Deterioration Mechanisms and Advanced Inspection Technologies of Aluminum Windows

Abstract

:1. Introduction

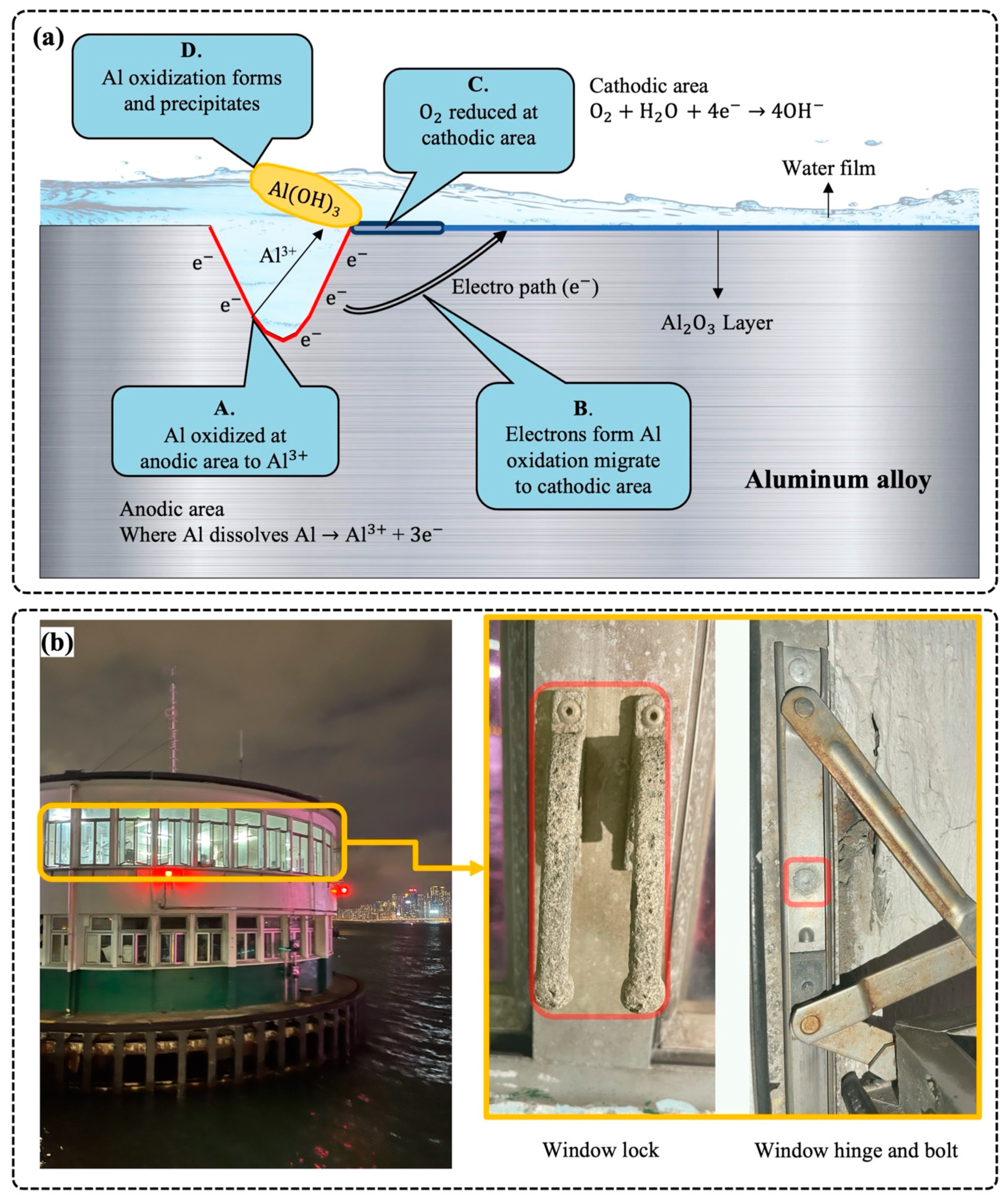

2. Deterioration of Aluminum Windows

2.1. Moisture

2.2. Chloride Ions

2.3. Air Pollutants

2.4. Temperature

2.5. Mechanical Loadings

2.6. Challenge of Current Studies in Aluminum Alloy Corrosion

3. Technologies for Aluminum Window Inspection

3.1. Ultrasonic Testing

3.2. Active Infrared Thermal Image

3.3. Comparison

4. Future Outlook

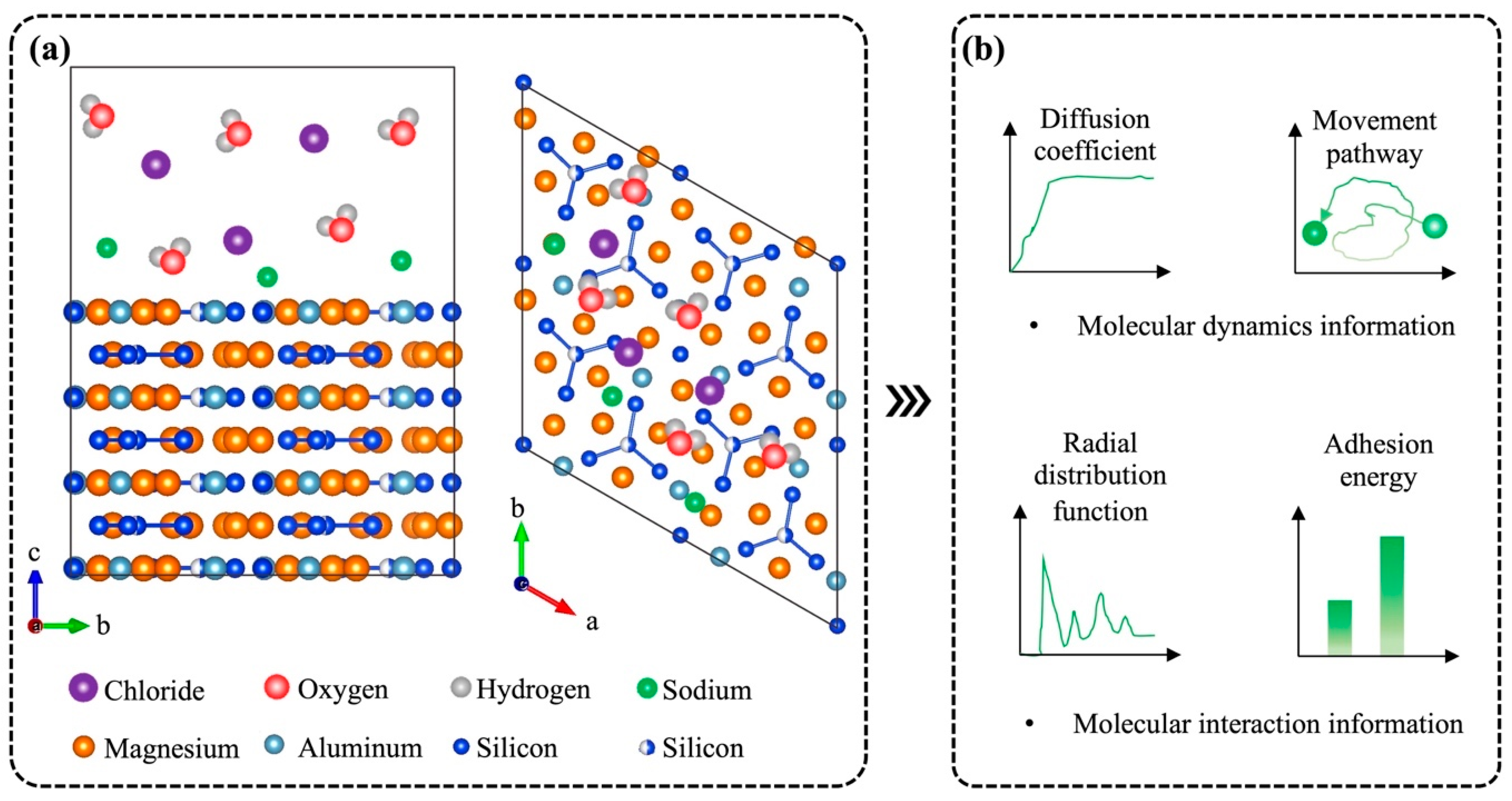

4.1. Using MD Simulations for Understanding Corrosion Mechanisms of Aluminum Alloy

4.2. Using AI Technologies for Predicting the Health State of Aluminum Windows

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akbari, M.; Gunalan, S.; Gilbert, B.P.; Guan, H. Bearing Behaviour of Aluminium Sub-Heads with Removable Beads in Façade Systems. Structures 2021, 32, 1934–1954. [Google Scholar] [CrossRef]

- Chowdhary, A.K.; Sikdar, D. Solar Energy Materials and Solar Cells Design of Electrotunable All-Weather Smart Windows. Sol. Energy Mater. Sol. Cells 2021, 222, 110921. [Google Scholar] [CrossRef]

- Turner, W.J.N.; Awbi, H.B. Experimental Investigation into the Thermal Performance of a Residential Hybrid Ventilation System. Appl. Therm. Eng. 2015, 77, 142–152. [Google Scholar] [CrossRef]

