Physical Properties and Durability of Lime-Cement Mortars Prepared with Water Containing Micro-Nano Bubbles of Various Gases

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Properties

- Reference—reference mortar with ordinary tap water;

- 50% CO2—mortar with 50% CO2 micro-nano bubble water;

- 100% CO2—mortar with 100% CO2 micro-nano bubble water;

- 50% O2—mortar with 50% O2 micro-nano bubble water;

- 100% O2—mortar with 100% O2 micro-nano bubble water;

- 50% O3—mortar with 50% O3 micro-nano bubble water;

- 100% O3—mortar with 100% O3 micro-nano bubble water.

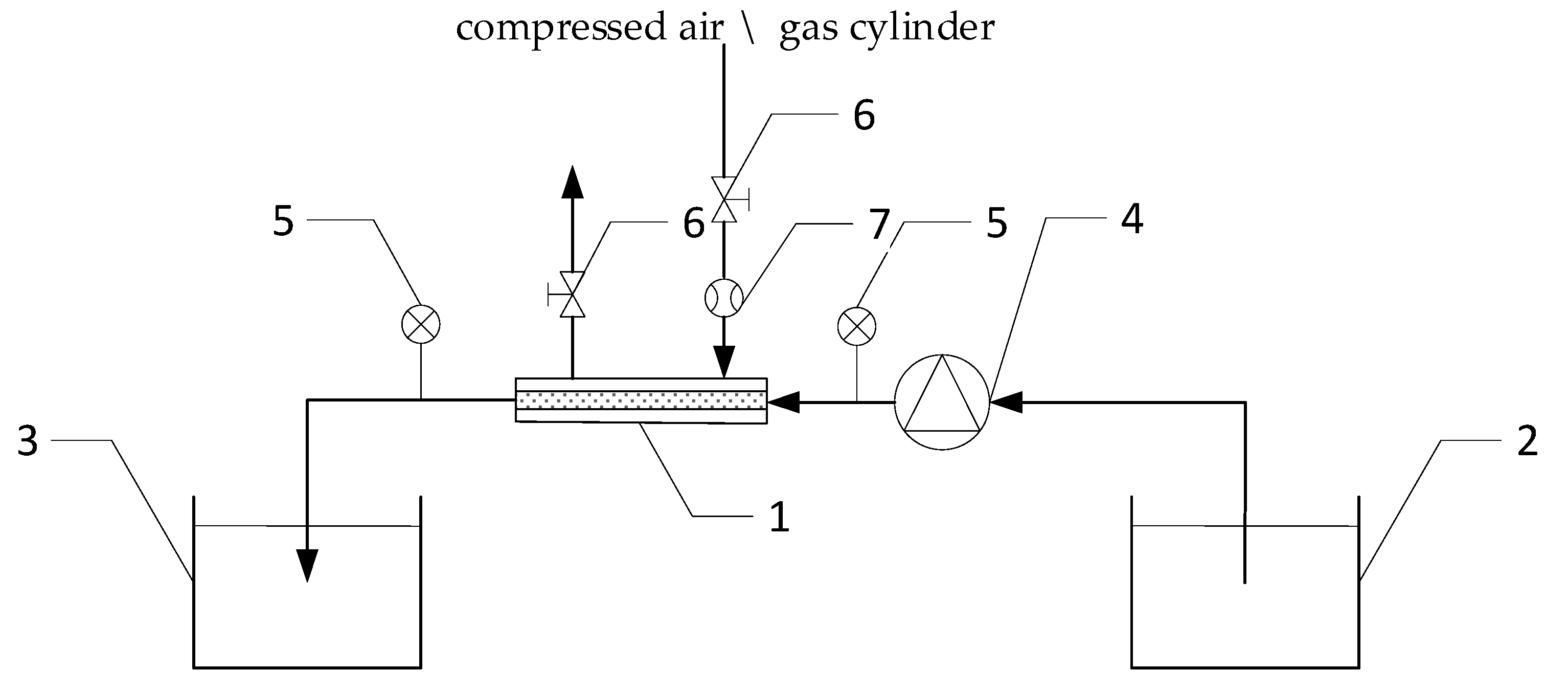

2.2. Methods of Micro-Nano Bubbles of Gases Obtaining

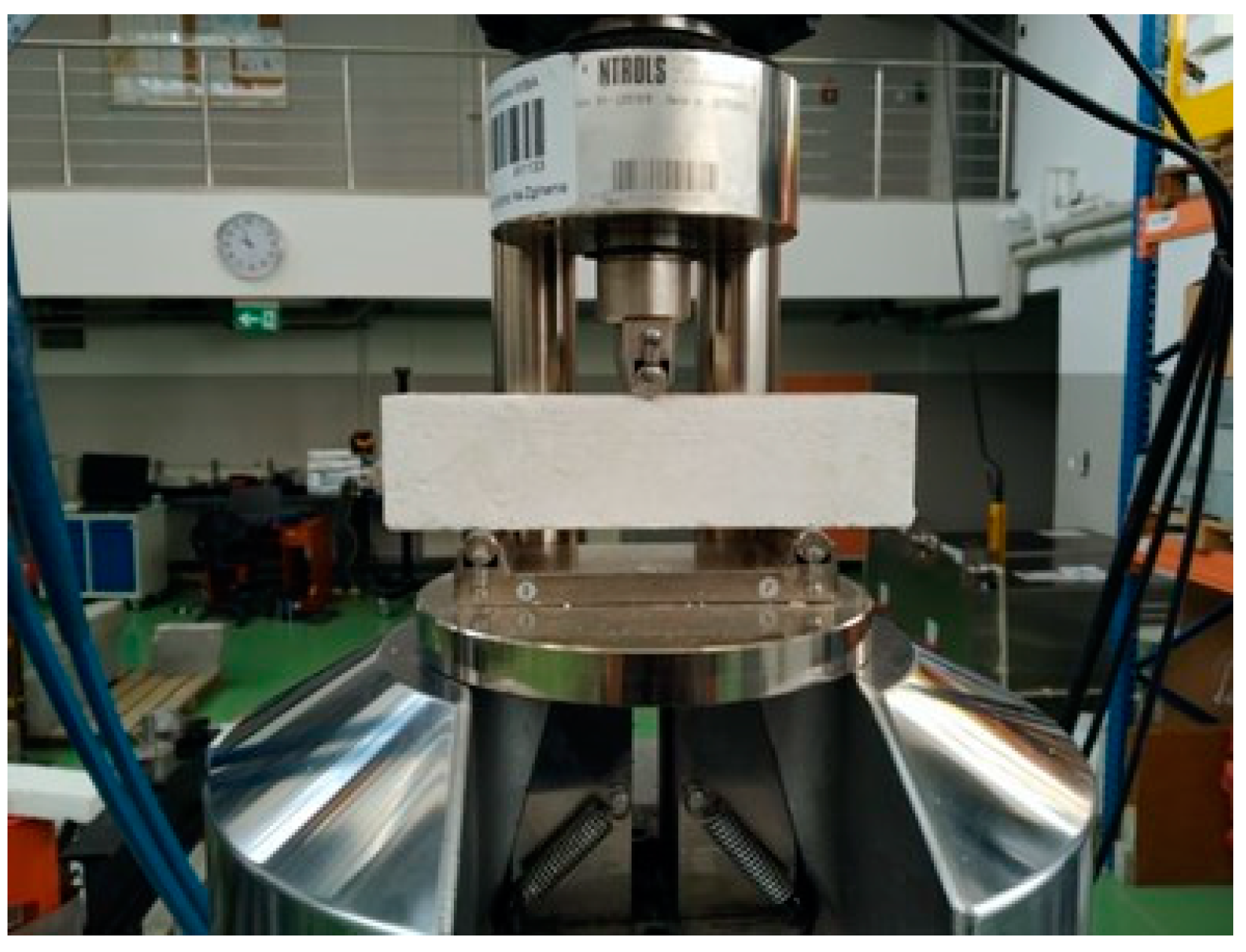

2.3. Methods of Mortar Analysis

- —bulk density [g/cm3],

- —specific density [g/cm3].

- C—water absorption coefficient [kg/m2],

- mw24—sample weight determined after 24 h of capillary water rise [g],

- ms—sample weight after drying to constant mass [g].

