The Penetration–Explosion Effects of Differently Distributed Inactive/Active Composite Shaped Charge Jets

Abstract

:1. Introduction

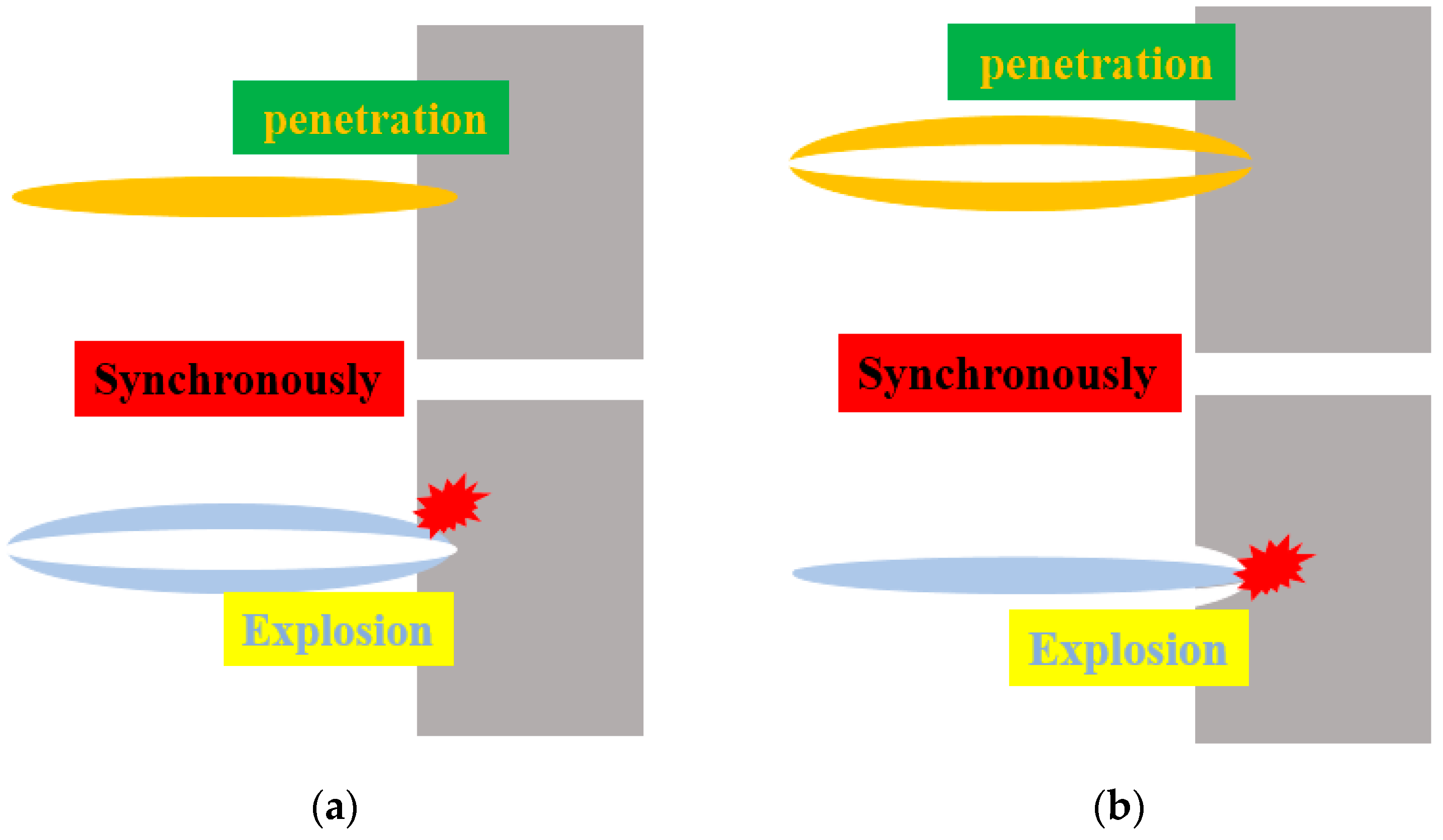

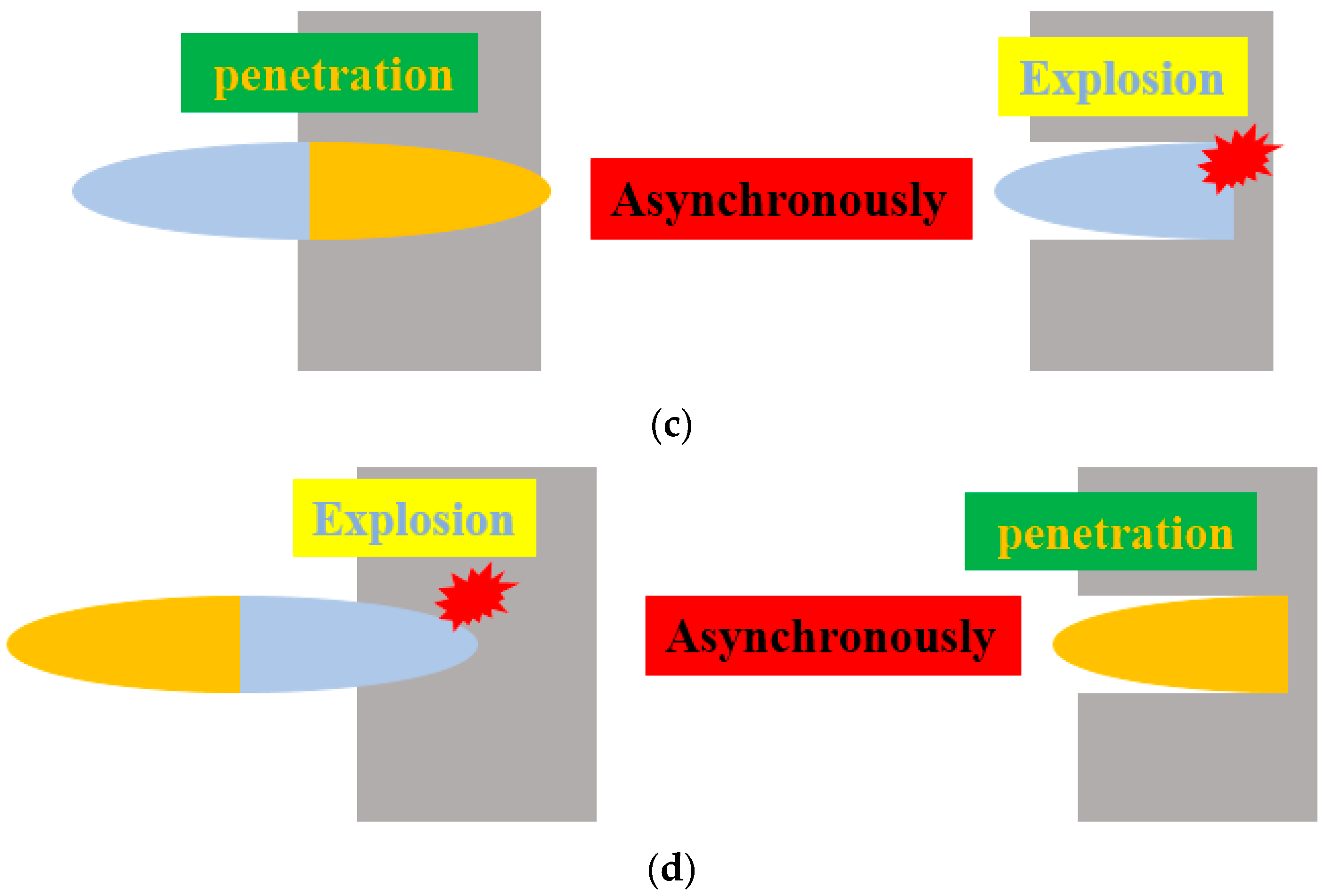

2. PE Effects of Jets with Different Elemental Distribution

3. Penetration Experiment

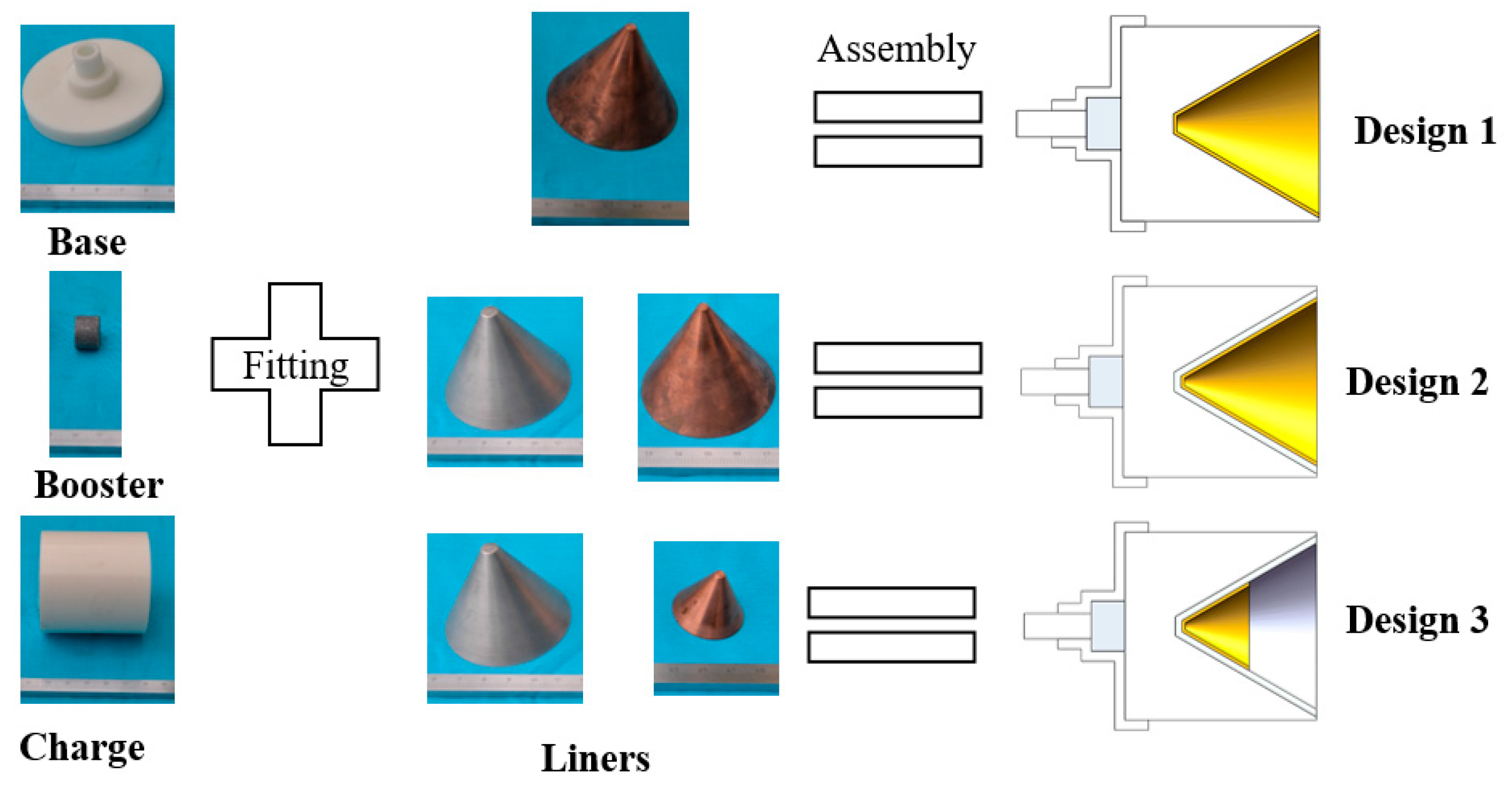

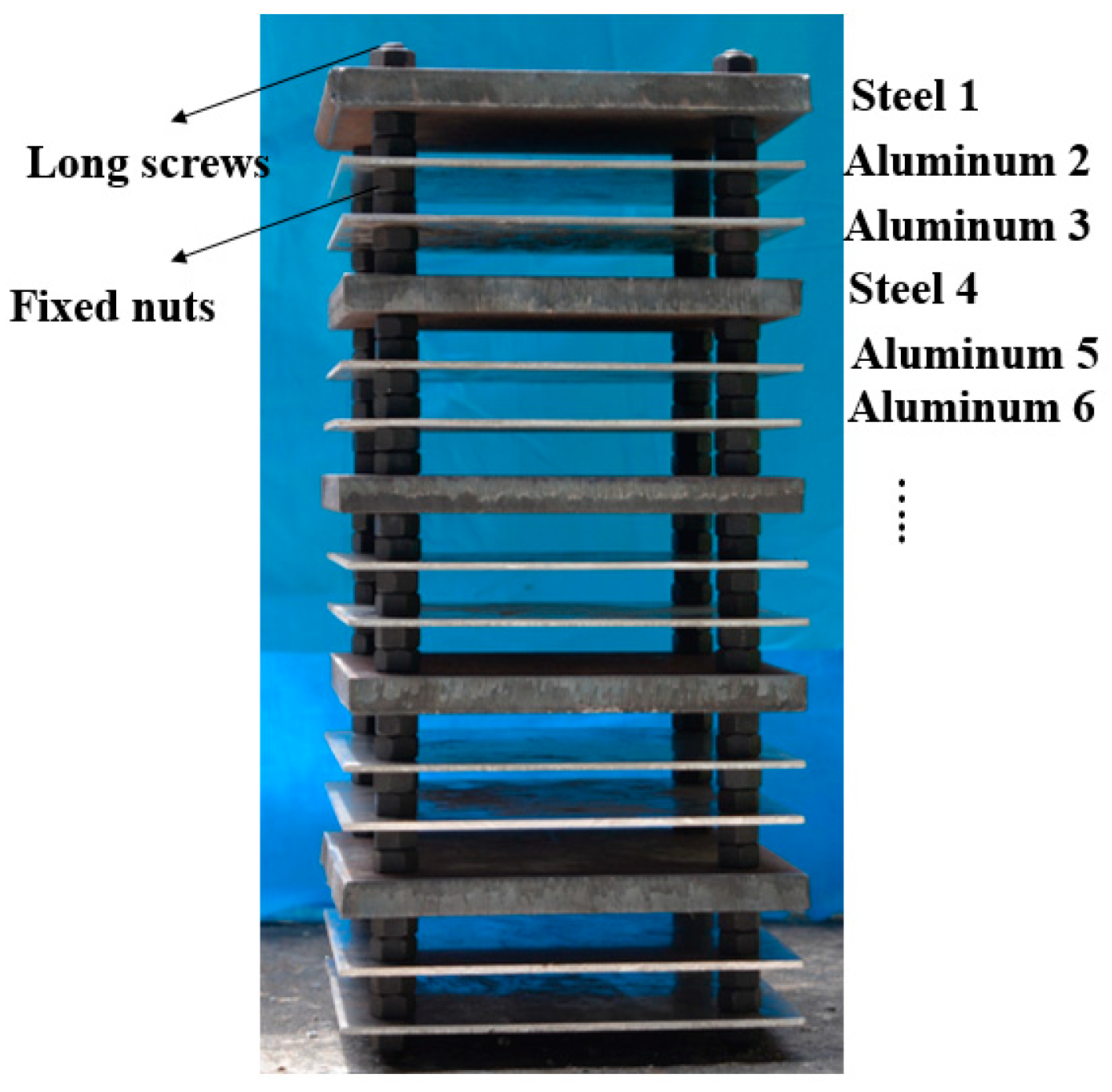

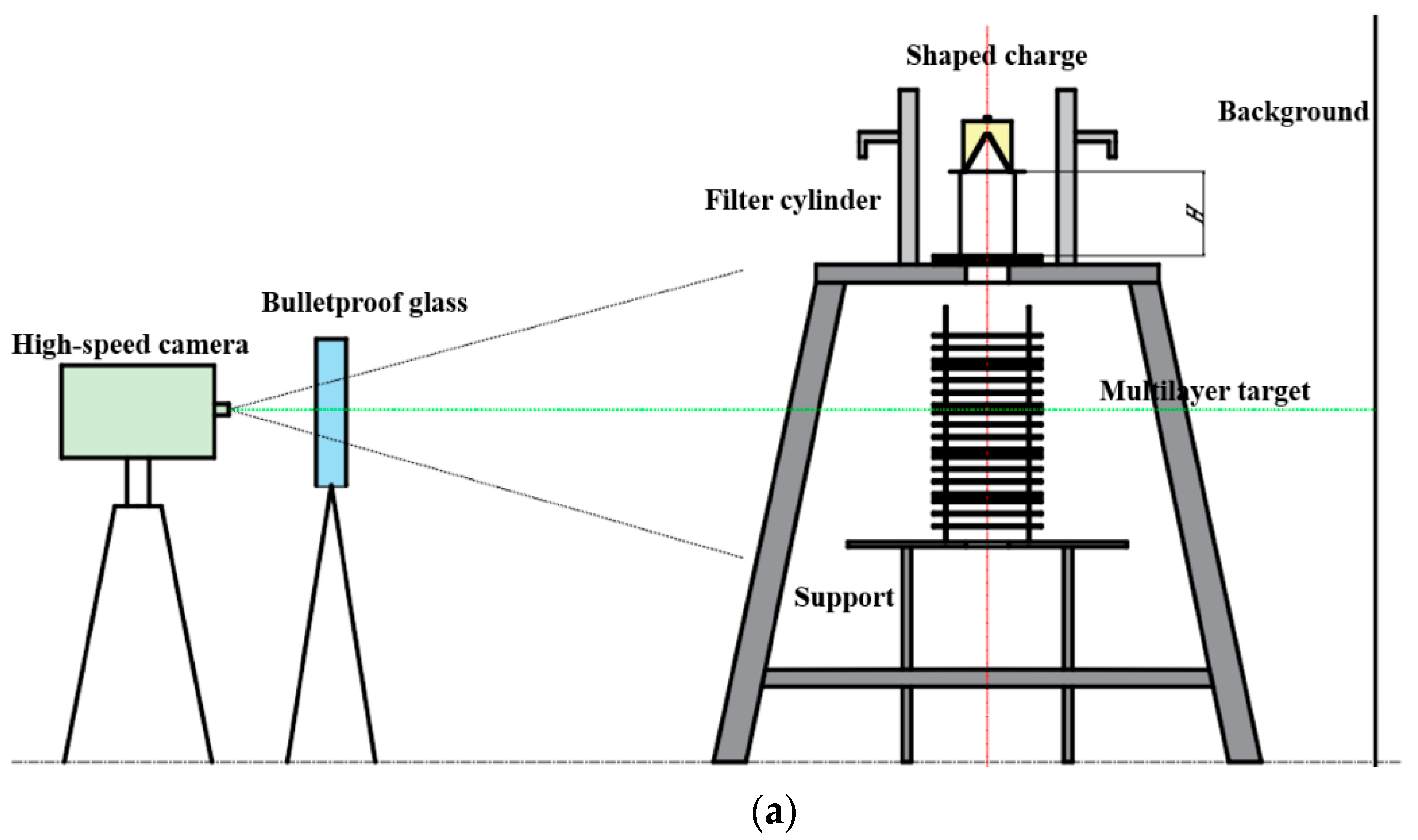

3.1. Experimental Setup

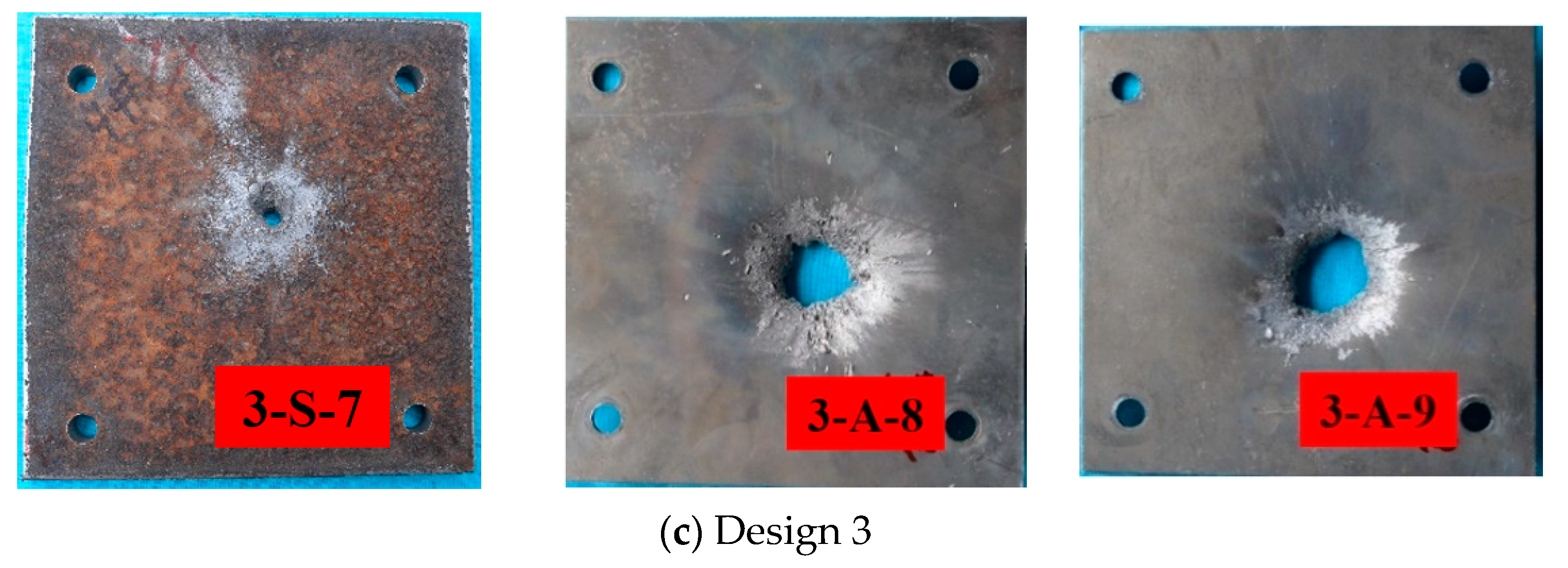

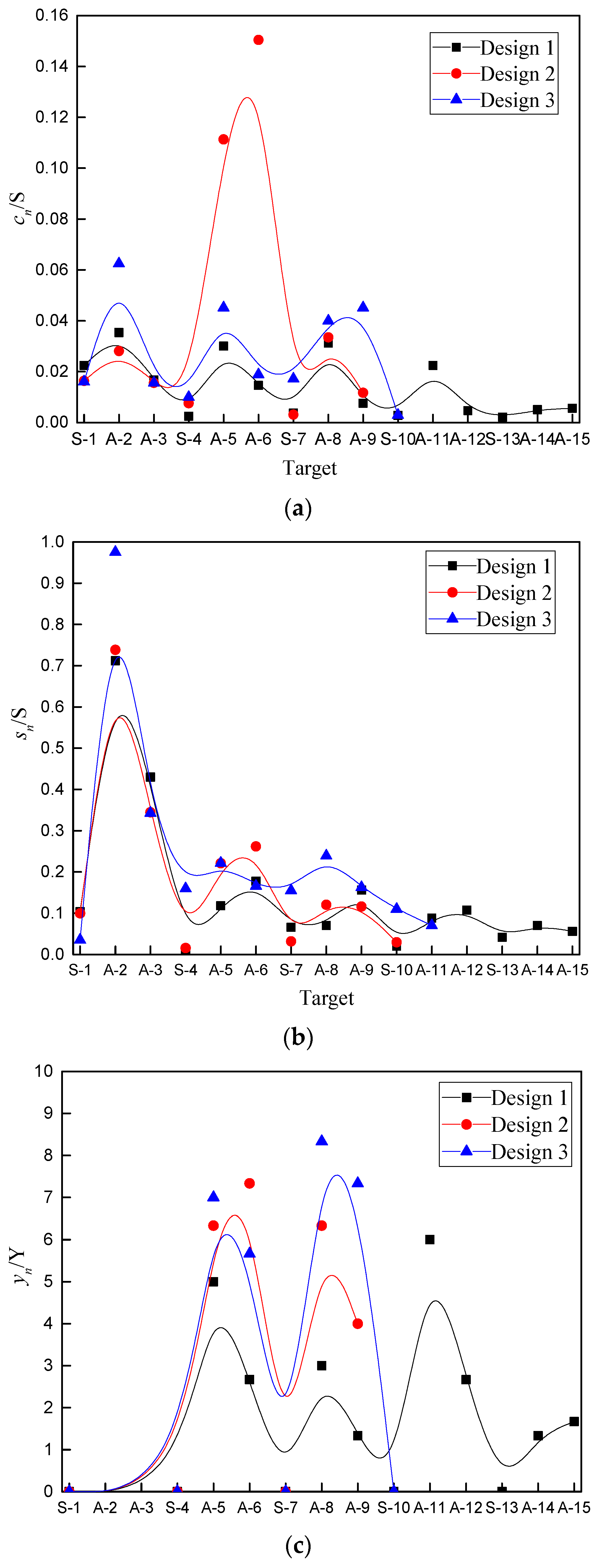

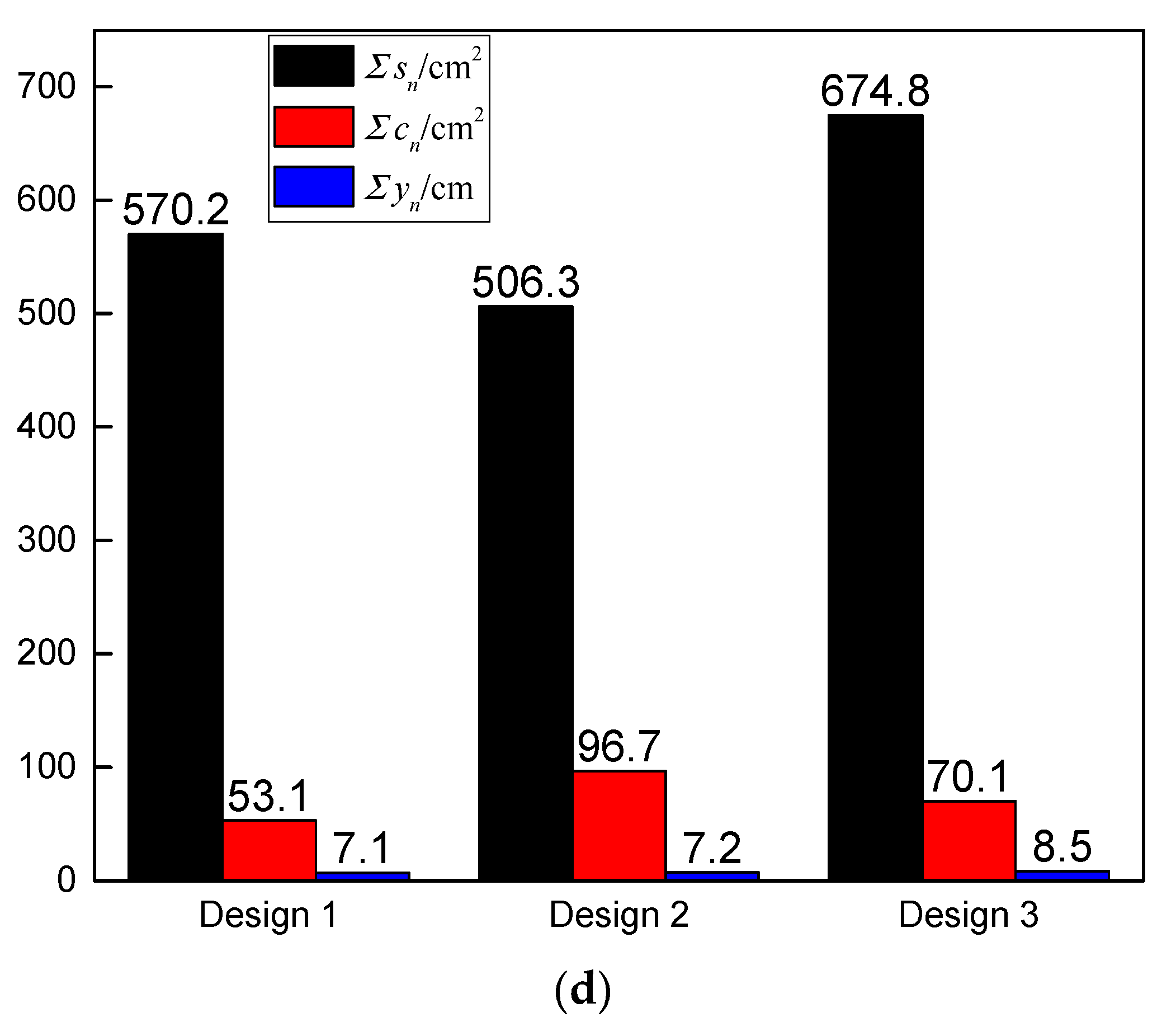

3.2. Destruction of Multilayer Targets

