Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Macro-Structural Characterization

2.3. Microstructural Characterization

2.4. Mix Proportioning and Sample Preparation

2.5. Casting and Curing of Specimens

2.6. Testing Program

3. Discussions of Results

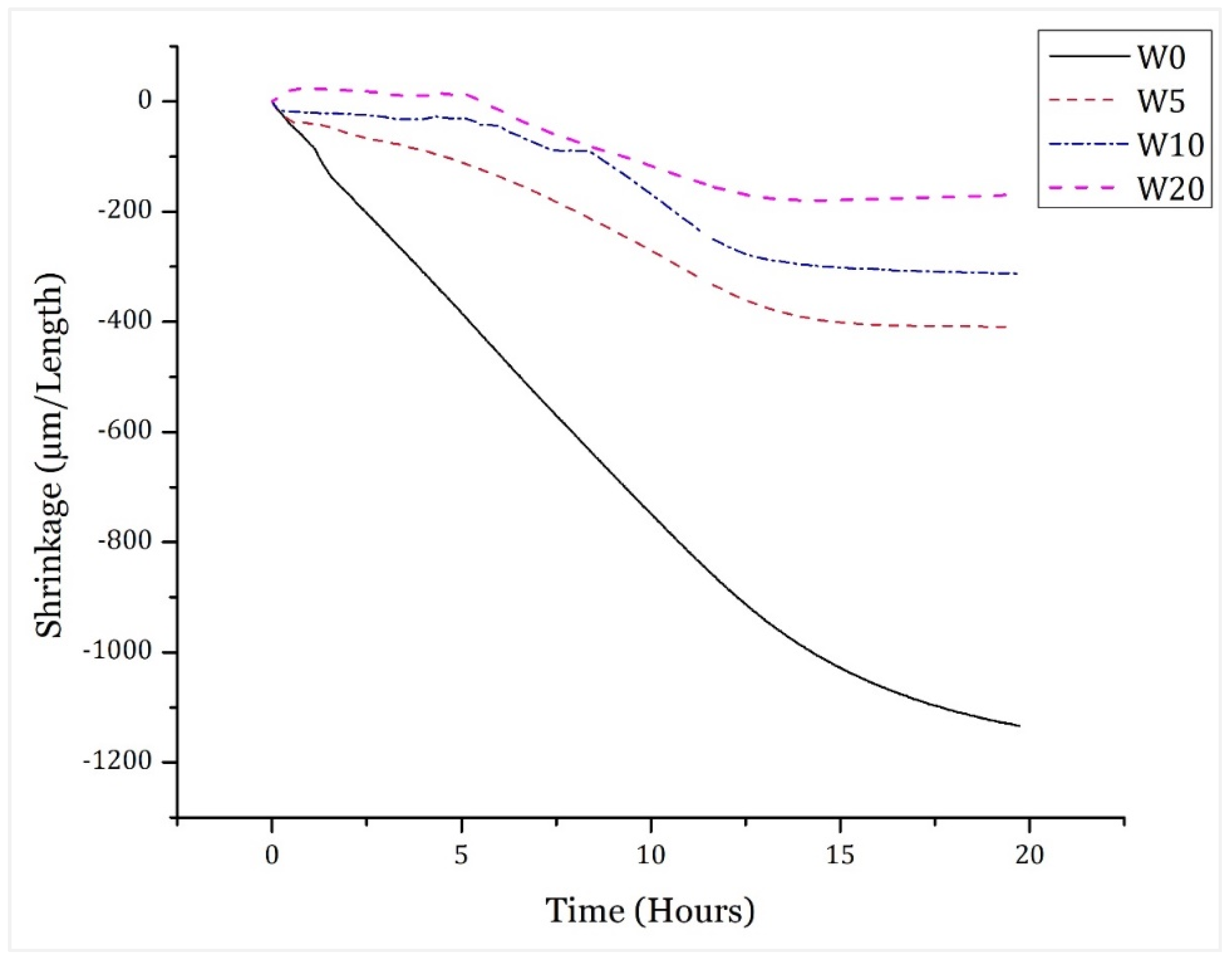

3.1. Linear Shrinkage Response

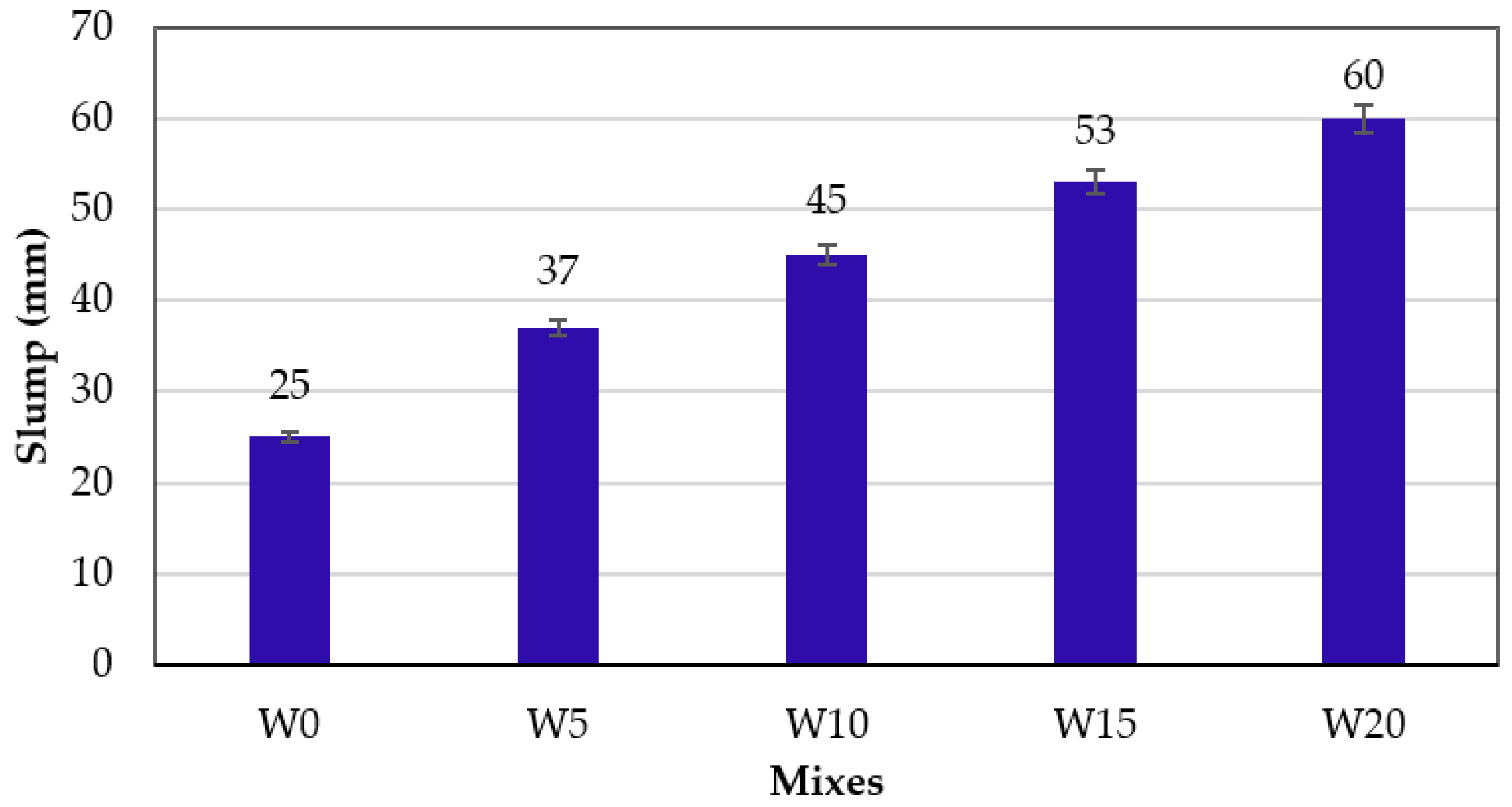

3.2. Fresh Concrete Properties

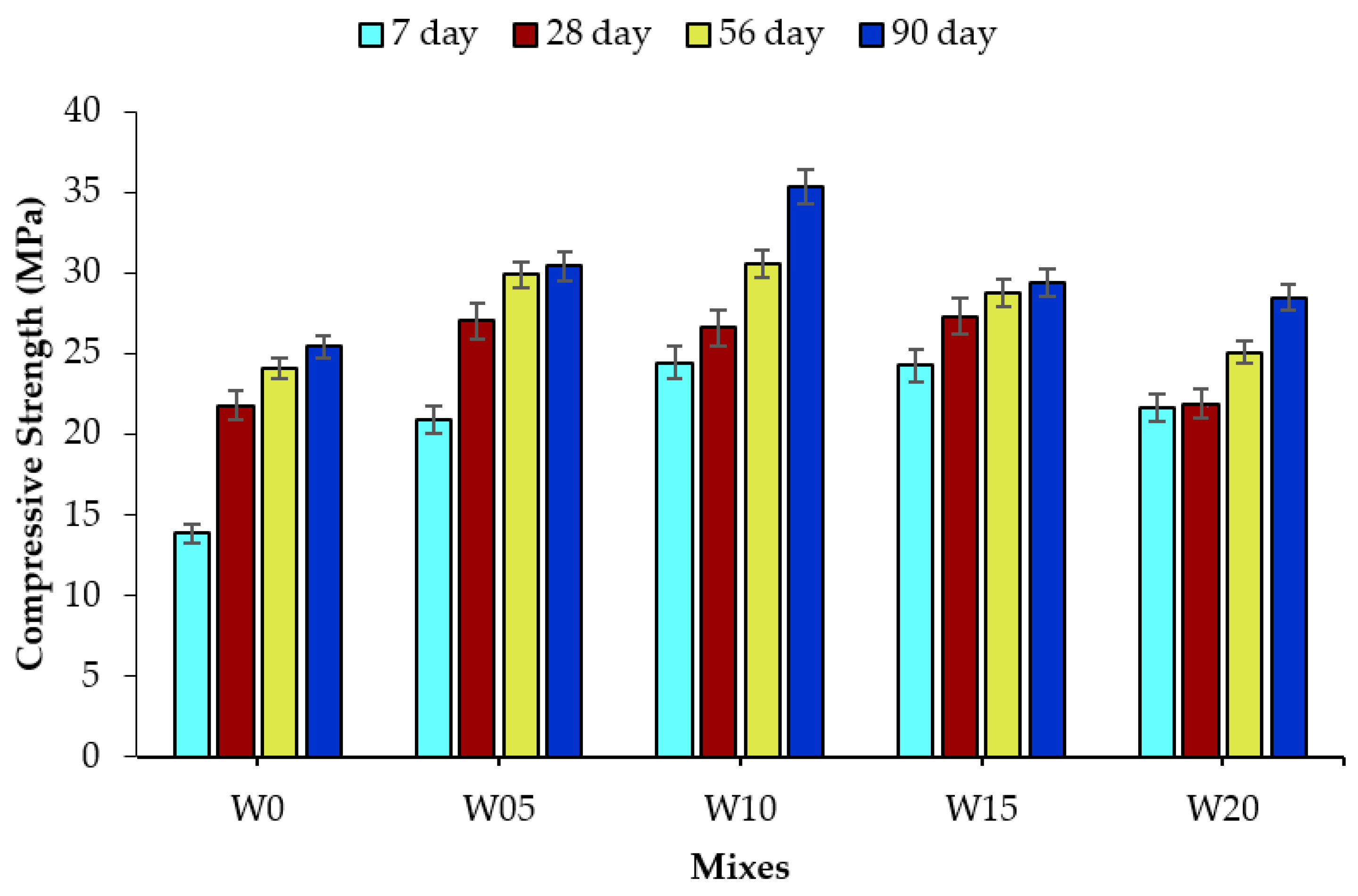

3.3. Compressive Strength

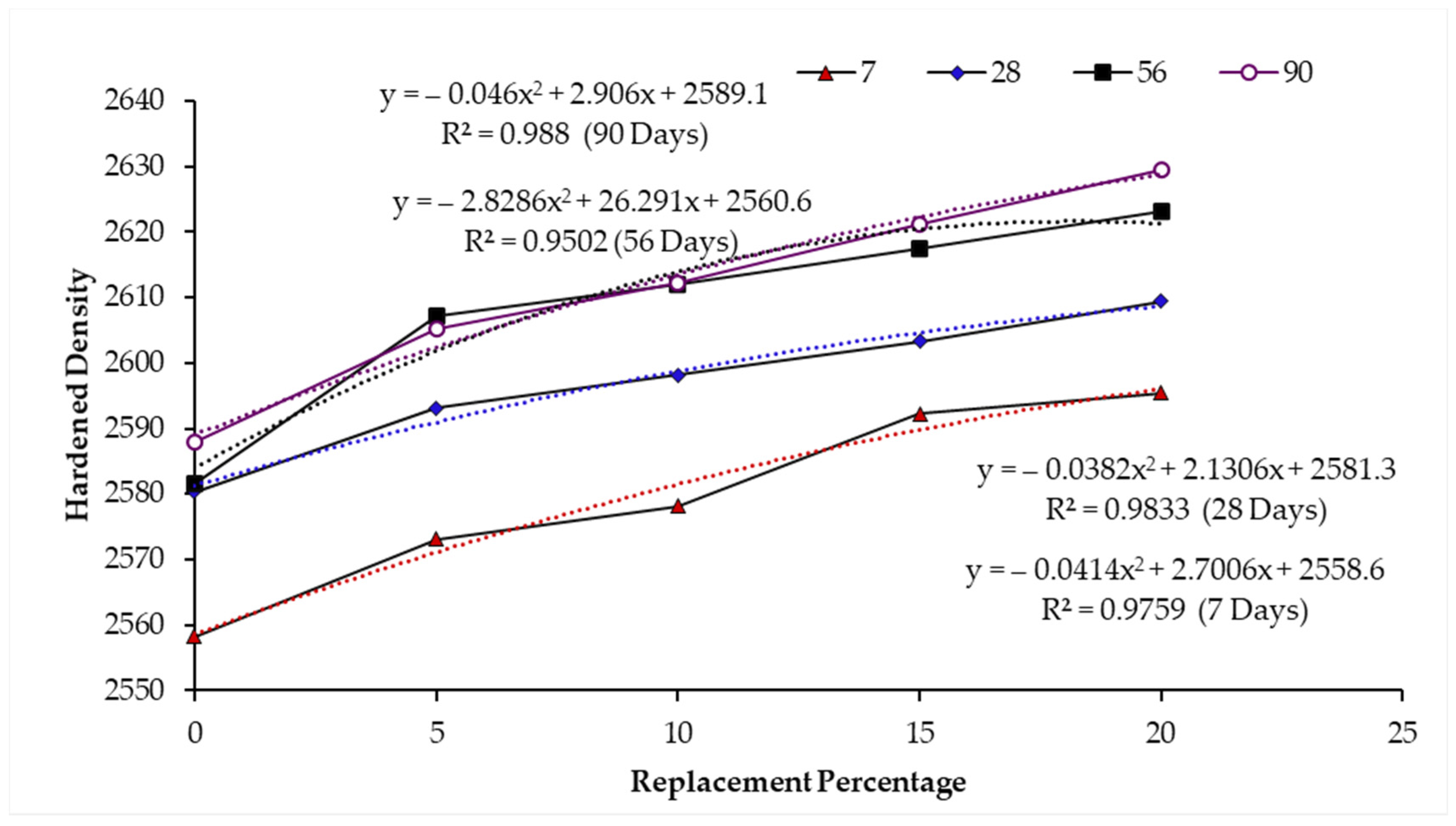

