Prompt Determination of the Mechanical Properties of Industrial Polypropylene Sandwich Pipes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Making of Specimens

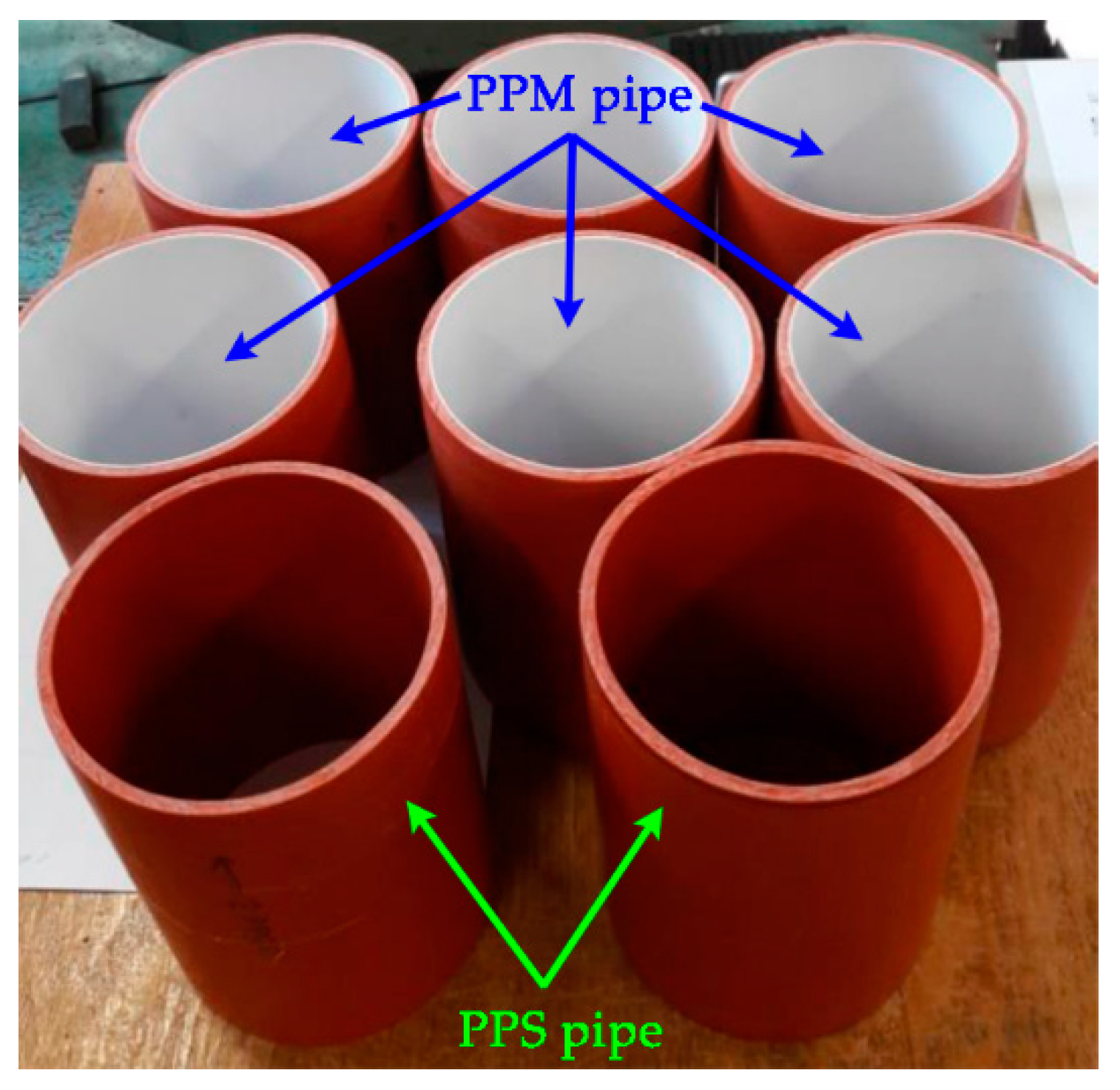

- A RIGID MONO PP single-layer solid-wall pipe (designated as PPS), produced from PP material with a homogenous flexural modulus;

- RIGID MULTI PP pipes (designated as PPM) produced using three-layer technologies. The pipes had external (e) and internal (i) layers made of polypropylene with a high flexural modulus. The intermediate (m) layer was made of PP foam.

