Improvement in Bending Strength of Silicon Nitride through Laser Peening

Abstract

:1. Introduction

2. Experiments

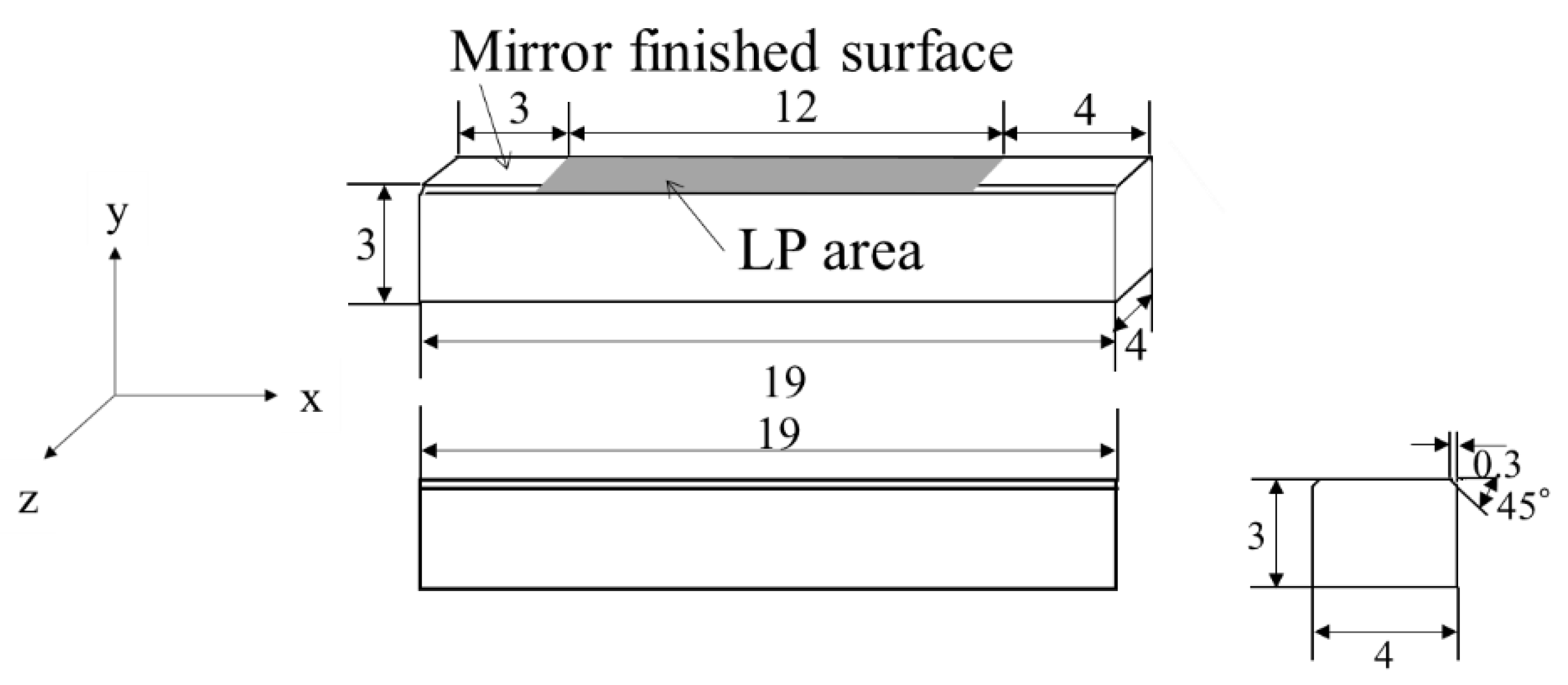

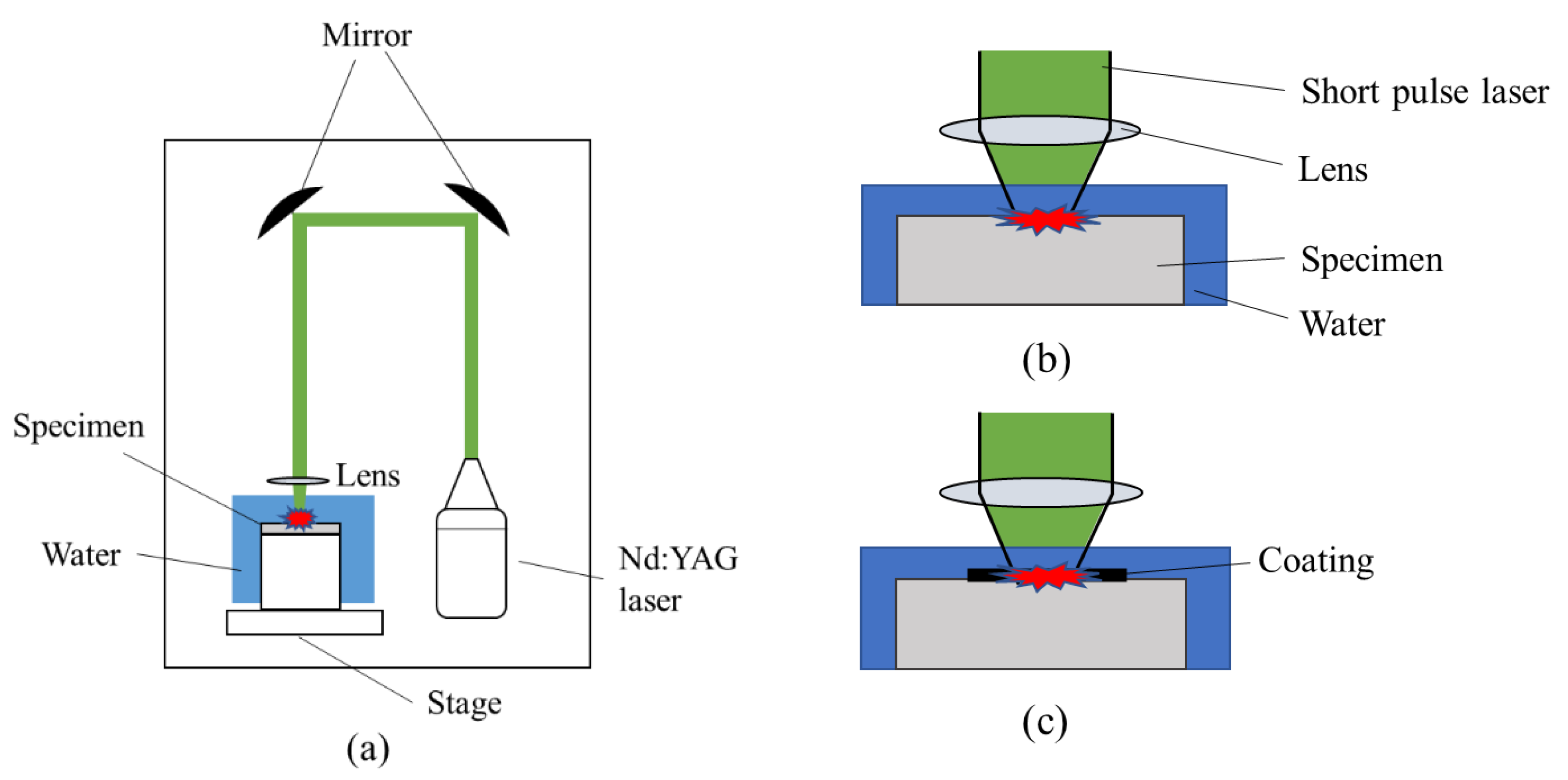

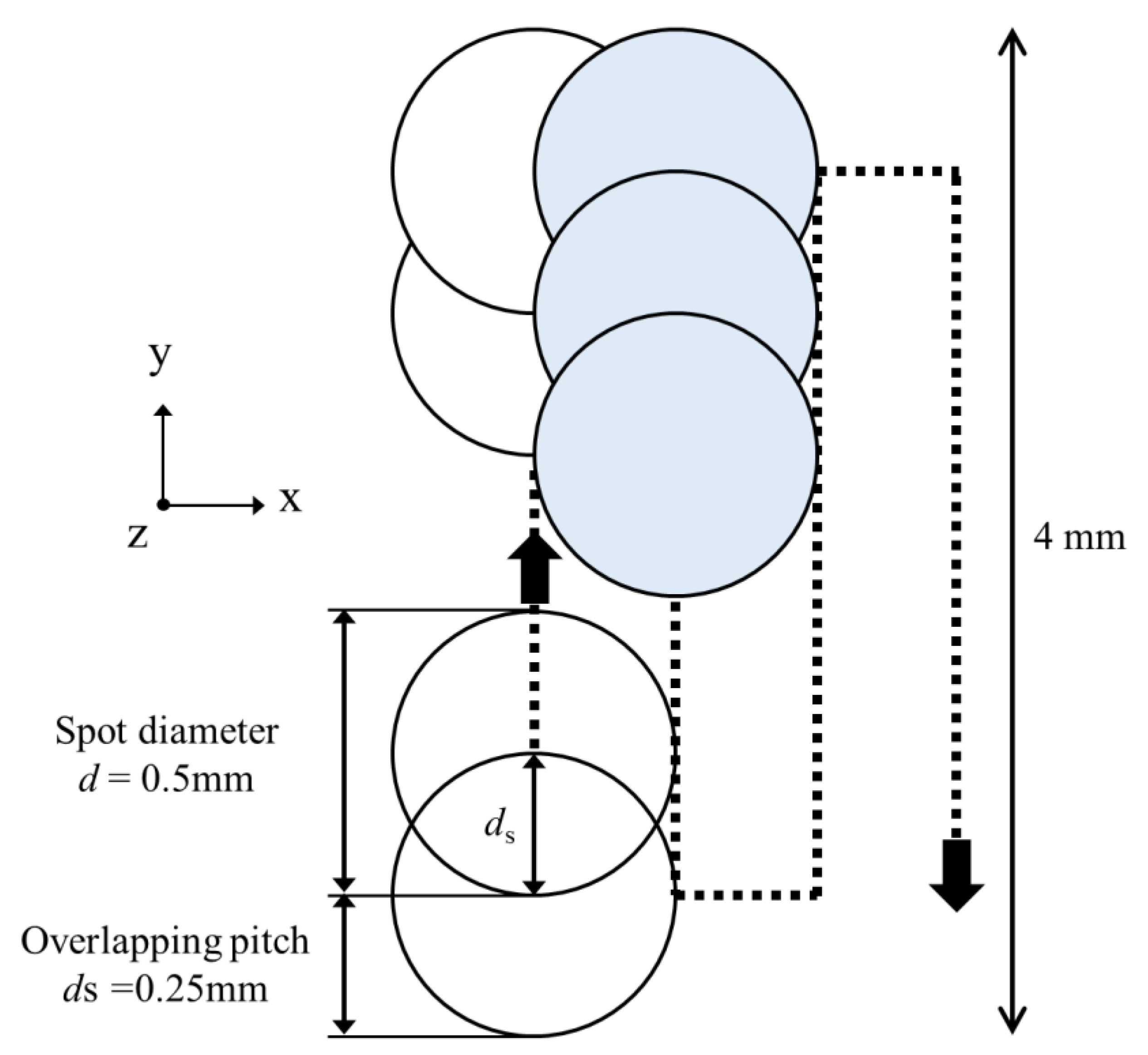

2.1. Specimens and LP Conditions

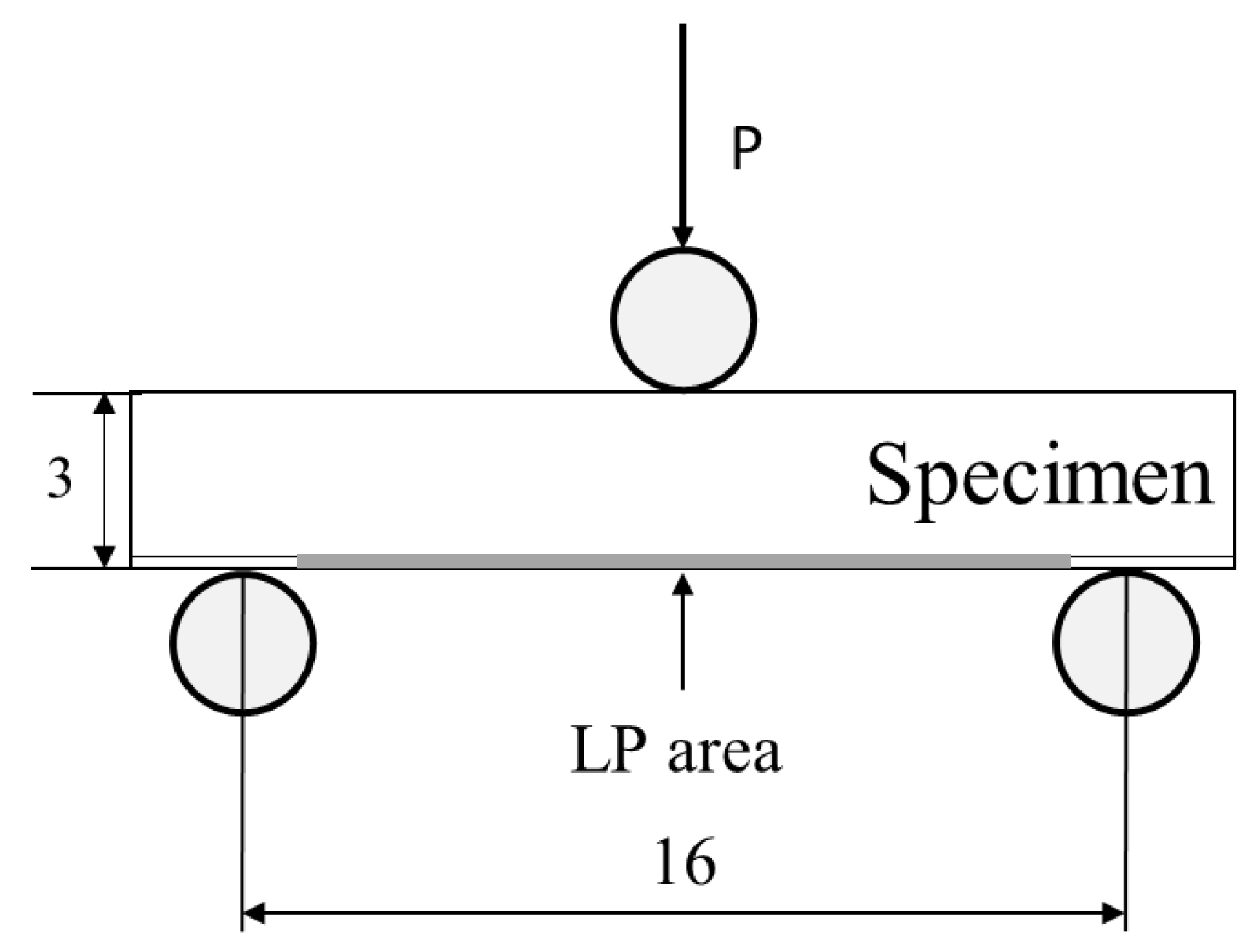

2.2. Experimental Procedure

3. Results and Discussion

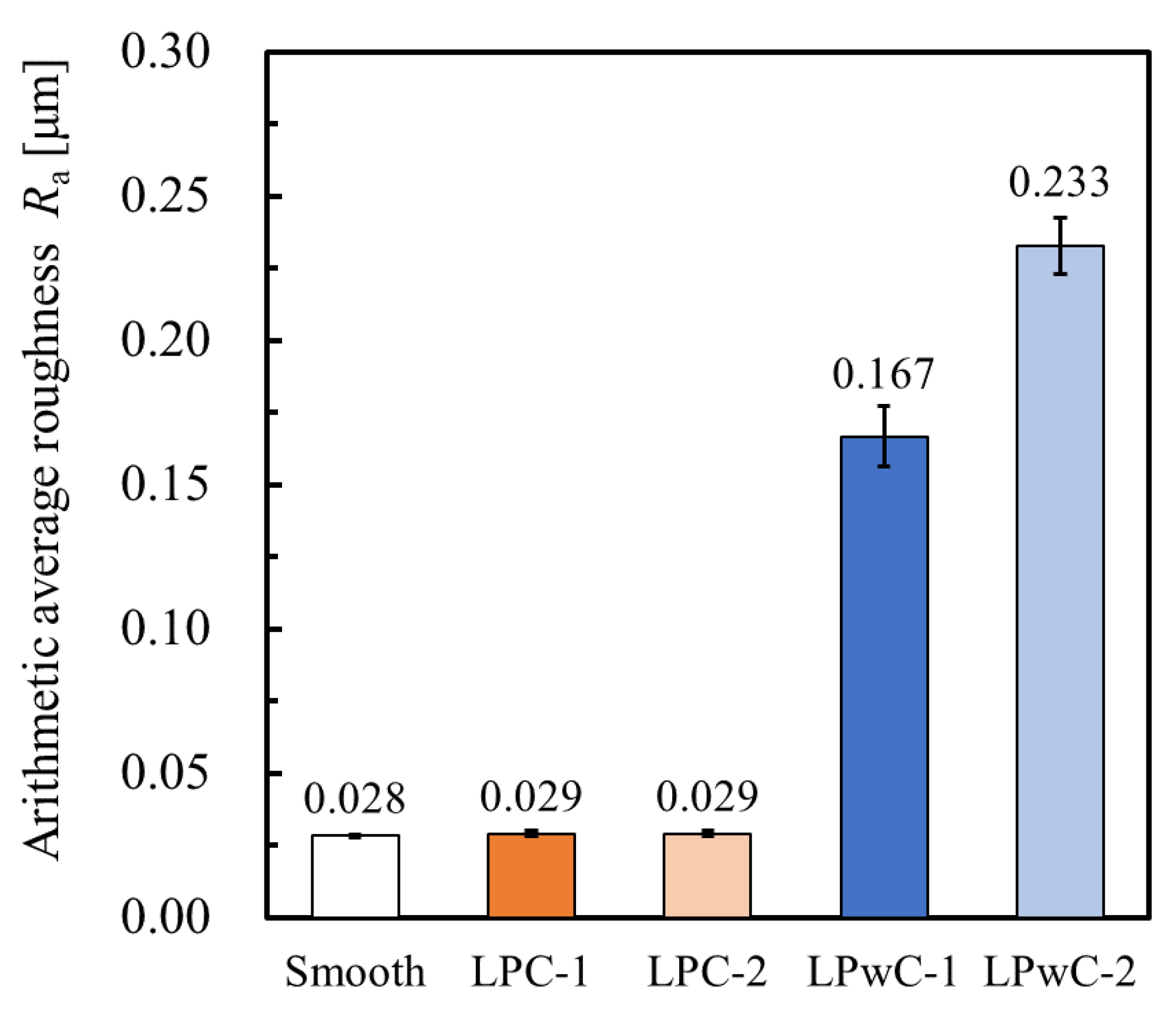

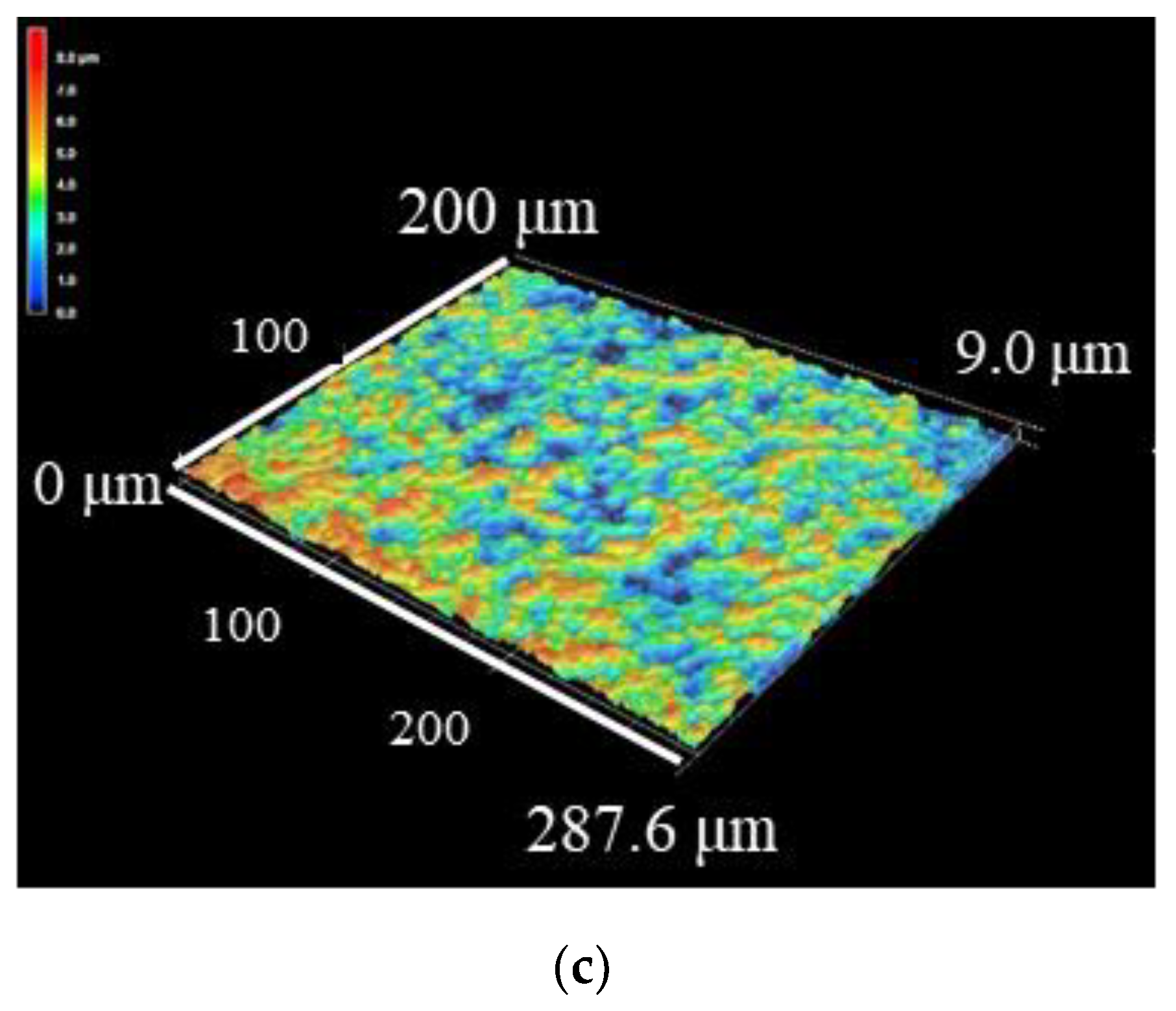

3.1. Surface Roughness of Specimens