3.4. Hardened Concrete Density

3.5. Water Absorption

3.6. Ultrasonic Pulse Velocity

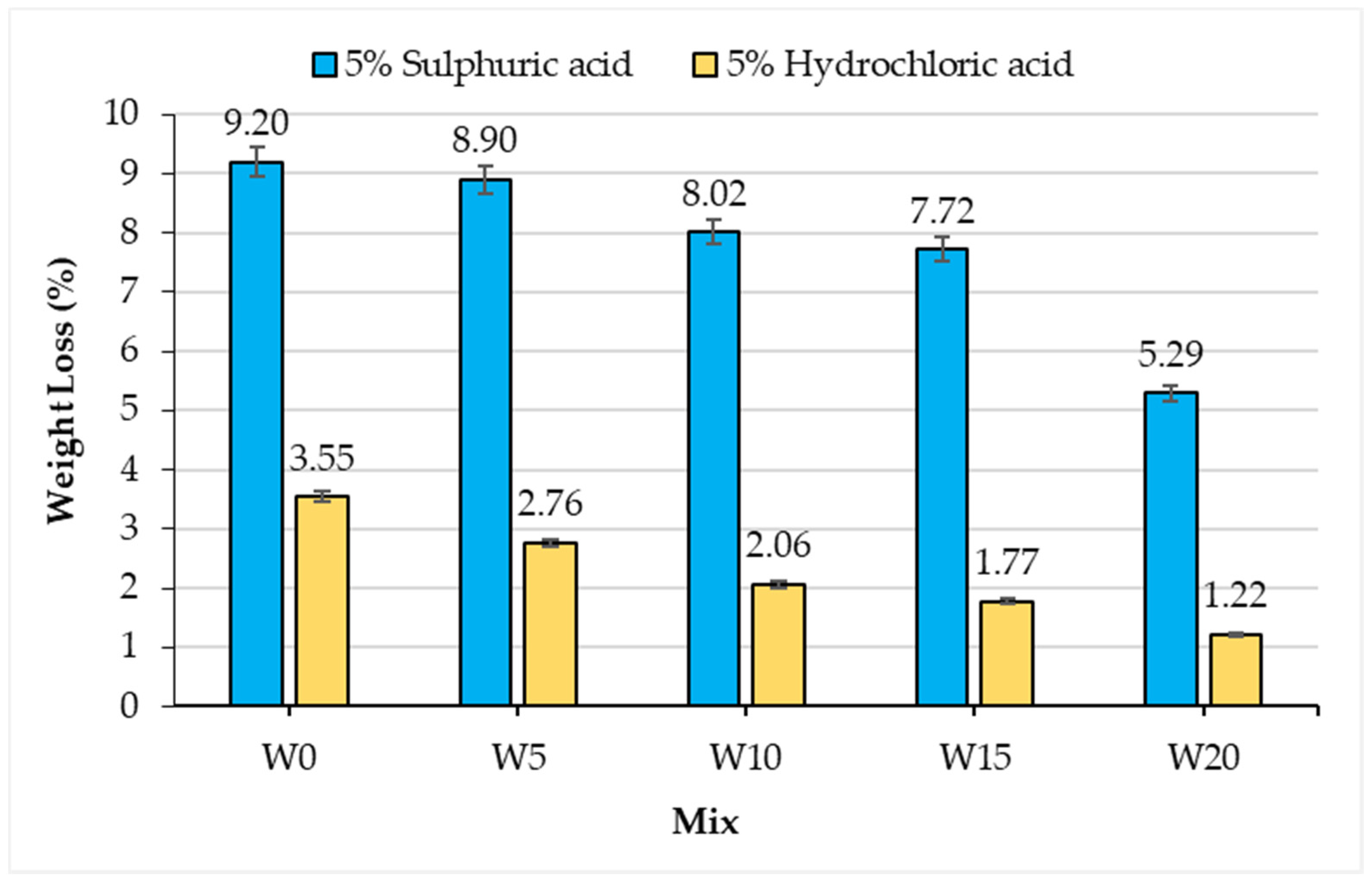

3.7. Response in Acidic Media

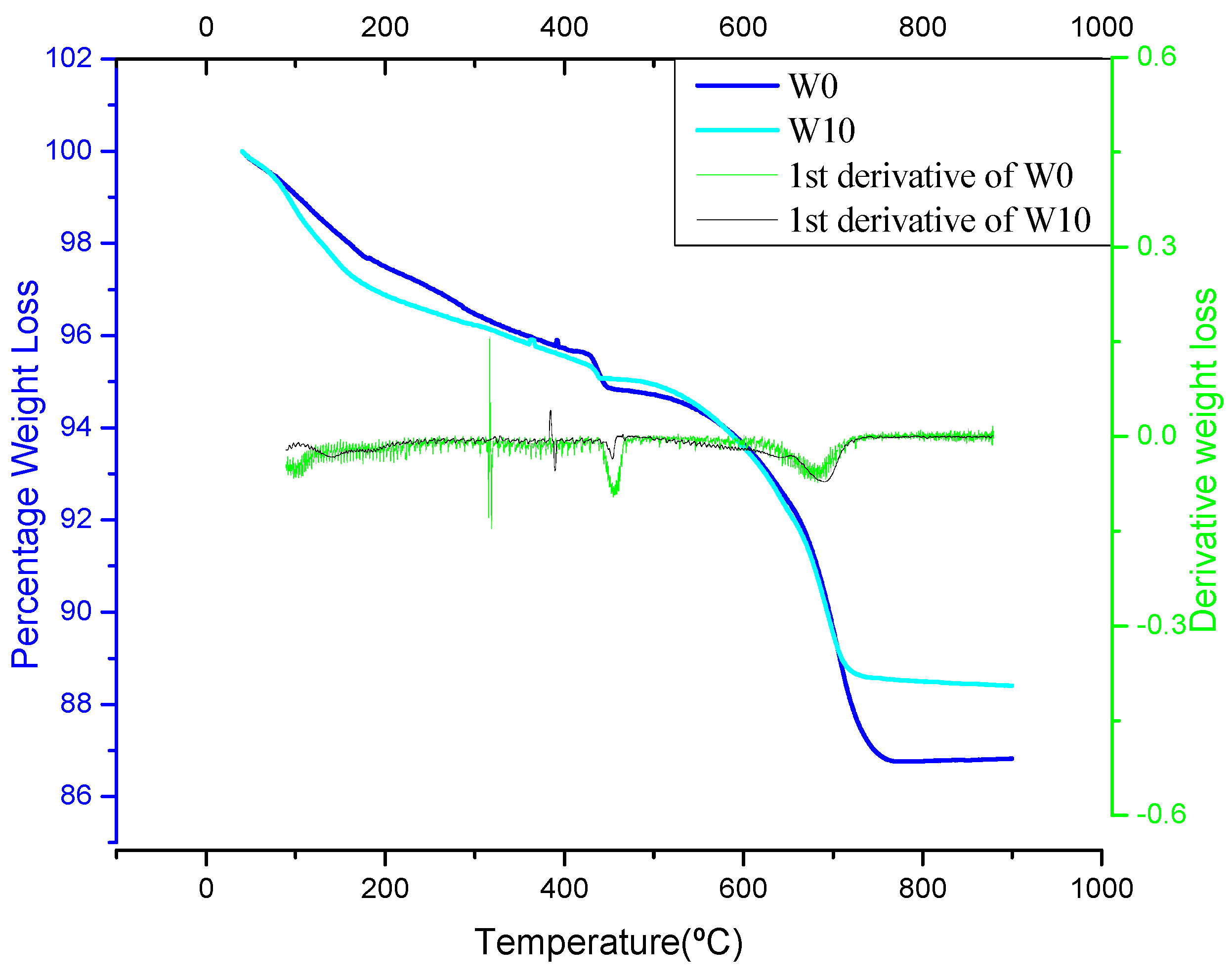

3.8. Thermogravimetric Analysis (TGA)

4. Conclusions

- (a)

