Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review

Abstract

:1. Introduction

- Reduction of the cement-to-clinker ratio, by replacing clinker with supplementary cementitious materials (SCM’s);

- The use of alternative fuels in the production of clinker together with the increase of energy efficiency of the kiln process;

- Development of alternative clinker technologies (ACTs), that lead to lower CO2 emissions.

- Carbon capture, use and storage (CCUS), i.e., the sequestration and use of the emitted CO2 for specific applications;

- Electrification of the clinker production process, especially if renewable electricity produced from non-fossil energy sources is used;

- The best available technology (BAT) of OPC production cannot be easily converted into a fully electrified process, since it would require very significant changes not only in the technology itself but also in the dimensioning of the industrial installation due to the lower volume of material (gases and dust) in circulation.

- At least 60% of the released CO2 comes from the decarbonation stage, while only 35 to 40% of the remaining CO2 emissions come from the energy needed to promote the high-temperature reactions that characterize the clinkering stage. Thus, acting in the material composition stage is mandatory to achieve a significant reduction of CO2 emissions in cement production. Therefore, at the present point, other emerging technologies or alternative materials will also play an important role in emissions mitigation in the medium/longer term.

- Mechanical performance, both at early ages and later ages;

- Rheological performance, enabling an adequate pumping, spreading, molding and compaction of the material [20];

- Reduced chemical shrinkage, since this phenomenon causes serious loss on the durability and bearing capacity of concrete structure, increasing the risk for cracking and decreasing the lifespan of the structures [24],

- Chemical stability, which will be translated into structure durability when submitted to the natural elements.