2.2. Mechanical Tests and Determination of Density

3. Approaches to the Issue and Numerical Simulations

3.1. Assumptions

3.2. Numerical Models

4. Results of Tests and Simulations

4.1. Ring Characteristics

4.2. Ring Stiffness and Flexibility in Numerical Simulations

4.3. Tensile Characteristics

4.4. Numerical Tensile Characteristics

4.5. Properties of the Layers

4.6. Recommendations for Engineering Assessments

5. Conclusions

- ○

- The smooth-wall single- and multilayer (with a foam core) polypropylene pipes manufactured at SIA EVOPIPES, with a nominal/external pipe diameter of 110 mm, demonstrated an experimental conformity to the same nominal class SN8 (in ring stiffness and flexibility tests) but exhibited markedly different tensile properties (the modulus and ultimate strength) of their materials;

- ○

- The use of simple analytical formulas of linear interpolation, linear elastic approximation, and rule of mixtures (instead of using a more rigorous time-consuming approach) makes it possible to predict, with sufficient accuracy, the effective tensile properties of a multilayer pipe material based on the experimental data for each layer. The formulas mentioned can be used for estimating any unknown characteristic of layers and of the entire pipe from other known pipes and pipe geometry;

- ○

- An expression connecting the multilayer PP pipe permissible thickness and relative position of the foam core with the expected tensile moduli of the entire pipe, and each layer can be applied to planning the pipe production process in order to minimize production costs by controlling the changes in pipe properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spitael, P.; Macosko, C.M. Strain hardening in polypropylenes and its role in extrusion foaming. Polym. Eng. Sci. 2004, 44, 2090–2100. [Google Scholar] [CrossRef]

- Sara, L.; Abdelkhalek, L.; M’hamed, C.; Abdellah, C.; Ahmed, D. Gravimetric, mechanical and chemical characterization of different materials used in sewers systems: Polyvinyl chloride (PVC), polypropylene (PP) and high density polyethylene (HDPE), aged in sulfuric acid at 60 °C. Res. Inven. Int. J. Eng. Sci. 2015, 5, 1–10. [Google Scholar]

- Weon, J.-I. Effects of thermal ageing on mechanical and thermal behaviors of linear low density polyethylene pipe. Polym. Degrad. Stab. 2010, 95, 14–20. [Google Scholar] [CrossRef]

- Genis, A.V. Analysis of the global and Russian markets of polypropylene and of its main consumption areas. Russ. J. Gen. Chem. 2017, 87, 2137–2150. [Google Scholar] [CrossRef]

- De La Fuente, A.; Pons, O.; Josa, A.; Aguado, A. Multi-criteria decision making in the sustainability assessment of sewerage pipe systems. J. Clean. Prod. 2016, 112, 4762–4770. [Google Scholar] [CrossRef] [Green Version]

- Wierzbicki, Ł.; Szymiczek, M. Mechanical and chemical properties of sewage pipes. Arch. Mater. Sci. Eng. 2012, 53, 38–45. [Google Scholar]

- Mazurkiewicz, ł.; Małachowski, J.; Damaziak, K.; Tomaszewski, M. Evaluation of the response of fibre reinforced composite repair of steel pipeline subjected to puncture from excavator tooth. Compos. Struct. 2018, 12, 1126–1135. [Google Scholar] [CrossRef]

- Mazurkiewicz, ł.; Małachowski, J.; Tomaszewski, M.; Baranowski, P.; Yukhymets, P. Performance of steel pipe reinforced with composite sleave. Compos. Struct. 2018, 183, 199–211. [Google Scholar] [CrossRef]

- Zouhar, M.; Vallet, L.; Hutar, P.; Náhlik, L. Life time estimation of the multilayer plastic pipes. Key Eng. Mat. 2011, 452–253, 33–36. [Google Scholar] [CrossRef]

- Farshad, M. Determination of the long-term hydrostatic strength of multilayer pipes. Polym. Test. 2005, 24, 1041–1048. [Google Scholar] [CrossRef]

- Naguib, H.E.; Park, C.B.; Reichelt, N. Fundamental foaming mechanisms governing the volume expansion of extruded polypropylene foams. J. Appl. Polym. Sci. 2003, 91, 2661–2668. [Google Scholar] [CrossRef]

- Naguib, H.E.; Park, C.B.; Lee, P.C.; Xu, D. A study on the foaming behaviors of PP resins with talc as nucleating agent. J. Polym. Eng. 2006, 2, 565–587. [Google Scholar] [CrossRef]

- Reichelt, N.; Stadlbauer, M.; Folland, R.; Park, C.B.; Wang, J. PP-blends with tailored foamability and mechanical properties. Cell. Polym. 2003, 22, 315–327. [Google Scholar] [CrossRef]