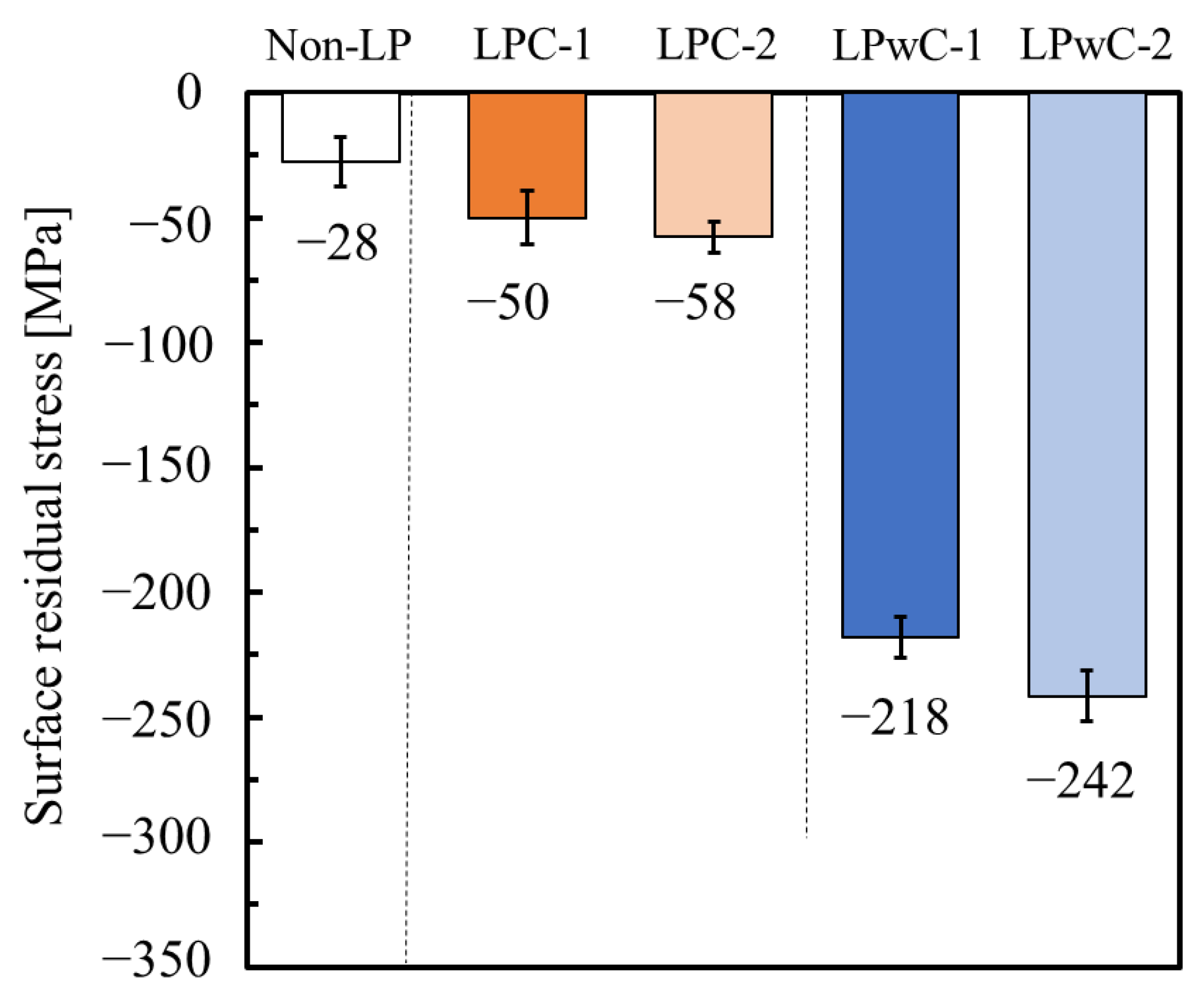

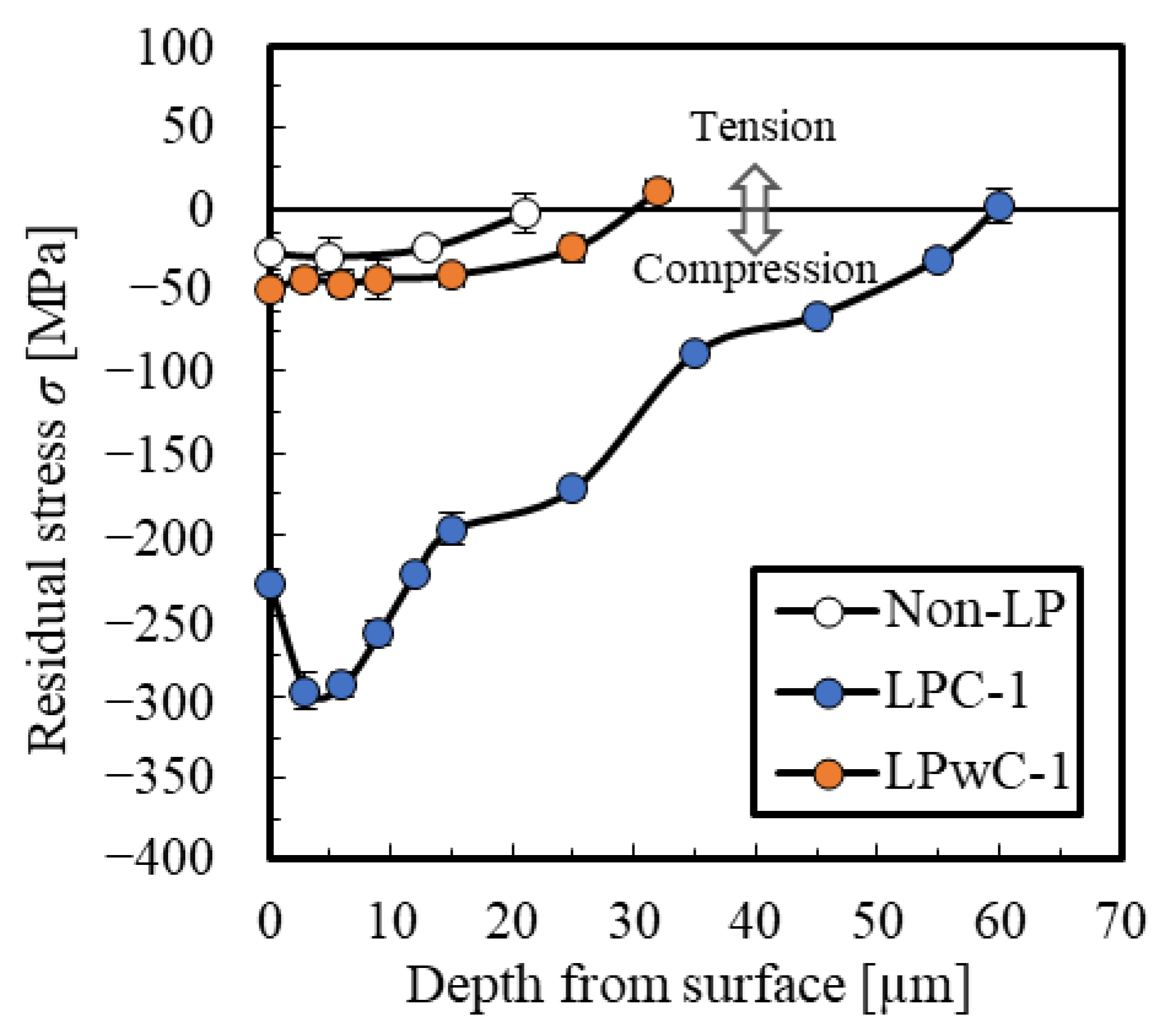

3.2. Residual Stress

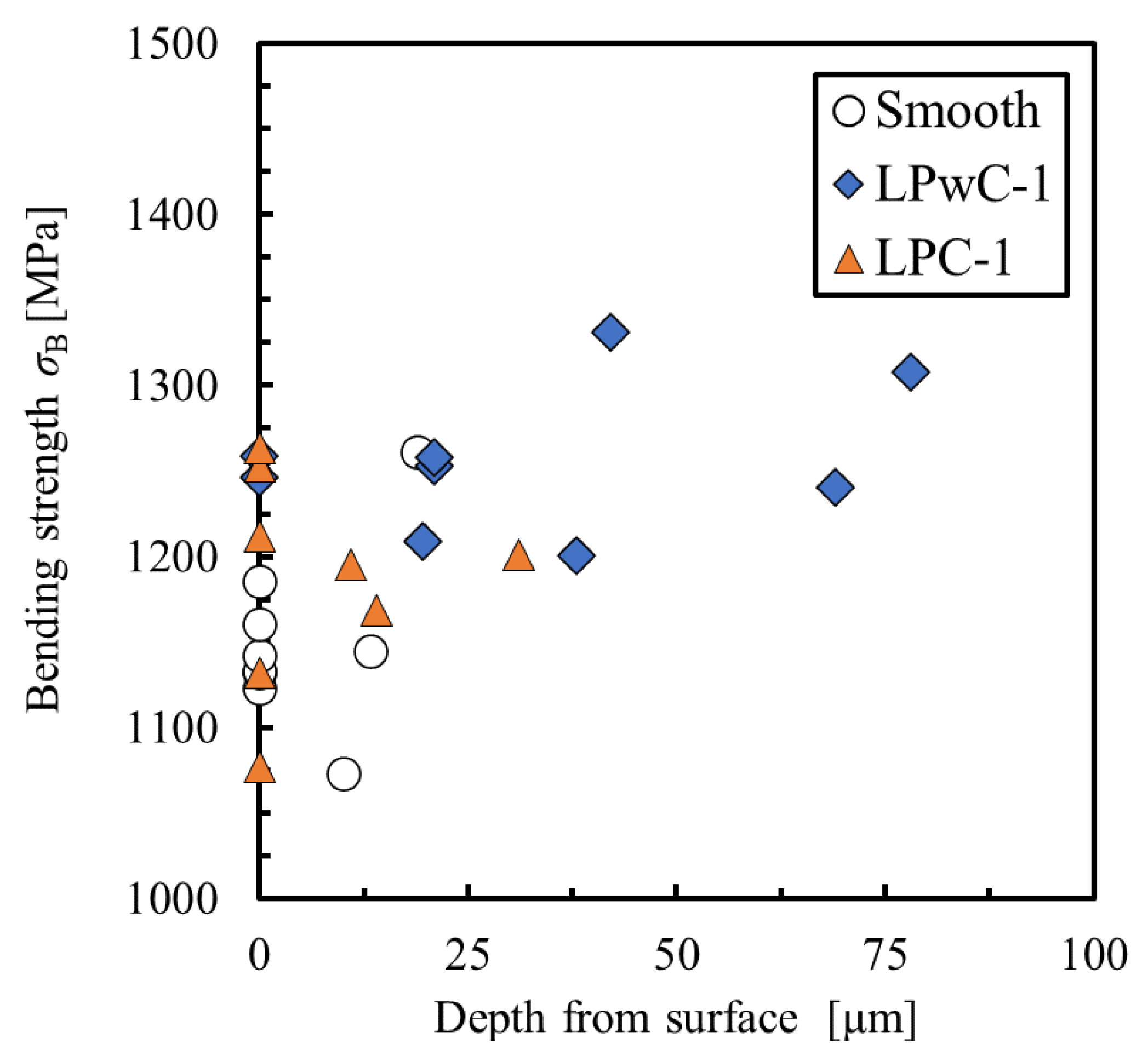

3.3. Bending Strength

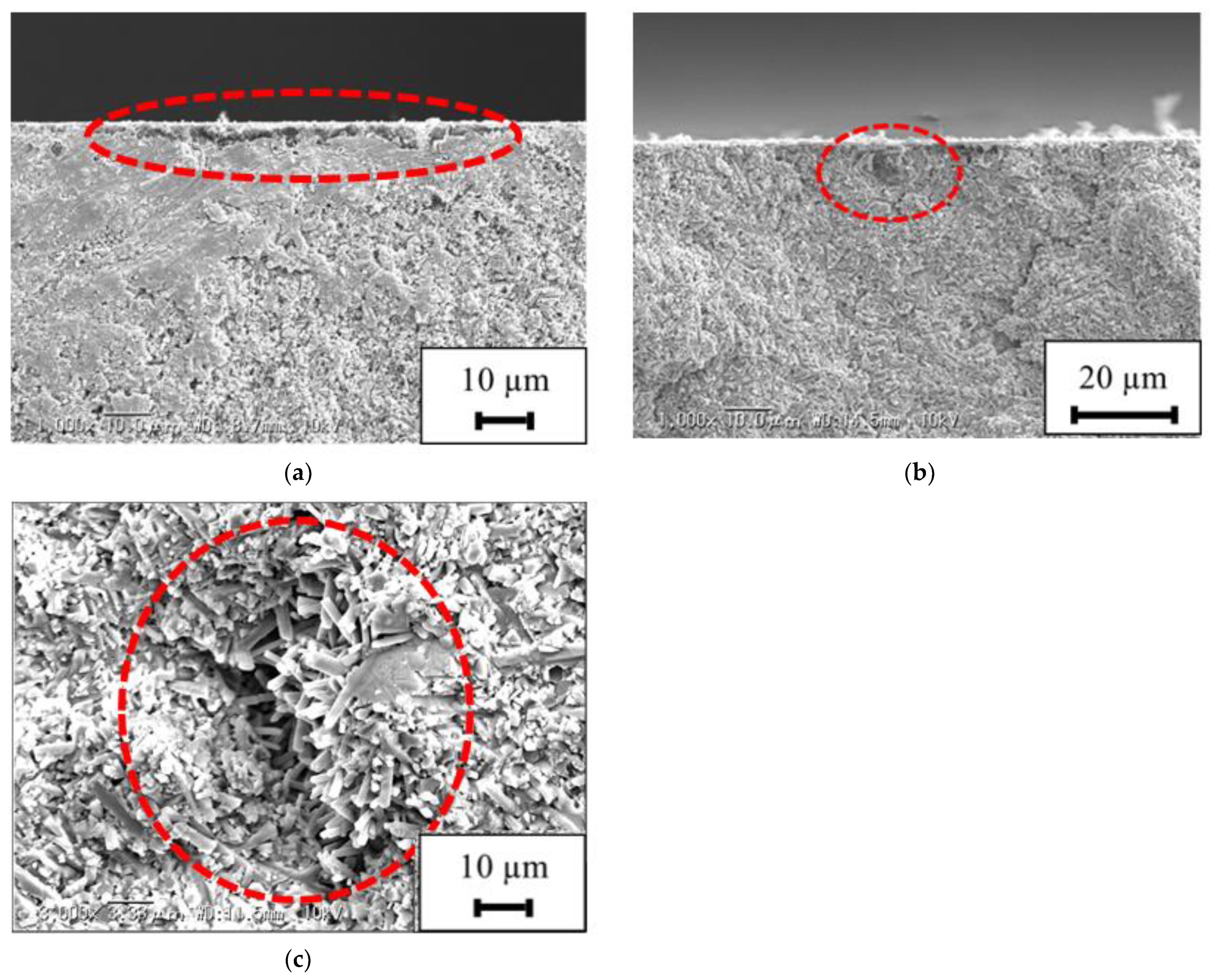

3.4. Fracture Surface Observation

4. Conclusions

- (1)

- The results of residual stress and surface roughness measurements on LPwC and LPC specimens showed that large and deep compressive residual stress can be introduced when the coating is not applied, although the surface roughness increases.