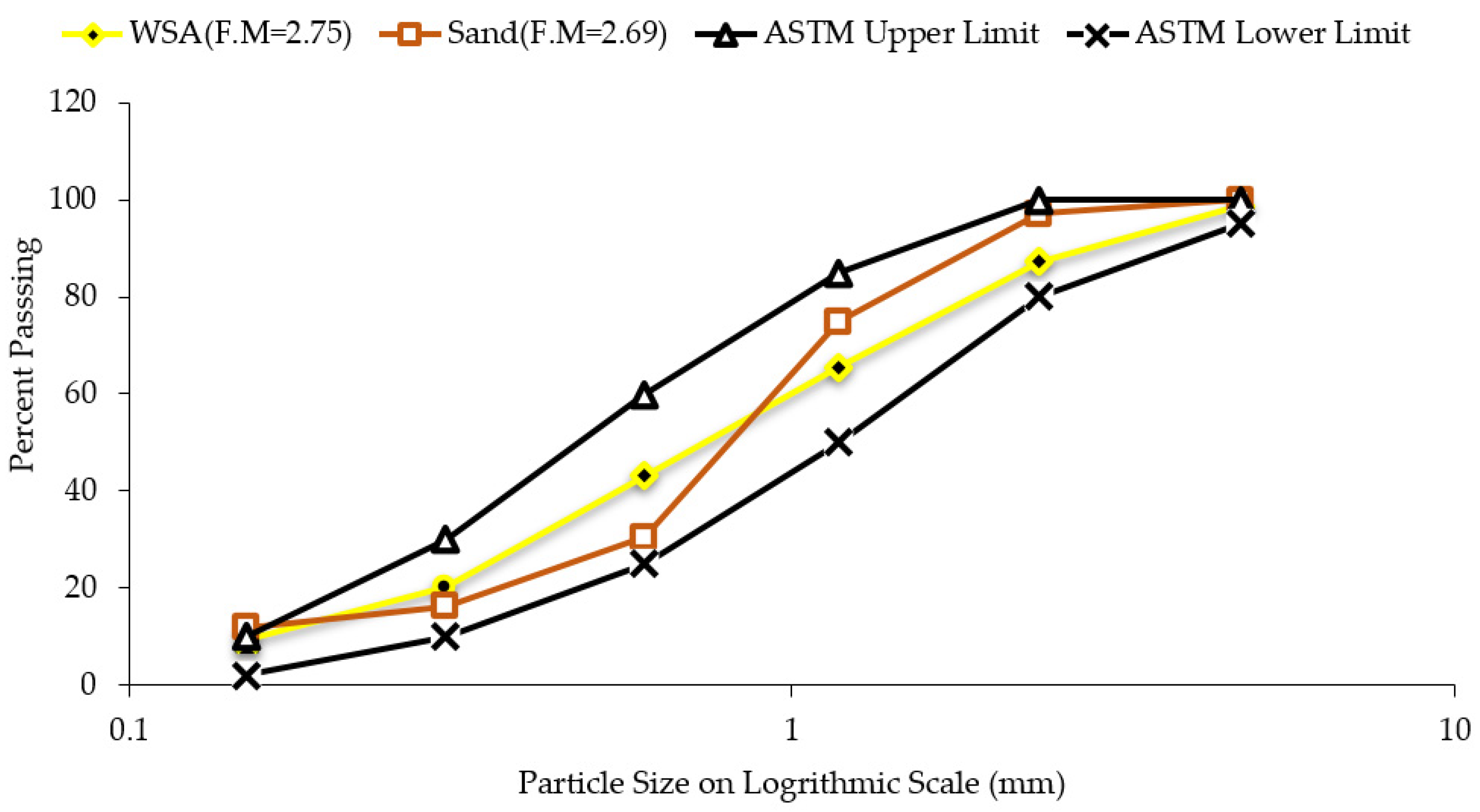

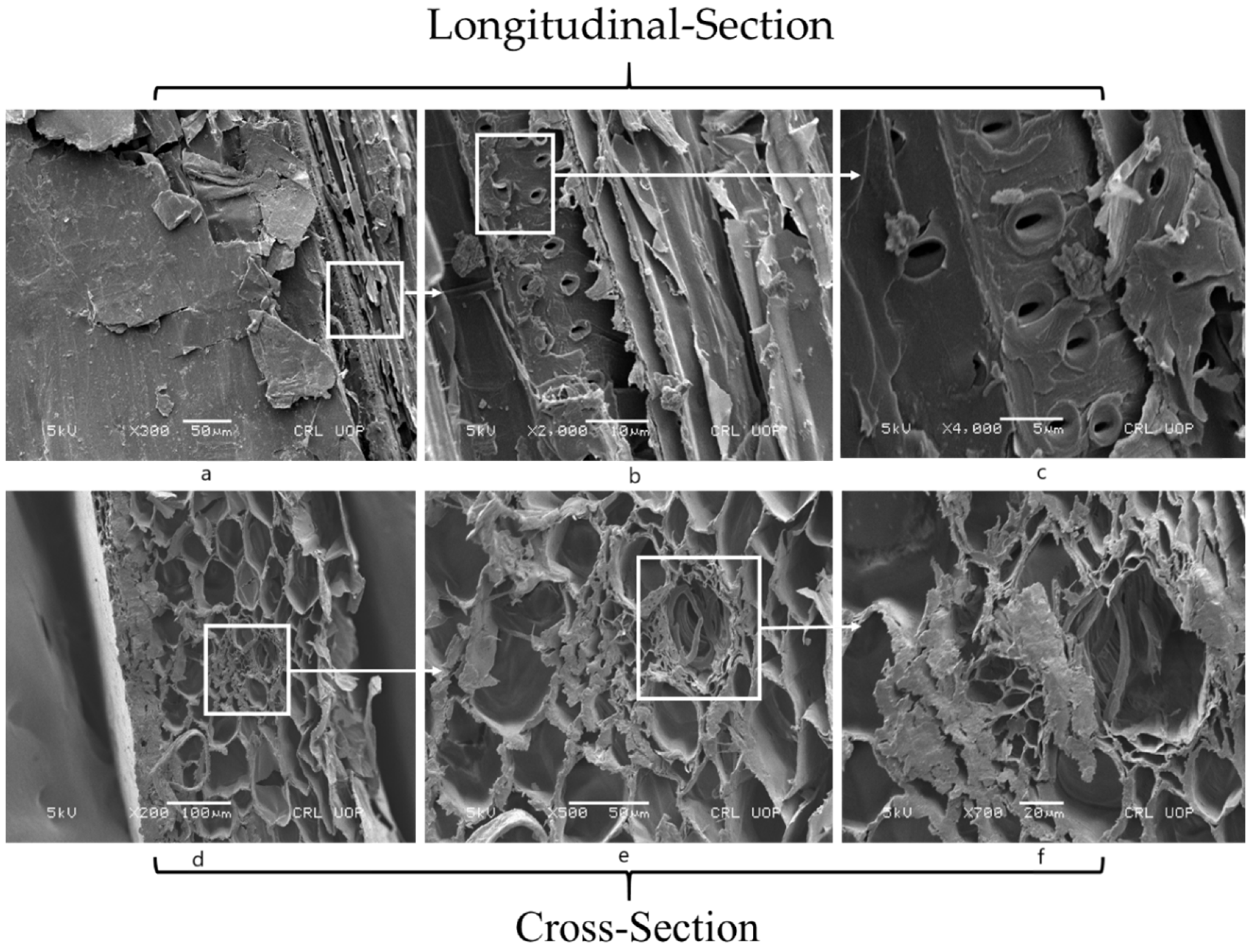

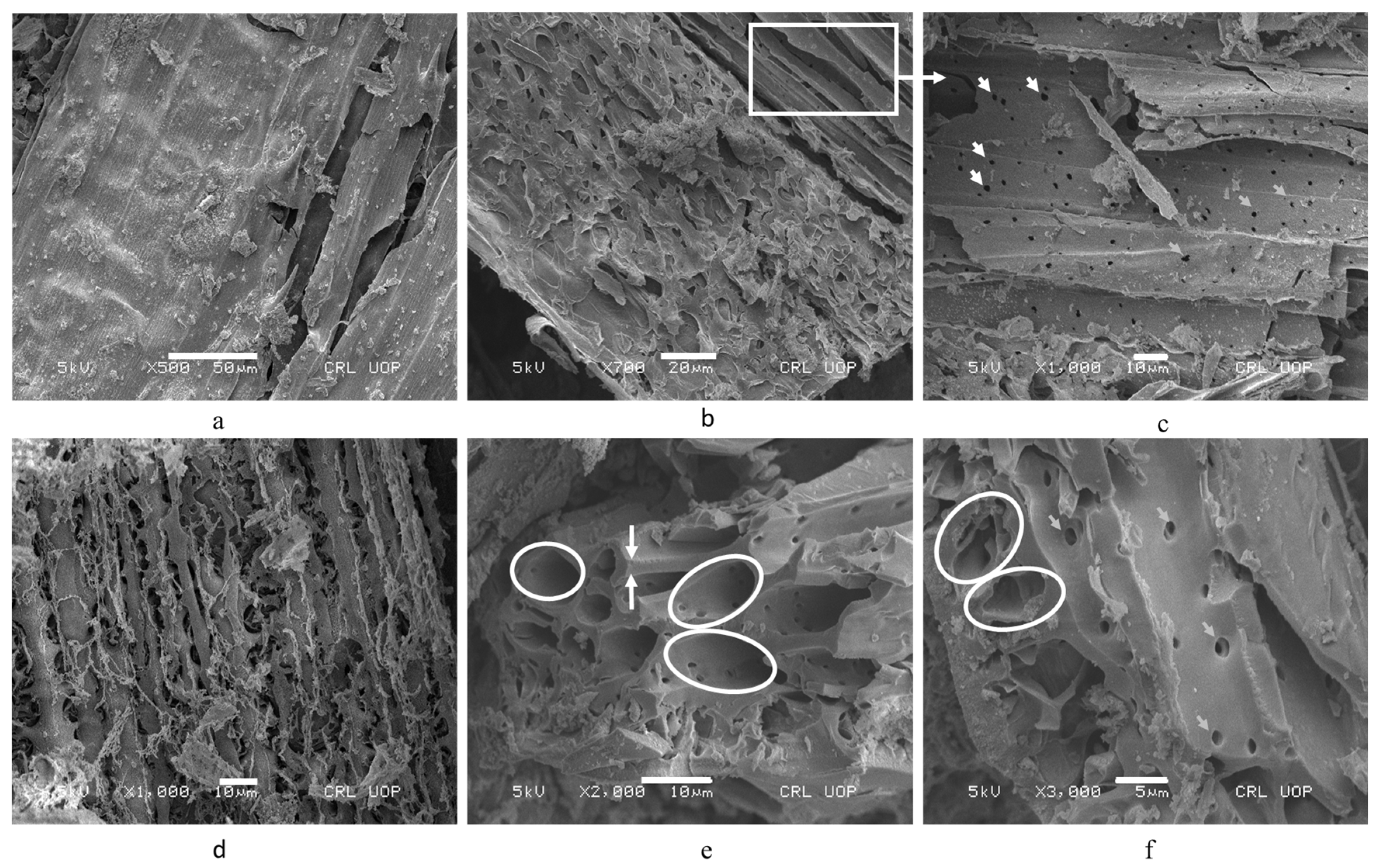

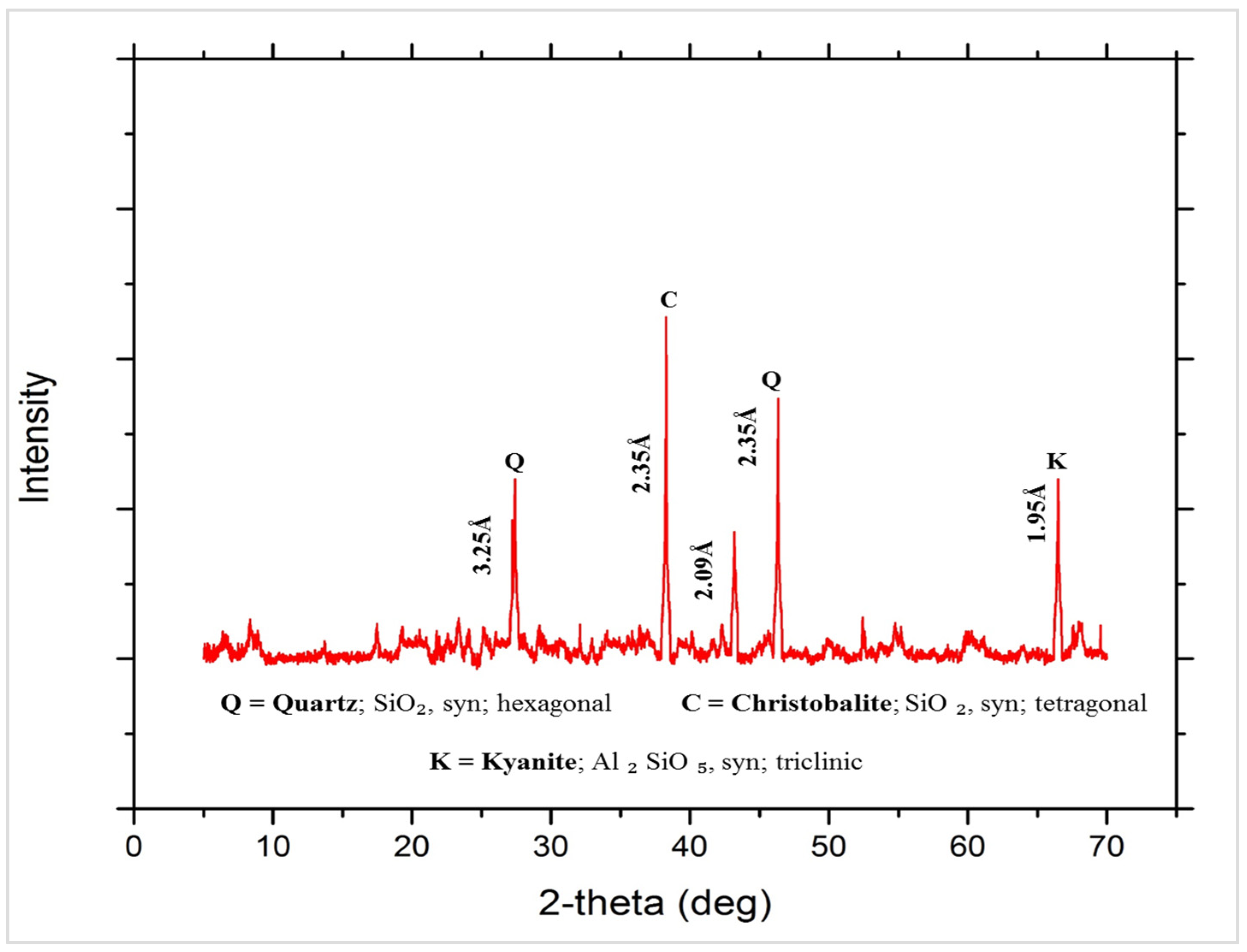

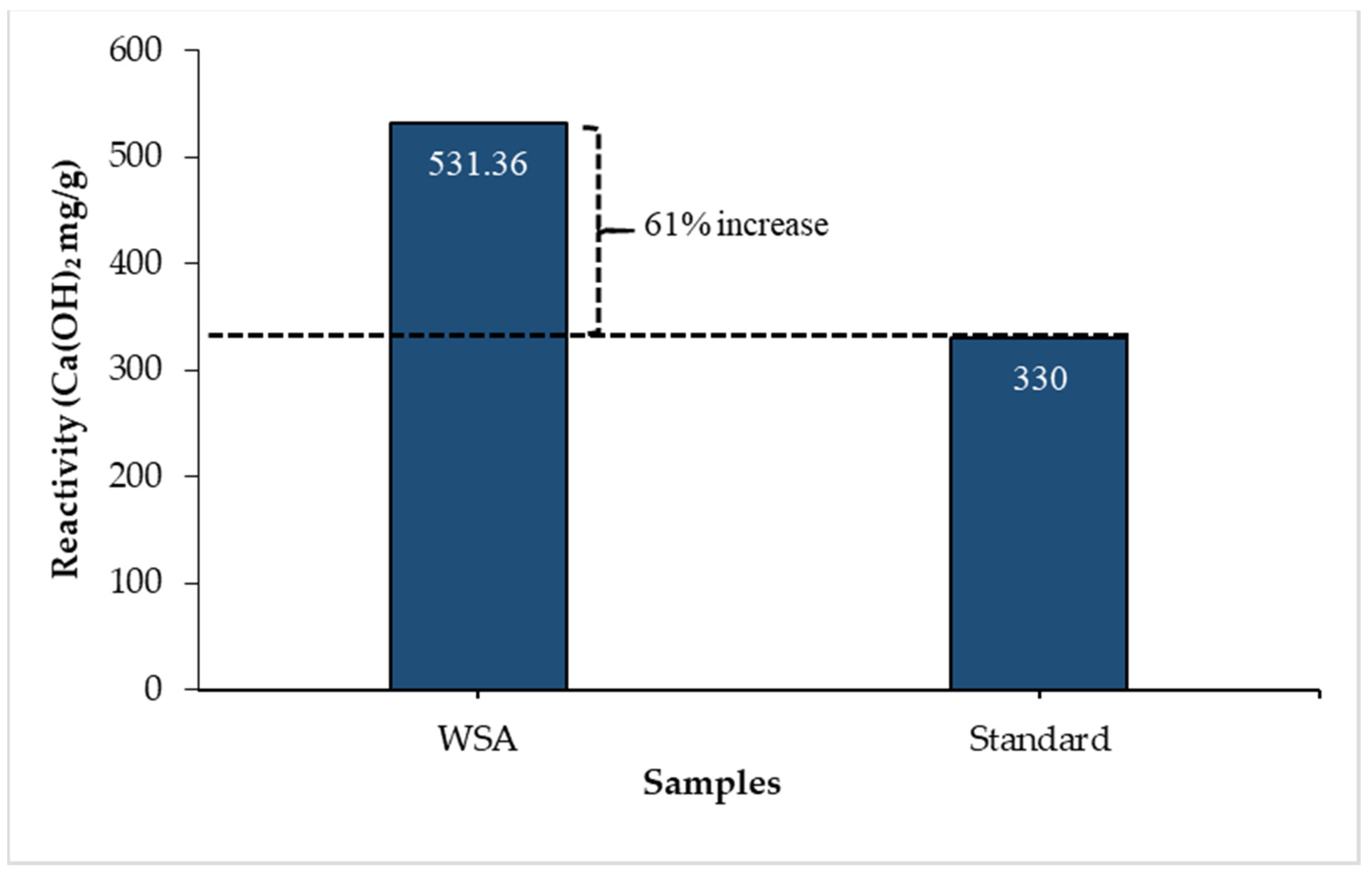

- Macro and microstructural characterization results of WSA revealed that it is pozzolanic in nature, well-graded with a fineness modulus of 2.76, free from organic impurities, and compliant with the ASTM C33 gradation requirement along with porous morphology due to the presence of tubules and microperforations.

- (b)

- Increasing slump values were observed with increased WSA replacement levels. This trend was predictable because of the lubrication effect of excessive availability of water absorbed by WSA, hence increased the fluidity of WSA concrete mixes. A maximum value of 85.36% reduction in total shrinkage response at 20% incorporation of WSA might be due to the readily available absorbed water that minimizes the self-desiccation of the cement paste matrix. The maximum decrease in fresh density was 9.5% compared to the control mix.

- (c)

- Increasing compressive strength values were attained with both increases in the age of testing and the WSA replacement percentage in concrete mixes. This increase was attributed due to the pozzolanic potential. At 28 days curing age, the compressive strength of all concrete formulations comply with the requirement of structural concrete as the minimal compressive strength of the mixes was higher than 17 MPa being specified in ACI 318, therefore it can potentially be used in various structural configurations.

- (d)

- The hardened concrete density of WSA incorporated concrete mixes increased along with the replacement percentages as a result of a pozzolanic reaction and filler effect. The water absorption of the concrete decreased upon the replacement of WSA due to suspected pore refinement by clogging of capillary voids which occurred due to synergic action of pozzolanic reaction and filler effect caused by WSA.

- (e)