- Torres-Ramo, J.; González-Martínez, P.; Arriazu-Ramos, N.; Sánchez-Ostiz, A. Influence of the Water Vapour Permeability of Airtight Sheets on the Behaviour of Facade. Sustainability 2020, 12, 10480. [Google Scholar] [CrossRef]

- Dao, T.N.; Van de Lindt, J.W.; Prevatt, D.O.; Gupta, R. Probabilistic Procedure for Wood-Frame Roof Sheathing Panel Debris Impact to Windows in Hurricanes. Eng. Struct. 2012, 35, 178–187. [Google Scholar] [CrossRef] [Green Version]

- Konstantinov, A.; Motina, M. Influence of Sashes Stiffness on PVC Windows Resistance to Wind Load. IOP Conf. Ser. Mater. Sci. Eng. 2018, 463, 032044. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Li, S.; Meng, Y.; Yu, M.; Liu, J.; Li, B. Corrosion Inhibition of Aluminum Current Collector with Molybdate Conversion Coating in Commercial LiPF 6 -Esters Electrolytes. Corros. Sci. 2021, 190, 109632. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Yue, X.; Cai, W. Multiphysics Modeling and Uncertainty Quantification of Tribocorrosion in Aluminum Alloys. Corros. Sci. 2021, 178, 109095. [Google Scholar] [CrossRef]

- Georgantzia, E.; Gkantou, M.; Kamaris, G.S. Aluminium Alloys as Structural Material: A Review of Research. Eng. Struct. 2021, 227, 111372. [Google Scholar] [CrossRef]

