Viscoelastic Polyurethane Foams with Reduced Flammability and Cytotoxicity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Viscoelastic Polyurethane Foams

2.2. Apparent Density

2.3. Microstructure and Porosity

2.4. Surface Wettability

2.5. Fourier Transform Infrared Spectroscopy

2.6. Differential Scanning Calorimetry

2.7. Thermogravimetric Analysis

2.8. Compression Set and Rebound Resilience

2.9. Burning Behaviour

2.10. Cell Culture and Cytotoxicity Testing

3. Results and Discussion

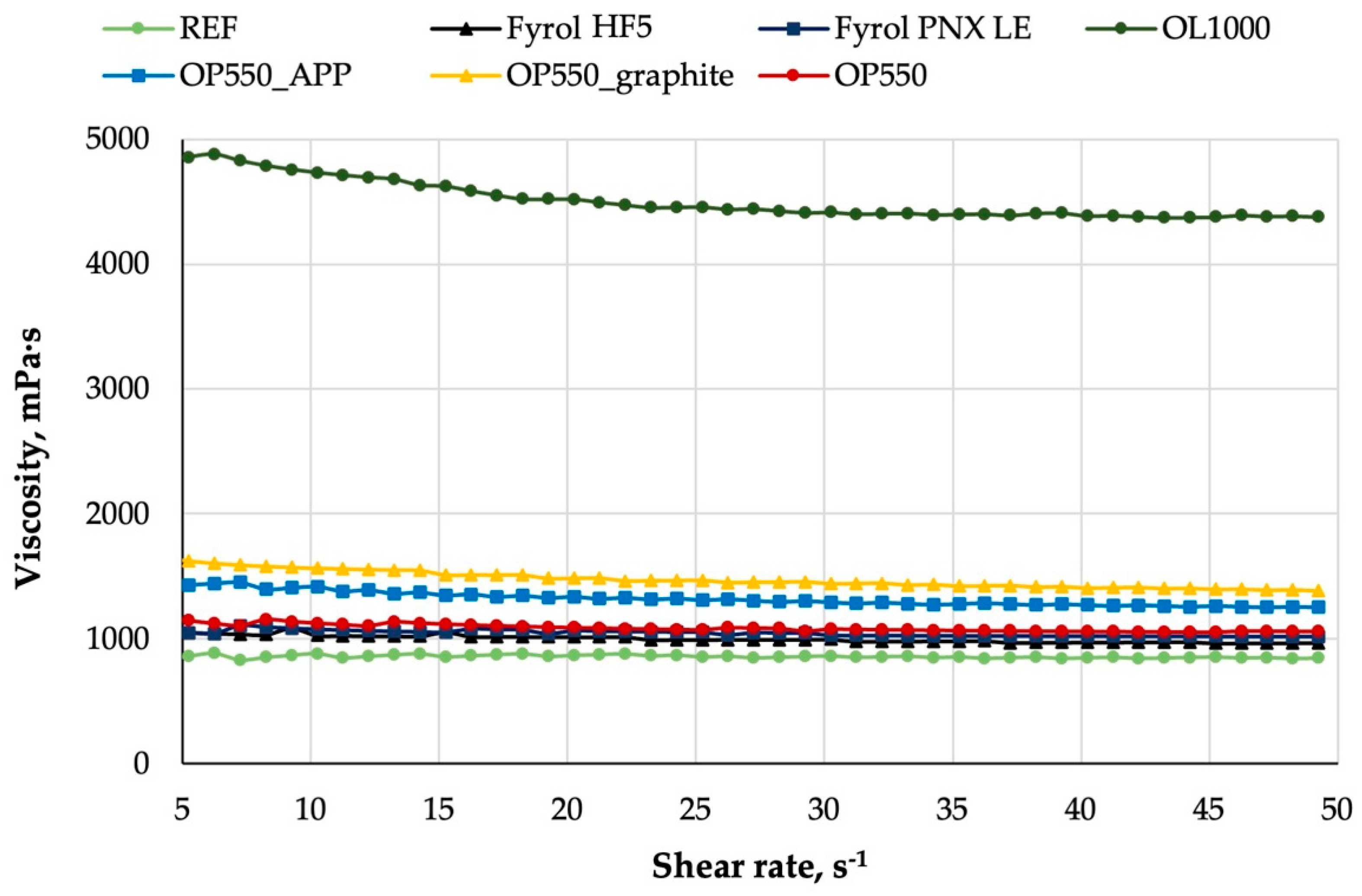

3.1. Viscosity

3.2. Apparent Density

