. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–6. [Google Scholar] [CrossRef]

- Okada, T.; Uchida, S.; Nakata, K. Direct Joining of Aluminum Alloy and Plastic Sheets by Friction Lap Processing. Mater. Sci. Forum 2014, 794–796, 395–400. [Google Scholar] [CrossRef]

- Nagatsuka, K.; Yoshida, S.; Tsuchiya, A.; Nakata, K. Direct joining of carbon-fiber–reinforced plastic to an aluminum alloy using friction lap joining. Compos. Part B Eng. 2015, 73, 82–88. [Google Scholar] [CrossRef]

- Liu, F.C.; Nakata, K.; Liao, J.; Hirota, S.; Fukui, H. Reducing bubbles in friction lap welded joint of magnesium alloy and polyamide. Sci. Technol. Weld. Join. 2014, 19, 578–587. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Paoletti, A. Friction Stir Joining of CFRP laminates with amorphous polymers: Influence of processing speeds. J. Manuf. Process. 2020, 55, 186–197. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Paoletti, A. Effect of tilt angle in FSW of polycarbonate sheets in butt configuration. Int. J. Adv. Manuf. Technol. 2020, 107, 489–501. [Google Scholar] [CrossRef]

- Manente André, N.; dos Santos, J.F.; TAmancio-Filho, S. Evaluation of Joint Formation and Mechanical Performance of the AA7075-T6/CFRP Spot Joints Produced by Frictional Heat. Materials 2019, 12, 891. [Google Scholar] [CrossRef] [Green Version]

- Lambiase, F.; Genna, S. Laser-assisted direct joining of AISI304 stainless steel with polycarbonate sheets: Thermal analysis, mechanical characterization, and bonds morphology. Opt. Laser Technol. 2017, 88, 205–214. [Google Scholar] [CrossRef]

- Liu, F.C.; Dong, P.; Lu, W.; Sun, K. On formation of Al-O-C bonds at aluminum/polyamide joint interface. Appl. Surf. Sci. 2019, 466, 202–209. [Google Scholar] [CrossRef]

- Liu, F.C.; Liao, J.; Gao, Y.; Nakata, K. Effect of plasma electrolytic oxidation coating on joining metal to plastic. Sci. Technol. Weld. Join. 2015, 20, 291–296. [Google Scholar] [CrossRef]

- Nagatsuka, K.; Kitagawa, D.; Yamaoka, H.; Nakata, K. Friction Lap Joining of Thermoplastic Materials to Carbon Steel. ISIJ Int. 2016, 56, 1226–1231. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.H.; Nagatsuka, K.; Nakata, K. Direct joining of oxygen-free copper and carbon-fiber-reinforced plastic by friction lap joining. J. Mater. Sci. Technol. 2018, 34, 192–197. [Google Scholar] [CrossRef]

- Nagatsuka, K.; Xiao, B.; Wu, L.; Nakata, K.; Saeki, S.; Kitamoto, Y.; Iwamoto, Y. Resistance spot welding of metal/carbon-fibre-reinforced plastics and applying silane coupling treatment. Sci. Technol. Weld. Join. 2018, 23, 181–186. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L. Resistance welding of metal/thermoplastic composite joints. J. Thermoplast. Compos. 2001, 14, 449–475. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y. Laser direct joining of metal and plastic. Scr. Mater. 2008, 59, 1247–1250. [Google Scholar] [CrossRef]

- Kawahito, Y.; Niwa, Y.; Terajima, T.; Katayama, S. Laser Direct Joining of Glassy Metal Zr55Al10Ni5Cu30 to Engineering Plastic Polyethylene Terephthalate. Mater. Trans. 2010, 51, 1433–1436. [Google Scholar] [CrossRef] [Green Version]

- Farazila, Y.; Miyashita, Y.; Hua, W.; Mutoh, Y.; Otsuka, Y. YAG Laser Spot Welding of PET and Metallic Materials. J. Laser Micro Nanoen. 2011, 6, 69–74. [Google Scholar] [CrossRef]