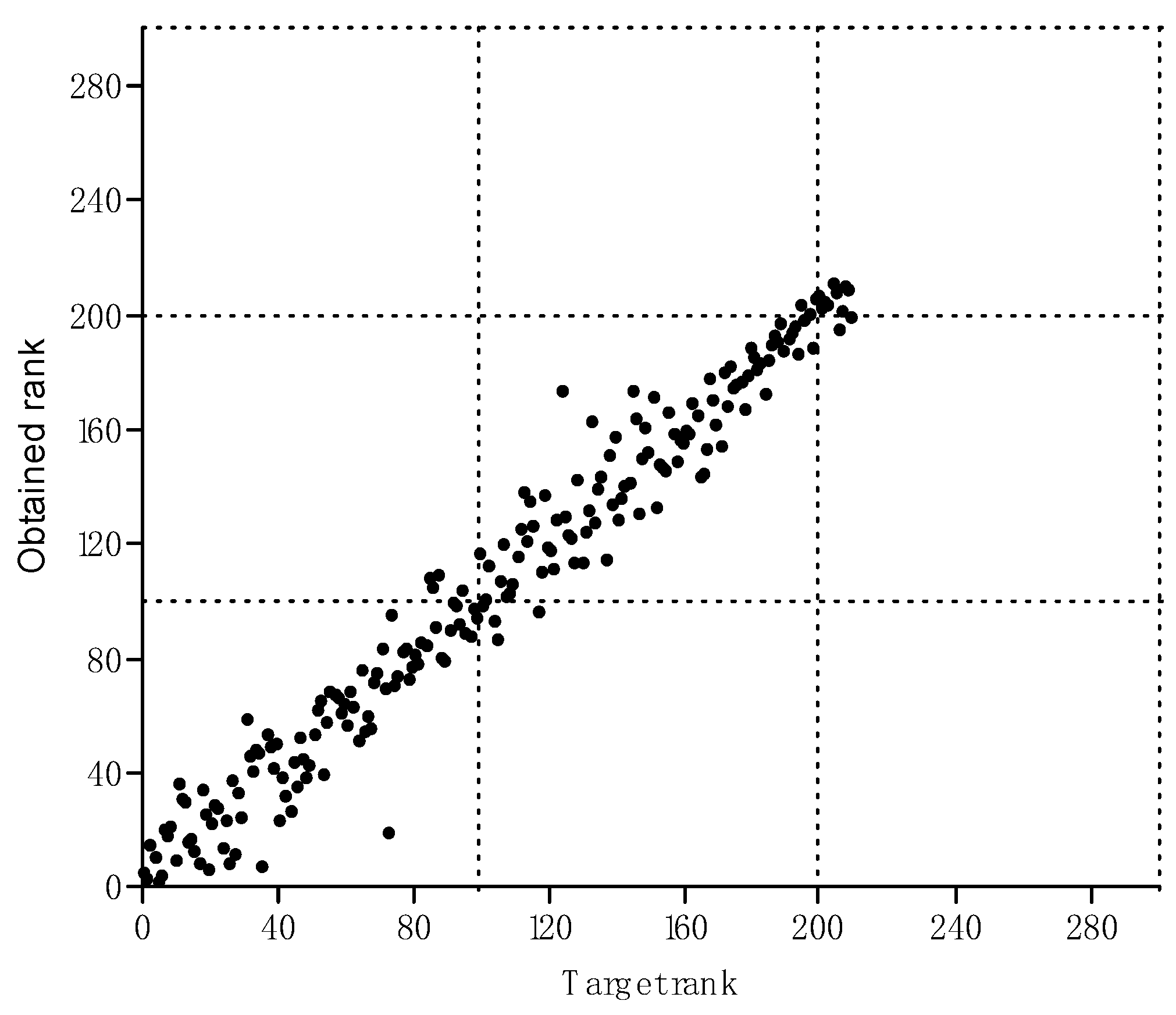

2.4. Visualization of Obtained Data Using Multidimensional Scaling Method

3. Results and Discussion

4. Conclusions

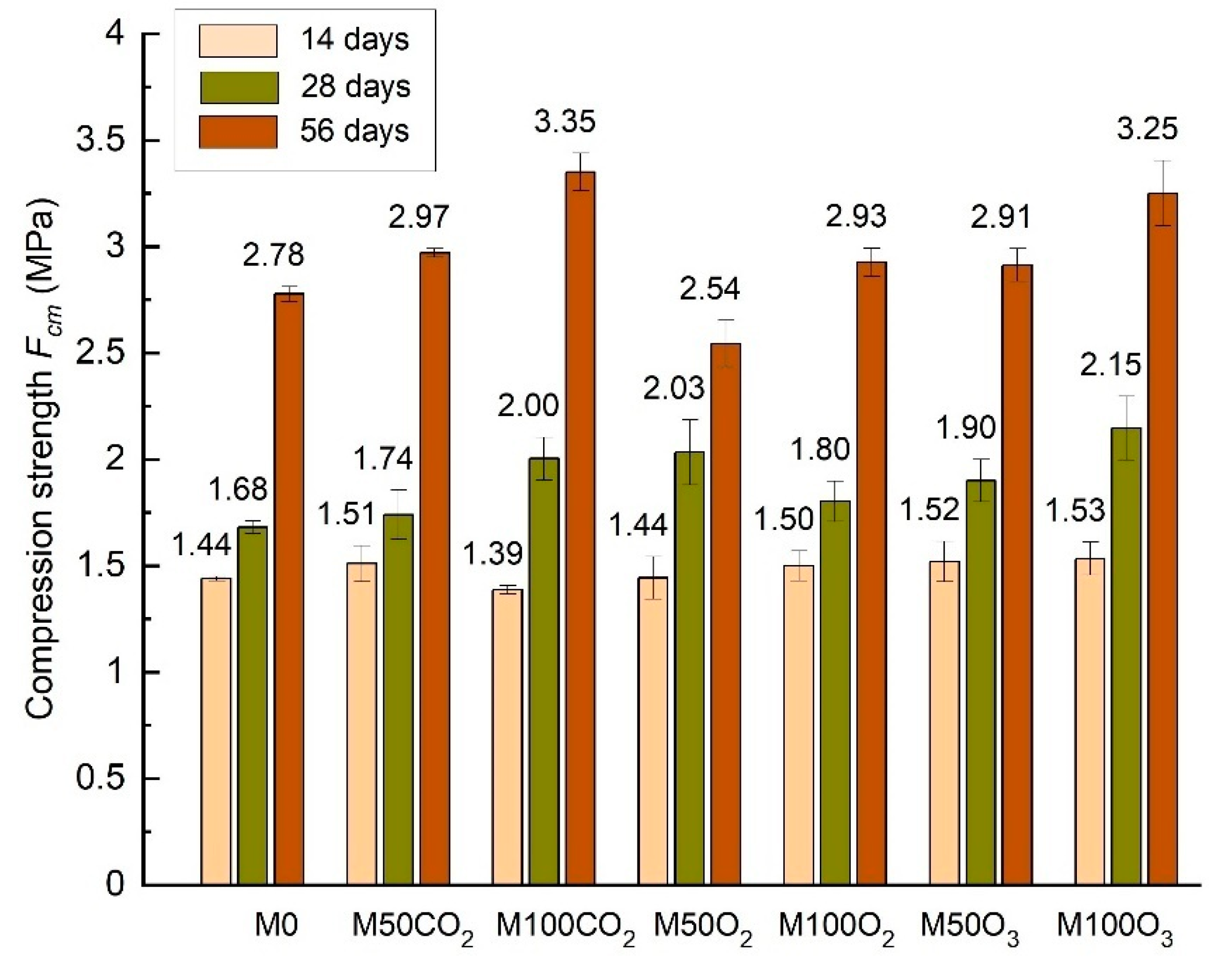

- Along with an increase in the amount of MNB, the compressive strength is markedly proved. The highest strength after 28 days was achieved by the 50% O2 mortars, which translates into a 31% improvement in relation to the reference sample. The 50% O3 mortar, in which strength dropped by 2.6%, constitutes an exception. Almost all mortars indicated an increase in flexural strength after 56 days, ranging from 8.3% to 34% and increased compressive strength in the range of 4–19.4%, compared to the reference mortar.

- The studies of the physical properties indicated a diversified influence of micro-nano bubbles on the density of mortars. The oxygen and ozone micro-nano bubble water reduced the specific density of the investigated mortars, whereas the water with CO2 increased the specific density, which resulted from faster CaCO3 formation in the mortar. The CO2 micro-nano bubble water increased the bulk density of the considered mortars by 0.9% and 1.5% in the case of the 50% CO2 and 100% CO2, respectively. These mortars were also characterized by a comparable porosity to that of the reference mortars, reaching the highest porosity values out of all mortars.

- A general reduction in capillary absorption of the mortars with micro-nano bubble water was observed in the range of 0.9–8.5% in relation to the reference mortar. This is caused by a reduced size of capillary pores resulting from the application of MNB water, which is confirmed by the studies concerning the water absorption by weight of the mortars with ozone and oxygen micro-nano bubbles, which reduced the water absorption of the investigated mortars by 2.7–2.8% in relation to the reference mortars.