- Huo, Y.; Tan, M.Y.; Shu, L. Effects of High Salt Concentration and Residue on Copper and Aluminum Corrosion. Chem. Res. Chin. Univ. 2013, 29, 538–544. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Chow, C.L.; Lau, D. Structural Performance of FRP Confined Seawater Concrete Columns under Chloride Environment. Compos. Struct. 2019, 216, 12–19. [Google Scholar] [CrossRef]

- Gou, G.; Zhang, M.; Chen, H.; Chen, J.; Li, P.; Yang, Y.P. Effect of Humidity on Porosity, Microstructure, and Fatigue Strength of A7N01S-T5 Aluminum Alloy Welded Joints in High-Speed Trains. Mater. Des. 2015, 85, 309–317. [Google Scholar] [CrossRef]

- Zaid, B.; Saidi, D.; Benzaid, A.; Hadji, S. Effects of PH and Chloride Concentration on Pitting Corrosion of AA6061 Aluminum Alloy. Corros. Sci. 2008, 50, 1841–1847. [Google Scholar] [CrossRef]

- Qin, R.; Qiu, Q.; Lam, J.H.M.; Tang, A.M.C.; Leung, M.W.K.; Lau, D. Health Assessment of Tree Trunk by Using Acoustic-Laser Technique and Sonic Tomography. Wood Sci. Technol. 2018, 52, 1113–1132. [Google Scholar] [CrossRef]

- Qiu, Q.; Lau, D. Defect Detection in FRP-Bonded Structural System via Phase-Based Motion Magnification Technique. Struct. Control Health Monit. 2018, 25, 1–17. [Google Scholar] [CrossRef]

- Qiu, Q.; Qin, R.; Lam, J.H.M.; Tang, A.M.C.; Leung, M.W.K.; Lau, D. An Innovative Tomographic Technique Integrated with Acoustic-Laser Approach for Detecting Defects in Tree Trunk. Comput. Electron. Agric. 2019, 156, 129–137. [Google Scholar] [CrossRef]

- Zhou, Z. Application of P4 Polyphase Codes Pulse Compression Method to Air-Coupled Ultrasonic Testing Systems. Ultrasonics 2017, 78, 57–69. [Google Scholar] [CrossRef]

- Le Jeune, L.; Robert, S.; Villaverde, E.L.; Prada, C. Multimodal Plane Wave Imaging for Non-Destructive Testing. Phys. Procedia 2015, 70, 570–573. [Google Scholar] [CrossRef]

- Felice, M.V.; Fan, Z. Sizing of Flaws Using Ultrasonic Bulk Wave Testing: A Review. Ultrasonics 2018, 88, 26–42. [Google Scholar] [CrossRef]

- Aggarwal, N.; Garg, M.; Dwarakanathan, V.; Gautam, N.; Kumar, S.S.; Jadon, R.S.; Gupta, M.; Ray, A. Diagnostic Accuracy of Non-Contact Infrared Thermometers and Thermal Scanners: A Systematic Review and Meta-Analysis. J. Travel Med. 2020, 27, 1–17. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared Thermography for Condition Monitoring—A Review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Calin, M.A.; Mologhianu, G.; Savastru, R.; Calin, M.R.; Brailescu, C.M. A Review of the Effectiveness of Thermal Infrared Imaging in the Diagnosis and Monitoring of Knee Diseases. Infrared Phys. Technol. 2015, 69, 19–25. [Google Scholar] [CrossRef]

- Jung, J.; Oh, S.; Kwon, H. Effects of Environmental Factors on Corrosion Behavior of Aluminum. Mater. Corros. 2021, 72, 557–563. [Google Scholar] [CrossRef]

- Cai, Z.; Zhu, M.; Shen, H.; Zhou, Z.; Jin, X. Torsional Fretting Wear Behaviour of 7075 Aluminium Alloy in Various Relative Humidity Environments. Wear 2009, 267, 330–339. [Google Scholar] [CrossRef]

- Peacock, H.B.; Sindelar, R.L.; Lam, P.S. Temperature and Humidity Effects Aluminum-Base Reactor Fuel Cladding Materials During Dry Storage, Report Number WSRC-MS-95-0354—United States; Paris (France). Presented at the International Meeting on Reduced Enrichment for Research and Test Reactors, Paris, France, 18–21 September 1995. [Google Scholar]

- Seetharaman, R.; Ravisankar, V.; Balasubramanian, V. Corrosion Performance of Friction Stir Welded AA2024 Aluminium Alloy under Salt Fog Conditions. Trans. Nonferr. Met. Soc. China 2015, 25, 1427–1438. [Google Scholar] [CrossRef]

- Knight, S.P.; Salagaras, M.; Trueman, A.R. The Study of Intergranular Corrosion in Aircraft Aluminium Alloys Using X-ray Tomography. Corros. Sci. 2011, 53, 727–734. [Google Scholar] [CrossRef]

- Mu, Z.T.; Su, W.G.; Chen, W.J. Research of Environmental Factors of Aluminum Alloys Atmospheric Corrosion Based on Grey Relational Analysis. Adv. Mater. Res. 2011, 152–153, 756–763. [Google Scholar] [CrossRef]

- Xie, L.; Lei, Q.; Wang, M.; Sheng, X.; Li, Z. Effects of Aging Mechanisms on the Exfoliation Corrosion Behavior of a Spray Deposited Al-Zn-Mg-Cu-Zr Aluminum Alloy. J. Mater. Res. 2017, 32, 1105–1117. [Google Scholar] [CrossRef]

- Wang, B.B.; Wang, Z.Y.; Han, W.; Ke, W. Atmospheric Corrosion of Aluminium Alloy 2024-T3 Exposed to Salt Lake Environment in Western China. Corros. Sci. 2012, 59, 63–70. [Google Scholar] [CrossRef]