- Wahba, M.; Kawahito, Y.; Katayama, S. Laser direct joining of AZ91D thixomolded Mg alloy and amorphous polyethylene terephthalate. J. Mater. Process. Technol. 2011, 211, 1166–1174. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Katayama, S. Laser direct joining of carbon fibre reinforced plastic to stainless steel. Sci. Technol. Weld. Join. 2011, 16, 676–680. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Takahashi, M.; Katayama, S. Laser direct joining of carbon fiber reinforced plastic to zinc-coated steel. Mater. Des. 2013, 47, 179–188. [Google Scholar] [CrossRef]

- Yusof, F.; Yukio, M.; Yoshiharu, M.; Shukor, M.H.A. Effect of anodizing on pulsed Nd:YAG laser joining of polyethylene terephthalate (PET) and aluminium alloy (A5052). Mater. Des. 2012, 37, 410–415. [Google Scholar] [CrossRef]

- Hussein, F.I.; Akman, E.; Oztoprak, B.G.; Gunes, M.; Gundogdu, O.; Kacar, E.; Hajim, K.I.; Demir, A. Evaluation of PMMA joining to stainless steel 304 using pulsed Nd:YAG laser (vol 49, pg 143, 2013). Opt. Laser Technol. 2013, 49, 143–152. [Google Scholar] [CrossRef]

- Hussein, F.I.; Salloomi, K.N.; Akman, E.; Hajim, K.I.; Demir, A. Finite element thermal analysis for PMMA/st.st.304 laser direct joining. Opt. Laser Technol. 2017, 87, 64–71. [Google Scholar] [CrossRef]

- Zhang, Z.; Shan, J.G.; Tan, X.H. Evaluation of the CFRP grafting and its influence on the laser joining CFRP to aluminum alloy. J. Adhes. Sci. Technol. 2018, 32, 390–406. [Google Scholar] [CrossRef]

- Ai, Y.W.; Zheng, K.; Shin, Y.C.; Wu, B.X. Analysis of weld geometry and liquid flow in laser transmission welding between polyethylene terephthalate (PET) and Ti6A14V based on numerical simulation. Opt. Laser Technol. 2018, 103, 99–108. [Google Scholar] [CrossRef]

- Chan, C.W.; Smith, G.C. Fibre laser joining of highly dissimilar materials: Commercially pure Ti and PET hybrid joint for medical device applications. Mater. Des. 2016, 103, 278–292. [Google Scholar] [CrossRef] [Green Version]

- Jung, D.J.; Cheon, J.; Na, S.J. Effect of surface pre-oxidation on laser assisted joining of acrylonitrile butadiene styrene (ABS) and zinc-coated steel. Mater. Des. 2016, 99, 1–9. [Google Scholar] [CrossRef]

- Yusof, F.; Miyashita, Y.; Seo, N.; Mutoh, Y.; Moshwan, R. Utilising friction spot joining for dissimilar joint between aluminium alloy (A5052) and polyethylene terephthalate. Sci. Technol. Weld. Join. 2012, 17, 544–549. [Google Scholar] [CrossRef]

- Esteves, J.V.; Goushegir, S.M.; Dos Santos, J.F.; Canto, L.B.; Hage, E.; Amancio, S.T. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly(phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater. Des. 2015, 66, 437–445. [Google Scholar] [CrossRef] [Green Version]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer-joints. Mater. Werkst 2007, 38, 934–938. [Google Scholar] [CrossRef]

