Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material

Abstract

:1. Introduction

2. Materials

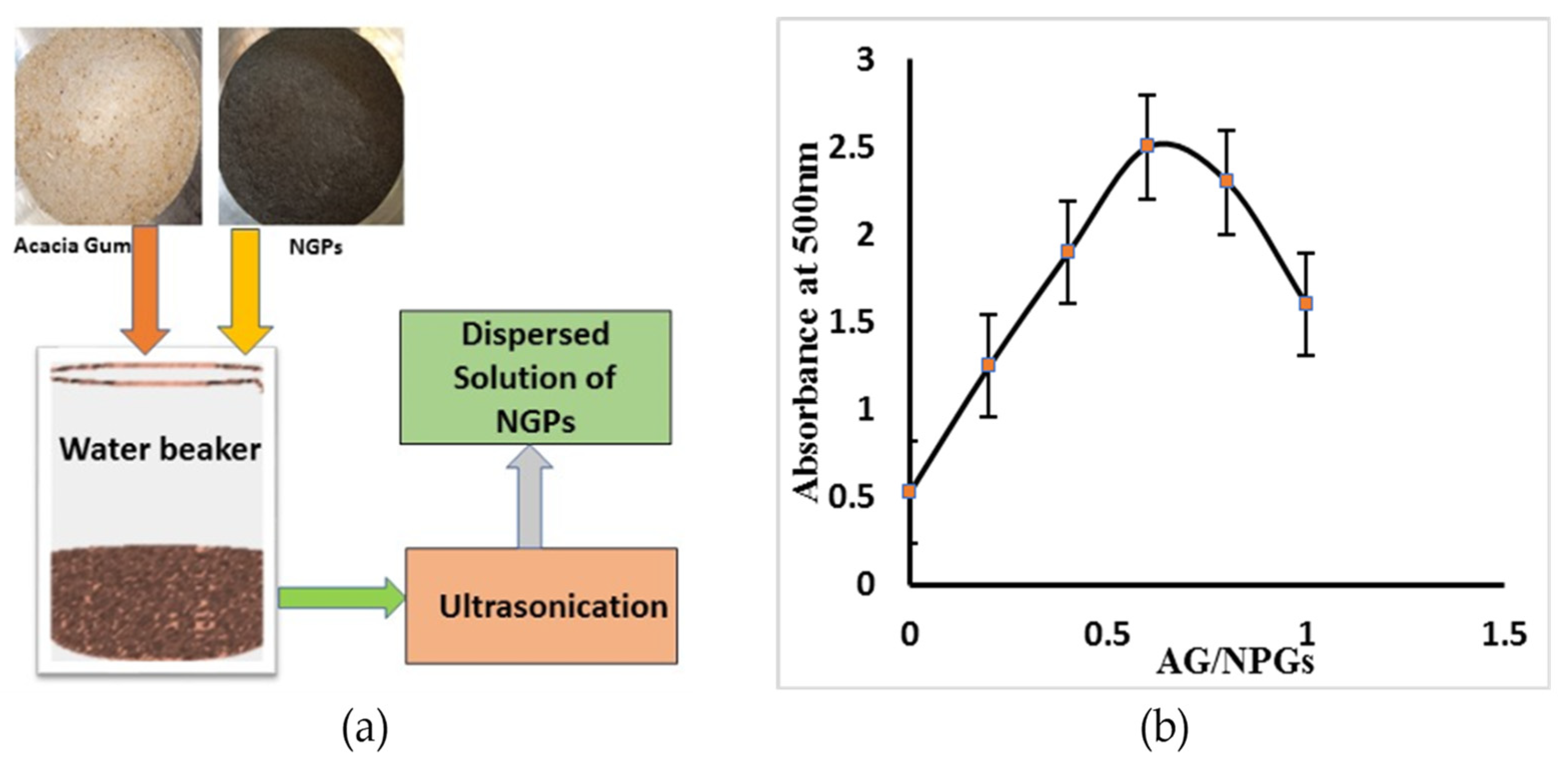

2.1. Dispersion Scheme of NGPs

2.2. Concrete Mix Proportions

2.3. Specimen Preparation

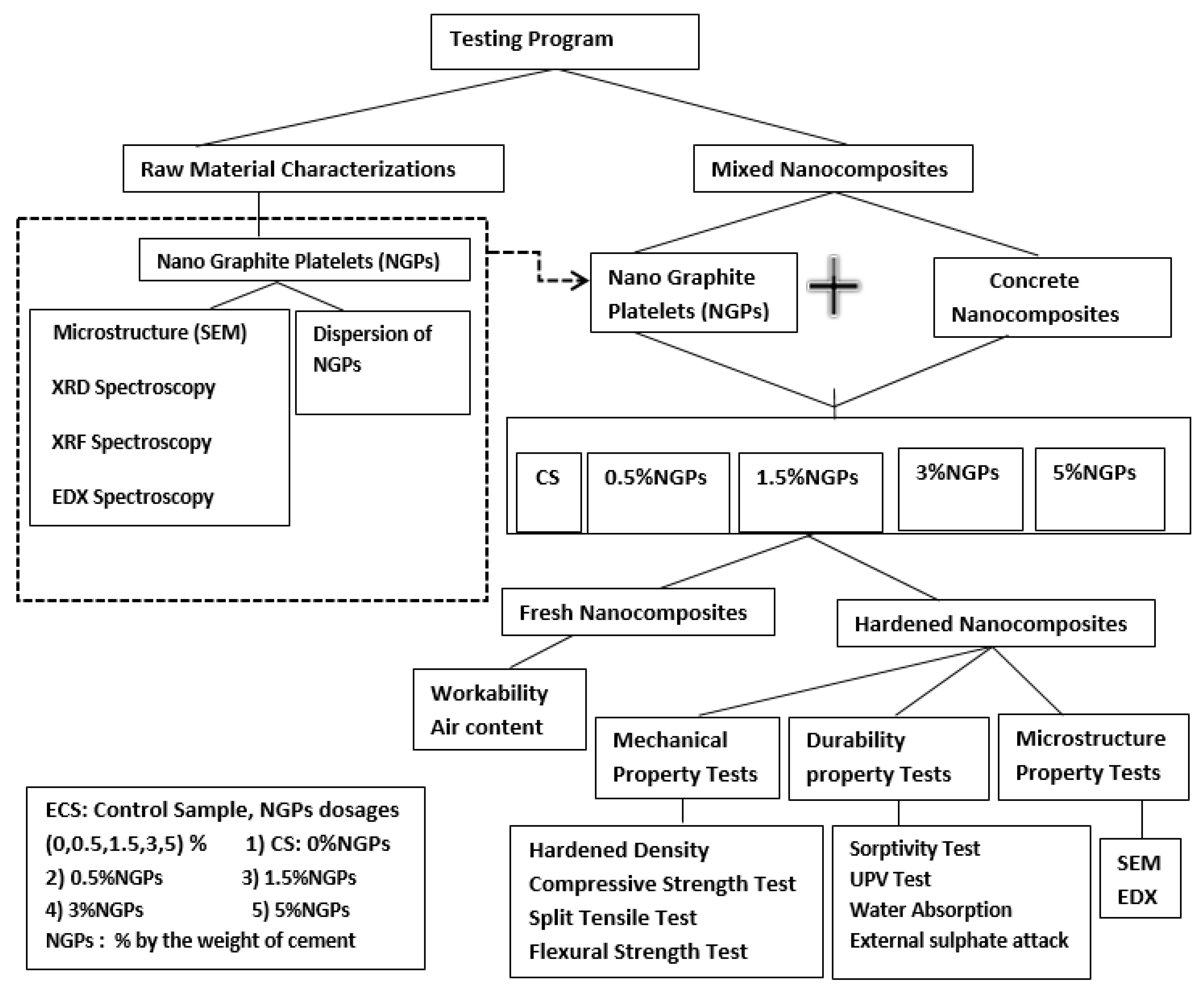

3. Experimental Methods

3.1. Fresh Concrete Properties

3.2. Hardened Concrete Properties/Mechanical Properties

3.3. Durability Properties

3.4. Microstructure Investigation

4. Results and Discussion

4.1. Structural Characterization of NGPs

4.2. Fresh Concrete Properties

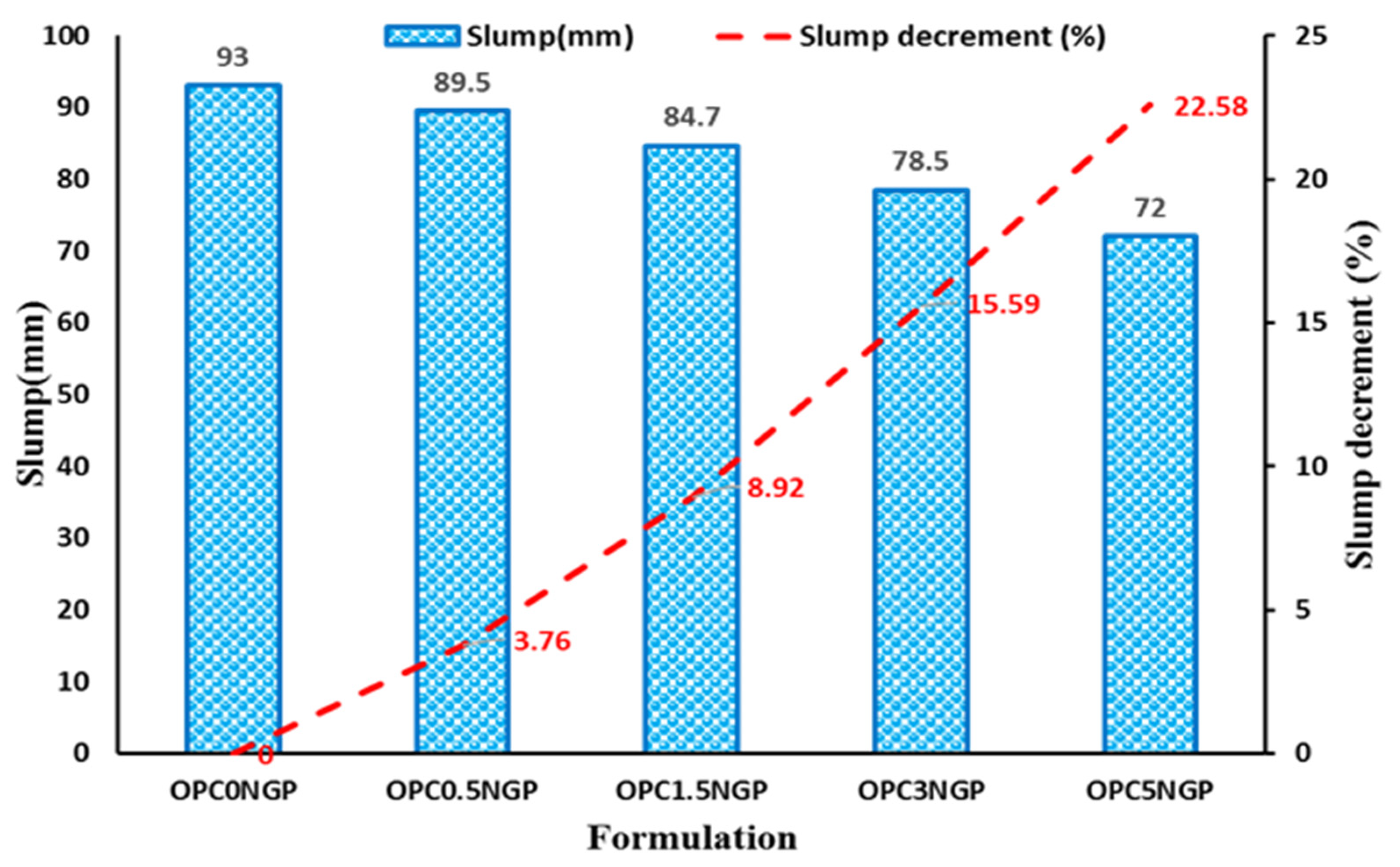

4.2.1. Workability

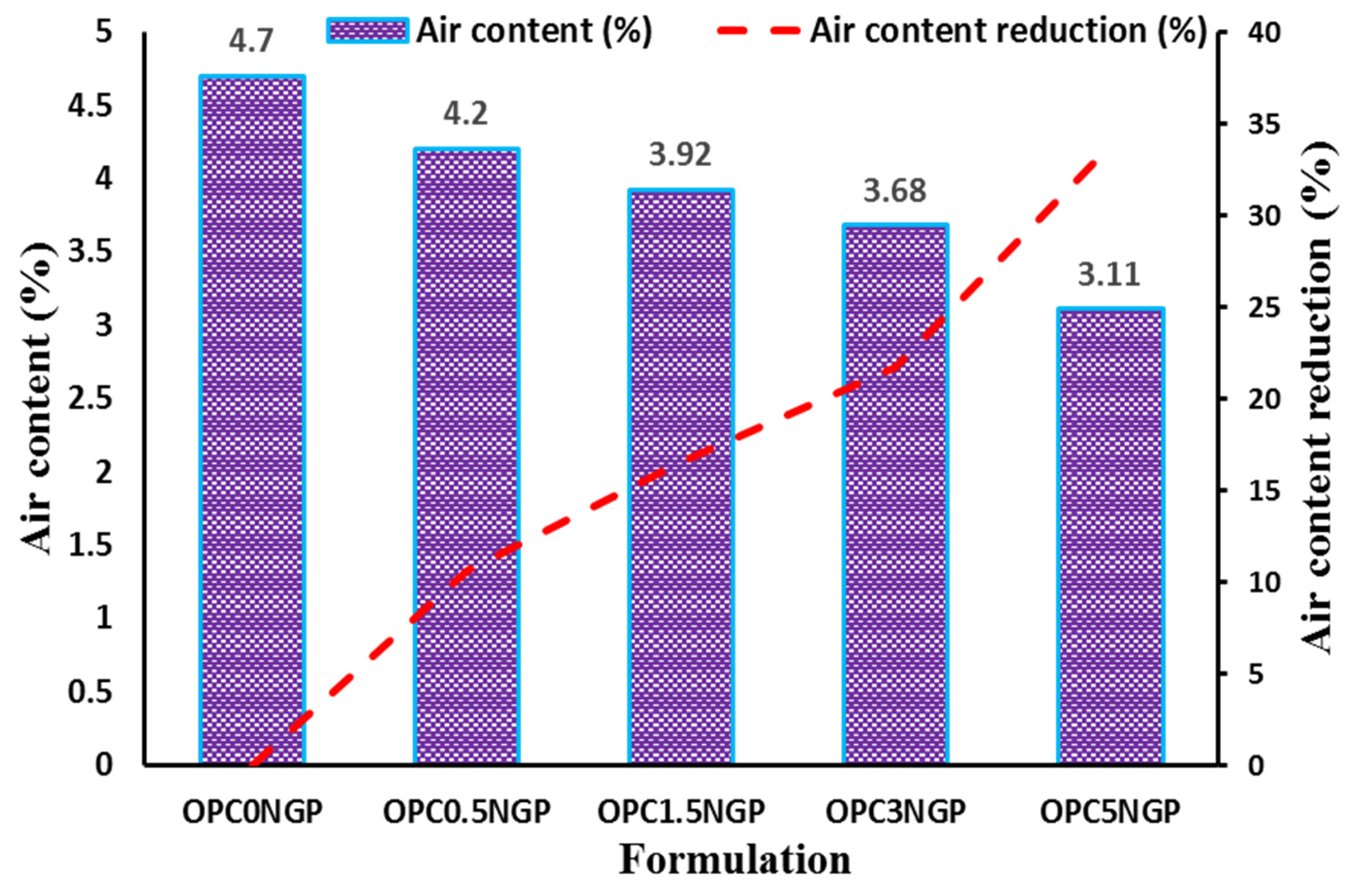

4.2.2. Air Content

4.3. Hardened Concrete Mechanical Properties

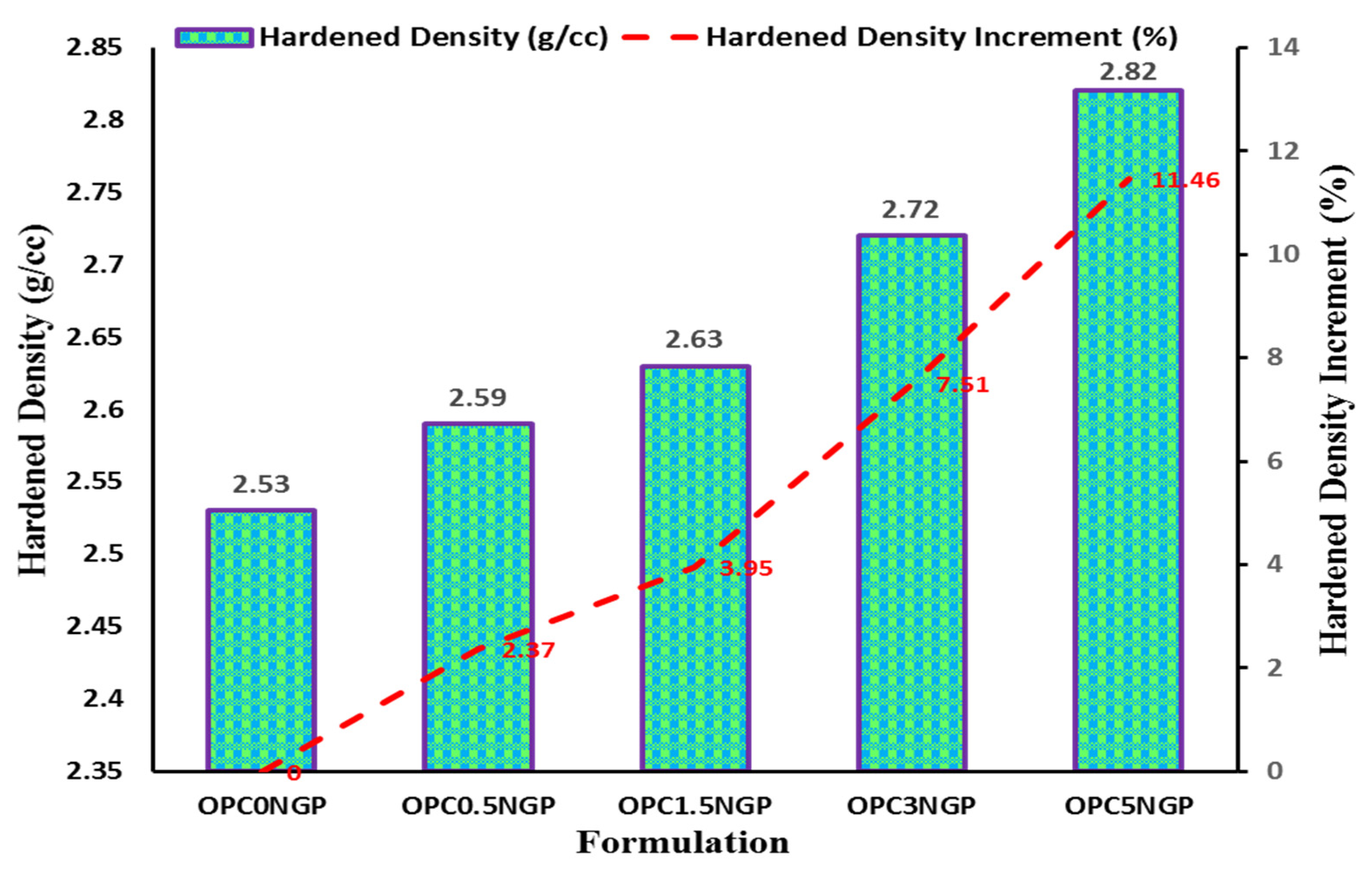

4.3.1. Hardened Density

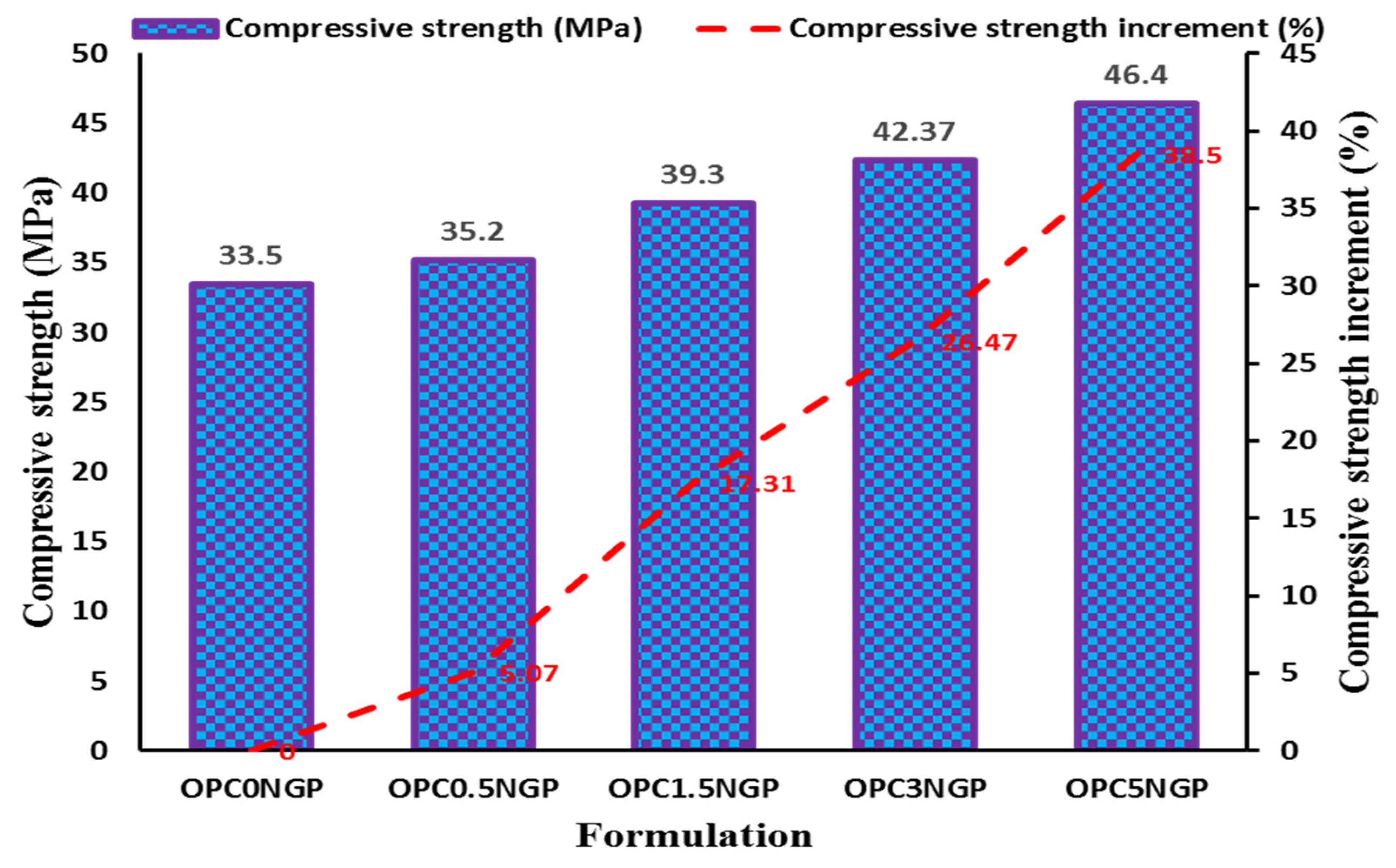

4.3.2. Compressive Strength

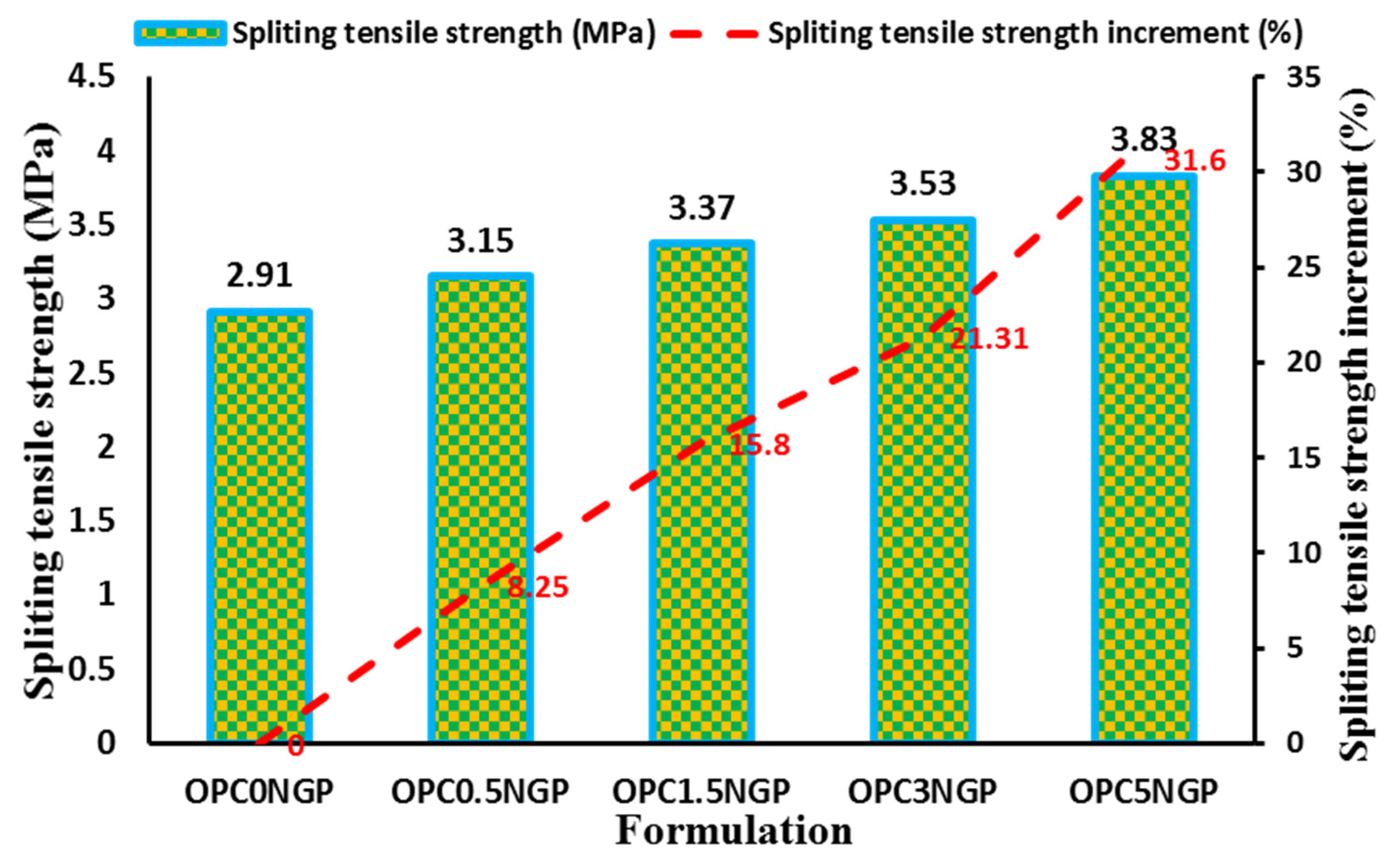

4.3.3. Split Tensile Strength

4.3.4. Flexural Strength

4.4. Durability Properties

4.4.1. Sorptivity

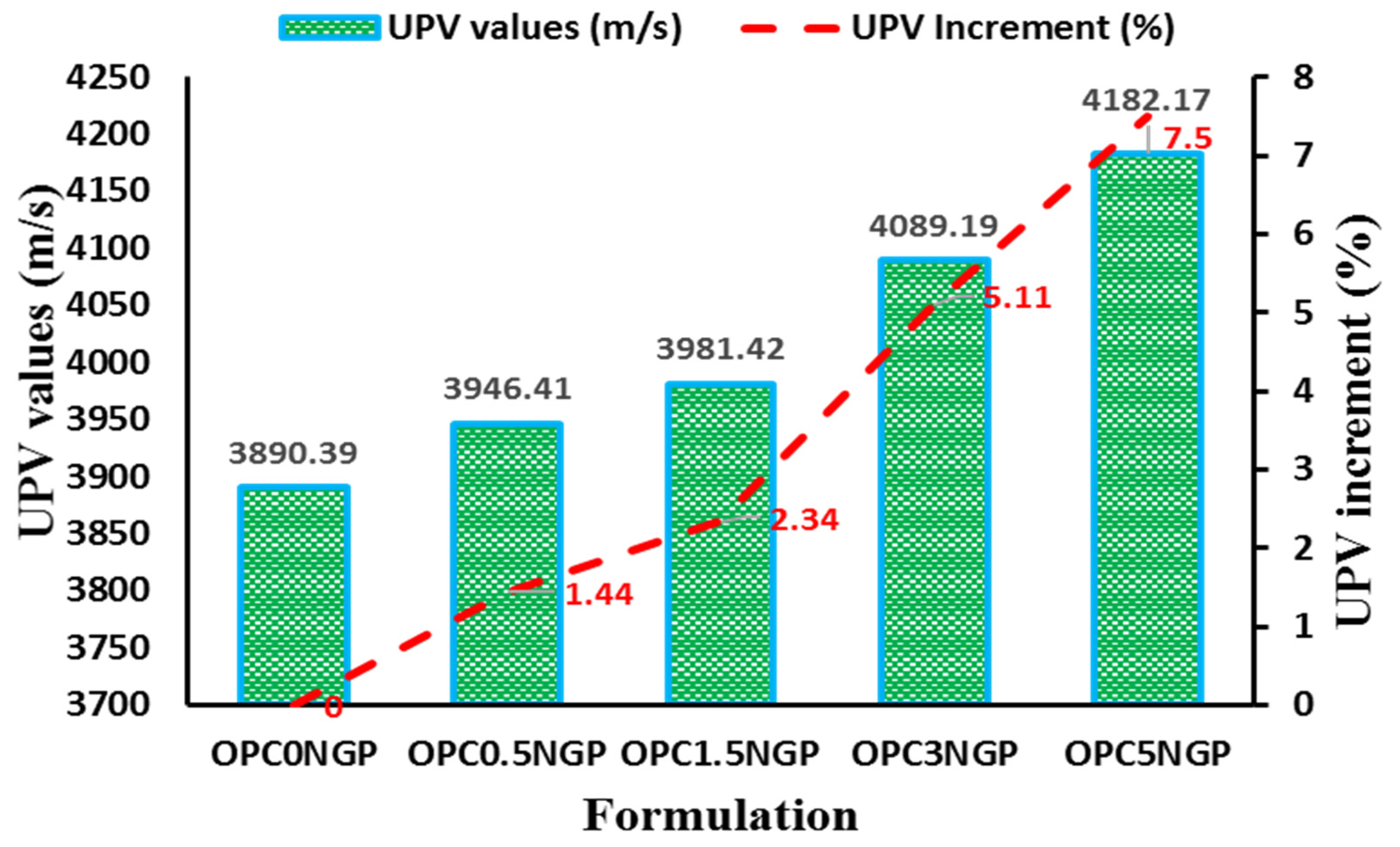

4.4.2. Ultrasonic Pulse Velocity (UPV)

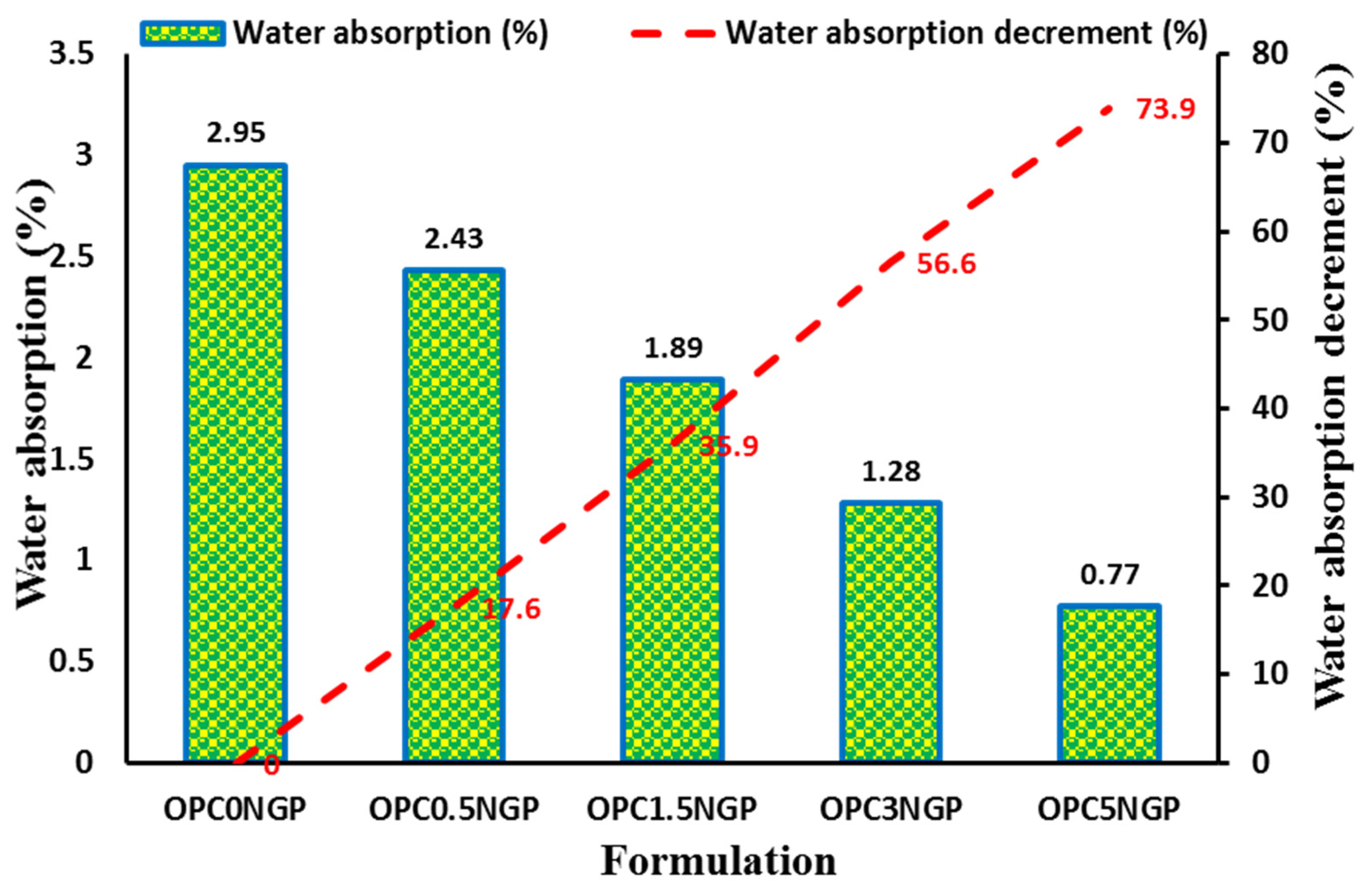

4.4.3. Water Absorption

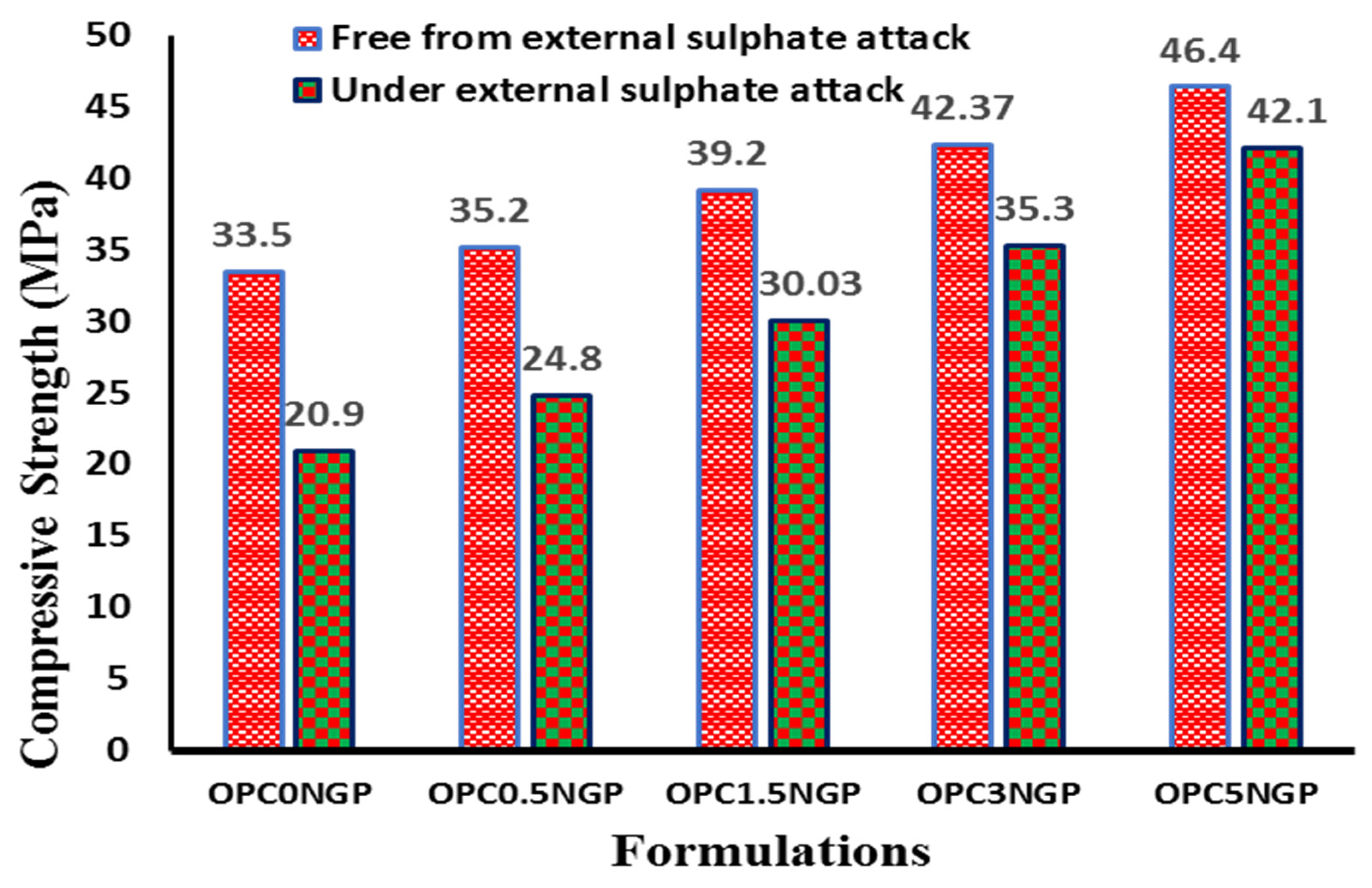

4.4.4. External Sulfate Attack

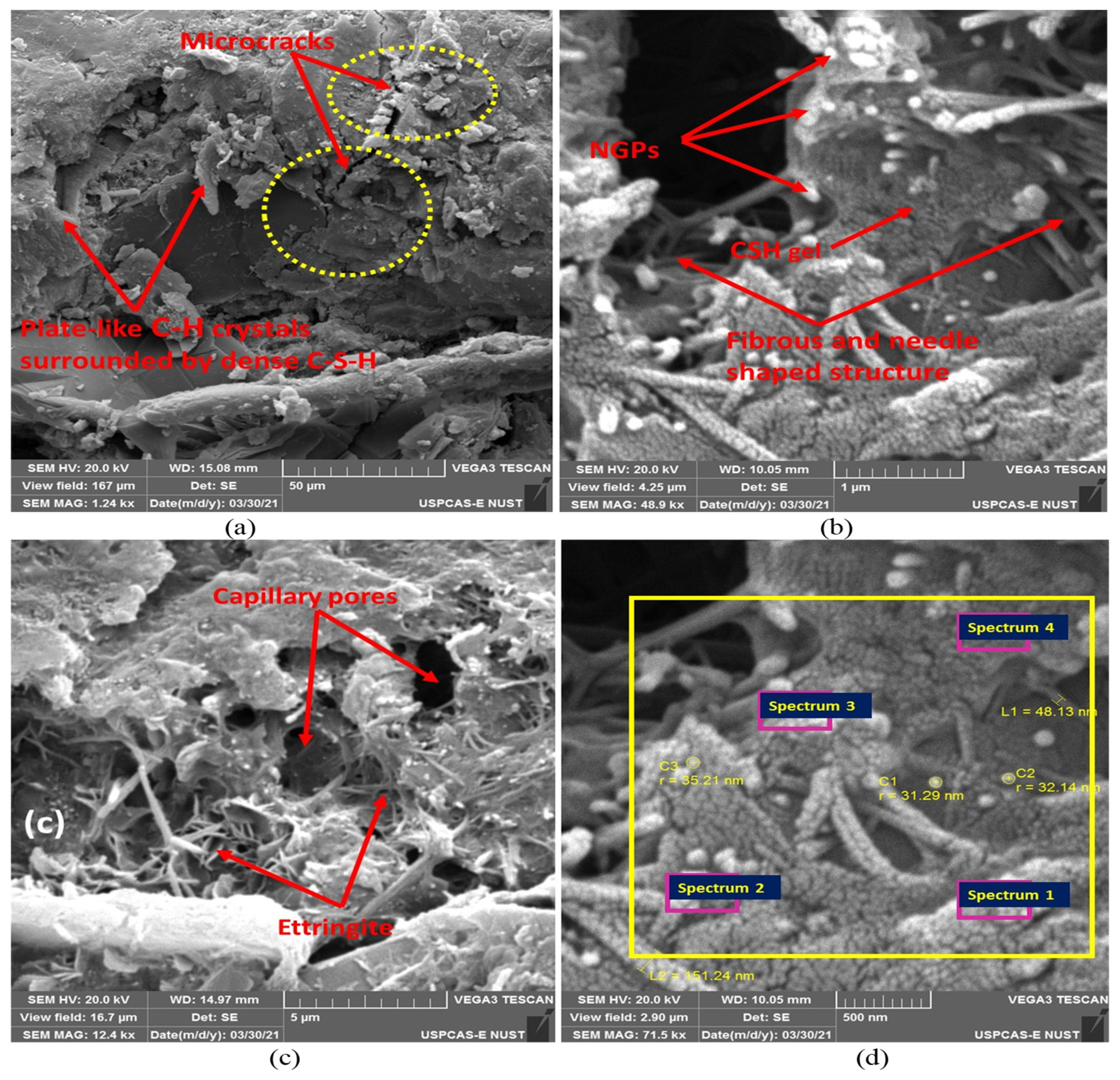

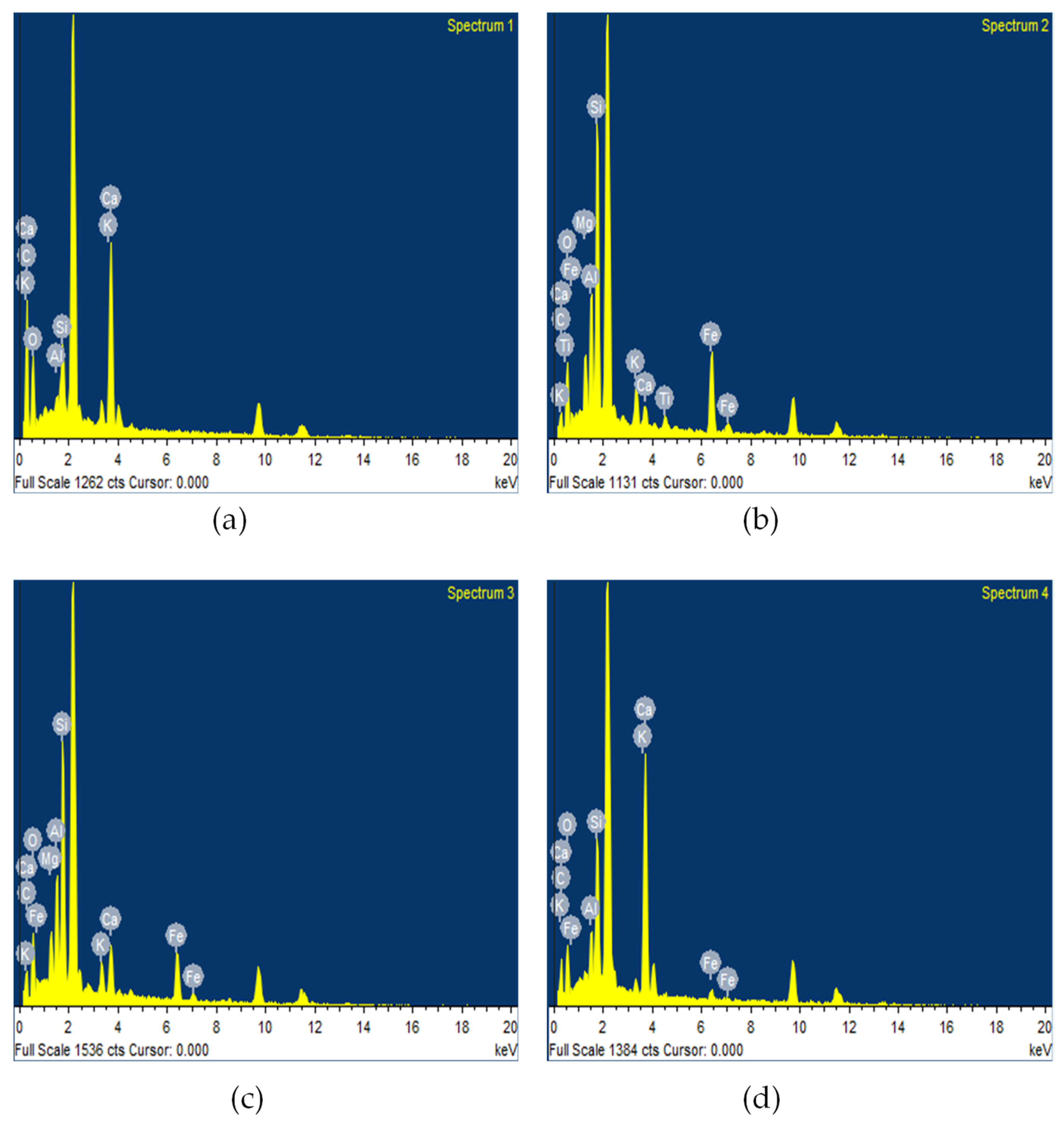

4.5. Microstructure Investigation Using SEM–EDX Analysis

5. Conclusions