- Ngai, S.; Ngai, T.; Vogel, F.; Story, W.; Thompson, G.B.; Brewer, L.N. Saltwater Corrosion Behavior of Cold Sprayed AA7075 Aluminum Alloy Coatings. Corros. Sci. 2018, 130, 231–240. [Google Scholar] [CrossRef]

- Shahidi, M.; Gholamhosseinzadeh, M.R. Electrochemical Evaluation of AA6061 Aluminum Alloy Corrosion in Citric Acid Solution without and with Chloride Ions. J. Electroanal. Chem. 2015, 757, 8–17. [Google Scholar] [CrossRef]

- Vargel, C.; Germain, J.; Dunlop, H. Corrosion of Aluminium, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 9780080999258. [Google Scholar]

- McCafferty, E. Sequence of Steps in the Pitting of Aluminum by Chloride Ions. Corros. Sci. 2003, 45, 1421–1438. [Google Scholar] [CrossRef]

- Abdul-Wahab, S.A. Effect of Air Pollution on Atmospheric Corrosion of Engineering Metals. Pract. Period. Hazard. Toxic. Radioact. Waste Manag. 2004, 8, 274–285. [Google Scholar] [CrossRef]

- Oesch, S.; Faller, M. Environmental Effects on Materials: The Effect of the Air Pollutants SO2, NO2, NO and O3 on the Corrosion of Copper, Zinc and Aluminium. A Short Literature Survey and Results of Laboratory Exposures. Corros. Sci. 1997, 39, 1505–1530. [Google Scholar] [CrossRef]

- Chen, H.; Qin, R.; Lau, D. Recycling Used Engine Oil in Concrete Design Mix: An Ecofriendly and Feasible Solution. J. Clean. Prod. 2021, 329, 129555. [Google Scholar] [CrossRef]

- Boukerche, I.; Djerad, S.; Benmansour, L.; Tifouti, L.; Saleh, K. Degradability of Aluminum in Acidic and Alkaline Solutions. Corros. Sci. 2014, 78, 343–352. [Google Scholar] [CrossRef]

- Mendoza, A.R.; Corvo, F. Outdoor and Indoor Atmospheric Corrosion of Non-Ferrous Metals. Corros. Sci. 2000, 42, 1123–1147. [Google Scholar] [CrossRef]

- Zor, S.; Doǧan, P.; Yazici, B. Inhibition of Acidic Corrosion of Iron and Aluminium by SDBS at Different Temperatures. Corros. Rev. 2005, 23, 217–232. [Google Scholar] [CrossRef]

- Soltis, J.; Laycock, N.J.; Krouse, D. Temperature Dependence of the Pitting Potential of High Purity Aluminium in Chloride Containing Solutions. Corros. Sci. 2011, 53, 7–10. [Google Scholar] [CrossRef]

- Laycock, N.J.; Newman, R.C. Temperature Dependence of Pitting Potentials for Austenitic Stainless Steels above Their Critical Pitting Temperature. Corros. Sci. 1998, 40, 887–902. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Q.; Wang, Y.; Zhao, H.; Sun, J.; He, L. Experimental and Numerical Study of Window Glass Breakage with Varying Shaded Widths under Thermal Loading. Fire Technol. 2017, 53, 43–64. [Google Scholar] [CrossRef]

- Chinnam, R.K.; Fossati, P.C.M.; Lee, W.E. Degradation of Partially Immersed Glass: A New Perspective. J. Nucl. Mater. 2018, 503, 56–65. [Google Scholar] [CrossRef]

- Lu, W.; Chen, H.; Wang, Y.; Duan, Q.; Jiang, L.; Wang, Q.; Sun, J. Study of Point-Supported Glass Breakage Behavior with Varying Point-Covered Areas under Thermal Loading. Int. J. Therm. Sci. 2018, 132, 65–75. [Google Scholar] [CrossRef] [Green Version]

- Lei, D.; Fu, X.; Ren, Y.; Yao, F.; Wang, Z. Temperature and Thermal Stress Analysis of Parabolic Trough Receivers. Renew. Energy 2019, 136, 403–413. [Google Scholar] [CrossRef]

- Rathnayake, U.; Lau, D.; Chow, C.L. Review on Energy and Fire Performance of Water Wall Systems as a Green Building Façade. Sustainability 2020, 12, 8713. [Google Scholar] [CrossRef]

- Preventing Thermal Stress Breakage. Available online: https://glassed.vitroglazings.com/Topics/Preventing-Thermal-Stress-Breakage (accessed on 16 December 2021).

- Yang, J.; Chen, H.; Hu, S.; Gan, V.J.L. Experimental Studies on the Fl Exural Behaviour of Steel-Concrete Composite Beams with Transverse and Longitudinal Hidden Girders. Eng. Struct. 2019, 179, 583–594. [Google Scholar] [CrossRef]

- Huang, Y.; Gan, V.J.L.; Chen, H.; Yang, J. Behavior of a Two-Way Lightweight Steel–Concrete Composite Slab Voided with Thin-Walled Core Boxes towards Sustainable Construction. Materials 2020, 13, 4129. [Google Scholar] [CrossRef]

- Xu, Y.; Becker, T.C.; Guo, T. Design Optimization of Triple Friction Pendulums for High-Rise Buildings Considering Both Seismic and Wind Loads. Soil Dyn. Earthq. Eng. 2021, 142, 106568. [Google Scholar] [CrossRef]