- The analysis based on the MDS method showed that taking into account the results of all analyzed parameters simultaneously, it is possible to clearly distinguish the mortars prepared with the addition of the water containing micro-nano bubbles of various gases as well as reference mortars. The changes in the properties of the mortar are most clearly visible with the increased proportion of water with the CO2 micro-nano bubbles as mixing water.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dahlan, A.S. Impact of nanotechnology on high performance cement and concrete. J. Mol. Struct. 2021, 1223, 128896. [Google Scholar] [CrossRef]

- Ge, Z.; Gao, Z. Applications of nanotechnology and nanomaterials in construction. In Proceedings of the First International Conference on Construction in Developing Countries (ICCIDC–I), Karachi, Pakistan, 4–5 August 2008. [Google Scholar]

- Ghazanlou, S.I.; Jalaly, M.; Sadeghzadeh, S.; Korayem, A.H. A comparative study on the mechanical, physical and morphological properties of cement-micro/nanoFe3O4 composite. Sci. Rep. 2020, 10, 2859. [Google Scholar] [CrossRef] [Green Version]

- Dębek, P.; Feliczak-Guzik, A.; Nowak, I. Nanostructures: General information. The use of nanoobjects in medicine and cosmetology. Postepy Hig. Med. Dosw. 2017. [Google Scholar] [CrossRef]

- Pulit-Prociak, J.; Banach, M. Silver nanoparticles—A material of the future...? Open Chem. 2016, 14, 76–91. [Google Scholar] [CrossRef]

- Mobasser, S.; Firoozi, A.A. Review of Nanotechnology Applications in Science and Engineering. J. Civ. Eng. Urban. 2016, 6, 84–93. [Google Scholar]

- Tsuge, H. Micro- and Nanobubbles—Fundamentals and Applications; Jenny Stanford Publishing: Singapore, Singapore, 2014; ISBN 9789814463119. [Google Scholar]

- Wu, Z.; Chen, H.; Dong, Y.; Mao, H.; Sun, J.; Chen, S.; Craig, V.S.J.; Hu, J. Cleaning using nanobubbles: Defouling by electrochemical generation of bubbles. J. Colloid Interface Sci. 2008, 328, 10–14. [Google Scholar] [CrossRef]