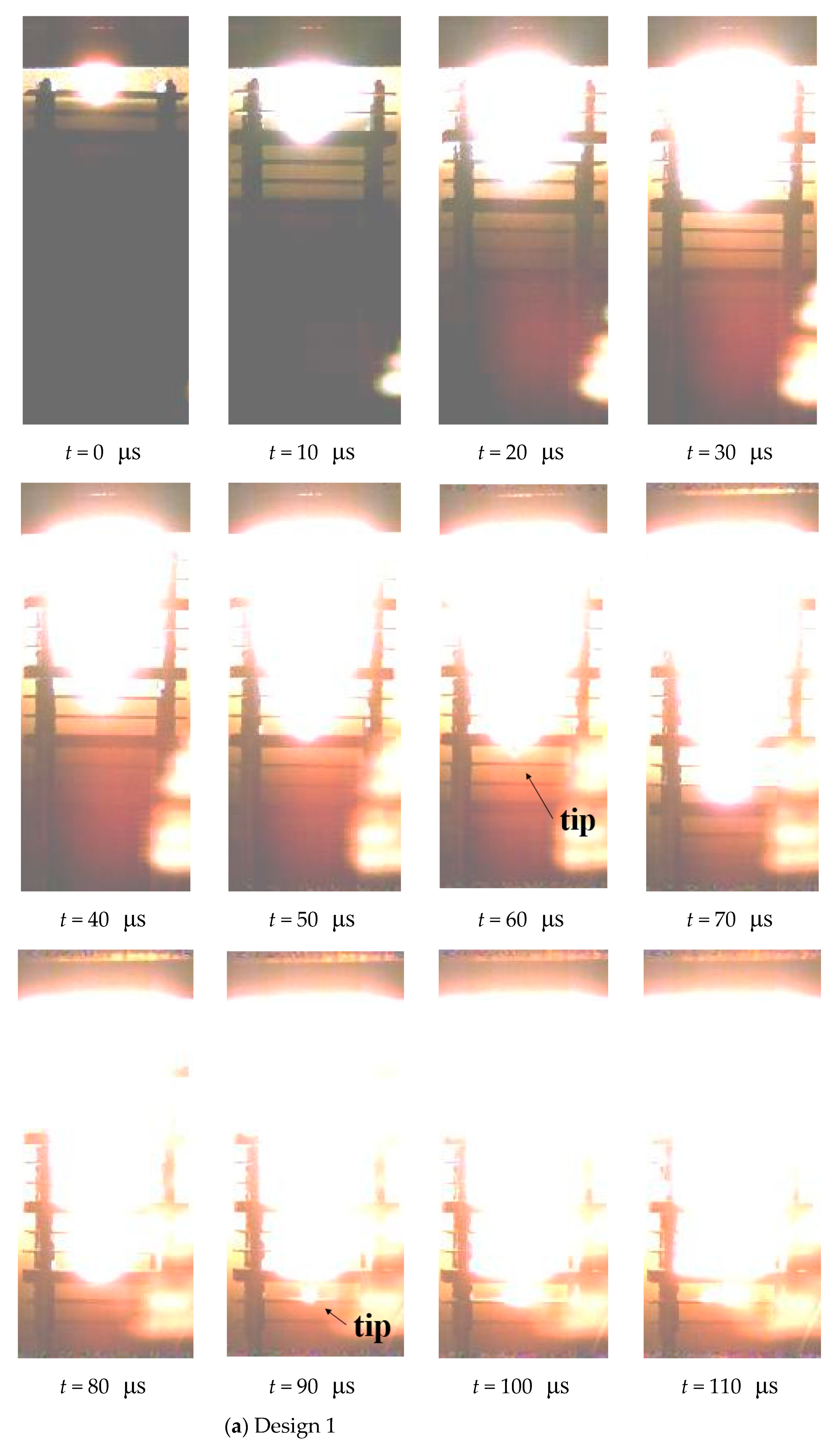

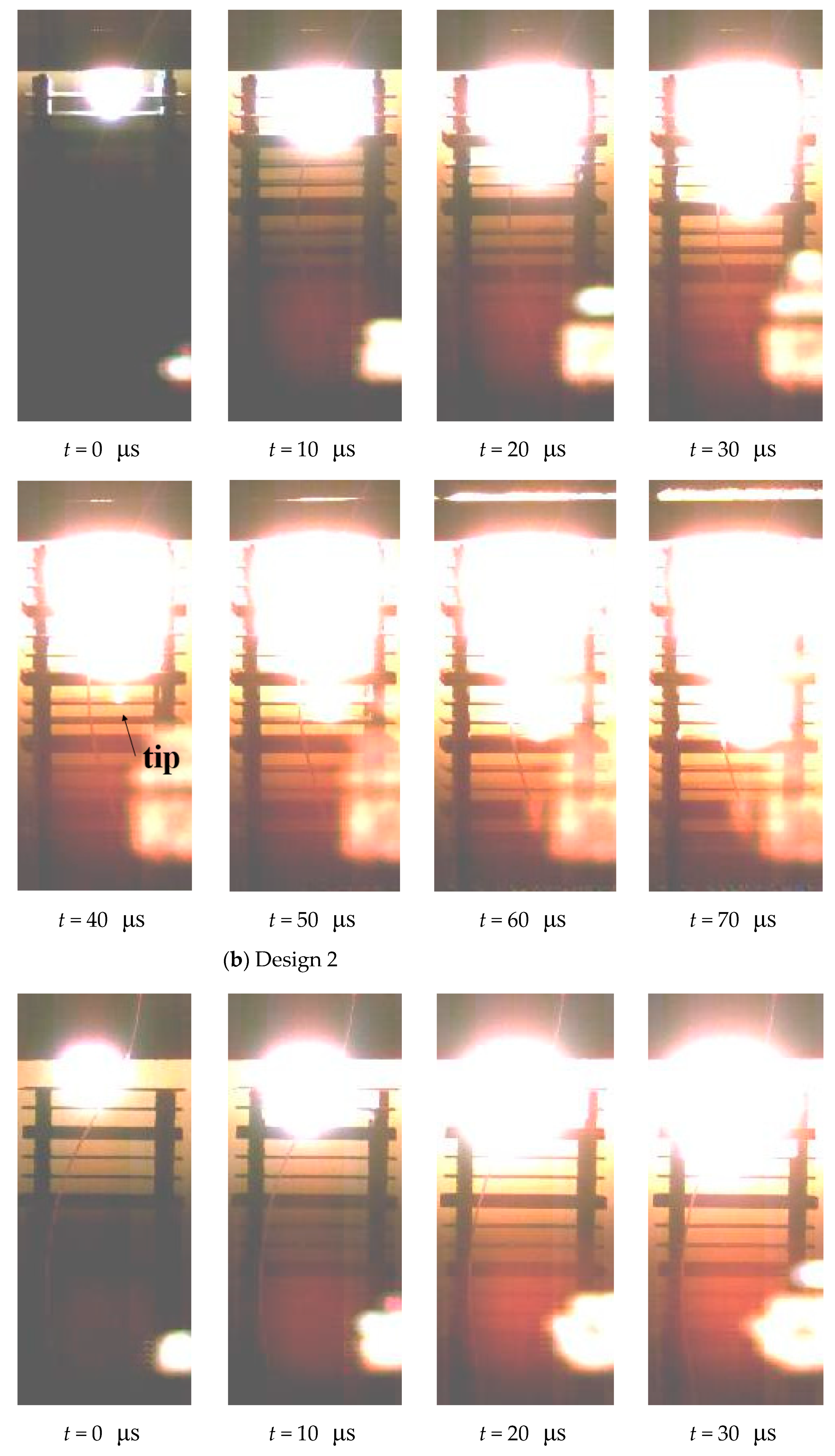

3.3. Impacting Behavior and Firelight

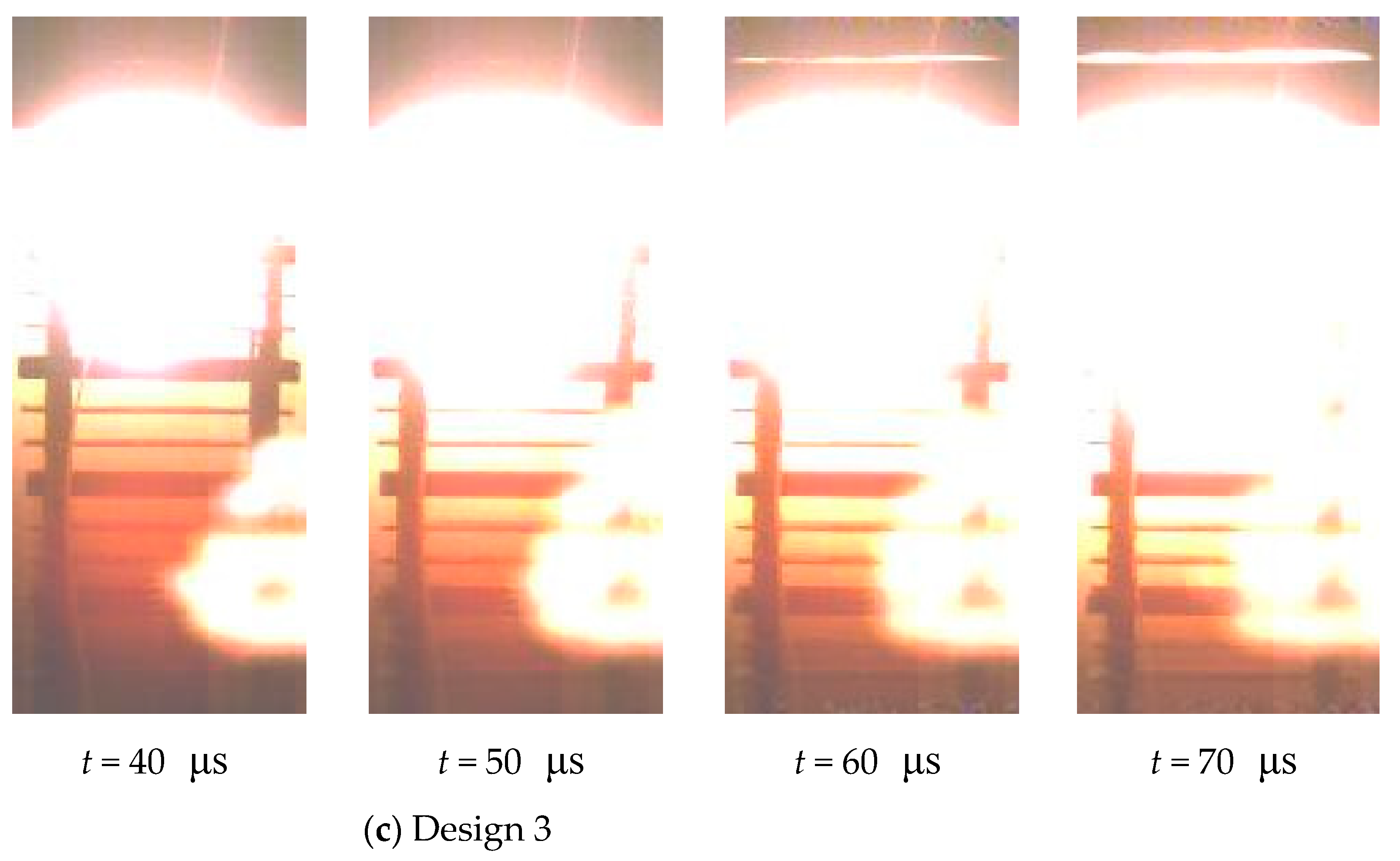

4. Numerical Simulation of Jet Formation

4.1. Numerical Setup

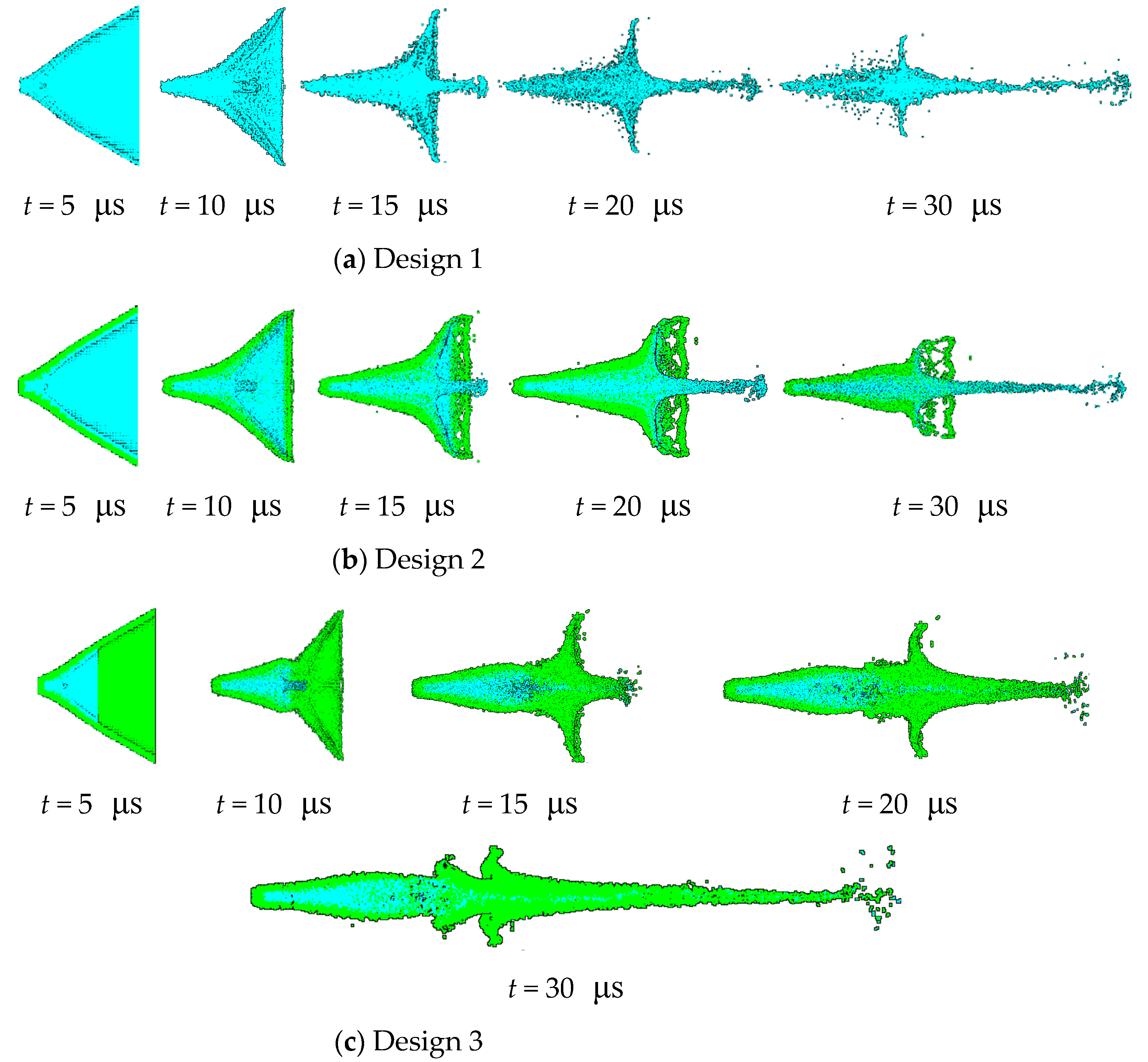

4.2. Formation, Velocity Gradient, and Velocity Distribution

5. Conclusions

- Significant PE effects were observed for the Cu/Al composite jets according to the perforation and deformation of the target plates and the observed firelight characteristics.

