Simple Method for Apples’ Bruise Area Prediction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics and Preparation of Research Material

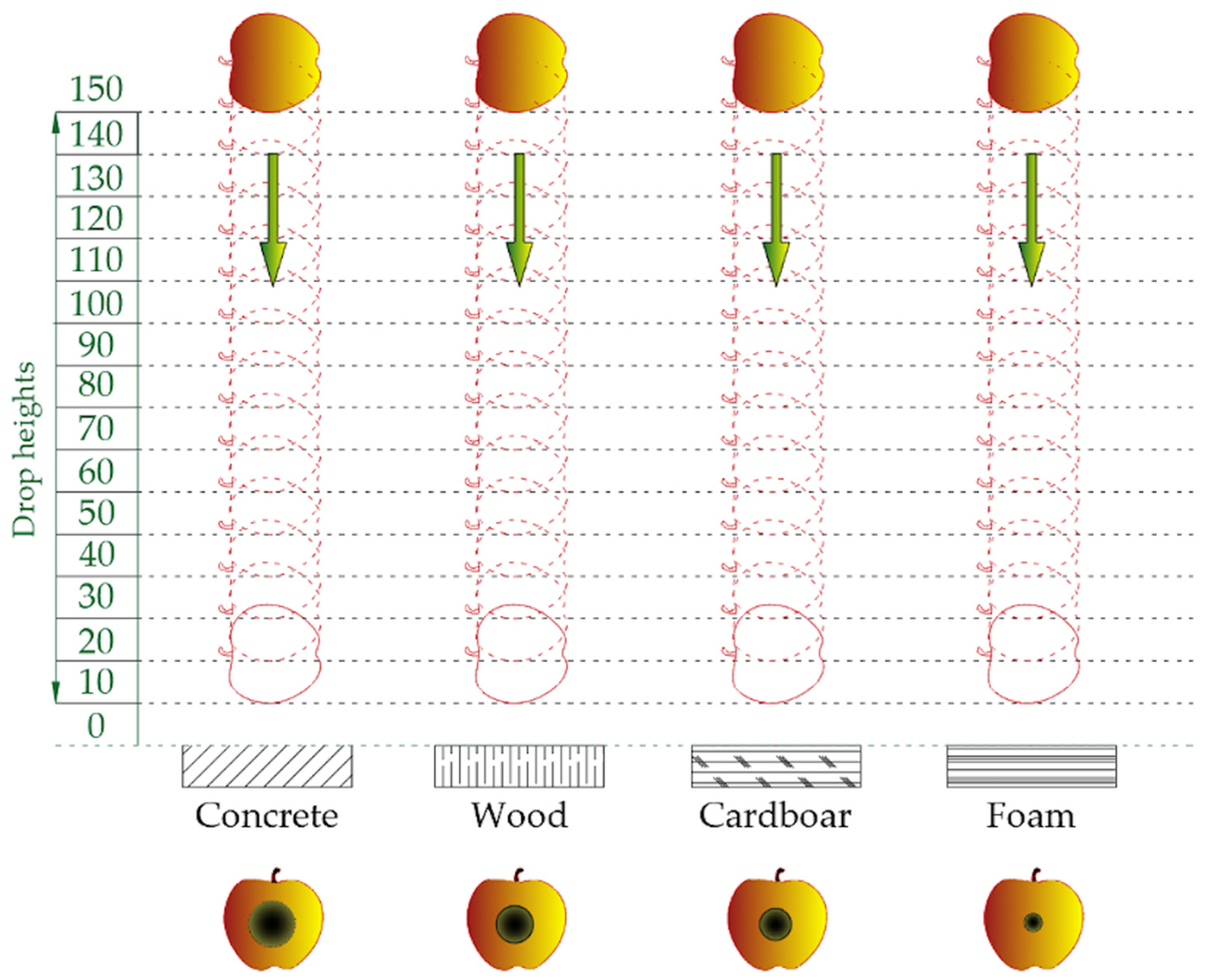

2.2. Free Fall Test