- Balle, F.; Eifler, D. Statistical test planning for ultrasonic welding of dissimilar materials using the example of aluminum-carbon fiber reinforced polymers (CFRP) joints. Mater. Werkst. 2012, 43, 286–292. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A. Mechanical behavior of AA5053/polyetheretherketone (PEEK) made by Friction Assisted Joining. Compos. Struct. 2018, 189, 70–78. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Grossi, V.; di Ilio, A. Friction assisted joining of aluminum and PVC sheets. J. Manuf. Process. 2017, 29, 221–231. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S. Homogenization of temperature distribution at metal-polymer interface during Laser Direct Joining. Opt. Laser Technol. 2020, 128, 106226. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Paoletti, A. Machine learning applied for process design of hybrid metal-polymer joints. J. Manuf. Process. 2020, 58, 92–100. [Google Scholar] [CrossRef]

- Lee, C.-J.; Shen, G.; Kim, B.-M.; Lambiase, F.; Ko, D.-C. Analysis of Failure-Mode Dependent Joint Strength in Hole Clinching from the Aspects of Geometrical Interlocking Parameters. Metals 2018, 8, 1020–1031. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhuang, W. Self-piercing riveted-bonded hybrid joining of carbon fibre reinforced polymers and aluminium alloy sheets. Thin-Walled Struct. 2019, 144, 106340. [Google Scholar] [CrossRef]

- Abibe, A.B.; Sônego, M.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. On the feasibility of a friction-based staking joining method for polymer–metal hybrid structures. Mater. Des. 2016, 92, 632–642. [Google Scholar] [CrossRef] [Green Version]

- Zinn, C.; Bobbert, M.; Dammann, C.; Wang, Z.; Tröster, T.; Mahnken, R.; Meschut, G.; Schaper, M. Shear strength and failure behaviour of laser nano-structured and conventionally pre-treated interfaces in intrinsically manufactured CFRP-steel hybrids. Compos. Part B Eng. 2018, 151, 173–185. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; Dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Paoletti, A. Defects formation during Friction Assisted Joining of metals and semi crystalline polymers. J. Manuf. Process. 2021, 62, 833–844. [Google Scholar] [CrossRef]

- André, N.M.; Goushegir, S.M.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Friction Spot Joining of aluminum alloy 2024-T3 and carbon-fiber-reinforced poly(phenylene sulfide) laminate with additional PPS film interlayer: Microstructure, mechanical strength and failure mechanisms. Compos. Part B Eng. 2016, 94, 197–208. [Google Scholar] [CrossRef]

- André, N.M.; Goushegir, S.M.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Influência da Espessura do Filme Polimérico Intermediário na Resistência Mecânica de Juntas Híbridas de Alumínio 2024-T3 e CF-PPS Produzidas por União Pontual por Fricção. Soldag. Inspeção 2016, 21, 2–15. [Google Scholar] [CrossRef] [Green Version]

- André, N.M.; Goushegir, S.M.; Scharnagl, N.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Composite surface pre-treatments: Improvement on adhesion mechanisms and mechanical performance of metal–composite friction spot joints with additional film interlayer. J. Adhes. 2018, 94, 723–742. [Google Scholar] [CrossRef]

| Bond Type | Equilibrium Length (nm) | Bonding Energy (kJ mol−1) |

|---|---|---|

| Ionic (primary, chemical) | 0.2–0.4 | 560–1000 |

| Covalent (primary, chemical) | 0.1–0.3 | 60–800 |

| Metallic (primary, chemical) | 0.2–0.6 | 100–350 |

| Hydrogen (secondary, physical) | 0.3–0.5 | 50 |

| London (secondary, physical) | 0.3–0.5 | 1–40 |

| Debye (secondary, physical) | 0.3–0.5 | 2 |

| Keesom (secondary, physical) | 0.3–0.5 | 2–8 |

| Authors | Polymers | Metals | Joining Methods | C=O Groups | Specific Surface Modification |

|---|---|---|---|---|---|

| Liu et al. [30] | PA | 6061 Al | FLW | Yes | No |

| Liu et al. [91] | PA | AZ31B Mg | FLW | Yes | No |

| Liu et al. [90] | PE | Non-combustible Mg | FLW | No | Plasma electrolytic oxidation |