- The two composite jets are distinct in their effects, including perforation, deformation, and synchronous firelight. The distinct PE effects can be attributed to the different elemental distributions. Simulation shows that for design 2, the tip of the composite jet is exclusively Cu and the rest of the jet is wrapped with Al. In contrast, for design 3, the Cu jet is almost wrapped entirely in Al from the tip to the tail.

- The PE effects of four basic distributions in composite jets are analyzed according to different damaging characteristics of the inactive and active parts. The Cu/Al composite jet in design 3 corresponds to the basic distribution (a), whereas design 2 corresponds to a combination of (a) and (c). Design 2 differs from design 3 only from its full-height Cu liner, and consequently cause different elemental distributions of the jets, which leads to poorer penetration depth and lateral damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed, M.; Qadeer Malik, A. A Review of Works on Shaped Charges. Technol. Appl. Sci. Res. 2017, 7, 2098–2103. [Google Scholar] [CrossRef]

- Hastings, D.L.; Dreizin, E.L. Reactive Structural Materials: Preparation and Characterization. Adv. Eng. Mater. 2018, 20, 1700631. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, J.; Li, M.; Men, J.; Wang, S. Improving the damage potential of -Zr reactive structure material under extreme loading condition. Def. Technol. 2020, 17, 467–477. [Google Scholar] [CrossRef]

- Zhang, X.F.; Shi, A.S.; Qiao, L.; Zhang, J.; Zhang, Y.G.; Guan, Z.W. Experimental study on impact-initiated characters of multifunctional energetic structural materials. J. Appl. Phys. 2013, 113, 083508. [Google Scholar] [CrossRef]

- Xiao, Y.W. Research on Penetration-Induced Blast Effect and Damage Mechanism of Reactive Material Fragment; Beijing Institute of Technology: Beijing, China, 2016. [Google Scholar]

