Establishing the Relationship between Cutting Speed and Output Parameters in Belt Grinding on Steels, Aluminum and Nickel Alloys: Development of Recommendations

Abstract

:1. Introduction

- To study and establish the dependences on the cutting speed of grinding belts and the most widely used characteristics in metalworking;

- To develop and select the resulting surface roughness and material removal rate, reflecting the influence of the cutting speed on grinding different alloys with cloth grinding belts;

- To develop recommendations for the selection and setting of the cutting speed during metalworking with cloth grinding belts.

2. Materials and Methods

2.1. Theoretical Provisions

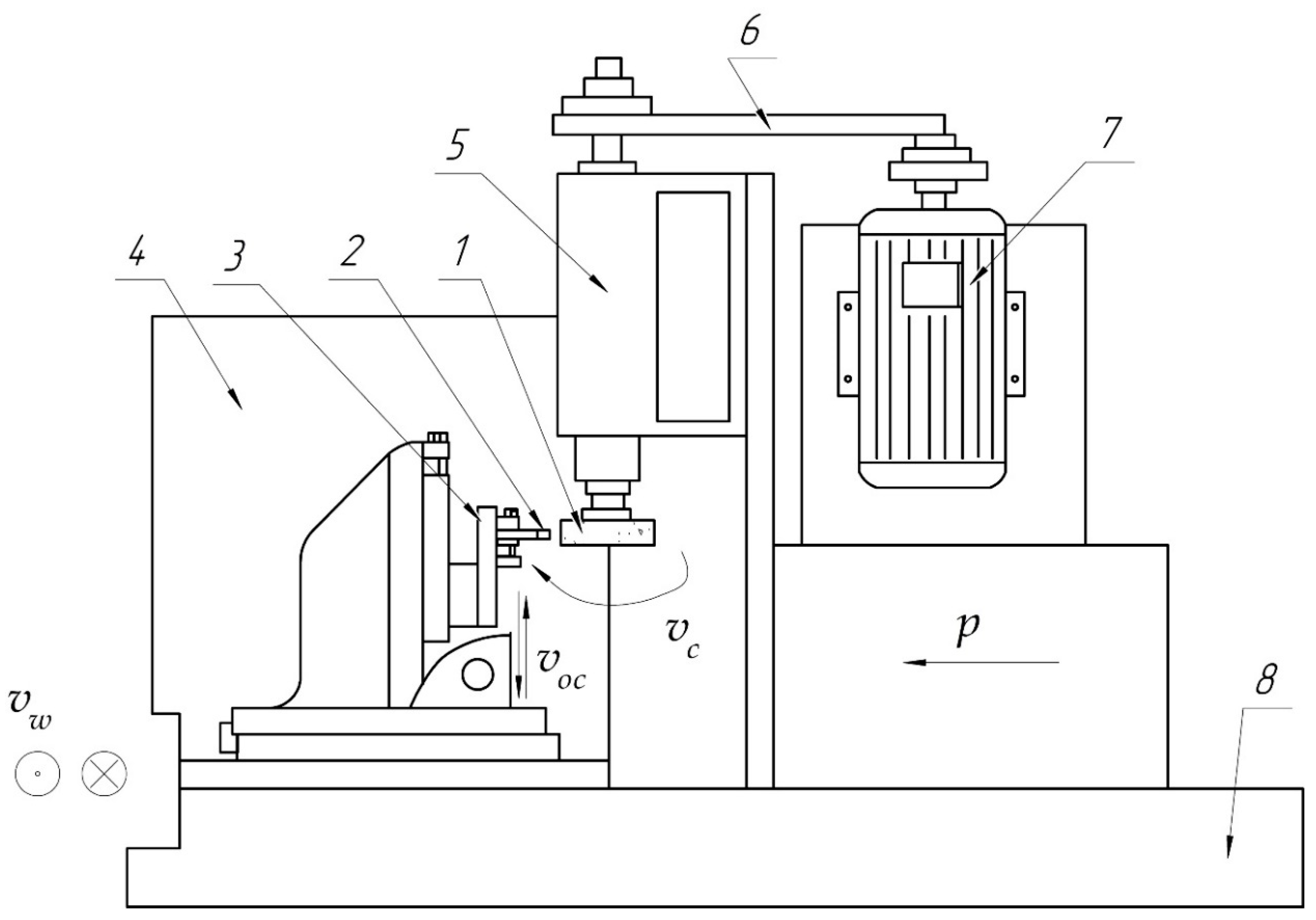

2.2. Experimental Details

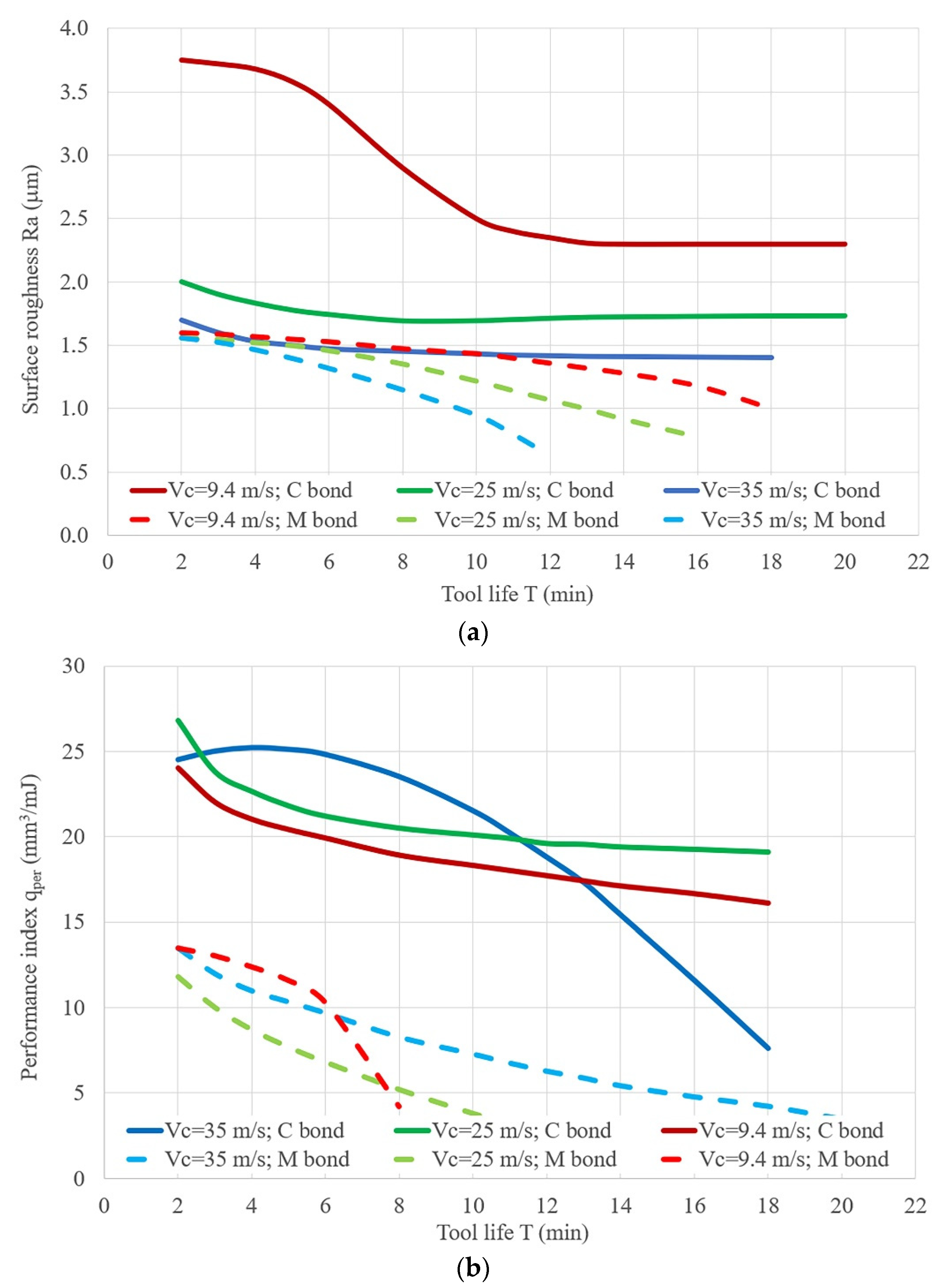

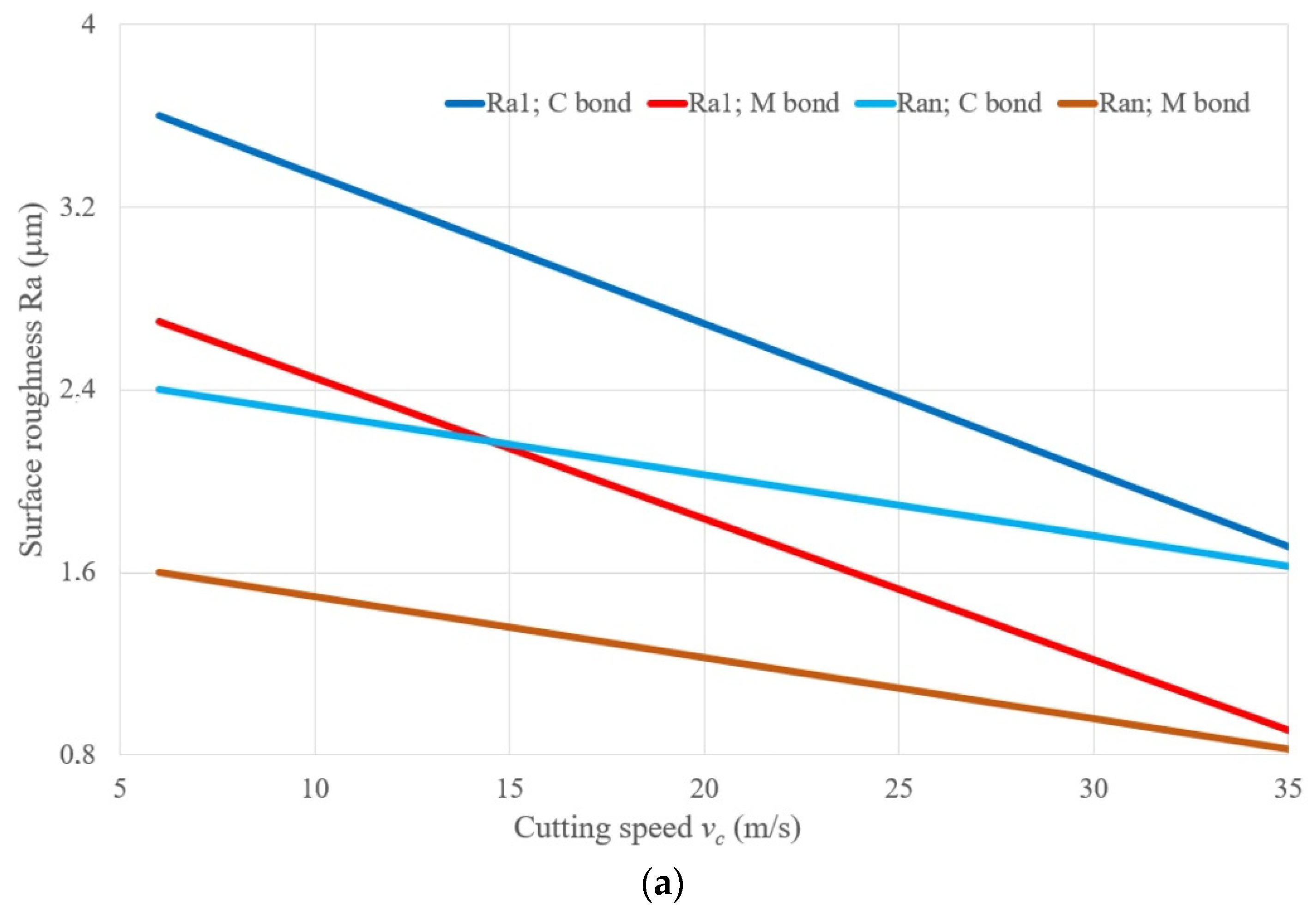

