The Structure and Compression of Medical Compression Stockings

Abstract

:1. Introduction

2. Experimental Part

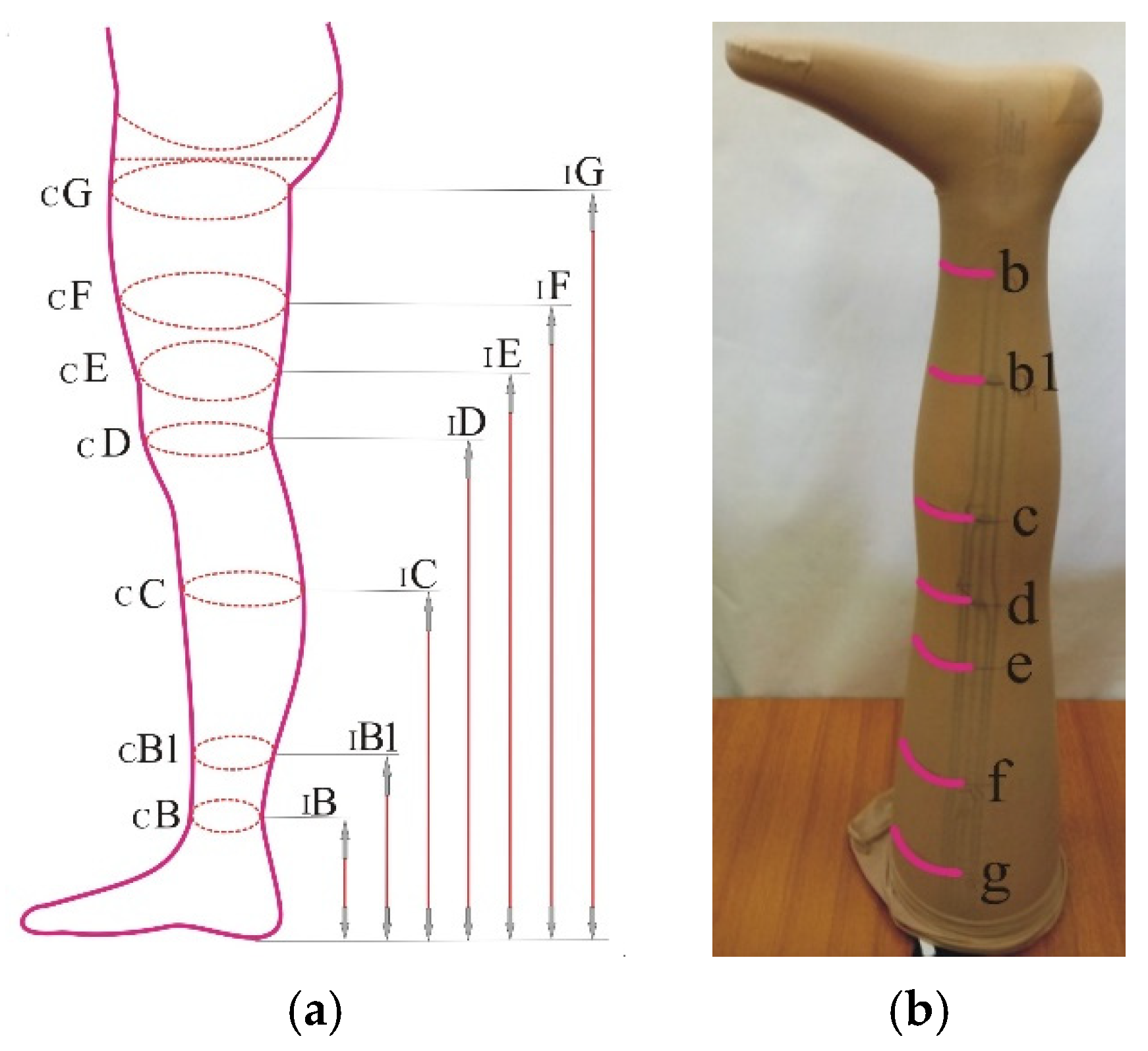

2.1. Wooden Model Leg

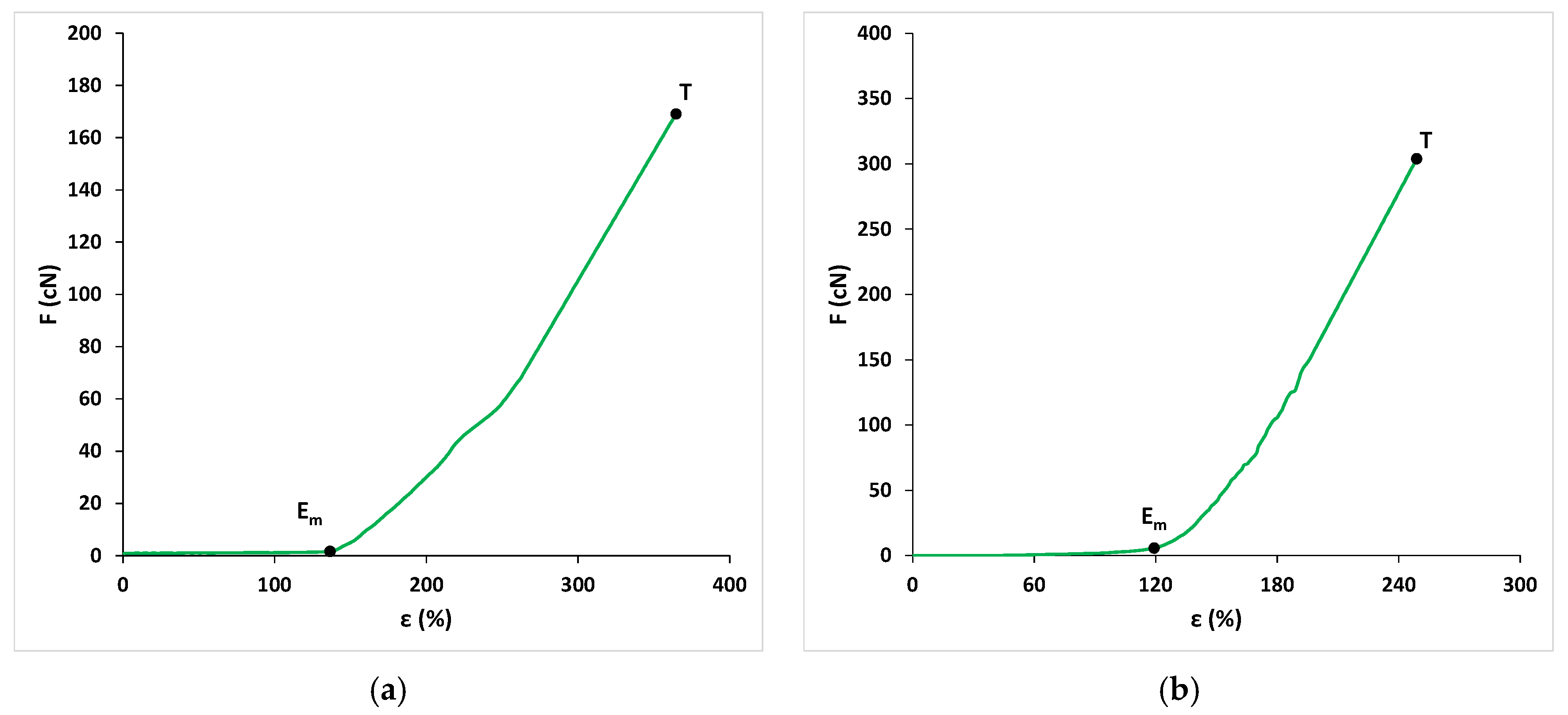

2.2. Characteristic Parameters of Yarns

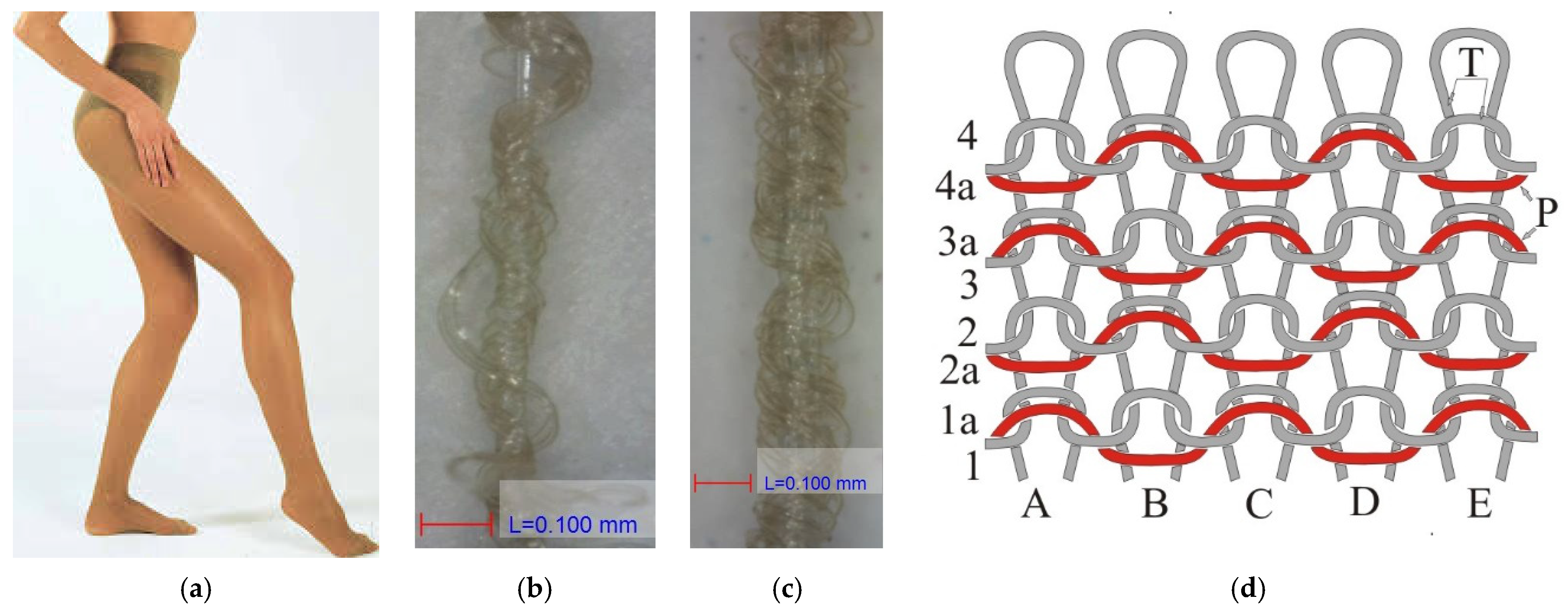

2.3. Characteristic Parameters of Medical Moderate Compression Pantyhose

- ISO 2062:2003: Textiles—Yarn from packages. Determination of single-end breaking force and elongation at break.

- ASTM D8007-15 (2019) was used to determine the wale and course counts of weft-knitted fabrics per unit of length.

- ISO 3801:1977. Determination of mass per unit length and mass per unit area.

- ISO 7211-5:1984. Woven fabrics—construction—methods of analysis—part 5: determination of linear density of yarn removed from the fabric.

2.4. Characteristic Parameters of Medical High-Compression Pantyhose

3. Results and Discussion

3.1. For Medical Moderate-Compression Pantyhose

3.2. For Medical High-Compression Pantyhose

4. Conclusions