- The workability of NGP-modified concrete decreased as compared to the control sample due to the fine particle size and large surface area of NGPs. The decreasing trend in workability was found with increasing NGP dosages. Moreover, a decrement in percentage air content was observed with increasing dosages of NGPs. The concrete mix with 5% NGPs indicated the maximum reduction in air content, about 33.83%, with reference to the control mix.

- The hardened density of concrete increased with the rise in dosages of NGPs. The maximum increase in density of about 11.46% was observed for the sample containing 5% NGPs, with reference to the control mix. The compressive and split tensile strength of the concrete also increased. Compressive and tensile strength values increased in the range of 5–38.5% and 8.25–31.6%, respectively. This is because of the intrusion of NGPs, which strengthened the concrete composites at the nano level; increasing the density and hardness of concrete make NGP a promising reinforcing agent in cementitious composites. In addition, the mix containing 5% NGP intrusion showed a maximum enhancement in flexural strength of 44.34%.

- The incorporation of NGPs significantly reduced the sorptivity value (32.3% reduction for 5% NGPs intrusion) due to its filler effect. The values of UPV also improved. The maximum increase in the UPV value was from 3890 m/s to 4182 m/s at 5% intrusion of NGPs.

- The addition of NGPs in concrete composites proved effective at reducing water absorption. The mix with 5% NGPs showed a 73.9% reduction in water absorption compared to the control mix.