- (2)

- The bending strength of the specimens increased in the order of non-LP, LPC, and LPwC specimens. For LPwC, the scatter of bending strength improved compared with that of the non-LP specimen. However, for LPC, the scatter in bending strength was similar to that of the non-LP specimen.

- (3)

- Fracture surface observations showed that a higher proportion of specimens in the LPwC specimen fractured due to internal defects than in the non-LP specimen. It is considered that the compressive residual stress introduced by the LP suppresses the crack growth from the surface, resulting in a more internal transition of the fracture origin. This transition of the fracture origin to the inside of the specimen is considered to be the reason for the improvement in bending strength in the LPwC specimen.

- (4)

- The proportion of specimens that fractured from an internal origin in the LPC specimen was similar to that in the non-LP specimen, probably due to the shallower depth of introduction of compressive residual stress in the LPC specimen compared to the LPwC specimen. The slight increase in bending strength in LPC specimens can be attributed to the effect of the compressive residual stress introduced by LP.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Itoh, Y.; Suyama, S.; Fuse, T. Effect of soft shot peening on bending strength of partially stabilized zirconia. J. Ceram. Soc. Jpn. 2003, 111, 776–780. [Google Scholar] [CrossRef] [Green Version]

- Moon, W.J.; Ito, T.; Uchimura, S.; Saka, H. Toughening of ceramics by dislocation sub-boundaries. Mat. Sci. Eng. 2004, 387, 837–839. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y.; Morishita, Y. Residual stress distribution in the sub-surface region of shot-peened ceramics. Trans. Jpn. Soc. Mech. Eng. 2005, 71, 1714–1721. [Google Scholar] [CrossRef] [Green Version]

- Pfeiffer, W.; Frey, T. Strengthening of ceramics by shot peening. J. Eur. Ceram. Soc. 2006, 26, 2639–2645. [Google Scholar] [CrossRef]

- Takahashi, K.; Nishio, Y.; Kimura, Y.; Ando, K. Improvement of strength and reliability of ceramics by shot peening and crack healing. J. Euro. Ceram. Soc. 2010, 30, 3047–3052. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, K.; Iwanaka, K.; Osada, T.; Koike, H. Increase in strength of partially stabilized zirconia after shot peening. J. Mat. Eng. Perform. 2015, 24, 3573–3578. [Google Scholar] [CrossRef]