- It is important to know the purpose of the stocking, e.g., if it is intended for someone who is healthy or sick, mobile or immobile or if the stocking is used in an air-conditioned, cold or hot area/space.

- According to the purpose of the stocking, it is necessary to choose a machine of certain construction, fineness and needle bed diameter (length) that will be used to produce the stocking. The knitting technologist who designs the stocking structure must be given a sketch of the leg shape (pictogram) that contains leg lengths and circumferences at specific main points and the desired compression on each specific leg part. In modern production, compression stockings are made according to the personalization principle.

- The count and structure of the elastane yarns used to produce stockings are chosen based on the obtained input data. A certain width of knitted fabric in a specific part of the stocking (leg of the stocking) that is to exert the required compression at certain elongation is achieved by regulating the sinking depth and elongation force when the yarn is fed into the knitting zone. Elongation properties achieved by knitting must remain largely unaffected by the refinement process.

- The structure of the knitted fabric and the stretching and compression values of the stocking were analyzed in this study. The analyzed stocking whose compression above the ankle was about 32 hPa and 11 hPa below the groin was a stocking of moderate compression. According to the German norm, this stocking belongs to class II. The second analyzed stocking achieved high compression above the ankle (class III), which was about 60 hPa and 27 hPa below the groin. These stockings are usually intended for the treatment of various venous diseases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Simončič, K.N. Women’s Fashion in Zagreb, Croatia, 1900–1918. J. Dress Hist. 2019, 3, 104–129. [Google Scholar]

- Ilska, A.; Kowalski, K.; Klonowska, M.; Kuzanski, W.; Kowalski, T.M.; Sujka, W. Using 3D Body Scanner in Designig Compresion Products Supporting External Treatment. Fibres Text. East. Eur. 2017, 25, 107–112. [Google Scholar] [CrossRef]