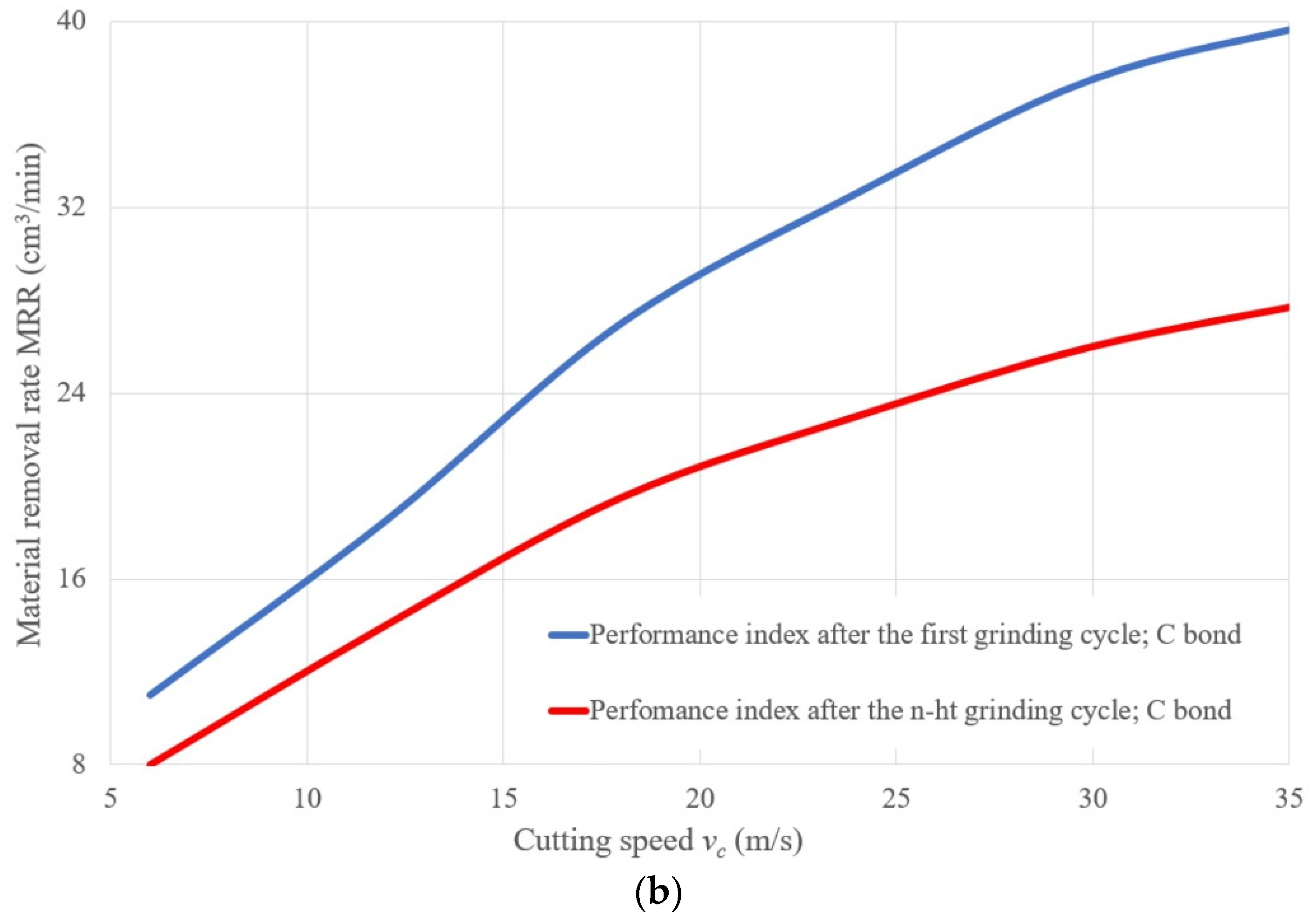

3. Results and Discussion

4. Summary

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| f (τ) | Actual contact area between the tool and the workpiece |

| Allowance | |

| Aos | Amplitude of the vertical oscillation |

| Ra | Arithmetic mean deviation of the assessed profile (surface roughness) |

| Vb | Belt speed |

| Pc | Clamping force |

| Code value of the i-th factor | |

| vc | Cutting speed |

| ρ | Density |

| ß | Deviation angle of the cutting grain from the vertical position during grinding |

| Exponent taking into account the machinable material | |

| Grain blunting area (flank wear) | |

| GPU | Graphics processor |

| HB | Hardness |

| Longitudinal feed rate | |

| Q | Material removal |

| MRR | Material removal rate |

| Material removal rate over the i-th grinding period | |