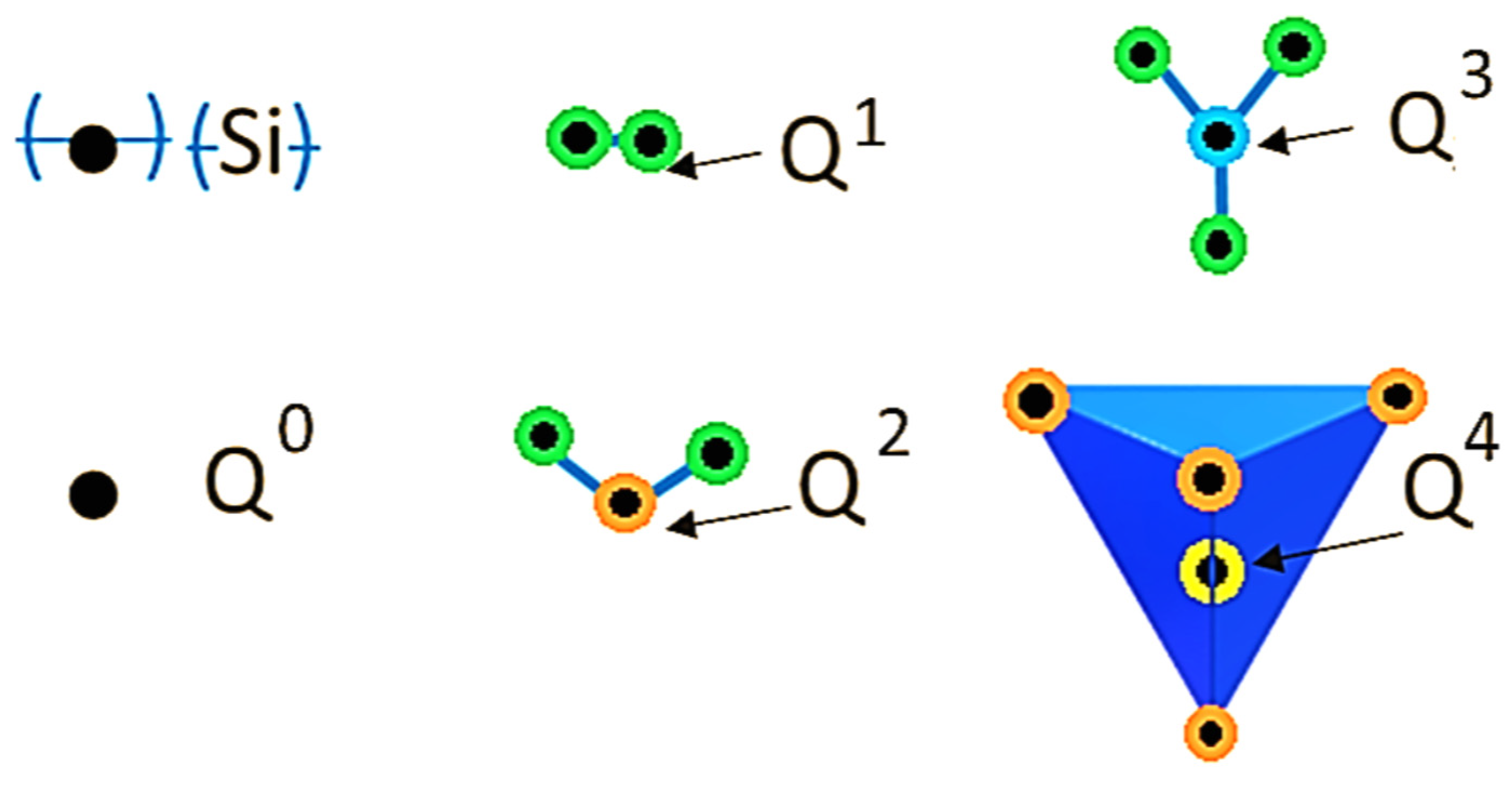

2. The Chemistry of the CaO-SiO2 System

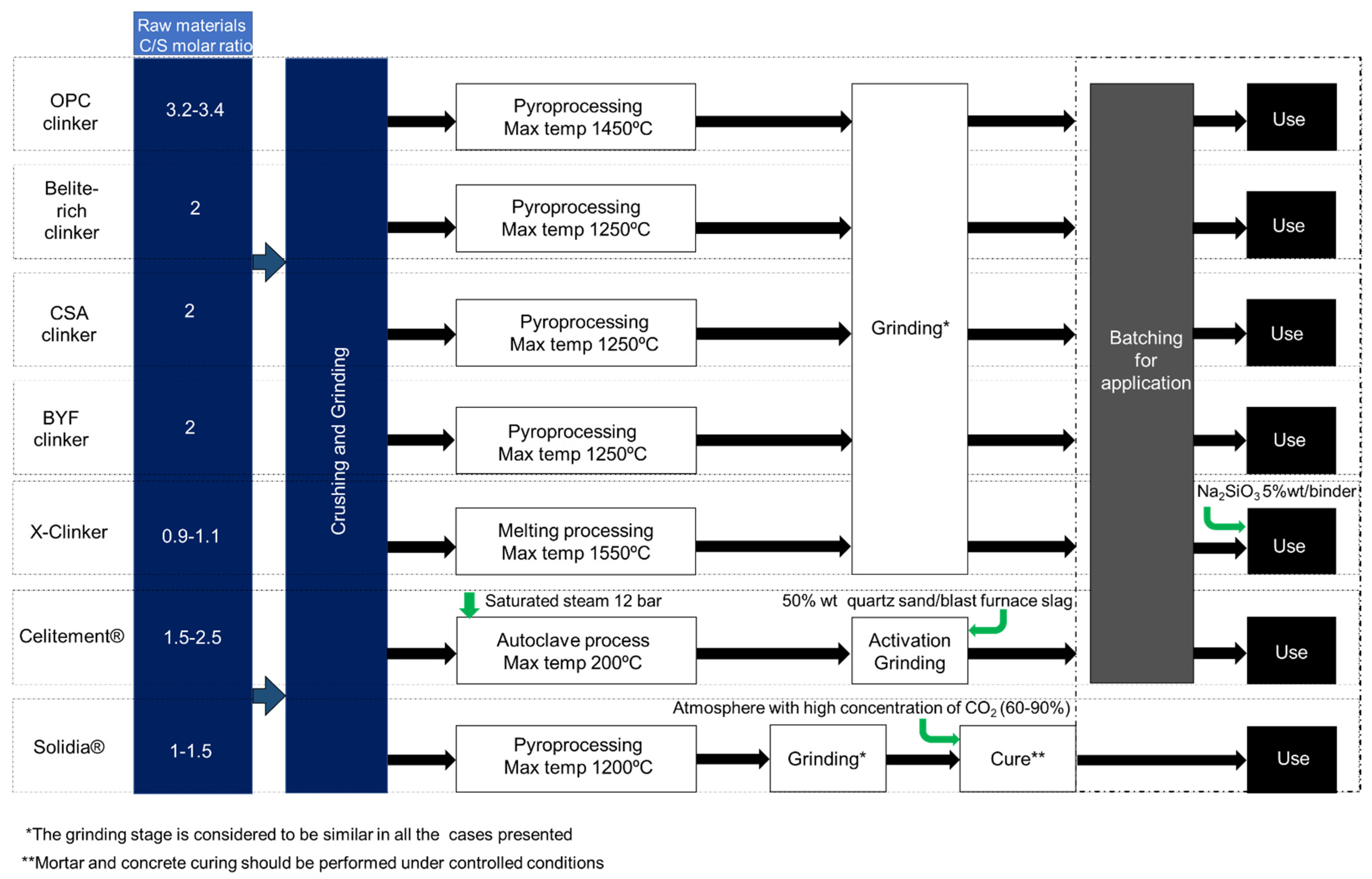

3. ACTs: Alternative Clinker Technologies

- The capacity to mimic OPC properties, namely the production of mortar, concrete and reinforced concrete.