2.3. Determining the Surface of the Upholstery on the Basis of Image Analysis

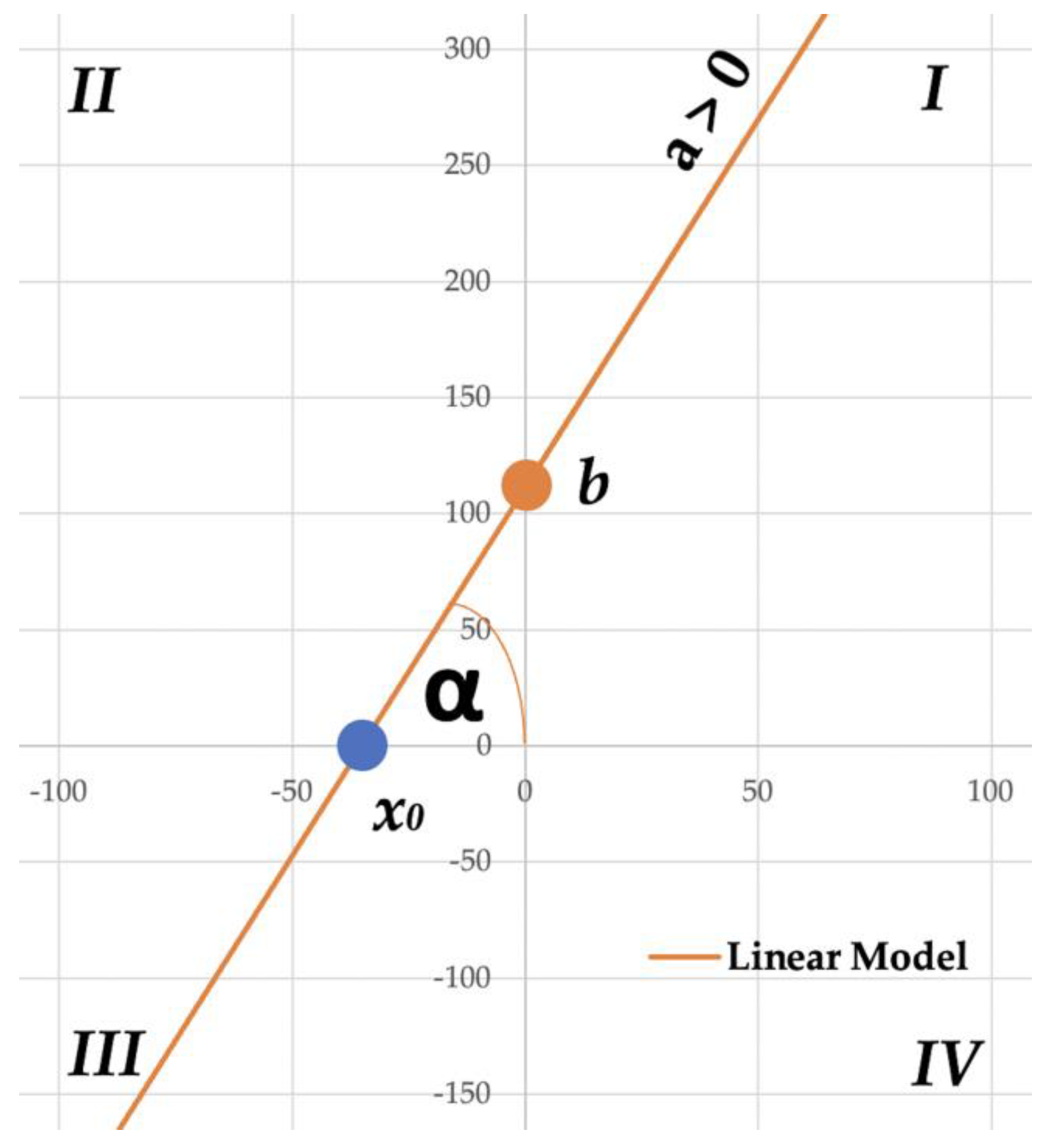

2.4. Linear Model

- B—bruise area, mm2

- H—drop height, mm

- a—slope,

- b—intercept.