- Yu, K.; Morozov, E.V.; Ashraf, M.A.; Shankar, K. A review of the design and analysis of reinforced thermoplastic pipes for offshore applications. J. Reinf. Plast. Compos. 2017, 36, 1514–1530. [Google Scholar] [CrossRef]

- Ek, C.-G.; Liedauer, S.; Mcgoldrick, J.; Ruemer, F. Polypropylene Compositions Especially for Pipes. U.S. Patent US20050277720A1, 15 December 2005. [Google Scholar]

- Hesse, A.; Lindstroem, T.; Ek, C.-G.; Rydin, C.; Hansen, A. Singlelayer and Multilayer Polyolefin Foam Pipes. U.S. Patent US7462307B2, 9 December 2008. [Google Scholar]

- Bocian, M.; Jamroziak, K.; Kulisiewicz, M.; Pach, J.; Pyka, D. Numerical study of dynamic properties of a selected material layer of bul-letproof shields. In EURODYN 2020: XI International Conference on Structural Dynamics; Papadrakakis, M., Fragiadakis, M., Papadimitriou, C., Eds.; Institute of Structural Analysis and Antiseismic Research School of Civil Engineering National Technical University of Athens (NTUA): Athens, Greece, 2020; pp. 265–272. [Google Scholar] [CrossRef]

- Mayer, P.; Pyka, D.; Jamroziak, K.; Pach, J.; Bocian, M. Experimental and numerical studies on ballistic laminates on the polyethylene and polypropylene matrix. J. Mech. 2017, 35, 187–197. [Google Scholar] [CrossRef]

- Blasiak, S.; Takosoglu, J.E.; Laski, P.A. Optimizing the flow rate in a pneumatic directional control valve. Eng. Mech. 2014, 96–99. [Google Scholar]

- Takosoglu, J. Experimental research of flow servo-valve. In Proceedings of the EPJ Web of Conferences; EDP Sciences—Web of Conferences: Les Ulis, France, 2017; Volume 143, p. 02127. [Google Scholar] [CrossRef] [Green Version]

- Blasiak, S.; Takosoglu, J.E.; Laski, P.A.; Pietrala, D.S.; Zwierzchowski, J.; Bracha, G.; Nowakowski, L.; Blasik, M. Experimental and simulation flow rate analysis of the 3/2 directional pneumatic valve. In Proceedings of the EPJ Web of Conferences; EDP Sciences—Web of Conferences: Les Ulis, France, 2017; Volume 143, p. 02008. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Dong, B.; Yang, Z.; Xu, J.; Chen, Q.; Li, H.; Xing, F.; Jiang, Z. Recent advances in intrinsic self-Healing cementitious materials. Adv. Mater. 2018, 30, e1705679. [Google Scholar] [CrossRef] [PubMed]

- Makris, K.F.; Langeveld, J.; Clemens, F.H.L.R. A review on the durability of PVC sewer pipes: Research vs. practice. Struct. Infrastruct. Eng. 2020, 16, 880–897. [Google Scholar] [CrossRef]

- Alzabeebee, S.; Chapman, D.N.; Faramarzi, A. A comparative study of the response of buried pipes under static and moving loads. Transp. Geotech. 2018, 15, 39–46. [Google Scholar] [CrossRef]

- Yang, K.; Xue, B.; Fang, H.; Du, X.; Li, B.; Chen, J. Mechanical sensitivity analysis of pipe-liner composite structure under multi-field coupling. Structures 2021, 29, 484–493. [Google Scholar] [CrossRef]

- Fang, H.; Tan, P.; Du, X.; Li, B.; Yang, K.; Zhang, Y. Mechanical response of buried HDPE double-wall corrugated pipe under traffic-sewage coupling load. Tunn. Undergr. Sp. Technol. 2020, 108, 103664. [Google Scholar] [CrossRef]

- ISO 6259-1. Thermoplastics Pipes—Determination of Tensile Properties—Part 1: General Test Method; International Organization for Standardization ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ASTM D2412-21. Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading; ASTM: West Conshohocken, PA, USA, 2021. [Google Scholar]

- ISO 13968. Plastics Piping and Ducting Systems—Thermoplastics Pipes—Determination of Ring Flexibility; International Organization for Standardization ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Pi, L.; Nie, M.; Wang, Q. Crystalline composition and morphology in isotactic polypropylene pipe under combining effects of rotation extrusion and fibril β-nucleating agent. J. Vinyl. Addit. Technol. 2019, 25, e195–e202. [Google Scholar] [CrossRef] [Green Version]