- Like trends of hardened density, the pulse velocity values increased at all testing ages and replacement percentages. Based on the values of UPV, all WSA incorporated mixes fall in the category of excellent quality concrete. Therefore, higher UPV values show that the quality of the cement paste matrix has been enhanced upon the incorporation of WSA in concrete.

- (f)

- Weight loss of concrete containing WSA decreased with the increase in replacement percentage under the action of sulfuric acid and hydrochloric acid. The adverse effects of acids on concrete reduced with the addition of WSA due to densification in the microstructure. Therefore, the resistance toward deleterious agents increased with the increase of WSA incorporation in concrete.

- (g)

- The incorporation of WSA in the W10 mix has shown the lower value of weight loss in the second region which corresponds to the lower percentage of portlandite than that in control concrete. Thus, the WSA also shows pozzolanic activity when used as fine aggregate replacement in concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wiedmann, T.O.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The material footprint of nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef] [Green Version]

- Collien, E. Food Outlook Biannual Report on Global Food Market 2017; FAO: Rome, Italy, 2019. [Google Scholar]

- Pan, X.; Sano, Y. Fractionation of wheat straw by atmospheric acetic acid process. Bioresour. Technol. 2005, 96, 1256–1263. [Google Scholar] [CrossRef]

- Gadde, B.; Bonnet, S.; Menke, C.; Garivait, S. Air pollutant emissions from rice straw open field burning in India, Thailand and the Philippines. Environ. Pollut. 2009, 157, 1554–1558. [Google Scholar] [CrossRef]

- Bridgeman, T.; Jones, J.; Shield, I.; Williams, P. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Gadde, B.; Menke, C.; Wassmann, R. Rice straw as a renewable energy source in India, Thailand, and the Philippines: Overall potential and limitations for energy contribution and greenhouse gas mitigation. Biomass Bioenergy 2009, 33, 1532–1546. [Google Scholar] [CrossRef]

- Eriksson, O.; Reich, M.C.; Frostell, B.; Björklund, A.; Assefa, G.; Sundqvist, J.-O.; Granath, J.; Baky, A.; Thyselius, L. Municipal solid waste management from a systems perspective. J. Clean. Prod. 2005, 13, 241–252. [Google Scholar] [CrossRef] [Green Version]