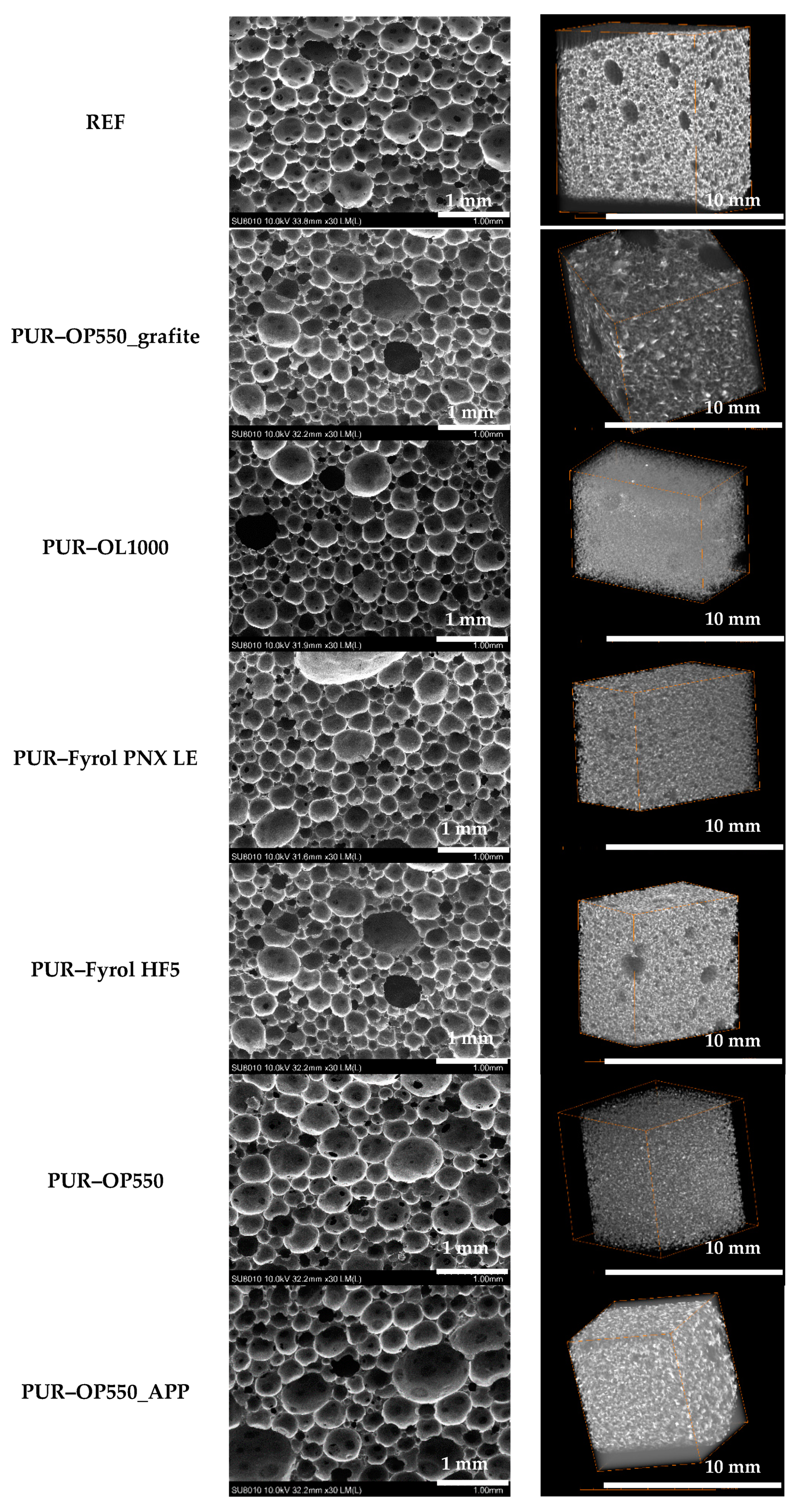

3.3. Microstructure and Porosity

3.4. Surface Wettability

3.5. Fourier Transform Infrared Spectroscopy

3.6. Differential Scanning Calorimetry

3.7. Thermogravimetric Analysis

3.8. Compression Set and Rebound Resilience

3.9. Burning Behaviour

3.10. Cytotoxicity of Polyurethane Foam Extracts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Foereland, S.; Robertsen, O.; Hegseth, M.N. Do various respirator models fit the workers in the Norwegian smelting industry? Saf. Health Work 2019, 10, 370–376. [Google Scholar] [CrossRef]