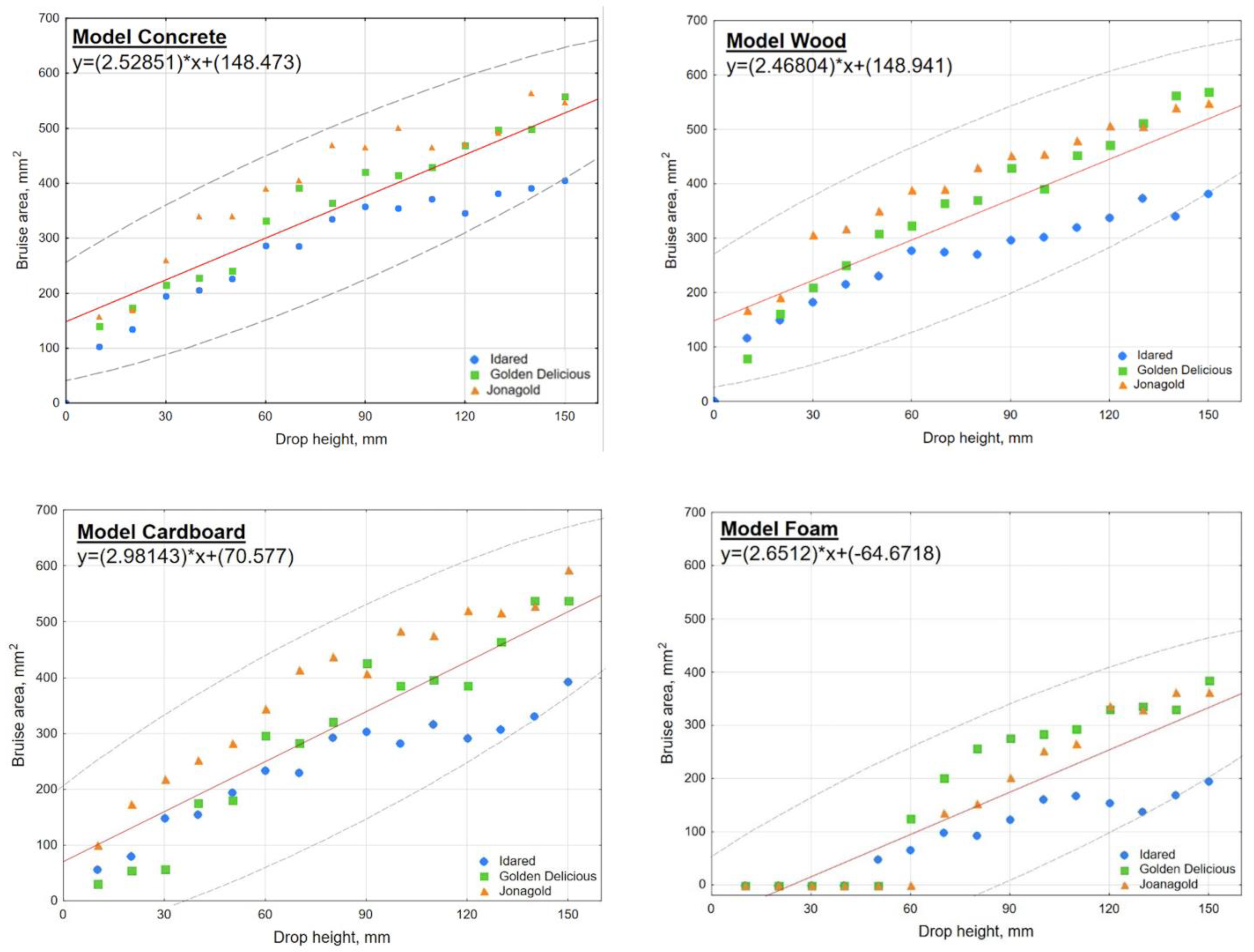

3. Results

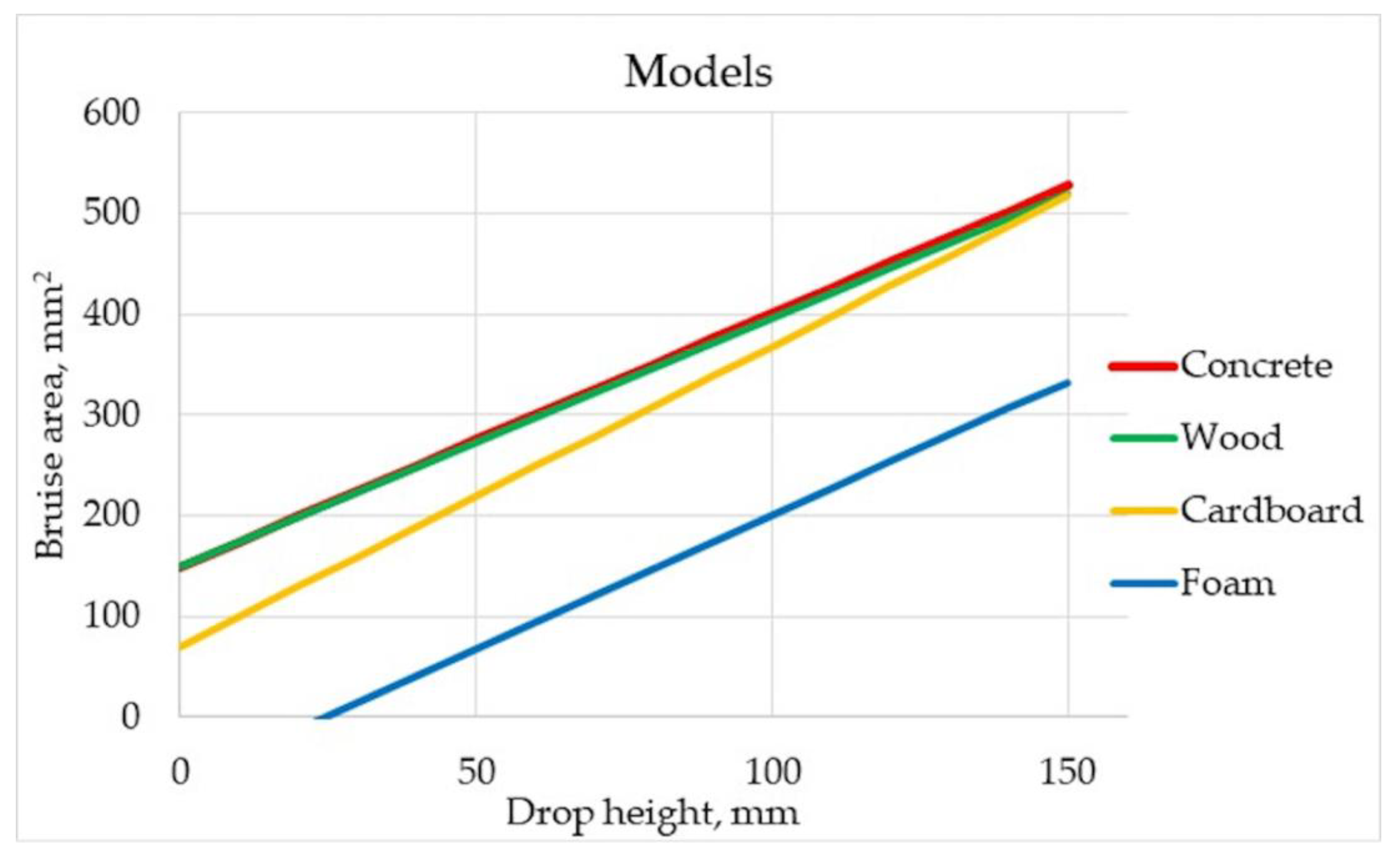

4. Discussion

5. Conclusions

- A fresh, sweeter, and acid-poor variety will be close to the endurance characteristics of a strongly mature but acidic and sugar-poor variety.

