Assessment of the Corrosion Behavior of Friction-Stir-Welded Dissimilar Aluminum Alloys

Abstract

:1. Introduction

2. Methods and Materials

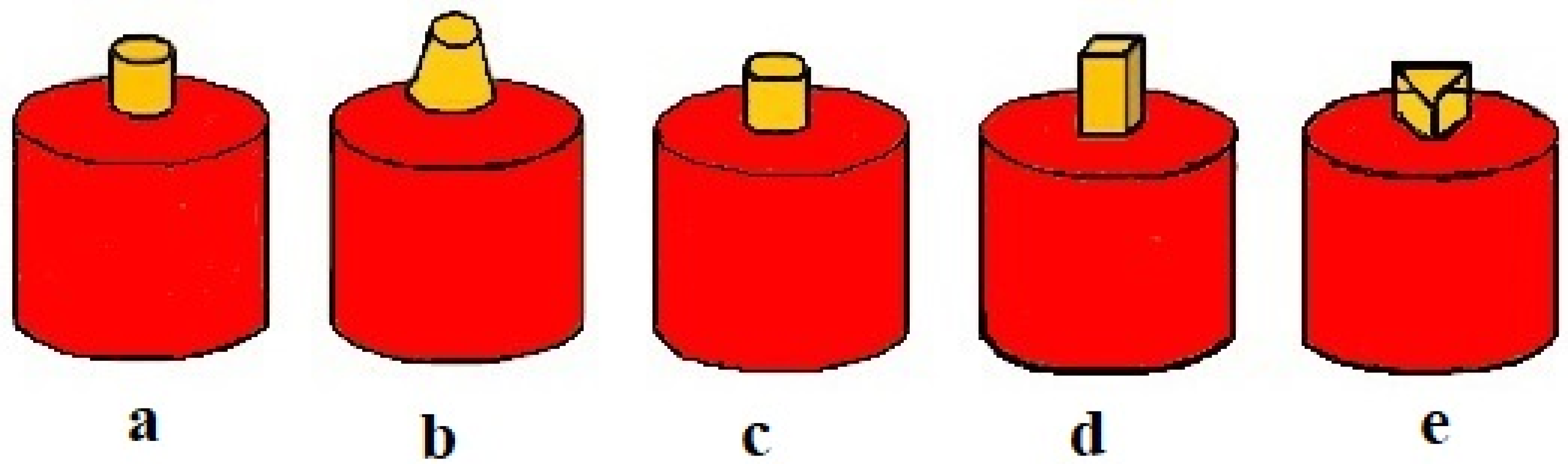

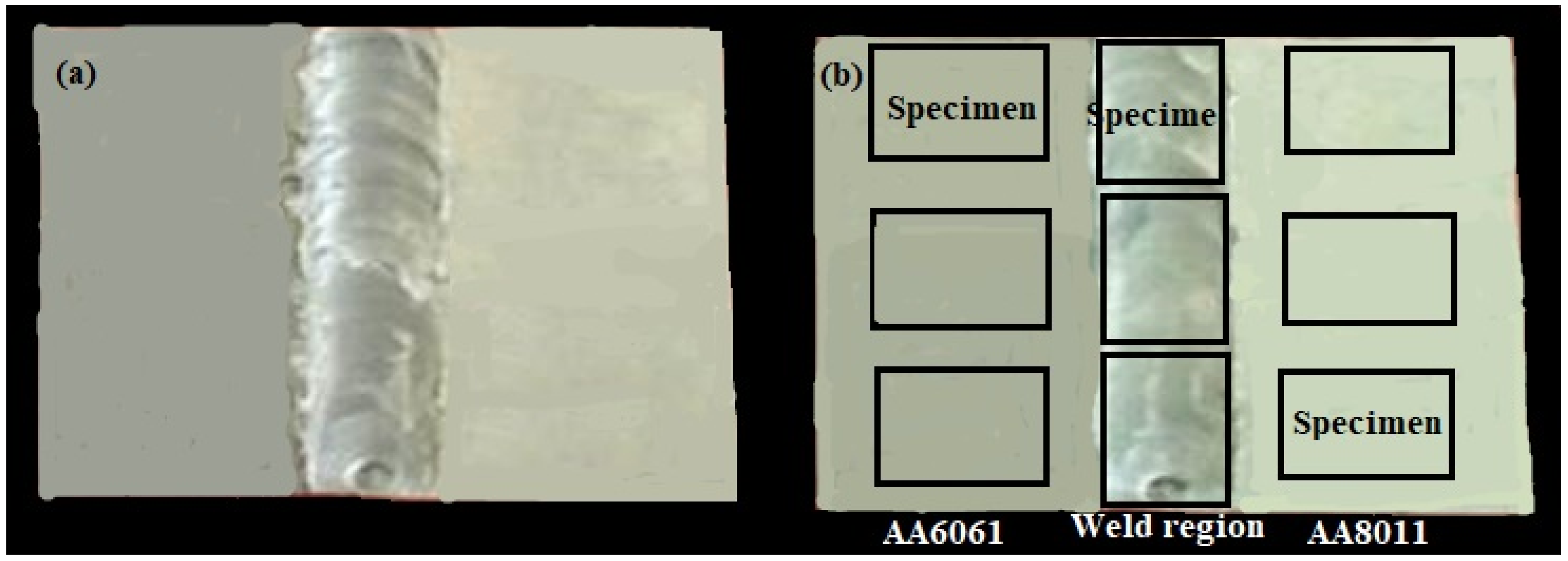

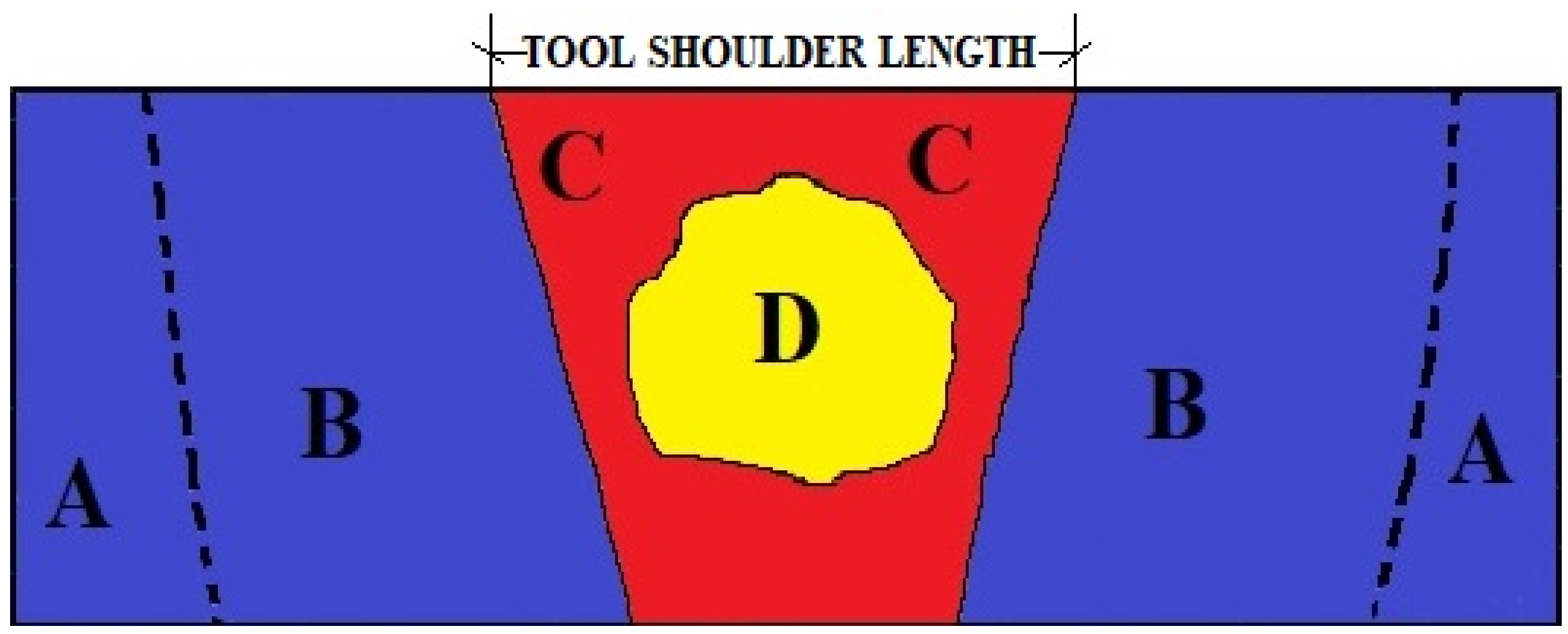

2.1. Friction Stir Welding (FSW) Process

2.2. Corrosion Analysis Tests