- The current study focused on the physical and mechanical characteristics of NGP-incorporated concrete. The NGPs can potentially be used to achieve high-density concrete with improved performance for sustainability and nuclear infrastructure. It is strongly recommended to see the influence of NGPs in the freeze–thaw cycles, alkali–silica reaction, salt scaling, and carbonation; the optimum dosage levels of NGPs for future implementations; the effects of NGPs on drying shrinkage of cementitious composites; the influence of different water to cement (W/C) ratios on NGP-modified concrete composites; NGP-modified concrete at low and high W/C ratios; statistical analyses of NGP-incorporated concrete specimens to analyze the deviation from the experimental results.

- The paradigm shift in regression models using machine learning significantly contributes to solving engineering problems [67,68,69,70,71]. The current study investigated the effect of changing dosages of NGPs on the mechanical characteristics of concrete. To avoid the laborious testing, the data used in the manuscript, alongside other similar data from experiments or the literature, can potentially be used to develop multiple artificial intelligent models, according to previous literature [31,71,72,73,74,75,76,77].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NGPs | nano graphite platelets |

| GNPs | graphite nano platelets |

| GO | graphene oxide |

| AG | acacia gum |

| GONPs | graphene oxide nano platelets |

| CNTs | carbon nanotubes |

| CNFs | carbon nanofibers |

| GNMPs | graphite nano-micro particles |

| OPC | Ordinary Portland Cement |

| CH | calcium hydroxide |

| UPV | ultrasonic pulse velocity |

| UHPC | ultrahigh performance concrete |

| ITZ | interfacial transition zone |

| EDX | energy dispersive x-rays |

| XRD | X-ray diffraction |

| XRF | X-ray fluorescence |

| MWCNTs | multi-walled carbon nanotubes |

| UV–Vis | ultra violet visible spectroscopy |

| SEM | scanning electron microscopy |

| C-S-H | calcium silicate hydrate |

References

- Marvila, M.T.; De Azevedo, A.R.G.; Alexandre, J.; Colorado, H.; Antunes, M.L.P.; Vieira, C.M.F. Circular economy in cementitious ceramics: Replacement of hydrated lime with a stoichiometric balanced combination of clay and marble waste. Int. J. Appl. Ceram. Technol. 2021, 18, 192–202. [Google Scholar] [CrossRef]

- Liu, L.; Yang, G.; He, J.; Liu, H.; Gong, J.; Yang, H.; Yang, W.; Joyklad, P. Impact of fibre factor and temperature on the mechanical properties of blended fibre-reinforced cementitious composite. Case Stud. Constr. Mater. 2022, 16, e00773. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, J.-Y.; Kim, Y.-H.; Kim, D.; Kim, J.; Han, J.-G. Evaluating the eco-compatibility of mortars with feldspar-based fine aggregate. Case Stud. Constr. Mater. 2022, 16, e00781. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Ahmad, F.; Qureshi, M.I.; Ahmad, Z. Influence of nano graphite platelets on the behavior of concrete with E-waste plastic coarse aggregates. Constr. Build. Mater. 2021, 316, 125980. [Google Scholar] [CrossRef]

- Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Kalpogiannaki, M.; Petrounias, P. Evaluation of Cement Performance Using Industrial Byproducts Such as Nano MgO and Fly Ash from Greece. Appl. Sci. 2021, 11, 11601. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C. Influence of graphene oxide as dispersed phase in cement mortar matrix in defining the crystal patterns of cement hydrates and its effect on mechanical, microstructural and crystallization properties. RSC Adv. 2015, 5, 52642–52657. [Google Scholar] [CrossRef]

- Azeem, M.; Saleem, M.A. Role of electrostatic potential energy in carbon nanotube augmented cement paste matrix. Constr. Build. Mater. 2020, 239, 117875. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Chen, Z.; Han, Z.; Zhang, Y.; Pacheco-Torgal, F. Nano-carbon black and carbon fiber as conductive materials for the diagnosing of the damage of concrete beam. Constr. Build. Mater. 2013, 43, 233–241. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Dong, S.; Yu, X.; Han, B. Mechanical properties of graphene-reinforced reactive powder concrete at different strain rates. J. Mater. Sci. 2019, 55, 3369–3387. [Google Scholar] [CrossRef]

- Snehal, K.; Das, B.; Akanksha, M. Early age, hydration, mechanical and microstructure properties of nano-silica blended cementitious composites. Constr. Build. Mater. 2020, 233, 117212. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, H.G.; Qudoos, A.; Ryou, J.S. Effect of leaching on the hardened, microstructural and self-cleaning characteristics of titanium dioxide containing cement mortars. Constr. Build. Mater. 2019, 207, 640–650. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C. Synergistic effect of zero-dimensional spherical carbon nanoparticles and one-dimensional carbon nanotubes on properties of cement-based ceramic matrix: Microstructural perspectives and crystallization investigations. Compos. Interfaces 2015, 22, 899–921. [Google Scholar] [CrossRef]

- Chougan, M.; Marotta, E.; Lamastra, F.R.; Vivio, F.; Montesperelli, G.; Ianniruberto, U.; Ghaffar, S.H.; Al-Kheetan, M.J.; Bianco, A. High performance cementitious nanocomposites: The effectiveness of nano-Graphite (nG). Constr. Build. Mater. 2020, 259, 119687. [Google Scholar] [CrossRef]

- Cui, X.; Sun, S.; Han, B.; Yu, X.; Ouyang, J.; Zeng, S.; Ou, J. Mechanical, thermal and electromagnetic properties of nanographite platelets modified cementitious composites. Compos. Part A Appl. Sci. Manuf. 2017, 93, 49–58. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.; Wu, R. Using graphene oxide to improve the properties of ultra-high-performance concrete with fine recycled aggregate. Constr. Build. Mater. 2020, 259, 120657. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Zhou, Q. Regulation of GO on cement hydration crystals and its toughening effect. Mag. Concr. Res. 2013, 65, 1246–1254. [Google Scholar] [CrossRef]