- Regli, A.; Sommerfield, A.; Ungern-Sternberg, B.S. The role of fit testing N95/FFP2/FFP3 masks: A narrative review. Anaesthesia 2021, 76, 91–100. [Google Scholar] [CrossRef]

- Pan, X.; Li, X.; Kong, P.; Wang, L.; Deng, R.; Wen, B.; Xiao, L.; Song, H.; Sun, Y.; Zhou, H.; et al. Assessment of use and fit of face masks among individuals in public during the COVID-19 pandemic in China. JAMA Netw. Open 2021, 4, e212574. [Google Scholar] [CrossRef]

- Xu, M.; Lee, P.; Collins, D. The critical importance of mask seals on respirator performance: An analytical and simulation approach. PLoS ONE 2021, 16, e0246720. [Google Scholar] [CrossRef]

- Makowski, K.; Okrasa, M. Application of 3D scanning and 3D printing for designing and fabricating customized half-mask facepieces: A pilot study. Work 2019, 63, 125–135. [Google Scholar] [CrossRef]

- Okrasa, M.; Leszczyńska, M.; Sałasińska, K.; Szczepkowski, L.; Kozikowski, P.; Majchrzycka, K.; Ryszkowska, J. Viscoelastic polyurethane foams for use in seals of respiratory protective devices. Materials 2021, 14, 1600. [Google Scholar] [CrossRef]

- Sonnenschein, M.F. Polyurethanes: Science, Technology, Markets, and Trends; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; ISBN 9781118901274. [Google Scholar]

- Prociak, A.; Rokicki, G.; Ryszkowska, J. Polyurethane Materials; PWN: Warsaw, Poland, 2014; ISBN 9788301187842. (In Polish) [Google Scholar]

- European Union. Regulation (EU) 2016/425 of the European Parliament and of the Council of 9 March 2016 on personal protective equipment and repealing Council Directive 89/686/EEC. Off. J. Eur. Union 2016, 81, 51–98. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32016R0425&from=EN (accessed on 24 October 2021).

- Graveling, R. The Ergonomics of Respiratory Protection. In Handbook of Respiratory Protection; Racz, L., Yamamoto, D.P., Eninger, R.M., Eds.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Akbar-Khanzadeh, F.; Bisesi, M.S.; Rivas, R.D. Comfort of personal protective equipment. Appl. Ergon. 1995, 26, 195–198. [Google Scholar] [CrossRef]

- Yumiao, C.; Jianping, W.; Zhongliang, Y. The human factors/ergonomics studies for respirators: A review and future work. Int. J. Cloth. Sci. Technol. 2015, 27, 652–676. [Google Scholar] [CrossRef]

- EN 13274-4:2001; Respiratory Protective Devices. Methods of Test. Flame Tests. European Committee for Standardization: Bruxelles, Belgium, 2001.

- European Communities. 89/656/EEC Council Directive of 30 November 1989 on the minimum health and safety requirements for the use by workers of personal protective equipment at the workplace. Off. J. Eur. Communities 1989, 393, 18. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31989L0656&from=EN (accessed on 24 October 2021).

- Landers, R.; Hubel, R.; Borgogelli, R. The Importance of Cell Structure for Viscoelastic Foams. Available online: https://www.pu-additives.com/product/pu-additives/downloads/importance-of-cell-structure-for-viscoelastic-foams.pdf (accessed on 10 December 2021).

- Szycher, M. Szycher’s Handbook of Polyurethanes, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9780429108907. [Google Scholar]

- Singh, H.; Jain, A.K. Ignition, combustion, toxicity, and fire retardancy of polyurethane foams: A comprehensive review. J. Appl. Polym. Sci. 2009, 111, 1115–1143. [Google Scholar] [CrossRef]

- Iwko, J. Behavior of plastics in fire conditions—Part I. Tworzywa Sztuczne Chem. 2009, 3, 38–42. (In Polish) [Google Scholar]

- Kicko-Walczak, E.W.A. Novel halogen-free flame retardants—Flame retardation of unsaturated polyester resins with use of boron compound. Polimery 2008, 53, 126–132. [Google Scholar] [CrossRef] [Green Version]