- Separate models (including a single variety dropped on each of the given substrate) can be used to quickly estimate bruise volume with an accuracy of about 93% while dropping fruit from the particular height. However, combined models can be used with an accuracy of about 75%.

- Above a certain stiffness of the substrate, there is little difference between bruise areas, as the fruit absorbs most of the kinetic energy.

- Compared to the rest of the substrates, cardboard gave the most average results relative to the others. For low drop heights, it behaved more like foam, and for high drop heights, more like wood.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zarifneshat, S.; Rohani, A.; Ghassemzadeh, H.R.; Sadeghi, M.; Ahmadi, E.; Zarifneshat, M. Predictions of apple bruise volume using artificial neural network. Comput. Electron. Agric. 2012, 82, 75–86. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Razavi, M.S.; Golmohammadi, A.; Sedghi, R.; Asghari, A. Prediction of bruise volume propagation of pear during the storage using soft computing methods. Food Sci. Nutr. 2020, 8, 884–893. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Timmermans, A.J.M.; Ambuko, J.; Belik, W.; Huang, J. Food Losses and Waste in the Context of Sustainable Food Systems; HLPE: Rome, Italy, 2014; pp. 1–117. [Google Scholar]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Harvest and Postharvest Factors Affecting Bruise Damage of Fresh Fruits. Hortic. Plant J. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Li, Z.; Thomas, C. Quantitative evaluation of mechanical damage to fresh fruits. Trends Food Sci. Technol. 2014, 35, 138–150. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. A new method for measuring impact related bruises in fruits. Postharvest Biol. Technol. 2015, 110, 131–139. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Giefer, L.A.; Castellanos, J.D.A.; Babr, M.M.; Freitag, M. Deep learning-based pose estimation of apples for inspection in logistic centers using single-perspective imaging. Processes 2019, 7, 424. [Google Scholar] [CrossRef] [Green Version]

- Cofelice, M.; Lopez, F.; Cuomo, F. Quality control of fresh-cut apples after coating application. Foods 2019, 8, 189. [Google Scholar] [CrossRef] [Green Version]

- Pathare, P.B.; Opara, U.L.; Vigneault, C.; Delele, M.A.; Al-Said, F.A.J. Design of Packaging Vents for Cooling Fresh Horticultural Produce. Food Bioprocess Technol. 2012, 5, 2031–2045. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Pathare, P.; Opara, U.L. Susceptibility to impact damage of apples inside ventilated corrugated paperboard packages: Effects of package design. Postharvest Biol. Technol. 2016, 111, 286–296. [Google Scholar] [CrossRef]

- Mohammad Shafie, M.; Rajabipour, A.; Castro-García, S.; Jiménez-Jiménez, F.; Mobli, H. Effect of Fruit Properties on Pomegranate Bruising. Int. J. Food Prop. 2015, 18, 1837–1846. [Google Scholar] [CrossRef] [Green Version]

- Du, Z.; Zeng, X.; Li, X.; Ding, X.; Cao, J.; Jiang, W. Recent advances in imaging techniques for bruise detection in fruits and vegetables. Trends Food Sci. Technol. 2020, 99, 133–141. [Google Scholar] [CrossRef]

- Cavallo, D.P.; Cefola, M.; Pace, B.; Logrieco, A.F.; Attolico, G. Non-destructive and contactless quality evaluation of table grapes by a computer vision system. Comput. Electron. Agric. 2019, 156, 558–564. [Google Scholar] [CrossRef]

- Patel, K.K.; Khan, M.A.; Kar, A. Recent developments in applications of MRI techniques for foods and agricultural produce—An overview. J. Food Sci. Technol. 2015, 52, 1–26. [Google Scholar] [CrossRef]

