Device Modeling and Design of Inverted Solar Cell Based on Comparative Experimental Analysis between Effect of Organic and Inorganic Hole Transport Layer on Morphology and Photo-Physical Property of Perovskite Thin Film

Abstract

:1. Introduction

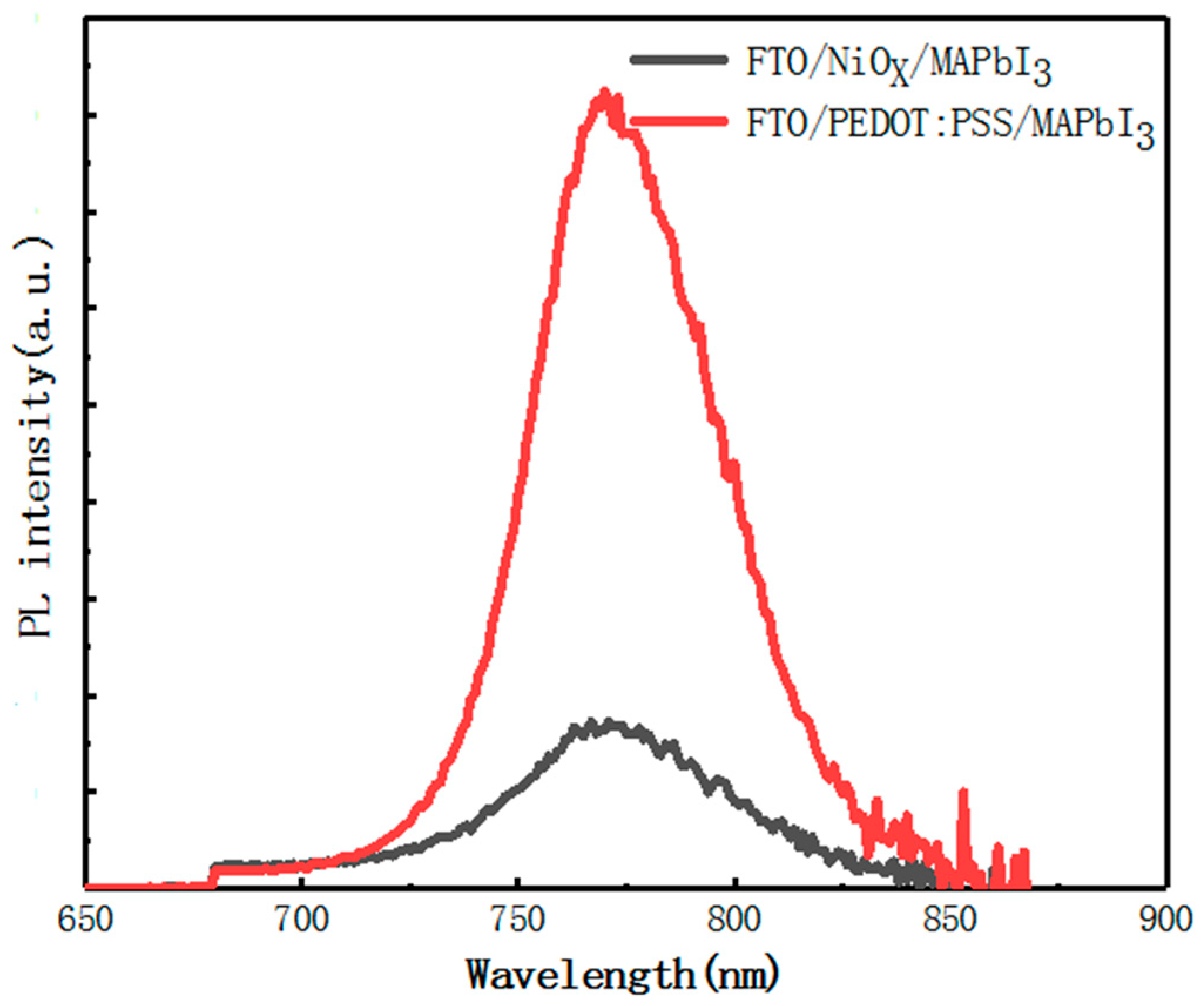

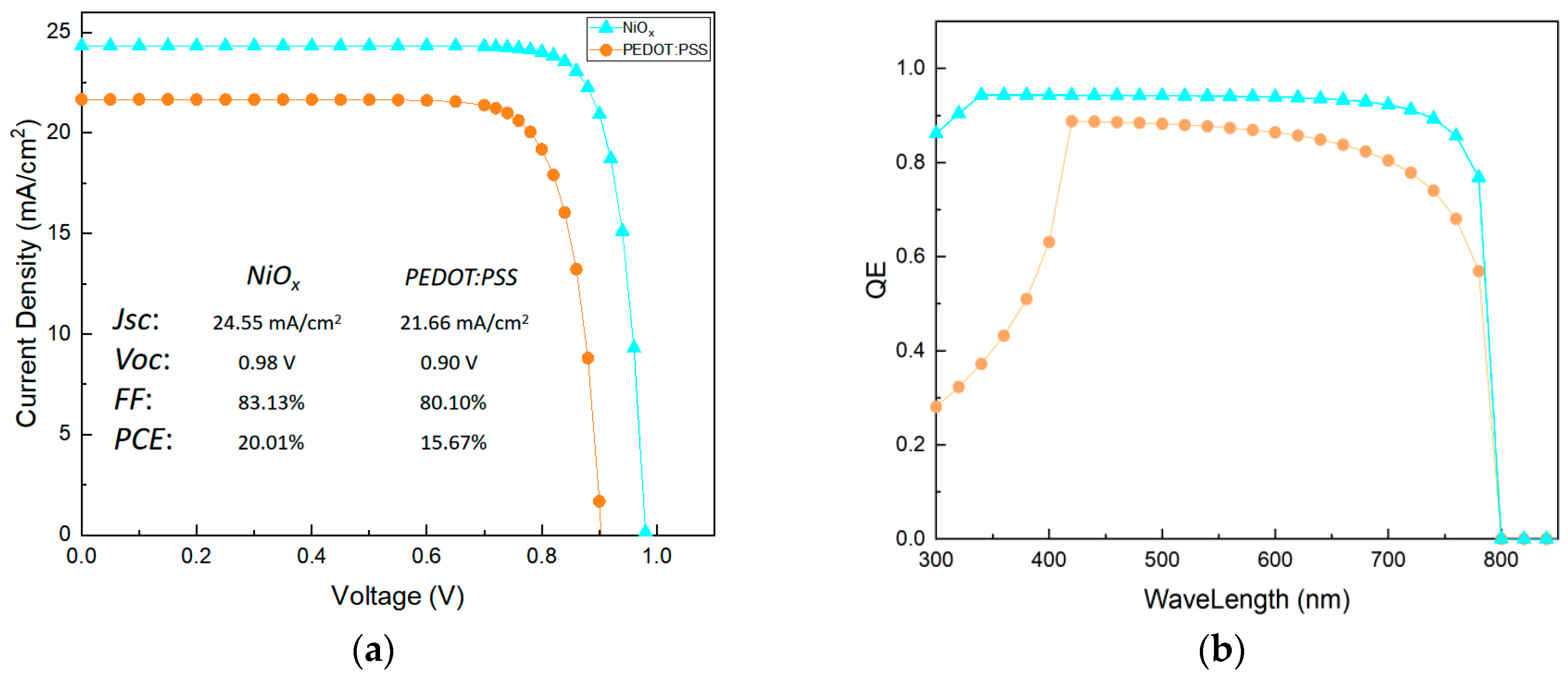

2. Experimental and Simulation

2.1. Materials

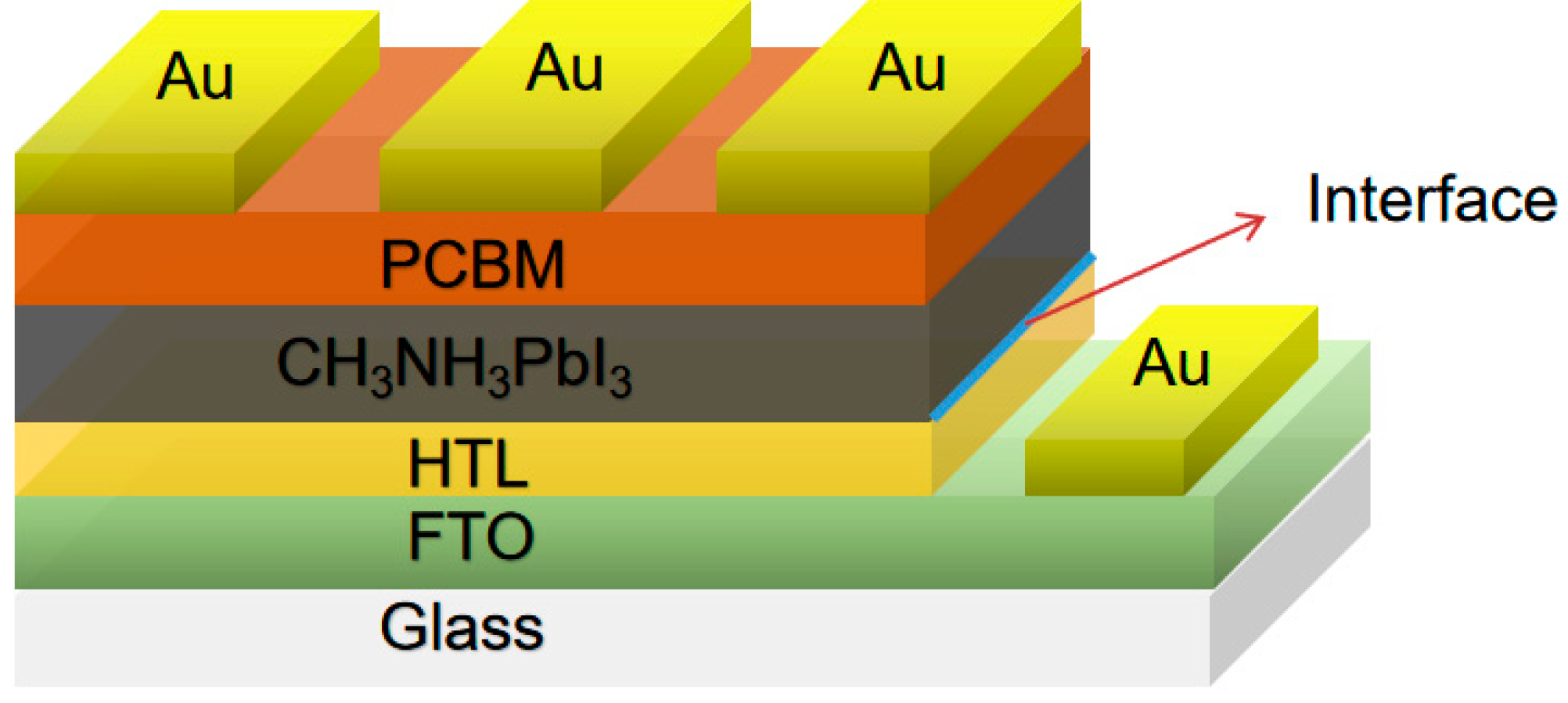

2.2. Device Fabrication

2.3. Characterization

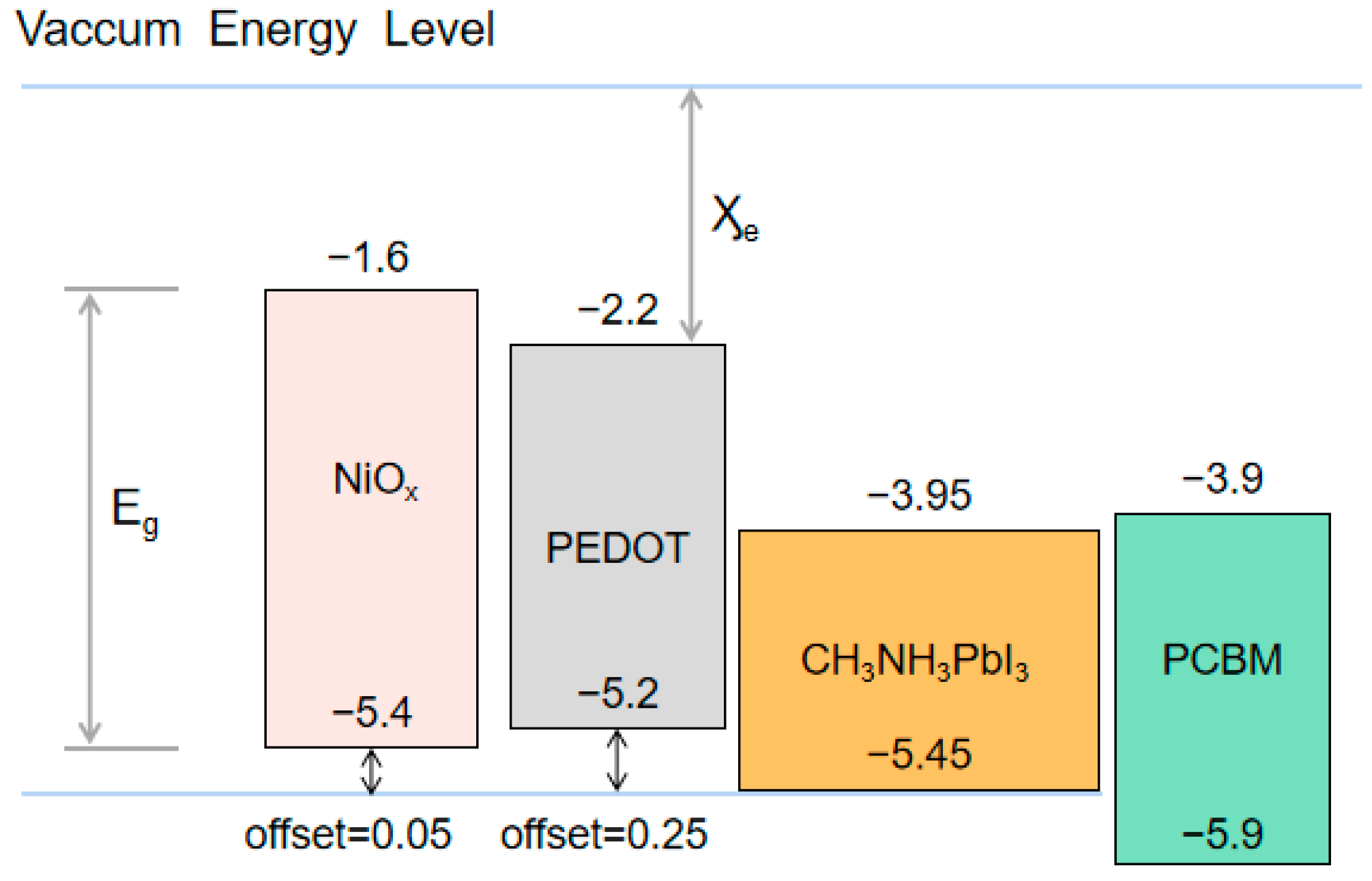