- Maddalena, L.; Gomez, J.; Fina, A.; Carosio, F. Effects of Graphite Oxide Nanoparticle Size on the Functional Properties of Layer-by-Layer Coated Flexible Foams. Nanomaterials 2021, 11, 266. [Google Scholar] [CrossRef]

- Sun, H.; Schiraldi, D.A.; Chen, D.; Wang, D.; Sánchez-Soto, M. Tough Polymer Aerogels Incorporating a Conformal Inorganic Coating for Low Flammability and Durable Hydrophobicity. ACS Appl. Mater. Interfaces 2016, 8, 13051–13057. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Hu, J.; Shang, Y.; Zhong, Y.; Zhang, X.; Yu, Z. The cytotoxicity of organophosphate flame retardants on HepG2, A549 and Caco-2 cells. J. Environ. Sci. Health Part A 2016, 51, 980–988. [Google Scholar] [CrossRef] [PubMed]

- ISO 845:2006; Cellular Plastics and Rubbers—Determination of Apparent Density. International Organization for Standardization: Geneva, Switzerland, 2006.

- Żenkiewicz, M. Adhesion and Modification of the Surface Layer of Macromolecular Materials; WNT: Warsaw, Poland, 2000; ISBN 83-204-2547-6. (In Polish) [Google Scholar]

- ISO 1856:2018; Flexible Cellular Polymeric Materials—Determination of Compression Set. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 8307:2018; Flexible Cellular Polymeric Materials—Determination of Resilience by Ball Rebound. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 5659-2:2006; Plastics—Smoke Generation Part 2: Determination of Optical Density by a Single Chamber Test. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 10993-12:2012; Biological Evaluation of Medical Devices—Part 12: Sample Preparation and Reference Materials. International Organization for Standardization: Geneva, Switzerland, 2012.

- Boukamp, P.; Petrussevska, R.T.; Breitkreutz, D.; Hornung, J.; Markham, A.; Fusenig, N.E. Normal keratinization in a spontaneously immortalized aneuploid human keratinocyte cell line. J. Cell Biol. 1988, 106, 761–771. [Google Scholar] [CrossRef] [Green Version]

- ISO 10993-5:2009; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity 2009. International Organization for Standardization: Geneva, Switzerland, 2009.

- Ginn, M.E.; Noyes, C.M.; Jungermann, E. The contact angle of water on viable human skin. J. Colloid Interface Sci. 1968, 26, 146–151. [Google Scholar] [CrossRef]

- Carriço, C.S.; Fraga, T.; Pasa, V.M.D. Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur. Polym. J. 2016, 85, 53–61. [Google Scholar] [CrossRef]

- Kirpluks, M.; Kalnbunde, D.; Benes, H.; Cabulis, U. Natural oil based highly functional polyols as feedstock for rigid polyurethane foam thermal insulation. Ind. Crop. Prod. 2018, 122, 627–636. [Google Scholar] [CrossRef]

- Gaidukova, G.; Ivdre, A.; Fridrihsone, A.; Verovkins, A.; Cabulis, U.; Gaidukovs, S. Polyurethane rigid foams obtained from polyols containing bio-based and recycled components and functional additives. Ind. Crop. Prod. 2017, 102, 133–143. [Google Scholar] [CrossRef]

- El-Kabbany, F.; Taha, S.; Hafez, M. IR spectroscopic analysis of polymorphism in C13H14N4O. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2011, 78, 981–988. [Google Scholar] [CrossRef]

- Pretsch, T.; Jakob, I.; Müller, W. Hydrolytic degradation and functional stability of a segmented shape memory poly(ester urethane). Polym. Degrad. Stab. 2009, 94, 61–73. [Google Scholar] [CrossRef]

- Bryśkiewicz, A.; Zieleniewska, M.; Przyjemska, K.; Chojnacki, P.; Ryszkowska, J. Modification of flexible polyurethane foams by the addition of natural origin fillers. Polym. Degrad. Stab. 2016, 132, 32–40. [Google Scholar] [CrossRef]

- Günther, M.; Levchik, S.V.; Schartel, B. Bubbles and collapses: Fire phenomena of flame-retarded flexible polyurethane foams. Polym. Adv. Technol. 2020, 31, 2185–2198. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, Y.; Liang, D.; Liu, S.; Chi, Z.; Xu, J. Influence of zinc borate on the flame retardancy and thermal stability of intumescent flame retardant polypropylene composites. J. Anal. Appl. Pyrolysis 2015, 115, 224–232. [Google Scholar] [CrossRef]

- IARC (International Agency for Research on Cancer) Monographs on the Evaluation of Carcinogenic Risks to Humans: Agents Classified by the IARC Monographs. Volumes 1–130. Available online: https://monographs.iarc.who.int/agents-classified-by-the-iarc/ (accessed on 24 October 2021).