- Razavi, M.S.; Asghari, A.; Azadbakh, M.; Shamsabadi, H.A. Analyzing the pear bruised volume after static loading by Magnetic Resonance Imaging (MRI). Sci. Hortic. 2018, 229, 33–39. [Google Scholar] [CrossRef]

- Sanchez, P.D.C.; Hashim, N.; Shamsudin, R.; Mohd Nor, M.Z. Applications of imaging and spectroscopy techniques for non-destructive quality evaluation of potatoes and sweet potatoes: A review. Trends Food Sci. Technol. 2020, 96, 208–221. [Google Scholar] [CrossRef]

- He, Y.; Xiao, Q.; Bai, X.; Zhou, L.; Liu, F.; Zhang, C. Recent progress of nondestructive techniques for fruits damage inspection: A review. Crit. Rev. Food Sci. Nutr. 2021, 13, 1–19. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. Bruise susceptibility and energy dissipation analysis in pears under impact loading conditions. Postharvest Biol. Technol. 2020, 163, 111120. [Google Scholar] [CrossRef]

- Stopa, R.; Komarnicki, P.; Szyjewicz, D.; Kuta, Ł. Modeling of carrot root radial press process for different shapes of loading elements using the finite element method. Int. J. Food Prop. 2017, 20, S340–S352. [Google Scholar] [CrossRef]

- Komarnicki, P.; Stopa, R.; Szyjewicz, D.; Młotek, M. Evaluation of bruise resistance of pears to impact load. Postharvest Biol. Technol. 2016, 114, 36–44. [Google Scholar] [CrossRef]

- Bollen, A.F.; Nguyen, H.X.; Dela Rue, B.T. Comparison of methods for estimating the bruise volume of apples. J. Agric. Eng. Res. 1999, 74, 325–330. [Google Scholar] [CrossRef]

- Stopa, R.; Szyjewicz, D.; Komarnicki, P.; Kuta, Ł. Determining the resistance to mechanical damage of apples under impact loads. Postharvest Biol. Technol. 2018, 146, 79–89. [Google Scholar] [CrossRef]

- Celik, H.K.; Rennie, A.E.W.; Akinci, I. Deformation behaviour simulation of an apple under drop case by finite element method. J. Food Eng. 2011, 104, 293–298. [Google Scholar] [CrossRef]

- Komarnicki, P.; Stopa, R.; Szyjewicz, D.; Kuta, Ł.; Klimza, T. Influence of Contact Surface Type on the Mechanical Damages of Apples Under Impact Loads. Food Bioprocess Technol. 2017, 10, 1479–1494. [Google Scholar] [CrossRef] [Green Version]

- Komarnicki, P.; Stopa, R.; Kuta, Ł.; Szyjewicz, D. Determination of apple bruise resistance based on the surface pressure and contact area measurements under impact loads. Comput. Electron. Agric. 2017, 142, 155–164. [Google Scholar] [CrossRef]

- Pang, D.W.; Studman, C.J.; Banks, N.H.; Baas, P.H. Rapid assessment of the susceptibility of apples to bruising. J. Agric. Eng. Res. 1996, 64, 37–47. [Google Scholar] [CrossRef]

- Jaros, D.; Thamke, I.; Raddatz, H.; Rohm, H. Single-cultivar cloudy juice made from table apples: An attempt to identify the driving force for sensory preference. Eur. Food Res. Technol. 2009, 229, 51–61. [Google Scholar] [CrossRef]

- Babu, D.R.; Rao, K.N.; Kumar, M.S.; Kumar, B.S. Handling of Apples during Sorting-Grading Operation and Measuring the Mechanical Properties Firmness after Controlled Atmosphere Storage. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 617–634. [Google Scholar] [CrossRef]