| Natural value of the factor at the zero level | |

| Natural value of the variation interval | |

| N | Number of experiments |

| k | Number of factors |

| Number of levels | |

| τ | Operating time of the tool till the resistance criterion (tool life) |

| Performance index | |

| p | Pressure |

| Py | Radial cutting force |

| Strain intensity | |

| Strain rate | |

| σi | Stress intensity in the shear zone of the material being machined |

| Surface roughness after the first grinding cycle | |

| Surface roughness after the n-th grinding cycle | |

| The coefficients accounting for the geometry of the cutting part of abrasive grains and the nature of metal yielding in the deformation zone | |

| Temperature | |

| Tensile strength of the grinding belt | |

| Tool wear | |

| Xn | Transition from the code expression of the factor to the natural value of the i-th factor |

| σD | Ultimate Stress |

| wos | Vertical oscillation frequency |

| Vw | Workpiece speed |

| σy | Yield Stress |

| X1 | Groups of the machined material |

| X2 | The type of machining determined by the size of the allowance P up to 1.00 mm and 0.05 mm |

| X3 | Strength groups of the grinding belt |

References

- Duan, J.; Zhang, Y.; Shi, Y. Belt grinding process with force control system for blade of aero-engine. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016, 230, 858–869. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Kaplonek, W.; Nadolny, K. Operational Wear Resistance of a Grinding Belt. Russ. Eng. Res. 2021, 41, 157–161. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y. Wear of a flexible abrasive tool. J. Frict. Wear 2019, 40, 139–145. [Google Scholar] [CrossRef]