- Lu, W.; Wang, Y.; Chen, H.; Jiang, L.; Duan, Q.; Li, M.; Wang, Q.; Sun, J. Investigation of the Thermal Response and Breakage Mechanism of Point-Supported Glass Facade under Wind Load. Constr. Build. Mater. 2018, 186, 635–643. [Google Scholar] [CrossRef]

- Renou, R.; Soulard, L.; Lescoute, E.; Dereure, C.; Loison, D.; Guin, J.P. Silica Glass Structural Properties under Elastic Shock Compression: Experiments and Molecular Simulations. J. Phys. Chem. C 2017, 121, 13324–13334. [Google Scholar] [CrossRef]

- Misiopecki, C.; Bouquin, M.; Gustavsen, A.; Petter, B. Thermal Modeling and Investigation of the Most Energy-Efficient Window Position. Energy Build. 2018, 158, 1079–1086. [Google Scholar] [CrossRef]

- Liu, M.; Mi, B. Life Cycle Cost Analysis of Energy-Efficient Buildings Subjected to Earthquakes. Energy Build. 2017, 154, 581–589. [Google Scholar] [CrossRef]

- Aiello, C.; Caterino, N.; Maddaloni, G.; Bonati, A.; Franco, A.; Occhiuzzi, A. Experimental and Numerical Investigation of Cyclic Response of a Glass Curtain Wall for Seismic Performance Assessment. Constr. Build. Mater. 2018, 187, 596–609. [Google Scholar] [CrossRef]

- Bedon, C.; Zhang, X.; Santos, F.; Honfi, D.; Kozłowski, M.; Arrigoni, M.; Figuli, L.; Lange, D. Performance of Structural Glass Facades under Extreme Loads—Design Methods, Existing Research, Current Issues and Trends. Constr. Build. Mater. 2018, 163, 921–937. [Google Scholar] [CrossRef]

- Vega, J.M.; Granizo, N.; De La Fuente, D.; Simancas, J.; Morcillo, M. Corrosion Inhibition of Aluminum by Coatings Formulated with Al-Zn-Vanadate Hydrotalcite. Prog. Org. Coat. 2011, 70, 213–219. [Google Scholar] [CrossRef] [Green Version]

- Trentin, A.; Harb, S.V.; Uvida, M.C.; Pulcinelli, S.H.; Santilli, C.V.; Marcoen, K.; Pletincx, S.; Terryn, H.; Hauffman, T.; Hammer, P. Dual Role of Lithium on the Structure and Self-Healing Ability of PMMA-Silica Coatings on AA7075 Alloy. ACS Appl. Mater. Interfaces 2019, 11, 40629–40641. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Du, J.; Ye, S.; Tan, L.; Fu, J. Triple-Stimuli-Responsive Smart Nanocontainers Enhanced Self-Healing Anticorrosion Coatings for Protection of Aluminum Alloy. ACS Appl. Mater. Interfaces 2019, 11, 4425–4438. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, W.; Yang, M.; Yang, Y.; Wang, D.; Liu, Z.; Shuai, C. Laser-Sintered Mg-Zn Supersaturated Solid Solution with High Corrosion Resistance. Micromachines 2021, 12, 1368. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Castaneda, H.; Gao, H.; Srivastava, A. Synergistic e Ff Ects of Corrosion and Slow Strain Rate Loading on the Mechanical and Electrochemical Response of an Aluminium Alloy. Corros. Sci. 2019, 153, 53–61. [Google Scholar] [CrossRef]

- Dan, Z.; Muto, I.; Hara, N. Effects of Environmental Factors on Atmospheric Corrosion of Aluminium and Its Alloys under Constant Dew Point Conditions. Corros. Sci. 2012, 57, 22–29. [Google Scholar] [CrossRef]

- Bunget, C.; Ngaile, G. Influence of Ultrasonic Vibration on Micro-Extrusion. Ultrasonics 2011, 51, 606–616. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dziedziech, K.; Pieczonka, L.; Kijanka, P.; Staszewski, W.J. Enhanced Nonlinear Crack-Wave Interactions for Structural Damage Detection Based on Guided Ultrasonic Waves. Struct. Control Health Monit. 2016, 23, 1108–1120. [Google Scholar] [CrossRef]

- Honarvar, F.; Varvani-Farahani, A. A Review of Ultrasonic Testing Applications in Additive Manufacturing: Defect Evaluation, Material Characterization, and Process Control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Sun, H.; Tian, J.; Yang, Q.; Wan, Q. Mechanical and Ultrasonic Testing of Self-Compacting Concrete. Energies 2019, 12, 2187. [Google Scholar] [CrossRef] [Green Version]

- Armitage, P.R.; Wright, C.D. Design, Development and Testing of Multi-Functional Non-Linear Ultrasonic Instrumentation for the Detection of Defects and Damage in CFRP Materials and Structures. Compos. Sci. Technol. 2013, 87, 149–156. [Google Scholar] [CrossRef] [Green Version]

- Kusano, M.; Takizawa, S.; Sakai, T.; Arao, Y.; Kubouchi, M. Simultaneous Sound Velocity and Thickness Measurement by the Ultrasonic Pitch-Catch Method for Corrosion-Layer-Forming Polymeric Materials. Ultrasonics 2018, 82, 178–187. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Durham, N.; Abdel-Hadi, K.; McKenzie, C.A.; Thomson, D.J. Acoustic Guided Wave Techniques for Detecting Corrosion Damage of Electrical Grounding Rods. Meas. J. Int. Meas. Confed. 2019, 147, 106858. [Google Scholar] [CrossRef]