- Lee, B.-J.; Kim, B.; Lee, K. Air Pollution Exposure and Cardiovascular Disease. Toxicol. Res. 2014, 30, 71–75. [Google Scholar] [CrossRef]

- Li, J.-S.; Xue, Q.; Fang, L.; Poon, C.S. Characteristics and metal leachability of incinerated sewage sludge ash and air pollution control residues from Hong Kong evaluated by different methods. Waste Manag. 2017, 64, 161–170. [Google Scholar] [CrossRef]

- Streets, D.G.; Yarber, K.F.; Woo, J.-H.; Carmichael, G.R. Biomass burning in Asia: Annual and seasonal estimates and atmospheric emissions. Glob. Biogeochem. Cycles 2003, 17, 1759–1768. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Hu, J.; Qi, Y.; Li, C.; Chen, J.; Wang, X.; He, J.; Wang, S.; Hao, J.; Zhang, L.; et al. Emission characterization, environmental impact, and control measure of PM2.5 emitted from agricultural crop residue burning in China. J. Clean. Prod. 2017, 149, 629–635. [Google Scholar] [CrossRef]

- Aïtcin, P.C. Cements of yesterday and today—Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Bin Mahmud, H.; Jumaat, M.Z. Engineering properties of lightweight aggregate concrete containing limestone powder and high volume fly ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, S.; Nagar, R. Feasibility assessment for partial replacement of fine aggregate to attain cleaner production perspective in concrete: A review. J. Clean. Prod. 2016, 135, 490–507. [Google Scholar] [CrossRef]

- Hanif, A.; Kim, Y.; Lu, Z.; Park, C. Early-age behavior of recycled aggregate concrete under steam curing regime. J. Clean. Prod. 2017, 152, 103–114. [Google Scholar] [CrossRef]

- Shi, C.; Zheng, K. A review on the use of waste glasses in the production of cement and concrete. Resour. Conserv. Recycl. 2007, 52, 234–247. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. Properties of high strength concrete containing scrap tire rubber. J. Clean. Prod. 2016, 113, 86–92. [Google Scholar] [CrossRef]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of Waste Glass Addition as a Replacement for Fine Aggregate on Properties of Mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef]