- Konował, E.; Sybis, M.; Modrzejewska-Sikorska, A.; Milczarek, G. Synthesis of dextrin-stabilized colloidal silver nanoparticles and their application as modifiers of cement mortar. Int. J. Biol. Macromol. 2017, 104, 165–172. [Google Scholar] [CrossRef] [PubMed]

- Jalal, M.; Pouladkhan, A.; Harandi, O.F.; Jafari, D. Comparative study on effects of Class F fly ash, nano silica and silica fume on properties of high performance self compacting concrete. Constr. Build. Mater. 2015, 94, 90–104. [Google Scholar] [CrossRef]

- Rong, Z.; Zhao, M.; Wang, Y. Effects of Modified Nano-SiO2 Particles on Properties of High-Performance Cement-Based Composites. Materials 2020, 13, 646. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Szostak, B.; Golewski, G.L. Effect of nano admixture of CSH on selected strength parameters of concrete including fly ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Barbesta, M.; Schaffer, D. Concrete that cleans itself and the air. Concr. Int. 2009, 31, 49–51. [Google Scholar]

- Jaishankar, P.; Karthikeyan, C. Characteristics of cement concrete with nano alumina particles. IOP Conf. Ser. Earth Environ. Sci. 2017, 80, 012005. [Google Scholar] [CrossRef]

- Gong, K.; Pan, Z.; Korayem, A.H.; Qiu, L.; Li, D.; Collins, F.; Wang, C.M.; Duan, W.H. Reinforcing Effects of Graphene Oxide on Portland Cement Paste. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Szymańska-Chargot, M.; Łagód, G. Effect of Eco-Friendly Cellulose Nanocrystals on Physical Properties of Cement Mortars. Polymers 2019, 11, 2088. [Google Scholar] [CrossRef] [Green Version]

- Khan, P.; Zhu, W.; Huang, F.; Gao, W.; Khan, N.A. Micro-nanobubble technology and water-related application. Water Sci. Technol. Water Suppl. 2020, 20, 2021–2035. [Google Scholar] [CrossRef]

- Li, H.; Hu, L.; Song, D.; Lin, F. Characteristics of micro-nano bubbles and potential application in groundwater bioremediation. Water Environ. Res. 2014, 86, 844–851. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.H.; Ismail, A.B.; Menon, P.M.; Saththasivam, J.; Thu, K.; Choon, N.K. Case studies of microbubbles in wastewater treatment. Desalin. Water Treat. 2011, 30, 10–16. [Google Scholar] [CrossRef]

- Kutty, S.R.M.; Winarto, F.E.W.; Gilani, S.I.U.; Anizam, A.A.; Karimah, W.W.Z.; Isa, M.H. Degradation of organic matter using a submerged micro bubble diffuser in a biological wastewater treatment system. WIT Trans. Ecol. Environ. 2010, 140, 415–423. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Zhou, B.; Xu, F.; Muhammad, T.; Li, Y. Appropriate dissolved oxygen concentration and application stage of micro-nano bubble water oxygation in greenhouse crop plantation. Agric. Water Manag. 2019, 223, 105713. [Google Scholar] [CrossRef]

- Kumar, M. Ozone Nano Bubble Water: A magic wand for the treatment of periodontal disease. ARC J. Dent. Sci. 2016, 1. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Parveen, T.; Umar, K.; Mohamad Ibrahim, M.N. Role of nanomaterials in the treatment of wastewater: A Review. Water 2020, 12, 495. [Google Scholar] [CrossRef] [Green Version]

- Seo, J.H.; Choi, S.J.; Lee, S.H.; Lee, J.H. Characterization of arthrospira platensis cultured in nano-bubble hydrogen water. Appl. Chem. Eng. 2015. [Google Scholar] [CrossRef] [Green Version]

- Khoshroo, M.; Shirzadi Javid, A.A.; Katebi, A. Effects of micro-nano bubble water and binary mineral admixtures on the mechanical and durability properties of concrete. Constr. Build. Mater. 2018, 164, 371–385. [Google Scholar] [CrossRef]

- Arefi, A.; Saghravani, S.F.; Mozaffari Naeeni, R. Mechanical Behavior of Concrete, Made with Micro-Nano Air Bubbles. Civ. Eng. Infrastruct. J. 2016, 49, 139–147. [Google Scholar] [CrossRef]

- Kim, Y.H.; Park, Y.; Bae, S.; Kim, S.Y.; Han, J.G. Compressive Strength Evaluation of Ordinary Portland Cement Mortar Blended with Hydrogen Nano-Bubble Water and Graphene. J. Nanosci. Nanotechnol. 2020, 20, 647–652. [Google Scholar] [CrossRef] [PubMed]

- Asadollahfardi, G.; Mohsen Zadeh, P.; Saghravani, S.F.; Mohamadzadeh, N. The effects of using metakaolin and micro-nanobubble water on concrete properties. J. Build. Eng. 2019. [Google Scholar] [CrossRef]