- Xu, F.Y.; Yu, Q.B.; Zheng, Y.F.; Lei, M.A.; Wang, H.F. Damage effects of double-spaced aluminum plates by reactive material projectile impact. Int. J. Impact Eng. 2017, 104, 13–20. [Google Scholar] [CrossRef]

- Lee, R.J.; Mock, W., Jr.; Carney, J.R.; Holt, W.H.; Pangilinan, G.I.; Gamache, R.M.; Boteler, J.M.; Bohl, D.G.; Drotar, J.; Lawrence, G.W. Reactive materials studies. In Shock Compression of Condensedmatter-2005, Proceedings of the Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter, Baltimore, MD, USA, 31 July–5 August 2005; AIP Publishing: College Park, MD, USA, 2006; pp. 169–174. [Google Scholar]

- Baker, E.L.; Daniels, A.S.; Ng, K.W.; Martin, V.O.; Orosz, J.P. Barnie: A unitary demolition warhead. In Proceedings of the 19th International Symposium on Ballistics, Interlaken, Switzerland, 7–11 May 2001; pp. 7–11. [Google Scholar]

- Laszlo, J.; Kecskes, W.P.W. Investigation of a bulk metallic glass as a shaped charge liner material. In Proceedings of the 23rd International Symposium on Ballistics, Tarragona, Spain, 16–20 April 2007; pp. 31–38. [Google Scholar]

- Davison, D.; Pratt, D. Perforator with Energetic Liner. In Proceedings of the 26th International Symposium on Ballistics, Miami, FL, USA, 12–16 September 2011; pp. 123–133. [Google Scholar]