- Kim, J.H.; Qudoos, A.; Jakhrani, S.H.; Rehman, A.-U.; Lee, J.B.; Kim, S.S.; Ryou, J.-S. Mechanical Properties and Sulfate Resistance of High Volume Fly Ash Cement Mortars with Air-Cooled Slag as Fine Aggregate and Polypropylene Fibers. Materials 2019, 12, 469. [Google Scholar] [CrossRef] [Green Version]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Coutinho, J.S. The combined benefits of CPF and RHA in improving the durability of concrete structures. Cem. Concr. Compos. 2003, 25, 51–59. [Google Scholar] [CrossRef]

- Sales, A.; Lima, S.A. Use of Brazilian sugarcane bagasse ash in concrete as sand replacement. Waste Manag. 2010, 30, 1114–1122. [Google Scholar] [CrossRef] [PubMed]

- Aggarwal, Y.; Siddique, R. Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 2014, 54, 210–223. [Google Scholar] [CrossRef] [Green Version]

- Binici, H.; Yucegok, F.; Aksogan, O.; Kaplan, H. Effect of Corncob, Wheat Straw, and Plane Leaf Ashes as Mineral Admixtures on Concrete Durability. J. Mater. Civ. Eng. 2008, 20, 478–483. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Asavapisit, S.; Sombatsompop, K. Properties of autoclaved aerated concrete incorporating rice husk ash as partial replacement for fine aggregate. Cem. Concr. Compos. 2015, 55, 11–16. [Google Scholar] [CrossRef]

- Samantaray, S.; Panda, K.; Mishra, M. Rice Husk Ash as Fine Aggregate Sustainable Material for Strength Enhancement of Conventional and Self Compacting Concrete. Key Eng. Mater. 2016, 692, 94–103. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Properties of concrete containing high volumes of coal bottom ash as fine aggregate. J. Clean. Prod. 2015, 91, 269–278. [Google Scholar] [CrossRef]

- Siddique, R. Effect of fine aggregate replacement with Class F fly ash on the mechanical properties of concrete. Cem. Concr. Res. 2003, 33, 539–547. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.; Memon, S.A.; Tulliani, J.-M.; Ferro, G.A. Experimental Investigation on Use of Wheat Straw Ash and Bentonite in Self-Compacting Cementitious System. Adv. Mater. Sci. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Qudoos, A.; Ullah, Z.; Baloch, Z. Performance Evaluation of the Fiber-Reinforced Cement Composites Blended with Wheat Straw Ash. Adv. Mater. Sci. Eng. 2019, 2019, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Clean. Prod. 2016, 112, 620–630. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S. Concrete using agro-waste as fine aggregate for sustainable built environment–A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef] [Green Version]

- Rashad, A.M. A preliminary study on the effect of fine aggregate replacement with metakaolin on strength and abrasion resistance of concrete. Constr. Build. Mater. 2013, 44, 487–495. [Google Scholar] [CrossRef]

- Rashad, A.M. Cementitious materials and agricultural wastes as natural fine aggregate replacement in conventional mortar and concrete. J. Build. Eng. 2016, 5, 119–141. [Google Scholar] [CrossRef]

- Biricik, H.; Akoz, F.; Türker, F.; Berktay, I. Resistance to magnesium sulfate and sodium sulfate attack of mortars containing wheat straw ash. Cem. Concr. Res. 2000, 30, 1189–1197. [Google Scholar] [CrossRef]

- Memon, S.A.; Wahid, I.; Khan, M.K.; Tanoli, M.A.; Bimaganbetova, M. Environmentally Friendly Utilization of Wheat Straw Ash in Cement-Based Composites. Sustainability 2018, 10, 1322. [Google Scholar] [CrossRef] [Green Version]

- Biricik, H.; Aköz, F.; Berktay, I.; Tulgar, A.N. Study of pozzolanic properties of wheat straw ash. Cem. Concr. Res. 1999, 29, 637–643. [Google Scholar] [CrossRef]

- Saillio, M.; Baroghel-Bouny, V.; Bertin, M.; Pradelle, S.; Vincent, J. Phase assemblage of cement pastes with SCM at different ages. Constr. Build. Mater. 2019, 224, 144–157. [Google Scholar] [CrossRef]

- ASTM. C150: Standard Specification for Portland Cement; ASTM: Philadelphia, PA, USA, 2001. [Google Scholar]

- ASTM C136. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; ASTM: West Conshohocken, PA, USA, 2006. [Google Scholar]

- C40/C40M-11. Standard Test Methods for Organic Impurities in Fine Aggregates for Concrete; ASTM: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM C128. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C33-03. Standard Spesification for Concrete Agregates; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Newman, J.; Choo, B.S. Advanced Concrete Technology 3: Processes; Butterworth-Heinemann: Oxford, UK, 2003. [Google Scholar]

- Zongjin, L. Advanced Concrete Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Zhang, Y.; Ghaly, A.E.; Li, B. Physical Properties of Wheat Straw Varieties Cultivated Under Different Climatic and Soil Conditions in Three Continents. Am. J. Eng. Appl. Sci. 2012, 5, 98–106. [Google Scholar]

- Bahurudeen, A.; Santhanam, M. Influence of different processing methods on the pozzolanic performance of sugarcane bagasse ash. Cem. Concr. Compos. 2015, 56, 32–45. [Google Scholar] [CrossRef]

- ASTM C618-15. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Ondřej, J.; Pavlikova, M.; Sedmidubský, D.; Bouša, D.; Lojka, M.; Pokorný, J.; Zaleska, M.; Pavlík, Z. Study on pozzolana activity of wheat straw ash as potential admixture for blended cements. Ceram. Silikáty 2017, 61, 327–339. [Google Scholar]

- Chandrasekhar, S.; Pramada, P.N.; Majeed, J. Effect of calcination temperature and heating rate on the optical properties and reactivity of rice husk ash. J. Mater. Sci. 2006, 41, 7926–7933. [Google Scholar] [CrossRef]

- Stutzman, P.E.; Centeno, L. Compositional Analysis of Beneficiated Fly Ashes; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1995. [Google Scholar]

- Jaques, S.B.; Stehly, R.D.; Dunning, P.B. Processed Silica as a Natural Pozzolan for Use as a Cementitious Component in Concrete and Concrete Products. U.S. Patent No. 5,554,352, 10 September 1996. [Google Scholar]

- Standrads, E. Methods of Testing Cement-Part 5: Pozzolanicity Test for Pozzolanic Cements; NSAI: Dublin, Ireland, 2000; Volume EN 196-5. [Google Scholar]

- Cordeiro, G.C.; Toledo-Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Pozzolanic activity and filler effect ofsugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- ASTM C511. Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in The Testing of Hydraulic Cements and Concretes; ASTM: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM. C143-03, Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM, C138, Standard Test Method for Unit Weight; ASTM: West Conshohocken, PA, USA, 2001.

- Standrads C1698–09, Test Method for Autogenous Strain of Cement Paste and Mortar; ASTM: West Conshohocken, PA, USA, 2009.