- De Marchi, L.; Marzani, A.; Miniaci, M. A Dispersion Compensation Procedure to Extend Pulse-Echo Defects Location to Irregular Waveguides. NDT E Int. 2013, 54, 115–122. [Google Scholar] [CrossRef]

- Durham, N.; Zhao, J.; Bridges, G.; Thomson, D. Acoustic Guided Wave Detection of Grounding Rod Corrosion: Equivalent Circuit Model and Implementation. Smart Mater. Struct. 2020, 29, 055040. [Google Scholar] [CrossRef]

- Billeh Ishak Medfouni, E.M.; Kodjo, A.S.; Rivard, P.; Saleh, K.; Quirion, M. Assessment of Corroded Rock Bolts with Pulse Echo Tests. J. Infrastruct. Syst. 2017, 23, 04017007. [Google Scholar] [CrossRef]

- Howard, R.; Cegla, F. Detectability of Corrosion Damage with Circumferential Guided Waves in Reflection and Transmission. NDT E Int. 2017, 91, 108–119. [Google Scholar] [CrossRef]

- Ullmann, T.; Shi, Y.; Aoki, R. Capabilities of Lock-in Thermography for Non-Destructive Inspection of Fibre Reinforced Composites. In Proceedings of the Web-Based Proceedings of QIRT2012, Neapel, Italy, 11–14 June 2012. [Google Scholar]

- Drinkwater, B.W.; Wilcox, P.D. Ultrasonic Arrays for Non-Destructive Evaluation: A Review. NDT E Int. 2006, 39, 525–541. [Google Scholar] [CrossRef]

- Montinaro, N.; Epasto, G.; Cerniglia, D.; Guglielmino, E. Laser Ultrasonics Inspection for Defect Evaluation on Train Wheel. NDT E Int. 2019, 107, 102145. [Google Scholar] [CrossRef]

- Bai, Z.; Chen, S.; Jia, L.; Zeng, Z. Phased Array Ultrasonic Signal Compressive Detection in Low-Pressure Turbine Disc. NDT E Int. 2017, 89, 1–13. [Google Scholar] [CrossRef]

- Wilcox, P.D.; Holmes, C.; Drinkwater, B.W. Advanced Reflector Characterization with Ultrasonic Phased Arrays in NDE Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 1541–1550. [Google Scholar] [CrossRef] [PubMed]

- Xu, N.; Zhou, Z. Numerical Simulation and Experiment for Inspection of Corner-Shaped Components Using Ultrasonic Phased Array. NDT E Int. 2014, 63, 28–34. [Google Scholar] [CrossRef]

- Doshvarpassand, S.; Wu, C.; Wang, X. An Overview of Corrosion Defect Characterization Using Active Infrared Thermography. Infrared Phys. Technol. 2019, 96, 366–389. [Google Scholar] [CrossRef]

- Vidal, D.; Pitarma, R. Infrared Thermography Applied to Tree Health Assessment: A Review. Agriculture 2019, 9, 156. [Google Scholar] [CrossRef] [Green Version]

- Zhi, Q.; Peng, J.; Weixu, Z. Development and Application of Infrared Thermography Non-Destructive Testing Techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef]

- Li, M.; Lu, G.; Hu, Z.; Mei, X.; Li, L.; Wang, L. Research on Fire Endurance of Tempered Glass Based on Infrared Imaging Technology. Procedia Eng. 2014, 84, 553–557. [Google Scholar] [CrossRef] [Green Version]

- Le Cam, J.B.; Robin, E.; Balandraud, X.; Toussaint, E. A New Experimental Route in Thermomechanics of Inorganic Glasses Using Infrared Thermography. J. Non-Cryst. Solids 2013, 366, 64–69. [Google Scholar] [CrossRef]

- Robin, E.; Le Cam, J.B.; Balandraud, X.; Toussaint, E.; Brilland, L. First Steps towards the Thermomechanical Characterization of Chalcogenide Glass Using Quantitative Infrared Thermography. J. Non-Cryst. Solids 2014, 391, 101–105. [Google Scholar] [CrossRef]

- Gryś, S. Filtered Thermal Contrast Based Technique for Testing of Material by Infrared Thermography. Opto-Electron. Rev. 2011, 19, 234–241. [Google Scholar] [CrossRef] [Green Version]

- Hao, H.; Hui, D.; Lau, D. Material Advancement in Technological Development for the 5G Wireless Communications. Nanotechnol. Rev. 2020, 9, 683–699. [Google Scholar] [CrossRef]

- Zhao, B.; Kuo, N.; Member, S.; Niknejad, A.M. A Gain Boosting Array Technique for Weakly-Coupled Wireless Power Transfer. IEEE Trans. Power Electron. 2017, 32, 7130–7139. [Google Scholar] [CrossRef]

- Stokes, J.E.; Leach, K.A.; Main, D.C.J.; Whay, H.R. An Investigation into the Use of Infrared Thermography (IRT) as a Rapid Diagnostic Tool for Foot Lesions in Dairy Cattle. Vet. J. 2012, 193, 674–678. [Google Scholar] [CrossRef]

- Sun, G.; Nakayama, Y.; Dagdanpurev, S.; Abe, S.; Nishimura, H.; Kirimoto, T.; Matsui, T. Remote Sensing of Multiple Vital Signs Using a CMOS Camera-Equipped Infrared Thermography System and Its Clinical Application in Rapidly Screening Patients with Suspected Infectious Diseases. Int. J. Infect. Dis. 2017, 55, 113–117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Umair, M.; Farhaj, H.; Masud, M.; Dad, K.; Zafar, A. A Machine Learning Framework to Identify the Hotspot in Photovoltaic Module Using Infrared Thermography. Sol. Energy 2020, 208, 643–651. [Google Scholar] [CrossRef]