- A reduction of CO2 emissions large enough to justify the substitution of the BAT for cement production, since this represents a widespread technology with thousands of dedicated plants all over the world.

- A small impact on the need for modifications of national and international standards for cement use.

3.1. Belite-Rich Clinkers

3.2. Calcium Sulfoaluminate Cements and Belite-Ye’elimite-Ferrite Cements

3.3. The Solidia Cement Approach

3.4. The Celitement Approach

3.5. The C/S≈1 Amorphous Approach (X-Clinker)

3.6. Summary of the Alternative Clinker Technologies

4. Electrification of the Cement Production Process

4.1. Plasma Technology

4.2. Resistive Electrical Heating

4.3. Electromagnetic Heating

4.3.1. Induction Heating

4.3.2. Microwave Heating

4.4. Benefits and Difficulties of Electrification

5. Final Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Hewlett, P.C. Lea’s Chemistry of Cement and Concrete, 4th ed.; Butterworth Heinemann: Oxford, UK, 2003; ISBN 9780750662567. [Google Scholar]

- Cembureau the European Cement Association. Available online: https://cembureau.eu/cement-101/cement (accessed on 14 December 2021).

- Gagg, C.R. Cement and Concrete as an Engineering Material: An Historic Appraisal and Case Study Analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Cement IEA Paris. Available online: https://www.Iea.Org/Reports/Cement (accessed on 14 November 2021).

- International Energy Agency. Technology Roadmap—Low-Carbon Transition in the Cement Industry; Technical Report; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Andrew, R.M. Global CO2 Emissions from Cement Production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef] [Green Version]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and Developments in Green Cement and Concrete Technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef] [Green Version]

- UN The Sustainable Development Agenda. Available online: https://www.un.org/sustainabledevelopment/development-agenda/ (accessed on 14 November 2021).

- Aamar Danish, M.; Usama Salim, T.A. Trends and Developments in Green Cement “A Sustainable Approach”. Sustain. Struct. Mater. 2019, 2, 45–60. [Google Scholar] [CrossRef]

- Plaza, M.G.; Martínez, S.; Rubiera, F. CO2 Capture, Use, and Storage in the Cement Industry: State of the Art and Expectations. Energies 2020, 13, 5692. [Google Scholar] [CrossRef]

- Bacariza, M.C.; Spataru, D.; Karam, L.; Lopes, J.M.; Henriques, C. Promising Catalytic Systems for CO2 Hydrogenation into CH4: A Review of Recent Studies. Processes 2020, 8, 1646. [Google Scholar] [CrossRef]

- Lehne, J. Making Concrete Change Innovation in Low-Carbon; The Royal Institute of International Affairs: London, UK, 2018. [Google Scholar]

- Speight, J.G. Handbook of Industrial Hydrocarbon Processes, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 421–463. [Google Scholar]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Jain, V.; Sancheti, G.; Jain, B. Influence of Fine Supplementary Cementitious Materials on Compressive LpStrength of Concrete—A State of Art Review. J. Nano-Electron. Phys. 2021, 13, 02021. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Mohammadhosseini, H. State-of-the-Art-Review on Rice Husk Ash: A Supplementary Cementitious Material in Concrete. J. King Saud Univ. Eng. Sci. 2021, 33, 294–307. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of Silica Fume on Mechanical and Durability of Pervious Concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of High Volume Fly Ash Concrete Incorporating Additives: A Systematic Literature Review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Patra, R.K.; Mukharjee, B.B. Influence of Incorporation of Granulated Blast Furnace Slag as Replacement of Fine Aggregate on Properties of Concrete. J. Clean. Prod. 2017, 165, 468–476. [Google Scholar] [CrossRef]

- Lee, D.K.; Choi, M.S. Standard Reference Materials for Cement Paste: Part III—Analysis of the Flow Characteristics for the Developed Standard Reference Material According to Temperature Change. Materials 2018, 11, 2001. [Google Scholar] [CrossRef] [PubMed]

- Naqi, A.; Jang, J.G. Recent Progress in Green Cement Technology Utilizing Low-Carbon Emission Fuels and Raw Materials: A Review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef] [Green Version]

- Cembureau the European Cement Association Cementing the European Green Deal. 2020. Available online: https://cembureau.eu/media/kuxd32gi/cembureau-2050-roadmap_final-version_web.pdf (accessed on 14 December 2021).