- Rech, J.; Kermouche, G.; Grzesik, W.; García-Rosales, C.; Khellouki, A.; García-Navas, V. Characterization and modelling of the residual stresses induced by belt finishing on a AISI52100 hardened steel. J. Mater. Process. Technol. 2008, 208, 187–195. [Google Scholar] [CrossRef]

- News Bulletin. Rosstankoinstrument. Data for 12 Months 2019: News Bulletin; NIIMASH: Moscow, Russia, 2019; 63p. [Google Scholar]

- Grit paper and products from it manufactured in 2015–2019. In Stock Item Identification Guide; NIIMASH: Moscow, Russia, 2019; 63p.

- Wang, W.; Salvatore, F.; Rech, J.; Li, J. Comprehensive investigation on mechanisms of dry belt grinding on AISI52100 hardened steel. Tribol. Int. 2018, 121, 310–320. [Google Scholar] [CrossRef]

- Luo, G.; Zou, L.; Huang, Y.; Gong, M. Study on Material Removal and Surface Quality in Titanium Alloy Grinding with Alumina Hollow-sphere Abrasive Belt | [氧化铝空心球砂带磨削钛合金的材料去除及表面质量研究]. Zhongguo Jixie Gongcheng/China Mech. Eng. 2020, 31, 2363–2370. [Google Scholar] [CrossRef]

- Li, F.; Xue, Y.; Zhang, Z.; Song, W.; Xiang, J. Optimization of grinding parameters for the workpiece surface and material removal rate in the belt grinding process for polishing and deburring of 45 steel. Appl. Sci. 2020, 10, 6314. [Google Scholar] [CrossRef]

- Xie, H.-L.; Wang, Q.-H.; Ni, J.-L.; Li, J.-R. A GPU-based prediction and simulation method of grinding surface topography for belt grinding process. Int. J. Adv. Manuf. Technol. 2020, 106, 5175–5186. [Google Scholar] [CrossRef]

- Van Gorp, A.; Bigerelle, M.; Mansori, M.E.; Ghidossi, P.; Iost, A. Effects of working parameters on the surface roughness in belt grinding process: The size-scale estimation influence. Int. J. Mater. Prod. Technol. 2010, 38, 16–34. [Google Scholar] [CrossRef]

- Gowri, S.; Shireesha, K.; Kennedy, X. Taguchi analysis in optimisation of belt grinding of stainless steel 304. Int. J. Mach. Mach. Mater. 2009, 5, 41–59. [Google Scholar] [CrossRef]

- Zou, L.; Liu, X.; Ren, X.; Huang, Y. Investigation of robotic abrasive belt grinding methods used for precision machining of aluminum blades. Int. J. Adv. Manuf. Technol. 2020, 108, 3267–3278. [Google Scholar] [CrossRef]

- Xiao, G.; Song, K.; Liu, S.; Wu, Y.; Wang, W. Comprehensive investigation into the effects of relative grinding direction on abrasive belt grinding process. J. Manuf. Process. 2021, 62, 753–761. [Google Scholar] [CrossRef]

- Qu, C.; Lv, Y.; Yang, Z.; Xu, X.; Zhu, D.; Yan, S. An improved chip-thickness model for surface roughness prediction in robotic belt grinding considering the elastic state at contact wheel-workpiece interface. Int. J. Adv. Manuf. Technol. 2019, 104, 3209–3217. [Google Scholar] [CrossRef]

- Stadnik, T.; Sidorov, D.; Kharchenko, A. Investigation of diamond elastic belts characteristics effect on rotary belt grinding process output performance. Procedia Eng. 2017, 206, 1415–1418. [Google Scholar] [CrossRef]

- Bratan, S.; Kolesov, A.; Roshchupkin, S.; Stadnik, T. Theoretical-probabilistic model of the rotary belt grinding process. MATEC Web Conf. 2017, 129, 01078. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.Q.; Hou, B.; Liu, H.B.; Wang, F.B. Propeller material belt grinding parameters optimisation using Taguchi technique. Int. J. Ind. Syst. Eng. 2017, 25, 1–13. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V. Increasing the efficiency of processing with a coated abrasive tool in surface grinding operations. In Abstract of a Thesis of the Candidate of Engineering Sciences; South Ural State University: Chelyabinsk, Russia, 1989; 18p. [Google Scholar]