- Wu, J.; Jin, Z.; Jin, J.; Yan, Y. Study on the tensile modulus of seamless fabric and tight compression finite element modeling. Text. Res. J. 2020, 90, 110–122. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, D.; Cheng, L.; Yang, Z.; Li, J. Evaluating the biomechanical interaction between the medical compression stocking and human calf using a highly anatomical fidelity three-dimensional finite element model. Text. Res. J. 2020, 90, 1326–1340. [Google Scholar] [CrossRef]

- ISO 8559-1:2017. Size Designation of Clothes—Part 1: Anthropometric Definitions for Body Measurement; BSI: London, UK, 2017. [Google Scholar]

- Artec 3D—3D Body Scanning Solutions. Available online: https://www.artec3d.com (accessed on 17 June 2020).

- RAL-GZ 387/1 Medizinische Kompressionsstrümpfe. Available online: https://www.gzg-kompressionsstruempfe.de/uploads/media/RAL-GZ_387-1_Medizinische_Kompressionsstruempfe.pdf (accessed on 19 June 2020).

- BS 6612:1985. Specification for Graduated Compression Hosiery; BSI: London, UK, 2016. [Google Scholar]

- ASQAL: Chaussettes, Bas, Collants, et Manchons. Available online: https://www.asqual.com/fiche/chaussettes-bas-collants-et-manchons/ (accessed on 19 June 2020).

- Van Der Wegen-Franken, C.P.M. Medical Elastic Compression Stockings. Doctoral Dissertation, Erasmus Universiteit Rotterdam, Rotterdam, The Netherlands, 2009. [Google Scholar]

- Shahidi, A.M. The Development of Test Procedures for Controlling the Quality of the Manufacture of Engineered Compression Stockings. Ph.D. Dissertation, Faculty of Engineering and Physical Sciences, The University of Manchester, Manchester, UK, 2010. [Google Scholar]

- Lozo, M.; Vrljičak, Z. Structure and Elongation of fine Ladies’ Hosiery. In Proceedings of the 48th Conference of the International Federation of Knitting Technologists (IFKT), Moenchengladbach, Germany, 8–11 June 2016; pp. 1–10. [Google Scholar]

- Neumann, H.; Partsch, H.; Mosti, G.; Flour, M. Classification of compression stockings: Report of the meeting of the International Compression Club, Copenhagen. Int. Angiol. 2016, 35, 122–128. [Google Scholar]

- Bašić, R.; Rošić, D.; Ledinsky, I.; Lovričević, I. Orthostatics and Chronic Venous Insufficiency an Croatian Doctors of Dental Medicine. Acta Clin. Croat. 2014, 53, 3–6. [Google Scholar]

- Farrow, W. Phlebolymphedema—A Common Underdiagnosed and Undertreated Problem in the Wound Care Clinic. J. Am. Coll. Certif. Wound Spec. 2010, 2, 14–23. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Guo, X.; Lao, T.; Litte, T. A critical review on compression textiles for compression therapy: Textile-based compression interventions for chronic venous insufficiency. Text. Res. J. 2017, 87, 1121–1141. [Google Scholar] [CrossRef]

- Chen, Y.; Bruniaux, P.; Sun, Y.; Hong, Y. Modelization and identification of medical compression stocking: Part 2—3D interface pressure modelization. Text. Res. J. 2020, 90, 2184–2197. [Google Scholar] [CrossRef]

- Sari, B.; Oglakcioglu, N. Analysis of the parameters affecting pressure characteristics of medical stockings. J. Ind. Text. 2018, 47, 1083–1096. [Google Scholar] [CrossRef]

- Kumar, B.; Das, A.; Alagirusamy, R. Compression under static state. In Science of Compression Bandage; Woodhead Publishing India: New Delhi, India, 2014; pp. 56–72. [Google Scholar]

- MacRae, B.A.; Laing, R.M.; Partsch, H. General Considerations for Compression Garments in Sports: Applied Pressures and Body Coverage. In Compression Garments in Sports: Athletic Performance and Recovery; Engel, B., Sperlich, B., Eds.; Springer: Basel, Switzerland, 2016; pp. 1–32. [Google Scholar]

- Kowalski, K.; Mielicka, E.; Jasinska, I. Modelling and Analysis of the Circumferential Forces and Susceptibility of Vascular Prostheses to Internal Pressure Changes. Fibres Text. East. Eur. 2012, 20, 87–91. [Google Scholar]