- Rightor, B.E.; Whitlock, A.; Elliott, R.N. Beneficial Electrification in Industry; ACEEE Research Report; Industrial Electrification ACEE: Washington, DC, USA, 2020. [Google Scholar]

- Cai, Y.; Yu, L.; Yang, Y.; Gao, Y.; Yang, C. Effect of Early Age-Curing Methods on Drying Shrinkage of Alkali-Activated Slag Concrete. Materials 2019, 12, 1633. [Google Scholar] [CrossRef] [Green Version]

- Santos, R.L.; Horta, R.B.; Pereira, J.; Nunes, T.G.; Rocha, P.; Lopes, J.N.; Colaço, R. Microstructural Control and Hydration of Novel Micro-Dendritic Clinkers with CaO/SiO2 = 1.4. Cem. Concr. Res. 2015, 76, 212–221. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997; ISBN 0727725920. [Google Scholar]

- Freitas, A.A.; Santos, R.L.; Colaço, R.; Bayão Horta, R.; Canongia Lopes, J.N. From Lime to Silica and Alumina: Systematic Modeling of Cement Clinkers Using a General Force-Field. Phys. Chem. Chem. Phys. 2015, 17, 18477–18494. [Google Scholar] [CrossRef]

- Santos, R.L.; Horta, R.B.; Al, E. Alkali Activation of a Novel Calcium-Silicate Hydraulic Binder. Am. Ceram. Soc. 2018, 101, 4158–4170. [Google Scholar] [CrossRef]

- Chatterjee, A.K. High Belite Cements—Present Status and Future Technological Options: Part I. Cem. Concr. Res. 1996, 26, 1213–1225. [Google Scholar] [CrossRef]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si Ratio on the Compressive Strength of Cementitious Calcium-Silicate-Hydrate Binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef] [Green Version]

- Soler, J.M. Thermodynamic Description of the Solubility of C-S-H Gels in Hydrated Portland Cement Literature Review; Working Report 2007-88; Posiva Oy: Helsinki, Finland, 2007. [Google Scholar]

- Gartner, E.M.; Kurtis, K.E.; Monteiro, P.J.M. Proposed Mechanism of C-S-H Growth Tested by Soft X-ray Microscopy. Cem. Concr. Res. 2000, 30, 817–822. [Google Scholar] [CrossRef]

- Abdolhosseini Qomi, M.J.; Krakowiak, K.J.; Bauchy, M.; Stewart, K.L.; Shahsavari, R.; Jagannathan, D.; Brommer, D.B.; Baronnet, A.; Buehler, M.J.; Yip, S.; et al. Combinatorial Molecular Optimization of Cement Hydrates. Nat. Commun. 2014, 5, 4960. [Google Scholar] [CrossRef] [PubMed]

- Zayed, A. Effects of Portland Cement Particless Size on Heat of Hydration; Technical Report; Department of Civil and Environmental Engineering, University of South Florida: Tampa, FL, USA, 2013; Volume 1, pp. 36–39. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Nonat, A. Hydration of Cementitious Materials, Present and Future. Cem. Concr. Res. 2011, 41, 651–665. [Google Scholar] [CrossRef]

- Müller, N.; Harnisch, J.; Mesguen, J.-P. How to Turn Around the Trend of Cement Related Emissions in the Developing World; WWF—Lafarge Conservation Partnership: Gland, Switzerland, 2008; Available online: https://wwf.panda.org/wwf_news/?151621/A-blueprint-for-a-climate-friendly-cement-industry (accessed on 14 December 2021).

- Lower Clinker Cements CEMBUREAU The European Cement Association. 2020. Available online: https://cembureau.eu/about-Our-Industry/Innovation/Lower-Clinker-Cements/ (accessed on 14 December 2021).