- Reznikov, A.N.; Pilinskii, A.V.; Malyshev, V.I.; Pokladii, G.G. Contact strain in grinding with an elastic tool having a segmental working surface. Sov. J. Superhard Mater. 1985, 7, 49–54. [Google Scholar]

- Volkov, D.I.; Koryazhkin, A.A. Adaptive belt grinding of gas-turbine blades. Russ. Eng. Res. 2014, 34, 37–40. [Google Scholar] [CrossRef]

- Bratan, S.M.; Stadnik, T.V.; Kolesov, A.G. A balance of displacements in the technological system during rotary belt grinding. Bull. Tula State Univ. Tech. Sci. 2017, 8, 270–275. [Google Scholar]

- Kaplonek, W.; Nadolny, K.; Królczyk, G.M. The use of focus-variation microscopy for the assessment of active surfaces of a new generation of coated abrasive tools. Meas. Sci. Rev. 2016, 16, 42–53. [Google Scholar] [CrossRef] [Green Version]

- Anonymous. Productivity gains with rapid grinding system. Aust. Mach. Prod. Eng. 1986, 38, 12. [Google Scholar]

- Herman, D.; Markul, J. Influence of microstructures of binder and abrasive grain on selected operational properties of ceramic grinding wheels made of alumina. Int. J. Mach. Tool. Manuf. 2004, 44, 511–522. [Google Scholar] [CrossRef]

- Wang, T.; Chen, G.; Zhang, C. Energy partition to workpiece in grinding GH4169 superalloy with single alundum wheels. Zhongguo Jixie Gongcheng/China Mech. Eng. 2014, 25, 2901–2906. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Guzeev, V.I.; Ardashev, D.V.; Pimenov, D.Y.; Patra, K.; Kapłonek, W.; Nadolny, K. A Study on the Machinability of Steels and Alloys to Develop Recommendations for Setting Tool Performance Characteristics and Belt Grinding Modes. Materials 2020, 13, 3978. [Google Scholar] [CrossRef] [PubMed]

- Korchak, S.N. Performance of the Process of Grinding Steel Parts; Mashinostroenie (Mechanical Engineering): Moscow, Russia, 1974; p. 230. [Google Scholar]

- Pimenov, D.Y.; Guzeev, V.I.; Koshin, A.A. Influence of cutting conditions on the stress at tool’s rear surface. Russ. Eng. Res. 2011, 31, 1151–1155. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Guzeev, V.I. Mathematical model of plowing forces to account for flank wear using FME modeling for orthogonal cutting scheme. Int. J. Adv. Manuf. Technol. 2017, 89, 3149–3159. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Pimenov, D.Y.; Mikolajczyk, T.; Moldovan, L. Technological support of abrasive manufacturing of products on a flexible basis by evaluating performance indicators. Procedia Manuf. 2020, 46, 38–43. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Praveen, G. Predictive Modelling and Analysis of Process Parameters on Material Removal Characteristics in Abrasive Belt Grinding Process. Appl. Sci. 2017, 7, 363. [Google Scholar] [CrossRef]

- Shatko, D.B.; Lyukshin, V.S.; Shutko, L.G.; Strelnikov, P.A. Methods and approaches to improving the design of flexible backing grinding tools. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 032–063. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Tan, H.H. In-process tool condition monitoring in compliant abrasive belt grinding process using support vector machine and genetic algorithm. J. Manuf. Process. 2018, 31, 199–213. [Google Scholar] [CrossRef]

- He, Z.; Li, J.; Liu, Y.; Yan, J. Investigation on wear modes and mechanisms of abrasive belts in grinding of U71Mn steel. Int. J. Adv. Manuf. Technol. 2019, 101, 1821–1835. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Guzeev, V.I.; Ardashev, D.V. Development of the technological indicator of the grain bonding strength for coated abrasives. Procedia Manuf. 2020, 46, 55–63. [Google Scholar] [CrossRef]