- Kowalski, K.; Mielicka, E.; Kowalski, T.M. Modelling and Designing Compression Garments with Unit Pressure Assumed for Body Circumferences of a Variable Curvasture Radius. Fibres Text. East. Eur. 2012, 20, 98–102. [Google Scholar]

- Ramelet, A.A.; Monti, M. Phlebology: The Guide; Elsevier: Amsterdam, The Netherlands, 1999; pp. 154–196. [Google Scholar]

- Rabe, E.; Partsch, H.; Hafner, J.; Lattimer, C.; Mosti, G.; Neumann, M.; Urbanek, T.; Huebner, M.; Gaillard, S.; Carpentier, P. Indications for medical compression stockings in venous and lymphatic disorders: An evidence-based consensus statement. Phlebology 2018, 33, 163–184. [Google Scholar] [CrossRef] [Green Version]

- Swisslastic AG St. Gallen—Pressure Measuring Devices. Available online: https://swisslastic.ch/en/products/pressure-measuring-devices (accessed on 12 May 2019).

- Siddique, H.F.; Mazari, A.; Havelka, A.; Kus, Z.; Cirkl, D.; Hes, L. New approach for the prediction of compression pressure using the cut strip method. Text. Res. J. 2020, 90, 1689–1703. [Google Scholar] [CrossRef]

- Liu, R.; Lao, T.; Little, T.; Wu, X.; Ke, X. Can heterogeneous compression textile design reshape skin pressure? A fundamental study. Text. Res. J. 2018, 88, 1915–1930. [Google Scholar] [CrossRef]

- Hakala, T.; Puolakka, A.; Nousiainen, P.; Vuorela, T.; Vanhala, J. Application o fair bladders for medical compression hosieries. Text. Res. J. 2018, 88, 2169–2181. [Google Scholar] [CrossRef]

| Leg Sizes | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Circumference (cm) | gmax | 53 | 55 | 57.5 | 60 | 62.5 | 65 | 67 | 69.5 | 72 | 74.5 | 77 |

| fmax | 48 | 50 | 51.5 | 53 | 55 | 57 | 58.5 | 60 | 62 | 64 | 65.5 | |

| g | 44 | 46 | 48 | 50 | 52 | 54 | 56 | 58 | 60 | 62 | 64 | |

| f | 41 | 42.5 | 44 | 45.5 | 47 | 48.5 | 50 | 51.5 | 53 | 54.5 | 56 | |

| e | 31 | 32.5 | 34 | 35.5 | 37 | 38.5 | 40 | 41.5 | 43 | 44.5 | 46 | |

| d | 28 | 29.5 | 31 | 32.5 | 34 | 35.5 | 37 | 38.5 | 40 | 41.5 | 43 | |

| c | 30 | 31.5 | 33 | 34.5 | 36 | 37.5 | 39 | 40.5 | 42 | 43.5 | 45 | |

| b1 | 24 | 25.5 | 26.5 | 27.5 | 29 | 30 | 31.5 | 32.5 | 34 | 35 | 36.5 | |

| h | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | |

| b-b | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | |

| Height (cm) | I-B | 12 | ||||||||||

| I-B1 | 20 | |||||||||||

| I-C | 31 | |||||||||||

| I-D | 39 | |||||||||||

| I-E | 45 | |||||||||||

| I-F | 60 | |||||||||||

| I-G | 72 | |||||||||||

| Medical Moderate Compression Pantyhose; “Weft” in Each Course with Laying Rapport 1 + 1; 420 Wales | ||||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Points on the Wooden Leg Marked to Measure Certain Parameters | |||||||