- Provis, J.L.; Palomo, A.; Shi, C. Advances in Understanding Alkali-Activated Materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Kotsay, G.; Jaskulski, R. Belite Cement as an Ecological Alternative to Portland Cement—A Review. Mater. Struct. Technol. 2020, 2, 70–76. [Google Scholar] [CrossRef]

- Sui, T.; Fan, L.; Wen, Z.; Wang, J. Properties of Belite-Rich Portland Cement and Concrete in China. J. Civ. Eng. Archit. 2015, 9, 384–392. [Google Scholar] [CrossRef] [Green Version]

- Chi, L.; Zhang, A.; Qiu, Z.; Zhang, L.; Wang, Z.; Lu, S.; Zhao, D. Hydration Activity, Crystal Structural, and Electronic Properties Studies of Ba—Doped Dicalcium Silicate. Nanotechnol. Rev. 2020, 9, 1027–1033. [Google Scholar] [CrossRef]

- Pritts, I.M.; Daugherty, K.E. The Effect of Stabilizing Agents on the Hydration Rate of β-C2S. Cem. Concr. Res. 1976, 6, 783–795. [Google Scholar] [CrossRef]

- Horta, R.S.B.; Colaço, R.A.C.; Lopes, J.N.A.; Santos, R.L.; Pereira, J.C.; Rocha, P.J.P.; Lebreiro, S.M.M. Dendritic Belite Based Hydraulic Binders and Methods for Their Manufacturing. European Patent EP 3247685 B1 20200819 (EN), 19 January 2015. [Google Scholar]

- Tan, B.; Okoronkwo, M.U.; Kumar, A.; Ma, H. Durability of Calcium Sulfoaluminate Cement Concrete. J. Zhejiang Univ. -SCIENCE A 2020, 21, 118–128. [Google Scholar] [CrossRef]

- Aranda, M.A.G. Optimisation and Advanced Characterisation of Ye’elimite Based Ecocements; Woodhead Publishing Limited: Malaga, Spain, 2013; ISBN 9780857098993. [Google Scholar]

- Canbek, O.; Shakouri, S.; Erdo, S.T. Laboratory Production of Calcium Sulfoaluminate Cements with High Industrial Waste Content. Cem. Concr. Compos. 2020, 106, 103475. [Google Scholar] [CrossRef]

- Gartner, E.; Sui, T. Alternative Cement Clinkers. Cem. Concr. Res. 2018, 114, 27–39. [Google Scholar] [CrossRef]

- Zajac, M.; Skocek, J.; Stabler, C.; Bullerjahn, F.; Ben Haha, M. Hydration and Performance Evolution of Belite-Ye’elimite-Ferrite Cement. Adv. Cem. Res. 2019, 31, 124–137. [Google Scholar] [CrossRef]

- Li, C.; Wu, M.; Yao, W. Eco-Efficient Cementitious System Consisting of Belite-Ye’elimite-Ferrite Cement, Limestone Filler, and Silica Fume. ACS Sustain. Chem. Eng. 2019, 7, 7941–7950. [Google Scholar] [CrossRef]

- Sahu, S.; Data, R.U.S.A. Compositions and Methods for Controling Setting of Carbonatable Calcium Silicate Cements Containing Hydrating Materials. U.S. Patent US 2016/0096773 A1 2016, 8 September 2020. [Google Scholar]

- Meyer, V.; de Cristofaro, N.; Bryant, J.; Sahu, S. Solidia Cement an Example of Carbon Capture and Utilization. Key Eng. Mater. 2018, 761, 197–203. [Google Scholar] [CrossRef]

- Sahu, S.; Meininger, R.C. Sustainability and Durability of Solidia Cement Concrete. Concr. Int. 2020, 42, 29–34. [Google Scholar]

- Atakan, V.; Sahu, S.; Quinn, S.; Hu, X.; DeCristafaro, N. Why CO2 Matters—Advances in a New Class of Cement. ZKG Int. 2014, 3, 60–63. [Google Scholar]

- Beuchle, G.; Stemmermann, P.; Schweike, U.; Garbev, K. Single-Phase Hydraulic Binder, Methods for the Production Thereof and Structural Material Produced. U.S. Patent US 2010/0186634A1, 16 July 2008. [Google Scholar]

- Moller, H. Celitement—A Novel Cement Based on Hydraulic Calcium Hydrosilicates (HCHS). Celitement.de 2009, 1–5. Available online: https://celitement.de/wp-content/uploads/2020/10/2020_04_06_Description_Celitement_MOE.pdf (accessed on 14 December 2021).

- Stemmermann, P.; Beuchle, G.; Garbev, K.; Schweike, U. Celitement—A New Sustainable Hydraulic Binder Based on Calcium Hydrosilicates. In Proceedings of the 13th International Congress on the Chemistry of Cement, Madrid, Spain, 3–8 July 2011; pp. 1–7. [Google Scholar]

- Garbev, K.; Beuchle, G.; Schweike, U.; Stemmermann, P. Hydration Behavior of Celitement®: Kinetics, Phase Composition, Microstructure and Mechanical Properties. Celitement 2016, 41–50. [Google Scholar] [CrossRef]

- Schimitt, D.; Mohsen, B.H.; Itul, A.; Zajac, M.; Spencer, N. Method of Enhancing the Latent Hydraulic and/or Pozzolanic Reactivity of Materials. European Patent EP 2 801 559 B1, 4 September 2018. [Google Scholar]

- Celitement GmbH. Available online: Https://Celitement.de/En/about-Us/ (accessed on 4 October 2021).