- Yang, J.; Zhao, Y.; Li, M.; Du, M.; Li, X.; Li, Y. A review of a class of emerging contaminants: The classification, distribution, intensity of consumption, synthesis routes, environmental effects and expectation of pollution abatement to organophosphate flame retardants (OPFRs). Int. J. Mol. Sci. 2019, 20, 2874. [Google Scholar] [CrossRef] [Green Version]

- Lundin, J.G.; Daniels, G.C.; McGann, C.L.; Stanbro, J.; Watters, C.; Stockelman, M.; Wynne, J.H. Multi-functional polyurethane hydrogel foams with tunable mechanical properties for wound dressing applications. Macromol. Mater. Eng. 2017, 302, 1–10. [Google Scholar] [CrossRef]

- Tanzi, M.C.; Verderio, P.; Lampugnani, M.G.; Resnati, M.; Dejana, E.; Sturani, E. Cytotoxicity of some catalysts commonly used in the synthesis of copolymers for biomedical use. J. Mater. Sci. Mater. Med. 1994, 5, 393–396. [Google Scholar] [CrossRef]

- Jin, M.; Song, P.; Li, N.; Li, X.; Chen, J. A plastic stabilizer dibutyltin dilaurate induces subchronic neurotoxicity in rats. Neural Regen. Res. 2012, 7, 2213–2220. [Google Scholar] [CrossRef]

- Milton, F.A.; Lacerda, M.G.; Sinoti, S.B.P.; Mesquita, P.G.; Prakasan, D.; Coelho, M.S.; de Lima, C.L.; Martini, A.G.; Pazzine, G.T.; Borin, M.d.F.; et al. Dibutyltin compounds effects on PPARγ/RXRα activity, adipogenesis, and inflammation in mammalians cells. Front. Pharmacol. 2017, 8, 507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Król, P.; Uram, Ł.; Król, B.; Pielichowska, K.; Sochacka-Piętal, M.; Walczak, M. Synthesis and property of polyurethane elastomer for biomedical applications based on non-aromatic isocyanates, polyesters, and ethylene glycol. Colloid Polym. Sci. 2020, 298, 1077–1093. [Google Scholar] [CrossRef]

| Designation | Trade Name | Supplier | Description |

|---|---|---|---|

| Graphite | Graphite EG290 | Sinograf, Toruń, Poland | Flake graphite with a carbon content of approx. 90%, expansion degree 200–300 mL/g, and bulk density of 0.66 g/cm3, and average grain size of 352 μm |

| OP550 | Exolit OP550 | Clariant, Łódź, Poland | Reactive halogen-free phosphor flame retardant with functionality 2 |

| OL1000 | Nofia OL1000 | WTH Walter Thieme Handel GmbH, Stade, Germany | Halogen-free flame retardant with 10.4 wt% phosphor content |

| Fyrol PNX LE | Fyrol® PNX LE | ICL Industrial Products, Bitterfeld-Wolfen, Germany | Halogen-free phosphor flame retardant |

| Fyrol HF5 | Fyrol® HF5 | ICL Industrial Products, Bitterfeld-Wolfen, Germany | Halogen-free phosphorus ester flame retardant |

| APP | Addforce FR APP201 | WTH Walter Thieme Handel GmbH, Stade, Germany | Ammonium polyphosphate with 31.39 wt% and 14.69 wt% of phosphor and nitrogen content, respectively |