2.2.1. Salt Spray Corrosion Test

2.2.2. Laboratory Submersion Test

3. Results and Discussion

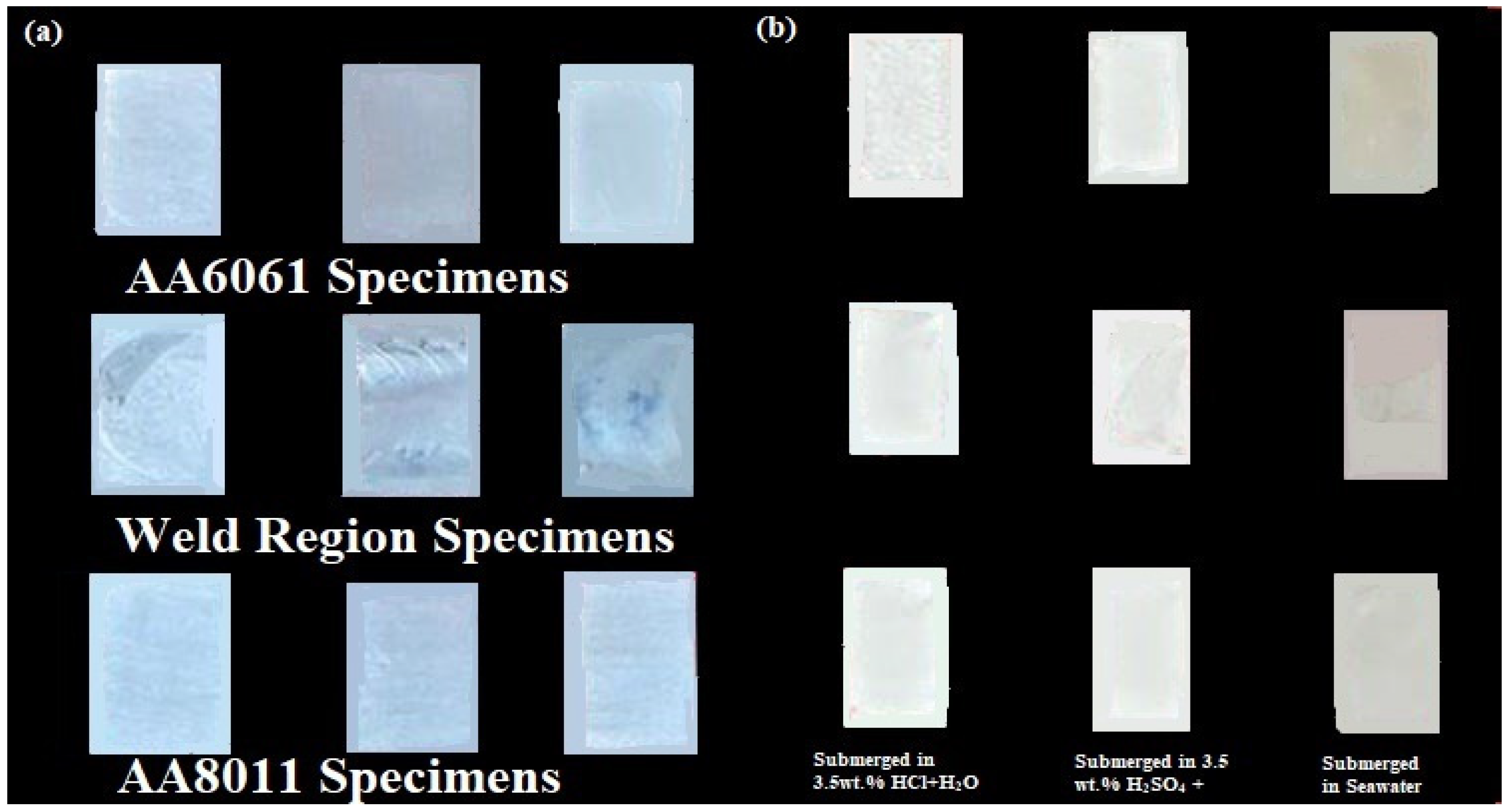

3.1. Salt Spraying Test Results

3.2. Submersion Test Results

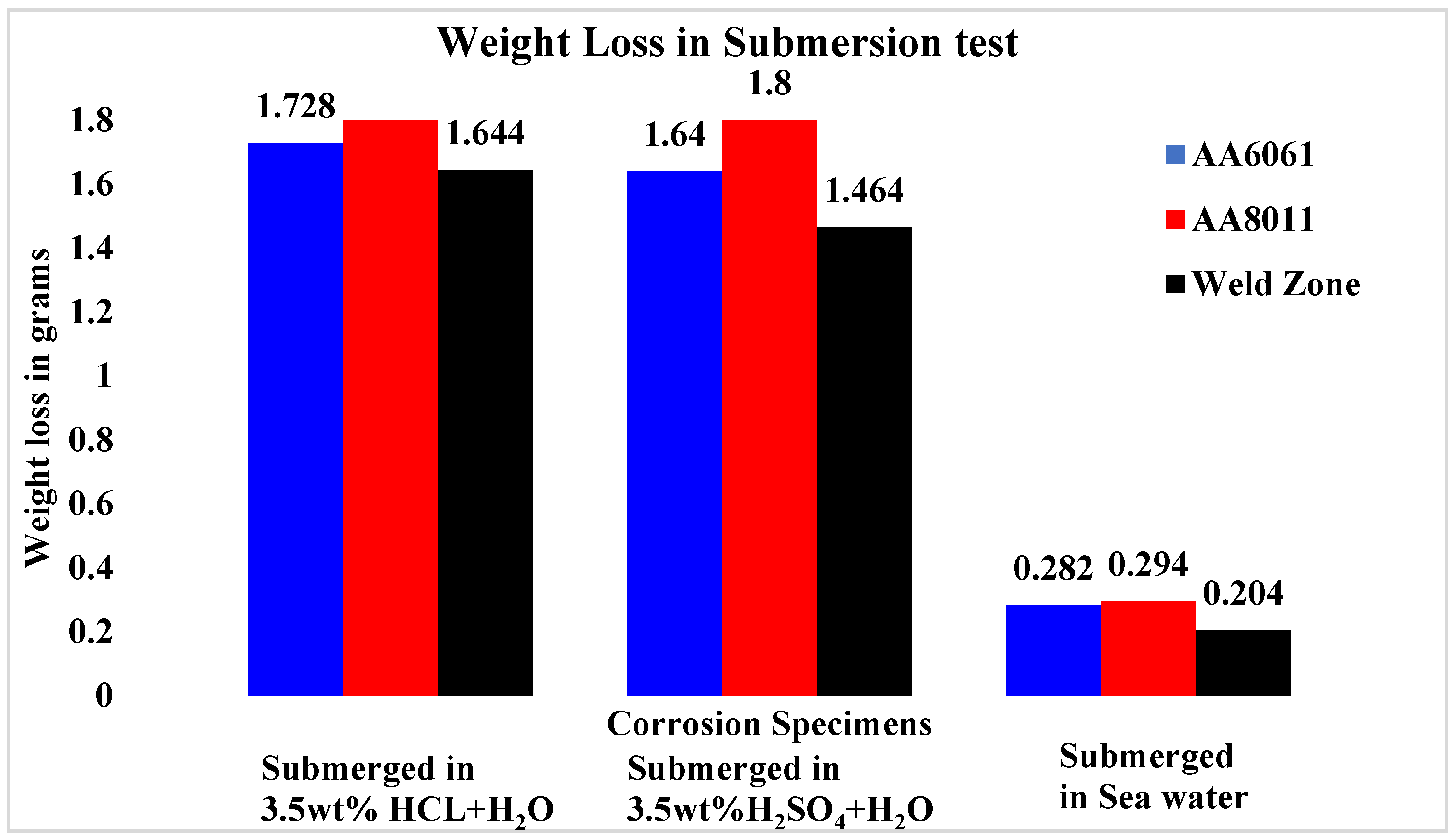

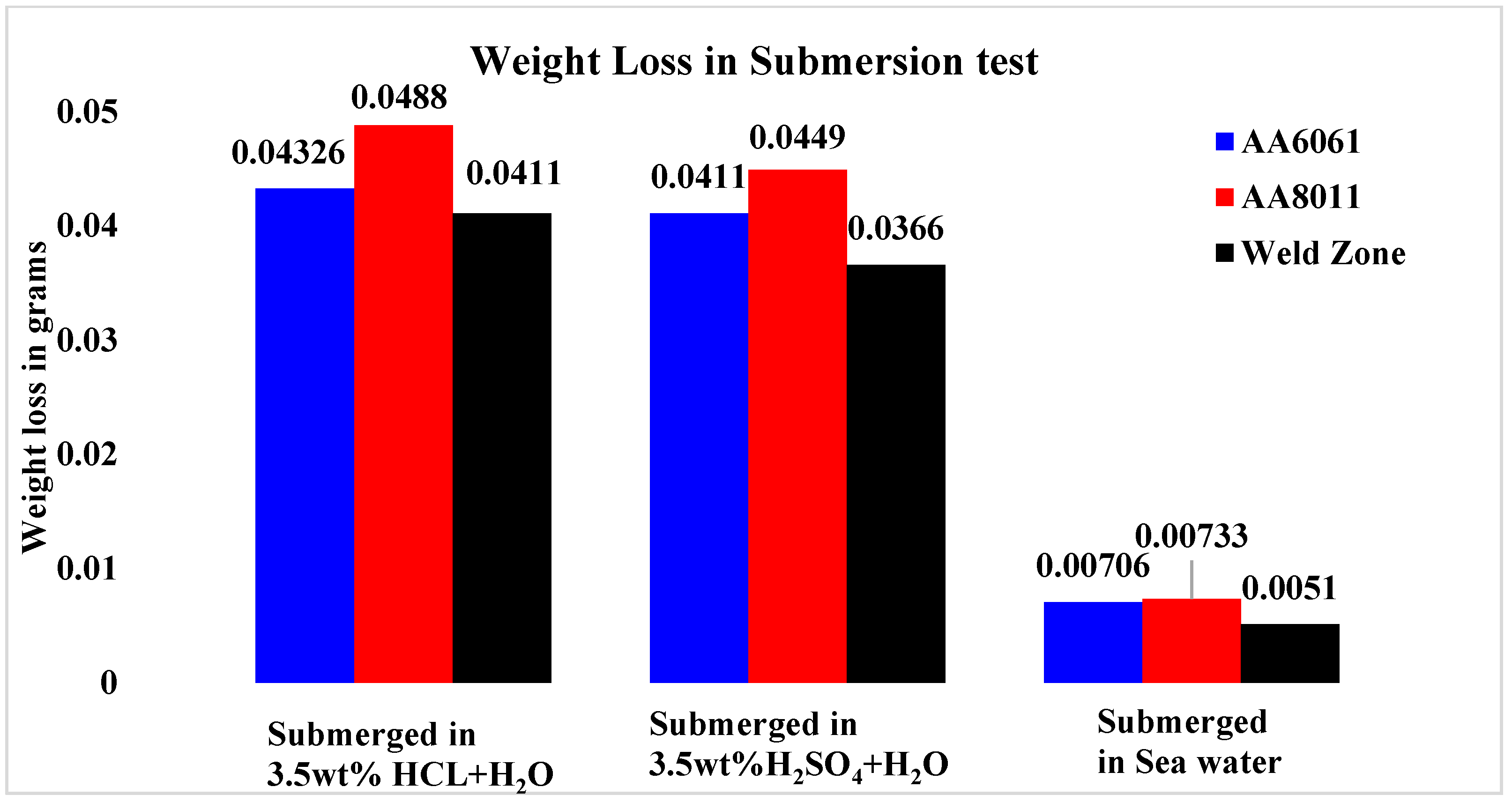

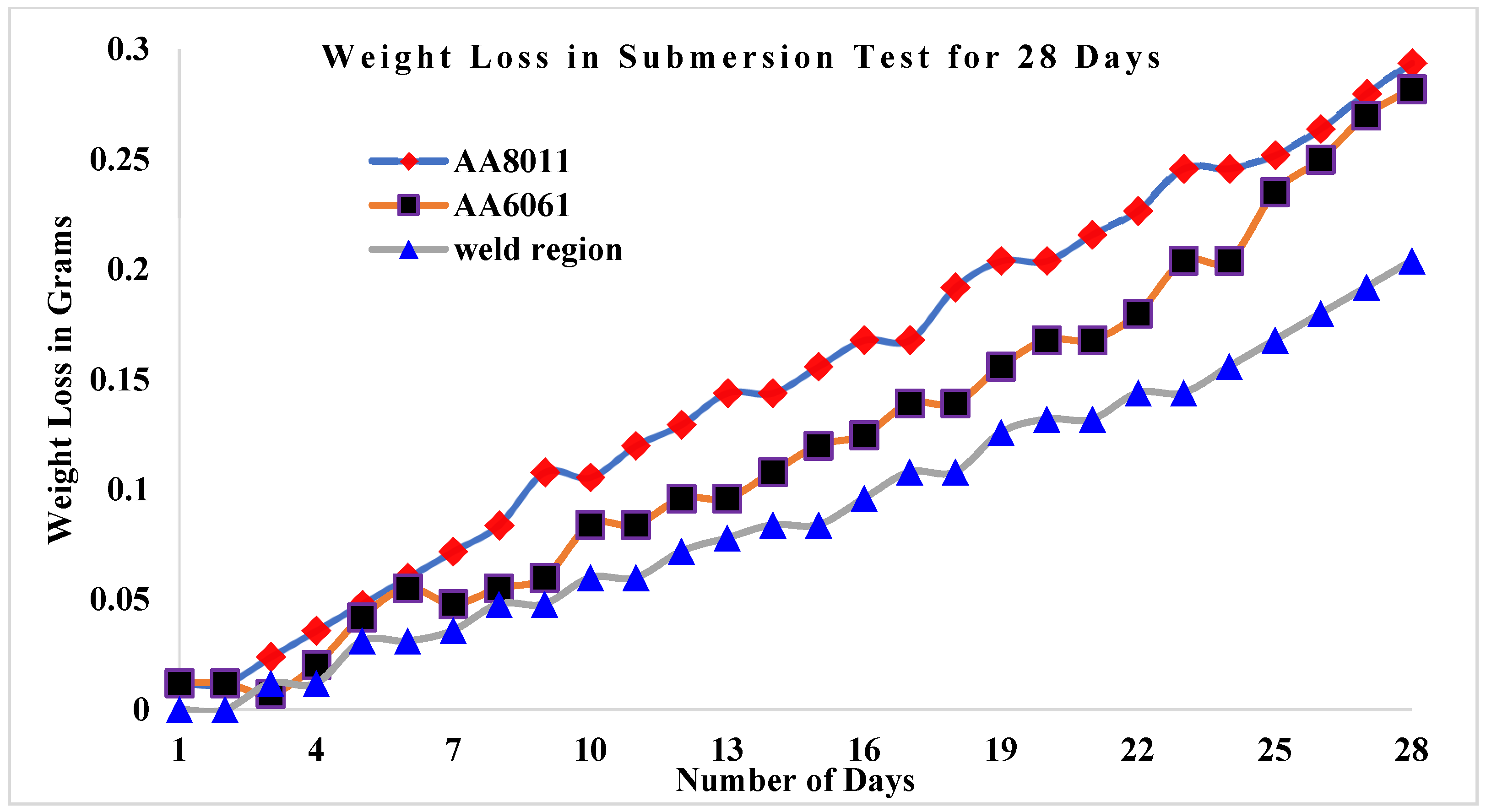