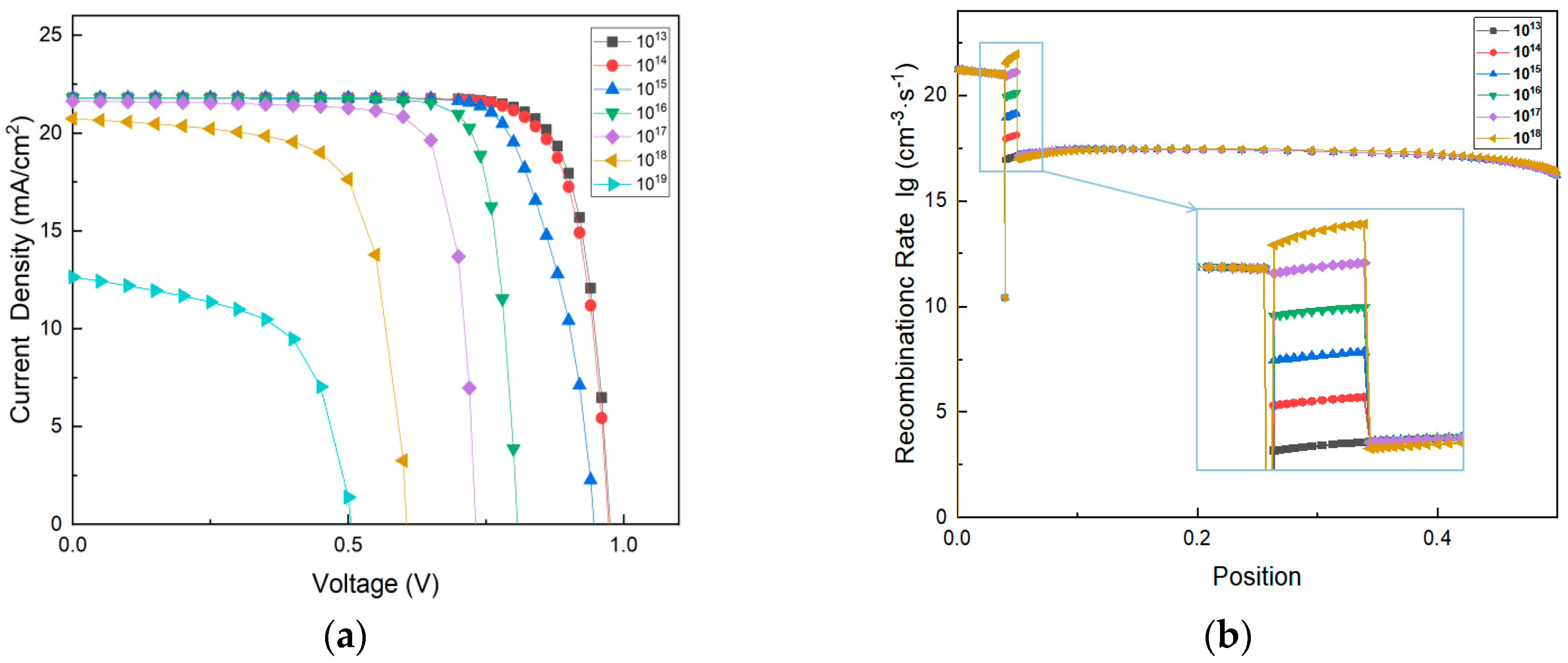

2.4. Device Simulation Parameters

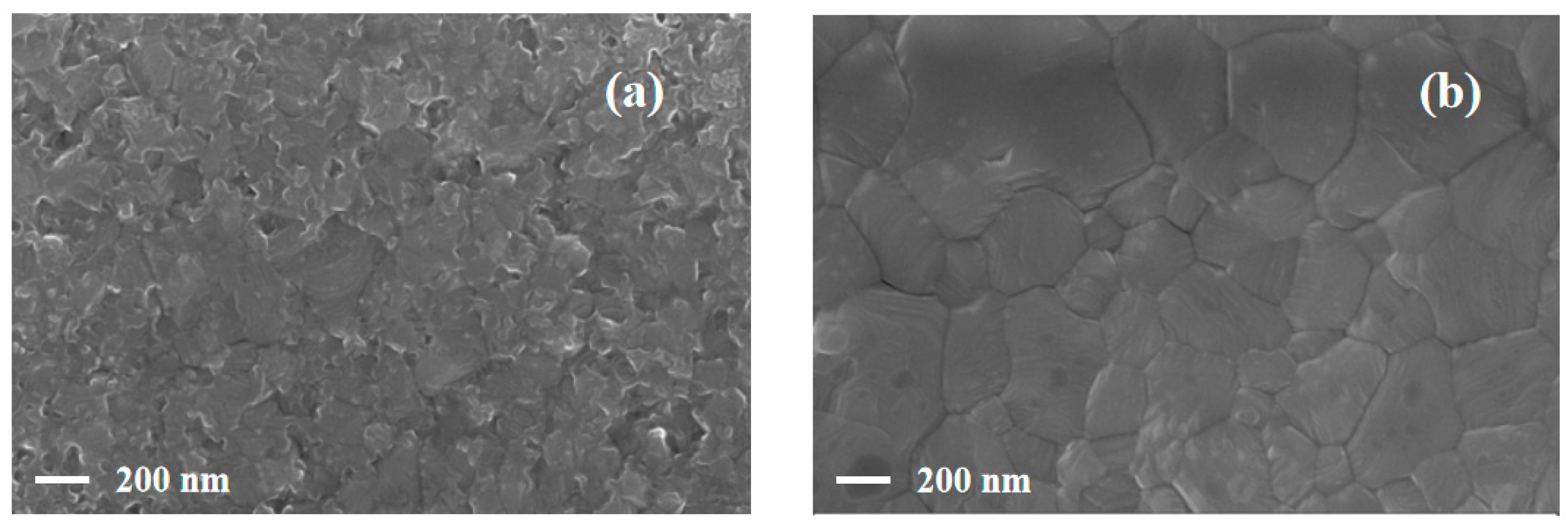

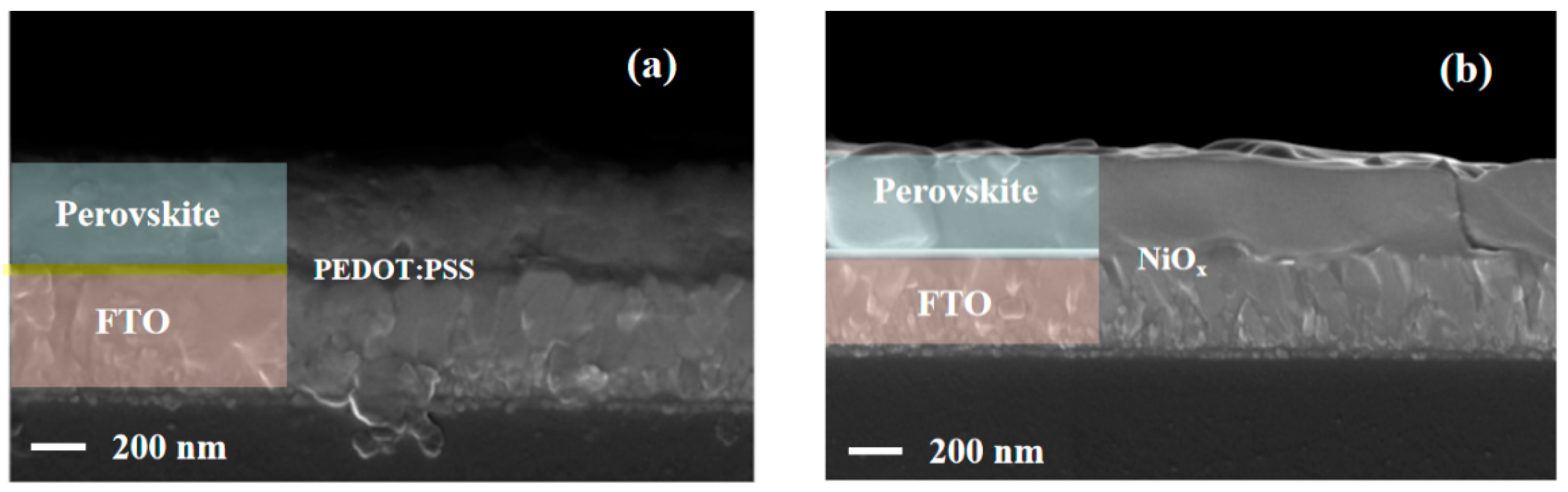

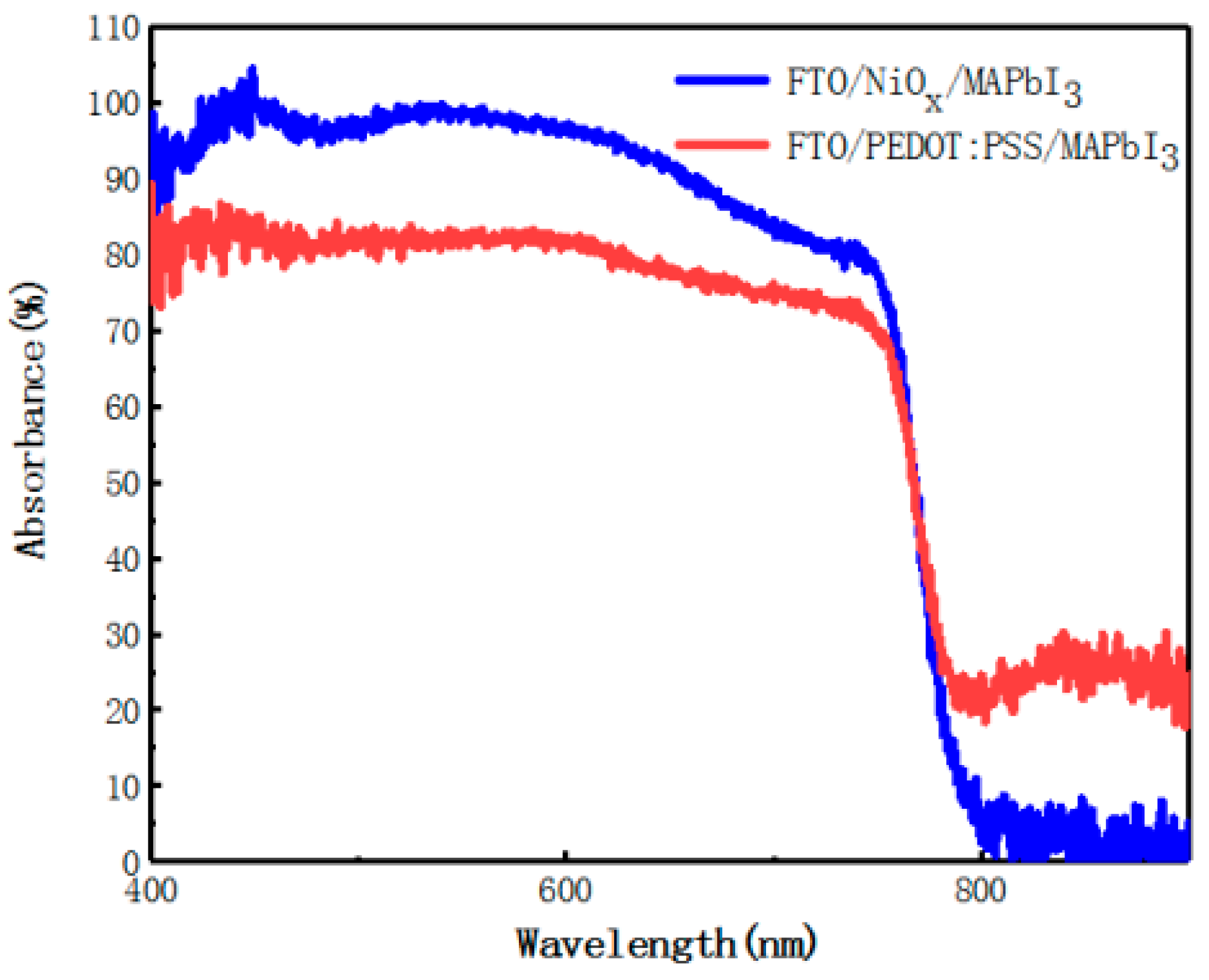

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, F.; Zhu, J.; Wei, J.; Li, Y.; Lv, M.; Yang, S.; Zhang, B.; Yao, J.; Dai, S. Numerical simulation: Toward the design of high-efficiency planar perovskite solar cells. Appl. Phys. Lett. 2014, 104, 253508. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, Z.G.; Liang, J.; Wang, X.W.; Liu, Y.M.; Liu, C.; Zhang, S.D.; Zhou, H. Towards printed perovskite solar cells with cu-prous oxide hole transporting layers: A theoretical design. Semicond. Sci. Technol. 2015, 30, 054004.1–054004.7. [Google Scholar]