- Ahmed, W.; Hanif, A.; Kallu, K.D.; Kouzani, A.Z.; Ali, M.U.; Zafar, A. Photovoltaic Panels Classification Using Isolated and Transfer Learned Deep Neural Models Using Infrared Thermographic Images. Sensors 2021, 21, 5668. [Google Scholar] [CrossRef]

- You, J.; Liu, Z. Atomistic Simulation of Corrosion Protection of Al2Cu Aluminum Alloy by 8-Hydroxyquinoline. Appl. Surf. Sci. 2021, 540, 148315. [Google Scholar] [CrossRef]

- Jian, W.; Hui, D.; Lau, D. Nanoengineering in Biomedicine: Current Development and Future Perspectives. Nanotechnol. Rev. 2020, 9, 700–715. [Google Scholar] [CrossRef]

- Lau, D.; Jian, W.; Yu, Z.; Hui, D. Nano-Engineering of Construction Materials Using Molecular Dynamics Simulations: Prospects and Challenges. Compos. Part B Eng. 2018, 143, 282–291. [Google Scholar] [CrossRef]

- Michalka, J.R.; Gezelter, J.D. Island Formation on Pt/Pd(557) Surface Alloys in the Presence of Adsorbed CO: A Molecular Dynamics Study. J. Phys. Chem. C 2015, 119, 14239–14247. [Google Scholar] [CrossRef]

- Jian, W.; Wang, X.; Lu, H.; Lau, D. Molecular Dynamics Simulations of Thermodynamics and Shape Memory Effect in CNT-Epoxy Nanocomposites. Compos. Sci. Technol. 2021, 211, 108849. [Google Scholar] [CrossRef]

- Qin, R.; Lau, D. Evaluation of the Moisture Effect on the Material Interface Using Multiscale Modeling. Multiscale Sci. Eng. 2019, 1, 108–118. [Google Scholar] [CrossRef] [Green Version]

- Van Huis, M.A.; Chen, J.H.; Zandbergen, H.W.; Sluiter, M.H.F. Phase Stability and Structural Relations of Nanometer-Sized, Matrix-Embedded Precipitate Phases in Al-Mg-Si Alloys in the Late Stages of Evolution. Acta Mater. 2006, 54, 2945–2955. [Google Scholar] [CrossRef]

- Chen, H.; Lu, J.; Kong, Y.; Li, K.; Yang, T.; Meingast, A.; Yang, M.; Lu, Q.; Du, Y. Atomic Scale Investigation of the Crystal Structure and Interfaces of the B’ Precipitate in Al-Mg-Si Alloys. Acta Mater. 2020, 185, 193–203. [Google Scholar] [CrossRef]

- Robustelli, P.; Piana, S.; Shaw, D.E. Developing a Molecular Dynamics Force Field for Both Folded and Disordered Protein States. Proc. Natl. Acad. Sci. USA 2018, 115, E4758–E4766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piana, S.; Robustelli, P.; Tan, D.; Chen, S.; Shaw, D.E. Development of a Force Field for the Simulation of Single-Chain Proteins and Protein-Protein Complexes. J. Chem. Theory Comput. 2020, 16, 2494–2507. [Google Scholar] [CrossRef] [PubMed]

- Qin, R.; Hao, H.; Rousakis, T.; Lau, D. Effect of Shrinkage Reducing Admixture on New-to-Old Concrete Interface. Compos. Part B Eng. 2019, 167, 346–355. [Google Scholar] [CrossRef]

- Hao, H.; Zhou, W.; Lu, Y.; Lau, D. Atomic Arrangement in CuZr-Based Metallic Glass Composites under Tensile Deformation. Phys. Chem. Chem. Phys. 2019, 22, 313–324. [Google Scholar] [CrossRef] [Green Version]

- Nie, F.; Jian, W.; Lau, D. An Atomistic Study on the Thermomechanical Properties of Graphene and Functionalized Graphene Sheets Modi Fi Ed Asphalt. Carbon 2021, 182, 615–627. [Google Scholar] [CrossRef]

- Yaphary, Y.L.; Yu, Z.; Lam, R.H.W.; Hui, D.; Lau, D. Molecular Dynamics Simulations on Adhesion of Epoxy-Silica Interface in Salt Environment. Compos. Part B Eng. 2017, 131, 165–172. [Google Scholar] [CrossRef]

- Chen, T.; Chen, M.; Chen, Z.; Fu, C. Comprehensive Investigation of Modified Polyethyleneimine as an Efficient Polymeric Corrosion Inhibitor in Neutral Medium: Synthesis, Experimental and Theoretical Assessments. J. Mol. Liq. 2021, 339, 116803. [Google Scholar] [CrossRef]

- Alareeqi, S.; Bahamon, D.; Nogueira, R.P.; Vega, L.F. Understanding the Relationship between the Structural Properties of Three Corrosion Inhibitors and Their Surface Protectiveness Ability in Different Environments. Appl. Surf. Sci. 2021, 542, 148600. [Google Scholar] [CrossRef]

- Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. The Role of Chrome and Zinc Free-Based Neodymium Oxide Nano Fi Lm on Adhesion and Corrosion Protection Properties of Polyester/Melamine Coating on Mild Steel: Experimental and Molecular Dynamics Simulation Study. J. Clean. Prod. 2019, 210, 872–886. [Google Scholar] [CrossRef]

