Structural Characterization of Al0.37In0.63N/AlN/p-Si (111) Heterojunctions Grown by RF Sputtering for Solar Cell Applications

Abstract

:1. Introduction

2. Materials and Methods

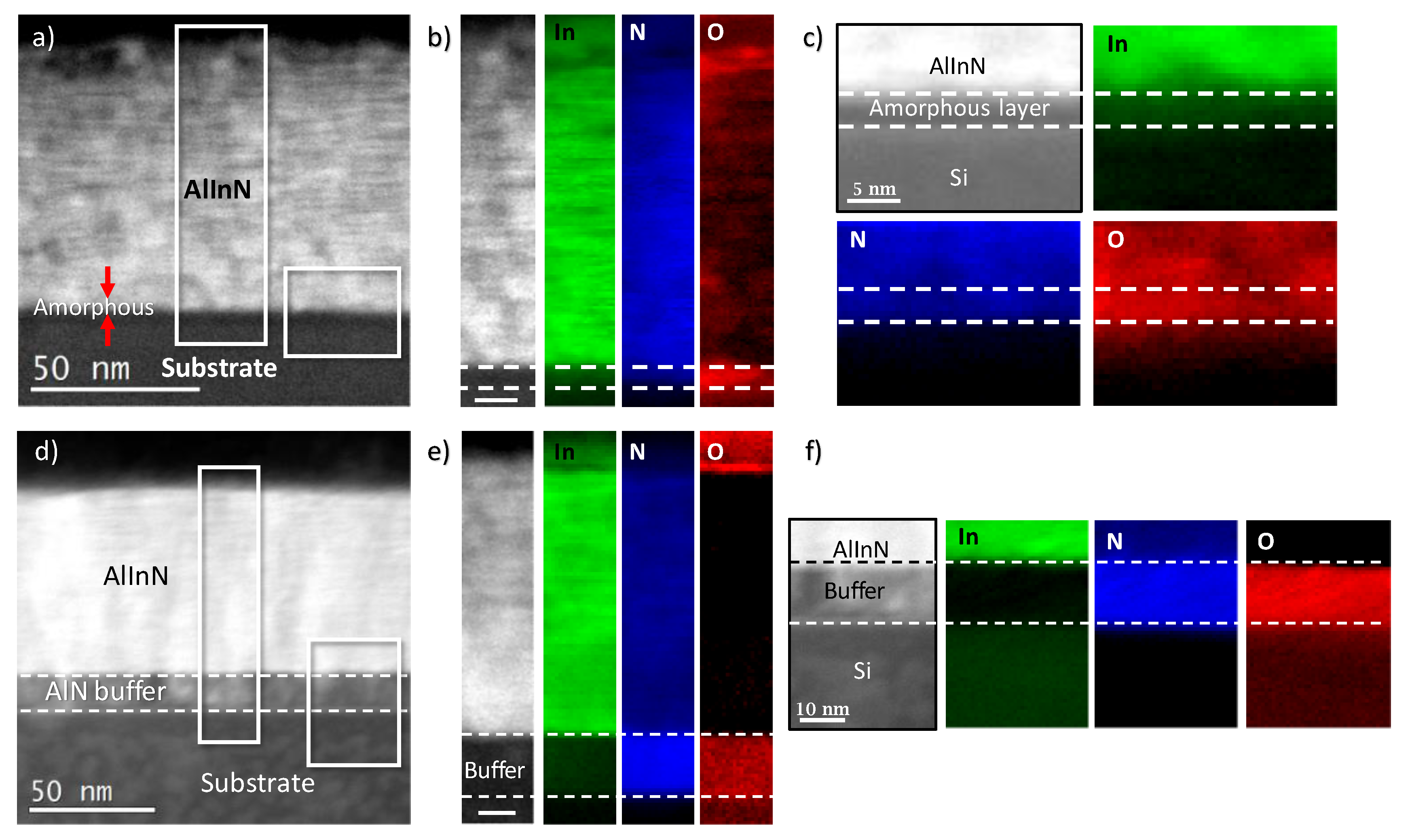

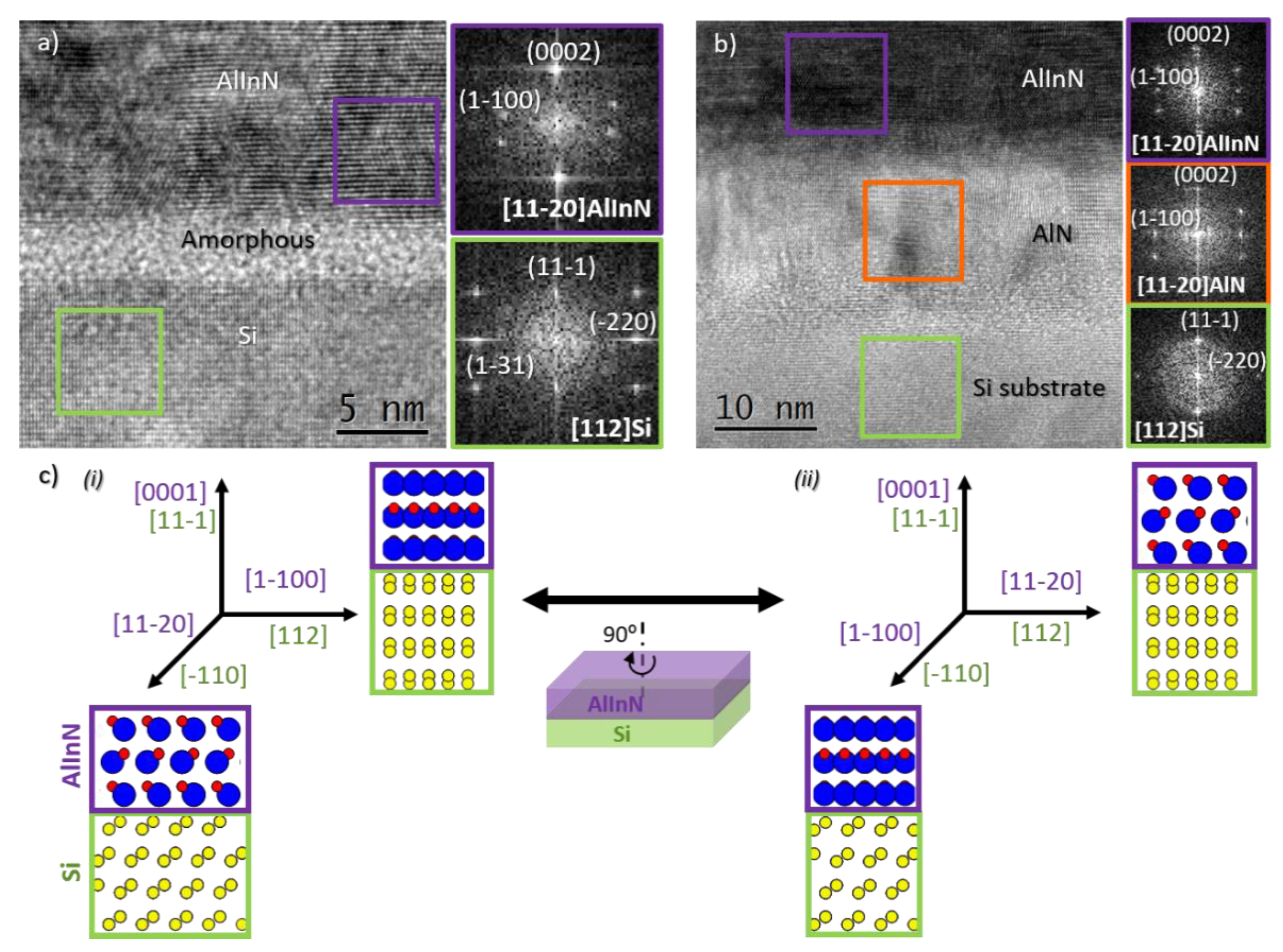

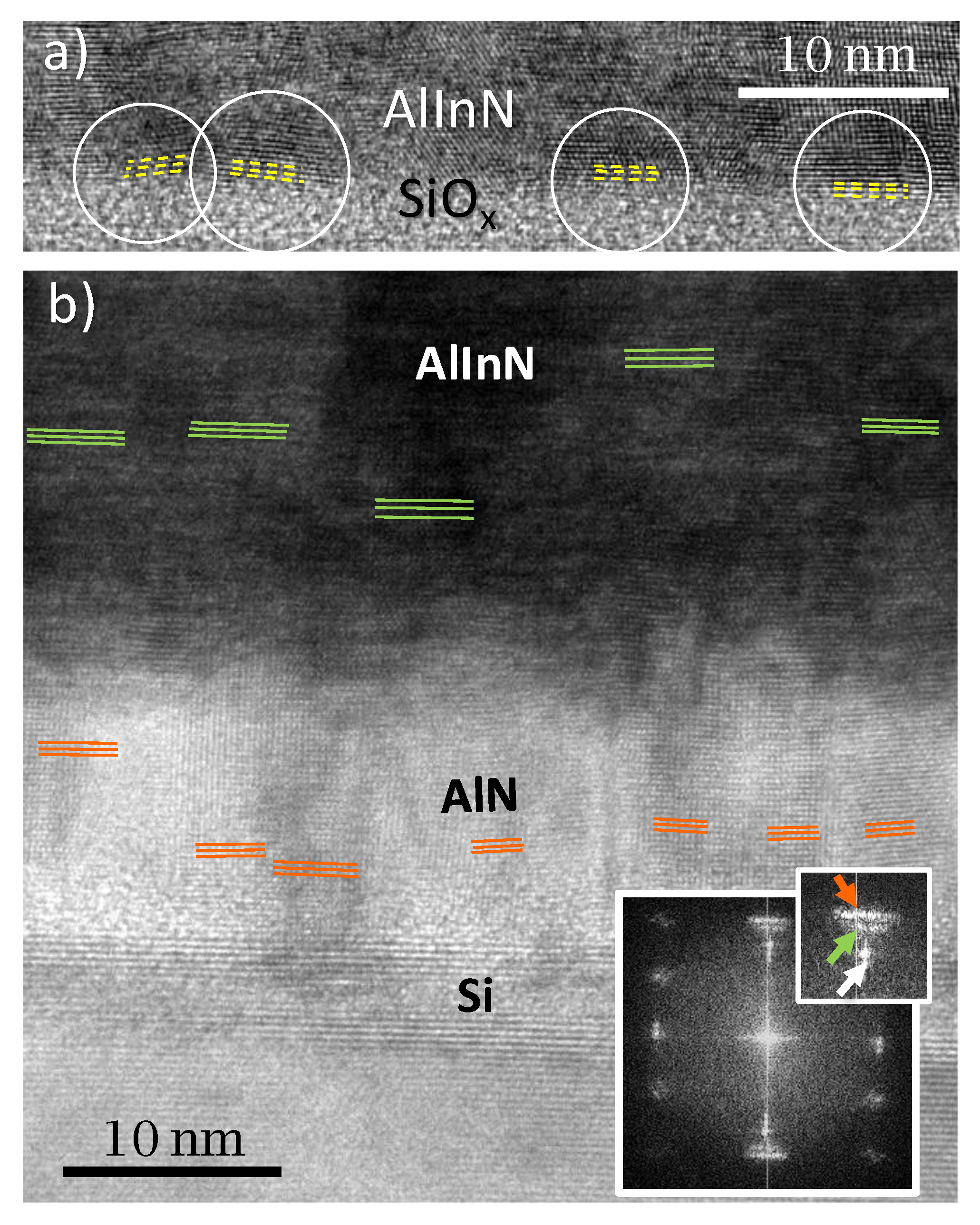

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alizadeh, M.; Ganesh, V.; Pandikumar, A.; Goh, B.T.; Azianty, S.; Huang, N.M.; Rahman, S.A. Photoelectrochemical behavior of AlxIn1−xN thin films grown by plasma-assisted dual source reactive evaporation. J. Alloys Compd. 2016, 670, 229–238. [Google Scholar] [CrossRef]

- Saidi, I.; Mejri, H.; Baira, M.; Maaref, H. Electronic and transport properties of AlInN/AlN/GaN high electron mobility transistors. Superlattices Microstruct. 2015, 84, 113–125. [Google Scholar] [CrossRef]

- Berger, C.; Dadgar, A.; Bläsing, J.; Krost, A. In-situ growth monitoring of AlInN/AlGaN distributed bragg reflectors for the UV-spectral range. J. Cryst. Growth 2013, 370, 87–91. [Google Scholar] [CrossRef]

- Yamamoto, A.; Islam, M.R.; Kang, T.T.; Hashimoto, A. Recent advances in InN-based solar cells: Status and challenges in InGaN and InAlN solar cells. Phys. Status Solidi C 2010, 7, 1309–1316. [Google Scholar] [CrossRef]

- Gonschorek, M.; Carlin, J.-F.; Feltin, E.; Py, M.; Grandjean, N. High electron mobility lattice-matched AlInN/GaN field-effect transistor heterostructures. Appl. Phys. Lett. 2006, 89, 062106. [Google Scholar] [CrossRef]