- Ji, H.; Zhou, X.; Chen, X.; Zhao, H.; Wang, Y.; Zhu, H.; Wang, Y.; Zhu, H.; Ma, Y.; Xie, L. Deformation-induced crystallization behavior of isotactic polypropylene sheets containing a β-nucleating agent under solid-state stretching. Polymers 2020, 12, 1258. [Google Scholar] [CrossRef] [PubMed]

- Barsanescu, P.D.; Comanici, A.M. von Mises hypothesis revised. Acta Mech. 2017, 228, 433–446. [Google Scholar] [CrossRef]

- Ziółkowski, G.; Pach, J.; Pyka, D.; Kurzynowski, T.; Jamroziak, K. X-ray computed tomography for the development of ballistic composite. Materials 2020, 13, 5566. [Google Scholar] [CrossRef]

- Xi, S.Z.; Ying, W.; Wei, J.P. Reliability analysis of buried polyethylene pipeline subject to traffic loads. Adv. Mech. Eng. 2019, 11, 1–11. [Google Scholar] [CrossRef]

- Park, J.-S.; Hong, W.-H.; Lee, W.; Park, J.-H.; Yoon, S.-J. Pipe stiffness prediction of buried GFRP flexible pipe. Polym. Polym. Compos. 2014, 22, 17–24. [Google Scholar] [CrossRef]

- de Leeuw, L.W.; Martin, G.; Milewski, H.; Dietz, M.S.; Diambra, A. Polypropylene pipe interface strength on marine sandy soils with varying coarse fraction. Proc. Inst. Civ. Eng. Geotech. Eng. 2020, 174, 3–18. [Google Scholar] [CrossRef]

- Thörnblom, K.; Nilsson, S.F.; Sällberg, S.-E.; Bergström, G. Durability of Non-Pressure Polypropylene Pipe Materials; SP Rapport 2007:30; SP Technical Research Institute of Sweden: Göteborg, Sweden, 2007. [Google Scholar]

- ISO 6259-3. Thermoplastics Pipes—Determination of Tensile Properties—Part 3: Polyolefin Pipes; International Organization for Standardization ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ASTM D638-14. Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Altan, M. Thermoplastic foams: Processing, manufacturing, and vharacterization. In Recent Research in Polymerization; Cankaya, N., Ed.; IntechOpen: London, UK, 2018; p. 117. [Google Scholar] [CrossRef] [Green Version]

- Sadik, T.; Pillon, C.; Carrot, C.; Ruiz, J.A.L.; Vincent, M.; Billon, N. Polypropylene structuralfoams: Measurementsof the core, skin, andoverall mechanicalproperties withevaluation ofpredictive models. J. Cell. Plast. 2017, 53, 25–44. [Google Scholar] [CrossRef]

- Albooyeh, A.; Eskandarzadeh, S.; Mousavi, A. Influence of different foaming conditions on the mechanical, physical, and structural properties of polypropylene foam. Mech. Adv. Compos. Struct. 2019, 6, 225–237. [Google Scholar] [CrossRef]

- Pyka, D. Dynamic Identification of Sandwich Composite Panels Subjected to Shock Loads. Ph.D. Thesis, Wroclaw University of Science and Technology, Wroclaw, Poland, 2020. [Google Scholar]

- Lee, S.; Zhu, L.; Maia, J. The effect of strain-hardening on the morphology and mechanical anddielectric properties of multi-layered PP foam/PPfilm. Polymer 2015, 70, 173–182. [Google Scholar] [CrossRef]

- SystemSpecification-for PROGEF Standard Piping Systems in Polypropylene (PP); Technical Guide; Georg Fischer Piping Systems Ltd.: Schaffhausen, Switzerland, 2018; Available online: https://www.gfps.com/content/dam/gfps/system-specifications/gfps-system-specification-progef-standard-pp-en.pdf (accessed on 30 January 2021).