- Church, P.; Claridge, R.; Ottley, P.; Lewtas, I.; Harrison, N.; Gould, P.; Braithwaite, C.; Williamson, D. Investigation of a Nickel-Aluminum Reactive Shaped Charge Liner. J. Appl. Mech. 2013, 80, 031701. [Google Scholar] [CrossRef]

- Zhang, Z.M.; Xu, B.Y.; Yan, F.; Liu, F.W.; Guo, J.L.; Fu, W. Penetrating Test of Active Metal Charge Liner Perforating Bullet. Explos. Mater. 2013, 42, 53–56. [Google Scholar]

- Guo, H.; Zheng, Y.; Yu, Q.; Ge, C.; Wang, H. Penetration behavior of reactive liner shaped charge jet impacting thick steel plates. Int. J. Impact Eng. 2019, 126, 76–84. [Google Scholar] [CrossRef]

- Zheng, Y.-F.; Su, C.-H.; Guo, H.-G.; Yu, Q.-B.; Wang, H.-F. Chain damage effects of multi-spaced plates by reactive jet impact. Def. Technol. 2021, 17, 393–404. [Google Scholar] [CrossRef]

- Guo, H.; Zheng, Y.; Tang, L.; Yu, Q.; Ge, C.; Wang, H. Effect of wave shaper on reactive materials jet formation and its penetration performance. Def. Technol. 2019, 15, 495–505. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Q.; Zheng, Y.; Wang, H. Formation and penetration of jets by shaped charges with reactive materials liners. Propellants Explos. Pyrotech. 2016, 41, 618–622. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, X.; Wang, Y.; Xu, F.; Wang, H. Demolition mechanism and behavior of shaped charge with reactive liner. Propellants Explos. Pyrotech. 2016, 41, 612–617. [Google Scholar] [CrossRef]

- Xu, S.C. Study on Jet Forming Mechanism and Penetration Property of Double-Layer Layer Liners Comprised of Reactive Material; Nanjing University of Science and Technology: Nanjing, China, 2015. [Google Scholar]

- Won, J.; Bae, G.; Kang, K.; Lee, C.; Kim, S.J.; Lee, K.-A.; Lee, S. Bonding, reactivity, and mechanical properties of the kinetic-sprayed deposition of Al for a thermally activated reactive Cu liner. J. Therm. Spray Technol. 2014, 23, 818–826. [Google Scholar] [CrossRef]

- Byun, G.; Kim, J.; Lee, C.; Kim, S.J.; Lee, S. Kinetic Spraying Deposition of Reactive-Enhanced Al-Ni Composite for Shaped Charge Liner Applications. J. Therm. Spray Technol. 2016, 25, 483–493. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.; Kim, S.; Lee, S.; Jeong, J.; Lee, C. Performance Comparison of Double-layer-Layer Liner for Shaped Charge Fabricated Using Kinetic Spray. J. Therm. Spray Technol. 2019, 28, 484–494. [Google Scholar] [CrossRef]

- Guo, H.; Lu, G.; He, S.; Wang, H.; Xiao, Y.; Zheng, Y. Penetration Enhancement Behavior of Reactive Material Double-layer-Layered Liner Shaped Charge. Trans. Beijing Inst. Technol. 2020, 40, 1259–1266. [Google Scholar]

- Huang, B.; Xiong, W.; Zhang, X.; Liu, C.; Du, N.; Tan, M. Experimental Study on Jet Formation and Penetration Performance of Double-layer⁃layered Reactive Liners with K-Charge. Chin. J. Energ. Mater. 2021, 29, 149–156. [Google Scholar]

- Han, J.; Chen, X.; Du, Z.; Fu, H.; Huang, D. Design and penetration of a new W-particle/Zr-based amorphous alloy composite liner. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 364. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, Y.-F.; Yu, Q.-B.; Ge, C.; Su, C.-H.; Wang, H.-F. Penetration and internal blast behavior of reactive liner enhanced shaped charge against concrete space. Def. Technol. 2021; in press. [Google Scholar] [CrossRef]

- Wang, H.; Guo, H.; Geng, B.; Yu, Q.; Zheng, Y. Materials Application of PTFE/Al Reactive Materials for Double-Layered Liner Shaped Charge. Materials 2019, 12, 2768. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, F.; Jiang, J.; Men, J.; Bai, Y.; Wang, S.; Li, M. Investigation on shaped charge jet density gradient for metal matrix composites: Experimental design and execution. Int. J. Impact Eng. 2017, 109, 311–320. [Google Scholar] [CrossRef]

- Ma, H.-B.; Zheng, Y.-F.; Wang, H.-F.; Ge, C.; Su, C.-H. Formation and impact-induced separation of tandem EFPs. Def. Technol. 2020, 16, 668–677. [Google Scholar] [CrossRef]

| No. | Main Charge | Inner Liner | Outer Liner | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | Mass/g | Material | Height/mm | Width/mm | Mass/g | Material | Height/mm | Width/mm | Mass/g | |

| Design 1 | JH-2 | 175.14 | / | Cu | 42.0 | 54.2 | 41.1 | |||

| Design 2 | 175.16 | Al | 42.0 | 54.2 | 25.1 | 40.0 | 49.5 | 32.8 | ||

| Design 3 | 175.12 | 25.9 | 20.0 | 26.4 | 9.2 | |||||

| Materials | /(g·cm−3) | A/GPa | B/GPa | C | np | mt |

|---|---|---|---|---|---|---|

| Copper | 8.96 | 0.090 | 0.292 | 0.025 | 0.31 | 1.09 |

| Al | 2.77 | 0.337 | 0.343 | 0.01 | 0.41 | 1.00 |

| Material | /(g·cm−3) | A/GPa | B/GPa | R1 | R2 | E0/GPa | PCJ/GPa | D/(m·s−1) | |

|---|---|---|---|---|---|---|---|---|---|

| explosive 8701 | 1.71 | 524.23 | 7.678 | 4.2 | 1.1 | 0.34 | 8.499 | 28.6 | 8315 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, J.; Jiang, J.; Men, J.; Li, J.; Zhou, D.; Hu, Y. The Penetration–Explosion Effects of Differently Distributed Inactive/Active Composite Shaped Charge Jets. Materials 2022, 15, 344. https://doi.org/10.3390/ma15010344

Peng J, Jiang J, Men J, Li J, Zhou D, Hu Y. The Penetration–Explosion Effects of Differently Distributed Inactive/Active Composite Shaped Charge Jets. Materials. 2022; 15(1):344. https://doi.org/10.3390/ma15010344

Chicago/Turabian StylePeng, Jiacheng, Jianwei Jiang, Jianbing Men, Jinlin Li, Dongkang Zhou, and Yuan Hu. 2022. "The Penetration–Explosion Effects of Differently Distributed Inactive/Active Composite Shaped Charge Jets" Materials 15, no. 1: 344. https://doi.org/10.3390/ma15010344