- Syreyshchikova, N.V.; Yaroslavova, E.N. Development of methodological recommendations for selection of flexible abrasive tool by performance indicator. Lect. Notes Mech. Eng. 2019, 1401–1409. [Google Scholar] [CrossRef]

| Type of Grinding | Operating Speed, m/s | Contact Temperature, °C | Accuracy Degree | Surface Roughness Ra, µm | Type of Residual Stresses after Machining |

|---|---|---|---|---|---|

| Abrasive wheel | 10–100 | 700–1200 | 5 | 0.08 | Stretch |

| Belt | 10–30 | 400–800 | 5,6 | 0.02 | Compression |

| Loose abrasive | 2–5 | 200–300 | 5 | 0.01 | Compression |

| Experiment Number | X1 | X2 | X3 |

|---|---|---|---|

| 1 | −1 | −1 | −1 |

| 2 | +1 | −1 | −1 |

| 3 | −1 | +1 | −1 |

| 4 | +1 | +1 | −1 |

| 5 | −1 | −1 | +1 |

| 6 | +1 | −1 | +1 |

| 7 | −1 | +1 | +1 |

| 8 | +1 | +1 | +1 |

| Material Group | Workpiece Material | Chemical Composition, % | Physical and Mechanical Properties | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbon, C | Silicon, Si | Manganese, Mn | Nickel, Ni | Sulfur, S | Phosphorus, P | Chromium, Cr | Cerium, Ce | Titanium, Ti | Boron, B | Lead, Pb | Iron, Fe | Aluminum, Al | Copper, Cu | Arsenic, As | Zinc, Zn | Magnesium, Mg | Other Impurities | Yield Stress, σy, MPa | Ultimate Stress, σD, MPa | Density, ρ, kg/m3 | Hardness, HB | ||

| Aluminum alloy | AK5M2/AL3V | — | 4–6 | 0.2–0.8 | to 0.5 | — | — | — | — | 0.05–0.2 | — | — | to 1.3 | 85.9–94.05 | 1.5–3.5 | — | to 1.5 | 0.2–0.8 | total 2.8 | 162 | — | 2900 | 70 |

| Structural alloy steel | 30KHGSN2 (30KHGSNA) | 0.27–0.34 | 0.9–1.2 | 1–1.3 | 1.4–1.8 | to 0.025 | to 0.025 | 0.9–1.2 | — | — | — | — | ≈95 | — | to 0.3 | — | — | — | — | 1375 | 1620 | 7770 | 255 |

| Structural carbon steel | 45 | 0.42–0.5 | 0.17–0.37 | 0.5–0.8 | to 0.25 | to 0.04 | to 0.035 | to 0.25 | — | — | — | — | ≈97 | — | to 0.25 | to 0.08 | — | — | — | 355 | 600 | 7826 | 207 |

| Corrosion- and heat-resistant stainless steel | KH18N10T | to 0.12 | to 0.8 | to 2.0 | 9–11 | to 0.02 | to 0.035 | 17–19 | — | 0.6–0.8 | — | — | ≈68 | — | — | — | — | — | — | 196 | 510 | 7920 | 179 |

| Heat-resistant nickel alloy | KHN77TYUR | to 0.07 | to 0.6 | to 0.4 | 70.076–77.4 | to 0.007 | to 0.015 | 19–22 | to 0.02 | 2.4–2.8 | to 0.01 | to 0.001 | to 1 | 0.6–1 | — | — | — | — | — | 650 | 1000 | 8200 | 255–321 |

| Material Grade | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MRR, cm3/min | mm3/mJ | MRR, cm3/min | mm3/mJ | MRR, cm3/min | mm3/mJ | |||||

| AK5M2 | 56.9 | 48.28 | 2.41 | 1.67 | 144.40 | 7.92 | 0.95 | 170.40 | 8.52 | 1.20 |

| 34.3 | 28.88 | 1.44 | 1.45 | 63.10 | 3.15 | 0.87 | 86.40 | 4.32 | 1.00 | |

| 30KhGSN2 | 56.9 | 10.28 | 0.51 | 1.55 | 52.08 | 2.60 | 0.88 | 67.02 | 3.35 | 1.20 |