- Santos, R.L.; Horta, R.B.; Pereira, J.; Nunes, T.G.; Rocha, P.; Lopes, J.N.C.; Colaço, R. Novel High-Resistance Clinkers with 1.10 < CaO/SiO2 < 1.25: Production Route and Preliminary Hydration Characterization. Cem. Concr. Res. 2016, 85, 39–47. [Google Scholar] [CrossRef]

- Horta, R.S.B.; Colaço, R.A.C.; Lopes, J.N.A.; Santos, R.L.; Pereira, J.C.; Rocha, P.J.P.; Lebreiro, S.M.M. Amorphous Low-Calcium Content Silicate Hydraulic Binders and Methods for Their Manufacturing. U.S. Patent US10414690B2, 17 September 2019. [Google Scholar]

- Wang, Y.; Winter, L.R.; Chen, J.G.; Yan, B. CO2 Hydrogenation over Heterogeneous Catalysts at Atmospheric Pressure: From Electronic Properties to Product Selectivity. Green Chem. 2021, 23, 249–267. [Google Scholar] [CrossRef]

- Alotaibi, M.A.; Din, I.U.; Alharthi, A.I.; Bakht, M.A.; Centi, G.; Shaharun, M.S.; Naeem, A. Green Methanol Synthesis by Catalytic CO2 Hydrogenation, Deciphering the Role of Metal-Metal Interaction. Sustain. Chem. Pharm. 2021, 21, 100420. [Google Scholar] [CrossRef]

- Santos, D.; Santos, R.L.; Pereira, J.; Horta, R.B.; Colaço, R.; Paradiso, P. Influence of Pseudowollastonite on the Performance of Low Calcium Amorphous Hydraulic Binders. Materials 2019, 12, 3457. [Google Scholar] [CrossRef] [Green Version]

- Paradiso, P.; Santos, R.L.; Horta, R.B.; Lopes, J.N.C.; Ferreira, P.J.; Colaço, R. Formation of Nanocrystalline Tobermorite in Calcium Silicate Binders with Low C/S Ratio. Acta Mater. 2018, 152, 7–15. [Google Scholar] [CrossRef]

- Wei, M.; McMillan, C.A. Electrification of Industry: Potential, Challenges and Outlook. Curr. Sustain. Renew. Energy Rep. 2019, 6, 140–148. [Google Scholar] [CrossRef]

- Are Electric Furnaces the Future of Glass Manufacturing. Available online: https://Mo-Sci.Com/Electric-Furnaces-Future-Glass-Manufacturing/ (accessed on 1 November 2021).

- Madeddu, S.; Ueckerdt, F.; Pehl, M.; Peterseim, J.; Lord, M.; Kumar, K.A.; Krüger, C.; Luderer, G. The CO2 Reduction Potential for the European Industry via Direct Electrification of Heat Supply (Power-to-Heat). Environ. Res. Lett. 2020, 15, 124004. [Google Scholar] [CrossRef]

- Wilhelmsson, B.; Kollberg, C.; Larsson, J.; Eriksson, J.; Eriksson, M. CemZero—A Feasibility Study Evaluating Ways to Reach Sustainable Cement Production via the Use of Electricity. Vattenfall Cem. 2018. Available online: https://group.vattenfall.com/press-and-media/pressreleases/2019/vattenfall-and-cementa-take-the-next-step-towards-a-climate-neutral-cement (accessed on 23 December 2021).

- Cementa Aims for Zero Emissions with Vattenfall; Vattenfall Press Office: Solna, Sweden, 2018; Available online: https://Group.Vattenfall.Com/Press-and-Media/Newsroom/2017/Cementa-Aims-for-Zero-Emissions-with-Vattenfall (accessed on 1 November 2021).

- Low Emissions Intensity Lime & Cement—LEILAC. Available online: https://Www.Project-Leilac.Eu/about-Leilac (accessed on 14 November 2020).

- Electrification Is Driving Sustainability in Cement and Mining. Available online: https://Foresightdk.Com/Electrification-Is-Driving-Sustainability-in-Cement-and-Mining/ (accessed on 3 October 2021).