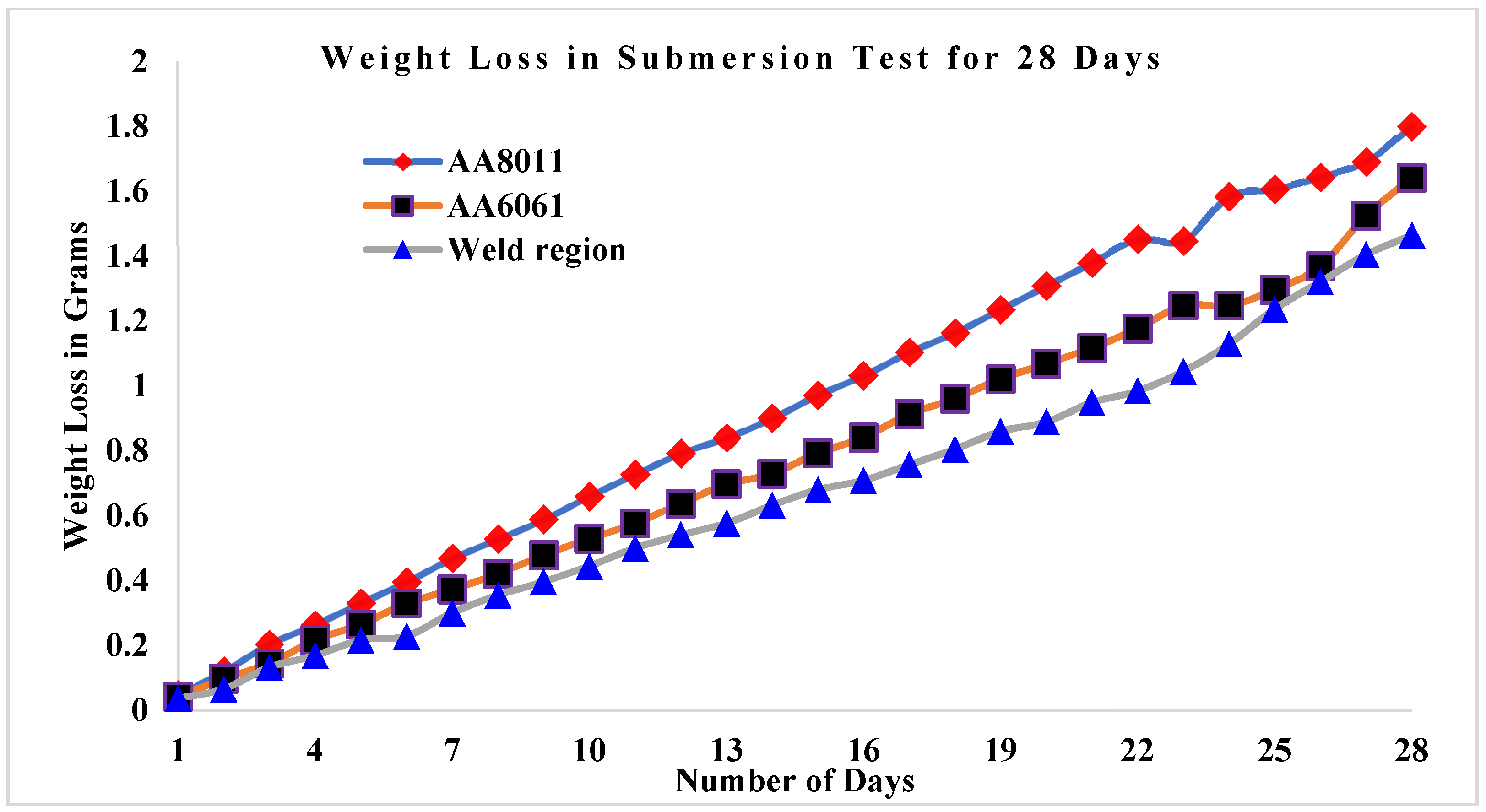

3.3. Weight Loss in Submersion Test

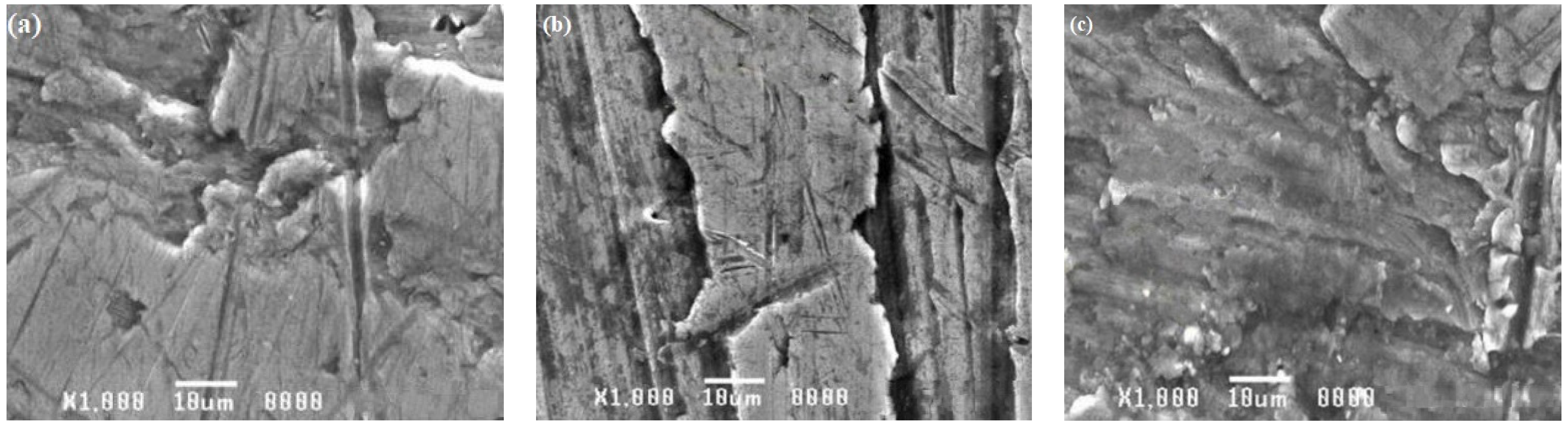

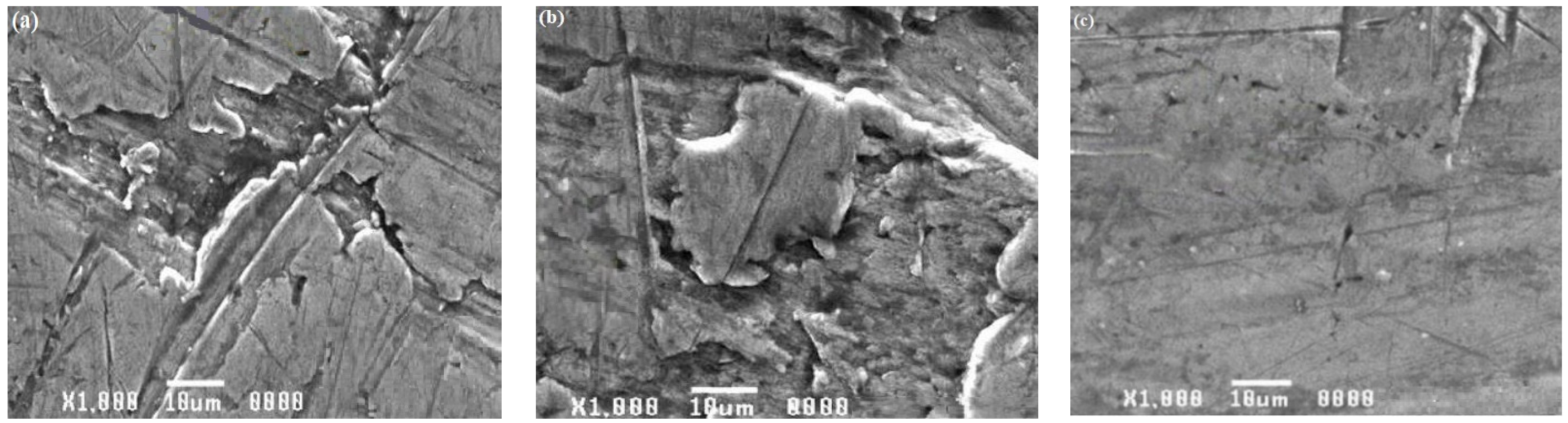

3.4. Microstructure Analysis by SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Wang, H.; Li, H.; Wang, X.; Ding, H.; Zhao, J.; Zhang, F. Investigation into the dissimilar friction stir welding of AA5052 and AA6061 aluminum alloys using pin-eccentric stir tool. Metals 2019, 9, 718. [Google Scholar] [CrossRef] [Green Version]

- Cole, E.; Fehrenbacher, A.; Duffie, N.; Zinn, M.; Pfefferkorn, F.; Ferrier, N. Weld temperature effects during friction stir welding of dissimilar aluminum alloys 6061-t6 and 7075-t6. Int. J. Adv. Manuf. Technol. 2014, 71, 643–652. [Google Scholar] [CrossRef]

- DebRoy, T.; Bhadeshia, H. Friction stir welding of dissimilar alloys—A perspective. Sci. Technol. Weld. Join. 2010, 15, 266–270. [Google Scholar] [CrossRef]

- Jonckheere, C.; de Meester, B.; Denquin, A.; Simar, A. Dissimilar friction stir welding of 2014 to 6061 aluminum alloys. In Proceedings of Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; pp. 269–274. [Google Scholar]

- Kumbhar, N.; Bhanumurthy, K. Friction stir welding of Al 5052 with Al 6061 alloys. J. Metall. 2012, 2012, 303756. [Google Scholar] [CrossRef] [Green Version]