- Mohsen Zadeh, P.; Saghravani, S.F.; Asadollahfardi, G. Mechanical and durability properties of concrete containing zeolite mixed with meta-kaolin and micro-nano bubbles of water. Struct. Concr. 2019, 20, 786–797. [Google Scholar] [CrossRef]

- Kim, H.J.; Choi, H.; Choi, H.; Lee, B.; Lee, D.; Lee, D.E. Study on physical properties of mortar for section restoration using calcium nitrite and CO2 nano-bubble water. Materials 2020, 13, 3897. [Google Scholar] [CrossRef] [PubMed]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E. Reverse engineering: A proper methodology for compatible restoration mortars. In Proceedings of the International RILEM Workshop on Repairs Mortars for Historic Masonry, Delft, The Netherlands, 26–28 January 2005. [Google Scholar]

- Ramesh, M.; Azenha, M.; Lourenço, P.B. Mechanical properties of lime–cement masonry mortars in their early ages. Mater. Struct. Constr. 2019, 52, 13. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Faria, J.; Jalali, S. Some considerations about the use of lime-cement mortars for building conservation purposes in Portugal: A reprehensible option or a lesser evil? Constr. Build. Mater. 2012, 30, 488–494. [Google Scholar] [CrossRef] [Green Version]

- PKN. PN-EN 459-1:2015-06 Building Lime. Definitions, Requirements and Criteria for Compatibility; PKN: Warsaw, Poland, 2015. [Google Scholar]

- PKN. PN-EN 197-1:2012 Cement. Composition, Specifications and Conformity Criteria for Common Cements; PKN: Warsaw, Poland, 2012. [Google Scholar]

- Hydrated Lime WAP 100. Available online: http://www.alpol.pl/pl/katalog_produktow/go:28:146/ (accessed on 20 December 2020).

- Aalborg White® cement CEM I 52,5 R—SR 5. Available online: https://www.aalborgwhite.com/products/aalborg-whiter-cem-i-525-r-sr-5-made-denmark (accessed on 20 December 2020).

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Klimek, B.; Pavlíková, M.; Pavlík, Z. Properties of Multi-Layer Renders with Fly Ash and Boiler Slag Admixtures for Salt-Laden Masonry. Constr. Build. Mater. 2021, 278, 122366. [Google Scholar] [CrossRef]

- Kukizaki, M.; Goto, M. Size control of nanobubbles generated from Shirasu-porous-glass (SPG) membranes. J. Memb. Sci. 2006, 281, 386–396. [Google Scholar] [CrossRef]

- Qiu, J.; Zou, Z.; Wang, S.; Wang, X.; Wang, L.; Dong, Y.; Zhao, H.; Zhang, L.; Hu, J. Formation and Stability of Bulk Nanobubbles Generated by Ethanol-Water Exchange. ChemPhysChem 2017, 18, 1345–1350. [Google Scholar] [CrossRef] [PubMed]

- Fan, M.; Zhao, Y.; Tao, D. Fundamental studies of nanobubble generation and applications in flotation. In Separation Technologies for Minerals, Coal, and Earth Resources; SME: Englewood, CO, USA, 2012. [Google Scholar]

- Ahmadi, R.; Darban, A.K. Modeling and optimization of nano-bubble generation process using response surface methodology. Int. J. Nanosci. Nanotechnol. 2013, 9, 151–162. [Google Scholar]

- Wu, C.; Nesset, K.; Masliyah, J.; Xu, Z. Generation and characterization of submicron size bubbles. Adv. Colloid Interface Sci. 2012, 179, 123–132. [Google Scholar] [CrossRef] [PubMed]

- Oeffinger, B.E.; Wheatley, M.A. Development and characterization of a nano-scale contrast agent. Ultrasonics 2004, 42, 343–347. [Google Scholar] [CrossRef]

- Cho, S.-H.; Kim, J.-Y.; Chun, J.-H.; Kim, J.-D. Ultrasonic formation of nanobubbles and their zeta-potentials in aqueous electrolyte and surfactant solutions. Colloids Surfaces A Physicochem. Eng. Asp. 2005, 269, 28–34. [Google Scholar] [CrossRef]

- Hung, I. Ultrafine Bubble-Enhanced Ozonation For Water Treatment. Doctoral dissertation, The University of Arizona, Tuscon, AZ, USA, 2016. Available online: http://hdl.handle.net/10150/621853 (accessed on 13 September 2020).

- Peneder, H.; Punz, E.; Joubert, I.A.; Geppert, M.; Himly, M. Nanoparticle tracking analysis. Open Sch. J. Open Sci. 2020, 1, 38–40. [Google Scholar] [CrossRef]

- Nanosight Visualizing, Sizing and Counting Nanobubbles Using Nanoparticle Tracking Analysis. Available online: https://www.azonano.com/article.aspx?ArticleID=2478 (accessed on 19 December 2020).