| Foam/Mixture Type | Flame Retardant Content, php | |||||

|---|---|---|---|---|---|---|

| Exolit OP550 | Graphite | OL1000 | Fyrol PNX LE | Fyrol HF5 | APP | |

| REF | 0 | 0 | 0 | 0 | 0 | 0 |

| PUR–OP550_graphite | 15 | 15 | 0 | 0 | 0 | 0 |

| PUR–OL1000 | 0 | 0 | 30 | 0 | 0 | 0 |

| PUR–Fyrol PNX LE | 0 | 0 | 0 | 20 | 0 | 0 |

| PUR–Fyrol HF5 | 0 | 0 | 0 | 0 | 20 | 0 |

| PUR–OP550 | 30 | 0 | 0 | 0 | 0 | 0 |

| PUR–OP550_APP | 15 | 0 | 0 | 0 | 0 | 15 |

| Foam Type | Apparent Density, g/cm3 |

|---|---|

| REF | 120 |

| PUR–OP550_graphite | 165 |

| PUR–OL1000 | 156 |

| PUR–Fyrol PNX LE | 153 |

| PUR–Fyrol HF5 | 149 |

| PUR–OP550 | 170 |

| PUR–OP550_APP | 181 |

| Foam Type | Mean Pore Equivalent Diameter *, d2, μm | Pore Aspect Ratio AR, a.u. | Total Porosity, % |

|---|---|---|---|

| REF | 211 ± 119 | 1.32 ± 0.18 | 82 ± 1.03 |

| PUR–OP550_graphite | 209 ± 113 | 1.29 ± 0.18 | 78 ± 1.11 |

| PUR–OL1000 | 182 ± 153 | 1.30 ± 0.18 | 76 ± 1.69 |

| PUR–Fyrol PNX LE | 225 ± 147 | 1.27 ± 0.14 | 76 ± 1.25 |

| PUR–Fyrol HF5 | 208 ± 131 | 1.30 ± 0.16 | 74 ± 1.87 |

| PUR–OP550 | 249 ± 115 | 1.27 ± 0.16 | 82 ± 1.16 |

| PUR–OP550_APP | 255 ± 127 | 1.28 ± 0.16 | 87 ± 1.01 |

| Foam Type | Contact Angle, ° | Surface Energy, mJ/m2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Distilled Water | Acidic Sweat | Alkaline Sweat | |||||||

| NC | 37 °C | NC | 37 °C | NC | 37 °C | ||||

| REF | 85.8 ± 1.8 | 95.2 ± 0.7 | 96.3 ± 4.5 | 97.5 ± 3.2 | 85.8 ± 4.6 | 96.2 ± 6.6 | 41.75 | 22.34 | 64.09 |

| PUR–OP550_graphite | 81.1 ± 0.6 | 89.1 ± 2.1 | 90.3 ± 0.6 | 95.3 ± 2.1 | 87.9 ± 0.6 | 90.1 ± 2.6 | 39.34 | 23.57 | 62.91 |

| PUR–OL1000 | 73.4 ± 1.3 | 83.8 ± 1.6 | 84.9 ± 1.6 | 88.0 ± 4.3 | 75.9 ± 1.5 | 84.8 ± 3.6 | 29.96 | 6.13 | 36.09 |

| PUR–Fyrol PNX LE | 77.3 ± 1.6 | 87.0 ± 1.9 | 88.2 ± 2.6 | 87.5 ± 1.4 | 94.2 ± 2.6 | 88.0 ± 4.6 | 35.31 | 8.23 | 43.54 |

| PUR–Fyrol HF5 | 87.0 ± 1.9 | 94.2 ± 3.3 | 95.4 ± 3.6 | 96.4 ± 1.6 | 95.2 ± 3.6 | 95.2 ± 5.6 | 45.89 | 26.2 | 72.09 |