- Akbari, M.; Aliha, M.R.; Keshavarz, S.M.; Bonyadi, A. Effect of tool parameters on mechanical properties, temperature, and force generation during FSW. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1033–1043. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Krishna, K.; Rajasekaran, T.; Siranjeevi, S. Investigations on friction stir welding of AA5083-H32 marine grade aluminium alloy by the effect of varying the process parameters. In Proceedings of IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012187. [Google Scholar]

- Kopyściański, M.; Węglowska, A.; Pietras, A.; Hamilton, C.; Dymek, S. Friction stir welding of dissimilar aluminum alloys. In Key Engineering Materials; Trans Tech Publ.: Stafa-Zurich, Switzerland, 2016. [Google Scholar]

- Khanna, N.; Sharma, P.; Bharati, M.; Badheka, V.J. Friction stir welding of dissimilar aluminium alloys AA 6061-T6 and AA 8011-h14: A novel study. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 7. [Google Scholar] [CrossRef]

- Abd El-Hafez, H.; El-Megharbel, A. Friction stir welding of dissimilar aluminum alloys. World J. Eng. Technol. 2018, 6, 408. [Google Scholar] [CrossRef] [Green Version]

- Koilraj, M.; Sathesh Kumar, A.; Belgin Paul, D.L.; Koteswara Rao, S.R. Mechanical properties and corrosion resistance of Friction Stir Welded dissimilar aluminum alloys 2219 to 5083. In Applied Mechanics and Materials; Trans Tech Publ.: Stafa-Zurich, Switzerland, 2015. [Google Scholar]

- Mallieswaran, K.; Padmanabhan, R.; Balasubramanian, V. Friction stir welding parameters optimization for tailored welded blank sheets of AA1100 with AA6061 dissimilar alloy using response surface methodology. Adv. Mater. Processing Technol. 2018, 4, 142–157. [Google Scholar] [CrossRef]

- Rao, T.; PV, R.R.; Venu, P.; Prince, G. Optimization of friction stir welding parameters during welding dissimilar aluminum alloys. Int. J. Mech. Eng. Technol. 2018, 9, 333–340. [Google Scholar]

- Shukla, S.; Shukla, H. Optimization of Process Parameters for Friction Stir Welding of Dissimilar Aluminium Alloy AA6061 to AA5183 using TOPSIS Technique. Int. J. Innov. Technol. Explor. Eng. 2019, 8. [Google Scholar] [CrossRef]

- Ahmadnia, M.; Shahraki, S.; Kamarposhti, M.A. Experimental studies on optimized mechanical properties while dissimilar joining AA6061 and AA5010 in a friction stir welding process. Int. J. Adv. Manuf. Technol. 2016, 87, 2337–2352. [Google Scholar] [CrossRef]

- Davoodi, A.; Esfahani, Z.; Sarvghad, M. Microstructure and corrosion characterization of the interfacial region in dissimilar friction stir welded AA5083 to AA7023. Corros. Sci. 2016, 107, 133–144. [Google Scholar] [CrossRef]

- Seo, B.; Song, K.H.; Park, K. Corrosion properties of dissimilar friction stir welded 6061 aluminum and HT590 steel. Met. Mater. Int. 2018, 24, 1232–1240. [Google Scholar] [CrossRef]

- Fahimpour, V.; Sadrnezhaad, S.; Karimzadeh, F. Corrosion behavior of aluminum 6061 alloy joined by friction stir welding and gas tungsten arc welding methods. Mater. Des. 2012, 39, 329–333. [Google Scholar] [CrossRef]

- Wang, H.-f.; Wang, J.-l.; Song, W.-w.; Zuo, D.-w.; Shao, D.-l. Analysis on the Corrosion Performance of Friction Stir Welding Joint of 7022 Aluminum Alloy. Int. J. Electrochem. Sci 2016, 11, 6933–6942. [Google Scholar] [CrossRef]

- Ezuber, H.; El-Houd, A.; El-Shawesh, F. A study on the corrosion behavior of aluminum alloys in seawater. Mater. Des. 2008, 29, 801–805. [Google Scholar] [CrossRef]

- Halambek, J.; Bubalo, M.C.; Redovniković, I.R.; Berković, K. Corrosion behaviour of aluminium and AA5754 alloy in 1% acetic acid solution in presence of laurel oil. Int. J. Electrochem. Sci 2014, 9, 5496–5506. [Google Scholar]

- Li, N.; Li, W.; Yang, X.; Alexopoulos, N. Corrosion performance and mechanical properties of friction stir welded AA2024-T3 joints under different corrosion solution exposure. Mater. Corros. 2017, 68, 970–976. [Google Scholar] [CrossRef]

- Amini, K.; Gharavi, F. Influence of welding speed on corrosion behaviour of friction stir welded AA5086 aluminium alloy. J. Cent. South Univ. 2016, 23, 1301–1311. [Google Scholar] [CrossRef]

- Pruthviraj, R. Corrosion Studies of AA2024 in Sea Water using Sodium Benzoate as an Inhibitor. J. Mater. Sci. Eng. 2016, 5, 2169-0022. [Google Scholar]

- Ratna Sunil, B.; Pradeep Kumar Reddy, G. Corrosion behavior of friction stir welded AZ31B Mg alloy-Al6063 alloy joint. Cogent Eng. 2016, 3, 1145565. [Google Scholar] [CrossRef]

- Seetharaman, R.; Ravisankar, V.; Balasubramanian, V. Corrosion performance of friction stir welded AA2024 aluminium alloy under salt fog conditions. Trans. Nonferrous Met. Soc. China 2015, 25, 1427–1438. [Google Scholar] [CrossRef]

- Rodriguez, R.; Jordon, J.; Allison, P.; Rushing, T.; Garcia, L. Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys. Mater. Des. 2015, 83, 60–65. [Google Scholar] [CrossRef]