| Nagatsuka et al. [97] | CFRP-PA | 5052Al | FLW | Yes | No |

| Nagatsuka et al. [98] | PA | Low carbon steel | FLW | Yes | No |

| Wu et al. [99] | CFRP-PA | Copper | FLW | Yes | No |

| Nagatsuka et al. [100] | CFRP-PA | 304 stainless steel | RSW | Yes | No |

| Nagatsuka et al. [100] | CFRP-PPS | 304 stainless steel | RSW | No | Coupling agent |

| Nagatsuka et al. [100] | CFRP-PP | 304 stainless steel | RSW | No | Acid-modified |

| Ageorges et al. [101] | PEI | 7075 Al | RSW | Yes | No |

| Katayama et al. [102] | PET | 304 stainless steel | LDJ | Yes | No |

| Kawahito et al. [103] | PET | Zr55Al10Ni5Cu30 | LDJ | Yes | No |

| Farazila et al. [104] | PET | copper | LDJ | Yes | No |

| Farazila et al. [104] | PET | 5052 Al | LDJ | Yes | No |

| Wahba et al. [105] | PET | AZ91D Mg | LDJ | Yes | No |

| Jung et al. [106] | CFRP-PA | 304 stainless steel | LDJ | Yes | No |

| Jung et al. [107] | CFRP-PA | Galvanized steel | LDJ | Yes | No |

| Yusof et al. [108] | PET | 5052Al | LDJ | Yes | No |

| Hussein et al. [109,110] | PMMA | 304 stainless steel | LDJ | Yes | No |

| Lambiase et al. [19] | PC | 304 stainless steel | LDJ | Yes | No |

| Zhang et al. [111] | CFRP-PA | 6061Al | LDJ | Yes | No |

| Ai et al. [112] | PET | Ti6Al4V | LDJ | Yes | No |

| Chan et al. [113] | PET | CP Ti | LDJ | Yes | No |

| Jung et al. [114] | ABS | Galvanized steel | LDJ | No | Surface oxidation |

| Yusof et al. [115] | PET | 5052Al | FAW | Yes | No |

| Amancio et al. [25] | CFRP-PPS | AZ31 Mg | RFSSW | No | Acetone rinsing |

| Goushegir et al. [26] | CFRP-PPS | 2024 Al | RFSSW | No | Acetone rinsing |

| Esteves et al. [116] | CFRP-PPS | 6181 Al | RFSSW | No | Acetone rinsing |

| Balle et al. [117] | CFRP-PA | 1050Al | USW | Yes | No |

| Balle et al. [118] | CFRP-PA | 5754Al | USW | Yes | No |

| Lionetto et al. [23] | CFRP-PA | 5754Al | USW | Yes | No |

| Lambiase et al. [119] | PEEK | 5053Al | FAW | Yes | Laser texturing |

| Lambiase et al. [120] | PVC | 5053Al | FAW | No | Laser texturing |

| Main characteristics | Advanced Mechanical Fastening | Thermomechanical Interlocking | Thermomechanical Joining |

|---|---|---|---|

| Main joining mechanism | Macro-mechanical. interlocking | Macro-mechanical interlocking. | Micromechanical interlocking. Chemical bonding. |

| How the joints are achieved | Moderate plastic deformation. | Large thermoplastic deformation. | Application of compression pressure and heating. |

| Main limitations/issues | Damage of the composite (when the process is performed without pre-drilled holes). Formability of the metal may lead to fracture (this can be solved by the adoption of heating systems). | The complexity of the process. May involve temperature-induced issues. Heavy joining forces. | The complexity of the process. Temperature-induced defects. Uneven joining conditions. |

| Process design | Difficulty to use FE models to design the tools since the difficulty to predict the composite behavior/damage. | Since the composite is often not deformed, numerical simulations can be used for design purposes. | Thermo-mechanical simulations enable to predict accurately the processing conditions (stress, temperature). |