- Tokheim, L.-A.; Mathisen, A.; Øi, L.E.; Jayarathna, C.; Eldrup, N.; Gautestad, T. Combined Calcination and CO2 Capture in Cement Clinker Production by Use of Electrical Energy. In Proceedings of the 10th International Trondheim CCS Conference, Trondheim, Norway, 17–19 June 2019; Volume 17. [Google Scholar]

- Lechtenböhmer, S.; Nilsson, L.J.; Åhman, M.; Schneider, C. Decarbonising the Energy Intensive Basic Materials Industry through Electrification—Implications for Future EU Electricity Demand. Energy 2016, 115, 1623–1631. [Google Scholar] [CrossRef] [Green Version]

- Bogaerts, A.; Berthelot, A.; Heijkers, S.; Kolev, S.; Snoeckx, R.; Sun, S.; Trenchev, G.; van Laer, K.; Wang, W. CO2 Conversion by Plasma Technology: Insights from Modeling the Plasma Chemistry and Plasma Reactor Design. Plasma Sources Sci. Technol. 2017, 26, 063001. [Google Scholar] [CrossRef]

- Shuanghui, H.; Baowei, W.; Yijun, L. Syngas Production via Methane Steam Reformingwith Oxygen: Plasma Reactors versus Chemicalreactors. J. Phys. D Appl. Phys. 2001, 34, 2798. [Google Scholar] [CrossRef]

- Seo, K.; Edgar, T.F.; Baldea, M. Optimal Demand Response Operation of Electric Boosting Glass Furnaces. Appl. Energy 2020, 269, 115077. [Google Scholar] [CrossRef]

- Electroglass. Available online: Http://Www.Electroglass.Co.Uk/ (accessed on 1 November 2021).

- Resource, I.B. European Container Glass Industry to Reduce Emissions with Green Furnace. Available online: https://Resource.Co/Article/European-Container-Glass-Industry-Reduce-Emissions-Green-Furnace (accessed on 1 November 2021).

- Technical Report All-Electric Melting Prospects for Glass Container Production. Glass WORLDWIDE FGM. 2020. Available online: https://www.glassworldwide.co.uk/sites/default/files/afgm-articles/AFGM%20Horn%20article.pdf (accessed on 27 December 2021).

- Jebavá, M.; Hrbek, L.; Cincibusová, P.; Němec, L. Energy Distribution and Melting Efficiency in Glass Melting Channel: Effect of Configuration of Heating Barriers and Vertical Energy Distribution. J. Non-Cryst. Solids 2021, 562, 120776. [Google Scholar] [CrossRef]

- Lord, M. Electrifying Industry, 2018—Zero Carbon Industry Plan; Technical Report; Beyond Zero Emissions: Melbourne, VIC, Australia, 2018. [Google Scholar]

- Induction Brazing. Available online: Https://Dw-Inductionheater.Com/Basic-Induction-Heating.HtmlInduc (accessed on 4 October 2021).

- Wheeler, M.B.R.; Buckham, J.A.; Mcbride, J.A. A Comparison of Various Calcination Process for Processing High-Level Radioactive Wastes; U.S Atomic Energy Commission: Idaho Falls, ID, USA, 1964.

- Induction Furnace for Melting of Metal. Available online: Https://Termolit.Com/En/Induction-Furnace-for-Melting-of-Metal/ (accessed on 1 November 2021).

- Corrêa, B.H.B.C.; Neto, J.C.B.; França, A.B.; Cordeiro, A.C.C. New Process to Obtain Unslaked Lime through Microwave Hybrid Heating and Its Fluid Dynamics Computational Modeling. J. Eng. Exact Sci. 2021, 7, 12300-01. [Google Scholar] [CrossRef]

- Priecel, P.; Lopez-Sanchez, J.A. Advantages and Limitations of Microwave Reactors: From Chemical Synthesis to the Catalytic Valorization of Biobased Chemicals. ACS Sustain. Chem. Eng. 2019, 7, 3–21. [Google Scholar] [CrossRef] [Green Version]

- Pakulska, T. Green Energy in Central and Eastern European (Cee) Countries: New Challenges on the Path to Sustainable Development. Energies 2021, 14, 884. [Google Scholar] [CrossRef]

- EUR-Lex A European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52018DC0773 (accessed on 1 November 2021).

- Eurostat, Statistic Expalained Renewable Energy Statistics. Available online: Https://Ec.Europa.Eu/Eurostat/Statistics-Explained/Index.Php?Title=Renewable_energy_statistics#Wind_and_water_provide_most_renewable_electricity.3B_solar_is_the_fastest-Growing_energy_source (accessed on 1 November 2021).