- Maheo, L.; Viot, P. Impact on multi-layered polypropylene foams. Int. J. Impact Eng. 2013, 53, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Domaneschi, M. Experimental and numerical study of standard impact tests on polypropylene pipes with brittle behaviour. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 2035–2046. [Google Scholar] [CrossRef]

- Rumianek, P.; Dobosz, T.; Nowak, R.; Dziewit, P.; Aromiński, A. Static mechanical properties of expanded polypropylene crushable foam. Materials 2021, 14, 249. [Google Scholar] [CrossRef] [PubMed]

- Barsoum, I.; Almansoori, H.; Almazroueiand, A.A.; Gunister, E. Fracture mechanics testing andcrack propagation modelling inpolypropylene pipes. Int. J. Struct. Integr. 2020, 12. [Google Scholar] [CrossRef]

| Designation | Diameter D (mm) | Declared Wall Thickness emin (mm) | Measured Wall Thickness e (mm) |

|---|---|---|---|

| PPS | 110 | 3.8 | 4.02 ± 0.06 |

| PPM | 110 | 3.8 | 4.25 ± 0.07 |

| Designation | ρ (kg/m3) | E (MPa) | v (-) | A (MPa) | B (MPa) | n (-) |

|---|---|---|---|---|---|---|

| PPS | 880 | 840 | 0.42 | 32 | 30 | 0.2 |

| PPM | 710 | 720 | 0.40 | 25 | 26 | 0.1 |

| Foam core | 700 | 620 | 0.03 | - | - | - |

| Designation | e (mm) | L (mm) | SR (kN/m2) | Ep (GPa) | F/L (kN/m) |

|---|---|---|---|---|---|

| PPS | 4.02 ± 0.06 | 153.50 ± 0.83 | 8.4 ± 0.3 (3.1) | 1.84 ± 0.05 (2.7) | 7.8 ± 0.2 (2.3) |

| PPM | 4.25 ± 0.07 | 153.44 ± 1.05 | 8.9 ± 0.3 (3.3) | 1.66 ± 0.07 (4.2) | 7.9 ± 0.1 (1.3) |

| Differences, (%) | - | - | 6.0 | −10.0 | 0.4 |

| Parameters | e (mm) | b (mm) | ρ (g/cm3) | εb (%) | E (MPa) | σmax (MPa) |

|---|---|---|---|---|---|---|

| PPS | 3.93 ± 0.08 | 5.70 ± 0.09 | 0.9 ± 0.01 | 112.0 ± 47.0 | 880 ± 0.02 | 32.3 ± 1.0 |

| PPM | 4.16 ± 0.11 | 5.70 ± 0.05 | 0.7 ± 0.02 | 47.2 ± 9.6 | 720 ± 0.01 | 24.3 ± 0.3 |

| Differences (%) | - | - | −22.2 | −57.7 | −18.8 | −24.7 |

| Designation | Thickness em (mm) | Density ρm (g/cm3) | Tensile Modulus Em (MPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|---|

| PPM | 2.3 ± 0.2 | 0.700 ± 0.020 | 620 (interpolation) | 20.4 (interpolation) |

| 3PPM | 6.4 ± 0.5 | 0.614 ± 0.004 | 510 ± 0.03 | 15.3 ± 0.7 |

| Parameters and Characteristics | Thickness e (mm) | Layer Volume Fraction v (-) | Density ρm (g/cm3) | Tensile Modulus Em (MPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|---|---|

| e-layer experiment | 1.08 ± 0.10 | 0.266 | 0.90 ± 0.01 | 880 ± 0.02 | 32 ± 1.0 |

| i-layer experiment | 0.81 ± 0.09 | 0.189 | 0.90 ± 0.01 | 880 ± 0.02 | 32 ± 1.0 |

| m-layer experiment | 2.30 ± 0.20 | 0.545 | 0.70 ± 0.02 | 620 (interpolation) | not required |

| PPM experiment | 4.20 ± 0.10 | 1.000 | 0.79 ± 0.02 | 720 ± 0.01 | 24.3 ± 0.3 |

| PPM modeling | - | - | 0.79 | 740 | 27.1 |

| Formula | - | - | (21) | (22) | (25) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidinejevs, S.; Chatys, R.; Aniskevich, A.; Jamroziak, K. Prompt Determination of the Mechanical Properties of Industrial Polypropylene Sandwich Pipes. Materials 2021, 14, 2128. https://doi.org/10.3390/ma14092128

Vidinejevs S, Chatys R, Aniskevich A, Jamroziak K. Prompt Determination of the Mechanical Properties of Industrial Polypropylene Sandwich Pipes. Materials. 2021; 14(9):2128. https://doi.org/10.3390/ma14092128

Chicago/Turabian StyleVidinejevs, Sergejs, Rafal Chatys, Andrey Aniskevich, and Krzysztof Jamroziak. 2021. "Prompt Determination of the Mechanical Properties of Industrial Polypropylene Sandwich Pipes" Materials 14, no. 9: 2128. https://doi.org/10.3390/ma14092128