- Deibuk, V.G. Thermodynamic Stability and Redistribution of Charges in Ternary AlGaN, InGaN, and InAlN Alloys. Semiconductors 2005, 39, 623. [Google Scholar] [CrossRef]

- Ferhat, M.; Bechstedt, F. First-principles calculations of gap bowing in InxGa1-xN and InxAl1-xN alloys: Relation to structural and thermodynamic properties. Phys. Rev. B 2002, 65, 075213. [Google Scholar] [CrossRef]

- Kim-Chauveau, H.; de Mierry, P.; Chauveau, J.-M.; Duboz, J.-Y. The influence of various MOCVD parameters on the growth of Al1−xInxN ternary alloy on GaN templates. J. Cryst. Growth 2011, 316, 30–36. [Google Scholar] [CrossRef]

- Neumayer, D.A.; Ekerdt, J.G. Growth of Group III Nitrides. A Review of Precursors and Techniques. Chem. Mater. 1996, 8, 9–25. [Google Scholar] [CrossRef]

- Hums, C.; Bläsing, J.; Dadgar, A.; Diez, A.; Hempel, T.; Christen, J.; Krost, A.; Lorenz, K.; Alves, E. Metal-organic vapor phase epitaxy and properties of AlInN in the whole compositional range. Appl. Phys. Lett. 2007, 90, 022105. [Google Scholar] [CrossRef]

- Lobanova, A.V.; Yakovlev, E.V.; Talalaev, R.A.; Thapa, S.B.; Scholz, F. Growth conditions and surface morphology of AlN MOVPE. J. Cryst. Growth 2008, 310, 4935–4938. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. Threading dislocations in heteroepitaxial AlN layer grown by MOVPE on SiC (0001) substrate. J. Cryst. Growth 2007, 298, 310–315. [Google Scholar] [CrossRef]

- Kamimura, J.; Kouno, T.; Ishizawa, S.; Kikuchi, A.; Kishino, K. Growth of high-In-content InAlN nanocolumns on Si (111) by RF-plasma-assisted molecular-beam epitaxy. J. Cryst. Growth 2007, 300, 160–163. [Google Scholar] [CrossRef]

- Chen, W.; Wu, Y.; Tian, J.; Yen, T.; Lin, P.; Chen, J.; Hsiao, C.; Chang, L. Effect of Growth Temperature on Structural Quality of In-Rich InxAl1-xN Alloys on Si (111) Substrate by RF-MOMBE. Int. Sch. Res. Not. 2014, 2014, 980206. [Google Scholar] [CrossRef]

- Karmann, S.; Schenk, H.P.; Kaiser, U.; Fissel, A.; Richter, W. Growth of columnar aluminum nitride layers on Si(111) by molecular beam epitaxy. Mater. Sci. Eng. B 1997, 50, 228–232. [Google Scholar] [CrossRef]

- Koblmueller, G.; Averbeck, R.; Geelhaar, L.; Riechert, H.; Hösler, W.; Pongratz, P. Growth diagram and morphologies of AlN thin films grown by molecular beam epitaxy. J. Appl. Phys. 2003, 93, 9591–9596. [Google Scholar] [CrossRef]

- Liu, H.F.; Dolmanan, S.B.; Tripathy, S.; Dalapati, G.K.; Tan, C.C.; Chi, D.Z. Effects of AlN thickness on structural and transport properties of In-rich n-AlInN/AlN/p-Si(0 0 1) heterojunctions grown by magnetron sputtering. J. Phys. D Appl. Phys. 2013, 46, 095106. [Google Scholar] [CrossRef]

- Afzal, N.; Devarajan, M.; Ibrahim, K. Influence of substrate temperature on the growth and properties of reactively sputtered In-rich InAlN films. J. Mater. Sci. Mater. Electron. 2016, 27, 4281–4289. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Monteagudo-Lerma, L.; Valdueza-Felip, S.; Navío, C.; Monroy, E.; González-Herráez, M.; Naranjo, F.B. Study of high In-content AlInN deposition on p-Si(111) by RF-sputtering. Jpn. J. Appl. Phys. 2016. [Google Scholar] [CrossRef]

- Zhang, J.X.; Cheng, H.; Chen, Y.Z.; Uddin, A.; Yuan, S.; Geng, S.J.; Zhang, S. Growth of AlN films on Si (100) and Si (111) substrates by reactive magnetron sputtering. Surf. Coat. Technol. 2005, 198, 68–73. [Google Scholar] [CrossRef]