- Gołacki, K.; Kołodziej, P. Impact Testing of Biological Material on the Example of Apple Tissue. Teka Kom. Motoryz. I Energetyki Rol. 2011, 11, 74–82. [Google Scholar]

- Schulte, N.L.; Brown, G.K.; Timm, E.T. Apple impact damage thresholds. Appl. Eng. Agric. 1992, 8, 55–60. [Google Scholar] [CrossRef]

- Lu, L.-X.; Wang, Z.-W. Dropping bruise fragility and bruise boundary of apple fruit. Trans. ASABE 2007, 50, 1323–1329. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. Relation between mass and drop height at impact causing the bruising of apple. Polish J. Food Nutr. Sci. 2007, 57, 165–167. [Google Scholar]

| Cultivar | Weight | Mean Diameter | Firmness | Water Content | Sugar Content |

|---|---|---|---|---|---|

| – | kg | mm | N | % | % |

| Jonagold | 0.171 ± 0.005 | 69.1 ± 2.3 | 63 ± 1.8 | 84.8 ± 0.5 | 14.3 ± 1.1 |

| Golden Delicious | 0.200 ± 0.004 | 74.3 ± 1.9 | 67.4 ± 4.6 | 87.8 ± 0.8 | 12.4 ± 0.8 |

| Idared | 0.210 ± 0.006 | 77.6 ± 2.5 | 75.4 ± 4.8 | 87.9 ± 1.1 | 11.8 ± 1.0 |

| Idared Model | Golden Delicious Model | Jonagold Model | Combined Model | ||

|---|---|---|---|---|---|

| Concrete | a | 2.07 | 2.86 | 2.66 | 2.53 |

| b | 126.22 | 129.59 | 189.61 | 148.47 | |

| R2 | 0.91 | 0.96 | 0.88 | 0.78 | |

| 64 | 71 | 69 | 68 | ||

| X0 | −60.98 | −45.15 | −71.28 | −58,68 | |

| Wood | a | 1.71 | 3.17 | 2.53 | 2.47 |

| b | 135.58 | 111.46 | 199.79 | 148.94 | |

| R2 | 0.94 | 0.93 | 0.93 | 0.72 | |

| 60 | 72 | 68 | 68 | ||

| X0 | −79.29 | −35.16 | −78.97 | −60.30 | |

| Cardboard | a | 2.05 | 3.68 | 3.21 | 2.98 |

| b | 77.08 | 8.71 | 125.95 | 70.58 | |

| R2 | 0.90 | 0.94 | 0.95 | 0.75 | |

| 64 | 75 | 73 | 71 | ||

| X0 | −37.60 | −2.37 | −39.24 | −23.68 | |

| Foam | a | 1.52 | 3.20 | 3.24 | 2.65 |

| b | −27.45 | −67.49 | −99.08 | −64.67 | |

| R2 | 0.92 | 0.91 | 0.93 | 0.77 | |

| 57 | 73 | 73 | 69 | ||

| X0 | 18.06 | 21.09 | 30.58 | 24.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Słupska, M.; Syguła, E.; Komarnicki, P.; Szulczewski, W.; Stopa, R. Simple Method for Apples’ Bruise Area Prediction. Materials 2022, 15, 139. https://doi.org/10.3390/ma15010139

Słupska M, Syguła E, Komarnicki P, Szulczewski W, Stopa R. Simple Method for Apples’ Bruise Area Prediction. Materials. 2022; 15(1):139. https://doi.org/10.3390/ma15010139

Chicago/Turabian StyleSłupska, Monika, Ewa Syguła, Piotr Komarnicki, Wiesław Szulczewski, and Roman Stopa. 2022. "Simple Method for Apples’ Bruise Area Prediction" Materials 15, no. 1: 139. https://doi.org/10.3390/ma15010139

APA StyleSłupska, M., Syguła, E., Komarnicki, P., Szulczewski, W., & Stopa, R. (2022). Simple Method for Apples’ Bruise Area Prediction. Materials, 15(1), 139. https://doi.org/10.3390/ma15010139