| PUR–OP550 | 70.5 ± 3.9 | 77.0 ± 1.4 | 78.2 ± 1.6 | 81.0 ± 2.2 | 73.7 ± 1.6 | 78.1 ± 0.6 | 28.9 | 11.8 | 40.7 |

| PUR–OP550_APP | 55.7 ± 1.1 | 64.1 ± 1.4 | 65.2 ± 1.1 | 68.0 ± 0.5 | 66.4 ± 1.1 | 65.0 ± 1.6 | 21.68 | 32.18 | 53.86 |

| Foam Type | Tg1, °C | Tg2, °C |

|---|---|---|

| REF | −32 ± 1 | −32 ± 2 |

| PUR–OP550_graphite | −32 ± 4 | −32 ± 1 |

| PUR–OL1000 | −14 ± 2 | −16 ± 1 |

| PUR–Fyrol PNX LE | −39 ± 2 | −41 ± 1 |

| PUR–Fyrol HF5 | −34 ± 3 | −34 ± 2 |

| PUR–OP550 | −29 ± 1 | −32 ± 0 |

| PUR–OP550_APP | −27 ± 2 | −29 ± 0 |

| Foam Type | T5%,°C | Tmax1, °C (Vmax1, %/°C) | ∆m1, % (Range, °C) | Tmax2, °C (Vmax2, %/°C) | ∆m2, % (Range, °C) | Tmax3, °C (Vmax3, %/°C) | ∆m3, % (Range, °C) | Tmax4,°C (Vmax4, %/°C) | ∆m4, % (Range, °C) | Tmax5, °C (Vmax5, %/°C) | ∆m5, % (Range, °C) | P600/P950, % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REF | 281 | - | - | 319 (0.86) | 32.64 (240–350) | 394 (1.42) | 57.5 (350–440) | - | - | - | - | 5.72/ 3.80 |

| PUR–OP550_graphite | 229 | 228 (0.125) | 5.4 (150–240) | 294 (0.53) | 24.72 (240–325) | 395 (0.89) | 47.5 (325–440) | 466 (0.059) | 4.59 (440–600) | - | - | 16.66/ 15.34 |

| PUR–OL1000 | 276 | - | 4.2 (150–274) | 310 (0.94) | 34.55 (274–345) | 402 (0.93) | 47.1 (345–447) | - | 3.12 (447–600) | - | - | 10.23/ 9.02 |

| PUR–Fyrol PNX LE | 216 | 225 (0.234) | 11.8 (140–252) | 292 (0.54) | 22.77 (252–331) | 399 (0.98) | 51.1 (330–441) | 467 (0.06) | 4.11 (440–600) | - | - | 9.67/ 8.37 |

| PUR–Fyrol HF5 | 237 | 226 (0.115) | 5.6 (150–240) | 304 (0.69) | 32.29 (255–335) | 394 (0.95) | 48.4 (255–430) | 462 (0.05) | 3.88 (440–600) | - | - | 8.76/ 7.52 |

| PUR–OP550 | 219 | 229 (0.224) | 9.7 (150–244) | 280 (0.43) | 15.51 (244–305) | 364 (0.96) | 46.3 (305–398) | 411 (0.17) | 11.01 (398–600) | - | - | 13.65/ 11.98 |

| PUR–OP550_ APP | 219 | 227 (0.194) | 8.6 (150–240) | 278 (0.46) | 18.46 (240–300) | 343 (0.99) | 38.5 (300–370) | 420 (0.20) | 12.10 (370–550) | 943 (0.06) | 5.1 (800–1000) | 20.89/ 14.83 |

| Foam Type | Compression Set at 50% (22 h, 70 °C), % | Compression Set at 90% (22 h, 70 °C), % | Rebound Resilience, % |

|---|---|---|---|

| REF | 8 ± 2 | 15 ± 2 | 11 |

| PUR–OP550_graphite | 4 ± 1 | 7 ± 1 | 8 |

| PUR–OL1000 | 2 ± 1 | 5 ± 3 | 2 |

| PUR–Fyrol PNX LE | 3 ± 2 | 6 ± 1 | 18 |

| PUR–Fyrol HF5 | 2 ± 2 | 10 ± 2 | 12 |

| PUR–OP550 | 5 ± 2 | 7 ± 3 | 8 |

| PUR–OP550 APP | 1 ± 2 | 4 ± 2 | 15 |

| Designation | TTI, s | pHRR, kW/m2 | MARHE, kW/m2 | THR, MJ/m2 | EHC, MJ/kg | SEA, m2/kg | TSR, m2/m2 |

|---|---|---|---|---|---|---|---|

| REF | 21 ± 3 | 400 ± 30 | 262 ± 5 | 46 ± 2 | 22 ± 1 | 255 ± 18 | 551 ± 16 |

| PUR–OP550_graphite | 11 ± 1 | 138 ± 4 | 80 ± 3 | 10 ± 1 | 13 ± 1 | 279 ± 40 | 234 ± 16 |

| PUR–OL1000 | 18 ± 2 | 407 ± 19 | 266 ± 6 | 41 ± 1 | 17 ± 0 | 686 ± 15 | 1690 ± 25 |

| PUR–Fyrol PNX LE | 13 ± 1 | 452 ± 7 | 337 ± 2 | 45 ± 2 | 19 ± 0 | 590 ± 9 | 1413 ± 61 |