- Koike, H.; Iwanaka, K.; Takahashi, K. Measurement of sliding wear of shot-peened partially stabilized zirconia plate. Appl. Mech. Mater. 2014, 597, 353–357. [Google Scholar] [CrossRef]

- Shukla, P.; Lawrence, J. Micro-shot peening of zirconia-advanced ceramic: An examination of surface integrity. J. Mater. Sci. 2015, 50, 1728–1739. [Google Scholar] [CrossRef]

- Clauer, A.H. Laser shock peening, the path to production. Metals 2019, 9, 626. [Google Scholar] [CrossRef] [Green Version]

- Sano, Y. Quarter century development of laser peening without coating. Metals 2020, 10, 152. [Google Scholar] [CrossRef] [Green Version]

- Akita, K.; Sano, Y.; Takahashi, K.; Tanaka, H.; Ohya, S. Strengthening of Si3N4 ceramics by laser peening. Mater. Sci. Forum 2006, 524, 141–146. [Google Scholar] [CrossRef]

- Shukla, P.; Smith, G.C.; Waugh, D.G.; Lawrence, J. Development in laser peening of advanced ceramics. In Industrial Laser Applications Symposium; Mike, G., Cath, R., Eds.; International Society for Optics and Photonics: Kenilworth, UK, 2015; pp. 77–85. [Google Scholar]

- Shukla, P.; Shen, X.; Allot, R.; Ertel, K.; Robertson, S.; Crookes, R.; Wu, H.; Zammit, A.; Swanson, P.; Fitzpatrick, M.E. Response of silicon nitride ceramics subject to shock treatment. Ceram. Int. 2021, 47, 34538–34553. [Google Scholar] [CrossRef]

- Shukla, P.; Crookes, R.; Wu, H. Shock-wave induced compressive stress on alumina ceramics by laser peening. Mater. Des. 2019, 167, 107626. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, C.; Yan, X.; Deng, L.; Lu, Y.; Nastasi, M.; Cui, B. Microstructure-property relation in alumina ceramics during post-annealing process after laser shock processing. J. Am. Ceram. Soc. 2018, 101, 4933–4941. [Google Scholar] [CrossRef]

- Saigusa, K.; Takahashi, K.; Shibuya, N. Evaluation of Surface Properties of Silicon Nitride Ceramics Treated with Laser Peening. Int. J. Peening Sci. Tech. 2019, 1, 221–232. [Google Scholar] [CrossRef]

- Wang, F.; Yan, X.; Zhang, C.; Deng, L.; Lu, Y.; Nastasi, M. Localized plasticity in silicon carbide ceramics induced by laser shock processing. Materialia 2019, 6, 100265. [Google Scholar] [CrossRef]

- Wang, F.; Chen, X.; DeLellis, D.P.; Krause, A.R.; Lu, Y.; Cui, B. Microstructures and mechanical properties of α-SiC ceramics after high-temperature laser shock peening. J. Am. Ceram. Soc. 2021, 1–10. [Google Scholar] [CrossRef]

- Wang, F.; Yan, X.; Liu, L.; Nastasi, M.; Lu, Y.; Cui, B. Surface strengthening of single-crystal alumina by high-temperature laser shock peening. Mater. Res. Lett. 2021, 9, 155–161. [Google Scholar] [CrossRef]

- Japan Fine Ceramics Center. Technical Report, TR-SN1; JFCC: Nagoya, Japan.

- Wang, F.; Zhang, C.; Lu, Y.F.; Nastasi, M.; Cui, B. Laser shock processing of polycrystalline alumina ceramics. J. Am. Ceram. Soc. 2016, 100, 911–919. [Google Scholar] [CrossRef]

- Smyth, N.A.; Toparli, M.B.; Fitzpatrick, M.E.; Irving, P.E. Recovery of fatigue life using laser peening on A2024-T351 aluminum sheet containing scratch damage: The role of residual stress. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1161–1174. [Google Scholar] [CrossRef]

- Takahashi, K.; Kogishi, Y.; Shibuya, N.; Kumeno, F. Effects of laser peening on the fatigue strength and defect tolerance of aluminum alloy. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 845–846. [Google Scholar] [CrossRef]

| LPC-1 | LPC-2 | LPwC-1 | LPwC-2 | |

|---|---|---|---|---|

| Laser | Nd:YAG laser | |||

| Pulse duration (ns) | 6.2 | |||

| Repetition rate (Hz) | 10 | |||

| Spot diameter (mm) | 0.5 | |||

| Pulse energy (mJ) | 37 | |||

| Irradiation density (pulse/mm2) | 16 | |||

| Power density (GW/cm2) | 3 | |||

| ) | 50 | |||

| Overlapping pitch (mm) | 0.25 | |||

| Path | 1 | 2 | 1 | 2 |

| Coating | With | With | Without | Without |

| Measuring Method | |

|---|---|

| Characteristic X-ray | |

| Diffraction angle [deg] | 131.614 |

| Diffraction plane | Si3N4 (212) |

| X-ray irradiation time [s] | 60 |

| Incident angle [deg] | 29 |

| Tube voltage [kV] | 30.0 |

| Tube current [mA] | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saigusa, K.; Yamamoto, J.; Takahashi, K.; Kumeno, F.; Shibuya, N. Improvement in Bending Strength of Silicon Nitride through Laser Peening. Materials 2022, 15, 315. https://doi.org/10.3390/ma15010315

Saigusa K, Yamamoto J, Takahashi K, Kumeno F, Shibuya N. Improvement in Bending Strength of Silicon Nitride through Laser Peening. Materials. 2022; 15(1):315. https://doi.org/10.3390/ma15010315

Chicago/Turabian StyleSaigusa, Kazuya, Joji Yamamoto, Koji Takahashi, Fumiaki Kumeno, and Norihito Shibuya. 2022. "Improvement in Bending Strength of Silicon Nitride through Laser Peening" Materials 15, no. 1: 315. https://doi.org/10.3390/ma15010315