| Type of joint | Spot. | Spot/continuous. | Spot/continuous. |

| Static behavior-ultimate shear force [kN] | Clinching 3-kN [123]. Self-pierce riveting up to 12 kN [124]. | Frict. riveting: 7 kN [83]. Frict. stir welding 3 kN [6]. Frict. based filling 1.2 kN [14]. Frict. based stacking 1 kN [125]. | Frict. assisted joining: 11 kN [31]. Frict. spot joining: 2.5 kN [27]. Ultrasonic welding: 8 kN [21]. Laser-assisted joining: 10 kN [126]. |

| Current design limitations | The demand for modeling techniques that enable the prediction of the onset of process-induced defects (e.g., damage) in the composite laminate. | Characterization of thermo-mechanical properties of the materials involved to develop a reliable numerical model of the processes. | Characterization of thermo-mechanical properties of the material involved to develop a reliable numerical model of the process. Uneven joining conditions make it even more difficult to determine optimal joining conditions. |

| Key development trends | New heating systems and control. Modeling and prediction of mechanical behavior. | New process control strategies [127]. Numerical modeling of the process. Modeling and prediction of mechanical behavior. | Localized characterization systems of the joints [21]. High-speed systems for process control. Structured approach for the process design for virtual process optimization (integration of numerical models with Artificial Intelligence [122]. New surface pretreatment processes to improve the adhesion of the components. |

| Advanced Joining process | Pros | Cons |

|---|---|---|

| Advanced mechanical fastening processes | ||

| Mechanical Clinching | Easy and fast Does not involve external material/components Does not involve temperature-induced issues | Spot connection Involves composite delamination The formability of the metal can involve severe limitation to the applicability |

| Self-pierce riveting | Easy and fast Does not involve temperature-induced issues | Spot connection Involves composite delamination Involves an external (and expensive) joining element |

| Thermomechanical interlocking processes | ||

| Friction Riveting | Easy and fast | Spot connection Involves an external joining element May involve temperature-induced issues Heavy joining forces |

| Friction self-riveting | High productivity Does not involve external material/components | Spot connection May involve temperature-induced issues Heavy joining forces |

| Injection clinching joining | Easy Low processing forces | Spot connection Demands of a preformed stud being produced on the polymer Requires the drilling of a hole in the metal component |

| Friction-based filling stacking | - | Spot connection Requires the drilling of a hole in the metal component May involve temperature-induced issues Heavy joining forces |

| Friction stir lap welding | Continuous joint | May involve temperature-induced issues Heavy joining forces May cause fiber interruption |

| Thermomechanical joining processes | ||

| Radiation based processes (laser, IR, etc.) | Continuous or spot joint Negligible processing forces | Involves temperature-induced issues Surface pretreatments are highly recommended Radiation absorption The connection is limited to the interface (likely adhesive bonds) |

| Friction-based processes | Continuous or spot joint | Involves temperature-induced issues Surface pretreatments are highly recommended Need medium compression forces The connection is limited to the interface (likely adhesive bonds); however, deep interlocking is possible if long protrusions are made on the metal surface. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lambiase, F.; Scipioni, S.I.; Lee, C.-J.; Ko, D.-C.; Liu, F. A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures. Materials 2021, 14, 1890. https://doi.org/10.3390/ma14081890

Lambiase F, Scipioni SI, Lee C-J, Ko D-C, Liu F. A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures. Materials. 2021; 14(8):1890. https://doi.org/10.3390/ma14081890

Chicago/Turabian StyleLambiase, Francesco, Silvia Ilaria Scipioni, Chan-Joo Lee, Dae-Cheol Ko, and Fengchao Liu. 2021. "A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures" Materials 14, no. 8: 1890. https://doi.org/10.3390/ma14081890

APA StyleLambiase, F., Scipioni, S. I., Lee, C.-J., Ko, D.-C., & Liu, F. (2021). A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures. Materials, 14(8), 1890. https://doi.org/10.3390/ma14081890