- Wang, T.; Chen, J.; Wu, G.; Li, M. Optimal design of efficient hole transporting layer free planar perovskite solar cell. Sci. China Mater. 2016, 59, 703–709. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Yao, Y.; Wu, C.-Q. Origin of the high open circuit voltage in planar heterojunction perovskite solar cells: Role of the reduced bimolecular recombination. J. Appl. Phys. 2015, 117, 095502. [Google Scholar] [CrossRef]

- Minemoto, T.; Murata, M. Device modeling of perovskite solar cells based on structural similarity with thin film inorganic semiconductor solar cells. J. Appl. Phys. 2014, 116, 054505. [Google Scholar] [CrossRef]

- Yadav, P.; Pandey, K.; Bhatt, P.; Raval, D.; Tripathi, B.; Pandey, M.K.; Kumar, M. Exploring the performance limiting parameters of perovskite solar cell through experimental analysis and device simulation. Sol. Energy 2015, 122, 773–782. [Google Scholar] [CrossRef]

- Casas, G.; Cappelletti, M.; Cédola, A.; Soucase, B.M.; Blancá, E.P.Y. Analysis of the power conversion efficiency of perovskite solar cells with different materials as Hole-Transport Layer by numerical simulations. Superlattices Microstruct. 2017, 107, 136–143. [Google Scholar] [CrossRef]

- Chouhan, A.S.; Jasti, N.P.; Avasthi, S. Effect of interface defect density on performance of perovskite solar cell: Correlation of simulation and experiment. Mater. Lett. 2018, 221, 150–153. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Cao, H.-L.; Jiao, W.-B.; Wang, Q.; Wei, M.; Cantone, I.; Lü, J.A. Abate. Biological impact of lead from halide perovskites re-veals the risk of introducing a safe threshold. Nat. Commun 2020, 11, 310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, S.; Jiao, S.; Tian, D.; Chen, H.-S.; Jiao, H.; Tu, J.; Liu, Y.; Fang, D.-N. A Novel Ultrafast Rechargeable Multi-Ions Battery. Adv. Mater. 2017, 29, 1606349. [Google Scholar] [CrossRef]

- Bi, D.; El-Zohry, A.M.; Hagfeldt, A.; Boschloo, G. Improved Morphology Control Using a Modified Two-Step Method for Efficient Perovskite Solar Cells. Acs. Appl. Mater. Interfaces 2014, 6, 18751–18757. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Fan, J.; Li, J.; Mai, Y.; Wang, L. Controllable Grain Morphology of Perovskite Absorber Film by Molecular Self-Assembly toward Efficient Solar Cell Exceeding 17%. J. Am. Chem. Soc. 2015, 137, 10399–10405. [Google Scholar] [CrossRef] [PubMed]

- Salim, T.; Sun, S.; Abe, Y.; Krishna, A.; Grimsdale, A.C.; Lam, Y.M. Perovskite-based solar cells: Impact of morphology and de-vice architecture on device performance. J. Mater. Chem. A 2015, 3, 8943–8969. [Google Scholar] [CrossRef]

- Pathak, S.; Sepe, A.; Sadhanala, A.; Deschler, F.; Haghighirad, A.; Sakai, N.; Goedel, K.C.; Stranks, S.D.; Noel, N.; Price, M.; et al. Atmospheric Influence upon Crystallization and Electronic Disorder and Its Impact on the Photophysical Properties of Organic–Inorganic Perovskite Solar Cells. Acs. Nano 2015, 9, 2311–2320. [Google Scholar] [CrossRef]

- Zaman, M.M.U.; Imran, M.; Saleem, A.; Komboh, A.H.; Muhammad, A.; Khan, N.; Akhter, P. Potassium doped methylammo-nium lead iodide (MAPbI3) thin films as a potential absorber for perovskite solar cells; structural, morphological, electronic and optoelectric properties. Phys. B Condens. Matter 2017, 522, 57–65. [Google Scholar] [CrossRef]

- Freppon, D.; Men, L.; Burkhow, S.J.; Petrich, J.W.; Vela, J.; Smith, E.A. Photophysical properties of wavelength-tunable me-thylammonium lead halide perovskite nanocrystals. J. Mater. Chem. C 2017, 5, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.K.; Lee, H.S.; Pae, S.R.; Kim, S.R.; Lee, D.J.; Gereige, J.Y.; Park, I.; Shin, S. Effects of temperature and coating speed on the morphology of solution-sheared halide perovskite thin-film. J. Mater. Chem. A 2018, 48, 24911–24919. [Google Scholar] [CrossRef]

- Sara, B.N.; Luo, B.B.; Abdelmageed, G.; Pu, Y.C.; Zhang, C.; Jin, Z. Photophysical properties and improved stability of organ-ic-inorganic perovskite by surface passivation. J. Phys. Chem. C 2018, 122, 5799–15818. [Google Scholar]

- Li, J.; Huang, J.; Zhao, A.; Li, Y.; Wei, M. An inorganic stable Sn-based perovskite film with regulated nucleation for solar cell application. J. Mater. Chem. C 2020, 8, 8840–8845. [Google Scholar] [CrossRef]

- Meng, L.; You, J.; Guo, T.-F.; Yang, Y. Recent Advances in the Inverted Planar Structure of Perovskite Solar Cells. Acc. Chem. Res. 2016, 49, 155–165. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Armin, A.; Nagiri, R.C.R.; Burn, P.L.; Meredith, P. Electro-optics of perovskite solar cells. Nat. Photon. 2015, 9, 106–112. [Google Scholar] [CrossRef]