- Liu, H.F.; Tan, C.C.; Dalapati, G.K.; Chi, D.Z. Magnetron-sputter deposition of high-indium-content n-AlInN thin film on p-Si(001) substrate for photovoltaic applications. J. Appl. Phys. 2012, 112, 063114. [Google Scholar] [CrossRef]

- Núñez-Cascajero, A.; Valdueza-Felip, S.; Blasco, R.; de la Mata, M.; Molina, S.I.; González-Herráez, M.; Monroy, E.; Naranjo, F.B. Quality improvement of AlInN/p-Si heterojunctions with an AlN buffer layer deposited by RF-sputtering. J. Alloys Compd. 2018, 769, 824–830. [Google Scholar] [CrossRef]

- Yeh, T.-S.; Wu, J.-M.; Lan, W.-H. The effect of AlN buffer layer on properties of AlxIn1−xN films on glass substrates. Thin Solid Films 2009, 517, 3204–3207. [Google Scholar] [CrossRef]

- Blasco, R.; Naranjo, F.B.; Valdueza-Felip, S. Design of AlInN on silicon heterojunctions grown by sputtering for solar devices. Curr. Appl. Phys. 2020, 20, 1244–1252. [Google Scholar] [CrossRef]

- Stemmer, J.; Fedler, F.; Klausing, H.; Mistele, D.; Rotter, T.; Semchinova, O.; Aderhold, J.; Sanchez, A.M.; Pacheco, F.J.; Molina, S.I.; et al. High temperature AlN intermediate layer in GaN grown by molecular beam epitaxy. J. Cryst. Growth 2000, 216, 15–20. [Google Scholar] [CrossRef]

- Sanchez, A.M.; Pacheco, F.J.; Molina, S.I.; Stemmer, J.; Aderhold, J.; Graul, J. Structural characterization of high temperature AlN intermediate layer in GaN grown by molecular beam epitaxy. Mater. Sci. Eng. B 2001, 80, 299–303. [Google Scholar] [CrossRef]

- Wang, W.; Yang, W.; Liu, Z.; Wang, H.; Wen, L.; Li, G. Interfacial reaction control and its mechanism of AlN epitaxial films grown on Si(111) substrates by pulsed laser deposition. Sci. Rep. 2015, 5, 11480. [Google Scholar] [CrossRef] [Green Version]

- Dadgar, A.; Schulze, F.; Wienecke, M.; Gadanecz, A.; Bläsing, J.; Veit, P.; Hempel, T.; Diez, A.; Christen, J.; Krost, A. Epitaxy of GaN on silicon—Impact of symmetry and surface reconstruction. New J. Phys. 2007, 9. [Google Scholar] [CrossRef]

- Serban, E.A.; Persson, P.O.Å.; Poenaru, I.; Junaid, M.; Hultman, L.; Birch, J.; Hsiao, C.-L. Structural and compositional evolutions of Inx Al1−xN core–shell nanorods grown on Si(111) substrates by reactive magnetron sputter epitaxy. Nanotechnology 2015, 26, 215602. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Núñez-Cascajero, A.; Naranjo, F.B.; de la Mata, M.; Molina, S.I. Structural Characterization of Al0.37In0.63N/AlN/p-Si (111) Heterojunctions Grown by RF Sputtering for Solar Cell Applications. Materials 2021, 14, 2236. https://doi.org/10.3390/ma14092236

Núñez-Cascajero A, Naranjo FB, de la Mata M, Molina SI. Structural Characterization of Al0.37In0.63N/AlN/p-Si (111) Heterojunctions Grown by RF Sputtering for Solar Cell Applications. Materials. 2021; 14(9):2236. https://doi.org/10.3390/ma14092236

Chicago/Turabian StyleNúñez-Cascajero, Arántzazu, Fernando B. Naranjo, María de la Mata, and Sergio I. Molina. 2021. "Structural Characterization of Al0.37In0.63N/AlN/p-Si (111) Heterojunctions Grown by RF Sputtering for Solar Cell Applications" Materials 14, no. 9: 2236. https://doi.org/10.3390/ma14092236

APA StyleNúñez-Cascajero, A., Naranjo, F. B., de la Mata, M., & Molina, S. I. (2021). Structural Characterization of Al0.37In0.63N/AlN/p-Si (111) Heterojunctions Grown by RF Sputtering for Solar Cell Applications. Materials, 14(9), 2236. https://doi.org/10.3390/ma14092236