- Sixuan, H. Multifunctional Graphite Nanoplatelets (Gnp) Reinforced Cementitious Composites. Master’s Thesis, National University of Singapore, Singapore, 2012. [Google Scholar]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. In Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific: Singapore, 2009; pp. 11–19. [Google Scholar]

- Akbar, A.; Liew, K.; Farooq, F.; Khushnood, R.A. Exploring mechanical performance of hybrid MWCNT and GNMP reinforced cementitious composites. Constr. Build. Mater. 2021, 267, 120721. [Google Scholar] [CrossRef]

- Chougan, M.; Marotta, E.; Lamastra, F.R.; Vivio, F.; Montesperelli, G.; Ianniruberto, U.; Bianco, A. A systematic study on EN-998-2 premixed mortars modified with graphene-based materials. Constr. Build. Mater. 2019, 227, 116701. [Google Scholar] [CrossRef]

- Le, J.-L.; Du, H.; Pang, S.D. Use of 2D Graphene Nanoplatelets (GNP) in cement composites for structural health evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, Q.; Yu, Q.; Gao, R.; Tong, T. Experimental investigation on mechanical and piezoresistive properties of cementitious materials containing graphene and graphene oxide nanoplatelets. Constr. Build. Mater. 2016, 127, 565–576. [Google Scholar] [CrossRef]

- Yang, M.; Chen, G.; Cao, N.; Zhang, Y.; Wang, Y. Effect of graphenene nanoplatelets on microstructure and properties of cement mortar under simulated acid rain. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 631, p. 022036. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Graphene Oxide Impact on Hardened Cement Expressed in Enhanced Freeze–Thaw Resistance. J. Mater. Civ. Eng. 2016, 28, 04016072. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Peyvandi, A.A.; Soroushian, P.; Balachandra, A.M.; Sobolev, K. Enhancement of the durability characteristics of concrete nanocomposite pipes with modified graphite nanoplatelets. Constr. Build. Mater. 2013, 47, 111–117. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Nawaz, A. Effect of adding graphite nano/micro platelets on salt freeze-thaw resistance of nano-modificent concrete. Mater. Res. Express 2019, 6, 095023. [Google Scholar] [CrossRef]

- Baloch, W.L.; Khushnood, R.A.; Memon, S.A.; Ahmed, W.; Ahmad, S. Effect of Elevated Temperatures on Mechanical Performance of Normal and Lightweight Concretes Reinforced with Carbon Nanotubes. Fire Technol. 2018, 54, 1331–1367. [Google Scholar] [CrossRef]

- Iqbal, H.W.; Khushnood, R.A.; Baloch, W.L.; Nawaz, A.; Tufail, R.F. Influence of graphite nano/micro platelets on the residual performance of high strength concrete exposed to elevated temperature. Constr. Build. Mater. 2020, 253, 119029. [Google Scholar] [CrossRef]

- Baloch, W.L.; Khushnood, R.A.; Khaliq, W. Influence of multi-walled carbon nanotubes on the residual performance of concrete exposed to high temperatures. Constr. Build. Mater. 2018, 185, 44–56. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM), C. 231/C231M-17a, A. Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. 2010. Available online: https://www.astm.org/c0231_c0231m-17a.html (accessed on 12 November 2021).

- American Society for testing and Materials (ASTM), C. 143/143m-10a Standard Test Method for Slump of Hydraulic-Cement Concrete. Annual Book of ASTM Standards, American Society for Testing and Materials (ASTM), Philadelphia 4. 2010. Available online: https://global.ihs.com/doc_detail.cfm?document_name=ASTM%20C143%2FC143M&item_s_key=00291491 (accessed on 12 November 2021).

- Standard, A. C496/c496m (2011) Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. Annual Book of ASTM Standards 9. 2004. Available online: https://infostore.saiglobal.com/en-gb/standards/astm-c-496-c496m-2011-162717_saig_astm_astm_400106/ (accessed on 13 November 2021).

- American Society for testing and Materials (ASTM), C. 39/C39M-12a, A. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. 2012. Available online: https://www.roadauthority.com/Standards/?id=4fd7c880-e35e-44d3-aa20-e2e542333cbe (accessed on 25 November 2021).

- American Society for testing and Materials (ASTM). C. 78/C78M, A. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ASTM. C. 1585-04. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; ASTM International: West Conshohocken, PA, USA, 2004. Available online: https://www.astm.org/c1585-04.html (accessed on 26 November 2021).

- ASTM. C. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. C642-13. 2013. Available online: https://pdfcoffee.com/c642-13-standard-test-method-for-density-absorption-and-voids-in-hardened-concretepdf-pdf-free.html (accessed on 26 November 2021).

- Zhang, L.; Sojobi, A.; Kodur, V.; Liew, K.M. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J. Clean. Prod. 2019, 236, 117600. [Google Scholar] [CrossRef]

- C-16, A. Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy. 2016. Available online: https://standards.globalspec.com/std/3862671/ASTM%20C1723-16 (accessed on 26 November 2021).

- Gong, K.; Pan, Z.; Korayem, A.H.; Qiu, L.; Li, D.; Collins, F.; Wang, C.; Duan, W.H. Reinforcing Effects of Graphene Oxide on Portland Cement Paste. J. Mater. Civ. Eng. 2015, 27, 4014010. [Google Scholar] [CrossRef]

- Chuah, S.; Li, W.; Chen, S.J.; Sanjayan, J.; Duan, W.H. Investigation on dispersion of graphene oxide in cement composite using different surfactant treatments. Constr. Build. Mater. 2018, 161, 519–527. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.; Wang, C.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Wang, M.-X.; Huang, Z.-H.; Lv, W.; Yang, Q.-H.; Kang, F.; Liang, K. Water vapor adsorption on low-temperature exfoliated graphene nanosheets. J. Phys. Chem. Solids 2012, 73, 1440–1443. [Google Scholar] [CrossRef]

- Song, J.; Wang, X.; Chang, C.-T. Preparation and Characterization of Graphene Oxide. J. Nanomater. 2014, 2014, 276143. [Google Scholar] [CrossRef]

- Tiwary, N.K.; Bhaskarwar, A.N. Air Entrainment in Cement and Cement Mortar Paste by Colloidal Gas Aphrons (CGAs). Available online: https://www.researchgate.net/publication/301621846_Air_Entrainment_in_cement_and_cement_mortar_paste_by_Colloidal_Gas_Aphrons_CGAs (accessed on 27 November 2021).

- Shah, H.A.; Yuan, Q.; Zuo, S. Air entrainment in fresh concrete and its effects on hardened concrete—A review. Constr. Build. Mater. 2021, 274, 121835. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Lv, S.; Liu, J.; Sun, T.; Ma, Y.; Zhou, Q. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Mokhtar, M.; Abo-El-Enein, S.; Hassaan, M.; Morsy, M.; Khalil, M. Mechanical performance, pore structure and micro-structural characteristics of graphene oxide nano platelets reinforced cement. Constr. Build. Mater. 2017, 138, 333–339. [Google Scholar] [CrossRef]

- Farooq, F.; Akbar, A.; Khushnood, R.A. Effect of hybrid carbon nanotubes/graphite nano platelets on mechanical properties of cementitious composite. In Proceedings of the 1st Conference on Sustainability in Civil Engineering, Bali, Indonesia, 29–30 August 2019. [Google Scholar]

- Devi, S.C.; Khan, R.A. Effect of graphene oxide on mechanical and durability performance of concrete. J. Build. Eng. 2020, 27, 101007. [Google Scholar] [CrossRef]

- Farooq, F.; Akbar, A.; Khushnood, R.A.; Muhammad, W.L.B.; Rehman, S.K.U.; Javed, M.F. Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM. Materials 2020, 13, 230. [Google Scholar] [CrossRef] [Green Version]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Compton, O.C.; Kim, S.; Pierre, C.; Torkelson, J.M.; Nguyen, S.T. Crumpled Graphene Nanosheets as Highly Effective Barrier Property Enhancers. Adv. Mater. 2010, 22, 4759–4763. [Google Scholar] [CrossRef] [PubMed]

- Khalil, A.; Ahmad, A.; Adil, M.R.M.; ur Rahman, Z. Evaluating the compactness of boardcrete blocks using pundit apparatus. Int. Res. J. Eng. Technol. 2019, 6, 431–437. [Google Scholar]

- Malhotra, V.M. Testing Hardened Concrete: Nondestructive Methods. 1976. Available online: https://books.google.com.pk/books/about/Testing_Hardened_Concrete.html?id=CchRAAAAMAAJ&redir_esc=y (accessed on 1 December 2021).