- Dagdag, O.; Hsissou, R.; El Harfi, A.; Berisha, A.; Sa, Z.; Verma, C. Fabrication of Polymer Based Epoxy Resin as e Ff Ective Anti-Corrosive Coating for Steel: Computational Modeling Reinforced Experimental Studies. Surf. Interfaces J. 2020, 18, 100454. [Google Scholar] [CrossRef]

- Da Silva, T.H.; Nelson, E.B.; Williamson, I.; Efaw, C.M.; Sapper, E.; Hurley, M.F.; Li, L. First-Principles Surface Interaction Studies of Aluminum-Copper and Aluminum-Copper-Magnesium Secondary Phases in Aluminum Alloys. Appl. Surf. Sci. 2018, 439, 910–918. [Google Scholar] [CrossRef]

- Zhang, C.; Chang, C.C.; Jamshidi, M. Concrete Bridge Surface Damage Detection Using a Single-Stage Detector. Comput. Civ. Infrastruct. Eng. 2020, 35, 389–409. [Google Scholar] [CrossRef]

- Dung, C.V.; Anh, L.D. Autonomous Concrete Crack Detection Using Deep Fully Convolutional Neural Network. Autom. Constr. 2019, 99, 52–58. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Nguyen, Q.D.; Le, T.A.; Shin, J.; Lee, K. Analyzing the Compressive Strength of Green Fly Ash Based Geopolymer Concrete Using Experiment and Machine Learning Approaches. Constr. Build. Mater. 2020, 247, 118581. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yu, Y.; Cheng, H.; Wu, X. Compressive Strength Prediction of Recycled Concrete Based on Deep Learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Chen, X.; Li, Q.; Wang, J. A Unified Sequence Labeling Model for Emotion Cause Pair Extraction. In Proceedings of the 28th International Conference on Computational Linguistics, Barcelona, Spain, 8–13 December 2020; pp. 208–218. [Google Scholar]

- Chen, X.; Li, Q.; Wang, J. Conditional Causal Relationships between Emotions and Causes in Texts. In Proceedings of the 2020 Conference on Empirical Methods in Natural Language Processing, Online, 16–20 November 2020; pp. 3111–3121. [Google Scholar]

- Hung, H.Y.; Gao, Z.M.; Li, S.S.; Gao, Y.; Chow, W.K.; Chow, C.L. Attenuation of Swirling Motion of a Fire Whirl in a Vertical Shaft. Fire Technol. 2021. [Google Scholar] [CrossRef]

- Chen, H.; Yang, J.; Chen, X. A Convolution-Based Deep Learning Approach for Estimating Compressive Strength of Fiber Reinforced Concrete at Elevated Temperatures. Constr. Build. Mater. 2021, 313, 125437. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Mao, J.; Huang, Z.; Huang, C.; Xu, W. CNN-RNN: A Unified Framework for Multi-Label Image Classification. In Proceedings of the IEEE conference on computer vision and pattern recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 2285–2294. [Google Scholar]

- Lee, H.; Kwon, H.; Member, S. Going Deeper with Contextual CNN for Hyperspectral Image Classification. IEEE Trans. Image Process. 2017, 26, 4843–4855. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.; Yairi, T. A Review on the Application of Deep Learning in System Health Management. Mech. Syst. Signal Process. 2018, 107, 241–265. [Google Scholar] [CrossRef]

- Fawaz, H.I.; Forestier, G.; Weber, J.; Idoumghar, L.; Muller, P.A. Deep Learning for Time Series Classification: A Review. Data Min. Knowl. Discov. 2019, 33, 917–963. [Google Scholar] [CrossRef] [Green Version]

| Techniques | Advantages | Limitations |

|---|---|---|

| Ultrasonic pulse-echo (reflection) technique | Low detection cost, easy operation. Adaptability to large, irregularly shaped test specimens. Low requirements for personnel quality. Sensitive to surface and volume flaws. | Long inspection time. Single probe detection. |

| Ultrasonic through-transmission technique | Applicable to multi-layer materials such as those with honeycomb or foam core. | Long inspection time. Inability to attain defect location information. Requirement for parallel component surface. |

| Ultrasonic phased arrays technique | Reduced inspection time. Flaws’ shape and size can be directly evaluated. Increased inspection quality. | Limitations for thick components. Requires qualified personnel. |

| Infrared thermography technique | Fast inspection. Non-contact and non-intrusive. Portable thermal camera. No infrared radiation attenuation. | Expensive instrumentation. Requires qualified personnel. Large dataset. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Chow, C.L.; Lau, D. Deterioration Mechanisms and Advanced Inspection Technologies of Aluminum Windows. Materials 2022, 15, 354. https://doi.org/10.3390/ma15010354

Chen H, Chow CL, Lau D. Deterioration Mechanisms and Advanced Inspection Technologies of Aluminum Windows. Materials. 2022; 15(1):354. https://doi.org/10.3390/ma15010354

Chicago/Turabian StyleChen, Huaguo, Cheuk Lun Chow, and Denvid Lau. 2022. "Deterioration Mechanisms and Advanced Inspection Technologies of Aluminum Windows" Materials 15, no. 1: 354. https://doi.org/10.3390/ma15010354

APA StyleChen, H., Chow, C. L., & Lau, D. (2022). Deterioration Mechanisms and Advanced Inspection Technologies of Aluminum Windows. Materials, 15(1), 354. https://doi.org/10.3390/ma15010354