| PUR–Fyrol HF5 | 12 ± 1 | 410 ± 4 | 311 ± 3 | 24 ± 2 | 18 ± 0 | 619 ± 2 | 1533 ± 83 |

| PUR–OP550 | 13 ± 1 | 485 ± 31 | 340 ± 8 | 52 ± 0 | 18 ± 0 | 546 ± 4 | 1582 ± 9 |

| PUR–OP550 APP | 13 ± 1 | 306 ± 4 | 219 ± 1 | 51 ± 1 | 17 ± 0 | 632 ± 38 | 1221 ± 126 |

| Sample | IC50, % | Cytotoxicity |

|---|---|---|

| Positive control (DMSO) | 2.02 | the highest |

| REF | 18.54 | 1—the highest |

| PUR–OP550_graphite | 32.11 | 3 |

| PUR–OL1000 | 72.12 | 7—the lowest |

| PUR–Fyrol PNX LE | 45.06 | 4 |

| PUR–Fyrol HF5 | 56.69 | 5 |

| PUR–OP550 | 58.00 | 6 |

| PUR–OP550_APP | 23.52 | 2 |

| Sample | Grade | Reactivity | Conditions of All Cultures According to ISO 10993-5 |

|---|---|---|---|

| Vehicle control | 0 | none | Discrete intracytoplasmic granules, no cell lysis, no reduction in cell growth |

| Positive control (DMSO) | 4 | severe | Nearly complete or complete destruction of the cell layer |

| REF | 4 | severe | Nearly complete or complete destruction of the cell layer |

| PUR–OP550_graphite | 3 | moderate | No more than 70% of the cell layers contain rounded cells or are lysed; cell layers not completely destroyed, but more than 50% growth inhibition observed |

| PUR–OL1000 | 0 | none | Discrete intracytoplasmic granules, no cell lysis, no reduction in cell growth |

| PUR–Fyrol PNX LE | 2 | mild | No more than 50% of the cells are round, devoid of intracytoplasmic granules; no extensive cell lysis; not more than 50% growth inhibition observable |

| PUR–Fyrol HF5 | 1 | slight | No more than 20% of the cells are round, loosely attached, and without intracytoplasmic granules or show changes in morphology; occasional lysed cells are present; only slight growth inhibition observable |

| PUR–OP550 | 1 | slight | No more than 20% of the cells are round, loosely attached, and without intracytoplasmic granules or show changes in morphology; occasional lysed cells are present; only slight growth inhibition observable |

| PUR–OP550_APP | 3 | moderate | No more than 70% of the cell layers contain rounded cells or are lysed; cell layers not completely destroyed, but more than 50% growth inhibition observed |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okrasa, M.; Leszczyńska, M.; Sałasińska, K.; Szczepkowski, L.; Kozikowski, P.; Nowak, A.; Szulc, J.; Adamus-Włodarczyk, A.; Gloc, M.; Majchrzycka, K.; et al. Viscoelastic Polyurethane Foams with Reduced Flammability and Cytotoxicity. Materials 2022, 15, 151. https://doi.org/10.3390/ma15010151

Okrasa M, Leszczyńska M, Sałasińska K, Szczepkowski L, Kozikowski P, Nowak A, Szulc J, Adamus-Włodarczyk A, Gloc M, Majchrzycka K, et al. Viscoelastic Polyurethane Foams with Reduced Flammability and Cytotoxicity. Materials. 2022; 15(1):151. https://doi.org/10.3390/ma15010151

Chicago/Turabian StyleOkrasa, Małgorzata, Milena Leszczyńska, Kamila Sałasińska, Leonard Szczepkowski, Paweł Kozikowski, Adriana Nowak, Justyna Szulc, Agnieszka Adamus-Włodarczyk, Michał Gloc, Katarzyna Majchrzycka, and et al. 2022. "Viscoelastic Polyurethane Foams with Reduced Flammability and Cytotoxicity" Materials 15, no. 1: 151. https://doi.org/10.3390/ma15010151

APA StyleOkrasa, M., Leszczyńska, M., Sałasińska, K., Szczepkowski, L., Kozikowski, P., Nowak, A., Szulc, J., Adamus-Włodarczyk, A., Gloc, M., Majchrzycka, K., & Ryszkowska, J. (2022). Viscoelastic Polyurethane Foams with Reduced Flammability and Cytotoxicity. Materials, 15(1), 151. https://doi.org/10.3390/ma15010151