- You, J.; Yang, Y.; Hong, Z.; Song, T.-B.; Meng, L.; Liu, Y.; Jiang, C.; Zhou, H.; Chang, W.-H.; Li, G. Moisture assisted perovskite film growth for high performance solar cells. Appl. Phys. Lett. 2014, 105, 183902. [Google Scholar] [CrossRef] [Green Version]

- Heo, J.H.; Han, H.J.; Kim, D.; Ahn, T.K.; Im, S.H. Hysteresis-less inverted CH3NH3PbI3 planar perovskite hybrid solar cells with 18.1% power conversion efficiency. Energy Environ. Sci. 2015, 8, 1602–1608. [Google Scholar] [CrossRef]

- Jeng, J.-Y.; Chiang, Y.-F.; Lee, M.-H.; Peng, S.-R.; Guo, T.-F.; Chen, P.; Wen, T.-C. CH3NH3PbI3Perovskite/Fullerene Planar-Heterojunction Hybrid Solar Cells. Adv. Mater. 2013, 25, 3727–3732. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.Y.; Salim, T.; Mathews, N.; Duchamp, M.; Boothroyd, C.; Xing, G.; Sum, T.C.; Lam, Y.M. The origin of high efficiency in lowtemperature solution-processable bilayer organometal halide hybridsolar cells. Energy Environ. Sci. 2014, 7, 399–407. [Google Scholar] [CrossRef] [Green Version]

- Jørgensen, M.; Norrman, K.; Krebs, F.C. Stability/degradation of polymer solar cells. Sol. Energy Mater. Sol. Cells 2008, 92, 686–714. [Google Scholar] [CrossRef]

- Kawano, K.; Pacios, R.; Poplavskyy, D.; Nelson, J.; Bradley, D.D.; Durrant, J.R. Degradation of organic solar cells due to air exposure. Sol. Energy Mater. Sol. Cells 2006, 90, 3520–3530. [Google Scholar] [CrossRef]

- Pacios, R.; Chatten, A.; Kawano, K.; Durrant, J.R.; Nelson, J.; Bradleyc, D.D.C. Effects of Photo-oxidation on the Performance of Poly[2-methoxy-5-(3′,7′-dimethyloctyloxy)-1,4-phenylenevinylene]:[6,6]-Phenyl C61-Butyric Acid Methyl Ester Solar Cells. Adv. Funct. Mater. 2010, 16, 2117–2126. [Google Scholar] [CrossRef]

- Li, J.; Hu, P.; Chen, Y.; Li, Y.; Wei, M. Enhanced Performance of Sn-Based Perovskite Solar Cells by Two-Dimensional Perovskite Doping. Acs. Sustain. Chem. Eng. 2020, 8, 8624–8628. [Google Scholar] [CrossRef]

- White, M.S.; Olson, D.C.; Shaheen, S.E.; Kopidakis, N.; Ginley, D.S. Inverted bulk-heterojunction organic photovoltaic device using a solution-derived ZnO underlayer. Appl. Phys. Lett. 2006, 89, 143517. [Google Scholar] [CrossRef]

- Takahashi, K.; Suzaka, S.; Sigeyama, Y.; Yamaguchi, T.; Yamaguchi, T.; Nakamura, J. Efficiency Increase by Insertion of Electro-deposited CuSCN Layer into ITO/Organic Solid Interface in Bulk Hetero-junction Solar Cells Consisting of Polythiophene and Fullerene. Chem. Lett. 2007, 36, 762–763. [Google Scholar] [CrossRef]

- Irwin, M.D.; Buchholz, D.B.; Hains, A.W.; Chang, R.P.H.; Markset, T.J. p-Type semiconducting nickel oxide as an efficien-cy-enhancing anode interfacial layer in polymer bulk-heterojunction solar cells. Proc. Natl. Acad. Sci. USA 2008, 105, 2783–2787. [Google Scholar] [CrossRef] [Green Version]

- Zuo, C.; Ding, L. Solution-Processed Cu2O and CuO as Hole Transport Materials for Efficient Perovskite Solar Cells. Small 2015, 11, 5528–5532. [Google Scholar] [CrossRef]

- Wang, S.; Jiao, S.; Wang, J.; Chen, H.-S.; Tian, D.; Lei, H.; Fang, D.-N. High-performance aluminum-ion battery with CuS@ C mi-crosphere composite cathode. Acs. Nano 2017, 11, 469–477. [Google Scholar] [CrossRef] [PubMed]

- Sajid, S.; Elseman, A.M.; Huang, H.; Ji, J.; Dou, S.; Jiang, H.; Liu, X.; Wei, D.; Cui, P.; Li, M. Breakthroughs in NiOx-HTMs towards Stable, Low-Cost and Efficient Perovskite Solar Cells. Nano Energy 2018, 51, 408–424. [Google Scholar] [CrossRef]

- Chen, P.-C.; Yang, S.-H. Potassium-Doped Nickel Oxide as the Hole Transport Layer for Efficient and Stable Inverted Perovskite Solar Cells. Acs. Appl. Energy Mater. 2019, 2, 6705–6713. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, Y.; Wang, C.Y.; Ma, R.X. NH4F as an interfacial modifier for high performance NiOx-based inverted perovskite solar cells. Org. Electron. 2020, 78, 105627. [Google Scholar] [CrossRef]

- Lian, X.; Chen, J.; Shan, S.; Wu, G.; Chen, H. Polymer Modification on NiOx Hole Transport Layer Boosts Open-Circuit Voltage to 1.19 V for Perovskite Solar Cells. Acs. Appl. Mater. Interfaces 2020, 12, 46340–46347. [Google Scholar] [CrossRef]