- Zheng, Q.; Han, B.; Cui, X.; Yu, X.; Ou, J. Graphene-engineered cementitious composites: Small makes a big impact. Nanomater. Nanotechnol. 2017, 7, 1847980417742304. [Google Scholar] [CrossRef]

- Du, H.; Gao, H.J.; Pang, S.D. Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem. Concr. Res. 2016, 83, 114–123. [Google Scholar] [CrossRef]

- Matalkah, F.; Soroushian, P. Graphene nanoplatelet for enhancement the mechanical properties and durability characteristics of alkali activated binder. Constr. Build. Mater. 2020, 249, 118773. [Google Scholar] [CrossRef]

- Breysse, D. Deterioration processes in reinforced concrete: An overview. In Non-Destructive Evaluation of Reinforced Concrete Structures; Elsevier: Amsterdam, The Netherlands, 2010; pp. 28–56. [Google Scholar]

- Bai, J. Durability of sustainable construction materials. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 397–414. [Google Scholar]

- Xu, Y.; Zeng, J.; Chen, W.; Jin, R.; Li, B.; Pan, Z. A holistic review of cement composites reinforced with graphene oxide. Constr. Build. Mater. 2018, 171, 291–302. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Tsikouras, B.; Rigopoulos, I.; Hatzipanagiotou, K. Petrographic and Mechanical Characteristics of Concrete Produced by Different Type of Recycled Materials. Geosciences 2019, 9, 264. [Google Scholar] [CrossRef] [Green Version]

- Onyelowe, K.C.; Iqbal, M.; Jalal, F.E.; Onyia, M.E.; Onuoha, I.C. Application of 3-algorithm ANN programming to predict the strength performance of hydrated-lime activated rice husk ash treated soil. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 259–274. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhang, D.; Jalal, F.E.; Javed, M.F. Computational AI prediction models for residual tensile strength of GFRP bars aged in the alkaline concrete environment. Ocean Eng. 2021, 232, 109134. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Li, X.; Jamhiri, B.; Iqbal, M. Fractal approach in expansive clay-based materials with special focus on compacted GMZ bentonite in nuclear waste disposal: A systematic review. Environ. Sci. Pollut. Res. 2021, 28, 43287–43314. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.-H.; Dam, N.D.; Jalal, F.E.; Al-Ansari, N.; Ho, L.S.; Van Phong, T.; Iqbal, M.; Van Le, H.; Nguyen, H.B.T.; Prakash, I.; et al. GIS-Based Soft Computing Models for Landslide Susceptibility Mapping: A Case Study of Pithoragarh District, Uttarakhand State, India. Math. Probl. Eng. 2021, 2021, 9914650. [Google Scholar] [CrossRef]

- Jamal, A.; Al-Ahmadi, H.M.; Butt, F.M.; Iqbal, M.; Almoshaogeh, M.; Ali, S. Metaheuristics for Traffic Control and Optimization: Current Challenges and Prospects. In Search Algorithm—Essence of Optimization; IntechOpen: London, UK, 2021. [Google Scholar]

- Iqbal, M.; Zhang, D.; Jalal, F.E. Durability evaluation of GFRP rebars in harsh alkaline environment using optimized tree-based random forest model. J. Ocean Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhao, Q.; Zhang, D.; Jalal, F.E.; Jamal, A. Evaluation of tensile strength degradation of GFRP rebars in harsh alkaline conditions using non-linear genetic-based models. Mater. Struct. 2021, 54, 1–20. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Jalal, F.E.; Iqbal, M.; Rehman, Z.U.; Ibe, K. Intelligent modeling of unconfined compressive strength (UCS) of hybrid cement-modified unsaturated soil with nanostructured quarry fines inclusion. Innov. Infrastruct. Solut. 2021, 7, 1–18. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Iqbal, M.; Jamhiri, B.; Javed, M.F. Predicting the compaction characteristics of expansive soils using two genetic programming-based algorithms. Transp. Geotech. 2021, 30, 100608. [Google Scholar] [CrossRef]

- Iqbal, M.; Onyelowe, K.C.; Jalal, F.E. Smart computing models of California bearing ratio, unconfined compressive strength, and resistance value of activated ash-modified soft clay soil with adaptive neuro-fuzzy inference system and ensemble random forest regression techniques. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 207–225. [Google Scholar] [CrossRef]

- Jalal, F.E.; Xu, Y.; Iqbal, M.; Javed, M.F.; Jamhiri, B. Predictive modeling of swell-strength of expansive soils using artificial intelligence approaches: ANN, ANFIS and GEP. J. Environ. Manag. 2021, 289, 112420. [Google Scholar] [CrossRef] [PubMed]

| Chemical Composition | Content | Physical Properties | Results |

|---|---|---|---|

| (Oxides) | (%) | ||

| SiO2 | 20.6 | Specific surface area (m2/kg) | 321 |

| CaO | 65.58 | Specific gravity | 3.14 |

| Fe2O3 | 3.1 | Initial setting time (min) | 185 |

| Al2O3 | 5.1 | Final setting time (min) | 241 |

| MgO | 2.42 | Consistency (%) | 29.15 |

| SO3 | 1.64 | Soundness (%) | 0.103 |

| K2O | 0.72 | Fineness modulus (%) | 93.3 |

| Na2O | 0.23 | Compressive strength (28 days MPa) | 46.56 |

| Loss on ignition (LOI) | 0.61 | - | - |

| Property | Coarse Aggregate | Fine Aggregate |

|---|---|---|

| Min. nominal size (mm) | 4.74 | 4.72 |

| Max. nominal size (mm) | 20 | 0.074 |

| SSD water absorption (%) | 1.08 | 0.5 |

| Specific gravity | 2.71 | 2.78 |

| Shape | Angular | _ |

| Color | Dark | Dark |

| Bulk density (lb/ft3) | 94.05 | 100 |

| Fineness modulus | NIL | 2.27 |

| Aggregate impact value (%) | 25.43 | NIL |

| Aggregate crushing value (%) | 27.42 | NIL |

| Elements | Weight (%) | Atomic (%) |

|---|---|---|

| C | 67.61 | 74.8 |

| O | 32.11 | 24.57 |

| K | 0.34 | 0.14 |

| Na | 0.20 | 0.09 |

| Ca | 0.90 | 0.12 |

| Mo | 0.84 | 0.28 |

| Total | 100 | 100 |

| Sample Name | NGPs:AG |

|---|---|

| R1 | 1:0 |

| R2 | 1:0.2 |

| R3 | 1:0.4 |

| R4 | 1:0.6 |

| R5 | 1:0.8 |

| R6 | 1:1 |

| Formulation | Cement | NGPs | Fine Aggregate | Coarse Aggregate | Water | Superplasticizer (mL) |

|---|---|---|---|---|---|---|

| OPC0NGP | 384 | 0 | 715 | 1113 | 173 | 192 |

| OPC0.5NGP | 384 | 1.92 | 715 | 1113 | 173 | 192 |

| OPC1.5NGP | 384 | 5.76 | 715 | 1113 | 173 | 192 |

| OPC3NGP | 384 | 11.52 | 715 | 1113 | 173 | 192 |

| OPC5NGP | 384 | 19.2 | 715 | 1113 | 173 | 192 |

| Elements | Nano Graphite Platelets (NGPs) | |

|---|---|---|

| Atomic (%) | Weight (%) | |

| C | 91.35 | 85.83 |

| Si | 1.37 | 2.98 |

| Ca | 0.59 | 1.70 |

| Al | 0.31 | 0.74 |

| O | 5.45 | 5.76 |

| Fe | 0.56 | 2.04 |

| Mg | 0.23 | 0.62 |

| S | 0.14 | 0.32 |

| Total | 100 | 100 |

| Oxides | CaO | SiO2 | Fe2O3 | K2O | MoO3 | CuO | TiO2 | ZnO | ZrO2 | MnO |

| Weight (%) | 25.52 | 36.4 | 32.67 | 2.177 | 0.244 | 0.612 | 1.434 | 0.105 | 0.125 | 0.165 |

| Elements | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| C K | 50.71 | 34.39 | 34.51 | 31.92 |

| O K | 34.42 | 29.64 | 33.11 | 36.48 |

| Al K | 0.68 | 4.43 | 5.51 | 2.68 |

| Si K | 1.99 | 15.35 | 12.47 | 6.33 |

| K | 1.22 | 2.86 | 2.36 | 0.99 |

| Ca K | 10.98 | 1.8 | 4.4 | 19.26 |

| Mg K | _ | 3.64 | 3.11 | _ |

| Fe K | _ | 6.52 | 4.54 | 2.35 |

| Ti K | _ | 1.37 | _ | _ |

| Total | 100 | 100 | 100 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, F.; Jamal, A.; Iqbal, M.; Alqurashi, M.; Almoshaogeh, M.; Al-Ahmadi, H.M.; E. Hussein, E. Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material. Materials 2022, 15, 290. https://doi.org/10.3390/ma15010290

Ahmad F, Jamal A, Iqbal M, Alqurashi M, Almoshaogeh M, Al-Ahmadi HM, E. Hussein E. Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material. Materials. 2022; 15(1):290. https://doi.org/10.3390/ma15010290

Chicago/Turabian StyleAhmad, Farhan, Arshad Jamal, Mudassir Iqbal, Muwaffaq Alqurashi, Meshal Almoshaogeh, Hassan M. Al-Ahmadi, and Enas E. Hussein. 2022. "Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material" Materials 15, no. 1: 290. https://doi.org/10.3390/ma15010290

APA StyleAhmad, F., Jamal, A., Iqbal, M., Alqurashi, M., Almoshaogeh, M., Al-Ahmadi, H. M., & E. Hussein, E. (2022). Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material. Materials, 15(1), 290. https://doi.org/10.3390/ma15010290