- Mahto, R.P.; Anishetty, S.; Sarkar, A.; Mypati, O.; Pal, S.K.; Majumdar, J.D. Interfacial microstructural and corrosion characterizations of friction stir welded AA6061-T6 and AISI304 materials. Met. Mater. Int. 2019, 25, 752–767. [Google Scholar] [CrossRef]

- Zheng, Y.; Pan, X.; Ma, Y.; Liu, S.; Zang, L.; Chen, Y. Microstructure and corrosion behavior of friction stir-welded 6061 Al/AZ31 Mg joints with a Zr interlayer. Materials 2019, 12, 1115. [Google Scholar] [CrossRef] [Green Version]

- Palanivel, R.; Mathews, P.K.; Murugan, N. Optimization of process parameters to maximize ultimate tensile strength of friction stir welded dissimilar aluminum alloys using response surface methodology. J. Cent. South Univ. 2013, 20, 2929–2938. [Google Scholar] [CrossRef]

- Yunus, M.; Alsoufi, M.S. Mathematical modelling of a friction stir welding process to predict the joint strength of two dissimilar aluminium alloys using experimental data and genetic programming. Model. Simul. Eng. 2018, 2018, 4183816. [Google Scholar] [CrossRef]

- Alnaser, I.A.; Yunus, M.; Alfattani, R.; Alamro, T. High-Temperature Corrosion of APS-and HVOF-Coated Nickel-Based Super Alloy under Air Oxidation and Melted Salt Domains. Materials 2021, 14, 5119. [Google Scholar] [CrossRef]

| Material | Mg | Mn | Cu | Fe | Si | Cr | Zn | Ti | Al | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HRB) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AA6061 | 0.84 | 0.40 | 0.24 | 0.70 | 0.54 | 0.25 | 0.20 | 0.10 | Remaining | 310 | 276 | 60 |

| AA8011 | 0.27 | 0.45 | 0.12 | 0.74 | 0.52 | 0.02 | 0.08 | 0.01 | Remaining | 110 | 87 | 50 |

| S. No | FSW Parameter | Value |

|---|---|---|

| 1. | Rotating speed of tool | 1100 rpm |

| 2. | Welding rate | 50 mm/min |

| 3. | Axial force | 3.5 kN |

| 4. | Tool tilt angle | 2° |

| S. No | Test Parameter | Value |

|---|---|---|

| 1. | Test solution | 5 wt.% NaCl |

| 2. | Chamber temperature | 34 °C |

| 3. | pH of salt solution | 6.8 |

| 4. | Collection of solution per hour | 1.1 mL |

| 5. | Air pressure | 15 Psi |

| 6. | Exposure period | 60 h |

| No | Solution | pH Value | Temperature (°C) | Submersion Time (Days/hours) |

|---|---|---|---|---|

| 1 | 3.5 wt% HCl + H2O | 3.08 | 32 | 28/672 |

| 2 | 3.5 wt% H2SO4 + H2O | 3.51 | ||

| 3 | Seawater | 7.52 |

| Specimen | Solution | Weight of the Specimen before Submersion (g) Wb | Weight of the Specimen after Submersion (g) Wa | Weight Loss (g) ΔW | Corrosion Rate (mm/yr) Cr |

|---|---|---|---|---|---|

| AA6061 | 5 wt% NaCl | 11.5 | 11.6474 | 0.1476 | 0.00324 |

| AA8011 | 11.51 | 11.75 | 0.24 | 0.00516 | |

| Weld Zone | 11.42 | 11.5312 | 0.1212 | 0.00264 |

| Specimen | Solution | Weight of the Specimen before Submersion (g) Wb | Weight of the Specimen after Submersion (g) Wa | Weight Loss (g) ΔW | Corrosion Rate (mm/yr) Cr |

|---|---|---|---|---|---|

| AA6061 | 3.5 wt% HCl + H2O | 11.5 | 9.772 | 1.728 | 0.04326 |

| AA8011 | 3.5 wt% HCl + H2O | 11.51 | 9.554 | 1.956 | 0.0488 |

| Weld Zone | 3.5 wt% HCl + H2O | 11.42 | 9.776 | 1.644 | 0.0411 |

| AA6061 | 3.5 wt% H2SO4 + H2O | 11.5 | 9.86 | 1.64 | 0.0411 |

| AA8011 | 3.5 wt% H2SO4 + H2O | 11.51 | 9.71 | 1.8 | 0.0449 |

| Weld Zone | 3.5 wt% H2SO4 + H2O | 11.42 | 9.956 | 1.464 | 0.0366 |

| AA6061 | Seawater | 11.5 | 11.218 | 0.282 | 0.00706 |

| AA8011 | Seawater | 11.51 | 11.216 | 0.294 | 0.00733 |

| Weld Zone | Seawater | 11.42 | 11.216 | 0.204 | 0.00510 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfattani, R.; Yunus, M.; Mohamed, A.F.; Alamro, T.; Hassan, M.K. Assessment of the Corrosion Behavior of Friction-Stir-Welded Dissimilar Aluminum Alloys. Materials 2022, 15, 260. https://doi.org/10.3390/ma15010260

Alfattani R, Yunus M, Mohamed AF, Alamro T, Hassan MK. Assessment of the Corrosion Behavior of Friction-Stir-Welded Dissimilar Aluminum Alloys. Materials. 2022; 15(1):260. https://doi.org/10.3390/ma15010260

Chicago/Turabian StyleAlfattani, Rami, Mohammed Yunus, Ahmed F. Mohamed, Turki Alamro, and Mohamed K. Hassan. 2022. "Assessment of the Corrosion Behavior of Friction-Stir-Welded Dissimilar Aluminum Alloys" Materials 15, no. 1: 260. https://doi.org/10.3390/ma15010260