- PKN. PN-EN 1015-3:2000 Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table); PKN: Warsaw, Poland, 2000. [Google Scholar]

- PKN. PN-EN 1015-10:2001 Methods of Test Mortar for Masonry. Determination of Density of the Dry Hardened Mortar; PKN: Warsaw, Poland, 2001. [Google Scholar]

- PKN. PN-EN 1936:2010 Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity; PKN: Warsaw, Poland, 2010. [Google Scholar]

- PKN. PN-EN 13755:2008 Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure; PKN: Warsaw, Poland, 2008. [Google Scholar]

- PKN. PN-EN 1015-18:2003: Methods of Test for Mortar for Masonry. Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; PKN: Warsaw, Poland, 2003. [Google Scholar]

- PKN. PN-EN 1015-11:2001 Determination of Flexural and Compressive Strength of Hardened Mortar; PKN: Warsaw, Poland, 2001. [Google Scholar]

- Kruskal, J.B. Multidimensional scaling by optimizing goodness of fit to a nonmetric hypothesis. Psychometrika 1964, 29, 1–27. [Google Scholar] [CrossRef]

- Mead, A. Review of the Development of Multidimensional Scaling Methods. Statistician 1992, 41, 27. [Google Scholar] [CrossRef]

- Borg, I.; Groenen, F. Modern Multidimensional Scaling; Springer Series in Statistics; Springer: New York, NY, USA, 2005; ISBN 978-0-387-25150-9. [Google Scholar]

- Borg, I.; Lingoes, J. Multidimensional Similarity Structure Analysis; Springer: New York, NY, USA, 1987; ISBN 978-1-4612-9147-3. [Google Scholar]

- Borg, I.; Groenen, P.J.F.; Mair, P. Applied Multidimensional Scaling; Springer Briefs in Statistics; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-31847-4. [Google Scholar]

- Kyriakou, L.; Theodoridou, M.; Ioannou, I. Optimization of hydraulic lime mortars with nano-SiO2. In Proceedings of the 4th Historic Mortars Conference, Santorini, Greece, 10–12 October 2016. [Google Scholar]

- Luo, K.; Li, J.; Lu, Z.; Jiang, J.; Niu, Y. Effect of nano-SiO2 on early hydration of natural hydraulic lime. Constr. Build. Mater. 2019, 216, 119–127. [Google Scholar] [CrossRef]

- Ergenç, D.; Sierra-Fernandez, A.; del Mar Barbero-Barrera, M.; Gomez-Villalba, L.S.; Fort, R. Assessment on the performances of air lime-ceramic mortars with nano-Ca(OH)2 and nano-SiO2 additions. Constr. Build. Mater. 2020. [Google Scholar] [CrossRef]

- Kim, J.; Kitagi, R.; Choi, H. Pore Filling Effect of Forced Carbonation Reactions Using Carbon Dioxide Nanobubbles. Materials 2020, 13, 4343. [Google Scholar] [CrossRef]

- Yahyaei, B.; Asadollahfardi, G.; Salehi, A.M. Study of using micro-nano bubble to improve workability and durability of self-compact concrete. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Theodoridou, M.; Kyriakou, L.; Ioannou, I. Salt crystallization resistance of nano-modified repair lime mortars. In Proceedings of the 3rd International Conference on Salt Weathering of Buildings and Stone Sculptures, Brussels, Belgium, 14–16 October 2014. [Google Scholar]

- Alvarez, J.I.; Fernández, J.M.; Navarro-Blasco, I.; Duran, A.; Sirera, R. Microstructural consequences of nanosilica addition on aerial lime binding materials: Influence of different drying conditions. Mater. Charact. 2013, 80, 36–49. [Google Scholar] [CrossRef] [Green Version]

- Maruyama, T.; Takahashi, N.; Hashimoto, S.; Date, S. Effect on the Flow Properties of the Mortar Using Micro-Nano Bubbles. Adv. Mater. Res. 2015, 1110, 249–252. [Google Scholar] [CrossRef]

| Components | Unit | Reference | 50% CO2 | 100% CO2 | 50% O2 | 100% O2 | 50% O3 | 100% O3 |

|---|---|---|---|---|---|---|---|---|

| Hydrated lime | (kg/m3) | 518.1 | 518.1 | 518.1 | 518.1 | 518.1 | 518.1 | 518.1 |

| White cement 52.5R | (kg/m3) | 172.7 | 172.7 | 172.7 | 172.7 | 172.7 | 172.7 | 172.7 |

| Natural quartz sand 0–2.0 mm | (kg/m3) | 518.1 | 518.1 | 518.1 | 518.1 | 518.1 | 518.1 | 518.1 |