- Roelofsen, O.; Somers, K.; Speelman, E.; Witteveen, M. Plugging in: What Electrification Can Do for Industry; Technical Report; McKinsey Company: New York, NY, USA, 2020. [Google Scholar]

- Justnes, A.H.; Justnes Hedda Vikan, H.; Arne Hammer, T.; Manager, C. Advanced Cementing Materials Reduced CO2 Emissions: Principles of Making Cement with Reduced CO2 Emission State of the Art; SINTEF Rep: Trondheim, Norway, 2007; p. 7019. ISBN 978-82-536-0982-9. [Google Scholar]

- Thomas, J.J.; Ghazizadeh, S.; Masoero, E. Kinetic Mechanisms and Activation Energies for Hydration of Standard and Highly Reactive Forms of β—Dicalcium Silicate (C2S). Cem. Concr. Res. 2018, 100, 322–328. [Google Scholar] [CrossRef] [Green Version]

- Ukrainczyk, N. Kinetic Study of Calcium Sulfoaluminate Cement Hydration. In Proceedings of the MATRIB2013 International Conference on Materials, Tribology, Recycling, Vela Luka, Croatia, 27–29 June 2013. [Google Scholar]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and Carbon Emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Brown, P.W. Kinetics of Tricalcium Aluminate and Tetracalcium Aluminoferrite Hydration in the Presence of Calcium Sulfate. J. Am. Ceram. Soc. 1993, 76, 2971–2976. [Google Scholar] [CrossRef]

- Li, G.S.; Walenta, G.; Gartner, E.M. Formation and Hydration of Low-CO2 Cements Based on Belite, Calcium Sulfoaluminate and Calcium Aluminoferrite. In Proceedings of the 12th International Congress on the Chemistry of Cement, Montreal, QC, Canada, 8–13 July 2007. [Google Scholar]

- Santos, R.L. New Hydraulic Binders with Low Calcium Content. Ph.D. Thesis, Universidade de Lisboa, Lisbon, Portugal, 2016. [Google Scholar]

- Antunes, M.; Santos, R.L.; Pereira, J.; Horta, R.B.; Paradiso, P.; Colaço, R. The Apparent Activation Energy of a Novel Low-Calcium Silicate Hydraulic Binder. Materials 2021, 14, 5347. [Google Scholar] [CrossRef] [PubMed]

| Technology-Related Characteristics | Binder Characteristics | |||||||

|---|---|---|---|---|---|---|---|---|

| Clinker | Process-Related CO2 (kg/ton) | Energy-Related CO2 (kg/ton) | Total CO2 (kg/tonne) | High Abundance of Raw Materials | Electrification Feasibility | Heat of Hydration (J/g) | Early and Late Age Strength | Curing Can Be Performed in Non-Controlled Conditions |

| OPC clinker | 535 [92] | 270 [92] | 805 | Yes | Challenging | 250–350 [34] | Both competitive | Yes |

| Belite-rich clinker | 512 [14] | 251 [47,92] | 763 | Yes | Challenging | 175–250 [93] | Long-time strength is competitive [39] | Yes |

| Calcium sulfoaluminate (CSA) clinker | 305 [92] | 245 [92] | 550 | No | Challenging | 130 [94] | Both competitive [45] | Yes |

| Belite-ye’elimite-ferrite (BYF) clinker | 362 [14] | 208 [95] | 570 | No | Challenging | 523 [96] | Competitive at early ages but not at long ages [97] | Yes |

| Celitement® clinker | 231 [56] | 252 [56] | May go from 231 to 483 | Yes * | Accessible | 120–150 [55] | Both competitive [55] | No |

| Solidia® clinker (crystalline CS) | 375 [52] | 190 [52] | 565 | Yes | Challenging | 150 [53] | Both competitive [52] | No |

| X-Clinker (amorphous CS) | 340 [98] | 247 [92,98] | May go from 377 to 624 | Yes | Accessible | 125 [28] | Both competitive ** [28] | Yes ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antunes, M.; Santos, R.L.; Pereira, J.; Rocha, P.; Horta, R.B.; Colaço, R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials 2022, 15, 209. https://doi.org/10.3390/ma15010209

Antunes M, Santos RL, Pereira J, Rocha P, Horta RB, Colaço R. Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials. 2022; 15(1):209. https://doi.org/10.3390/ma15010209

Chicago/Turabian StyleAntunes, Mónica, Rodrigo Lino Santos, João Pereira, Paulo Rocha, Ricardo Bayão Horta, and Rogério Colaço. 2022. "Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review" Materials 15, no. 1: 209. https://doi.org/10.3390/ma15010209

APA StyleAntunes, M., Santos, R. L., Pereira, J., Rocha, P., Horta, R. B., & Colaço, R. (2022). Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review. Materials, 15(1), 209. https://doi.org/10.3390/ma15010209