- ASTM C642-13. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM. ASTM C 597: Standard Test Method for Pulse Velocity through Concrete; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Hasnain, M.H.; Javed, U.; Ali, A.; Zafar, M.S. Eco-friendly utilization of rice husk ash and bagasse ash blend as partial sand replacement in self-compacting concrete. Constr. Build. Mater. 2021, 273, 121753. [Google Scholar] [CrossRef]

- Bentz, D.P.; Snyder, K.A. Protected paste volume in concrete: Extension to internal curing using saturated lightweight fine aggregate. Cem. Concr. Res. 1999, 29, 1863–1867. [Google Scholar] [CrossRef]

- Cheriaf, M.; Rocha, J.; Péra, J. Pozzolanic properties of pulverized coal combustion bottom ash. Cem. Concr. Res. 1999, 29, 1387–1391. [Google Scholar] [CrossRef]

- Memon, S.A.; Javed, U.; Khushnood, R.A. Eco-friendly utilization of corncob ash as partial replacement of sand in concrete. Constr. Build. Mater. 2019, 195, 165–177. [Google Scholar] [CrossRef]

- Bai, Y.; Darcy, F.; Basheer, P.A.M. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fineaggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

- Ghafoori, N.; Buchole, J. Properties of High-Calcium Dry Bottom Ash for Structural Concrete. Mater. J. 1997, 94, 90–101. [Google Scholar]

- Singh, M.; Siddique, R.J.C. Compressive strength, drying shrinkage and chemical resistance of concrete incor-porating coal bottom ash as partial or total replacement of sand. Build. Mater. 2014, 68, 39–48. [Google Scholar] [CrossRef]

- Her-Yung, W. A study of the engineering properties of waste LCD glass applied to controlled low strength materials concrete. Constr. Build. Mater. 2009, 23, 2127–2131. [Google Scholar] [CrossRef]

- Aggarwal, P.; Aggarwal, Y.; Gupta, S.M. Effect of Bottom Ash as Replacement of Fine. Asian J. Civ. Eng. Build. Hous. Vol. 2007, 8, 49–62. [Google Scholar]

- ACI 318-19. American Concrete Institute. In Building Code Requirements for Structural Concrete; ACI: Washington, DA, USA, 2019. [Google Scholar]

- Al-Rawas, A.A.; Hago, A.W.; Taha, R.; Al-Kharousi, K. Use of incinerator ash as a replacement for cement and sand in cement mortars. Build. Environ. 2005, 40, 1261–1266. [Google Scholar] [CrossRef]

- Mehta, K.P.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill Publishing: New York, NY, USA, 2006. [Google Scholar]

- Al-Akhras, N.M.; Abu-Alfoul, B.A. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2002, 32, 859–863. [Google Scholar] [CrossRef]

- Siddique, R.; de Schutter, G.; Noumowe, A. Effect of used-foundry sand on the mechanical properties of concrete. Constr. Build. Mater. 2009, 23, 976–980. [Google Scholar] [CrossRef]

- Etxeberria, M.; Pacheco, C.; Meneses, J.M.; Berridi, I. Properties of concrete using metallurgical industrial by-products as aggregates. Constr. Build. Mater. 2010, 24, 1594–1600. [Google Scholar] [CrossRef]

- Tennis, P.D.; Jennings, H.M. A model for two types of calcium silicate hydrate in the microstructure of Portland cement pastes. Cem. Concr. Res. 2000, 30, 855–863. [Google Scholar] [CrossRef]

- Arif, E.; Clark, M.W.; Lake, N. Sugar cane bagasse ash from a high-efficiency co-generation boiler as filler inconcrete. Constr. Build. Mater. 2017, 151, 692–703. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties and Materials; McGraw-Hill: New York, NY, USA, 2017. [Google Scholar]

- Hamzah, A.F.; Ibrahim, M.N.; Jamaluddin, N.; Jaya, R.P.; Arshad, M.F.; Abidin, N.E.Z. Fresh characteristic and mechanical compressive strength development of self-compacting concrete integrating coal bottom ash as partial fine aggregates replacement. Int. J. Eng. Technol. 2015, 5, 57. [Google Scholar]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of limestone powder to improve the properties of self-compacting concrete incorporating high volumes of untreated rice husk ash as fine aggregate. Constr. Build. Mater. 2013, 38, 455–464. [Google Scholar] [CrossRef]

- BIS 13311, Non-Destructive Testing of Concrete–Methods of Test-Part 1: Ultrasonic Pulse Velocity; Bureau of Indian Standards: New Delhi, India, 1992.

- Xu, W.; Lo, Y.T.; Ouyang, D.; Memon, S.A.; Xing, F.; Wang, W.; Yuan, X. Effect of rice husk ash fineness on porosity and hydration reaction of blended cement paste. Constr. Build. Mater. 2015, 89, 90–101. [Google Scholar] [CrossRef]

- Javed, U.; Khushnood, R.A.; Memon, S.A.; Jalal, F.E.; Zafar, M.S. Sustainable incorporation of lime-bentonite clay composite for production of ecofriendly bricks. J. Clean. Prod. 2020, 263, 121469. [Google Scholar] [CrossRef]

- Zafar, M.S.; Javed, U.; Khushnood, R.A.; Nawaz, A.; Zafar, T. Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Constr. Build. Mater. 2020, 250, 118878. [Google Scholar] [CrossRef]

| Sand | Wheat Straw Ash | Coarse Aggregate | |

|---|---|---|---|

| Water absorption (%) | 2.40 | 13.61 | 0.80 |

| Relative density (Ratio) | 2.62 | 1.89 | 2.63 |

| Oxide Composition | Percentage |

|---|---|

| SiO2 | 71.98 |

| Fe2O3 | 1.94 |

| Al2O3 | 2.30 |

| CaO | 3.05 |

| MgO | 2.58 |

| P2O5 | 1.27 |

| K2O | 9.12 |

| Na2O | 2.7 |

| TiO2 | 0.04 |

| MnO | 0.03 |

| LOI | 4.99 |

| (SiO2+Al2O3+ Fe2O3) | 76.22 |

| Ash content | 2.3 |

| Filtrate (mL) | Titration HCL Volume for Cement (V1) | Titration HCL Volume for WSA (V2) | Chappelle Activity (Ca(OH)₂ mg/g) ((V1 – V2)/V1) * 2642.86 |

|---|---|---|---|

| 25 | 18.6 | 15.10 | 497.32 |

| Mix Design | Cement (kg/m3) | Water to Cement Ratio | Sand (kg/m3) | Wheat Straw Ash (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) |

|---|---|---|---|---|---|---|

| W0(CM) | 426 | 0.50 | 911.22 | 0 | 1146.14 | 212.29 |

| W5 | 426 | 0.50 | 865.66 | 32.87 | 1146.14 | 216.76 |

| W10 | 426 | 0.50 | 820.00 | 65.73 | 1146.14 | 225.71 |

| W15 | 426 | 0.50 | 774.54 | 98.60 | 1146.14 | 239.13 |

| W20 | 426 | 0.50 | 728.98 | 131.47 | 1146.14 | 257.02 |

| Mix | Ultrasonic Pulse Velocity (m/s) | Concrete Quality Grading as per BIS 13311-92-Part-I | ||||

|---|---|---|---|---|---|---|

| 7 d | 28 d | 56 d | 90 d | Pulse Velocity(m/s) | Concrete quality grading | |

| W0 | 4360 | 4980 | 5120 | 5350 | Above 4500 | Excellent |

| W5 | 4880 | 5230 | 5430 | 5510 | 3500–4500 | Good |

| W10 | 5040 | 5380 | 5500 | 5670 | 3000–3500 | Medium |

| W15 | 5300 | 5480 | 5630 | 5750 | Less than 3000 | Doubtful |

| W20 | 5410 | 5550 | 5750 | 5880 | ||

| Concrete Specimens | Weight Loss (%) | Weight Loss with Respect to Total Weight Loss (%) | ||||

|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | Stage 1 | Stage 2 | Stage 3 | |

| W0 | 2.22 | 0.47 | 0.11 | 18.19 | 3.54 | 0.83 |

| W10 | 2.40 | 0.23 | 0.16 | 18.64 | 1.88 | 1.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memon, S.A.; Javed, U.; Haris, M.; Khushnood, R.A.; Kim, J. Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete. Materials 2021, 14, 2078. https://doi.org/10.3390/ma14082078

Memon SA, Javed U, Haris M, Khushnood RA, Kim J. Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete. Materials. 2021; 14(8):2078. https://doi.org/10.3390/ma14082078

Chicago/Turabian StyleMemon, Shazim Ali, Usman Javed, Muhammad Haris, Rao Arsalan Khushnood, and Jong Kim. 2021. "Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete" Materials 14, no. 8: 2078. https://doi.org/10.3390/ma14082078

APA StyleMemon, S. A., Javed, U., Haris, M., Khushnood, R. A., & Kim, J. (2021). Incorporation of Wheat Straw Ash as Partial Sand Replacement for Production of Eco-Friendly Concrete. Materials, 14(8), 2078. https://doi.org/10.3390/ma14082078