| b | b1 | c | d | e | f | g | ||

| Loc (mm) | 746 | 804 | 861 | 902 | 948 | 975 | 1014 | |

| ℓoc (mm) | 1.78 | 1.91 | 2.05 | 2.15 | 2.26 | 2.32 | 2.41 | |

| moc (g) | 0.0036 | 0.0040 | 0.0043 | 0.0047 | 0.0051 | 0.0054 | 0.0057 | |

| Lpo (mm) | 195 | 223 | 250 | 292 | 323 | 358 | 395 | |

| ℓpo (mm) | 0.46 | 0.53 | 0.60 | 0.70 | 0.77 | 0.85 | 0.94 | |

| mpo (g) | 0.0043 | 0.005 | 0.0057 | 0.0063 | 0.0075 | 0.0086 | 0.0096 | |

| Ttoc (dtex) | 48 | 49 | 50 | 52 | 52 | 55 | 56 | |

| Ttpo (dtex) | 218 | 224 | 228 | 216 | 232 | 241 | 243 | |

| me (g/m2) | 168 | 167 | 166 | 168 | 169 | 170 | 161 | |

| Sp (mm) | 150 | 164 | 176 | 184 | 194 | 204 | 220 | |

| εpl (%) | M7 | 47 | 72 | 96 | 105 | 114 | 123 | 127 |

| M9 | 60 | 87 | 113 | 121 | 129 | 138 | 145 | |

| M11 | 73 | 102 | 130 | 137 | 144 | 152 | 164 | |

| Medical High Compression Pantyhose; “Weft“ in Each Course with Laying Rapport 1 + 1; 420 Wales | ||||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Points on the Wooden Leg Marked to Measure Certain Parameters | |||||||

| b | b1 | c | d | e | f | g | ||

| Loc (mm) | 1000 | 1033 | 1067 | 1208 | 1258 | 1300 | 1332 | |

| ℓoc (mm) | 2.38 | 2.46 | 2.54 | 2.88 | 2.99 | 3.10 | 3.17 | |

| moc (g) | 0.0118 | 0.0122 | 0.0126 | 0.0147 | 0.0153 | 0.0159 | 0.0161 | |

| Lpo (mm) | 180 | 200 | 220 | 240 | 290 | 340 | 370 | |

| ℓpo (mm) | 0.43 | 0.48 | 0.52 | 0.57 | 0.69 | 0.81 | 0.88 | |

| mpo (g) | 0.0120 | 0.0137 | 0.0153 | 0.0165 | 0.0204 | 0.0243 | 0.0271 | |

| Ttoc (dtex) | 118 | 118 | 118 | 121 | 120 | 122 | 121 | |

| Ttpo (dtex) | 668 | 683 | 696 | 685 | 700 | 715 | 732 | |

| me (g/m2) | 298 | 293 | 288 | 278 | 275 | 272 | 260 | |

| Sp (mm) | 170 | 196 | 220 | 230 | 280 | 330 | 340 | |

| εpl (%) | M7 | 29 | 29 | 57 | 41 | 40 | 38 | 47 |

| M9 | 41 | 43 | 70 | 54 | 51 | 47 | 59 | |

| M11 | 53 | 69 | 84 | 67 | 62 | 56 | 71 | |

| Compression | Size of the Leg Model | Positions for Measuring Compression on the Wooden Leg Model | ||||||

|---|---|---|---|---|---|---|---|---|

| b | b1 | c | d | e | f | g | ||

| Measured compression (hPa) | M7 | 31 | 37 | 24 | 19 | 19 | 13 | 11 |

| M9 | 32 | 38 | 25 | 20 | 19 | 14 | 11 | |

| M11 | 33 | 40 | 27 | 20 | 20 | 15 | 12 | |

| Compression | Size of the Leg Model | Positions for Measuring Compression on the Wooden Leg Model | ||||||

|---|---|---|---|---|---|---|---|---|

| b | b1 | c | d | e | f | g | ||

| Measured compression (hPa) | M7 | 58 | 56 | 43 | 28 | 27 | 24 | 24 |

| M9 | 60 | 59 | 45 | 30 | 27 | 27 | 27 | |

| M11 | 61 | 60 | 47 | 32 | 29 | 27 | 27 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozo, M.; Penava, Ž.; Lovričević, I.; Vrljičak, Z. The Structure and Compression of Medical Compression Stockings. Materials 2022, 15, 353. https://doi.org/10.3390/ma15010353

Lozo M, Penava Ž, Lovričević I, Vrljičak Z. The Structure and Compression of Medical Compression Stockings. Materials. 2022; 15(1):353. https://doi.org/10.3390/ma15010353

Chicago/Turabian StyleLozo, Miloš, Željko Penava, Ivo Lovričević, and Zlatko Vrljičak. 2022. "The Structure and Compression of Medical Compression Stockings" Materials 15, no. 1: 353. https://doi.org/10.3390/ma15010353

APA StyleLozo, M., Penava, Ž., Lovričević, I., & Vrljičak, Z. (2022). The Structure and Compression of Medical Compression Stockings. Materials, 15(1), 353. https://doi.org/10.3390/ma15010353