| 34.3 | 8.65 | 0.43 | 0.80 | 27.41 | 1.37 | 0.73 | 30.59 | 1.53 | 1.55 | |

| 45 | 56.9 | 11.47 | 0.57 | 1.00 | 34.40 | 1.72 | 0.70 | 42.60 | 2.24 | 7.60 |

| 34.3 | 6.86 | 0.34 | – | 14.99 | 1.13 | 0.80 | 21.60 | 1.18 | 0.75 | |

| KhI8NI0T | 56.9 | 2.55 | 0.13 | 1.25 | 6.82 | 0.67 | 1.90 | 13.30 | 0.85 | 2.70 |

| 34.3 | 2.38 | 0.12 | – | 6.62 | 0.33 | 1.30 | 8.16 | 0.53 | 1.87 | |

| KhN77TYUR | 56.9 | 1.65 | 0.08 | 1.25 | 7.65 | 0.39 | 1.65 | 5.53 | 0.28 | 2.00 |

| 34.3 | 1.30 | 0.065 | – | 5.06 | 0.25 | 1.15 | 4.24 | 0.21 | 1.40 | |

| Grade of Metal | Correlation Coefficient | ||||

|---|---|---|---|---|---|

| AK5M2 | 3.4029 | - | −0.0149 | - | −0.9545 |

| - | 1.6489 | - | 0.0069 | −0.9703 | |

| 30KhGSN2 | 2.9987 | - | –0.0038 | - | 0.9891 |

| - | 2.4979 | - | −0.0398 | 0.9878 | |

| 45 | 2.2688 | - | 0.0223 | - | −0.9911 |

| - | 1.0996 | - | −0.0088 | −0.9840 | |

| Kh18N10T | 1.7021 | - | −0.0171 | - | 0.9561 |

| - | 0.8252 | - | −0.0071 | 0.9632 | |

| XH77TЮP | 1.4093 | - | −0.0219 | - | −0.9410 |

| - | 0.6428 | - | −0.0085 | −0.9980 | |

| Machinability Groups | ||||

|---|---|---|---|---|

| Dependency Equation | Correlation Coefficient | Dependency Equation | Correlation Coefficient | |

| 1 | = 31.825 + 9.545 | 0.9260 | = 26.581 + 9.988 | 0.9156 |

| 2 | = 27.819 + 9.641 | 0.9243 | = 23.953 + 9.420 | 0.9238 |

| 3 | = 19.511 + 12.216 | 0.9235 | = 14.550 + 12.211 | 0.9233 |

| 4 | = 16.585 + 12.179 | 0.9214 | = 11.521 + 12.145 | 0.9282 |

| 5 | = 12.7 + 12.115 | 0.9201 | = 9.3 + 12.105 | 0.9187 |

| Cloth Base of the Belts Grit Paper as Per GOST 5009, GOST 13344, GOST 27181 | Grinding Belt Strength Groups | |

|---|---|---|

| Group Number | Limits of the Tensile Strength in the Longitudinal Direction, N | |

| Light gray twill #1 Whole-colored semi-two-thread cloth Extra-light gray twill Extra-light whole-colored twill | 1 | 935–1039 |

| Medium whole-colored twill #1 Light gray twill #2 | 2 | 1040–1144 |

| Medium gray twill #1 | 3 | 1145–1249 |

| Medium whole-colored twill #2 Medium whole-colored twill #1 | 4 | 1250–1354 |

| Weighted whole-colored twill #1 Medium gray twill #2 Medium whole-colored twill #2 | 5 | 1355–1459 |

| Weighted whole-colored twill #2 Weighted gray twill #1 | 6 | 1460–1564 |

| Weighted whole-colored twill #1 Weighted gray twill #2 | 7 | 1565–1669 |

| Medium gray scoured twill #2 Weighted gray twill #2 Weighted whole-colored twill #2 Special durable twill Weighted gray scoured twill #2 Weighted gray desized twill #2 | 8 | 1670–1774 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syreyshchikova, N.V.; Pimenov, D.Y.; Gupta, M.K.; Nadolny, K.; Giasin, K.; Sharma, S. Establishing the Relationship between Cutting Speed and Output Parameters in Belt Grinding on Steels, Aluminum and Nickel Alloys: Development of Recommendations. Materials 2021, 14, 1974. https://doi.org/10.3390/ma14081974

Syreyshchikova NV, Pimenov DY, Gupta MK, Nadolny K, Giasin K, Sharma S. Establishing the Relationship between Cutting Speed and Output Parameters in Belt Grinding on Steels, Aluminum and Nickel Alloys: Development of Recommendations. Materials. 2021; 14(8):1974. https://doi.org/10.3390/ma14081974

Chicago/Turabian StyleSyreyshchikova, Nelli Vladimirovna, Danil Yurievich Pimenov, Munish Kumar Gupta, Krzysztof Nadolny, Khaled Giasin, and Shubham Sharma. 2021. "Establishing the Relationship between Cutting Speed and Output Parameters in Belt Grinding on Steels, Aluminum and Nickel Alloys: Development of Recommendations" Materials 14, no. 8: 1974. https://doi.org/10.3390/ma14081974