| Water | (L/m3) | 518.1 | 259.05 | – | 259.05 | – | 259.05 | – |

| Micro-nano water with CO2 | (L/m3) | – | 259.05 | 518.1 | – | – | – | – |

| Micro-nano water with O2 | (L/m3) | – | – | – | 259.05 | 518.1 | ||

| Micro-nano water with O3 | (L/m3) | – | – | – | – | – | 259.05 | 518.1 |

| Parameter | Unit | Value | |

|---|---|---|---|

| Activated lime content | (%, weight) | ≥80.0 | |

| Volume constant | (%, mm) | ≤4.0 | |

| Infiltration depth | (mm) | >10 and <25 | |

| Air content | (%, volume) | ≤5.0 | |

| Degree of grinding | Remains on the 0.09 mm sieve | (%) | ≤0.2 |

| Remains on the 0.20 mm sieve | ≤0.2 | ||

| Free water content | (%) | ≤0.2 | |

| Bulk density | (kg/dm3) | 0.51 | |

| Chemical composition | CaO + MgO | (%) | ≥93.0 |

| MgO | ≤1.2 | ||

| CO2 | ≤3.5 | ||

| SO3 | ≤1.0 | ||

| Parameter | Unit | Value | |

|---|---|---|---|

| Initial setting time | (min) | 120 | |

| Sulfate resistance | (%) | C3A ≤ 4–5 | |

| Alkali content | (%) | ≤0.3 | |

| Specific surface | (m2/kg) | 400 | |

| Chemical composition of cement | C3S | (%) | 77 |

| C2S | 16 | ||

| C3A | 5 | ||

| C4AF | 1 | ||

| others | 1 | ||

| Compressive strength after | 1 day | (MPa) | 23 |

| 2 days | 42 | ||

| 7 days | 60 | ||

| 28 days | 72 | ||

| Reference | 50% CO2 | 100% CO2 | 50% O2 | 100% O2 | 50% O3 | 100% O3 | |

|---|---|---|---|---|---|---|---|

| Flow diameter (cm) | 20.0 | 17.8 | 16.4 | 18.3 | 16.8 | 19.0 | 17.5 |

| Specific Density | Bulk Density | Water Absorptivity | Total Porosity | Water Absorption Coefficient | |

|---|---|---|---|---|---|

| (g/cm3) | (kg/m3) | (%) | (%) | (kg/m2) | |

| Reference | 2.38 | 1287 | 35.89 | 45.92 | 31.65 |

| 50% CO2 | 2.39 | 1299 | 34.87 | 45.48 | 31.36 |

| 100% CO2 | 2.44 | 1306 | 34.93 | 46.01 | 31.73 |

| 50% O2 | 2.14 | 1292 | 35.86 | 39.76 | 29.64 |

| 100% O2 | 2.16 | 1281 | 36.56 | 40.79 | 30.16 |

| 50% O3 | 2.26 | 1288 | 36.37 | 43.11 | 28.95 |

| 100% O3 | 2.24 | 1255 | 36.87 | 43.94 | 29.16 |

| Ffm,14 | Fcm,14 | Ffm,28 | Fcm,28 | Ffm,56 | Fcm,56 | |

|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (MPa) | (MPa) | (MPa) | |

| Reference | 0.72 | 1.44 | 0.87 | 1.68 | 0.94 | 2.78 |

| 50% CO2 | 0.76 | 1.50 | 0.90 | 1.70 | 1.04 | 2.97 |

| 100% CO2 | 0.78 | 1.38 | 1.10 | 2.01 | 1.26 | 3.32 |

| 50% O2 | 0.66 | 1.46 | 0.99 | 2.20 | 1.16 | 2.55 |

| 100% O2 | 0.72 | 1.50 | 1.05 | 1.80 | 1.13 | 2.91 |

| 50% O3 | 0.75 | 1.50 | 0.80 | 1.90 | 1.06 | 2.89 |

| 100% O3 | 0.78 | 1.55 | 0.90 | 2.14 | 1.10 | 3.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzegorczyk-Frańczak, M.; Barnat-Hunek, D.; Andrzejuk, W.; Zaburko, J.; Zalewska, M.; Łagód, G. Physical Properties and Durability of Lime-Cement Mortars Prepared with Water Containing Micro-Nano Bubbles of Various Gases. Materials 2021, 14, 1902. https://doi.org/10.3390/ma14081902

Grzegorczyk-Frańczak M, Barnat-Hunek D, Andrzejuk W, Zaburko J, Zalewska M, Łagód G. Physical Properties and Durability of Lime-Cement Mortars Prepared with Water Containing Micro-Nano Bubbles of Various Gases. Materials. 2021; 14(8):1902. https://doi.org/10.3390/ma14081902

Chicago/Turabian StyleGrzegorczyk-Frańczak, Małgorzata, Danuta Barnat-Hunek, Wojciech Andrzejuk, Jacek Zaburko, Monika Zalewska, and Grzegorz Łagód. 2021. "Physical Properties and Durability of Lime-Cement Mortars Prepared with Water Containing Micro-Nano Bubbles of Various Gases" Materials 14, no. 8: 1902. https://doi.org/10.3390/ma14081902

APA StyleGrzegorczyk-Frańczak, M., Barnat-Hunek, D., Andrzejuk, W., Zaburko, J., Zalewska, M., & Łagód, G. (2021). Physical Properties and Durability of Lime-Cement Mortars Prepared with Water Containing Micro-Nano Bubbles of Various Gases. Materials, 14(8), 1902. https://doi.org/10.3390/ma14081902