- You, J.; Meng, L.; Song, T.-B.; Guo, T.-F.; Yang, Y.; Chang, W.-H.; Hong, Z.; Chen, H.; Zhou, H.; Chen, Q.; et al. Improved air stability of perovskite solar cells via solution-processed metal oxide transport layers. Nat. Nanotechnol. 2016, 11, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.-T.; Tsai, M.-C.; Guo, T.-F.; Fu, Y.-S. The impact at polar solvent treatment on p-contact layers (PEDOT:PSS or NiOx) of hybrid perovskite solar cells. Org. Electron. 2019, 73, 273–278. [Google Scholar] [CrossRef]

- Bi, C.; Wang, Q.; Shao, Y.; Yuan, Y.; Xiao, Z.; Huang, J. Non-wetting surface-driven high-aspect-ratio crystalline grain growth for efficient hybrid perovskite solar cells. Nat. Commun. 2015, 6, 7747. [Google Scholar] [CrossRef] [PubMed]

- De Jong, M.M.; Van Ijzendoorn, L.L.; De Voigt, M.M. Stability of the interface between indium-tin-oxide and poly(3,4-ethylenedioxythiophene)/poly(styrenesulfonate) in polymer light-emitting diodes. Appl. Phys. Lett. 2000, 77, 2255–2257. [Google Scholar] [CrossRef]

- Voroshazi, E.; Verreet, B.; Buri, A.; Müllera, R.; Nuzzod, D.D.; Heremans, P. Influence of cathode oxidation via the hole extrac-tion layer in polymer:fullerene solar cells. Org. Electron. 2011, 12, 736–744. [Google Scholar] [CrossRef]

- Sriram, S.; Thayumanavan, A. Structural, Optical and Electrical Properties of NiO Thin Films Prepared by Low Cost Spray Pyrolysis Technique. Int. J. Mater. Sci. Eng. 2014, 1, 118–121. [Google Scholar] [CrossRef]

- Sato, K.; Kim, S.; Komuro, S.; Zhao, X. Characteristics of Cu-doped amorphous NiO thin films formed by RF magnetron sputtering. Jpn. J. Appl. Phys. 2016, 55, 06GJ10. [Google Scholar] [CrossRef]

- Talukdara, H.; Sarkar, S.; Kundu, S. Electrical Investigation on Thin Films of Poly(3,4-Ethylenedioxythiophene): Poly (Sty-renesulfonate) in Presence of Cationic Polyelectrolyte. Aip. Conf. Proc. 2019, 2115, 030286. [Google Scholar]

- Ning, W.; Wang, F.; Wu, B.; Lu, J.; Yan, Z.; Liu, X.; Tao, Y.; Liu, J.; Huang, W.; Fahlman, M. Long Electron-Hole Diffusion Length in High-Quality Lead-Free Double Perovskite Films. Adv. Mater. 2018, 30, 1706246. [Google Scholar] [CrossRef]

| Basic Parameters | NiOx | PEDOT:PSS | Interface Layer | CH3NH3PbI3 | PCBM |

|---|---|---|---|---|---|

| Eg (eV) | 3.8 | 3 | 1.5 | 1.5 | 2 |

| Ӽe (eV) | 1.6 | 2.2 | 3.95 | 3.95 | 3.9 |

| εr | 11 | 7.5 | 30 | 30 | 3.9 |

| Thickness (nm) | 30 | 40 | 10 | 500/450 | 100 |

| μn (cm2V−1s−1) | 2.8 | 0 | 14 | 14 | 0.2 |

| μp (cm2V−1s−1) | 2.8 | 0.001 | 14 | 14 | 0 |

| NA(cm−3) | 1.5 × 1018 | 1 × 1018 | 6 × 1014 | 6 × 1014 | 0 |

| ND(cm−3) | 0 | 0 | 0 | 0 | 2.93 × 1017 |

| NC(cm−3) | 1 × 1018 | 1 × 1016 | 2.5 × 1020 | 2.5 × 1020 | 2.5 × 1021 |

| NV(cm−3) | 1 × 1018 | 1 × 1019 | 2.5 × 1020 | 2.5 × 1020 | 2.5 × 1021 |

| Value band offset (eV) | 0.05 | 0.25 | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zou, X.; Zhu, J.; Zhang, C.; Cheng, J.; Zhou, Z.; Ren, H.; Wang, Y.; Li, X.; Ren, B.; et al. Device Modeling and Design of Inverted Solar Cell Based on Comparative Experimental Analysis between Effect of Organic and Inorganic Hole Transport Layer on Morphology and Photo-Physical Property of Perovskite Thin Film. Materials 2021, 14, 2191. https://doi.org/10.3390/ma14092191

Wang X, Zou X, Zhu J, Zhang C, Cheng J, Zhou Z, Ren H, Wang Y, Li X, Ren B, et al. Device Modeling and Design of Inverted Solar Cell Based on Comparative Experimental Analysis between Effect of Organic and Inorganic Hole Transport Layer on Morphology and Photo-Physical Property of Perovskite Thin Film. Materials. 2021; 14(9):2191. https://doi.org/10.3390/ma14092191

Chicago/Turabian StyleWang, Xiaolan, Xiaoping Zou, Jialin Zhu, Chunqian Zhang, Jin Cheng, Zixiao Zhou, Haiyan Ren, Yifei Wang, Xiaotong Li, Baokai Ren, and et al. 2021. "Device Modeling and Design of Inverted Solar Cell Based on Comparative Experimental Analysis between Effect of Organic and Inorganic Hole Transport Layer on Morphology and Photo-Physical Property of Perovskite Thin Film" Materials 14, no. 9: 2191. https://doi.org/10.3390/ma14092191